Patents

Literature

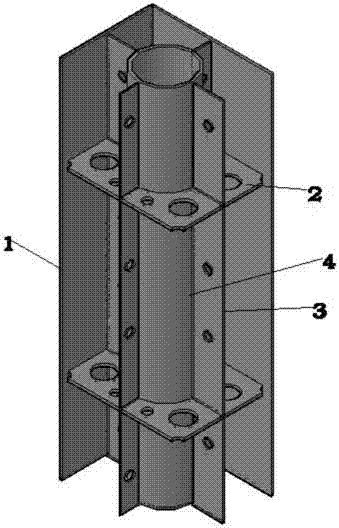

72results about How to "Increase the moment of inertia of the section" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

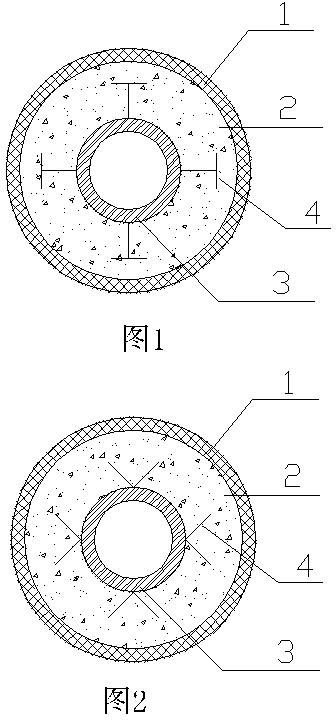

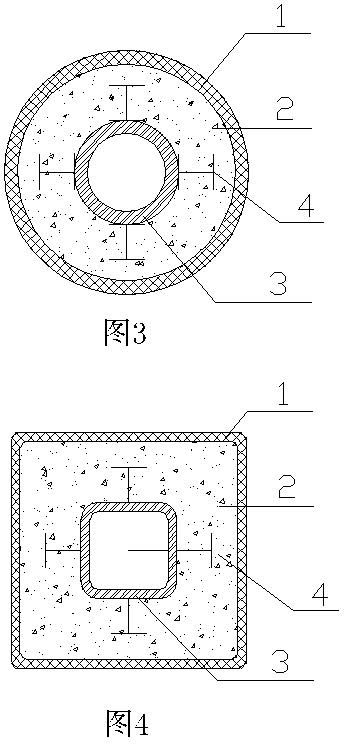

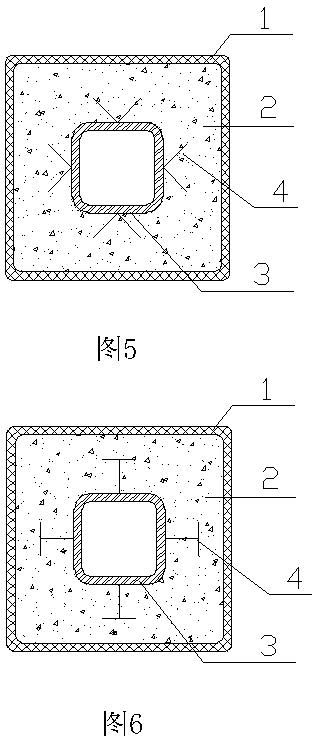

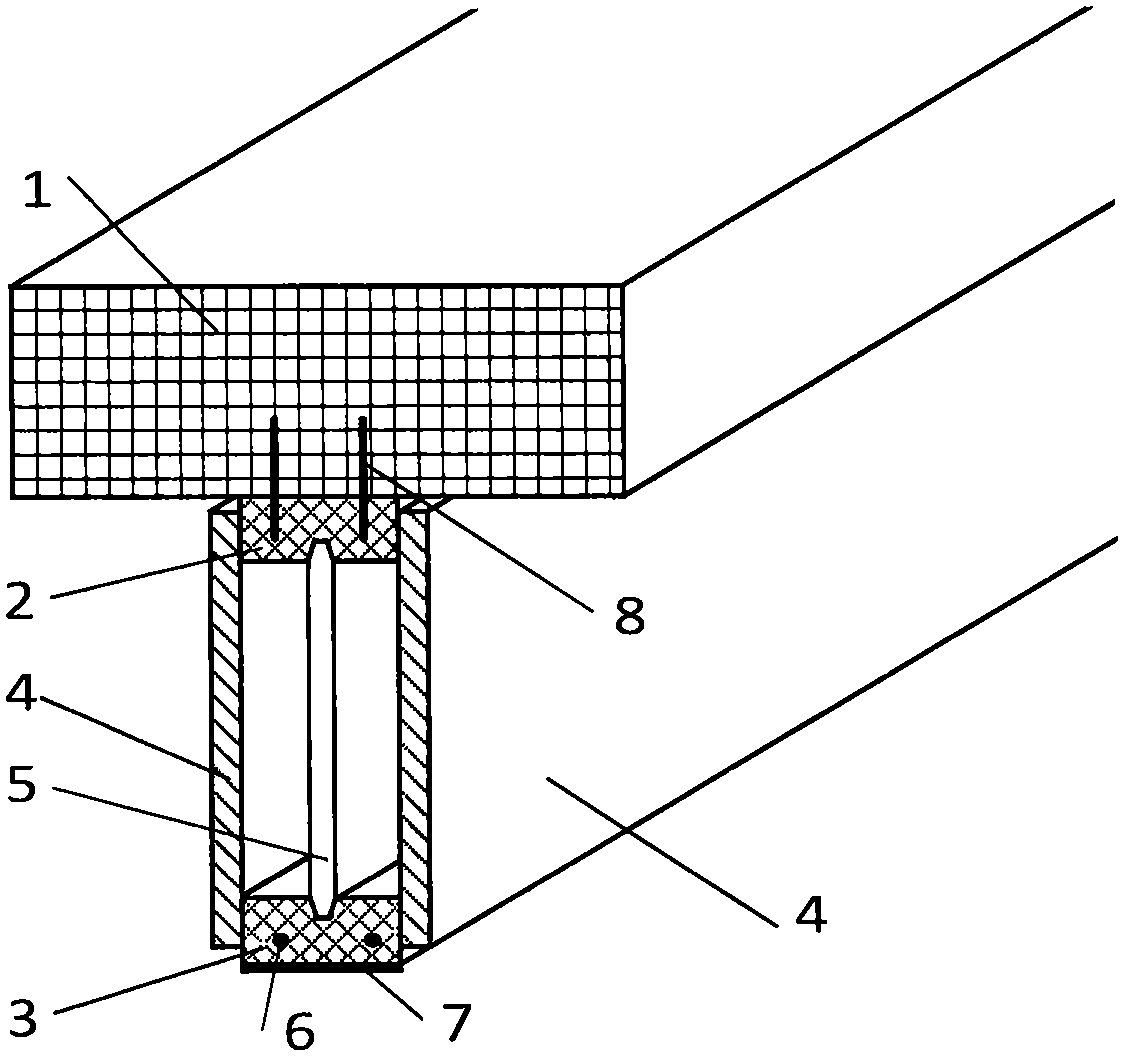

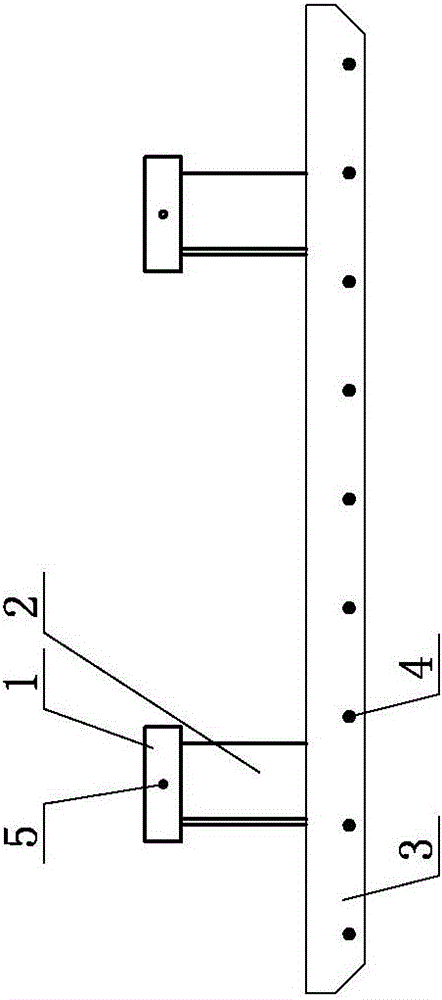

Double-pipe reinforced composite combined built pile

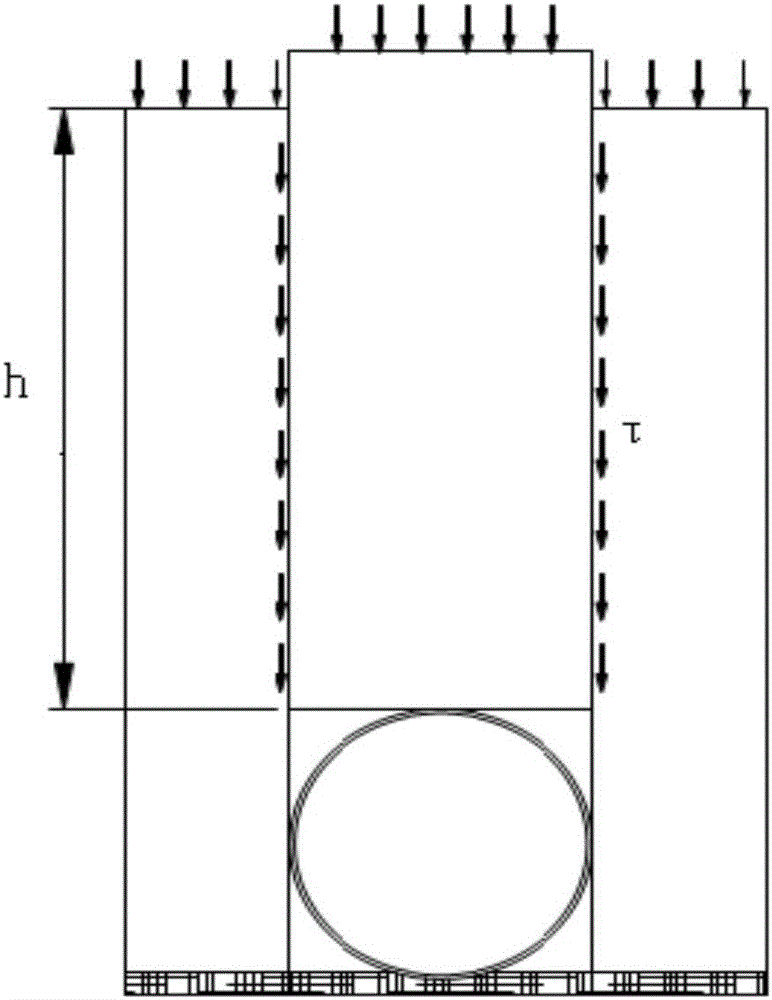

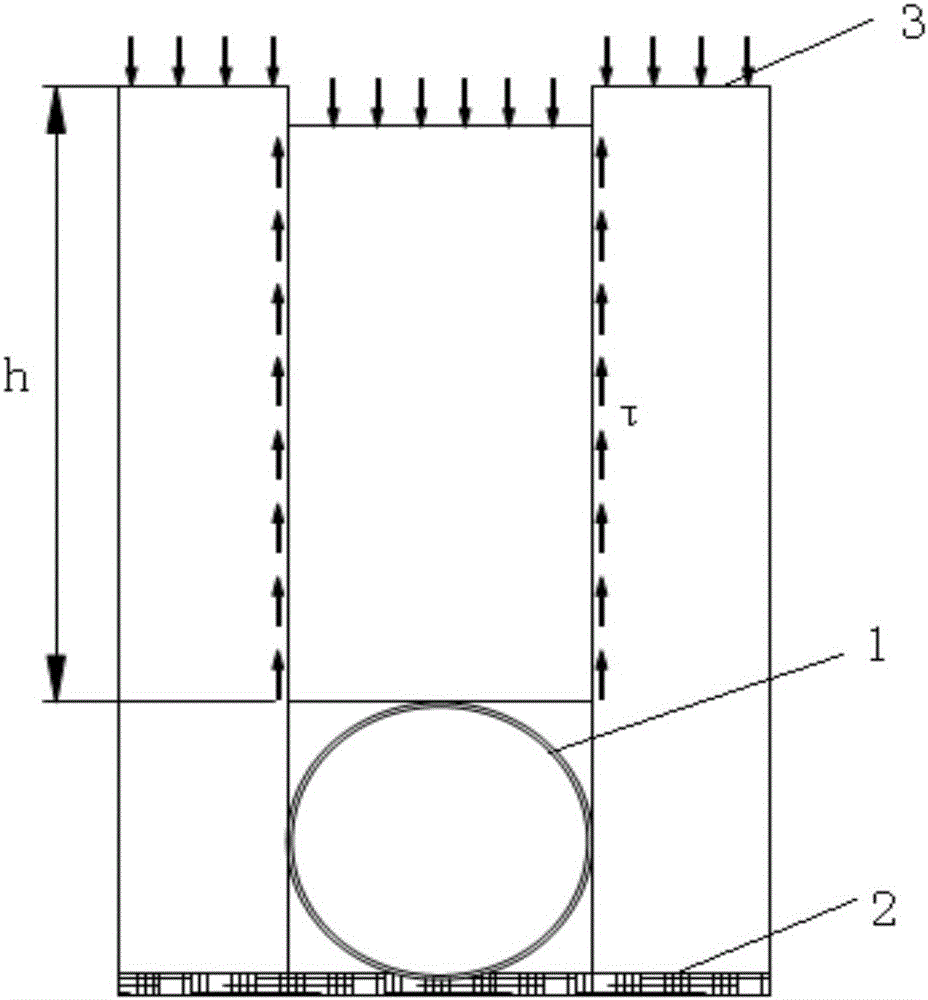

The invention disclose a double-pipe reinforced composite combined built pile, mainly consisting of a composite outer pipe (1), a metal inner pipe (3) and concrete (2) poured between the composite outer pipe (1) and the metal inner pipe (3). The invention is characterized in that the outer surface of the metal inner pipe (3) is welded with T-shaped, L-shaped or I-shaped metal ribs (4). The invention has the advantages of light weight, good rigidity and high strength and shock resistance.

