Patents

Literature

119results about How to "Stay cohesive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

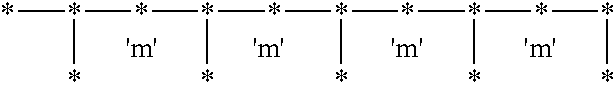

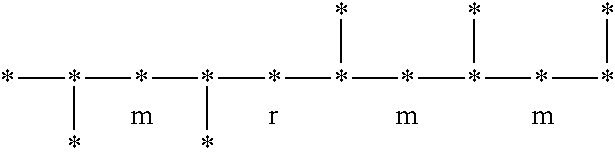

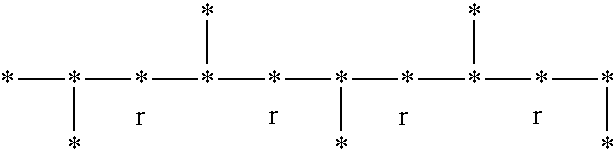

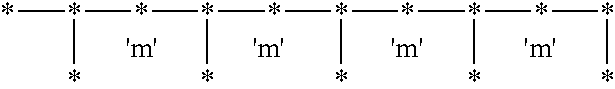

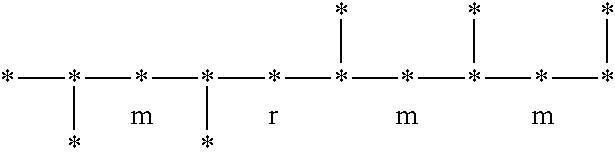

Syndiotactic rich polyolefins

Disclosed herein is a polymer comprising an amorphous syndiotactic rich polyolefin comprising greater than about 50 wt % C3-C40 alpha olefins and having about 50% to less than about 80% r dyads, based on the total number of r and m dyads present in the polymer; a heat of fusion of 10 joules / g or less according to the procedure described in ASTM E 794-85; and an ash content of 1 wt % or less. A functionalized amorphous syndiotactic rich polyolefin is also disclosed, along with methods to produce and a method to use the inventive polymer.

Owner:EXXONMOBIL CHEM PAT INC

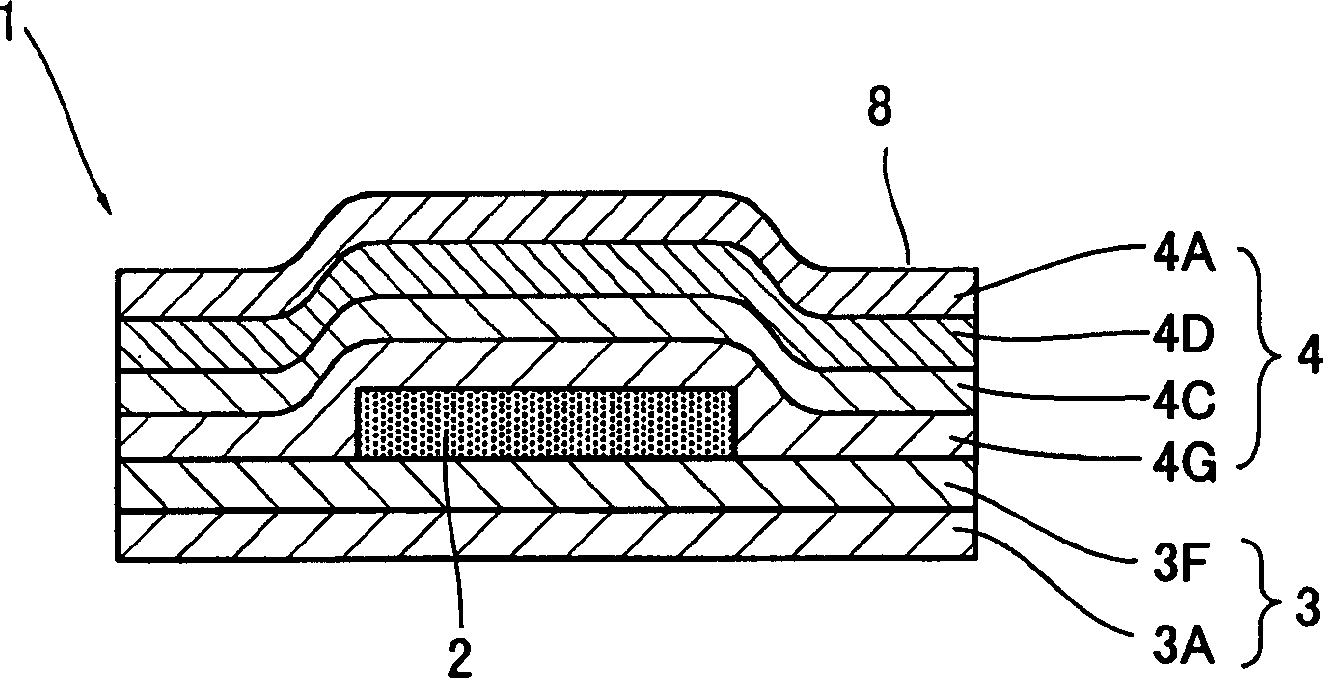

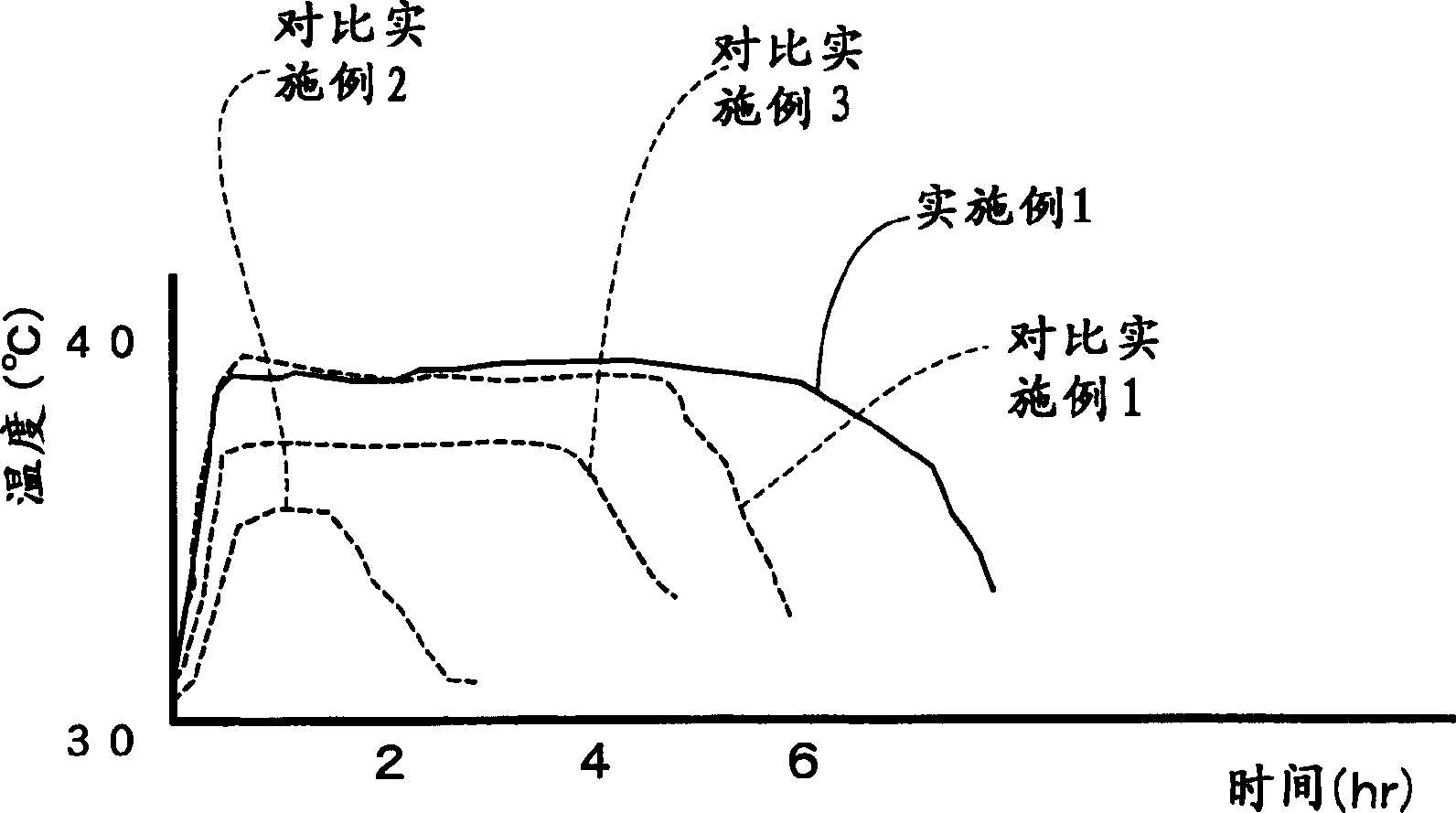

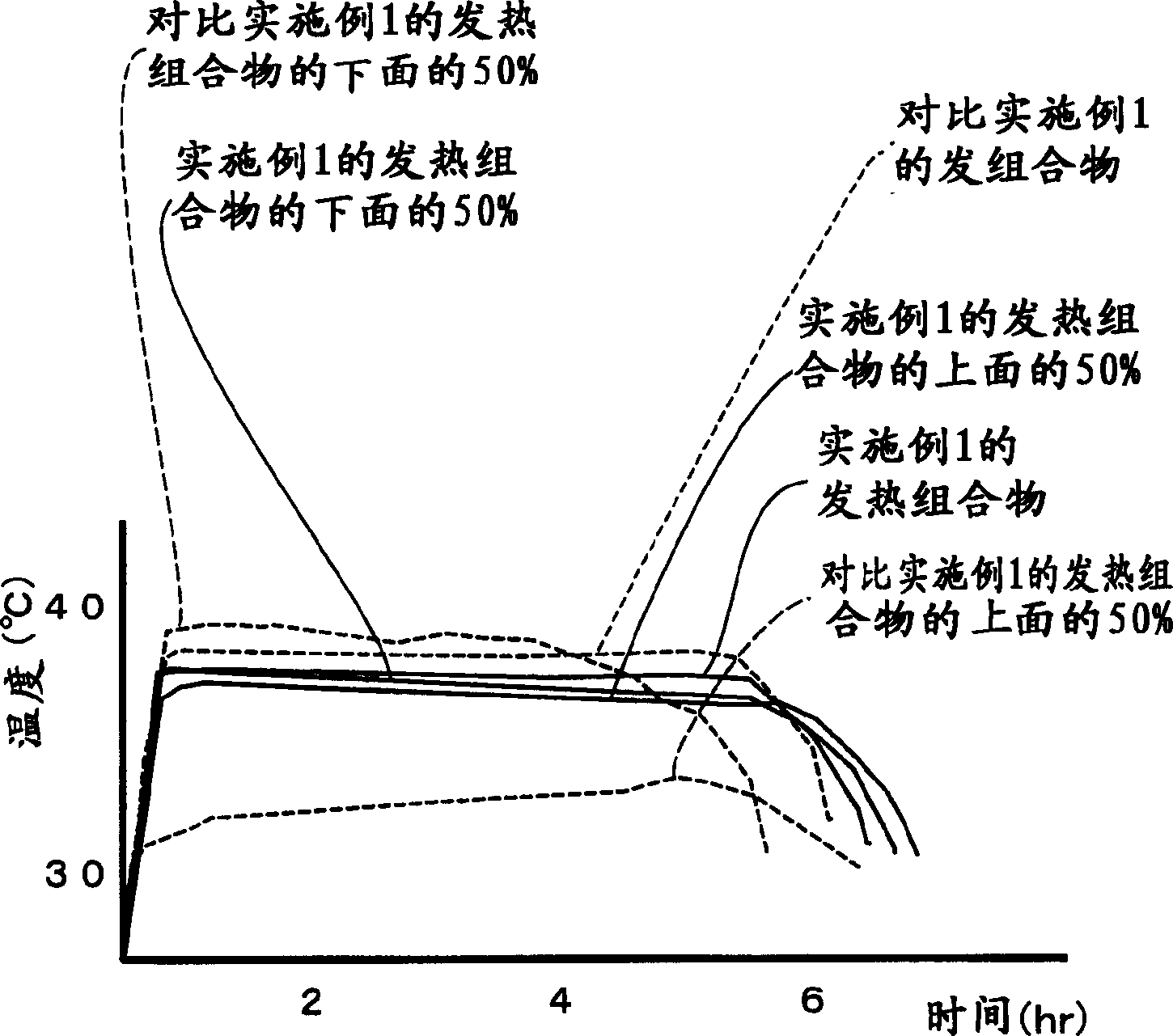

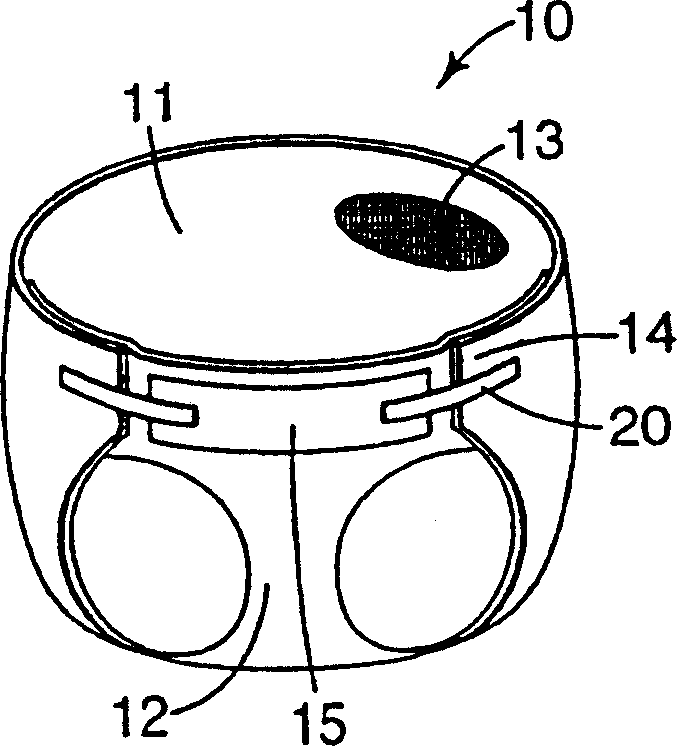

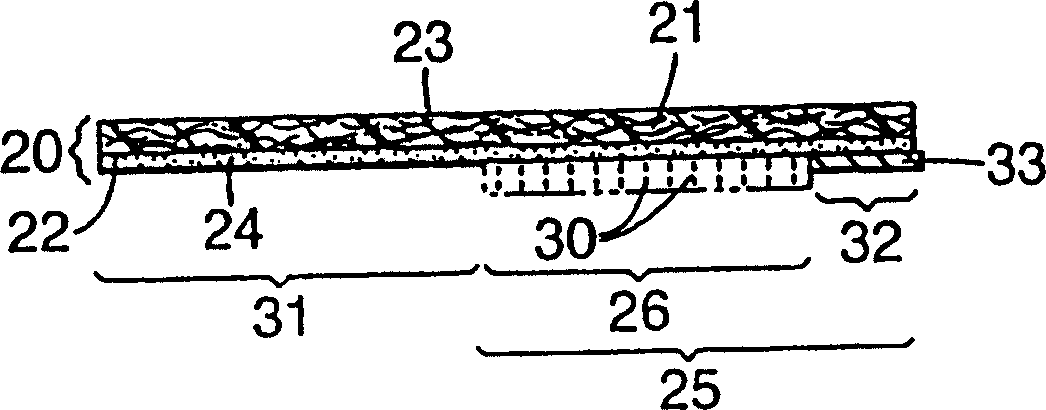

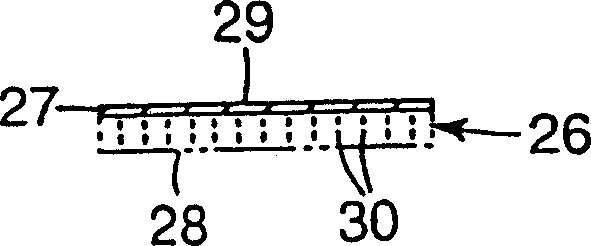

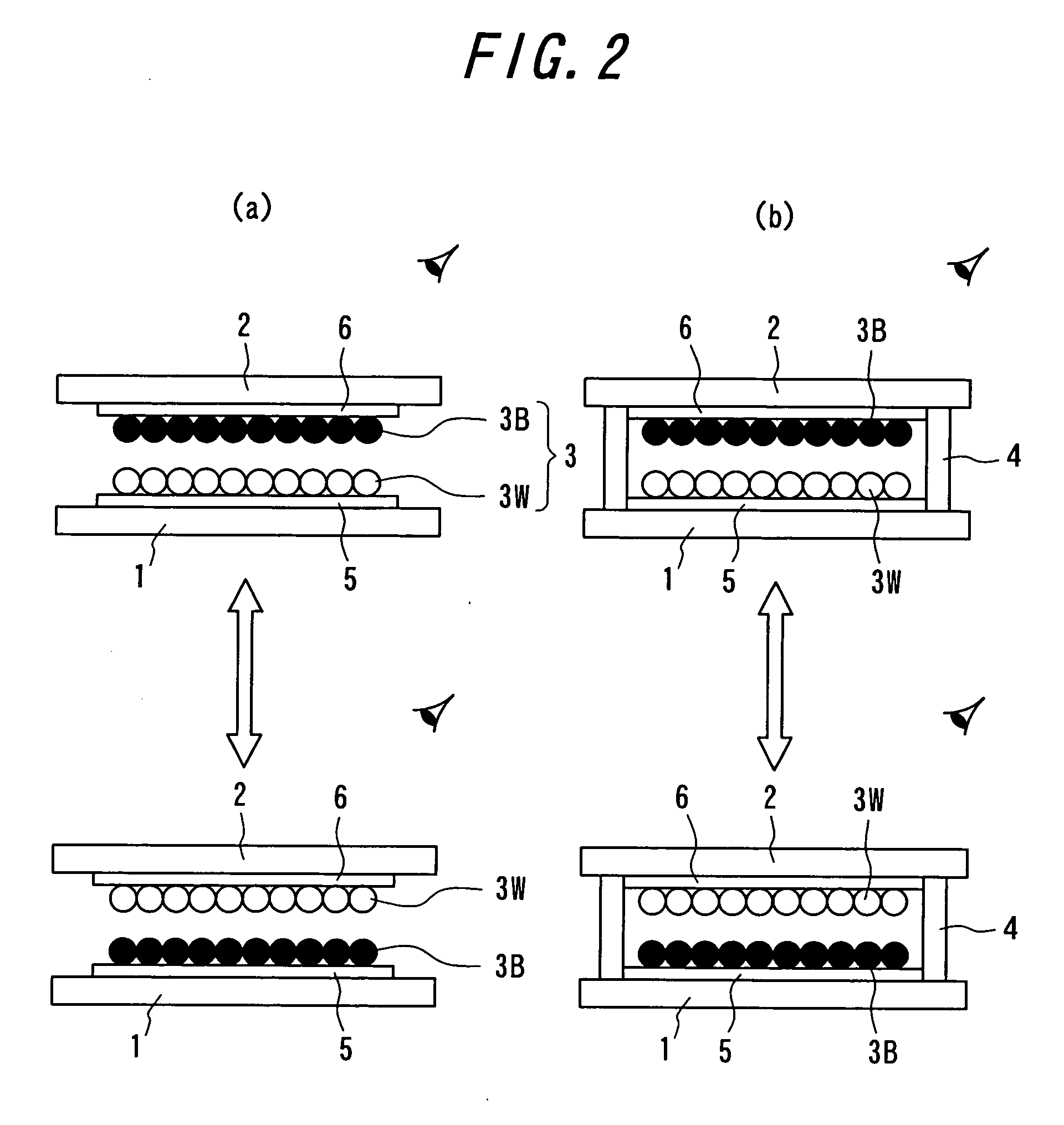

Exothermic composition and exothermic article using composition, and method for producing exothermic article

InactiveCN1491271AAccurate Guaranteed QuantityHas dispersion stabilityExothermal chemical reaction heat productionHeat-exchange elementsDispersion stabilityChemical composition

It relates to a heat-generating composition having such dispersion stability that withstands continuous molding, and has excellent drainage property, excellent heat-generating characteristics, excellent molding property and excellent shape retaining property, without becoming viscous, and relates to a heat-generating body using the same and a process for producing the heat-generating body. It contains, as essential components, a heat-generating substance generating heat upon reaction with oxygen, a carbon component, an oxidation promoter and water, characterized in that the composition further contains a water separation-preventing stabilizer in a proportion of from 0.001 to 0.25 part by mass per 100 parts by mass of the heat-generating composition, and has a water mobility value of from 7 to 40 and a separation degree of from 0 to 30.

Owner:MYCOAL

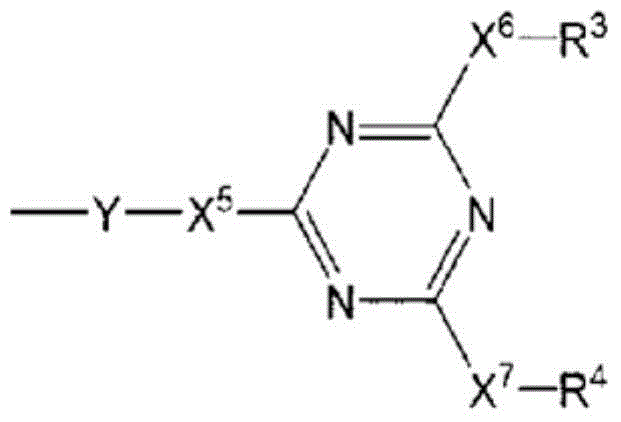

Syndiotactic rich polyolefins

Disclosed herein is a polymer comprising an amorphous syndiotactic rich polyolefin comprising greater than about 50 wt % C3-C40 alpha olefins and having about 50% to less than about 80% r dyads, based on the total number of r and m dyads present in the polymer; a heat of fusion of 10 joules / g or less according to the procedure described in ASTM E 794-85; and an ash content of 1 wt % or less. A functionalized amorphous syndiotactic rich polyolefin is also disclosed, along with methods to produce and a method to use the inventive polymer.

