Brazing flux used for melt-brazing of aluminum alloy/stainless steel

A stainless steel and fusion brazing technology, which is applied in the field of flux for aluminum alloy and stainless steel fusion brazing, can solve the problems of complex aluminum/stainless steel fusion brazing process, rising component raw material costs, and high overall cost, so as to reduce brittle metal The formation of intercompounds, the promotion of interfacial bonding, and the effect of improving weld strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

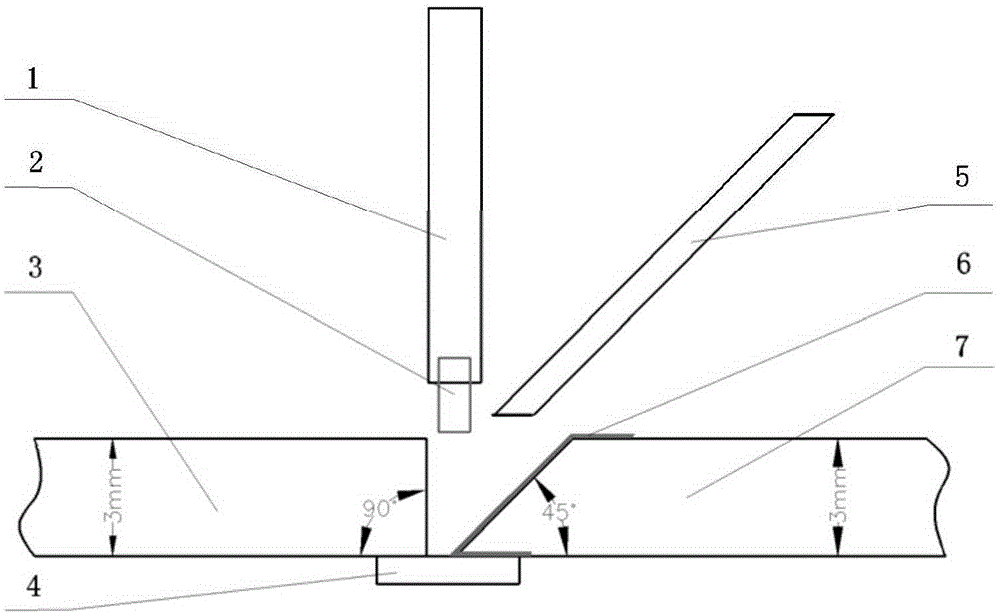

Image

Examples

Embodiment 1

[0018] A flux (powder) for aluminum alloy / stainless steel fusion brazing, which consists of potassium tetrafluoroaluminate+potassium hexafluoroaluminate eutectic, potassium fluorosilicate, potassium fluoroborate, aluminum, zinc, tin and copper The powder is mixed and ground, and the weight percentage of each raw material is: Potassium tetrafluoroaluminate + Potassium hexafluoroaluminate (KAlF 4 +K 3 AlF 6 ) eutectic 55%, potassium fluorosilicate (K 2 SiF 6 )5%, potassium fluoroborate (KBF 4 ) 5%, aluminum (Al) 15%, zinc (Zn) 5%, tin (Sn) 7%, copper (Cu) 8%. When in use, the prepared mixed powder is adjusted into a liquid state with absolute ethanol, and evenly coated on the surface of the stainless steel material to be welded.

[0019] Among them, KAlF 4 、K 3 AlF 6 、K 2 SiF 6 、KBF 4 , The state of Al, Zn, Sn, Cu is 200-500 mesh powder.

[0020] In the potassium tetrafluoroaluminate+potassium hexafluoroaluminate eutectic, the percentages by weight of potassium tetra...

Embodiment 2

[0023] A flux for aluminum alloy / stainless steel fusion brazing, which is prepared by mixing and grinding powders of potassium tetrafluoroaluminate + potassium hexafluoroaluminate, potassium fluorosilicate, potassium fluoroborate, aluminum, zinc, tin and copper Components, the percentage by weight of each raw material is: Potassium tetrafluoroaluminate+Potassium hexafluoroaluminate (KAlF 4 +K 3 AlF 6 ) eutectic 40%, potassium fluorosilicate (K 2 SiF 6 )10%, potassium fluoroborate (KBF 4 ) 10%, aluminum (Al) 10%, zinc (Zn) 10%, tin (Sn) 10%, copper (Cu) 10%.

[0024] Among them, KAlF 4 、K 3 AlF 6 、K 2 SiF 6 、KBF 4 , The state of Al, Zn, Sn, Cu is 200-500 mesh powder.

[0025] Carry out butt joint test, with embodiment 1, the result shows: the powdery flux of the present invention wets and spreads well on the surface of stainless steel, and the shape of the welded brazing joint that obtains is more attractive in appearance, and weld seam pore is less; Tensile test sho...

Embodiment 3

[0027]A flux for aluminum alloy / stainless steel fusion brazing, which is prepared by mixing and grinding powders of potassium tetrafluoroaluminate + potassium hexafluoroaluminate, potassium fluorosilicate, potassium fluoroborate, aluminum, zinc, tin and copper Components, the percentage by weight of each raw material is: Potassium tetrafluoroaluminate+Potassium hexafluoroaluminate (KAlF 4 +K 3 AlF 6 ) eutectic 60%, potassium fluorosilicate (K 2 SiF 6 )2%, potassium fluoroborate (KBF 4 ) 2%, aluminum (Al) 30%, zinc (Zn) 2%, tin (Sn) 2%, copper (Cu) 2%.

[0028] Among them, KAlF 4 、K 3 AlF 6 、K 2 SiF 6 、KBF 4 , The state of Al, Zn, Sn, Cu is 200-500 mesh powder.

[0029] Carry out butt joint test, with embodiment 1, the result shows: the powdery flux of the present invention wets and spreads well on the surface of stainless steel, and the shape of the welded brazing joint that obtains is more attractive in appearance, and weld seam pore is less; Tensile test shows joi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com