Owner:NANJING UNIV OF TECH

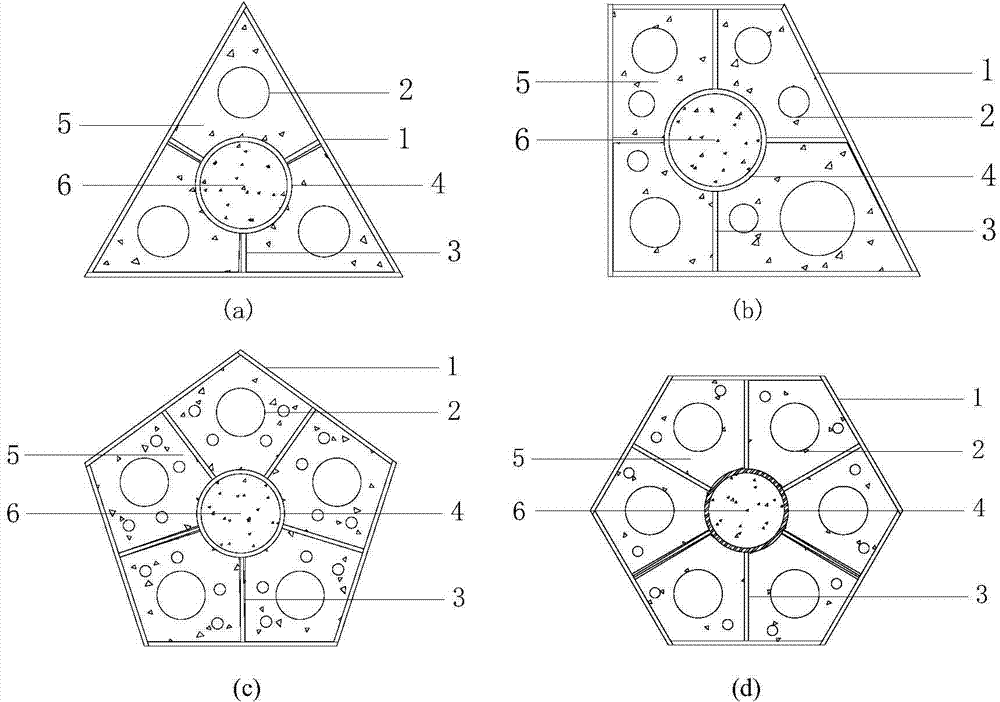

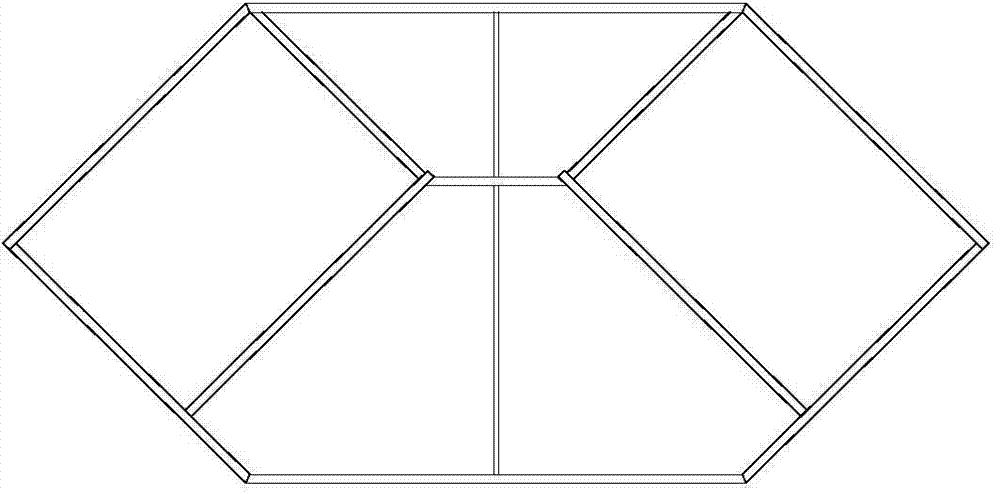

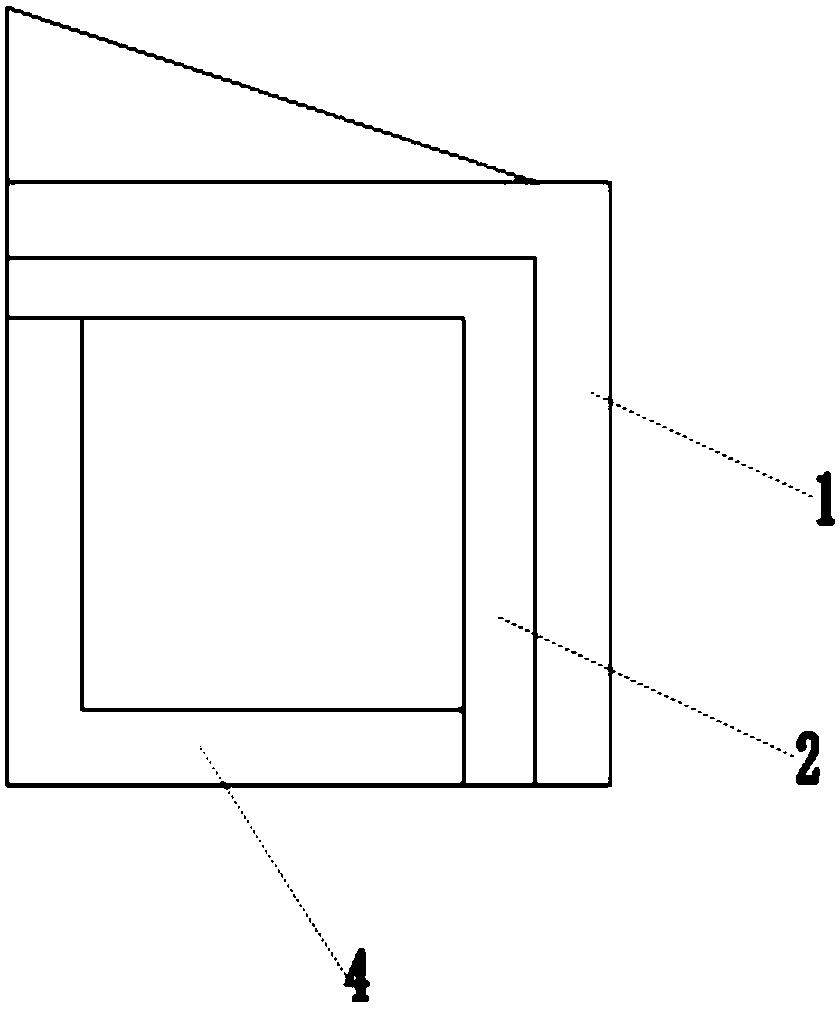

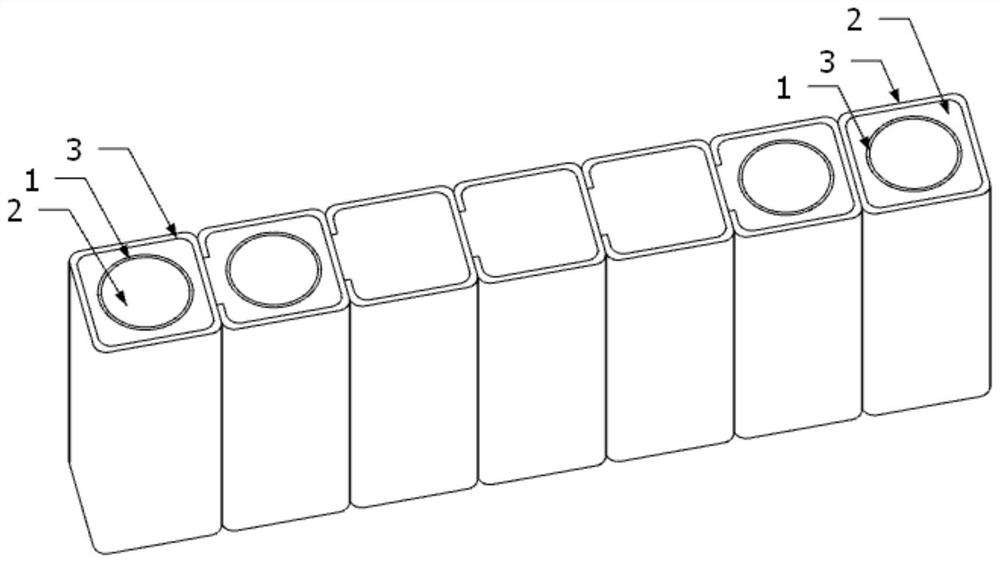

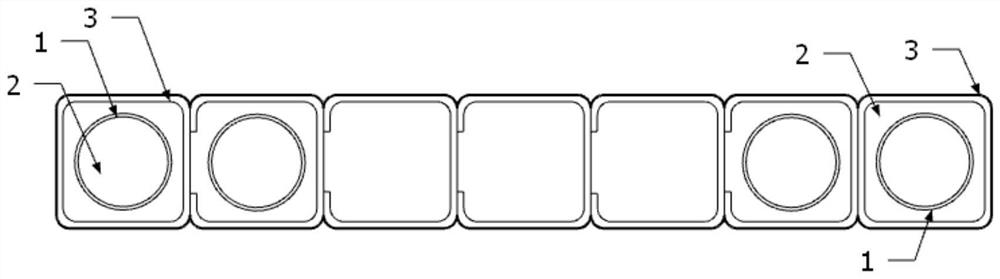

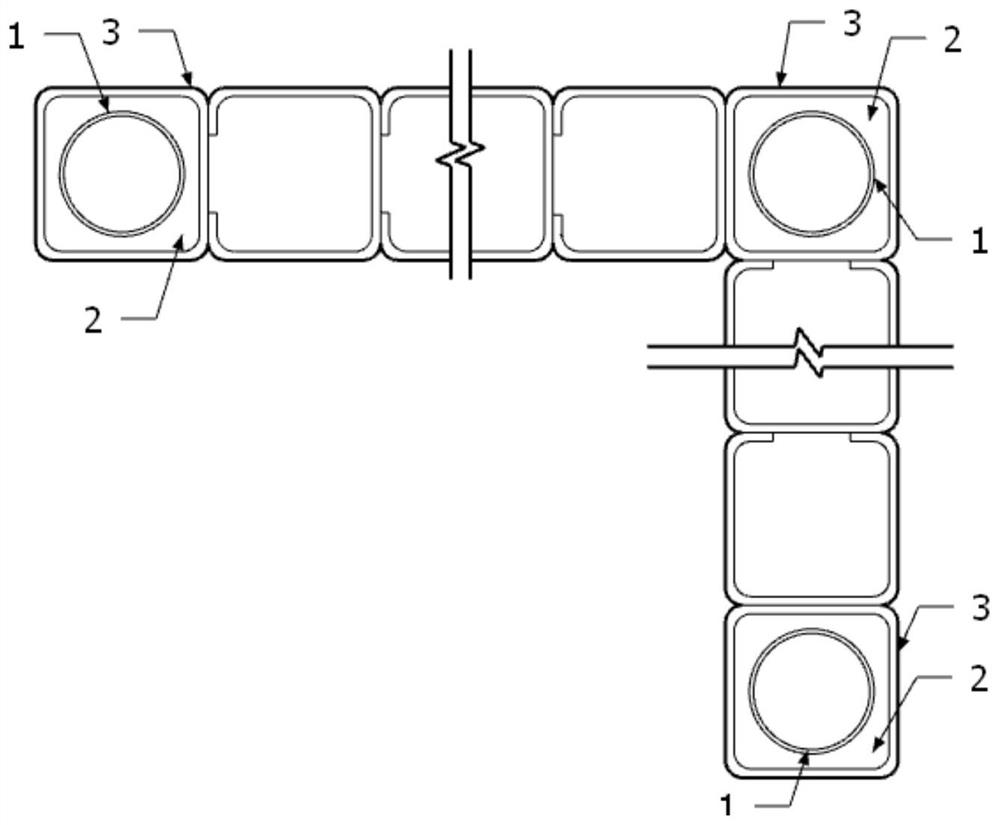

Combined giant column composed of irregular-section multi-cavity steel tube with built-in concrete-filled circular steel tube, and construction method thereof