Owner:EXXONMOBIL CHEM PAT INC

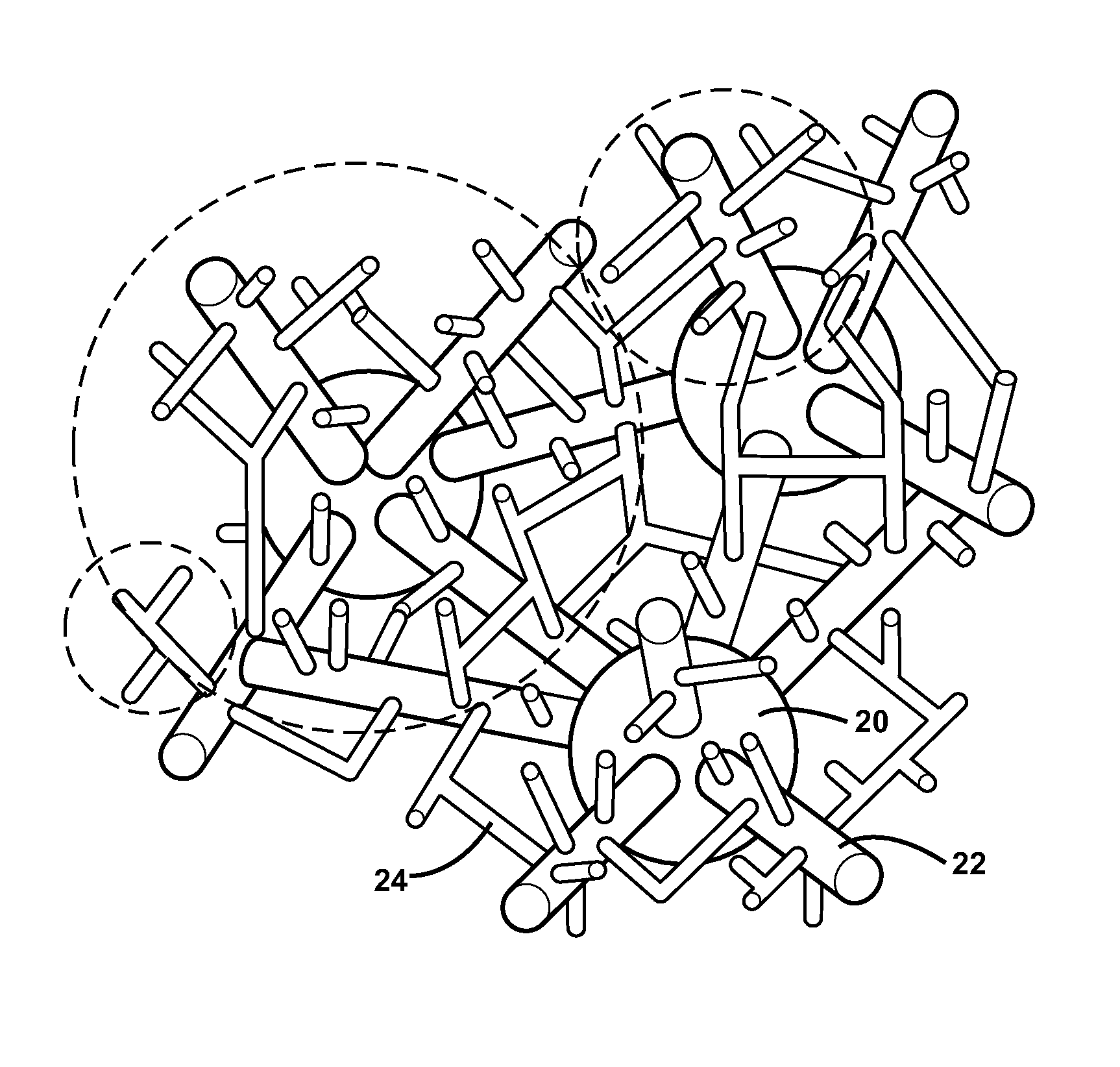

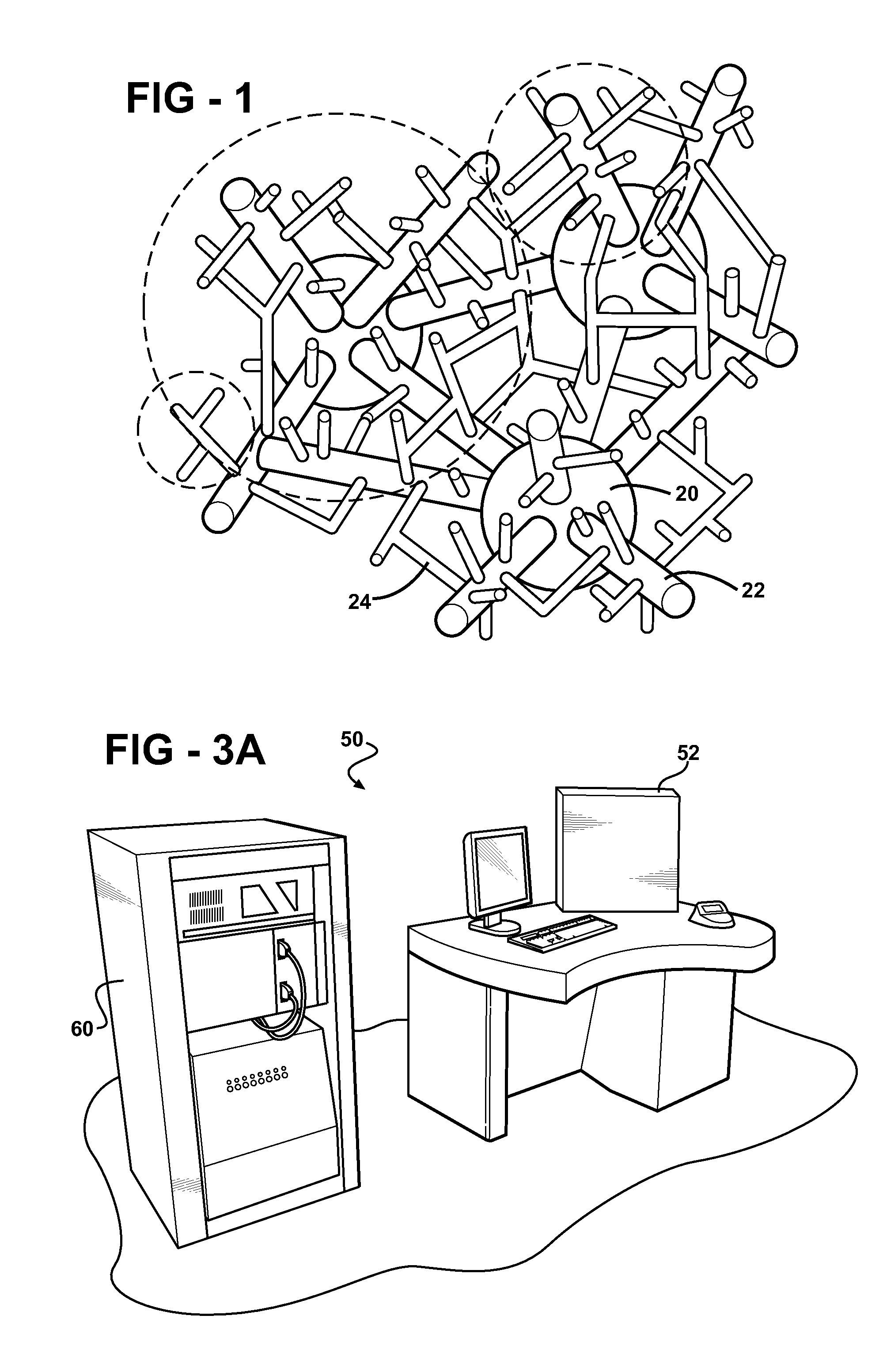

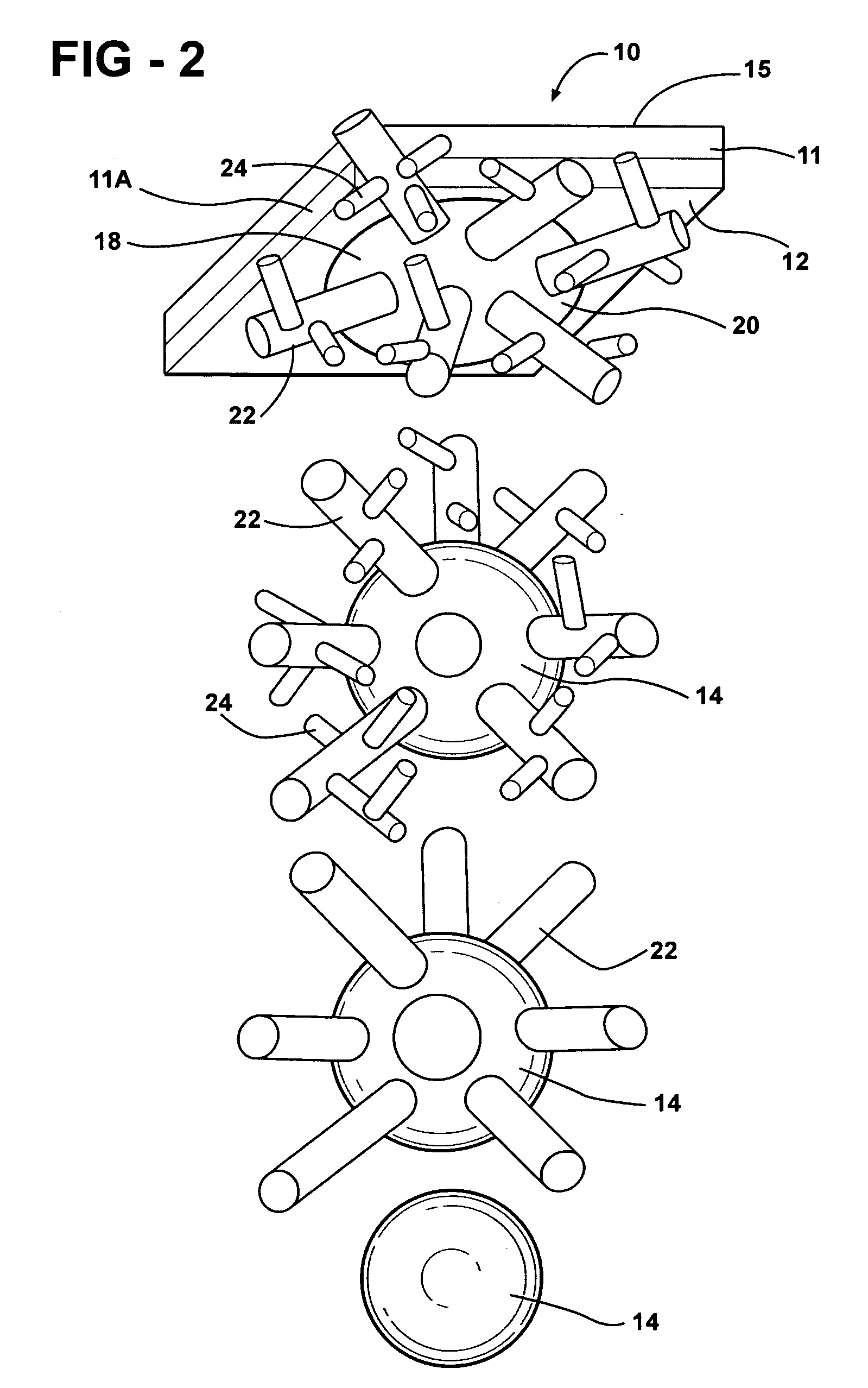

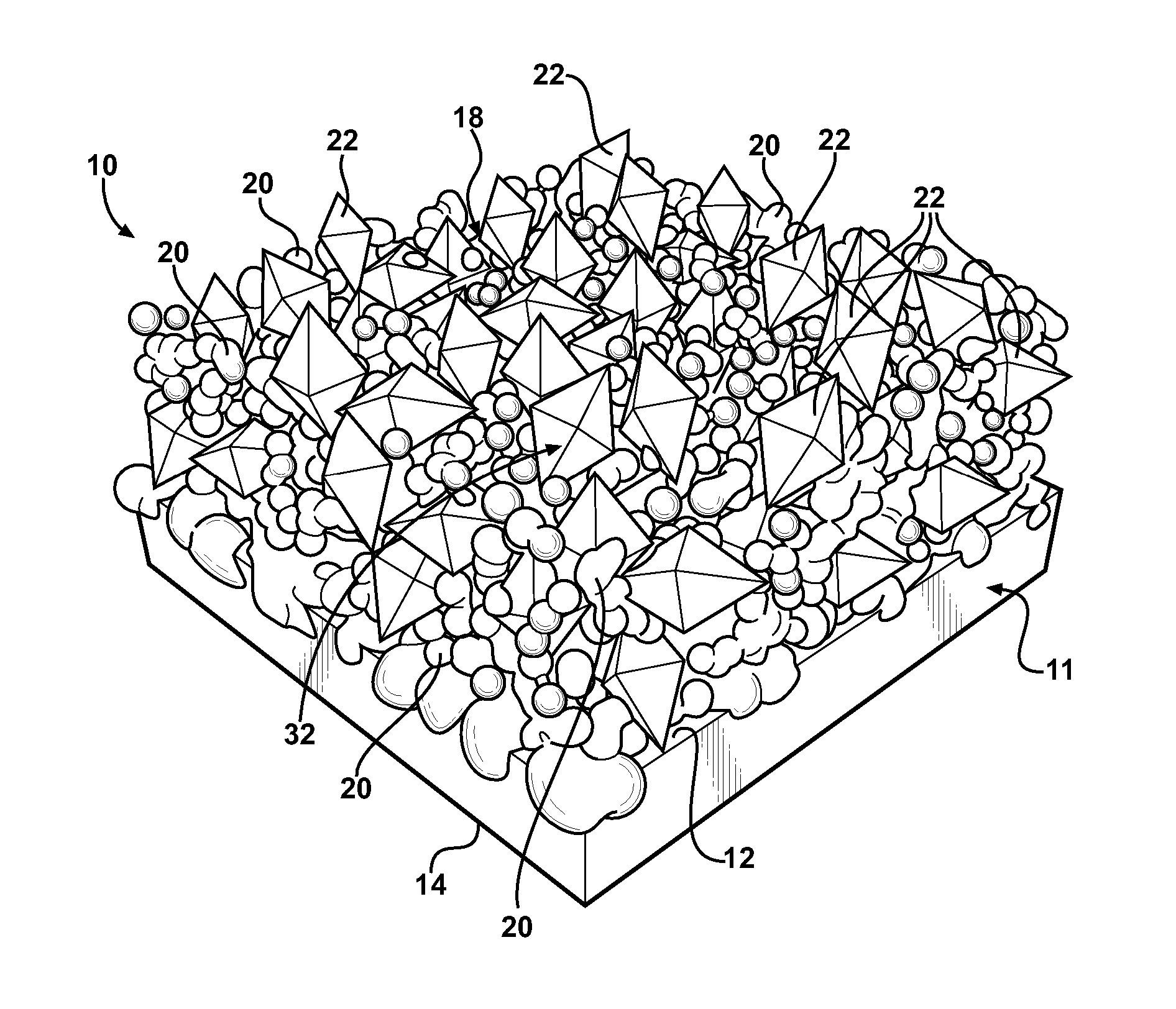

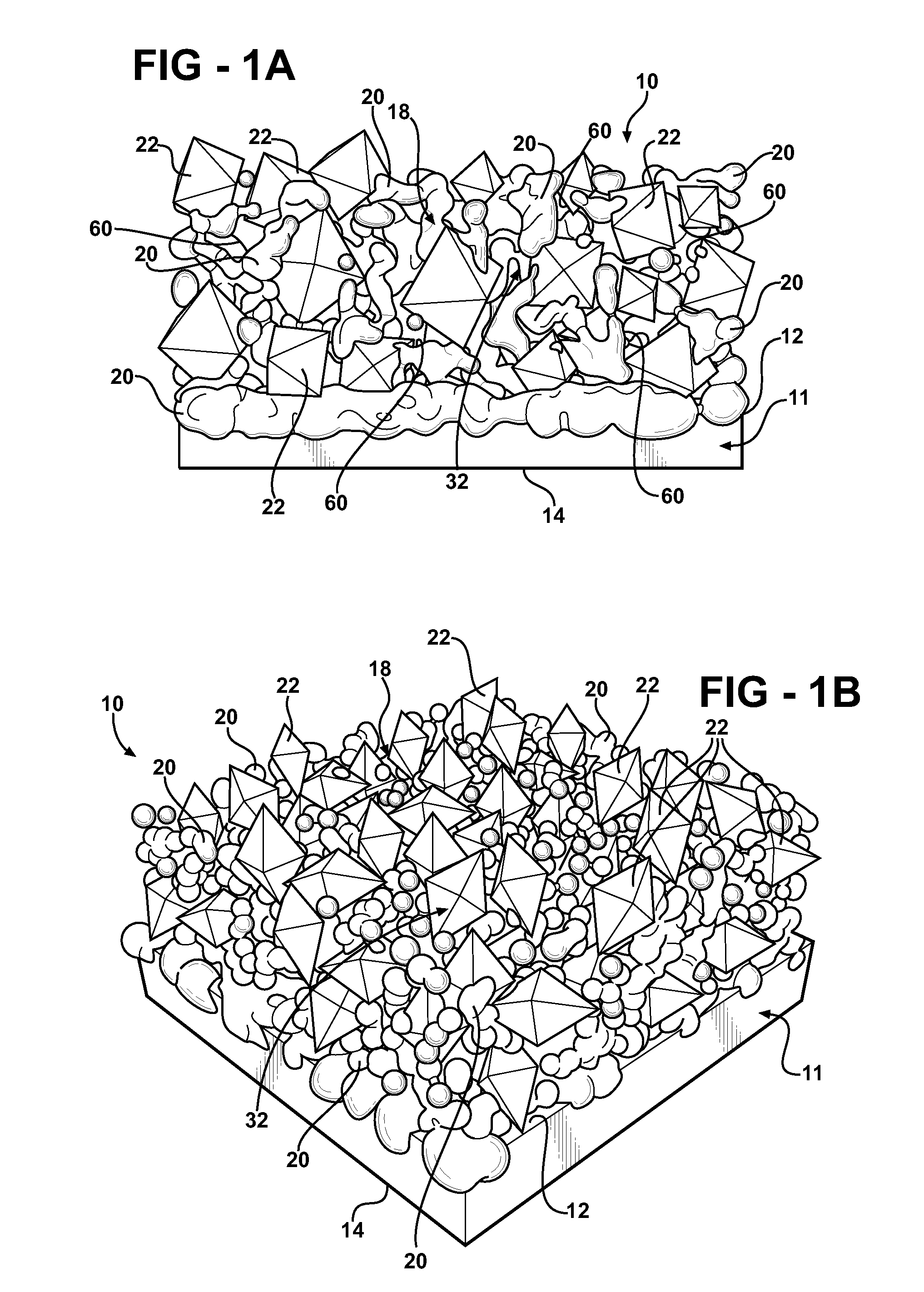

Nanostructural Electrode and Method of Forming the Same

InactiveUS20070154807A1Improve adhesionLow costActive material electrodesLi-accumulatorsPorosityHigh rate

An electrode and method of forming the same of the present invention is used for the high-rate deposition of materials, such as carbon, silicon, metals, metal oxides, and the like, onto a metal substrate defined by a metal tape used as cathode or anode combined with a separator to form a fuel cell of a secondary battery, metal-ceramic membranes, film composite metal-ceramaic materials for electronic devices. The method is cost effective and is directed to form the electrode with improved and high porosity.

Owner:NANOENER

Electrode for energy storage device and method of forming the same

InactiveUS20070218366A1Stay cohesiveLow costMolten spray coatingHybrid capacitorsHigh rateFuel cells

A method of the present invention is used for the high-rate deposition of materials, such as carbon, silicon, metals, metal oxides, and the like, onto a metal substrate defined by a metal tape. The particles of the material are mixed with fluid and are injected against the metal tape at high pressure and high velocity. The particles of the material form a current collection surface of the metal tape. The metal tape is used as cathode or anode combined with a spearator to form a fuel cell of a secondary battery, metal-ceramic membranes, film composite metal-ceramic materials for electronic devices.

Owner:NANOENER TECH INC +2

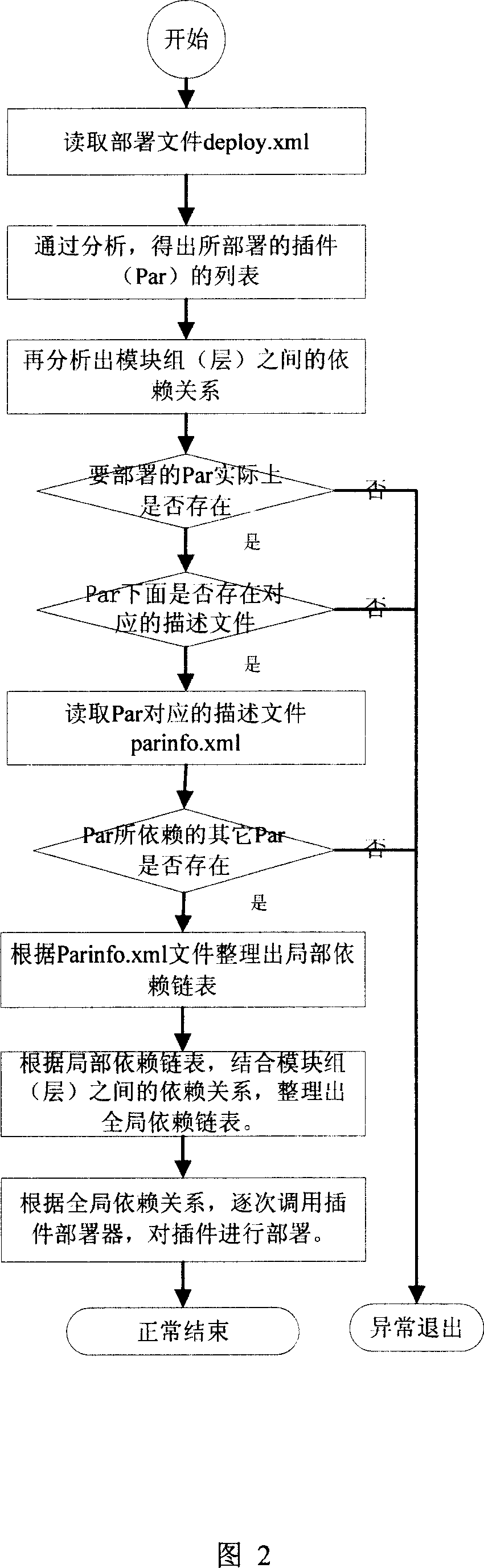

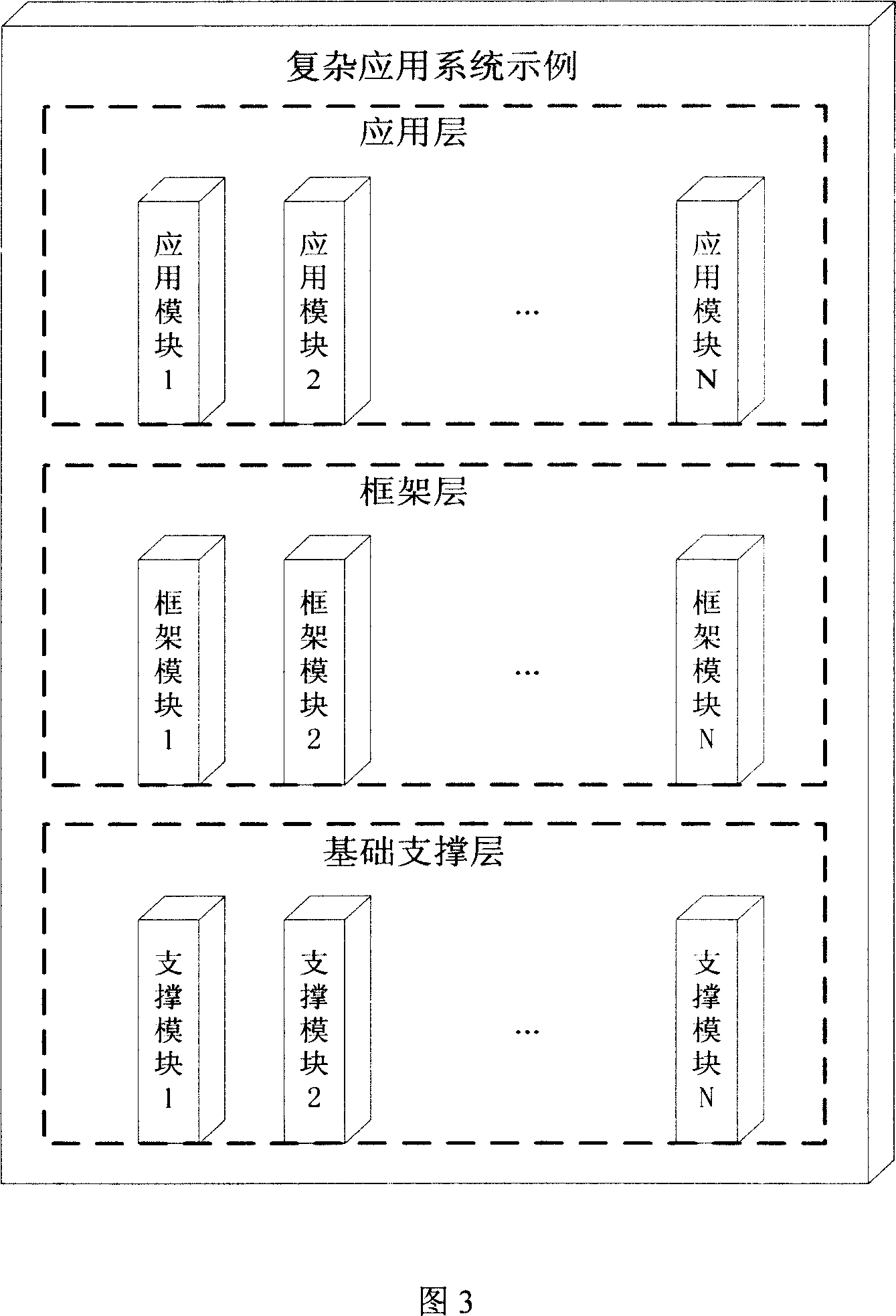

Arranging system and method for module having dependence

InactiveCN1945530ASimple and clear formatStay cohesiveSpecific program execution arrangementsMaintainabilityGranularity

The invention provides the deployment systems and methods which have dependent relation modules to solve the problems, such as unnecessary steps, thin packaging granularity, unrealizable modularization, and bad maintainability. The invention includes plug and plug deployment. The plug is used to encapsulate document concourse of complex application. The plug deployment designates the deployment range and deploy plug. The invention realizes modular deployment and greatly improves the maintainability of the system through plug mechanism.

