Spunlace non-woven material-based medical mask material and preparation method thereof

A spunlace nonwoven and spunlace nonwoven technology, applied in the field of medical materials, can solve the problems of difficult coexistence of protection and air permeability, poor wearing comfort, poor softness, etc., to improve corrosion resistance and structural stability. Sensitivity, soft feel, and the effect of accelerating conduction velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

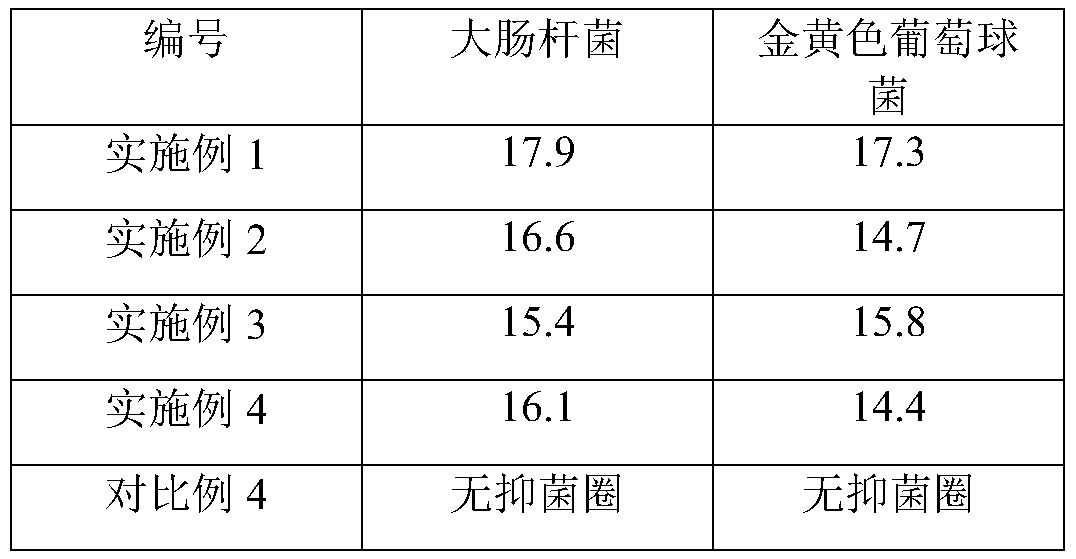

Examples

Embodiment 1

[0038] A medical mask material based on spunlace non-woven materials, including a 0.01mm outer protective layer, a 0.02mm adhesive layer, and a 0.40mm water-resistant finish that is water-repellent, oil-repellent, blood-resistant, and alcohol-resistant. The outer protective layer is PTFE film, the adhesive layer is commercially available polyurethane adhesive, and the spunlace non-woven layer is made of bamboo pulp fiber and antibacterial polyester fiber with a mass ratio of 1:1. Density: 200g / m 2 .

[0039] The preparation method of antibacterial polyester fiber is as follows: add chitosan to 2% acetic acid solution, add silver nitrate after magnetic stirring for 24 hours, and then irradiate the solution with ultraviolet light for 25 minutes to obtain antibacterial finishing solution. The mass fraction of polysaccharide is 3%, and the mass fraction of silver nitrate is 0.7%. The antibacterial polyester fiber is obtained after the antibacterial finishing solution is used to c...

Embodiment 2

[0044] A medical mask material based on spunlace non-woven materials, including a 0.01mm outer protective layer, a 0.02mm adhesive layer, and a 0.40mm water-resistant finish that is water-repellent, oil-repellent, blood-resistant, and alcohol-resistant. The spunlace non-woven fabric layer, the outer protective layer is PTFE film; the spunlace non-woven fabric layer is made of bamboo pulp fiber and antibacterial polyester fiber with a mass ratio of 1:1, and the surface density is 200g / m 2 , the adhesive material of the adhesive layer includes by weight: 70 parts of modified polyurethane elastomers, 50 parts of cellulose-based water-absorbing and water-retaining agents, 15 parts of rosin glycerides, 10 parts of medical grade mineral oil white oil, 4 parts sodium bicarbonate and 2 parts citric acid.

[0045] The preparation method of antibacterial polyester fiber is as follows: add chitosan to 2% acetic acid solution, add silver nitrate after magnetic stirring for 20 hours, and t...

Embodiment 3

[0053] A medical mask material based on spunlace non-woven materials, including a 0.02mm outer protective layer, a 0.01mm adhesive layer, and a 0.25mm water-resistant finish that is water-repellent, oil-repellent, blood-resistant, and alcohol-resistant. The spunlace non-woven fabric layer, the outer protective layer is PTFE film; the spunlace non-woven fabric layer is made of bamboo pulp fiber and antibacterial polyester fiber with a mass ratio of 1:1.5, and the surface density is 250g / m 2 The adhesive raw material of adhesive layer comprises by weight: 50 parts of modified polyurethane elastomers, 20 parts of cellulose-based water-absorbing and water-retaining agents, 10 parts of rosin glycerides, 5 parts of medical grade mineral oil white oils, 0.6 parts sodium bicarbonate and 0.4 parts citric acid.

[0054] The preparation method of antibacterial polyester fiber is as follows: add chitosan to 3% acetic acid solution, add silver nitrate after magnetic stirring for 30 hours, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com