ActiveCN104712099AImprove stabilityImprove bearing capacityStrutsPillarsHigh strength concreteStress concentration

The invention relates to a combined giant column composed of an irregular-section multi-cavity steel tube with a built-in concrete-filled circular steel tube, and a construction method thereof, and belongs to the field of building. The section form of the steel tube can be triangular, quadrilateral, pentagonal, hexagonal and the like, the composite giant column composed of the irregular-section multi-cavity steel tube with the built-in concrete-filled circular steel tube is formed under the combination or single use of different section forms. A diaphragm plate is welded with a square steel tube, a longitudinal stiffened rib is welded with the square steel tube and the diaphragm plate, and the circular steel tube is welded with the longitudinal stiffened rib and the diaphragm plate. High-strength concrete is poured in the steel tubes, the strength of concrete in the circular steel tube is higher than that of concrete in the square steel tubes, and recycled concrete can be poured in the circular steel tube. The bearing capacity of axial compression and partial compression of the irregular-section multi-cavity steel tube concrete giant column is improved; the combined giant column has an important significance on the improvement of stress concentration and hydration heat of concrete of the irregular-section multi-cavity steel tube concrete giant column; the method is simple, convenient, economical and effective and is beneficial to popularization and application in the design of building structures.

Owner:BEIJING UNIV OF TECH

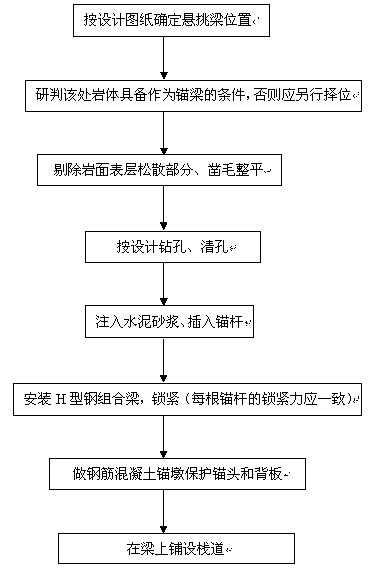

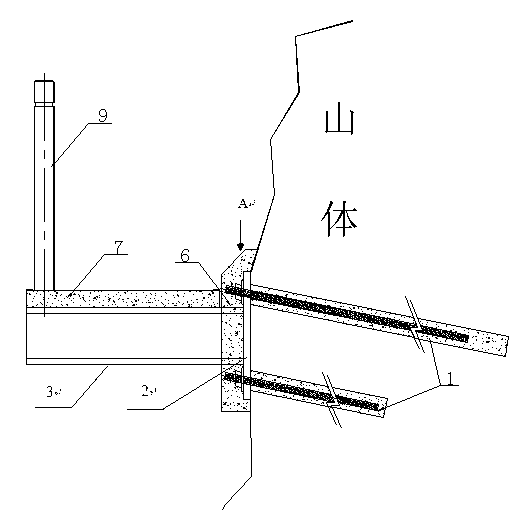

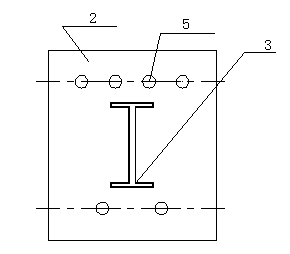

Cantilever beam structure of antique plank road along cliff and construction technology thereof

The invention discloses a cantilever beam structure of an antique plank road along a cliff and a construction technology thereof. The cantilever beam structure is formed by an H-type steel assembly, and a rock bolt assembly fixedly anchored on the rock wall of a mountain in a combining way, wherein the H-type steel assembly is formed by the combination of a steel backing plate (2) and H-type steel (3); the H-type steel (3) is welded on the steel backing plate (2) vertically and serves as the supporting beam of a road panel (7) of the antique plank road along the cliff; the rock bolt assembly is formed by the connection of rock bolts (1), bolts and nuts; and the rock bolts (1) are welded with the bolts in a surfacing manner. The construction technology of the cantilever beam structure is as follows: ensuring the position of the cantilever beam according to the design graph paper; eliminating the weathering surface and fractured rock mass of the locating-point rock surface, and scabbling and leveling; ensuring the length of the rock bolts (1) and drilling holes in the rock bolts; filling cement mortar into the rock bolt holes and inserting the rock bolts (1) welded with anchor heads; mounting the H-type steel assembly on the rock bolts after the cement mortar is solidified to a degree of the designed strength; and fastening with bolts. The cantilever beam structure is safe and reliable in structure, simple and convenient in construction technology, quick in speed, low in engineering cost, and good in simulating of the style of the antique, and is suitable for application along the cliff.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

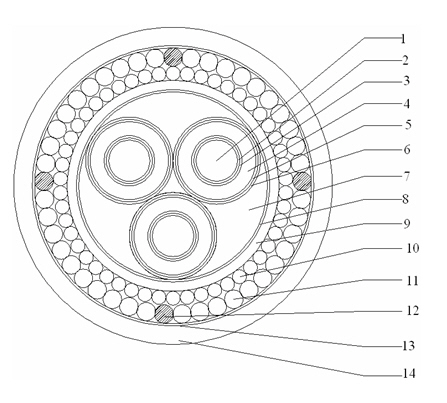

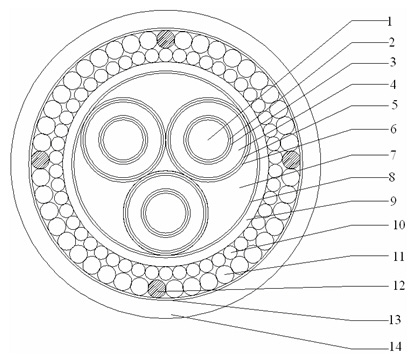

Seismic-resistant electrical cable

InactiveCN102157242AEven by forceLow elastic modulusPower cables with screens/conductive layersCopper conductorElastomer

The invention relates to a seismic-resistant electrical cable comprising a conductor, a semiconductive layer, a conductor shielding layer, an insulating layer, an insulating shielding layer, a copper strip shielding layer, an elastic body packing, a wrapping layer, an isolating sleeve, a thin round steel wire armoring layer, a thick round steel wire armoring layer, a copper conductor, an isolated layer and an outer sheath. The seismic-resistant electrical cable is characterized in that a semiconductive band layer is wrapped outside the conductor; insulating materials, packing materials, isolating sleeve materials and outer sheath materials are all elastic body polymers; and double-layer steel wire armoring is adopted for the armoring layers. The invention has higher shearing rigidity, bending rigidity and damping ratio, obvious effects of shear resistance, bending moment, axial force, torsion, and the like, and excellent seismic-resistant and seismic-proof capacity.