Owner:ZTE CORP

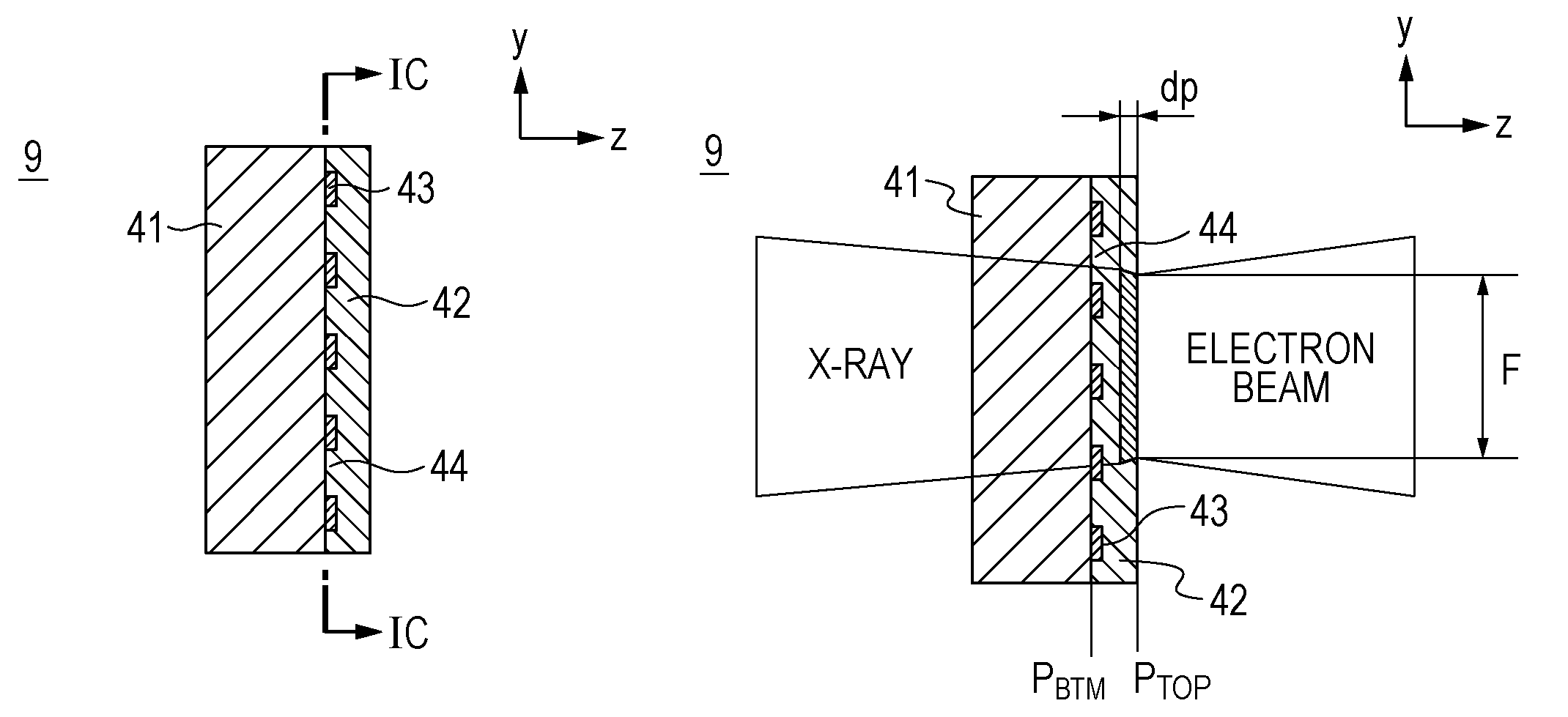

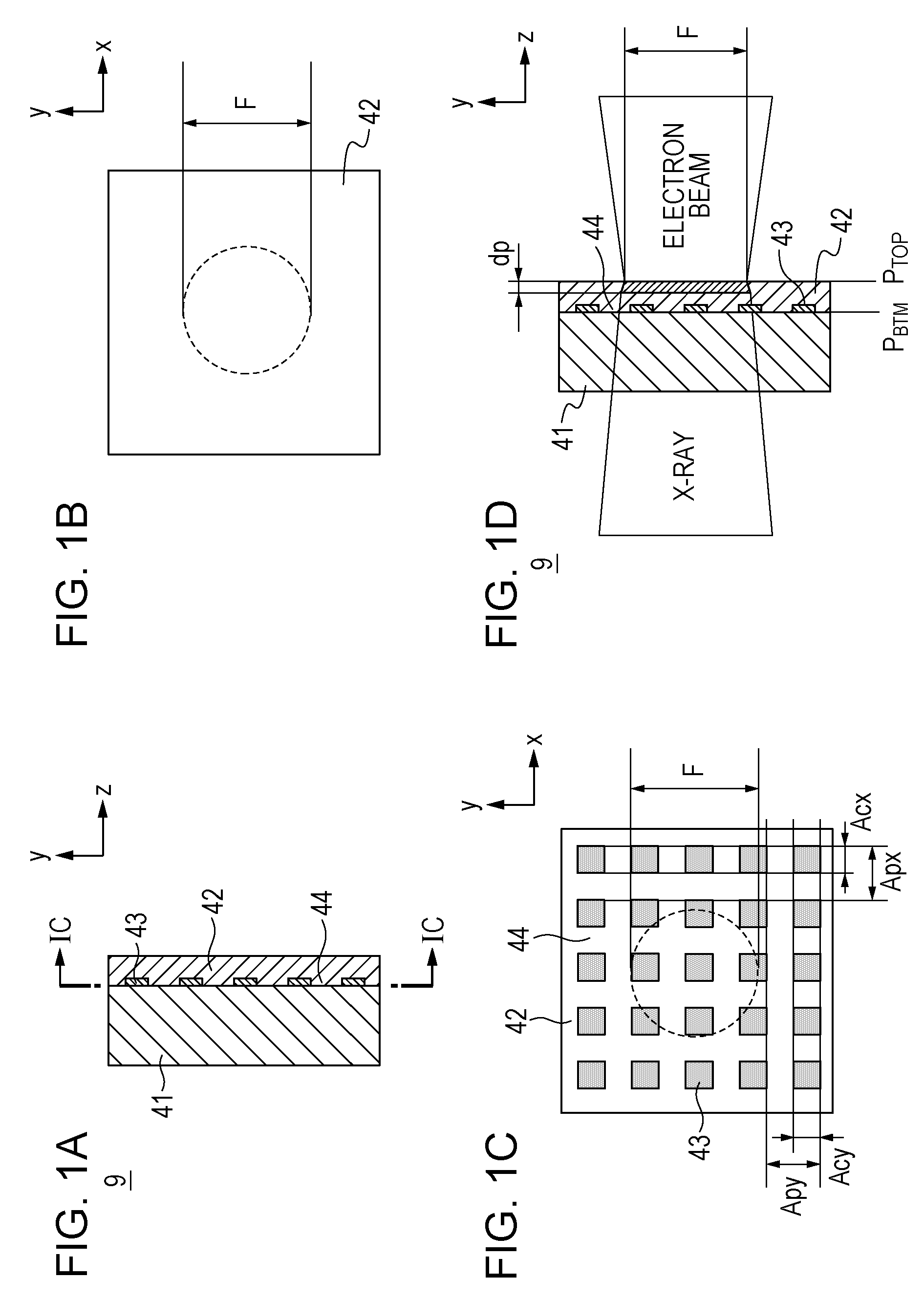

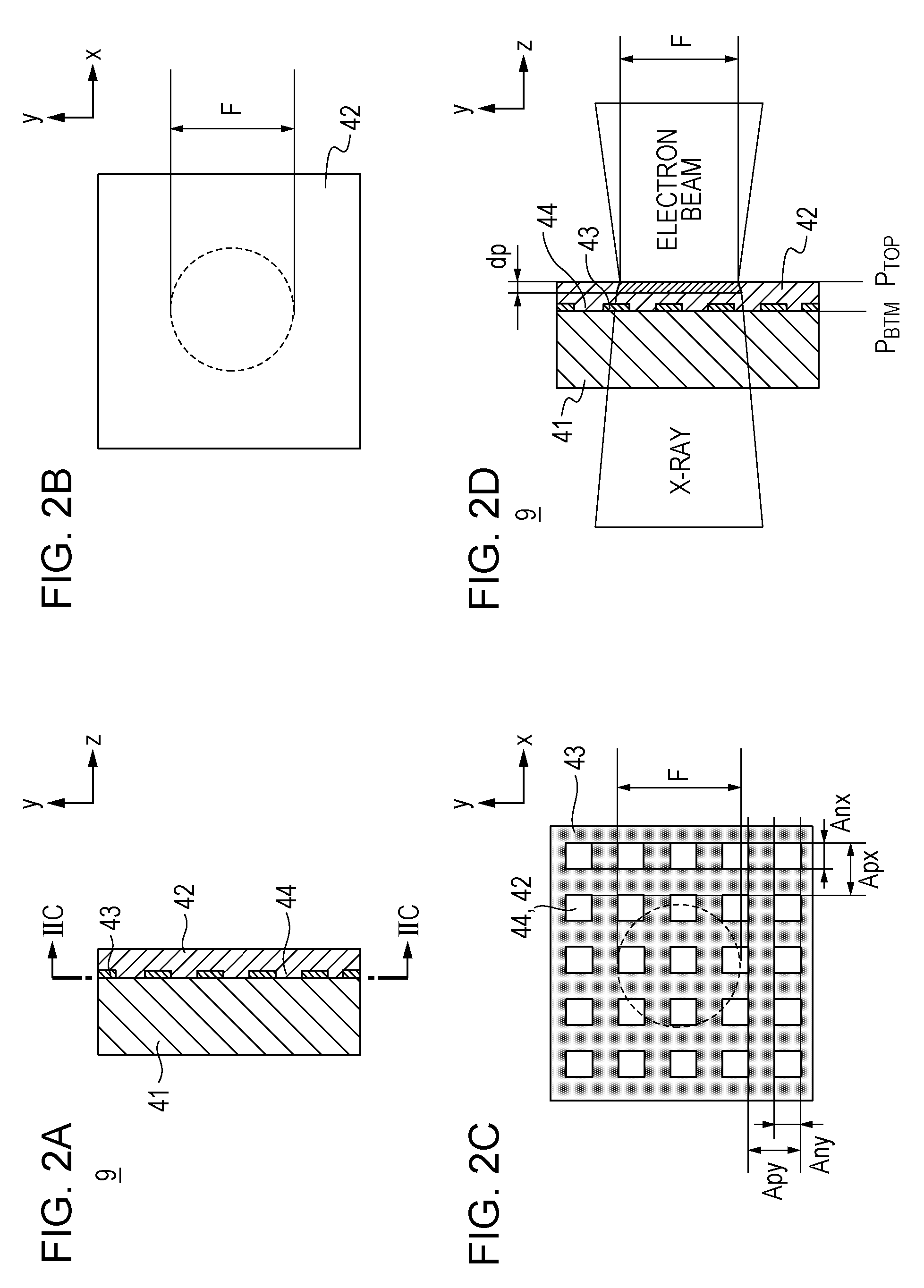

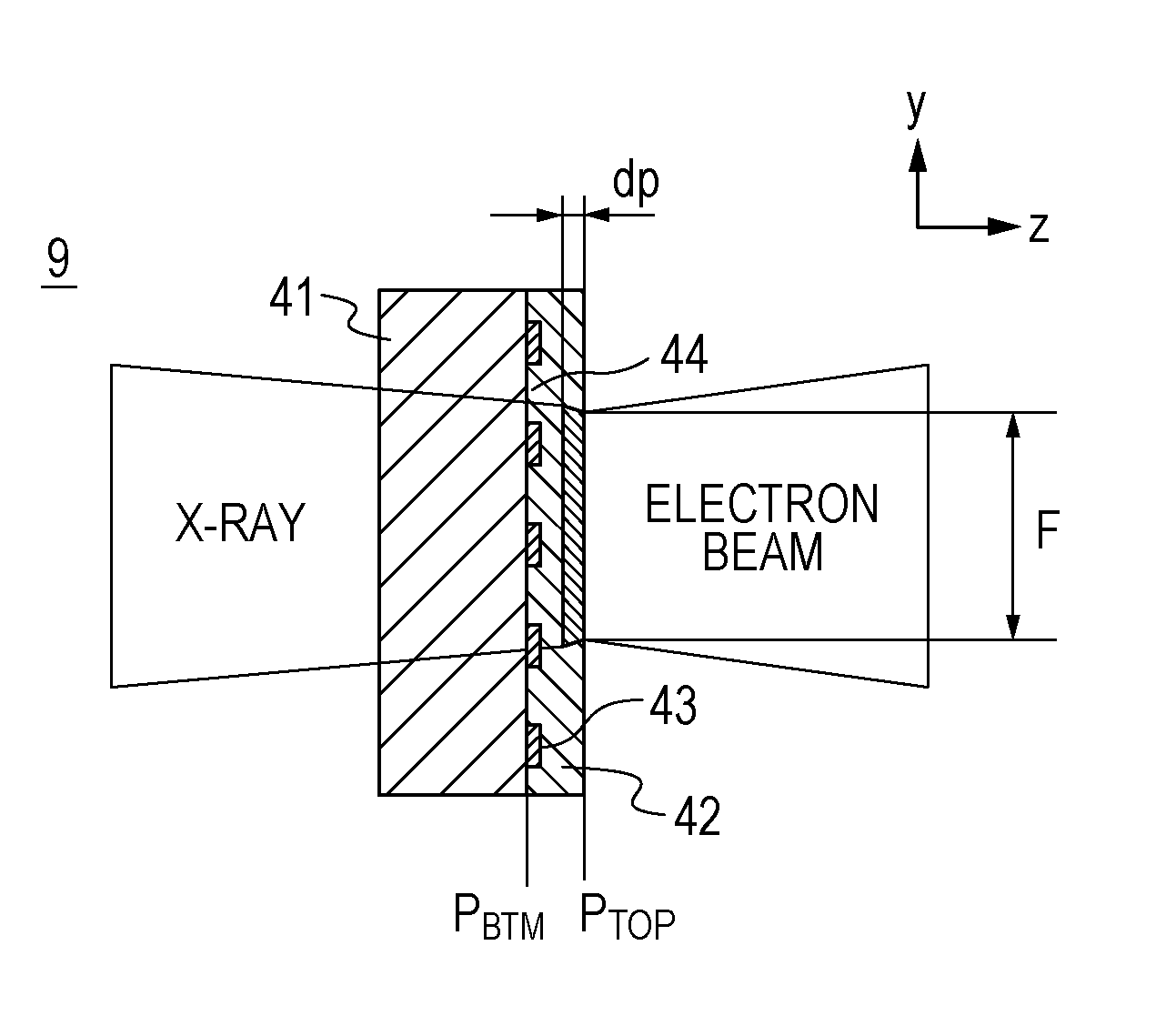

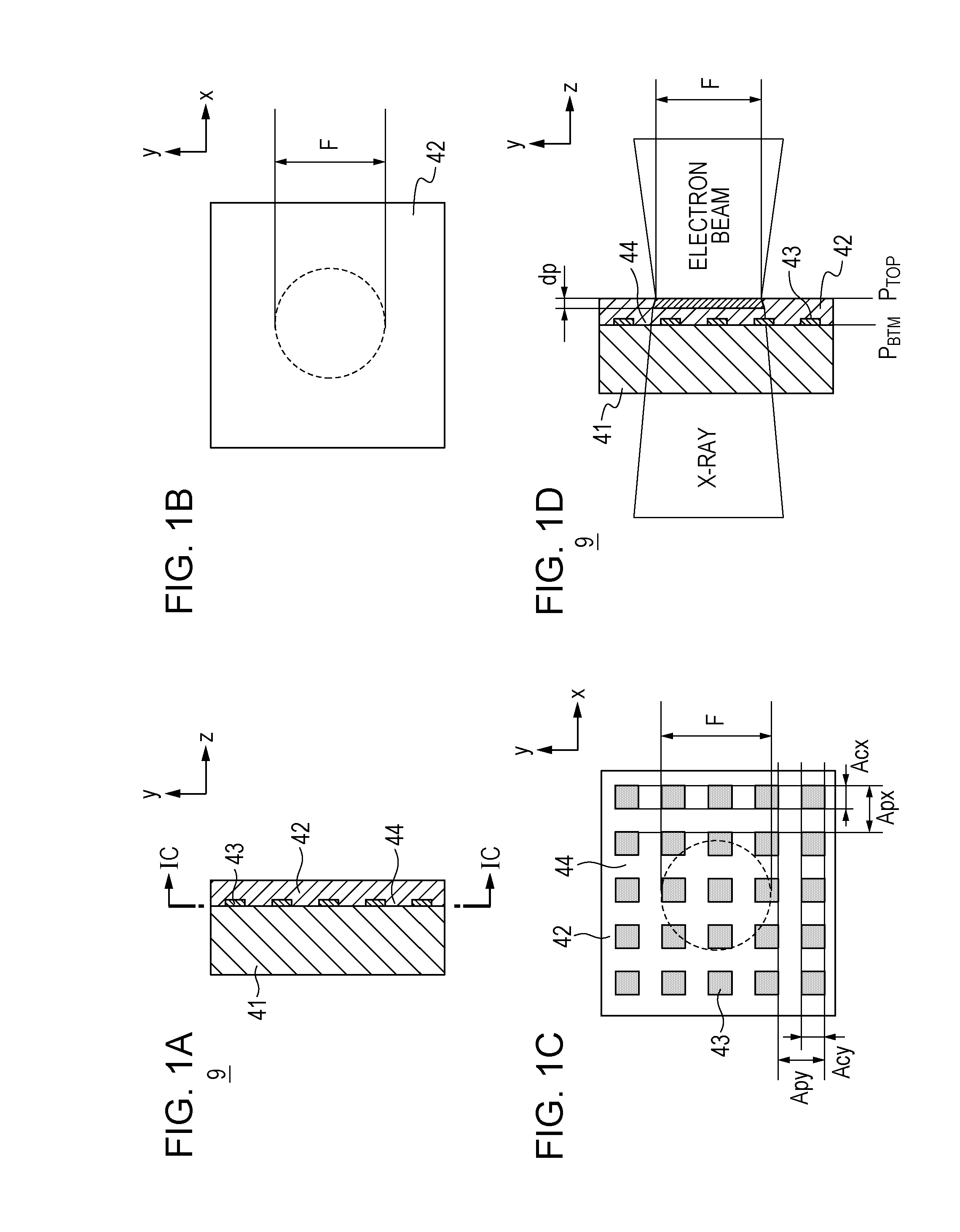

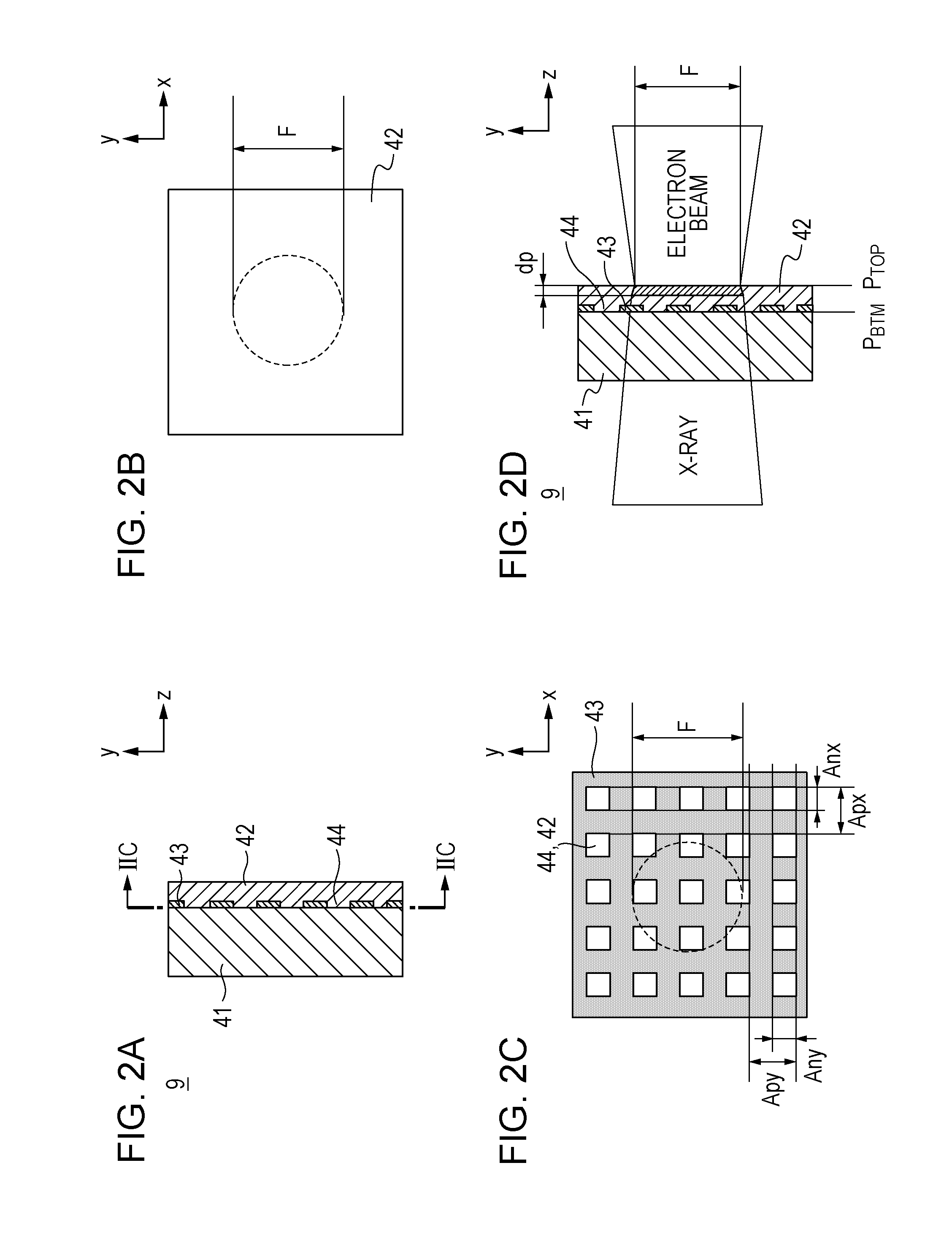

Transmissive target, X-ray generating tube including transmissive target, X-ray generating apparatus, and radiography system

ActiveUS9257254B2Suppressing variation of X-rayStable outputX-ray tube anode coolingX-ray tube electrodesSoft x rayX-ray

A transmissive target includes a target layer configured to include target metal and generate X-ray when receiving electrons and a substrate configured to support the target layer and include carbon as a main component. A carbide region including carbide of the target metal and a non-carbide region including the target metal are disposed in a mixed manner on a boundary surface between the substrate and the target layer on a target layer side.

