Colouring phototonus composition for color filter, color filter, manufacturing method thereof and liquid crystal display device

A technology of photosensitive composition and color filter, which is applied in chemical instruments and methods, photosensitive materials used in photomechanical equipment, instruments, etc., can solve the problems that there is no research on specific methods, and achieve improved development latitude and deep curing Improvement of properties and inhibition of alkali solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

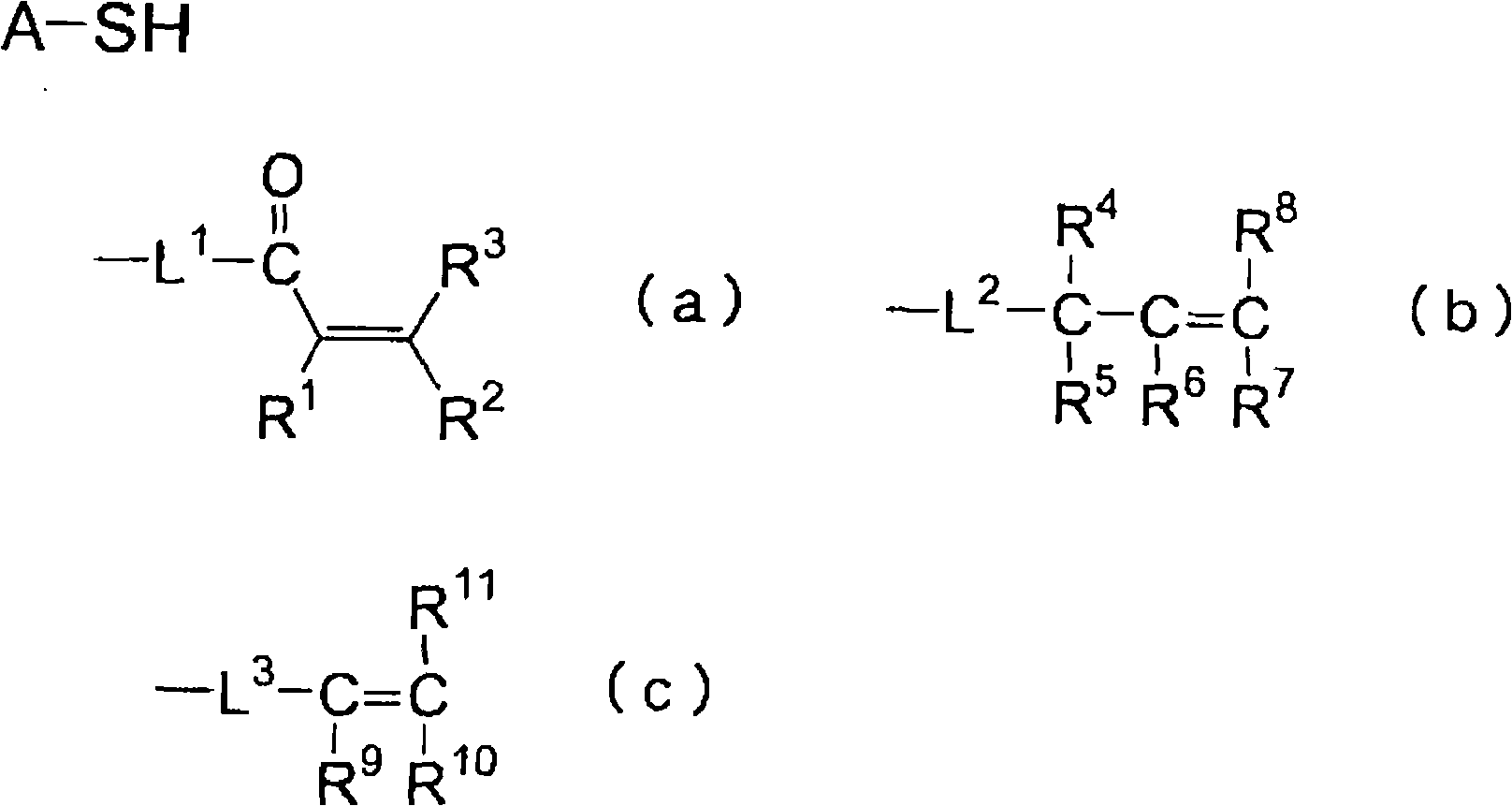

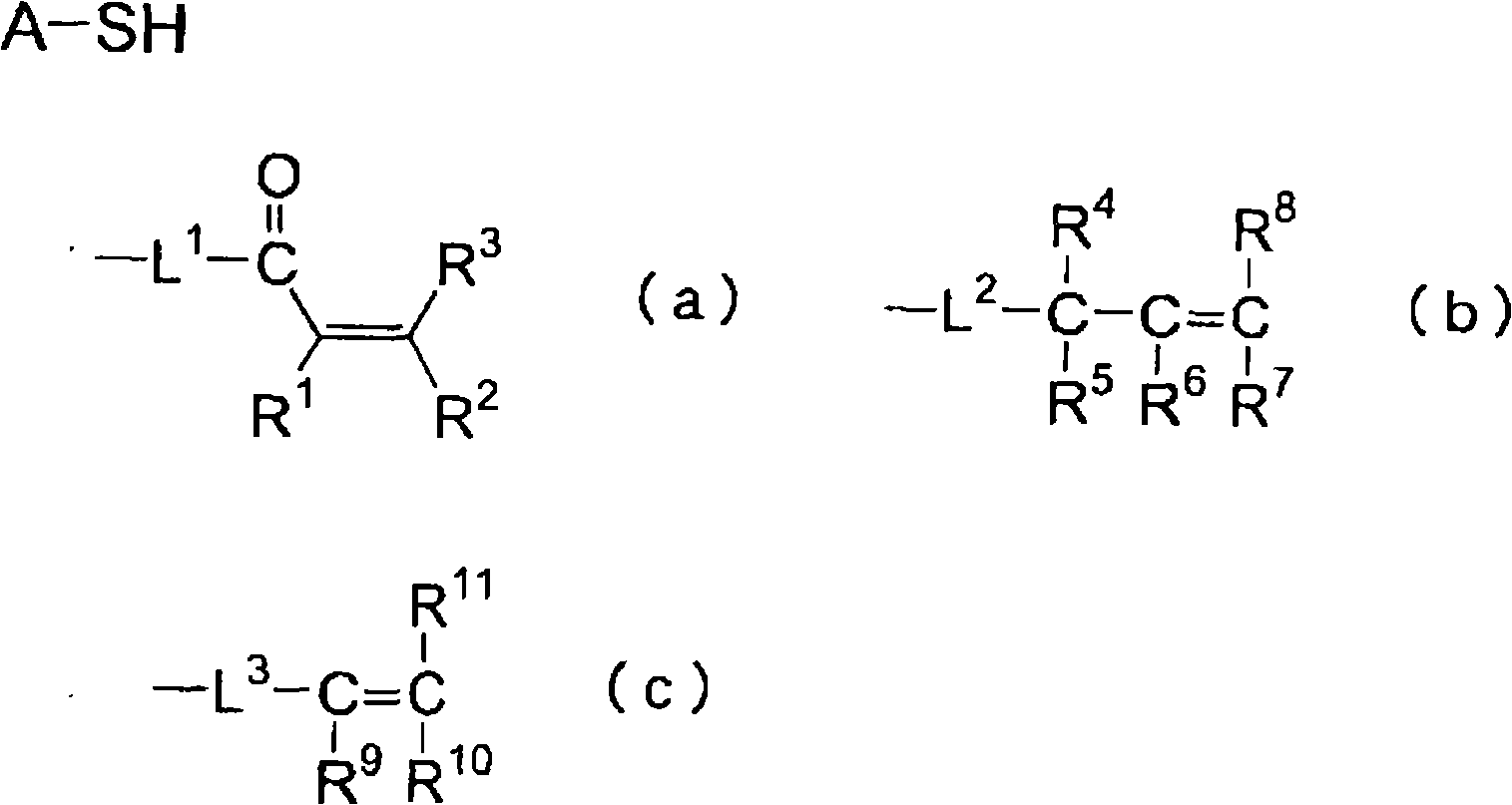

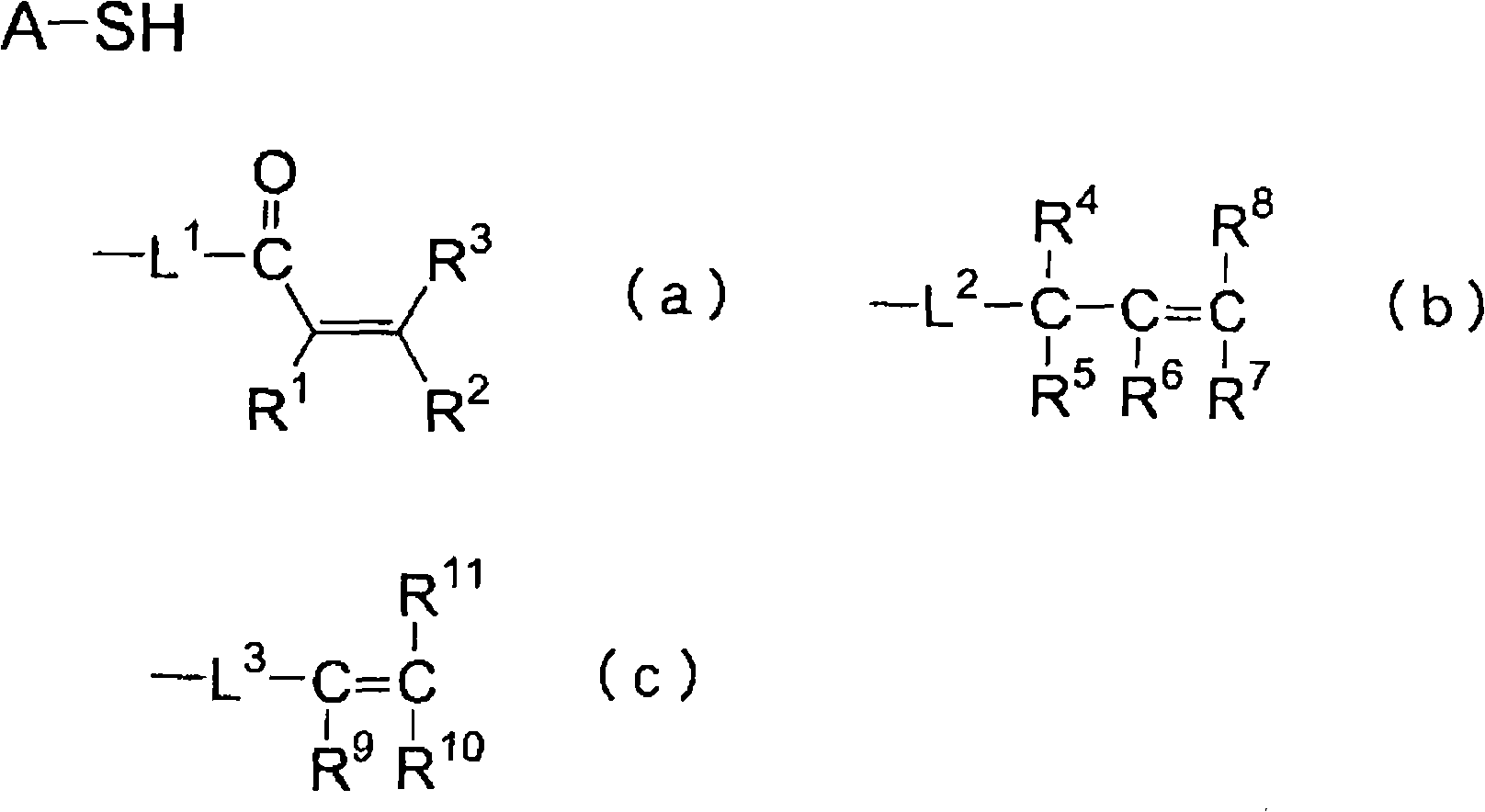

Method used

Image

Examples

Embodiment 1

[0395] (Preparation of Colored Photosensitive Composition)

[0396] Here, the example which prepared the coloring photosensitive composition A1 containing a coloring agent (pigment) as the color filter formation for liquid crystal display element use is mentioned and demonstrated.

[0397] 1-1. Preparation of Pigment Dispersion (P1)

[0398] 150 parts by mass of C.I. Pigment Green 36 and C.I. Pigment Yellow 150 (mass ratio) mixture of 150 parts by mass, alkali-soluble resin (benzyl methacrylate / methacrylic acid, molar ratio of 