Light-driving integrated LED fluorescent lamp and manufacture process thereof

A technology of LED fluorescent lamps and LED lamps, applied in the direction of light source, electric light source, light source fixation, etc., can solve the problems of LED light source breakdown, falling off, hidden safety hazards, etc., and achieve short-circuit avoidance, good insulation effect, and reliable adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the specific embodiments and accompanying drawings.

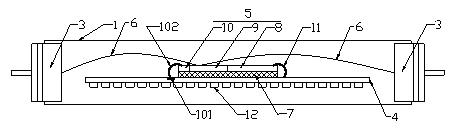

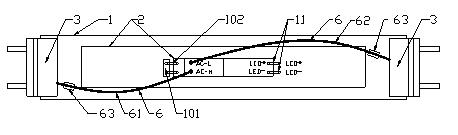

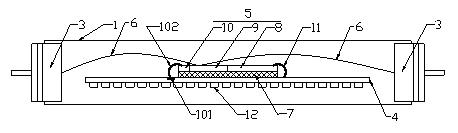

[0024] Reference attached figure 1 , the lamp-driven integrated LED fluorescent lamp of the present invention includes a fluorescent lamp tube 1 and an LED lamp driving board device 2 installed in the fluorescent lamp tube body. The end of the fluorescent lamp tube is provided with a plug 3 connected to an external power supply. That is: the LED lamp driving board device 2 includes a lamp board 4 equipped with LED lamps 12 and a power driving board 5 connected to the lamp board. The plugs on the head are 3-phase connected, and a heat-conducting silica gel sheet 7 is arranged between the power drive board 5 and the lamp board 4 .

[0025] The above-mentioned power driving board 5 is composed of a power board 8, a driving circuit board 9 and an independent soldering pad 10, and the power driving board 5 is welded to the lamp board 4 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com