Owner:CANON KK

Adhesive sheet for processing semiconductor wafers and/or substrates

ActiveCN101165131APrevents troubles such as flying outFull adhesionNon-macromolecular adhesive additivesSolid-state devicesUltravioletCohesive strength

An adhesive sheet of the present invention can be to lower the adhesive strength to the optimal level during pick up or the like after irradiation with UV rays and / or radiation, while maintaining adhesion with adherends before irradiation with UV rays and / or radiation by ensuring that, regardless of the texture on the surface of adherends such as semiconductor wafers and / or substrates, the adhering surface favorably conforms to the texture with preserving enough adhesive and cohesive strength. The adhesive sheet for processing semiconductor wafers and / or substrates comprises a UV- and / or radiation-transmittable base film and an adhesive layer that undergoes a polymerization curing reaction by means of UV rays and / or radiation, wherein the adhesive layer comprises at least a tackifier and a surfactant.

Owner:NITTO DENKO CORP

Transmissive target, x-ray generating tube including transmissive target, x-ray generating apparatus, and radiography system

ActiveUS20140369471A1Suppressing variation of X-rayStable X-ray outputX-ray tube anode coolingX-ray tube electrodesSoft x rayCarbide

A transmissive target includes a target layer configured to include target metal and generate X-ray when receiving electrons and a substrate configured to support the target layer and include carbon as a main component. A carbide region including carbide of the target metal and a non-carbide region including the target metal are disposed in a mixed manner on a boundary surface between the substrate and the target layer on a target layer side.

Owner:CANON KK

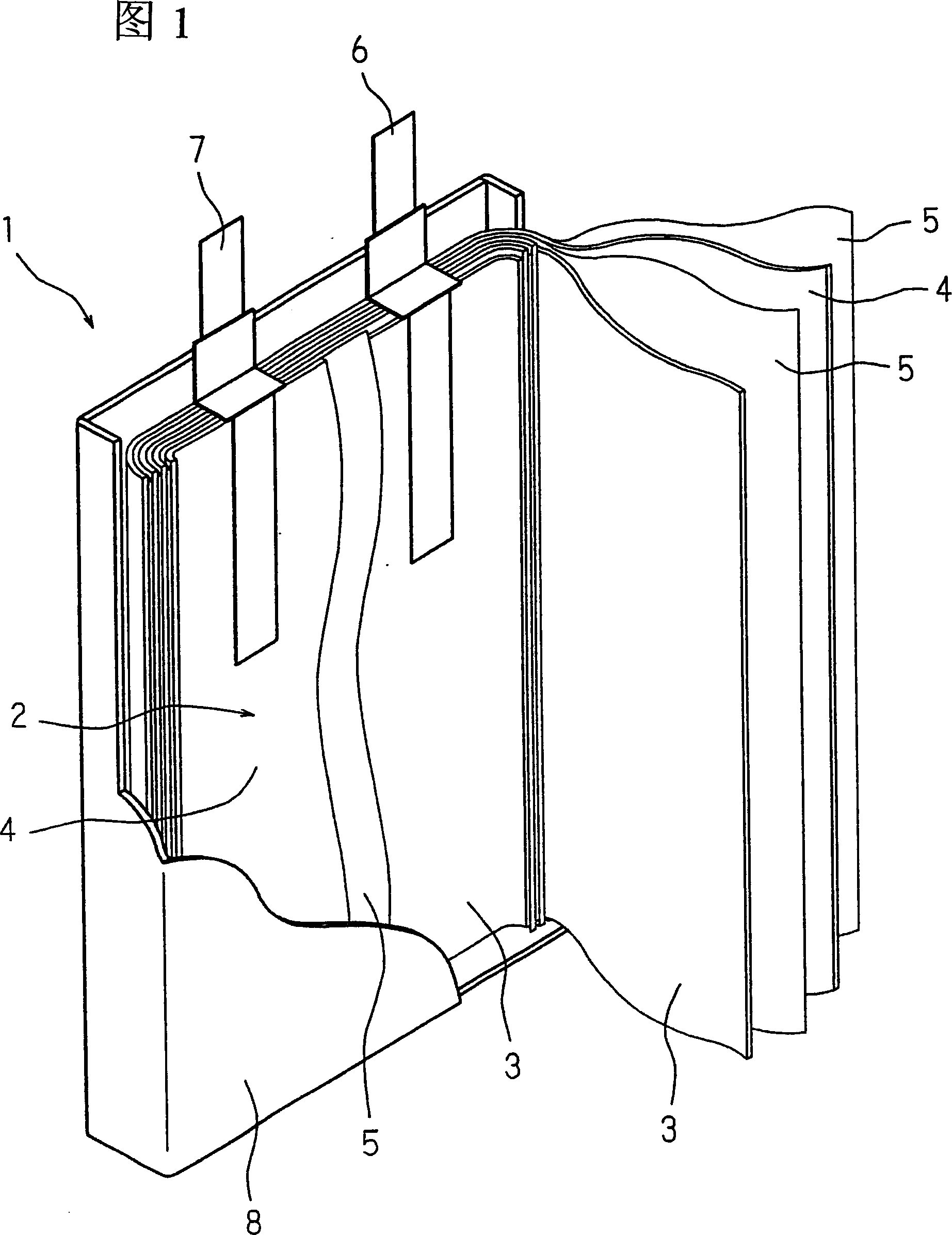

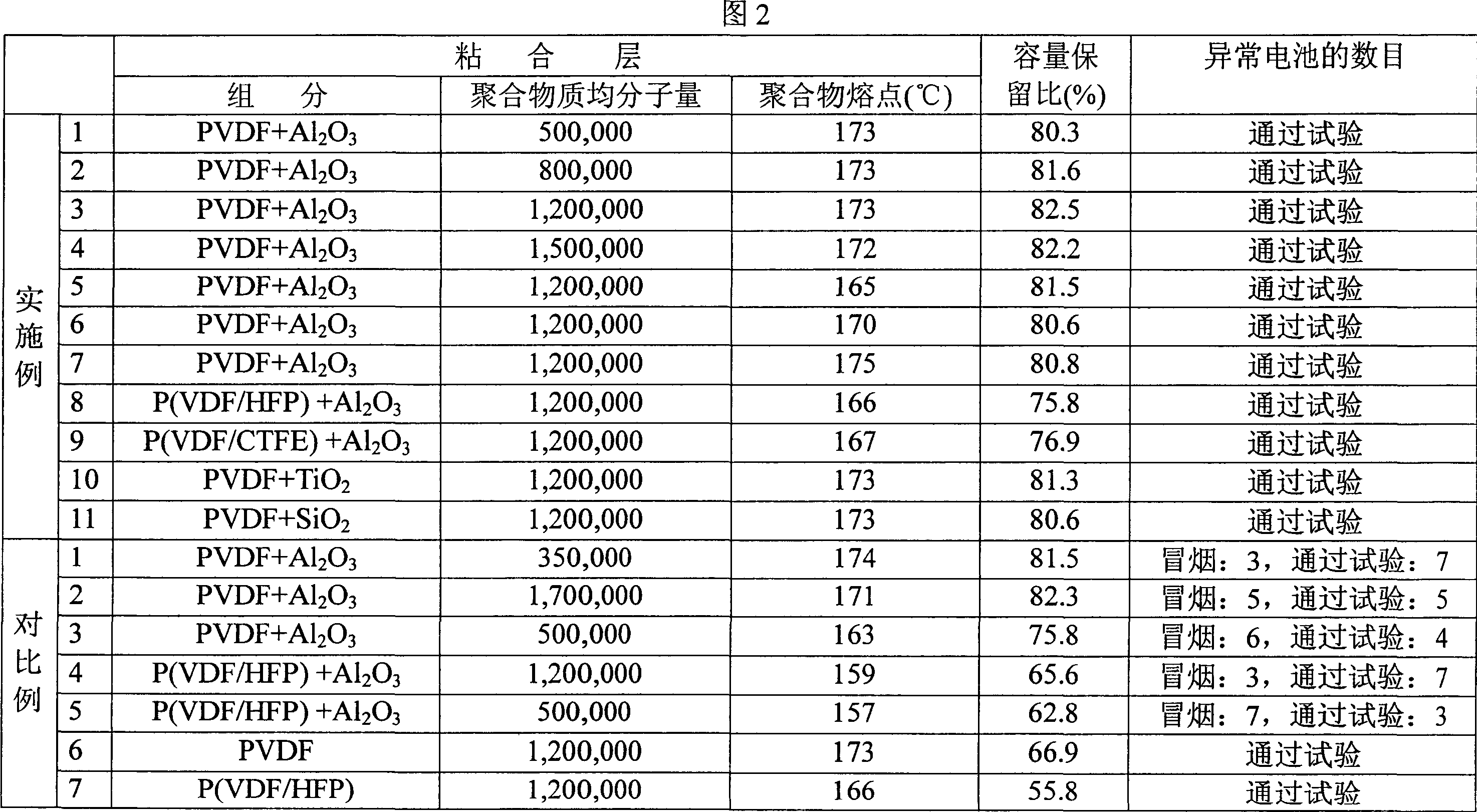

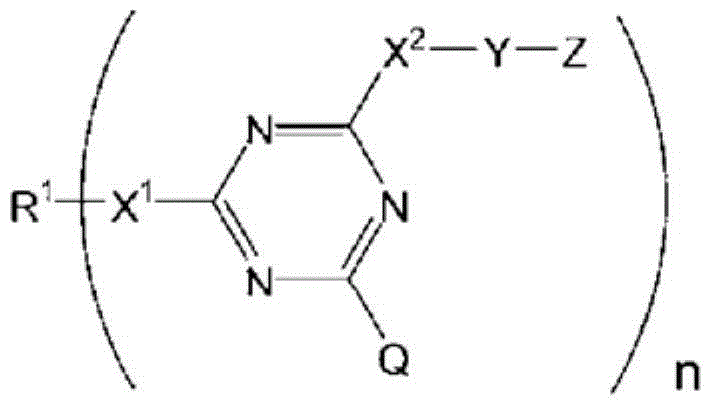

Non-aqueous electrolyte battery

InactiveCN1953268AStay porousImprove securityCell electrodesFinal product manufacturePolyvinylidene difluorideEthylene Homopolymers

In a non-aqueous electrolyte battery including a generating element having a separator bonded with an adhesive layer between a positive electrode plate and a negative electrode plate, the adhesive layer contains a fluorine-based polymer having a mass average molecular weight of from 500,000 to 1,500,000 and a melting point of from 165° C. to 175° C., and an inorganic-solid filler. The fluorine-based polymer is a polyvinylidene fluoride-based polymer such as a polyvinylidene fluoride homopolymer.

Owner:SANYO ELECTRIC CO LTD +1

Carbon black dispersion and use thereof

ActiveCN105073915ALow viscosityIncrease concentrationPigmenting treatmentNon-aqueous electrolyte accumulator electrodesHigh concentrationPolymer science

Provided is a carbon black dispersion in which N-methyl-2-pyrrolidone that can achieve dispersibility at a lower viscosity and a higher concentration and can also achieve superior storage stability compared with conventional resin-type dispersants is used as a solvent. Also provided are: a battery electrode mix layer which is homogeneous and has good coating film properties and low surface resistance; and a lithium ion secondary battery equipped with the battery electrode mix layer. The problems can be solved by, for example, a carbon black dispersion comprising carbon black, polyvinyl alcohol (or a combination of polyvinyl alcohol with a pigment derivative) that serves as a dispersant, and N-methyl-2-pyrrolidone that serves as a solvent, said carbon black dispersion being characterized in that the degree of saponification of polyvinyl alcohol is 60 to 85 mol% and the value (a) falls within the range from 0.00017 to 0.00256 inclusive wherein X (m2 / g) represents the BET specific surface area of carbon black and aX (g) represents the addition amount of polyvinyl alcohol relative to 1 g of carbon black.

Owner:TOYO INK SC HOLD CO LTD +1

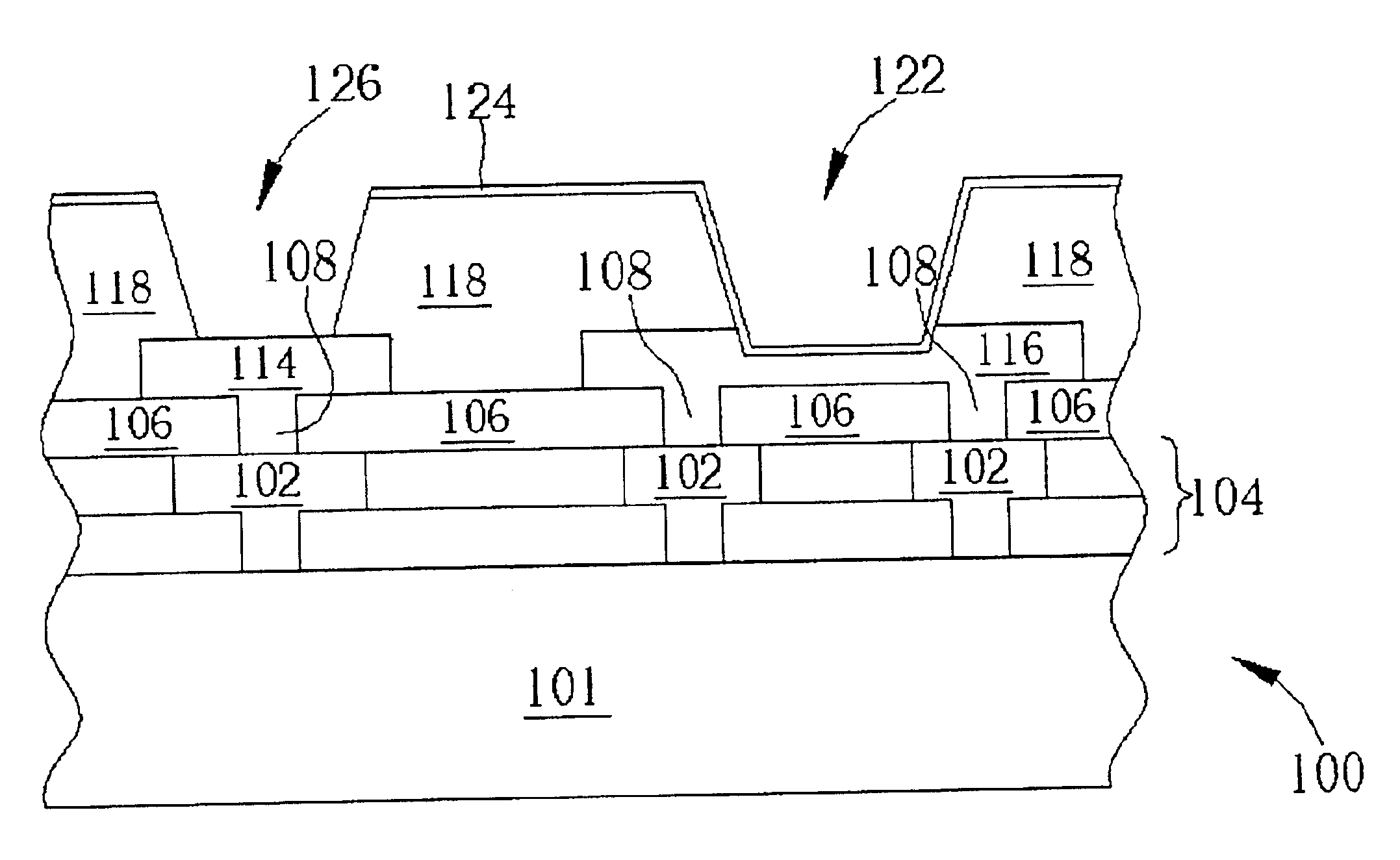

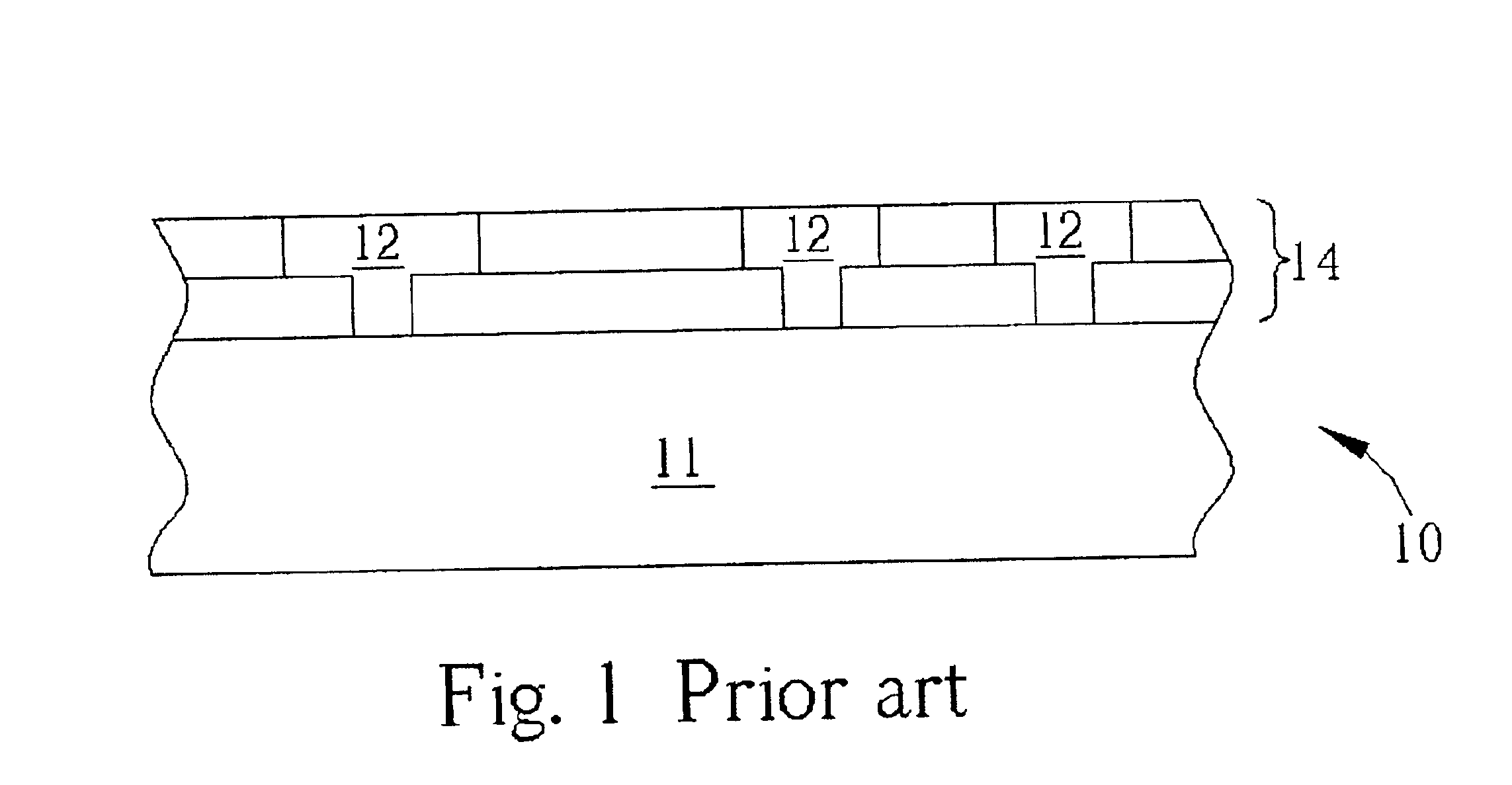

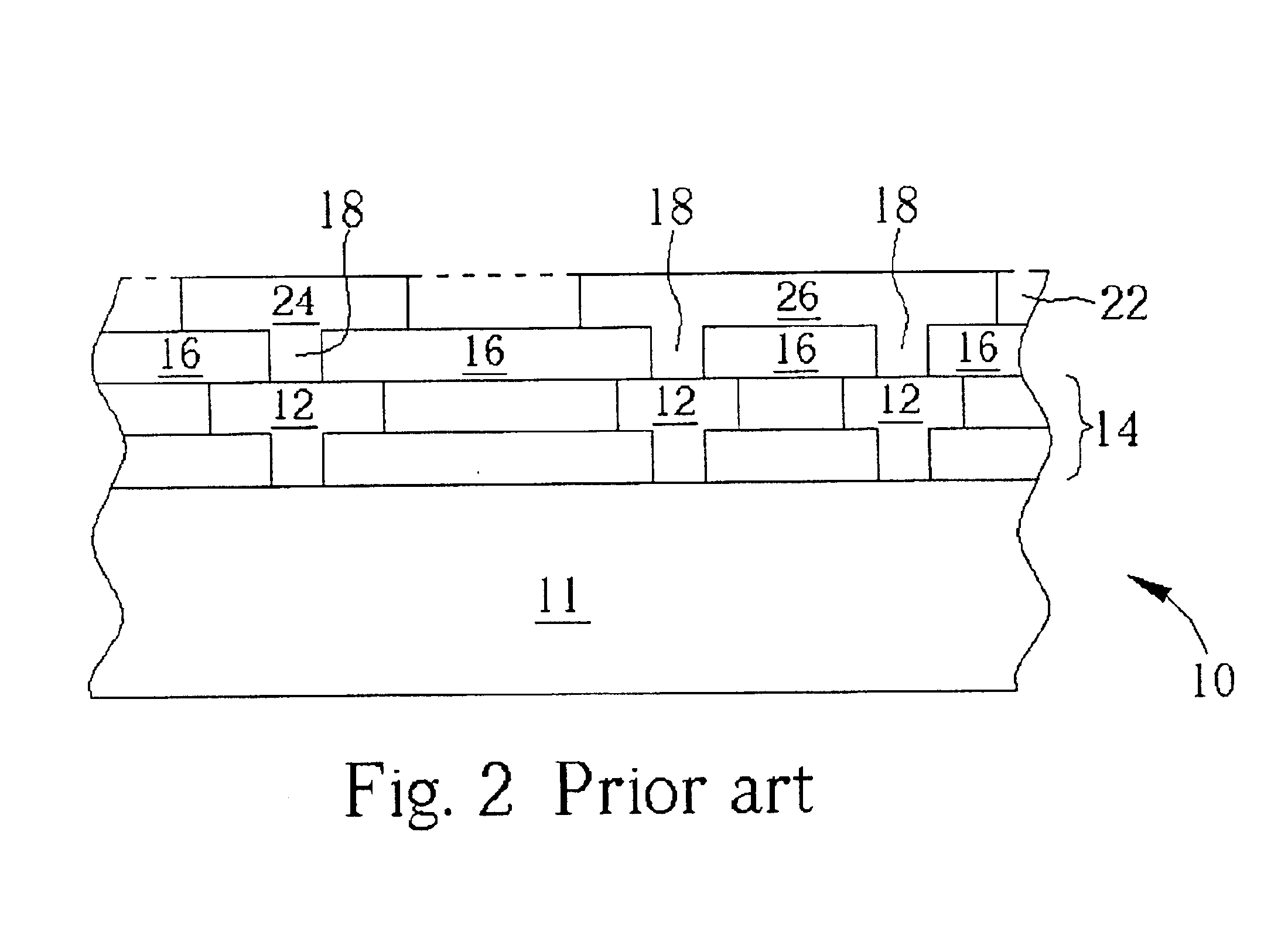

Method of forming a fuse

InactiveUS6864124B2Reduce thicknessImprove thickness uniformitySemiconductor/solid-state device detailsSolid-state devicesEngineeringDielectric layer

A surface of a semiconductor substrate defined with at least one fuse area and at least one bonding pad area. A conductive layer with a thickness of 12 kÅ and a protective layer are sequentially formed on the surface of the semiconductor substrate. Then portions of the protective layer and portions of the conductive layer in the fuse area are etched to make the thickness for the remaining conductive layer in the fuse area be approximately 5 kÅ. Finally a dielectric layer is formed on the surface of the semiconductor substrate, and portions of the first dielectric layer and portions of the protective layer in the bonding pad area are etched until reaching the top surface of the conductive layer.

