In-situ brazing repair method for aircraft suspended beam guide pipe

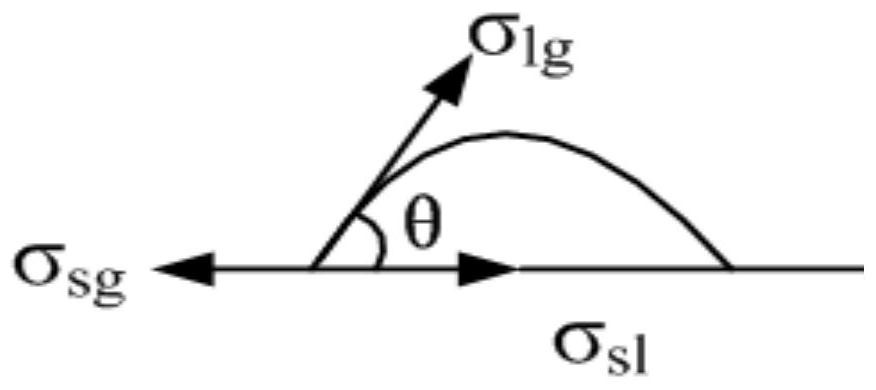

A catheter and brazing technology, which is applied to welding equipment, tubular objects, gas flame welding equipment, etc., can solve the problems of difficult repair and the inability to disassemble and replace the catheter, and achieve the effect of promoting spreading and wetting and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention are further explained below in conjunction with the examples and accompanying drawings, but are not intended to limit the present invention.

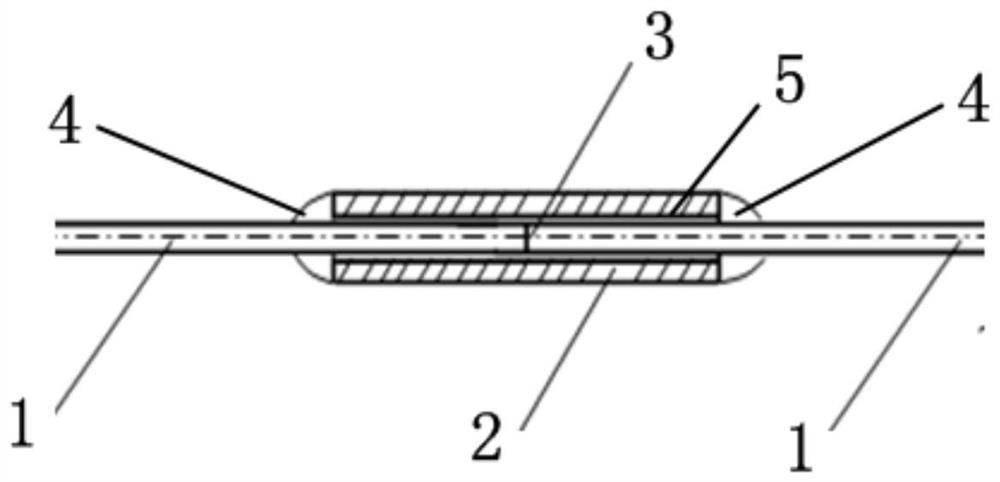

[0022] like figure 2 Shown, a kind of in-situ brazing repair method of aircraft hanging beam conduit, comprises the following steps:

[0023] Step 1: Carry out clamp repair on the two fractured end surfaces of the hanging beam conduit, so that the fractured end surface after clamp repair is flat and smooth, and ensure that the end surface is perpendicular to the axial direction, and the roughness of the end surface and the outer surface of the conduit within 30mm from the end surface is not higher than Ra0 .2mm;

[0024] Step 2: Refer to the pipe joint form in HB8165-2002 "Brazing Smooth Straight-through Pipe Joints" to design the connection sleeve 2 for flame brazing. The size of the connection sleeve 2: outer diameter Ф2.0mm, inner diameter Ф1.1mm, length 15mm .

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com