Owner:江苏天地龙电缆有限公司

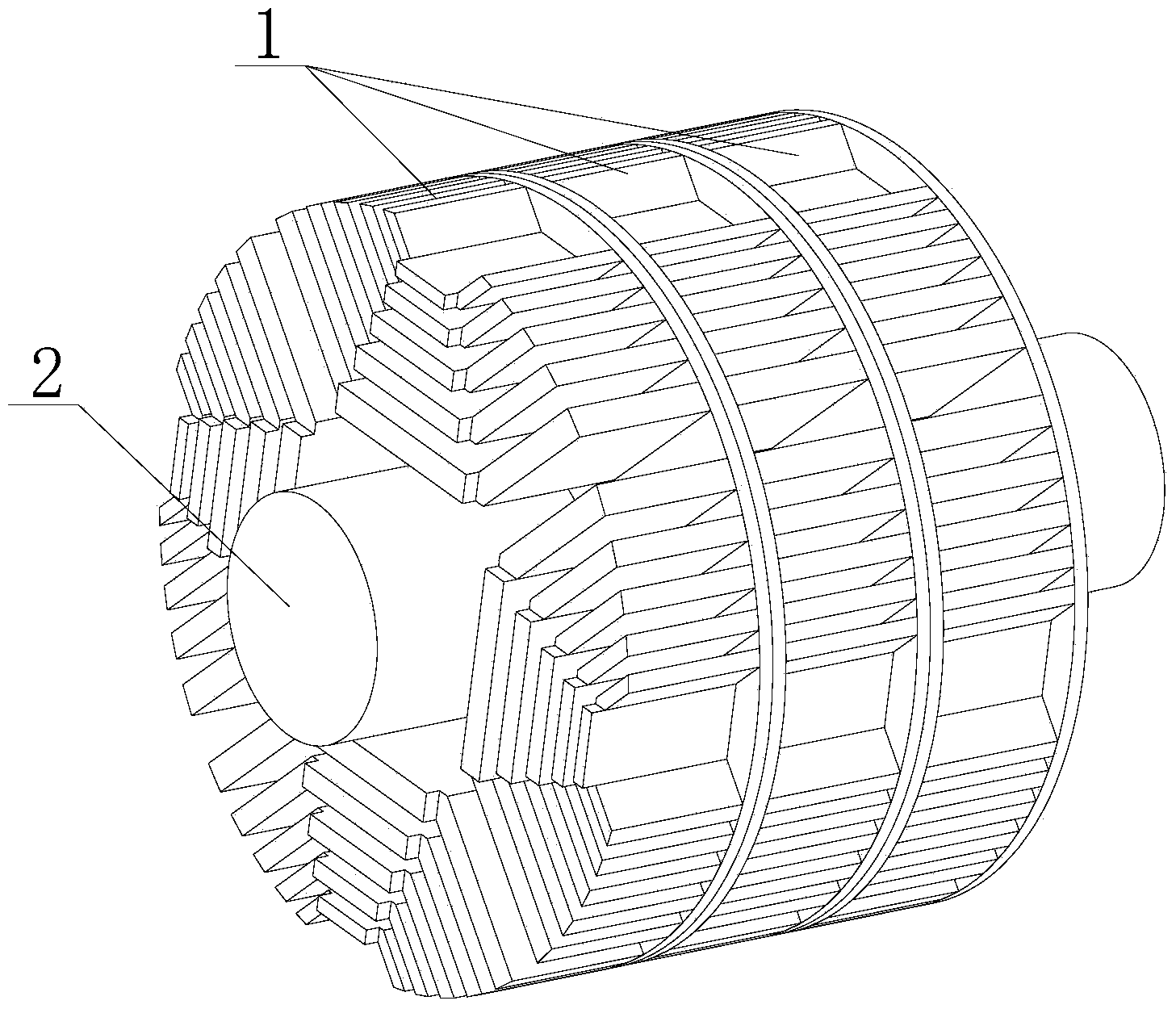

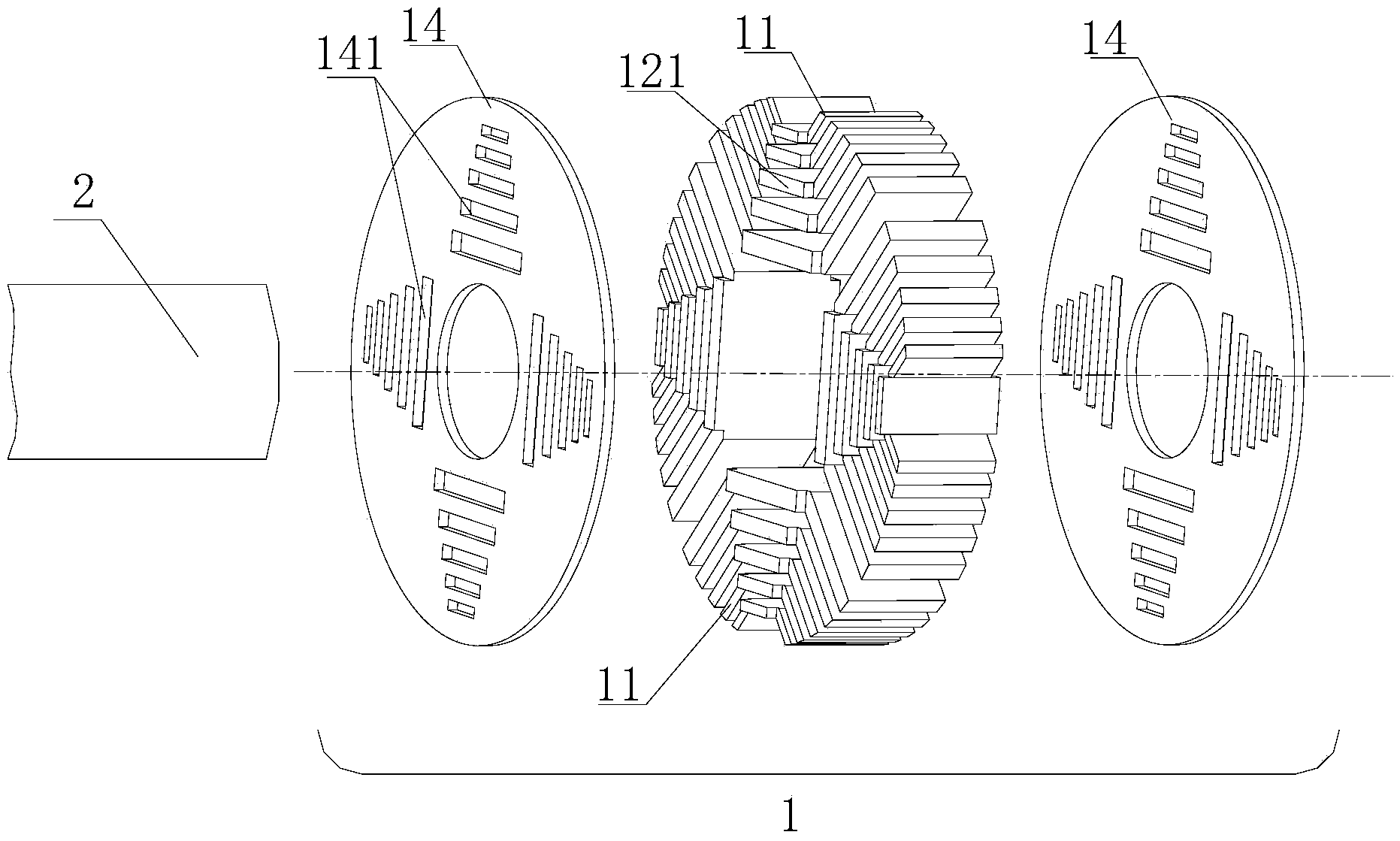

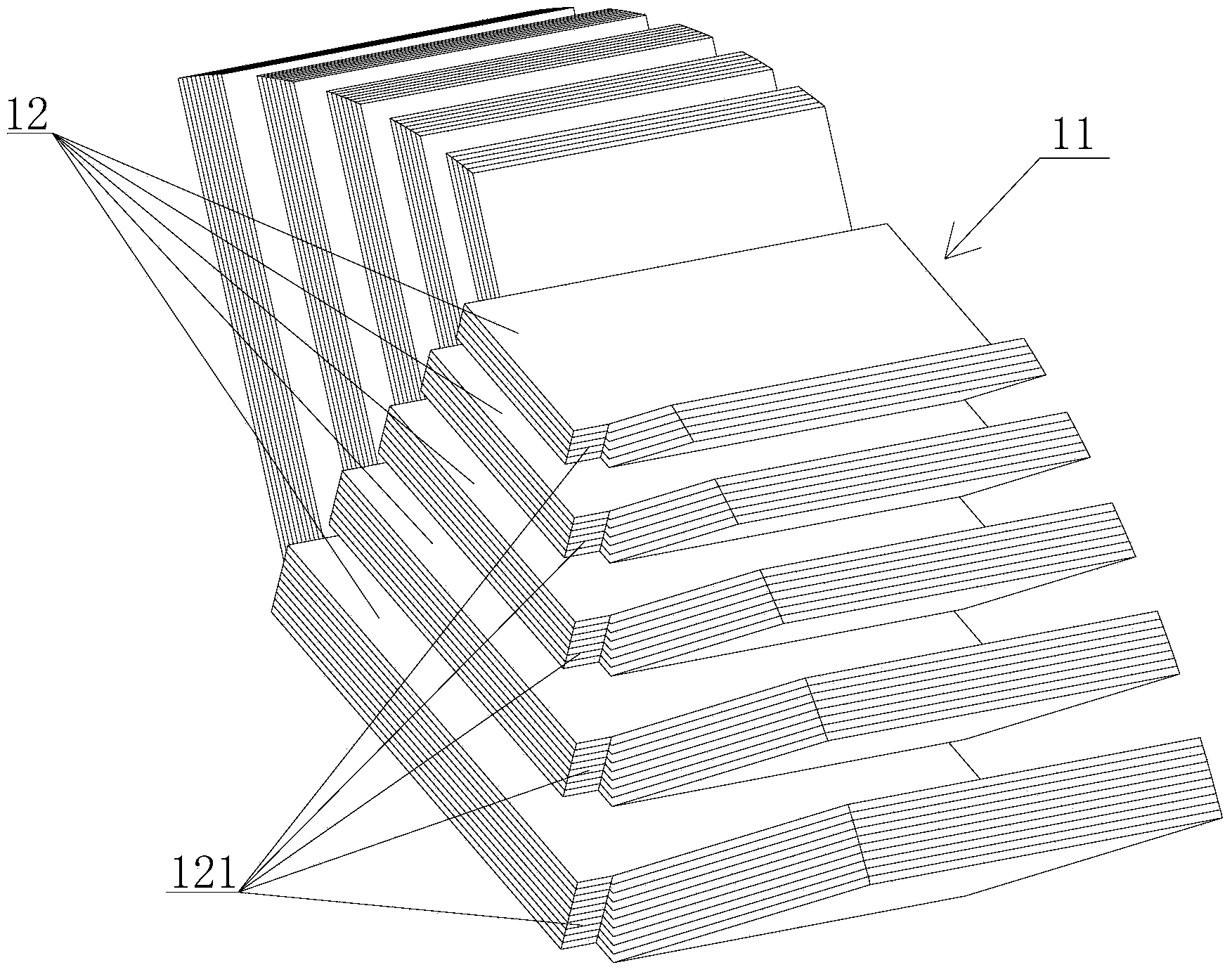

Rotor of synchronous reluctance motor

InactiveCN104242504AReduce in quantityStable structureMagnetic circuit rotating partsSynchronous reluctance motorPower factor

The invention provides a rotor of a synchronous reluctance motor. The rotor of the synchronous reluctance motor comprises multiple rotor modules which are arranged coaxially and staggered sequentially in the axial direction. Each rotor module comprises multiple magnetic poles, and the magnetic poles are arranged in adjacent sections around a common axis. Each magnetic pole comprises multiple magnetic ribs which are distributed in the radial direction at intervals. Each magnetic rib is composed of multiple punched sheets. Locating plates are connected to the two axial side faces of the magnetic poles. The locating plates are mounted on a rotating shaft in a sleeved mode. Bosses are arranged at the two axial ends of each magnetic rib respectively. Grooves are formed in the positions, corresponding to the bosses, of the locating plates. The axial end face of each magnetic pole is tightly attached to the axial end face of the corresponding locating plate in the mode that the bosses are inserted into the grooves. The magnetic poles and the locating plates of the rotor modules of the rotor are assembled through the matching between the bosses and the grooves, assembly is convenient to carry out, the magnetic poles are easy to locate, and position accuracy is high; the rotational inertia of the rotor is lower, manufacturing is easy and convenient to carry out, and the efficiency and the power factors of the motor are improved.

Owner:HANGZHOU EASITECH

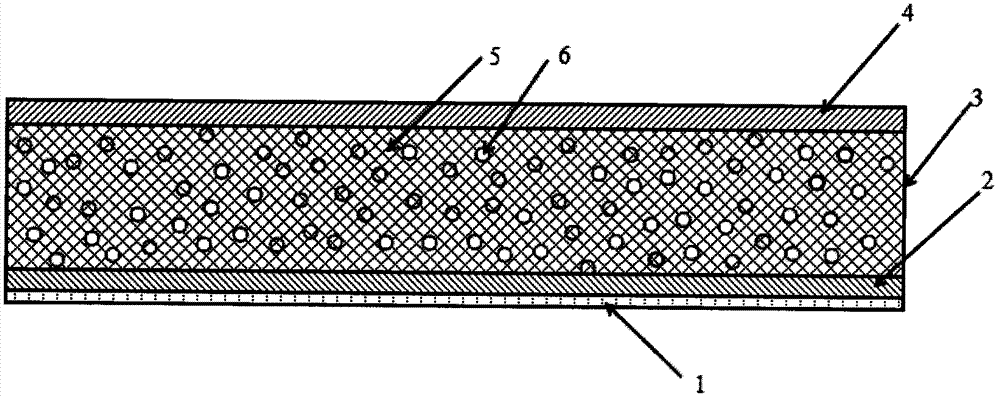

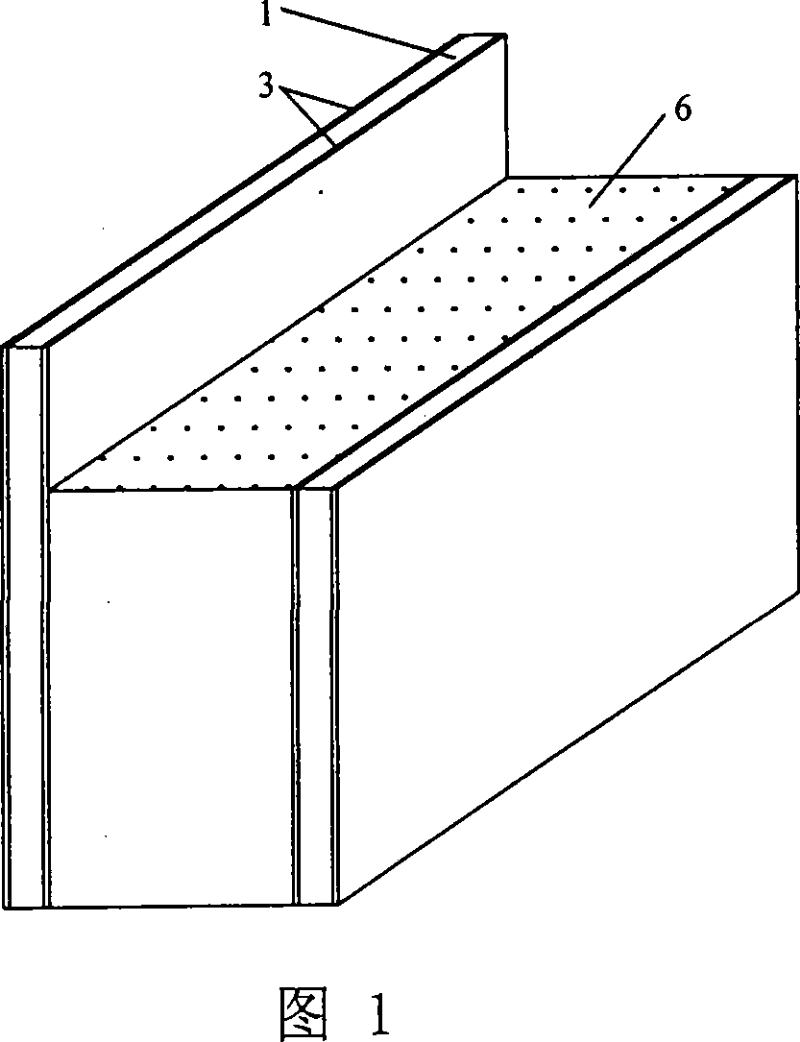

High-rigidity composite pipeline and manufacturing method thereof

InactiveCN106969213AReduce weightAchieve lightweightSynthetic resin layered productsRigid pipesOptoelectronicsResin-Based Composite

Disclosed are a high-rigidity composite pipeline and a manufacturing method thereof. A lining layer, a structure layer, an interlayer structure and a protective layer are arranged sequentially from inside to outside. The lining layer, the structure layer and the protective layer are all prepared from fibers or fabric-reinforced resin-based composites through a winding process. The surface of the structure layer is coated with the interlayer structure through warp-knitted spacer fabrics soaked with resin, and the hollow interlayer structure is formed through resin curing, or the hollow interlayer structure is filled with light foamed plastics to form a solid interlayer structure. According to the high-rigidity composite pipeline and the manufacturing method thereof, the hollow interlayer structure or the interlayer structure filled with the light foamed plastics is adopted, thus the weight of the pipeline is reduced substantially, and small weight is achieved. Meanwhile, due to the fact that the interlayer structure is adopted, larger pipe wall thickness can be achieved with less materials, the inertia moment of the pipe wall section is improved greatly, the rigidity of the pipeline is improved, and thus high rigidity and low cost are achieved.

