Optical sub module and optical module

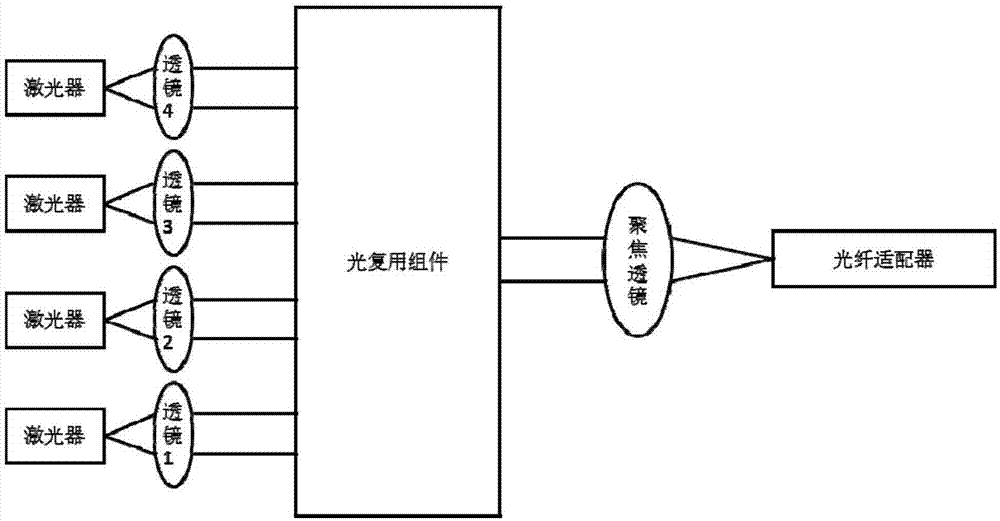

An optical sub-module and optical component technology, applied in the field of optical communication, can solve the problem of weak adhesion between the side wall of the cover plate and the side wall of the casing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

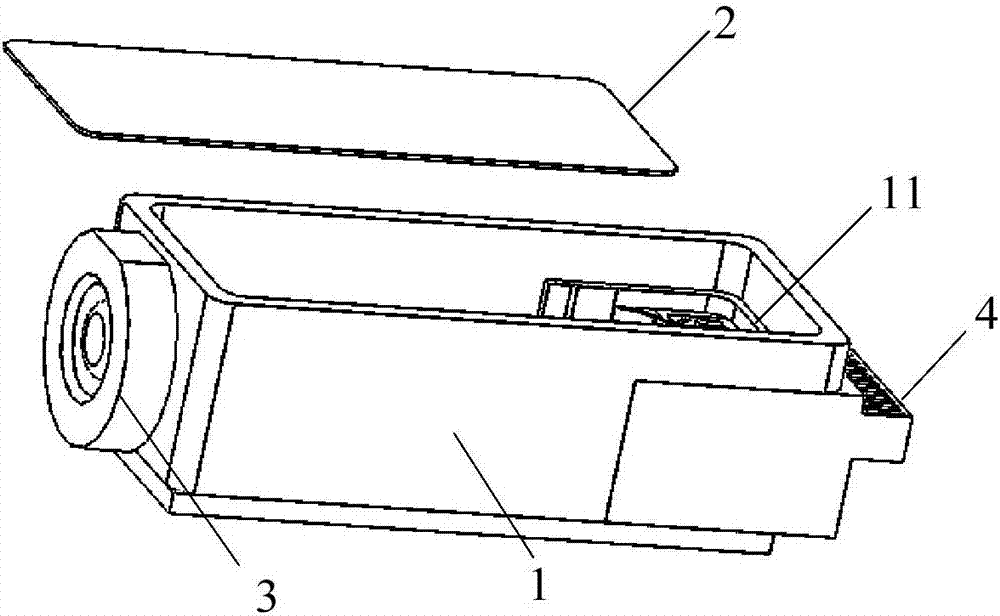

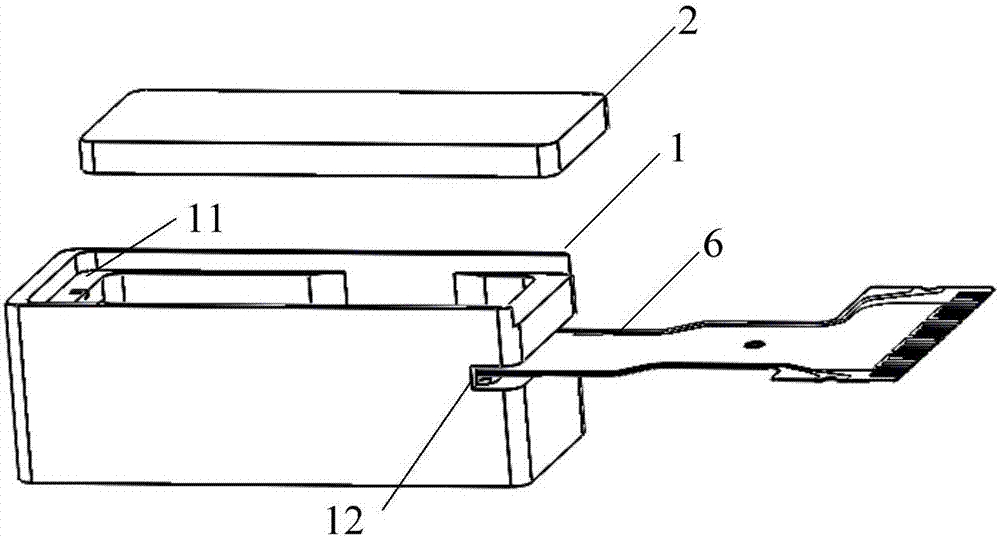

[0022] In view of the technical problem that the air inside the cavity is easy to be heated and expanded during the curing of the adhesive, so that the cover plate 2 is easily lifted by the internal hot air, which affects the sealing performance of the optical module, this application proposes an optical sub-module, which The core idea is: through the height difference between one of the side walls of the housing 1 and the other three side walls, a U-shaped structure with one side opening is formed on the upper end surface of the housing 1 . When encapsulating the optical sub-module, glue can be applied on the support plates 11 of the above-mentioned three side walls, and after the cover plate 2 is covered on the upper surface of the housing 1, the adhesive is cured. The hot air generated during the curing of the adhesive will be discharged from the gap between the other side wall and the cover plate 2 . Therefore, the force of the hot air inside the housing 1 will not adverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com