Owner:MARLIN SEMICON LTD

Non-woven adhesive band for making diaper closing part

InactiveCN1508204AEasy to unwindStay cohesiveOther chemical processesFilm/foil adhesivesMethacrylateAdhesive belt

The present invention provides an adhesive tape comprising a backing comprising a fibrous layer of woven fibers or of non-woven fibers of a thermoplastic polymer, said backing comprising on said fibrous layer a silicone release layer and the side of the backing opposite to the side comprising said silicone release layer comprises a pressure sensitive adhesive layer, said silicone release layer comprising a cured reaction product of a curable composition comprising (i) a polydialkylsiloxane having acrylate and / or methacrylate groups and (ii) an organic compound free of silicon and comprising at least two reactive groups selected from the group consisting of an acrylate and a methacrylate group, said adhesive tape having a 90 DEG peel adhesion of at least 6 N / 2.54 cm relative to a polyethylene film surface and said adhesive tape having a Keil test value of not more than 1 N / 2.54 cm. The adhesive tape is suitable for making cloth-like closure systems for absorbent articles such as diapers.

Owner:3M INNOVATIVE PROPERTIES CO

Three-layer composite water-absorption pad non-woven fabric and production method

InactiveCN107323011AImprove fitStay cohesiveSynthetic resin layered productsPulp and paper industryNonwoven fabric

The invention relates to a three-layer composite water-absorption pad non-woven fabric and a production method. According to the three-layer composite water-absorption pad non-woven fabric, polypropylene spunbond cloth and pulp composite cloth are taken as base materials and coated with a low-density polypropylene film. By taking a polypropylene spunbond cloth layer as a support layer, a product has very strong power, one side of the composited product has excellent water absorption property, and the other side of the composited product has anti-sliding and waterproof effects. Pulp fibers have super-hygroscopicity, the non-woven fabric is endowed with the super-hygroscopicity through spunlacing, and one side of the polypropylene spunbond cloth of the spunlaced product is coated with the film, so that the integral adhesiveness of the composite product is guaranteed, and the hygroscopicity and barrier property of the composite product are guaranteed. By utilizing a cross-pattern embossing roller, each layer of the product is well laminated, and meanwhile, the product has good skid resistance and wear resistance and a novel pattern appearance. The polypropylene spunbond cloth and the polyethylene film can be prepared into colored products, so that the composite product is integrally colorful and can meet various requirements of customers.

Owner:DALIAN RUIGUANG NONWOVEN GROUP

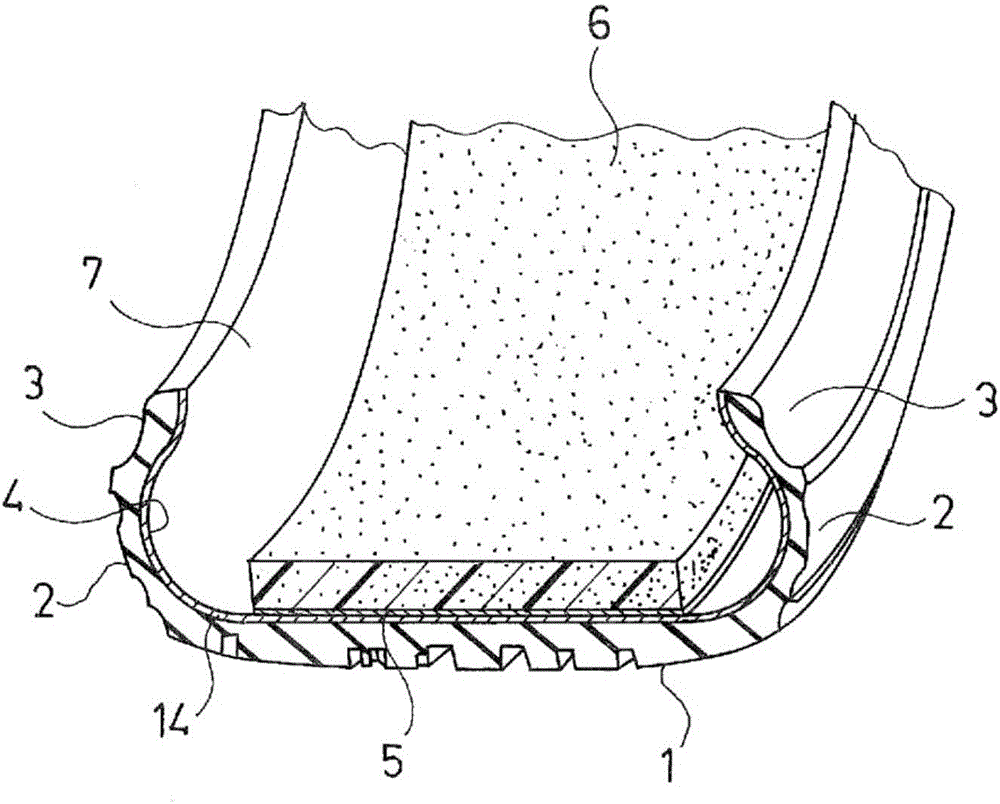

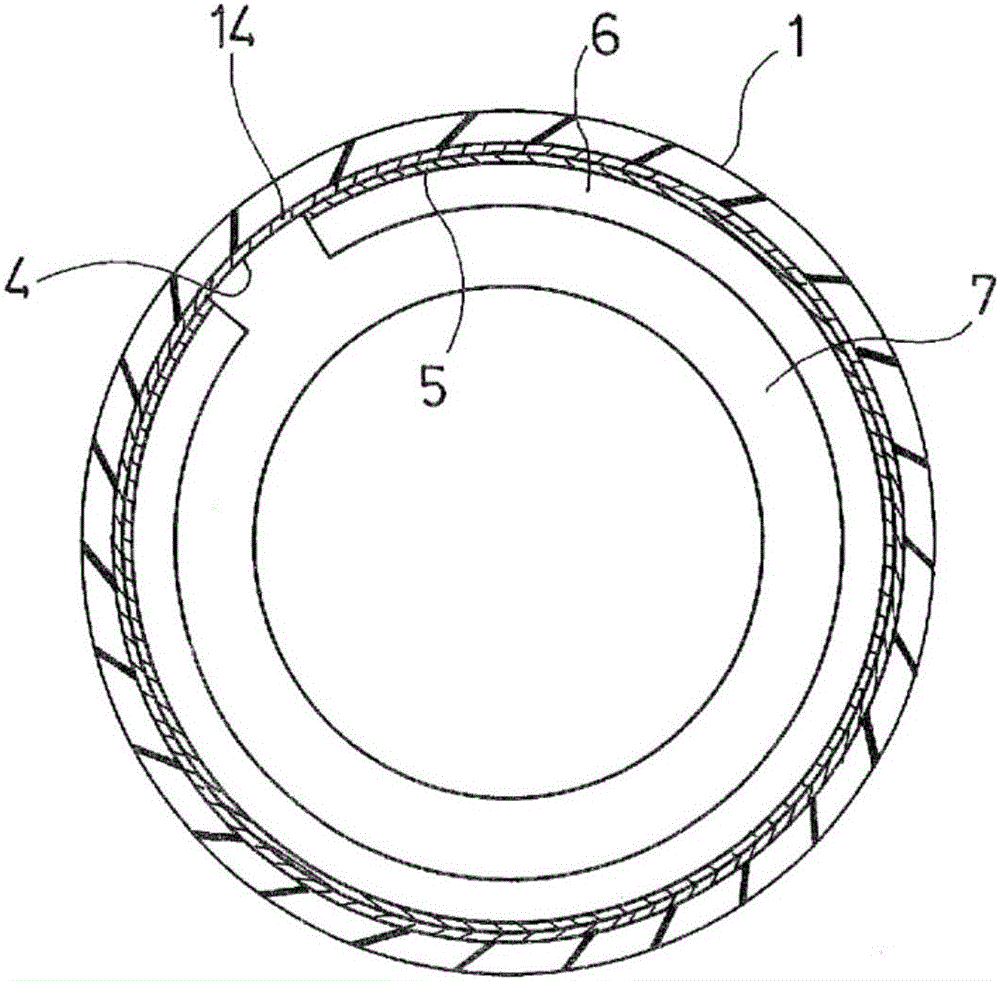

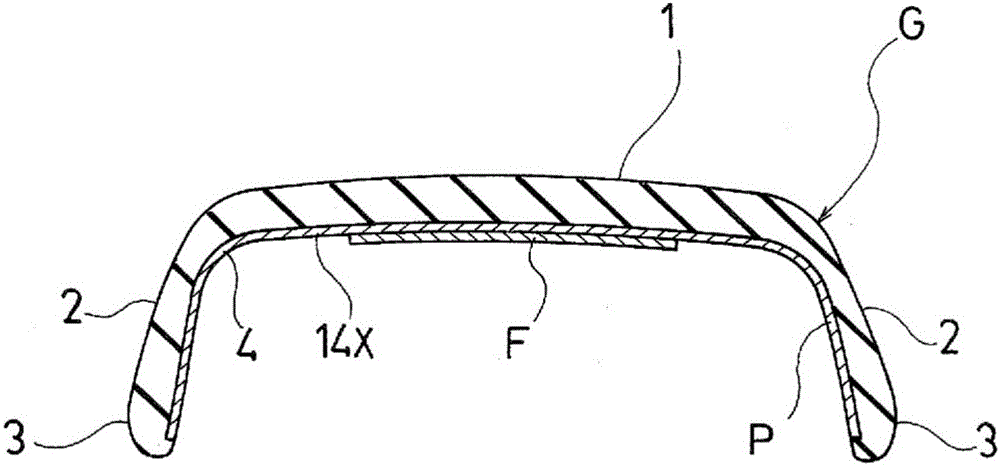

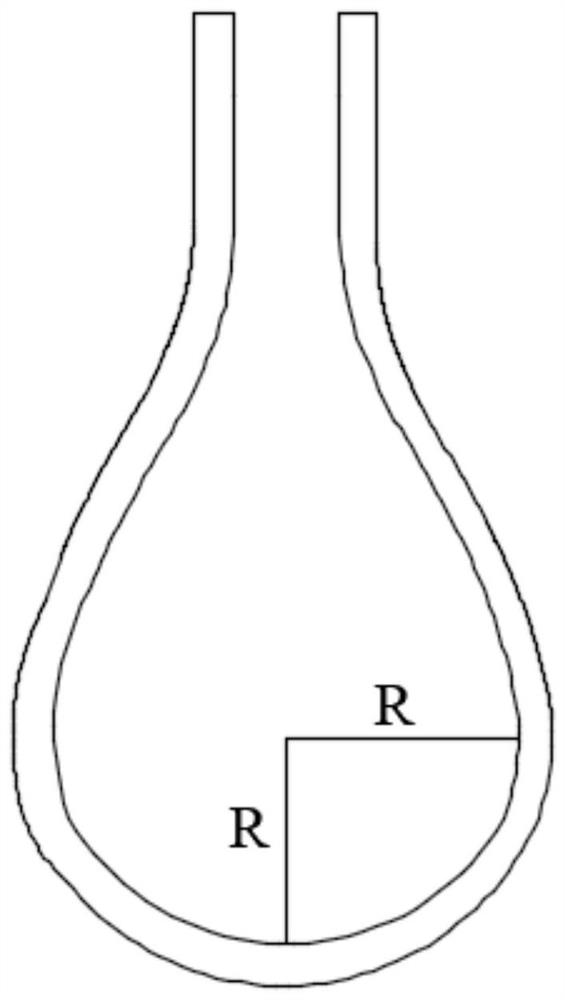

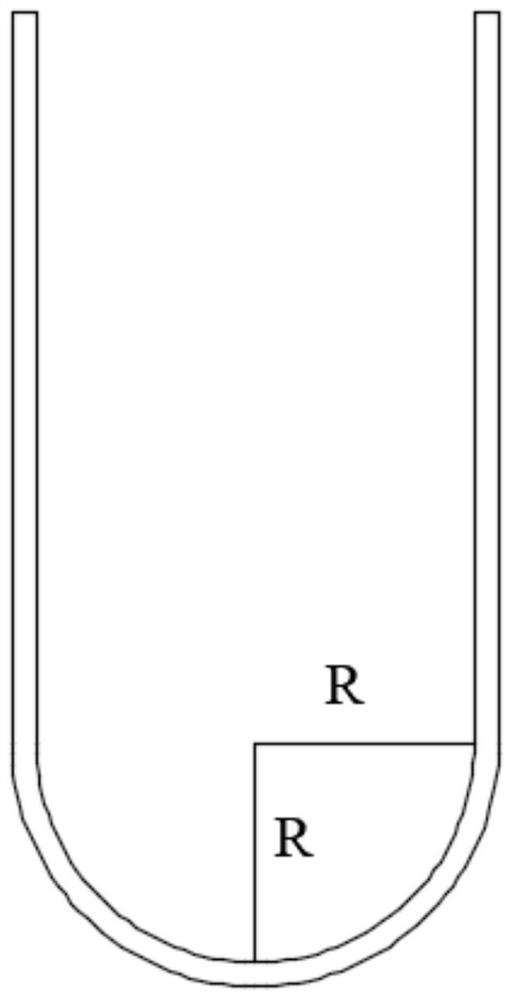

Method for producing pneumatic tire

ActiveCN105745064AGood removal effectPrevent peelingWithout separate inflatable insertsTyresVulcanizationBand shape

Provided is a method for producing a pneumatic tire which makes it possible to easily remove a parting agent from a region of the tire inner surface to which a sound-absorbing material is adhered, and as a result, suppresses the detachment of the sound-absorbing material. This method for producing a pneumatic tire involves: forming a green tire provided with an inner liner member; attaching a film to a region corresponding to a tread section on the inner surface of the green tire by using the adhesive force of the inner liner member; applying a coat of a parting agent to the inner surface of the green tire provided with the film; vulcanizing the green tire coated with the parting agent; removing the film from the inner surface of the pneumatic tire obtained through vulcanization; and adhering a belt-shaped sound-absorbing material via an adhesive layer in the tire-circumferential direction to an exposed region where the film is peeled away.

Owner:THE YOKOHAMA RUBBER CO LTD

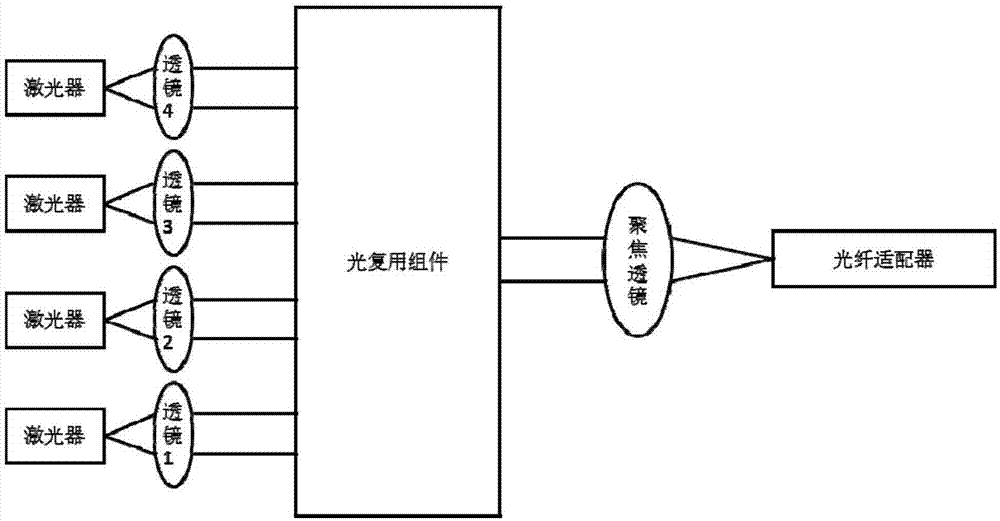

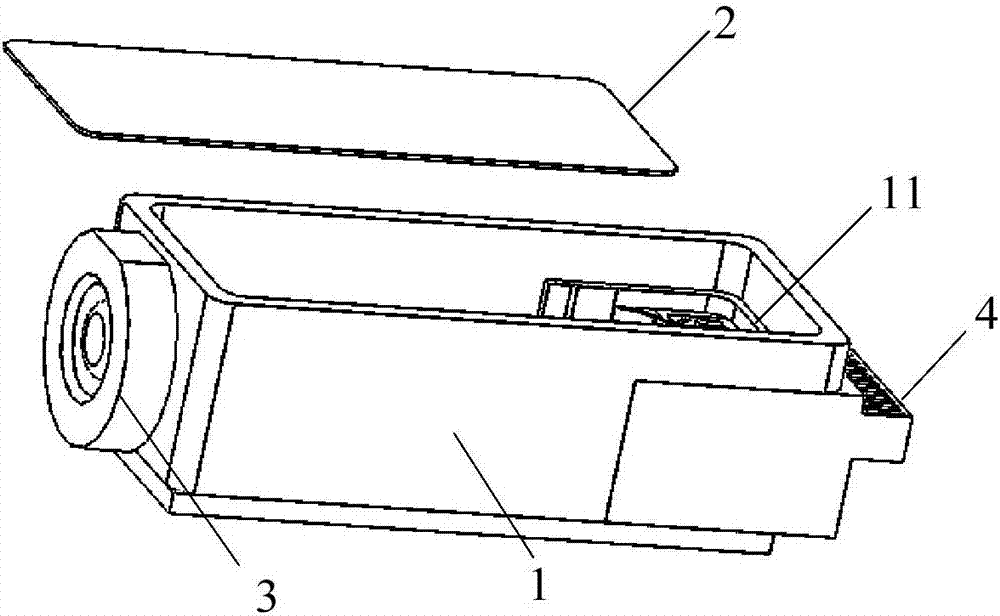

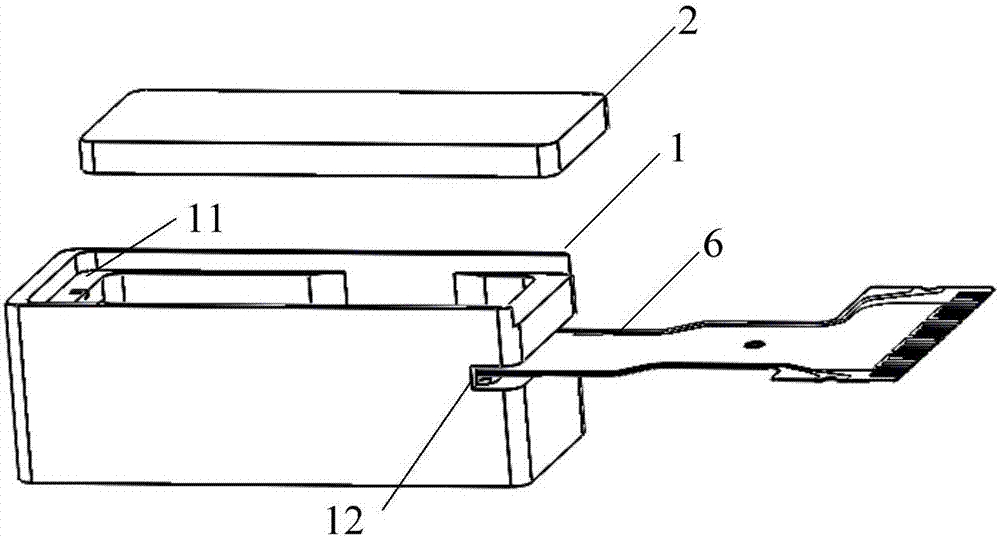

Optical sub module and optical module

ActiveCN107219596AImprove impact performanceStay cohesiveCoupling light guidesElectricityOptical Module

The invention discloses an optical sub module and an optical module. The optical sub module comprises a shell, a cover plate, an optical assembly, a flexible board and an optical window, wherein the shell comprises a bottom surface and four side walls vertical to the bottom surface, the inner surfaces of the side walls are provided with supporting plates with the same height, the height of one side wall is the same as that of the supporting plate, the heights of the other three side walls are larger than that of the supporting plate, and the cover plate is in sealed connection with the supporting plates; the flexible plate provides electric connection for the optical assembly; and optical connection between the optical assembly and the outer part through the optical window is realized. When the optical sub module is packaged, rubber coating is carried out on supporting plates on the higher side walls, after the cover plate covers the supporting plates, an adhesive is cured, hot air generated during the curing process of the adhesive is discharged from a gap between the lower side plate and the cover plate, and thus, the acting force of the hot air inside the shell does not generate bad influences on fixing of the cover plate, and the sealing performance of the optical sub module is ensured.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

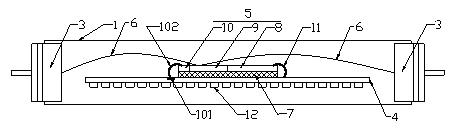

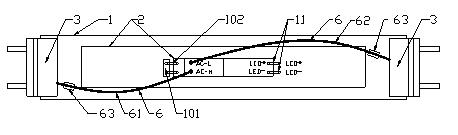

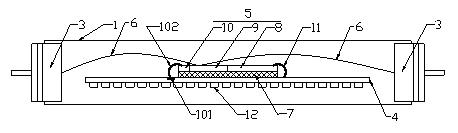

Light-driving integrated LED fluorescent lamp and manufacture process thereof

InactiveCN101922640AImprove insulation performanceExcellent adhesionPoint-like light sourceElectric circuit arrangementsInsulation layerDaylight

The invention relates to a light-driving integrated LED fluorescent lamp and a manufacture process thereof. The light-driving integrated LED fluorescent lamp comprises a fluorescent tube and an LED driving board device mounted in the fluorescent tube. A plug communicated with an external power supply is arranged at the end of the fluorescent tube. The light-driving integrated LED fluorescent lamp is characterized in that the LED driving board device comprises a light board distributed with LED lamps and a power supply driving board connected with the light board, the input end of the power supply driving board is communicated with the plug at the end of the fluorescent tube through a lead, and the power supply driving board and the light board are separated by a thermal conducting silicone film. In addition, the invention also provides a manufacture process of the LED fluorescent lamp which has reliable insulation, connection and quake resistance and reasonable wiring rule as well as a pin processing process of elements and devices, can avoid shorted-circuit phenomena caused by insufficient bottom wiring insulation and insulation layer piercing by the pins and can also prevent a creepage phenomenon due to the parallel operation of an AC power line of the light board and a DC from burning the light source.