Owner:TIANJIN POLYTECHNIC UNIV

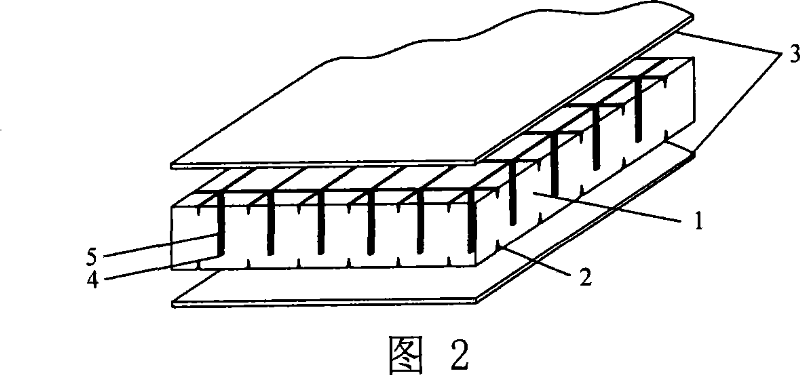

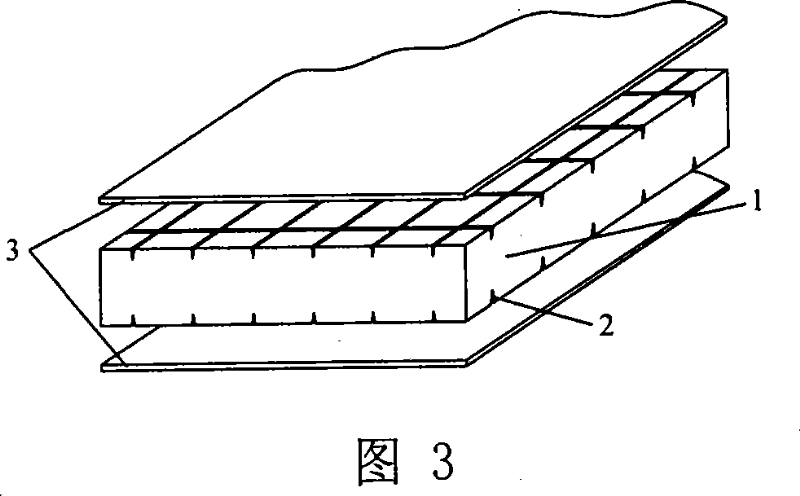

Composite material formwork

InactiveCN101042018AImprove mechanical performanceImprove bonding performanceConstruction materialForming/stuttering elementsFiberMaterials science

The composite material made mold plate comprises the core material, featuring in the slots on the surface of the core material, fiber cloth layer on the top and bottom surface of the core material, setting through holes that stuffed with resin pegs along the thickness direction of the core material at the crossing section of the slots based on requirement. It features in its lightness, high strength, obvious improvement of concrete building speed, not only being able to saving constructing expenses, but also applicable to construction under special conditions.

Owner:NANJING UNIV OF TECH

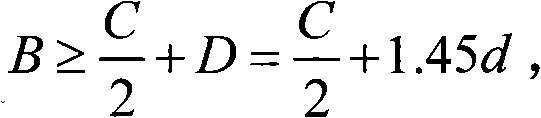

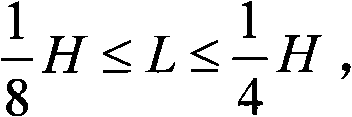

Method for reinforcing transmission angle steel tower

ActiveCN101852022AImprove stabilityImprove carrying capacityBuilding repairsTowersPower equipmentTransmission line

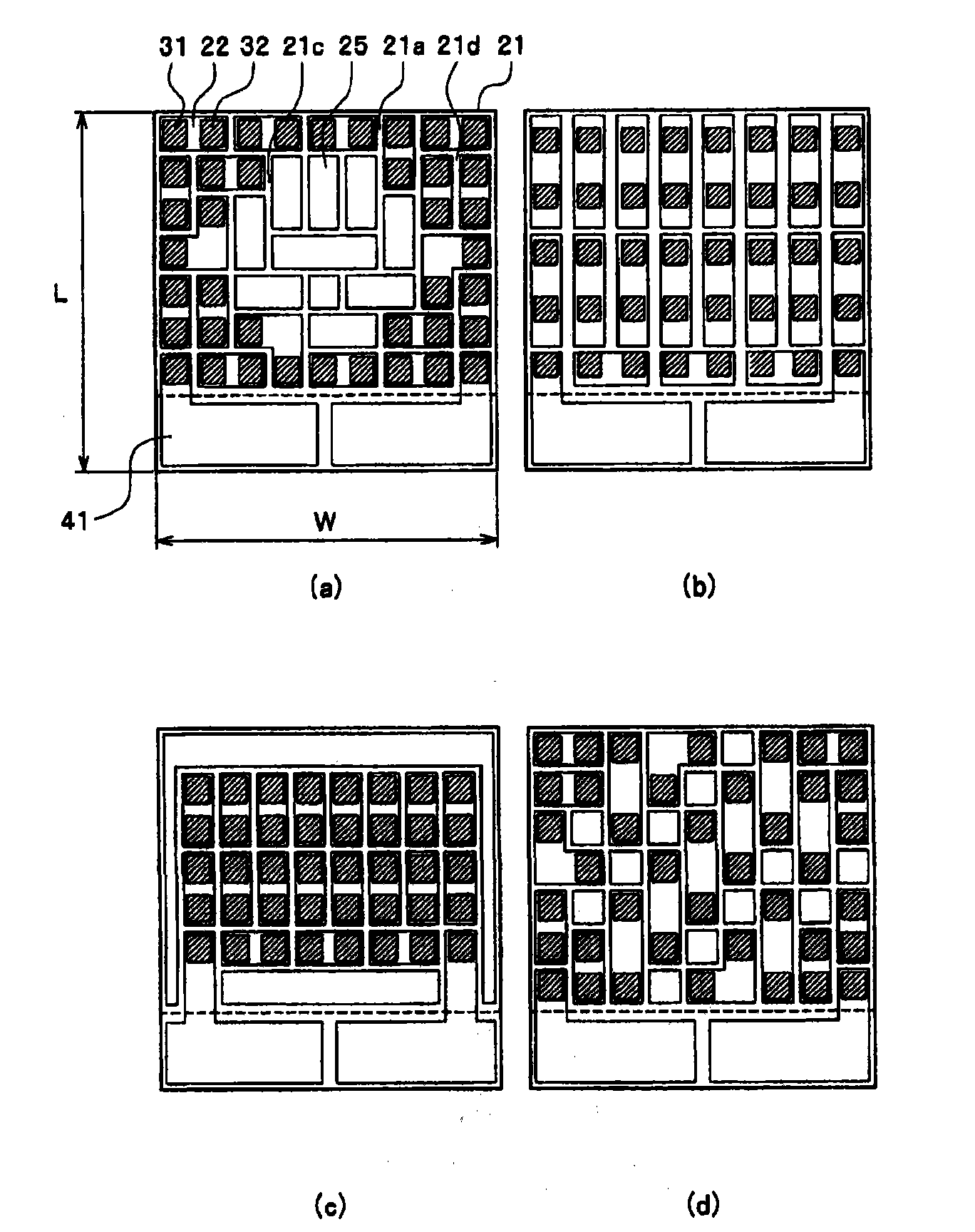

The invention relates to a method for reinforcing a transmission angle steel tower, in particular to the method for reinforcing the angle steel of a transmission line steel tower in power equipment. A layer of V-shaped section component is fixed outside the angle steel of the transmission angle steel tower and comprises smooth sections and a curved section, wherein B represents the length of the smooth section, R1 represents the inner arc radius of the curved section, R2 represents an outer arc radius, L represents a distance between the top of the curved section and an inner cross point of the smooth sections, t represents the section thickness of the V-shaped section component, and H represents the leg width of the reinforced hot-rolled angle steel. The curved section of the V-shaped section component is determined by the following conditions: R1 is equal to a difference obtained by subtracting x from t, wherein x is equal to 1 to t-1; R2 is equal to the summation of R1 and t; and a distance between the top of the curved section and the inner cross point of the smooth sections meets the condition that L is more than ore equal to one eighth of H and less than or equal to a quarter of H. Through the scheme, the steel tower can be reinforced under the condition of being electrified to guarantee the normal running of actual lines and improve the section stability of the hot-rolled angle steel.