70 / 30, Mw of 5000 ) 50 mass parts, 50 mass parts of pigment dispersant EFKA4330 (manufactured by EFKA company) and the mixed solution of 750 mass parts of propylene glycol methyl ether acetate as solvent were mixed with ball mill and dispersed for 15 hours to prepare pigment dispersion (P1).

[0399] About the obtained pigment dispersion liquid (P1), the average particle diameter of a pigment was measured by the dynamic light scattering method, and it w...

Embodiment 2~10

[0456] Except that the specific thiol compound in the composition A1 used in the preparation of the colored photosensitive composition A1 in Example 1: Exemplary compound (A-1) was replaced by the exemplary compound described in the following Table 1, all other Coloring photosensitive compositions A2 to A10 were prepared according to the following in the same manner as in Example 1, and a color filter having a colored pattern using the composition was obtained. Furthermore, the same evaluation as in Example 1 was performed. The results are shown in Table 1.

[0457]

[0458] · Pigment dispersion (P1) 8000 parts by mass

[0459] ・Alkali-soluble resin: benzyl methacrylate / methacrylic acid, molar ratio 70 / 30, Mw 5000 80 parts by mass

[0460] · Polymerizable compound: dipentaerythritol hexaacrylate having the following structure, 100 unsaturated equivalents, and 0 ethyleneoxy groups (manufactured by Nippon Kayaku Co., Ltd.) 450 parts by mass

[0461] ・Polymerizable compound...

Embodiment 11

[0470] Except for changing the polymerizable compound in the composition A1 and its amount used in the preparation of the colored photosensitive composition A1 in Example 1, everything is the same as in Example 1, and the colored photosensitive composition was prepared according to the following Composition A11 was used to obtain a color filter having a colored pattern using the composition. Furthermore, the same evaluation as in Example 1 was performed. The results are shown in Table 1.

[0471]

[0472]· Pigment dispersion (P1) 8000 parts by mass

[0473] ・Alkali-soluble resin: benzyl methacrylate / methacrylic acid, molar ratio 70 / 30, Mw 5000 80 parts by mass

[0474] · Polymerizable compound: dipentaerythritol hexaacrylate having the following structure, 100 unsaturated equivalents, and 0 ethyleneoxy groups (manufactured by Nippon Kayaku Co., Ltd.) 600 parts by mass

[0475] Photopolymerization initiator: 120 parts by mass of 2,2'-bis(2-chlorophenyl)-4,4',5,5'-tetraphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com