Owner:FUJIAN XIANGYUN PHOTOELECTRIC TECH

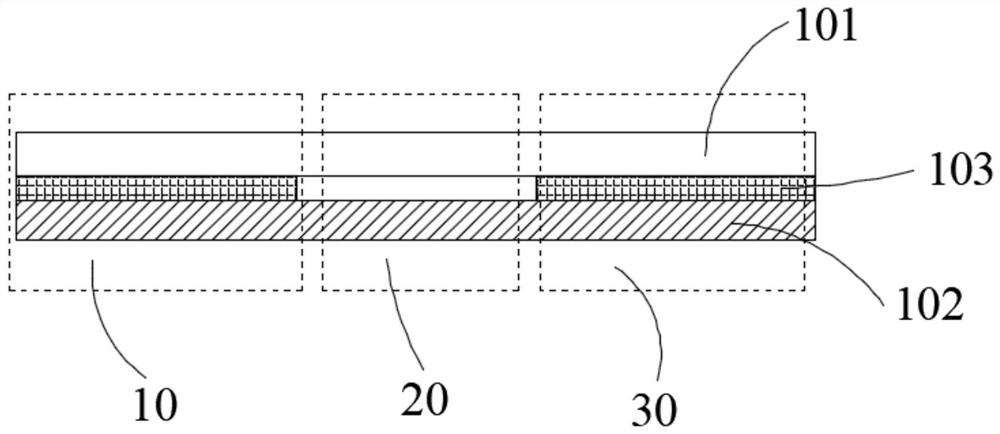

Display device

ActiveCN111816070AReduce deformationImprove flatnessDigital data processing detailsPhotovoltaic energy generationDisplay deviceEngineering

The invention discloses a display device, which comprises a flexible display panel, the flexible display panel comprises at least one bending area and at least two non-bending areas, the flexible display panel comprises a substrate, at least one supporting layer and at least one adhesive layer, and the adhesive layer is located between the supporting layer and the flexible display panel. Accordingto the display screen bending method, the display screen can be less restrained by a mechanism during bending through various attaching methods of the panel and the supporting layer on the display screen in the bending area and a reasonable non-adhesive distance theoretical calculation formula, and the phenomena of folding marks and waves of the display screen are relieved when the panel is flattened.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

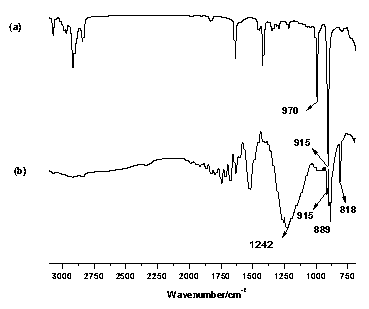

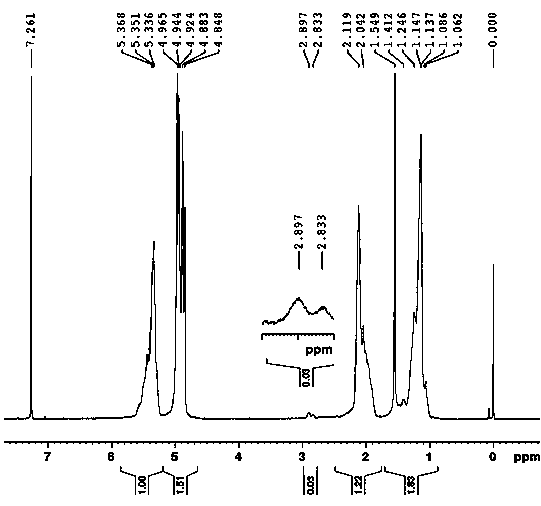

Preparation method of epoxidized 1, 2-polybutadiene

The invention relates to a preparation method of a polymeric material, in particular to a preparation method of epoxidized 1, 2-polybutadiene. Preparation steps of the preparation method are as follows: composition A and composition B are added to a reaction flask and stirred by magnetic force at the temperature of 65 DEG C until the composition A is dissolved; composition C and composition D are added to the reaction flask and stirred fully and uniformly; quantitative composition E is added to a system and reacted for a period at the constant temperature; after the reaction is finished, a product is poured out; absolute ethyl alcohol is added for precipitating a solid, sedimentation is performed for a period, suction filtration is performed, and a sodium bicarbonate solution and distilled water are used for washing a product solid for a plurality of times respectively; and the washed product solid is put into an oven for vacuum drying for 12 h at the temperature of 60 DEG C, and a product is obtained. The invention provides a synthesis method for epoxidizing 1, 2-polybutadiene. The prepared epoxidized 1, 2-polybutadiene can be used for toughening modification of other high polymer materials (such as nylon, epoxy resin and the like).

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

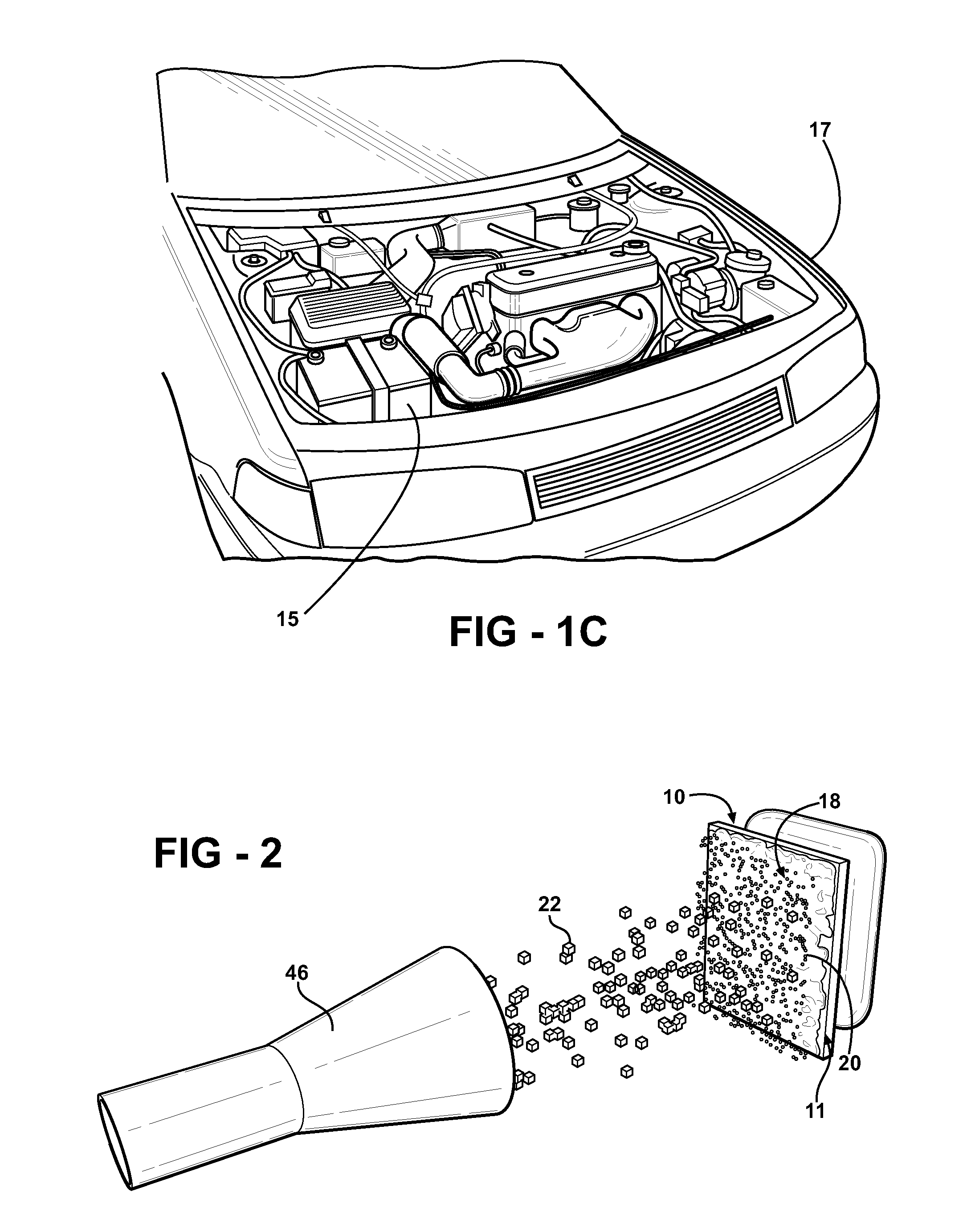

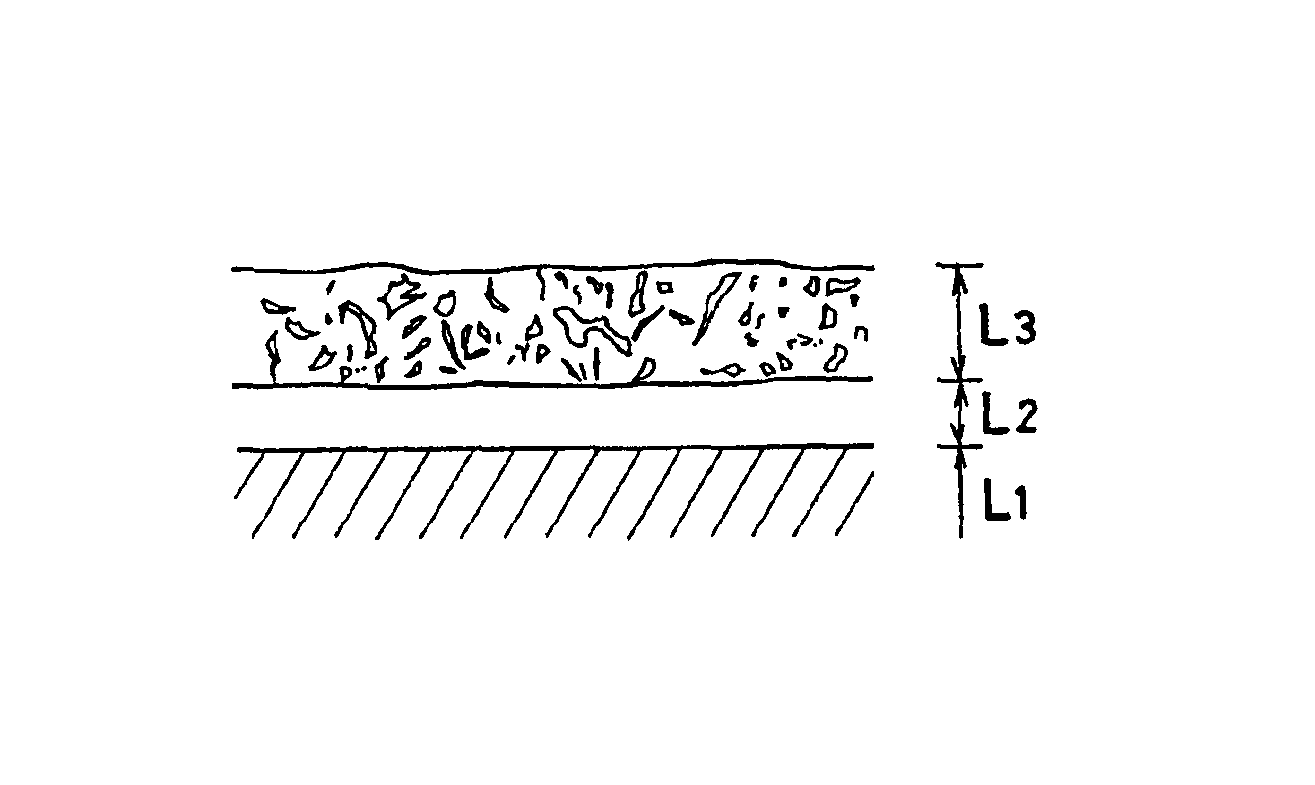

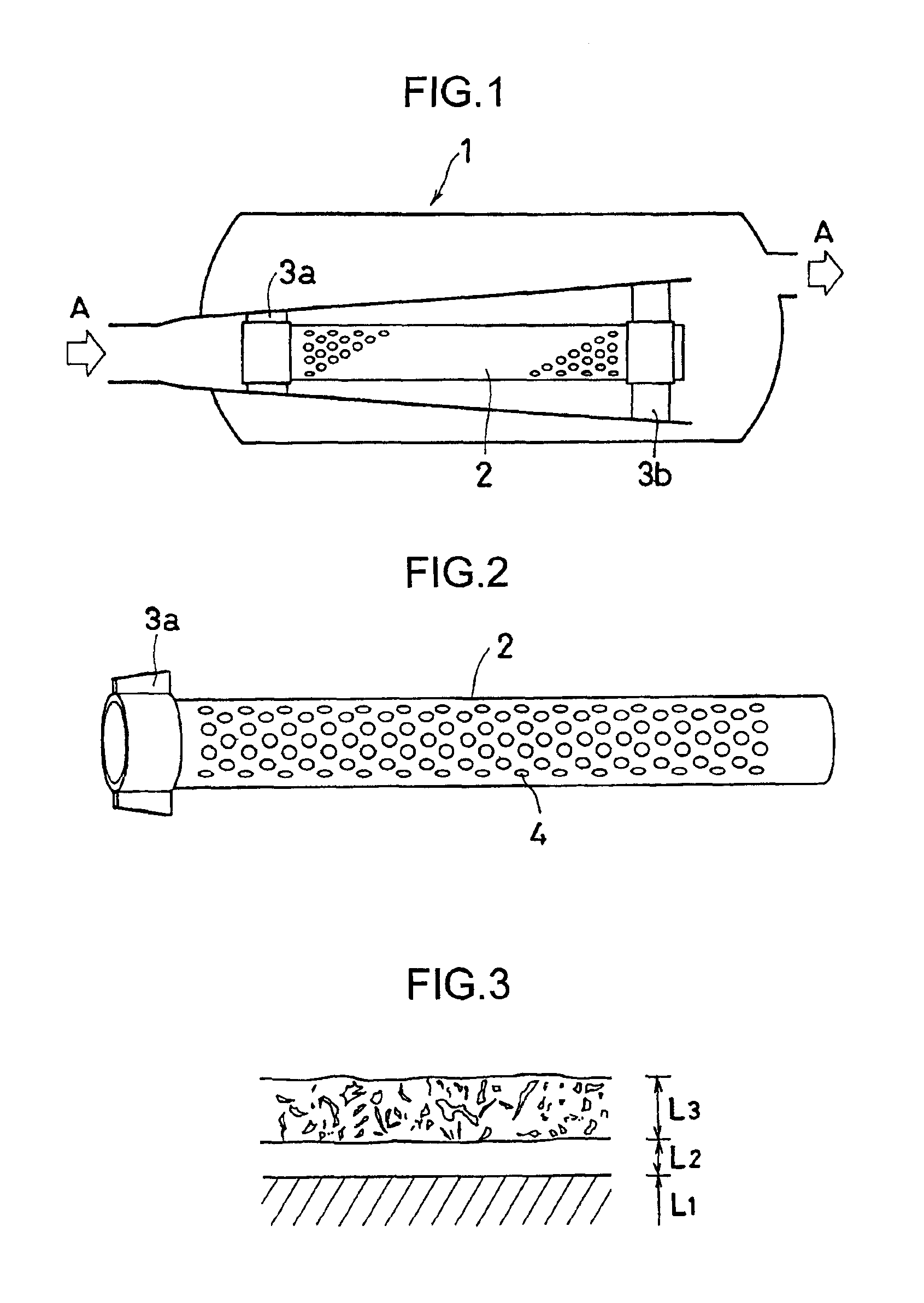

Exhaust gas purification catalyst for internal combustion

InactiveUS6875408B1Improve adhesionAvoid separationCombination devicesInternal combustion piston enginesCombustionOxygen

An object of the present invention is to provide an exhaust gas purification catalyst which can minimize the separation of the catalyst layer due to heat and vibration, can suppress thermal deterioration of the catalytic substance, and can exhibit excellent purification capabilities under severe conditions. Specifically, the present invention relates to an exhaust gas purification catalyst wherein an undercoat layer comprising a heat-resistant inorganic oxide having an oxygen-absorbing substance added thereto is formed on a surface of a metallic carrier, and a catalyst-carrying layer is formed on the undercoat layer.