Owner:CHINA ELECTRIC POWER RES INST +1

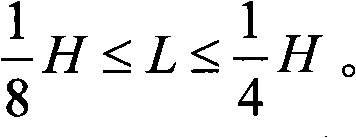

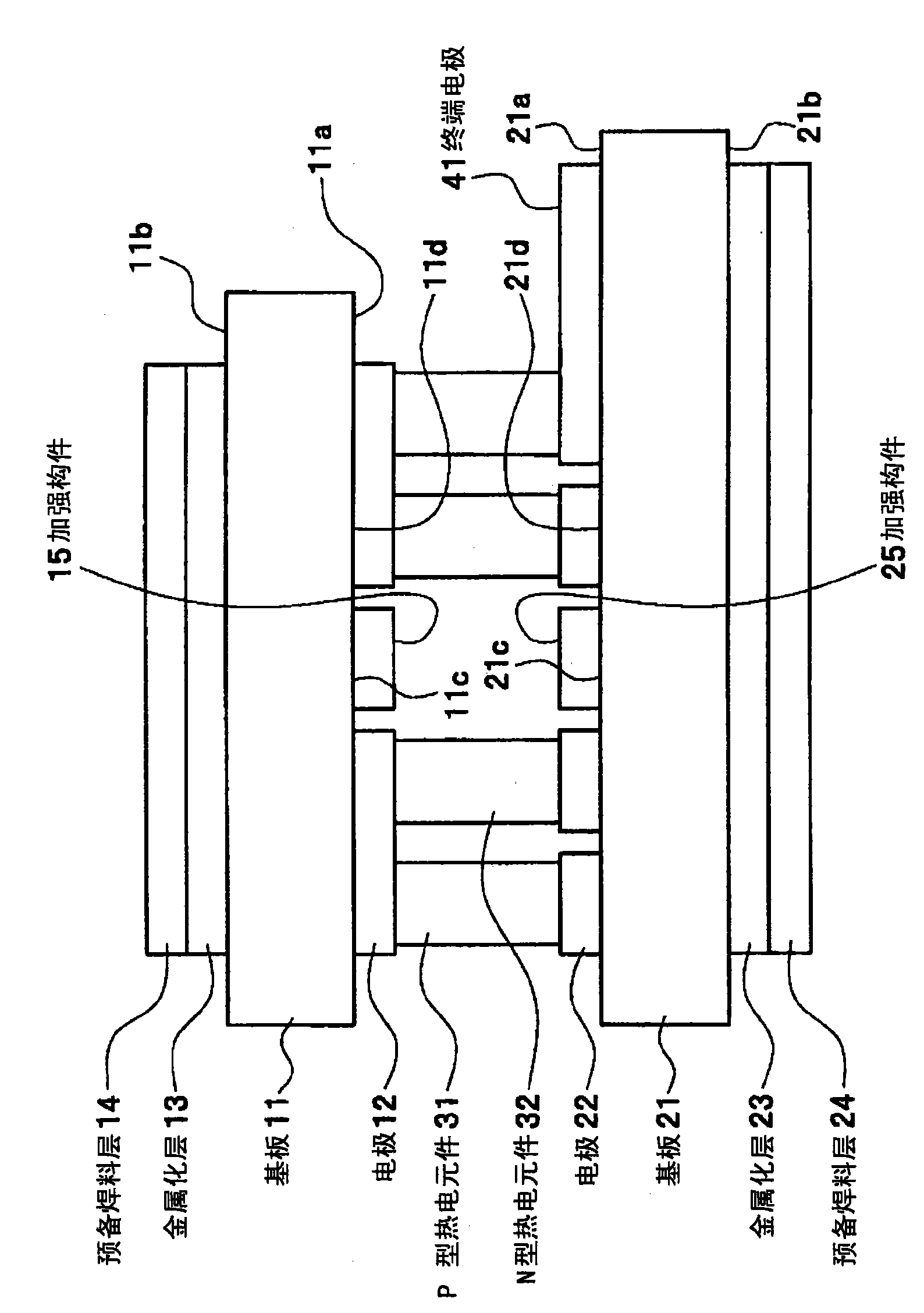

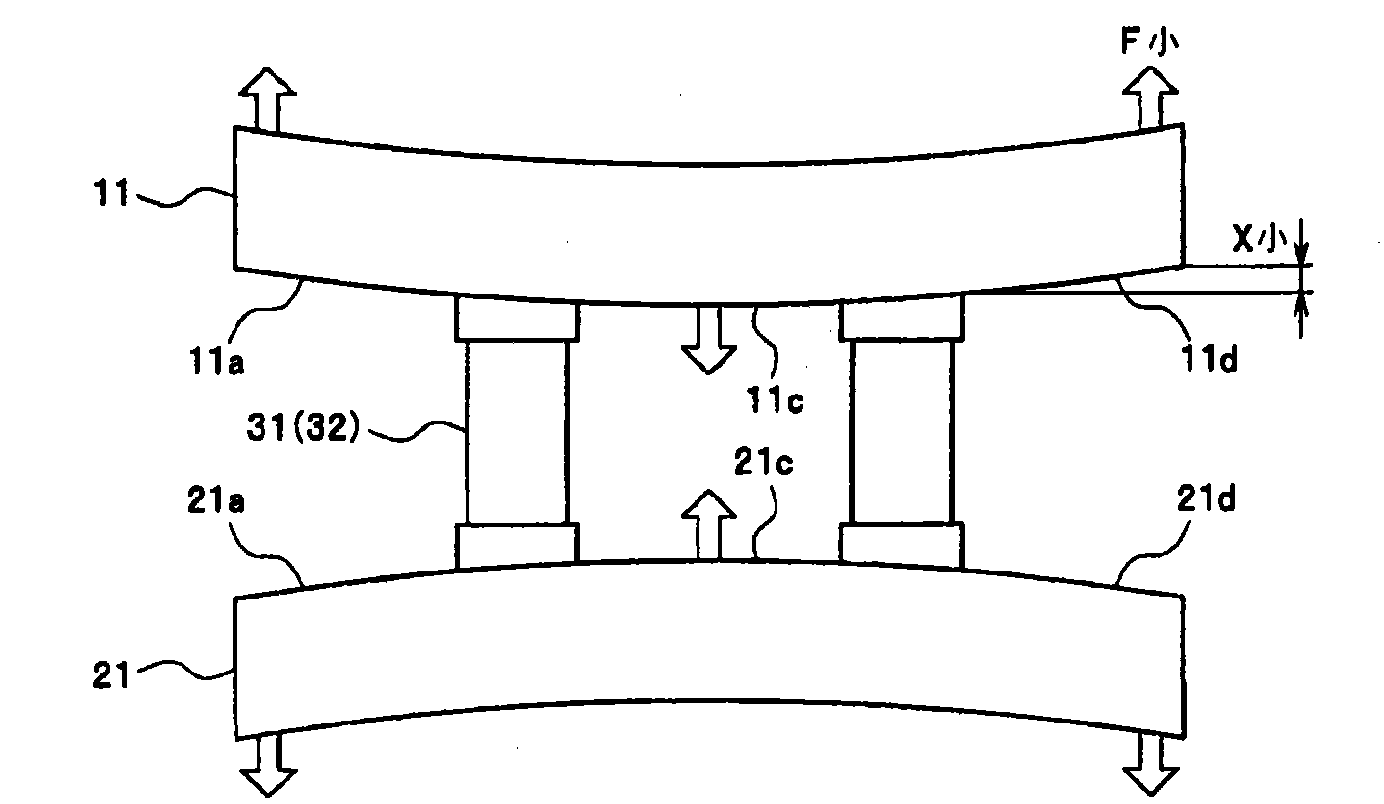

Thermoelectric module

ActiveCN101868867AAvoid damageDisplacement and small forceThermoelectric device with peltier/seeback effectHigh densityThermoelectric element

Thermoelectric elements are arranged with a high density in a peripheral region surrounding a center region or in an outer circumferential region of an opposing surface of a substrate instead of being arranged in the center region of the opposing surface. As compared to the case when the thermoelectric elements are arranged in the center of the opposing surface, when the thermoelectric elements are arranged in the region excluding the center region of the opposing surface, the thermoelectric element serving as a reference point of warp is positioned at an outer circumference side, i.e., the distance between the warp reference point and the outer circumference of the substrate becomes shorter. As the distance between the warp reference point and the outer circumference of the substrate becomes shorter, the displacement amount and the force of the warp caused at the outer circumference of the substrate become smaller. Moreover, when the thermoelectric elements are arranged with a high density, the force of each of the thermoelectric elements pulled by the substrate warp becomes smaller. Thus, by reducing the displacement amount and the force of the warp generated at the outer circumference of the substrate, it is possible to prevent a damage of the thermoelectric elements caused by the substrate warp.

Owner:KELK LTD

Composite steel plate shearing wall for improving stability

InactiveCN102691364ALarge shear buckling capacityGreatly increased shear buckling capacityWallsSheet steelSteel frame

The invention relates to a composite steel plate shearing wall for improving stability, which belongs to a lateral force resisting component in the technical field of structural engineering and is applied to newly construction of a frame-steel plate shearing wall and reinforcement and seismic rehabilitation of a constructed steel frame structure. Each of the top end and the bottom end of a composite plate is provided with a first channel steel connector, notches of the first channel steel connectors at the top end and the bottom end are arranged outwards, and a notch of a second channel steel connector is arranged inwards on the first channel steel connector at the top end of the composite plate. According to the composite steel plate shearing wall for improving stability, the form of clamping a hard polyurethane foam plate between two steel plates remarkably is adopted so as to increase the plane external stiffness of the cross section of the plate so that the steel plate shearing wall obtains great anti-shearing buckling bearing capacity to avoid entire buckling of the structure under the action of a larger horizontal load; and meanwhile, the steel plate is divided into small areas by dense bolts and is closely combined with the hard polyurethane foam plate to prevent partial buckling of the steel plate.

Owner:HOHAI UNIV

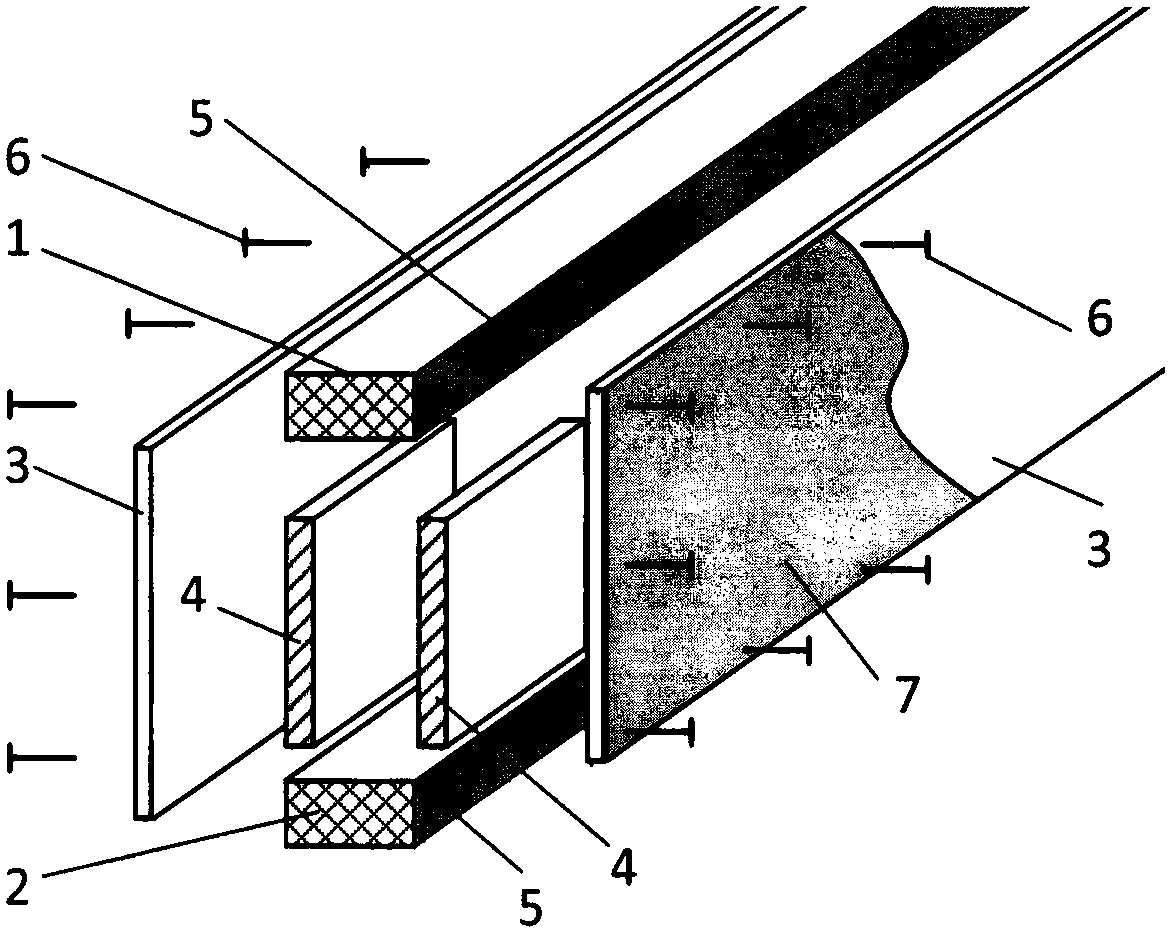

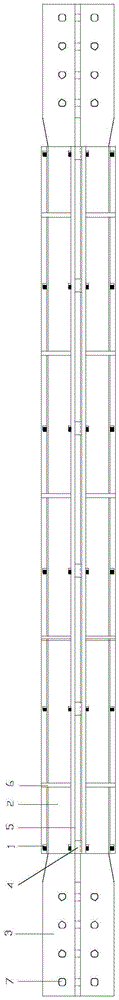

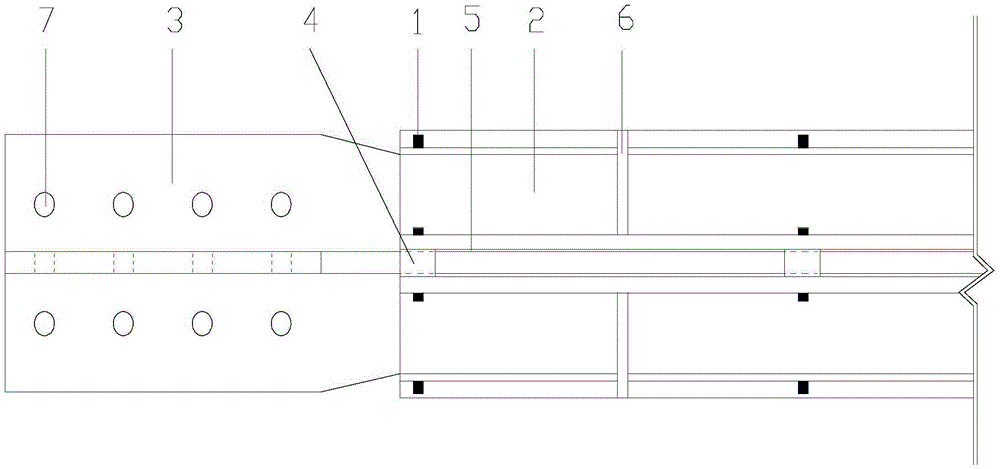

Bamboo glued box beam

PendingCN108331253AGood effectIncrease the moment of inertia of the sectionGirdersJoistsShear stressAdhesive

The invention provides a bamboo glued box beam. The bamboo glued box beam mainly comprises an upper flange (1), a lower flange (2), webs (3), stiffening ribs (4), an adhesive (5), nails (6) and waterproof coating (7) together forming the bamboo glued box beam, wherein the webs (3) are located at the side surfaces of the upper flange (1) and the lower flange (2) and bears the shear stress, the upper flange is located at the top surface of the box beam and bears the compressive stress, and the lower flange is located at the bottom surface of the box beam and bears the tensile stress; and the webs (3), the upper flange (1) and the lower flange (2) are connected by the adhesive. The stiffening ribs (4) are arranged at the end of the box beam, tightly abut against the lower flange (2), are closely adhered to the webs (3), and are connected by the nails (6) to improve the local instability of the webs (3). The waterproof coating (7) is applied to the surface of the box beam to take on the function of moisture and corrosion protection. The bamboo glued box beam fully utilizes the characteristics of six kinds of materials, greatly improves the cross sectional moment of inertia of beam members, has the characteristics of light weight, high strength, high rigidity, good durability and good ductility, and can replace traditional original bamboo beams, heavy bamboo beams and wooden beams to be applied to bent members in the fields of wood structure, bamboo structure and composite structure.

