Slurry direct cyclic rotation drilling punching and slurry return device of ground source heat pump

A ground source heat pump, positive circulation technology, applied in drilling equipment, drill bits, earthwork drilling, etc., can solve the problems of construction quality impact, incomplete dust settlement, and incomplete soil suction, and achieve the effect of reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

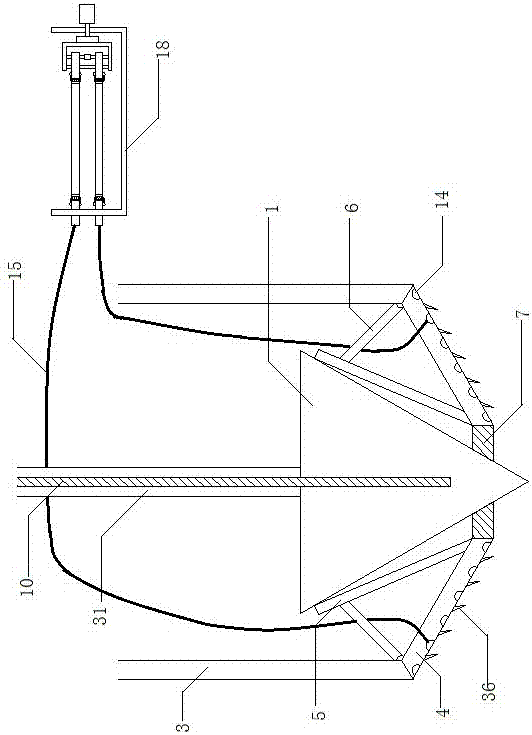

[0034] Such as figure 1 Shown is a schematic structural diagram of the present invention. The present invention is a ground source heat pump mud positive circulation rotary drilling, perforating and returning mud device, including a drilling and perforating part and a mud returning part.

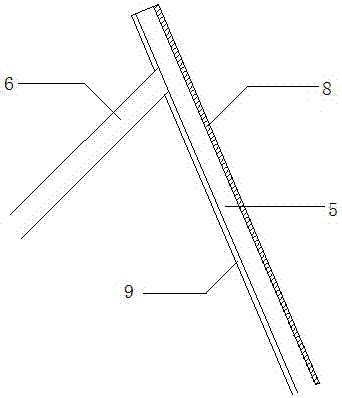

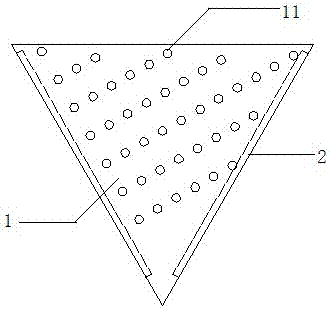

[0035] The drilling and perforating part includes a drill bit body 1 and a drill bit base; image 3The surface of the drill body 1 is even and downwardly provided with a surface groove 2, and the top center of the drill body 1 is fixed with a drill drive rod 31 vertically upward along the axial direction; the drill drive rod 31 is set as a hollow rod; the drill base includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com