Owner:SUZUKI MOTOR CORP

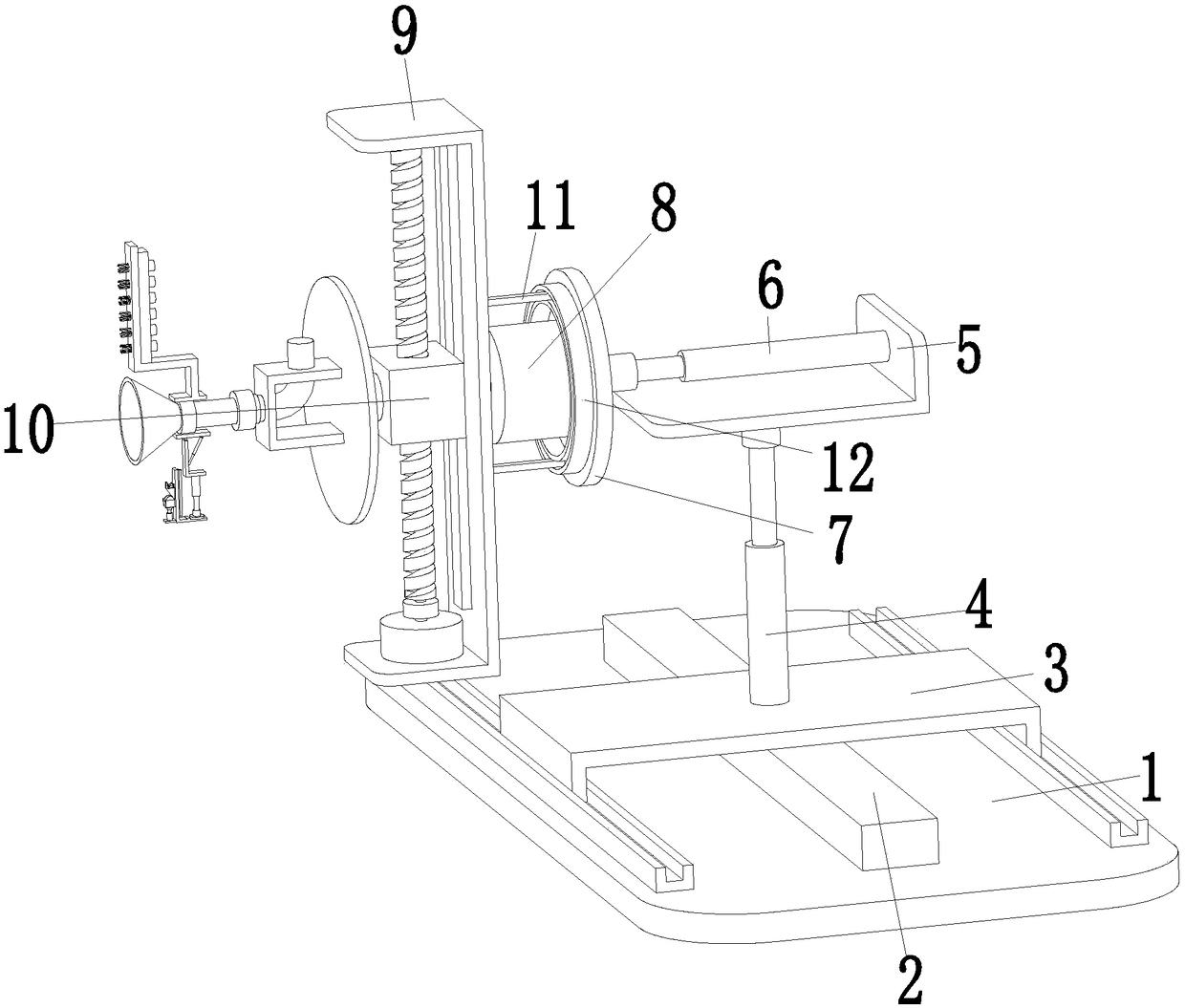

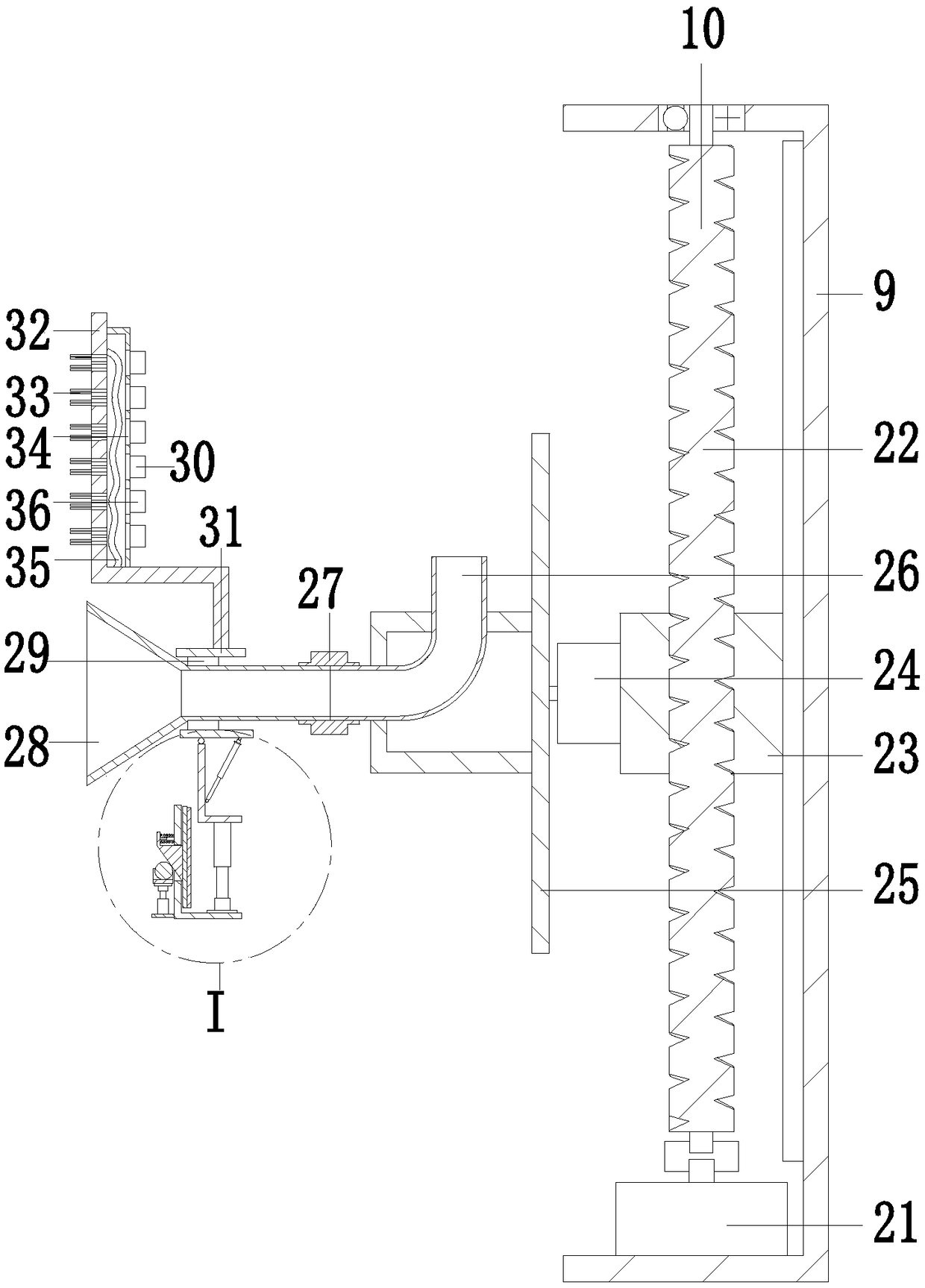

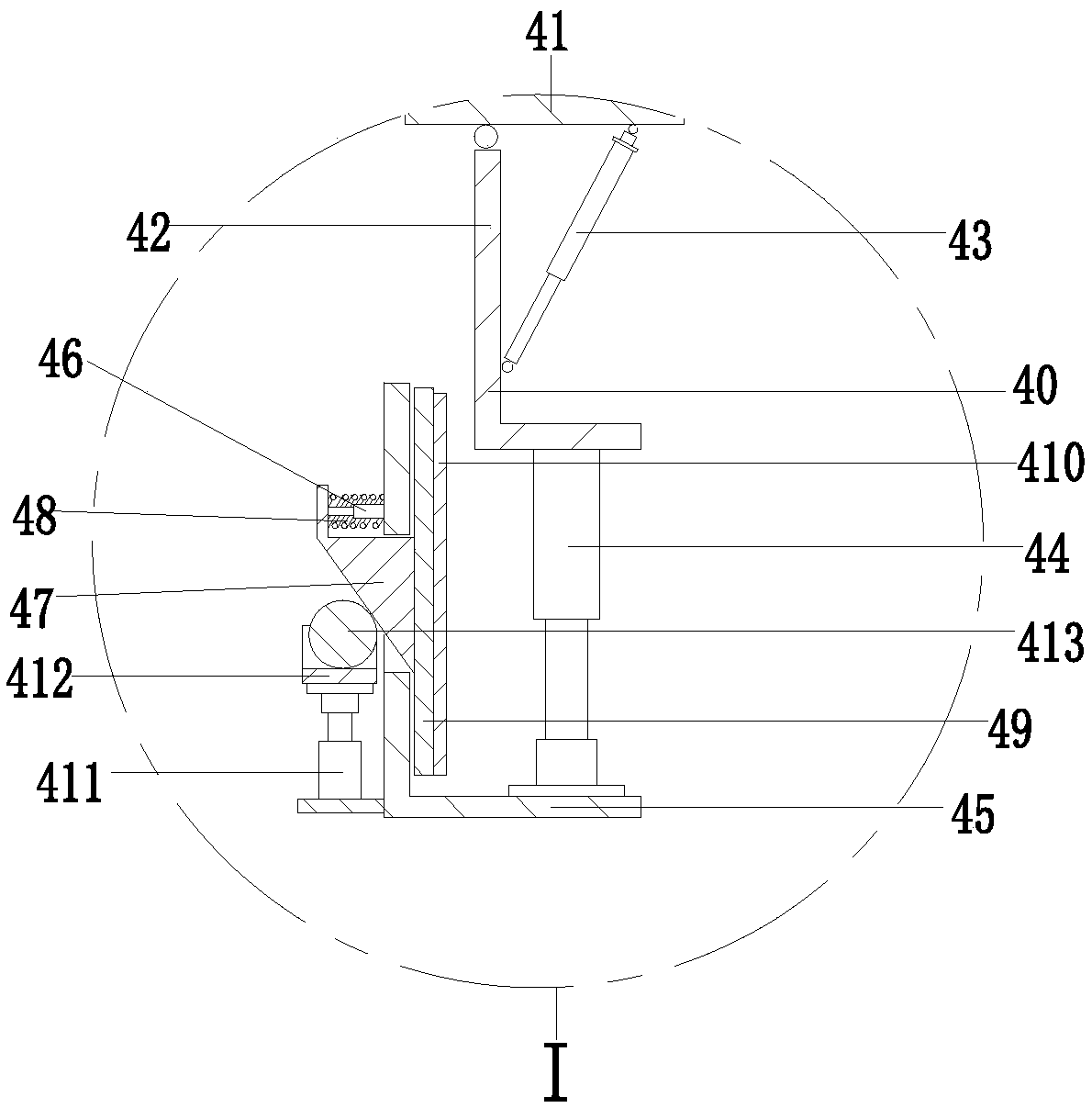

Automatic spraying robot for granite-like marble paint

PendingCN109365184AGuaranteed uniformityStay cohesiveSpraying apparatusPretreated surfacesGranolithicEngineering

The invention mainly relates to an automatic spraying robot for granite-like marble paint. The robot comprises a base plate; an adjusting electric slide block is mounted on the base plate; an adjusting movable plate is mounted on the adjusting electric slide block; and the adjusting movable plate is connected with the base plate through a sliding fit mode. The robot can solve the problems of needof manual control over a traditional spraying machine to spray in traditional paint spraying process, high labor intensity in manual control over the spraying machine, complicated operation, influences on the paint spraying efficiency and the paint spraying uniformity, the higher requirement for wall humidity in paint spraying, incapability of drying walls in real time during manual spraying, incapability of guaranteeing the adhesiveness between the paint and the walls, easy dispersion of the paint in air in the spraying process and environmental pollution during direct spraying by the traditional spraying machine, easy oxidation and cementation of a spraying pipe directly contacted with the air on the pipe wall of the spraying machine, and troublesome cleaning.

Owner:西安智强科技有限公司

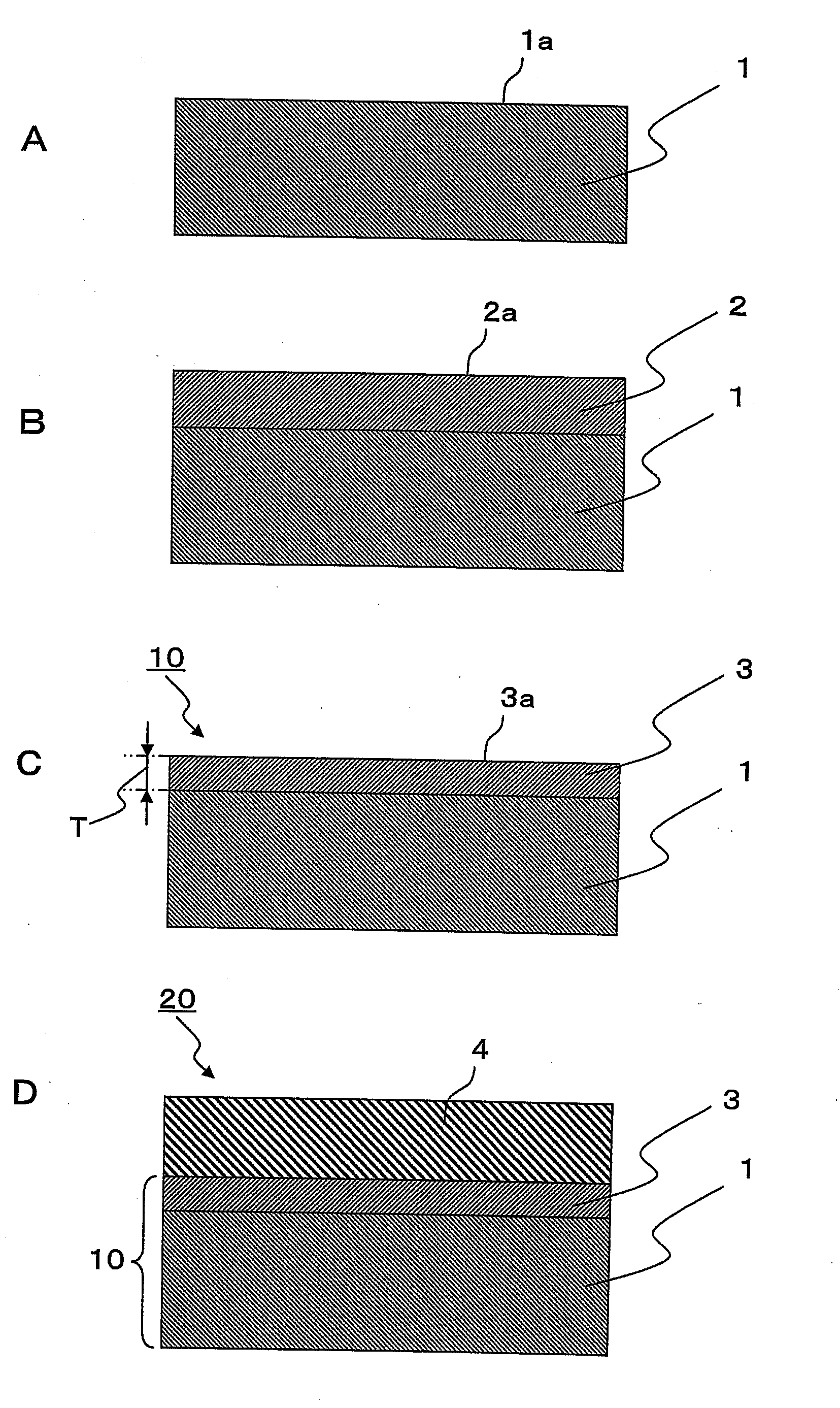

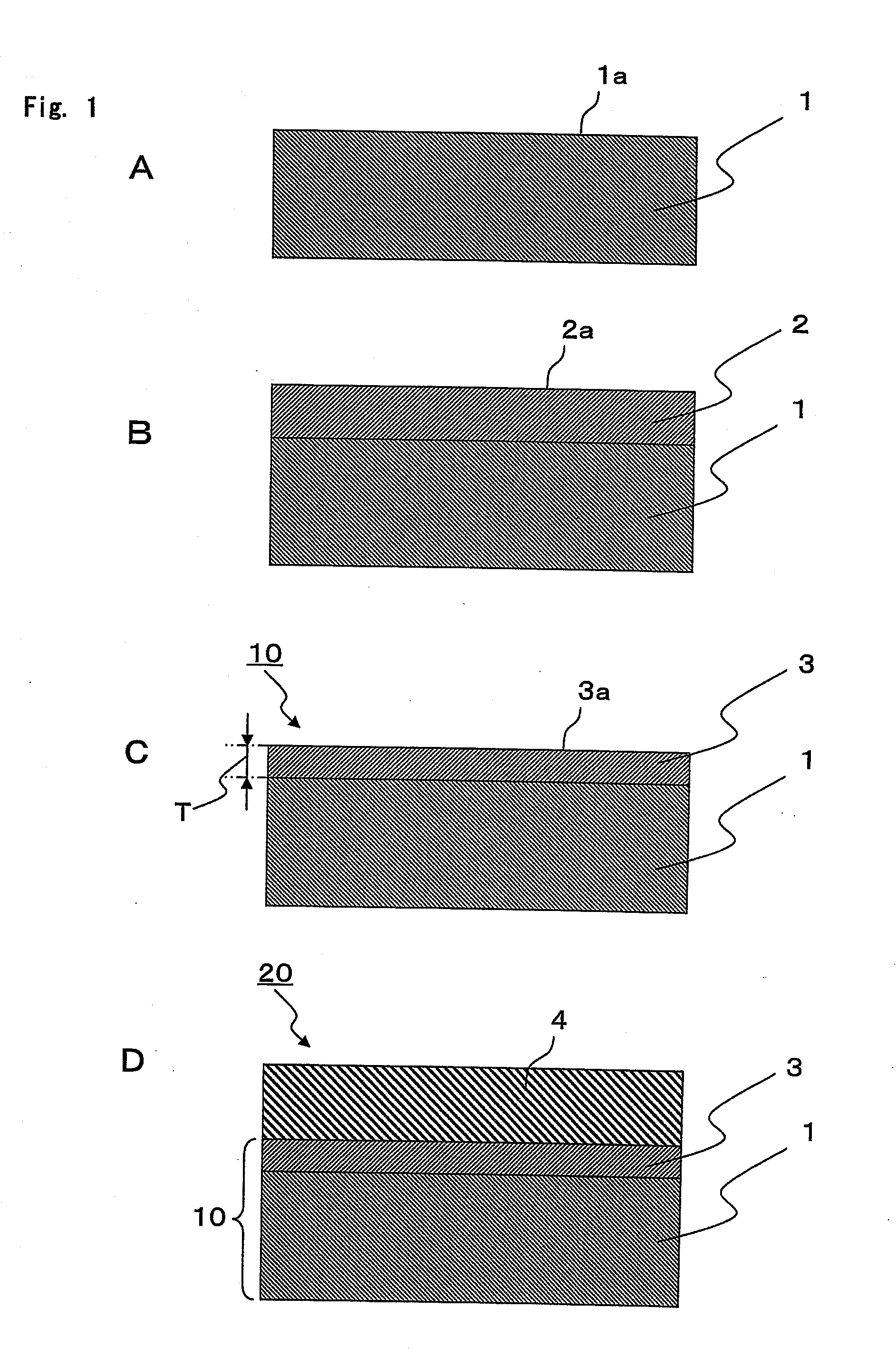

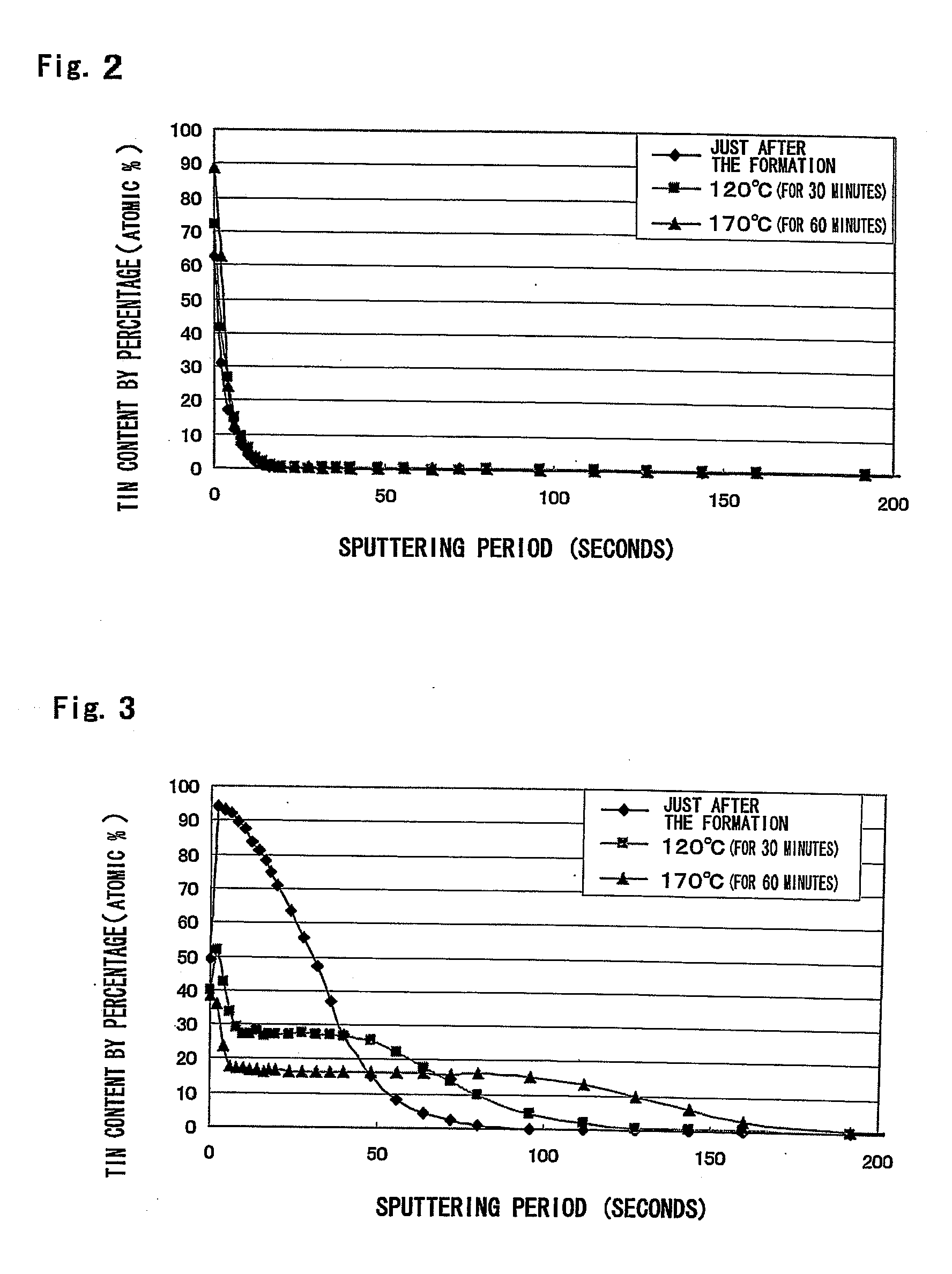

Electroconductive layer, laminate using the same, and producing processes thereof

ActiveUS20090197109A1Easily removePrevent diffusionInsulating substrate metal adhesion improvementPrinted circuit aspectsCopperAlloy

The object of the present invention is to provide an electroconductive layer that retains bondability to a resin layer certainly and is further a layer from which a copper-tin alloy layer is easily removed in a subsequent step, a laminate using this layer, and producing processes thereof. The electroconductive layer of the present invention is an electroconductive layer which is to be bonded to a resin layer, and which contains a copper layer and a copper-tin alloy layer laminated over the copper layer, wherein the copper-tin alloy layer has a thickness of 0.001 to 0.020 μm.

Owner:MEC CO LTD

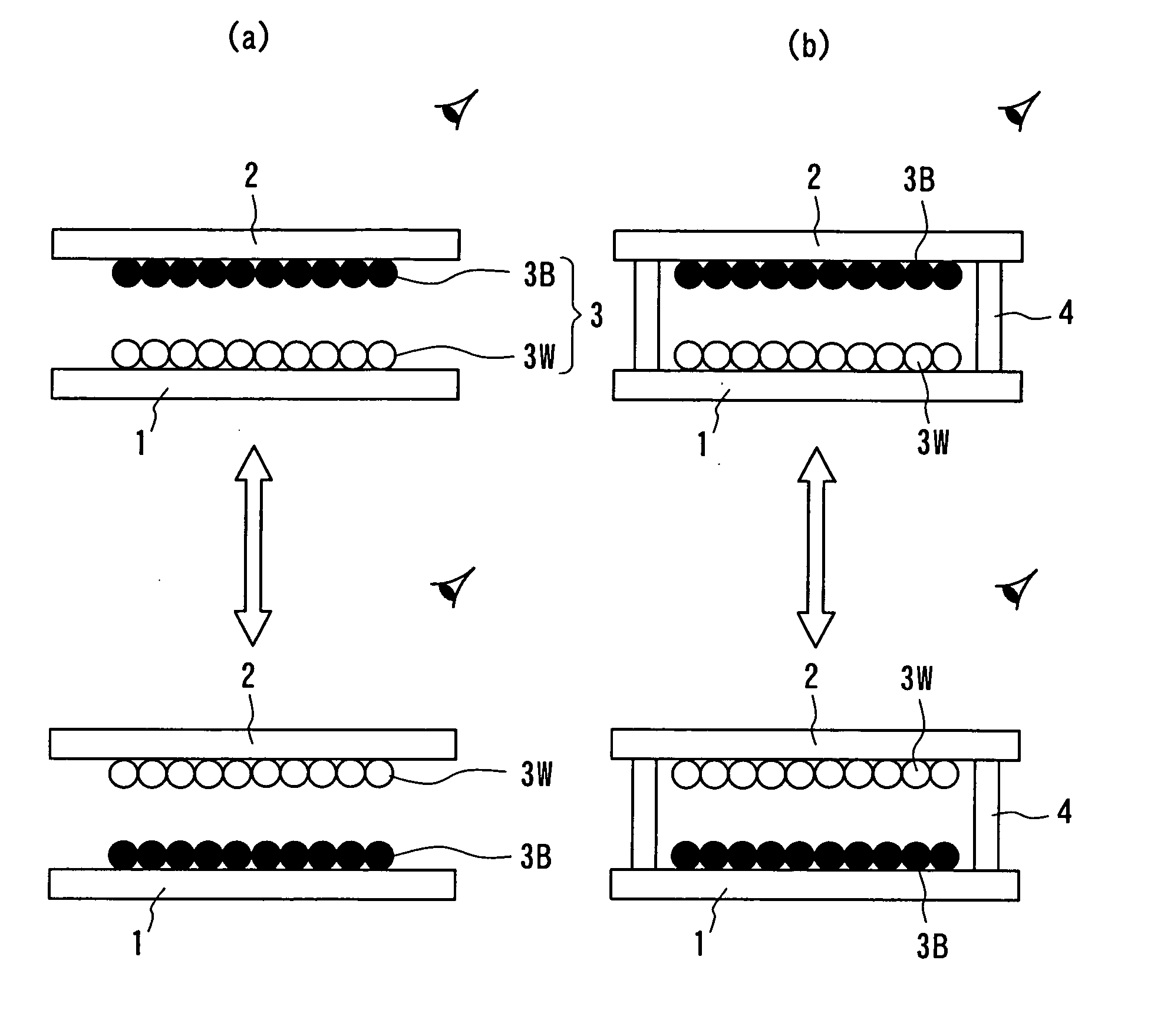

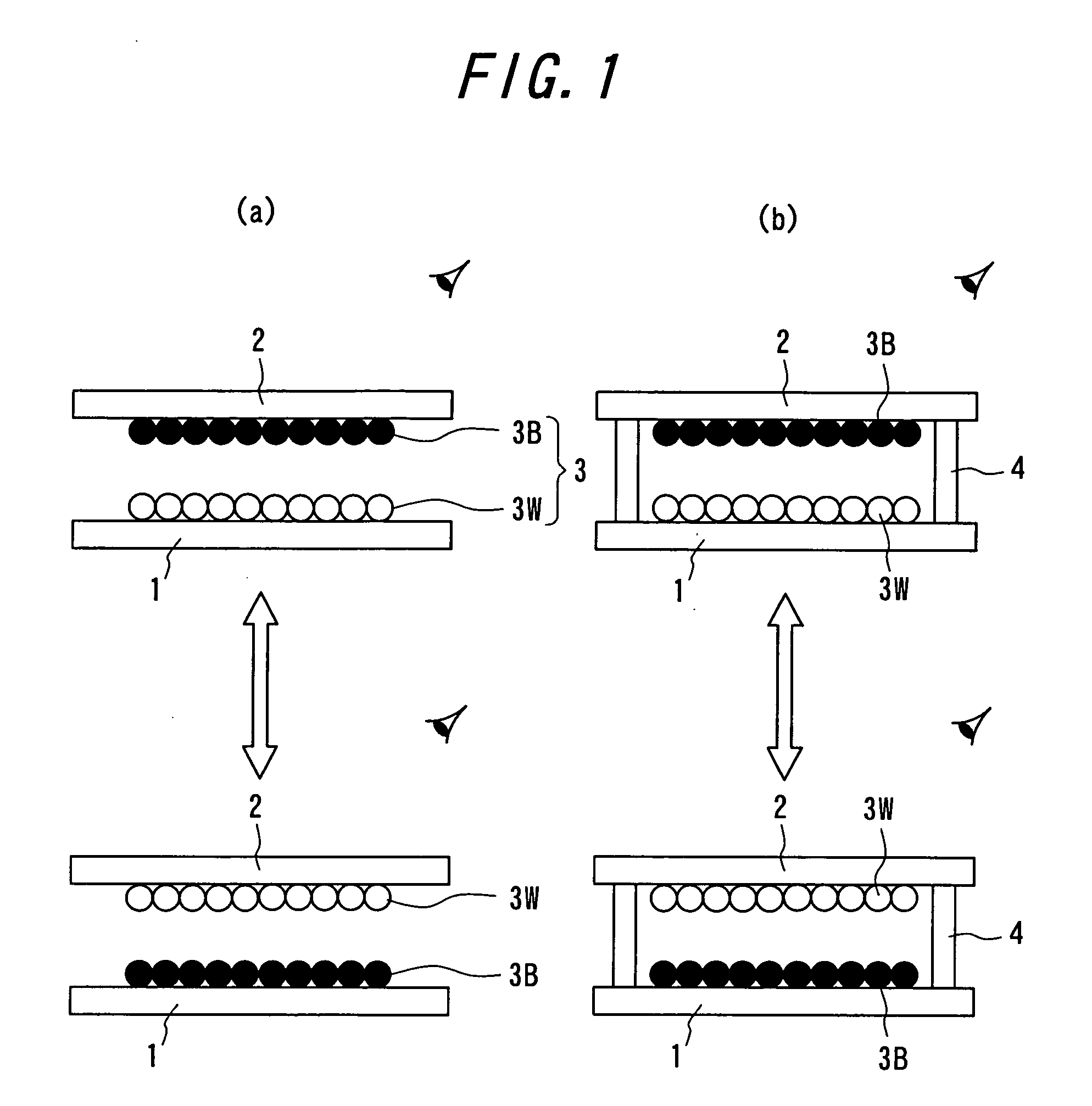

Method of manufacturing image display panel and image display panel

InactiveUS20070029931A1Improve adhesionPromote resultsAlternating current plasma display panelsCold-cathode tubesResistAdhesive

A method of manufacturing an image display panel, having one or more cells formed in an isolated manner from one another by partition walls and accommodating image display media and a plurality of image display elements, in which the image display media are sealed between opposed two substrates, at least one of the two substrates being transparent, and, in which the image display media, to which an electrostatic field is applied, are made to move so as to display an image, characterized in that the improvement comprises the steps of: (1) manufacturing a substrate with the partition walls on one substrate; applying an adhesive mixture obtained by mixing a photo-curing resin and a heat-hardening resin on the partition walls; and then connecting the other substrate to the partition walls through the adhesive mixture, the steps of: (2) manufacturing a substrate with the partition walls by forming the partition walls on one substrate; performing a washing by a dry treatment with respect to the thus manufactured substrate with the partition walls; applying an adhesive on the partition walls; and connecting the other substrate to the partition walls through the adhesive, or the steps of: (3) manufacturing the partition walls on one substrate by means of a pale color resist; applying an adhesive colored by a dark color on the partition walls; and connecting the other substrate to the partition walls through the adhesive.