Owner:NANJING FORESTRY UNIV

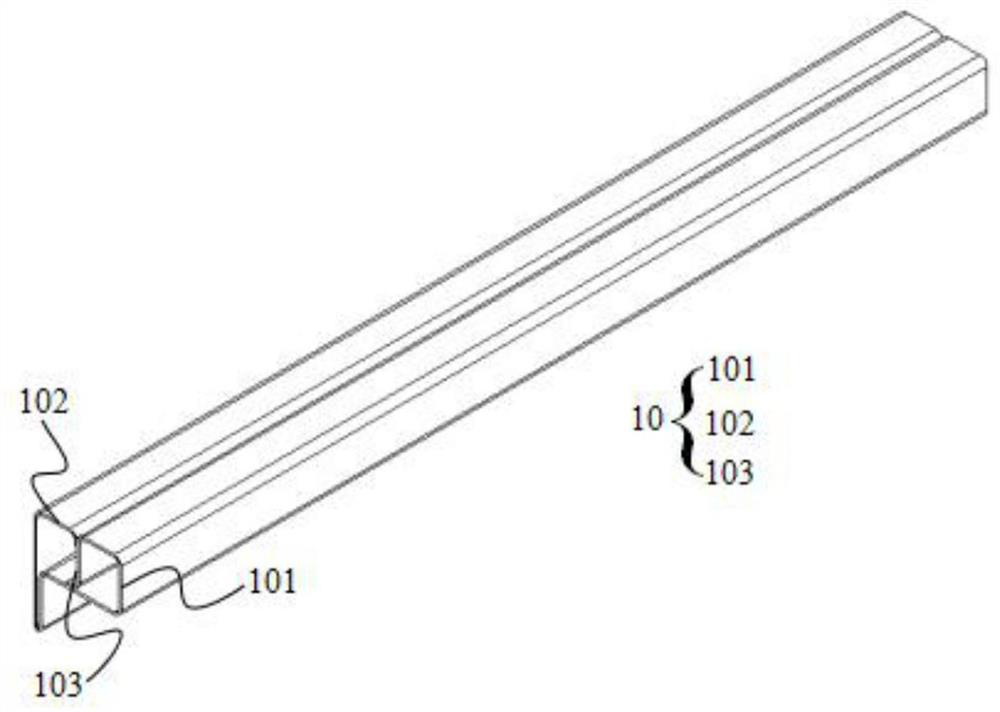

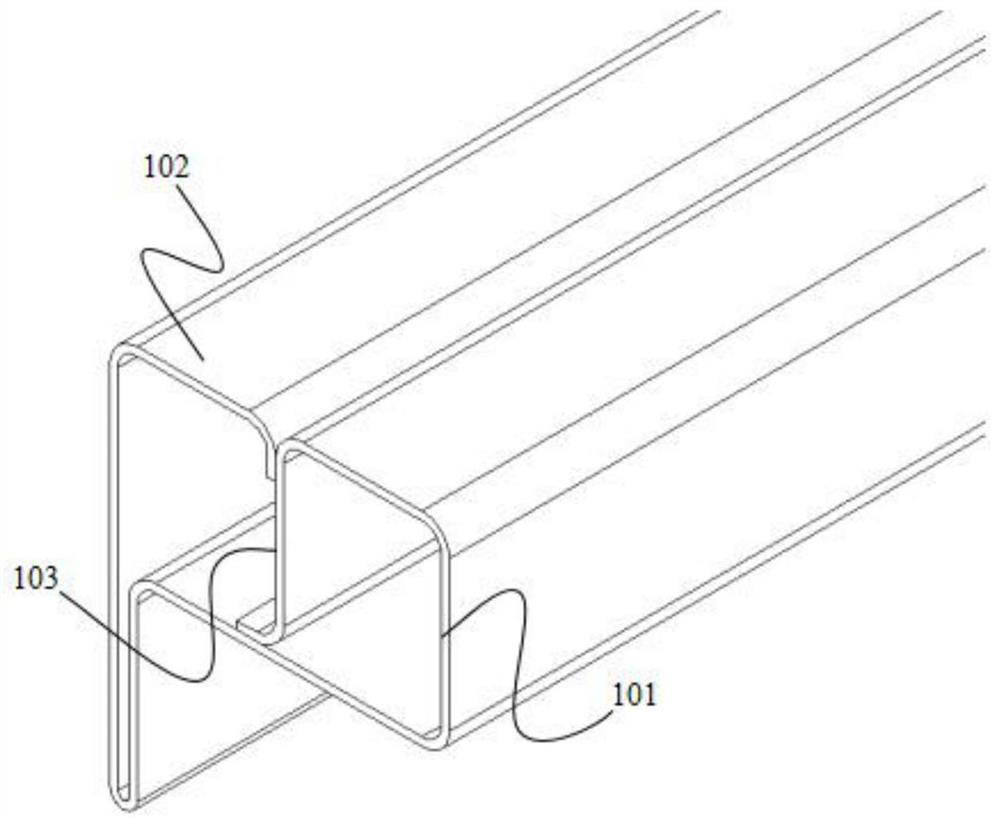

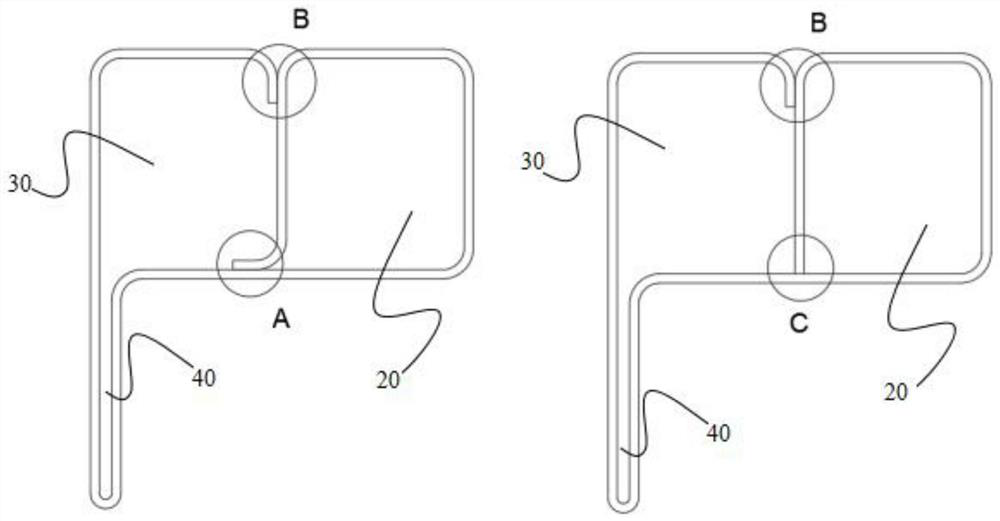

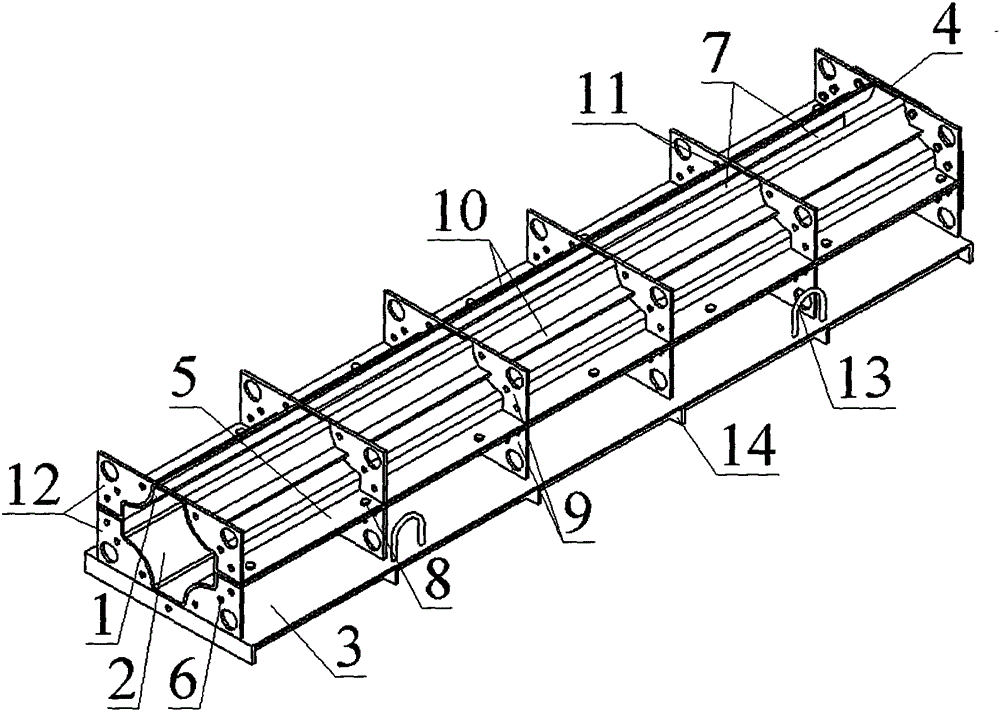

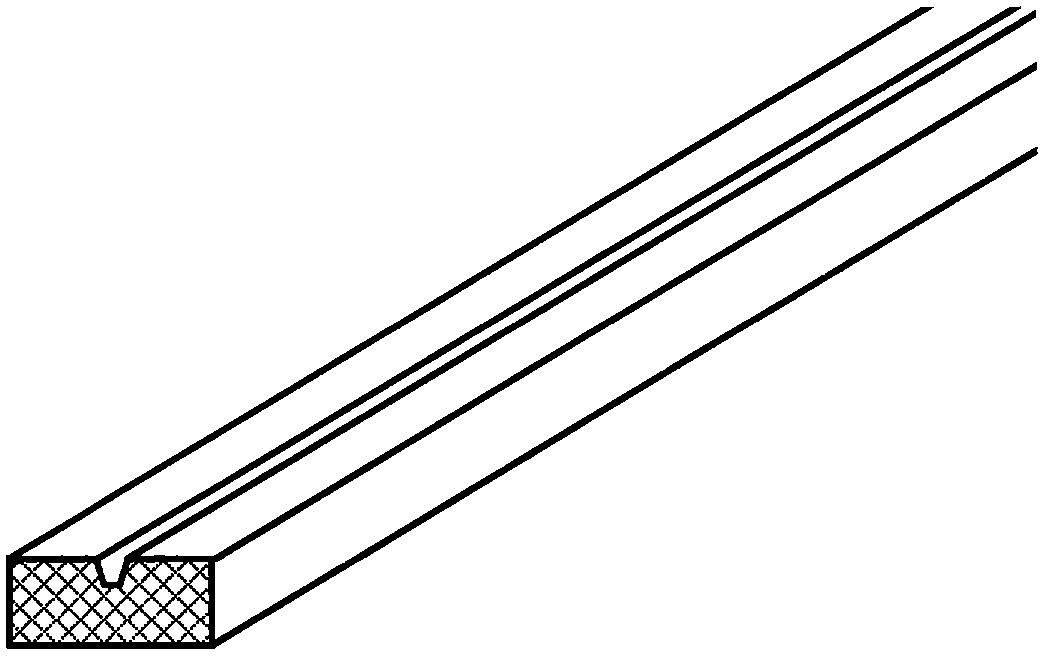

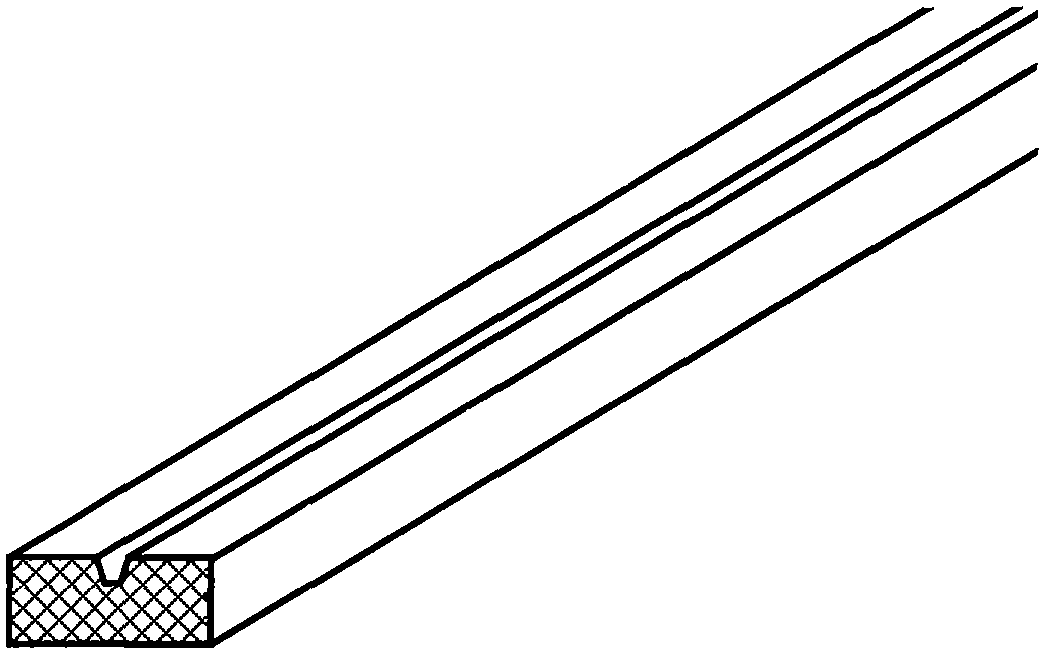

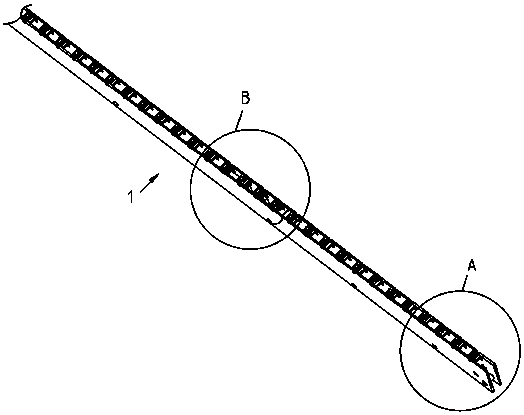

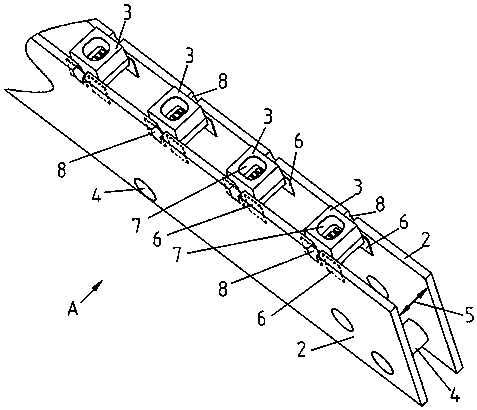

Rolled section bar and preparation method thereof, battery pack skeleton, and battery pack

ActiveCN111916603ARealize the bottom functionOvercoming Difficulties in WeldingCell component detailsBatteriesStructural engineeringSteel belt

The invention discloses a rolled section bar and a preparation method thereof, a battery pack skeleton, and a battery pack. The rolled section bar comprises a rolled section bar body prepared by multiple times of rolling and bending of a steel belt, and the rolled section bar body comprises a first part, a second part and a reinforcing rib; the middle reinforcing rib enables the rolled section barto be effectively further thinned and lightened under the condition that the strength and rigidity are not reduced, a battery pack skeleton can be defined by the roller section bar, and an L-shaped pipe structure defined by the second component and the reinforcing rib can achieve the bottom supporting function on a battery pack; meanwhile, the manufacturing process is integrated on line, continuous production is achieved, the welding difficulty of conventional production of complex rolling closed profile products is overcome, the defects of low efficiency, high cost and the like are overcome,and the manufacturability of the products is met.

