A kind of led-uv cured transfer glue and preparation method thereof

A transfer adhesive and formula technology, applied in coatings, polyurea/polyurethane coatings, epoxy resin coatings, etc., can solve problems such as workpiece damage, and achieve good flexibility, enhanced adhesion, and good adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

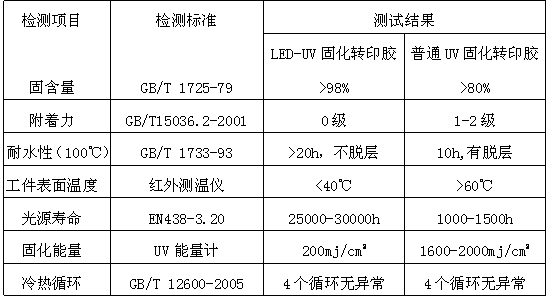

Image

Examples

Embodiment 1

[0029] A kind of LED-UV curing transfer adhesive, comprising the following components, by mass percentage:

[0030] Modified epoxy acrylate: 12%

[0031] Aliphatic Urethane Acrylate 30%

[0032] Special Functional Acrylates 36%

[0033] HDDA 15%

[0034] Photoinitiator 4%

[0035] Adhesion Promoter 3%,

[0036] The above-mentioned modified epoxy acrylate resin adopts HY-217 sold by our company;

[0037] The above-mentioned aliphatic polyurethane acrylate resin adopts Changxing Chemical Industry 5104D;

[0038] The above-mentioned special functional group acrylate resin adopts JS402 produced by the company;

[0039] The above photoinitiator uses 1-hydroxy-cyclohexylbenzophenone (184), 2,4,6-trimethylbenzoyl-diphenylphosphine oxide (TPO), bis(2,4,6-trimethyl Benzoyl) phenylphosphine oxide (819), 27 series products of Tianjin Jiuri;

[0040] The above adhesion promoter adopts Sartomer's CD-9051.

Embodiment 2

[0042] A kind of LED-UV curing transfer adhesive, comprising the following components, by mass percentage:

[0043] Modified epoxy acrylate: 15%

[0044] Aliphatic urethane acrylate 20%

[0045] Specially modified acrylate 36%

[0046] HDDA 20%

[0047] Photoinitiator 5%

[0048] Adhesion Promoter 4%,

[0049] The above-mentioned modified epoxy acrylate resin adopts HY-217 sold by our company;

[0050] The above-mentioned aliphatic polyurethane acrylate resin adopts Changxing Chemical Industry 5104D;

[0051] The above-mentioned special functional group acrylate resin adopts JS402 produced by the company;

[0052] The above photoinitiator uses 1-hydroxy-cyclohexylbenzophenone (184), 2,4,6-trimethylbenzoyl-diphenylphosphine oxide (TPO), bis(2,4,6-trimethyl Benzoyl) phenylphosphine oxide (819), 27 series products of Tianjin Jiuri;

[0053] The above adhesion promoter adopts Sartomer's CD-9051.

Embodiment 3

[0055] A kind of LED-UV curing transfer adhesive, comprising the following components, by mass percentage:

[0056] Modified epoxy acrylate: 10%

[0057] Aliphatic Urethane Acrylate 32%

[0058] Specially modified acrylate 40%

[0059] HDDA 12%

[0060] Photoinitiator 4%

[0061] Adhesion Promoter 2%,

[0062] The above-mentioned modified epoxy acrylate resin adopts HY-217 sold by our company;

[0063] The above-mentioned aliphatic polyurethane acrylate resin adopts Changxing Chemical Industry 5104D;

[0064] The above-mentioned special functional group acrylate resin adopts JS402 produced by the company;

[0065] The above photoinitiator uses 1-hydroxy-cyclohexylbenzophenone (184), 2,4,6-trimethylbenzoyl-diphenylphosphine oxide (TPO), bis(2,4,6-trimethyl Benzoyl) phenylphosphine oxide (819), 27 series products of Tianjin Jiuri;

[0066] The above adhesion promoter adopts Sartomer's CD-9051.

[0067] The preparation method of the above-mentioned LED-UV cured transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com