Owner:BRIDGESTONE CORP

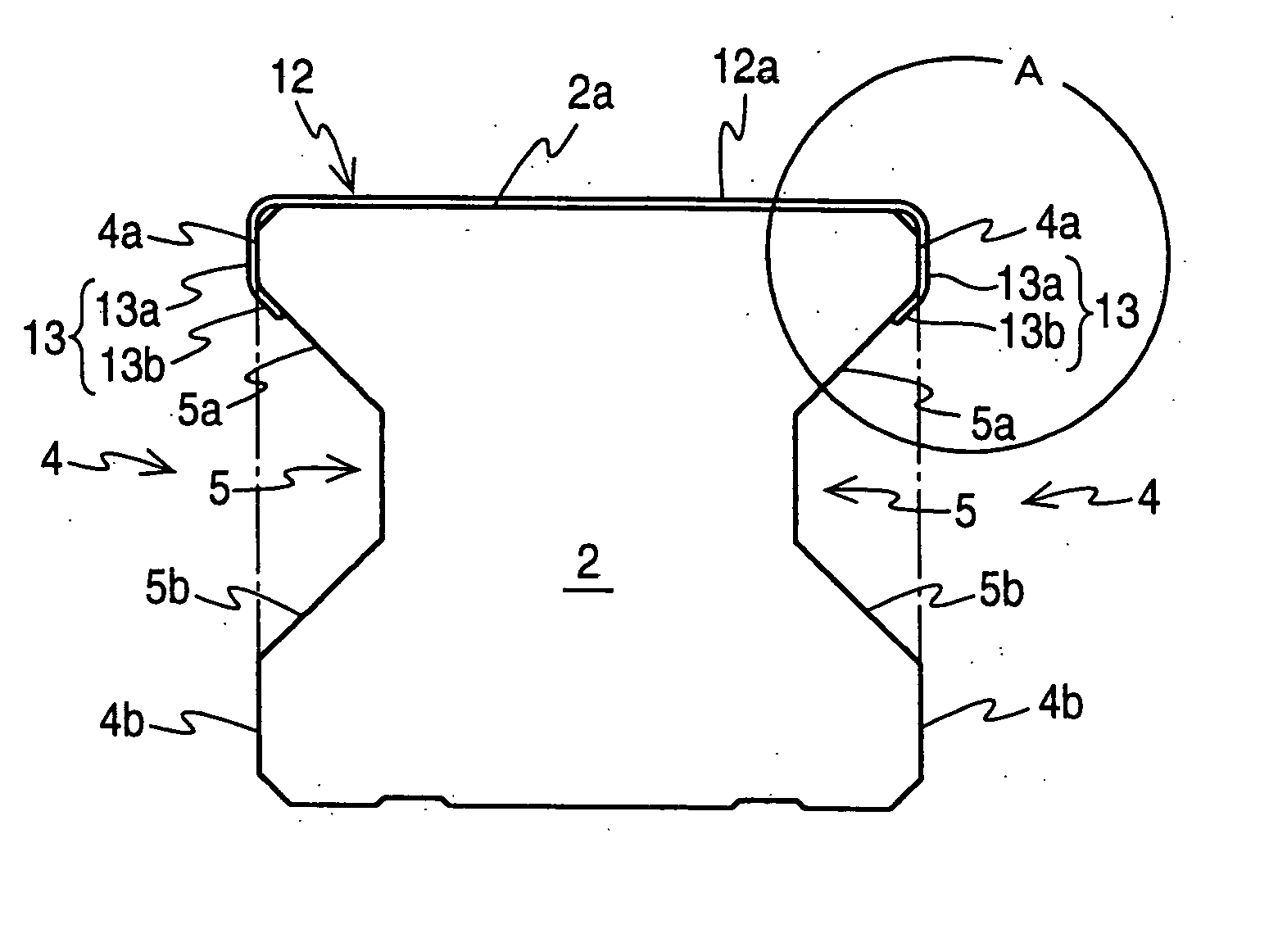

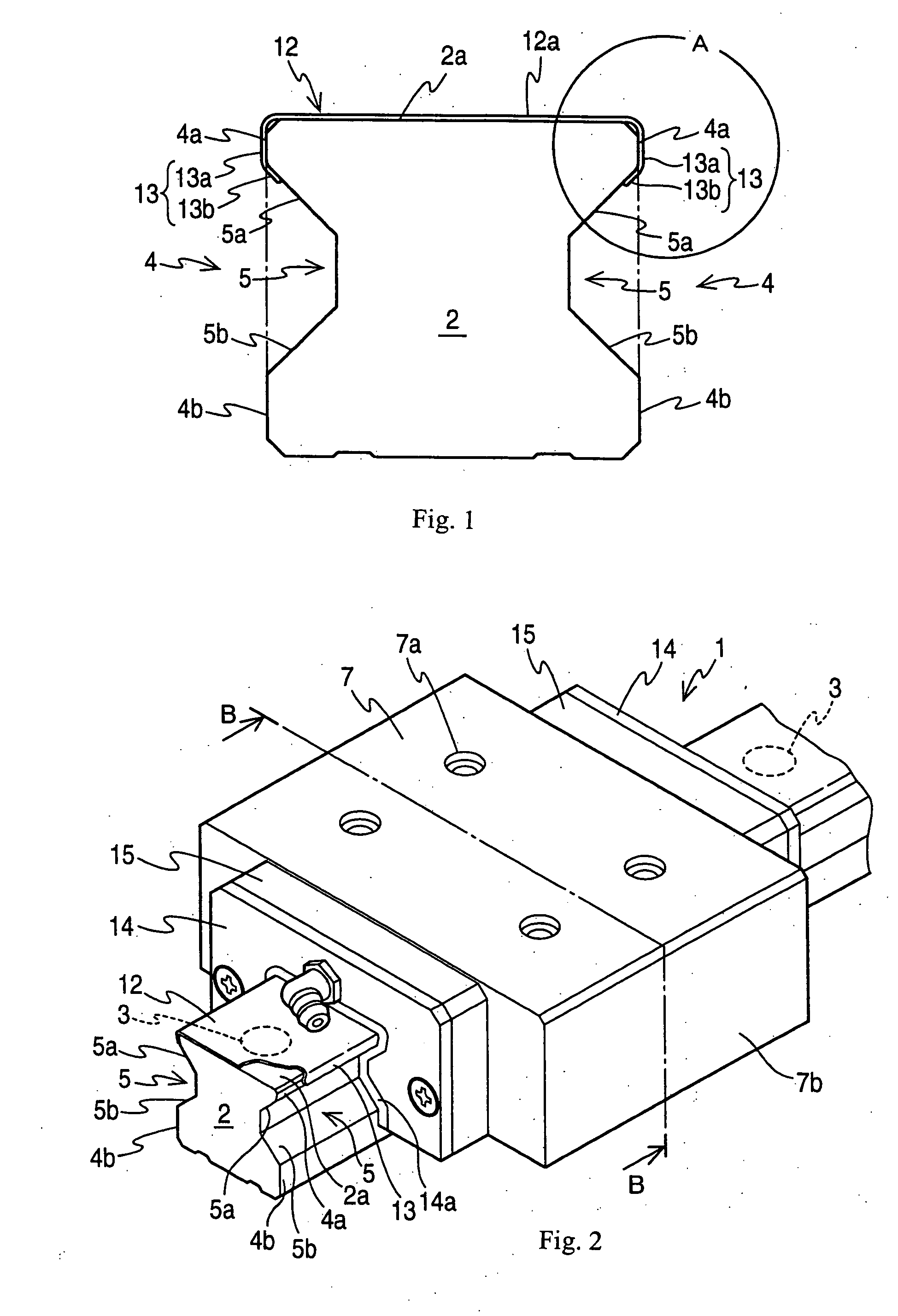

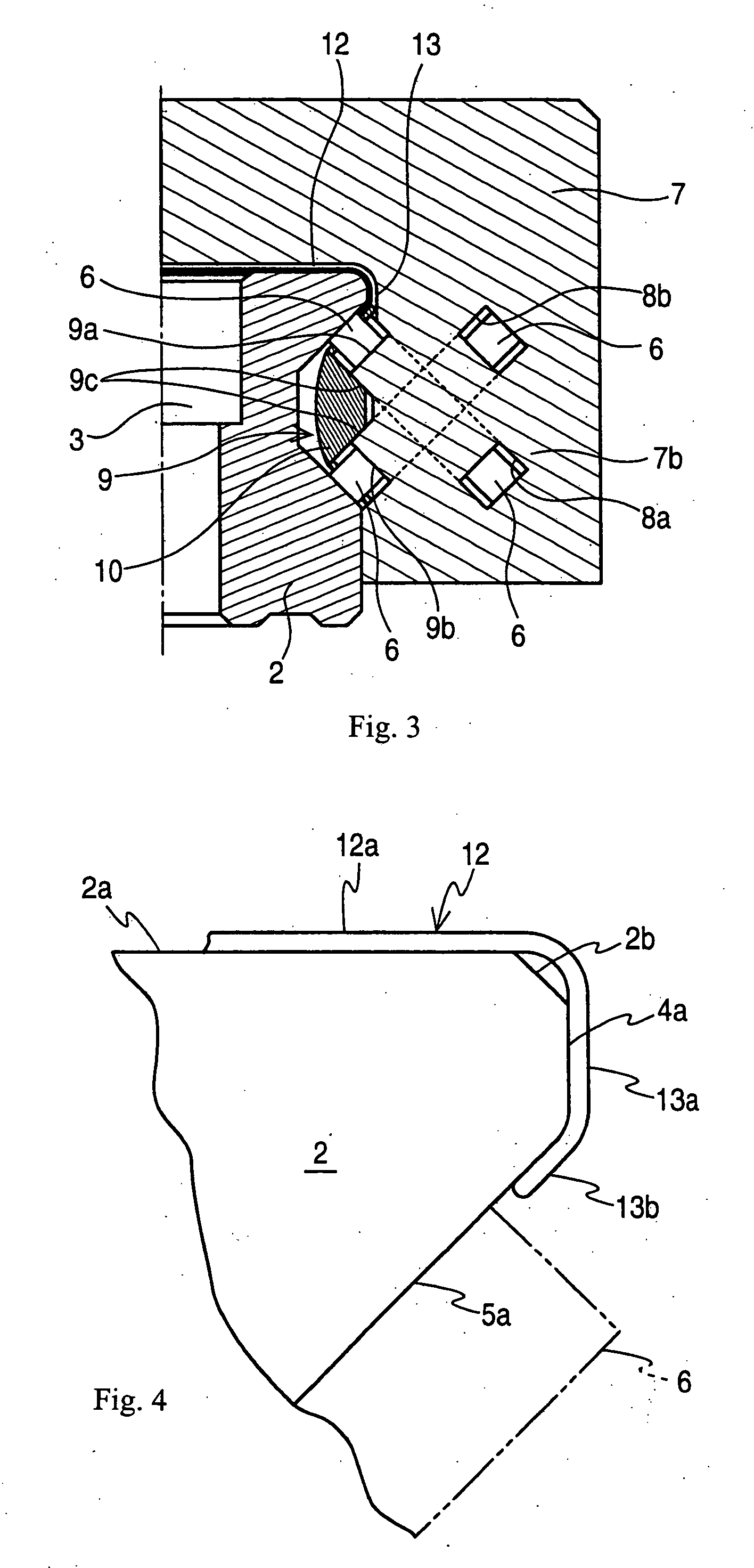

Linear guide device

ActiveUS20050190997A1Shortening rail machining timeImprove machine efficiencyLinear bearingsBearing componentsEngineeringLinearity

In a linear guide device including: a rail having on either side surface thereof a track recess with a track surface formed thereon; a rail cover covering a rail upper surface of the rail; a saddle-like slider moving linearly on the rail; and a rolling member circulating through a connection path provided in the slider and adapted to roll on the track surface of the rail, the rail cover is equipped with a side edge portion having an engagement portion, an upper track surface serving as an engagement surface is provided in a lower portion of an upper side surface of the rail, the engagement surface being a slope gradually diminishing in the rail width direction downwardly from the upper side surface, and an engagement portion of the rail cover is engaged with the engagement surface, whereby it is possible to achieve an increase in the speed of the rail grinding work for allowing engagement of the rail cover covering the rail upper surface of the liner guide device.

Owner:NSK LTD

Spunlace non-woven material-based medical mask material and preparation method thereof

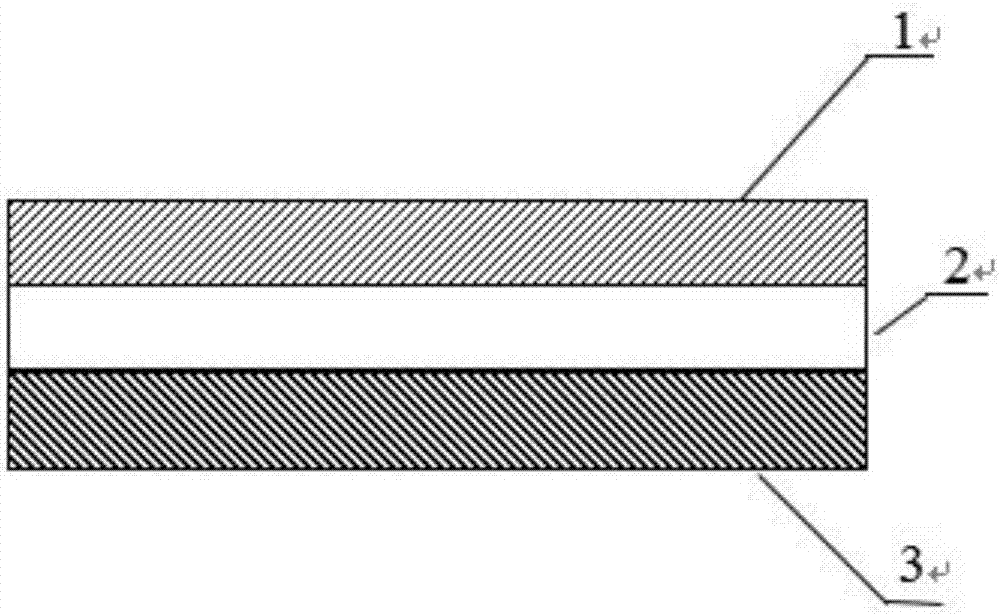

ActiveCN111409341ASoft touchGood drapabilityNon-macromolecular adhesive additivesFibre typesPolyesterCarding

The invention discloses a medical mask material based on a spunlace non-woven material and a preparation method of the medical mask material. The medical mask material comprises an outer protective layer, an adhesive layer and a spunlace non-woven fabric layer sequentially attached, the spunlace non-woven fabric layer is subjected to water-repellent, oil-repellent, blood-resistant and alcohol-resistant four-antibody finishing, the outer protective layer is a PTFE film, and the spunlace non-woven fabric layer is made of bamboo pulp fibers and antibacterial polyester fibers. The preparation method comprises the following steps: preparing the spunlace non-woven fabric layer, namely mixing bamboo pulp fibers and polyester fibers in proportion, carding, lapping, drafting, performing high-pressure spunlace, performing four-antibody finishing, drying at high temperature, sterilizing, slitting and rolling to obtain the spunlace non-woven fabric layer; coating the surface of the spunlace non-woven fabric layer with the adhesive, then covering the spunlace non-woven fabric layer with the PTFE film, and obtaining the final material through multi-stage tentering shaping after pressurization compounding of a heating roller. The medical mask material is free of any rolling point, soft in hand feeling, good in air permeability, comfortable to wear and good in protection performance.

Owner:杭州路先非织造股份有限公司

Method of making a semiconductor chip assembly with a copper/aluminum post/base heat spreader

InactiveUS8034645B2Low costNot easy to layerSemiconductor/solid-state device detailsPrinted circuit aspectsSurface layerAdhesive

A method of making a semiconductor chip assembly includes providing a post and a base that include a copper surface layer and an aluminum core, mounting an adhesive on the base including inserting the post into an opening in the adhesive, mounting a conductive layer on the adhesive including aligning the post with an aperture in the conductive layer, then flowing the adhesive into and upward in a gap located in the aperture between the post and the conductive layer, solidifying the adhesive, then providing a conductive trace that includes a pad, a terminal and a selected portion of the conductive layer, mounting a semiconductor device on a heat spreader that includes the post and the base, electrically connecting the semiconductor device to the conductive trace and thermally connecting the semiconductor device to the heat spreader.

Owner:BRIDGE SEMICON

Irradiation-resistant hot melt adhesive and preparation method thereof

ActiveCN103232824AImprove adhesionImprove low temperature resistanceMonocarboxylic acid ester polymer adhesivesMacromolecular adhesive additivesWaxPlasticizer

The invention relates to an irradiation-resistant hot melt adhesive, which comprises the following raw material ingredients by weight percentage: 10-40% of ethane-vinyl acetate copolymer, 20-50% of polyamide, 5-30% of irradiation-resistant rubber, 1-30% of adhesion agent, 1-10% of wax, 1-10% of stabilizing agent and 10% of plasticizer. The invention also provides a preparation method of irradiation-resistant hot melt adhesive. Compared with the present hot melt adhesive, the irradiation-resistant hot melt adhesive provided by the invention has the advantages of good caking property, low temperature-resistant performance and various oil products resistance. In addition, the preparation technology of the present invention is simple and stable and has good repeatability without harmful gas generation and harm to environment, low production energy consumption, and good economic effect and industrial production prospect.

Owner:CHINA NUCLEAR POWER ENG CO LTD +1

Method for producing copper-clad laminate

InactiveUS20090229750A1Improve adhesionProne to malfunctionAdhesive processesPrinted circuit aspectsLiquid crystallineCopper foil

The present invention provides a method for producing a copper-clad laminate, the method comprising the step of placing at least one copper foil onto a resin layer containing a liquid crystalline polymer so that the resin layer adheres to a surface of the copper foil, wherein the surface of the copper foil has 0.4 or more of a ratio of nickel concentration to copper concentration and has substantially no silicon detected when measured with X-ray photoelectron spectroscopy. The copper-clad laminate can sufficiently maintain excellent adhesion between the copper foil and the resin layer even under high temperature and humidity atmosphere.

Owner:SUMITOMO CHEM CO LTD

Brazing flux used for melt-brazing of aluminum alloy/stainless steel

InactiveCN105215575APromote spreading wettingGood jointWelding/cutting media/materialsSoldering mediaMechanical propertyTetrafluoroaluminate

The invention relates to brazing fluxes used for welding, in particular to a brazing flux used for melt-brazing of aluminum alloy / stainless steel. The brazing flux is characterized in that the brazing flux is prepared by mixing and grinding powder of potassium tetrafluoroaluminate+potassium hexafluoroaluminate (KAlF4+K3AlF6) eutectic, potassium fluorosilicate, potassium fluoroborate, aluminum, zinc, tin and copper; the brazing flux comprises, by weight, 40%-60% of potassium tetrafluoroaluminate+potassium hexafluoroaluminate (KAlF4+K3AlF6) eutectic, 0-10% of potassium fluorosilicate (K2SiF6), 0-10% of potassium fluoroborate (KBF4), 10%-30% of aluminum (Al), 0-10% of zinc (Zn), 0-10% of tin (Sn), and 0-10% of copper (Cu); the sum of the weight percents of all the raw materials is 100%. According to the brazing flux, the good wetting spreading property of an existing brazing flux is maintained, and meanwhile, the texture of a connector is improved, and forming of brittle intermetallic compounds is reduced, so that the mechanical property of the connector of melt-brazing is improved, and finally dissimilar metal of the aluminum alloy and the stainless steel is connected reliably with high quality. The brazing flux further has the advantages that the melt-brazing process is relatively simple; the energy consumption and the cost of the raw materials are low; the residual quantity of the brazing flux is small after welding; and residues are easy to clean up.

Owner:WUHAN UNIV OF TECH

Bladder rubber and its preparation method

A bladder rubber and its preparation method are provided. The bladder rubber contains brominated butyl rubber 45-60, carbon black 20-30, talcum powder 5-15, oil material 1-5, anti-aging agent 1-2, and vulcanizing agent 1-3 wt%. The inventive bladder rubber has performances of butyl rubber and active bromine, effectively improves gas tightness of bladder, accelerates vulcanizing speed, ensures adhesion property, and improves service life of bladder.

Owner:TAICANG GUANLIAN POLYMERIC MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com