Owner:苏州亿创特智能制造有限公司

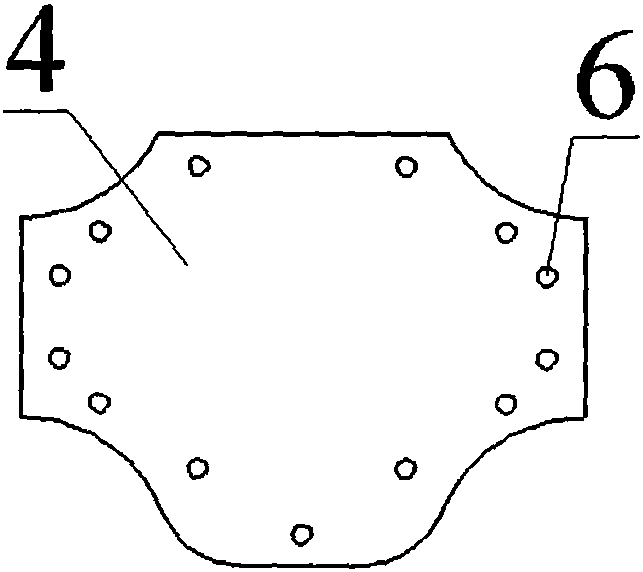

X-shaped precast reinforced concrete pile mould

InactiveCN105082330AIncrease the moment of inertia of the sectionIncrease stiffnessMouldsMould auxillary partsReinforced concreteRebar

The invention discloses an X-shaped precast reinforced concrete pile mould which comprises a V-shaped shaping mould plate, a reversed-V-shaped shaping mould plate, a bottom plate and an end head plate. The reversed-V-shaped shaping mould plate is connected and fixed above the V-shaped shaping mould plate through bolts to form an X-shaped cavity; the bottom plate is welded to the bottom of the V-shaped shaping mould plate to bring convenience to suspending and piling the mould; the end head plate is fixed to the two ends of a combined body formed by the reversed-V-shaped shaping mould plate and the V-shaped shaping mould plate through bolts to seal openings; and a feeding opening is formed in the junction between two lateral face plates of the reversed-V-shaped shaping mould plate. The X-shaped precast reinforced concrete pile mould is simple and compact in structure, good in forming effect and high in mould assembling and disassembling efficiency.

Owner:CHANGAN UNIV +1

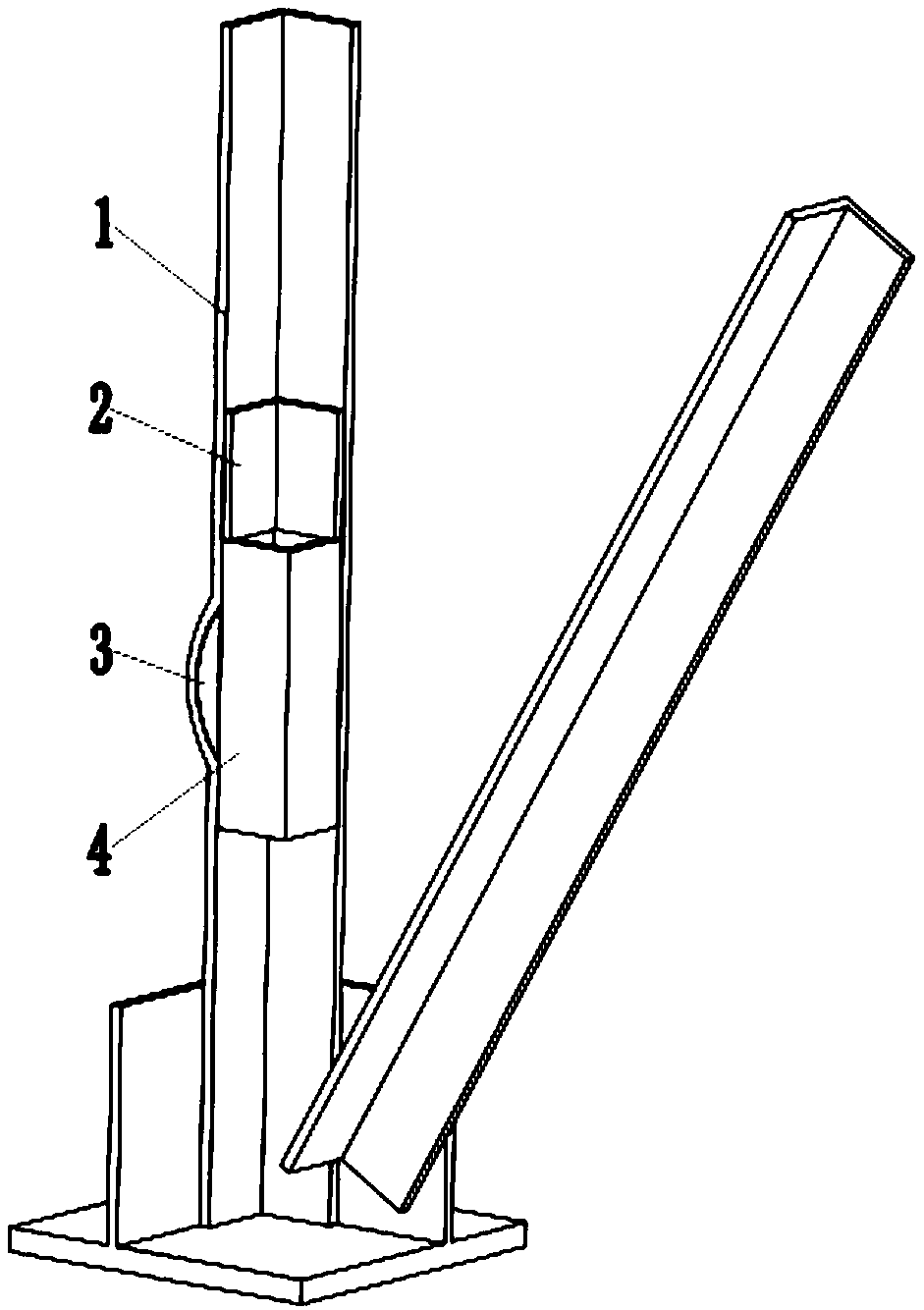

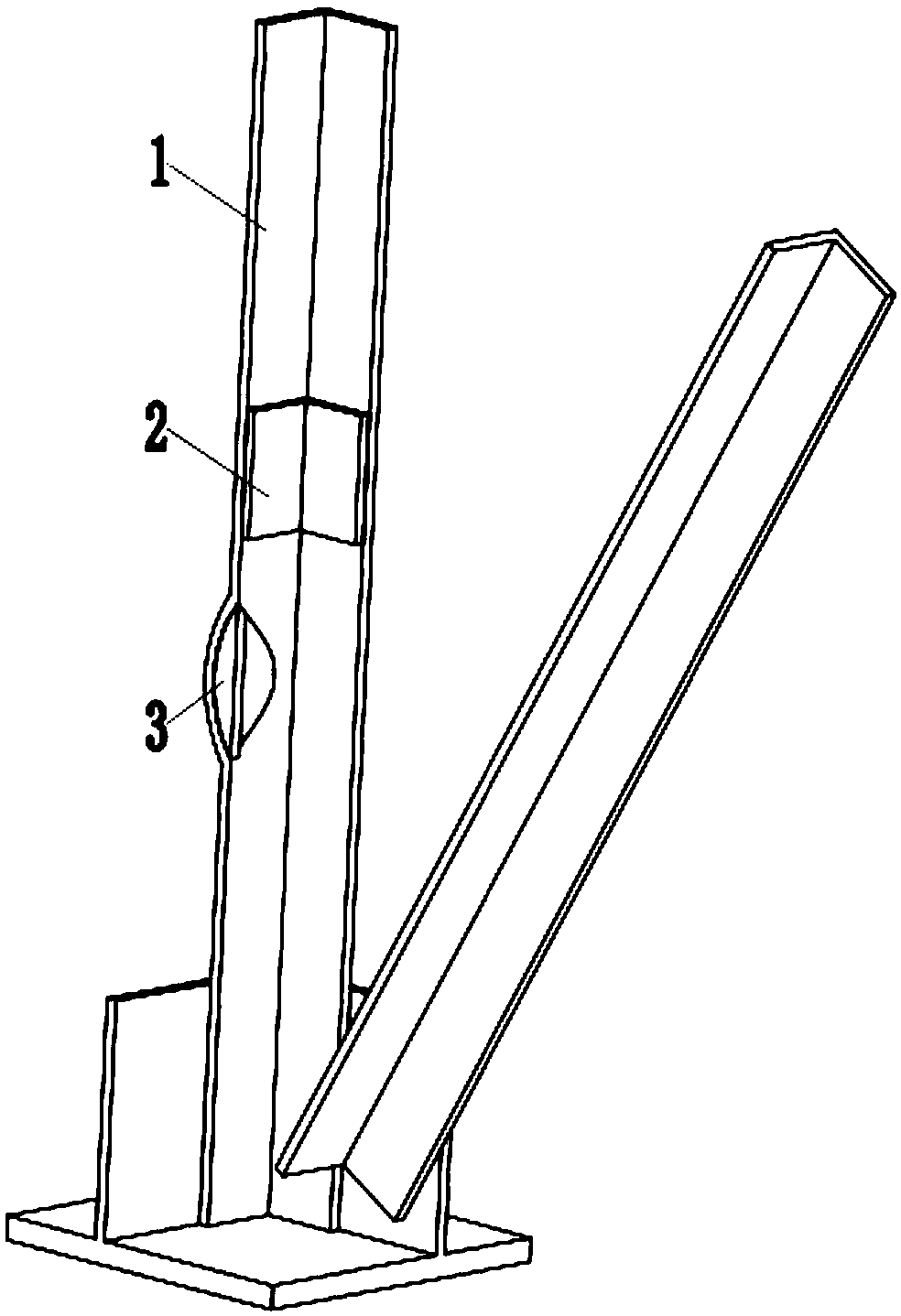

Reinforcing device and method for bending main material of tower leg of power transmission angle steel tower

ActiveCN108952302ATo achieve reinforcementImprove bending abilityBuilding repairsTowersButt jointEngineering

The invention discloses a reinforcing device and method for bending a main material of a tower leg of a power transmission angle steel tower. The device comprises the power transmission tower main material and reinforcing angle steel, and the power transmission tower main material is provided with a bent part. The device also comprises transition angle steel and a filling plate, the filling plateis arranged on the inner side of the bent part, the outer side of the filling plate is aligned with the end of the power transmission tower main material, one side of the filling plate is attached tothe inner wall of the bent part and is fixedly welded, and the other side of the filling plate is a straight edge and is aligned with the inner wall of the power transmission tower main material; thereinforcing angle steel is arranged on the inner side of the power transmission tower main material, the reinforcing steel angle and the power transmission tower main material form a rectangular rotating structure, and the reinforcing angle steel is in butt joint with the straight edge of the filling plate; the reinforcing angle steel is fixedly welded to the inner wall of the power transmission tower main material and the filling plate, the transition angle steel is attached to the inner wall of the power transmission tower main material, the two sides of the transition angle steel are fixedly welded to the power transmission tower main material, and the lower end of the transition angle steel is fixedly welded to the reinforcing angle steel.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

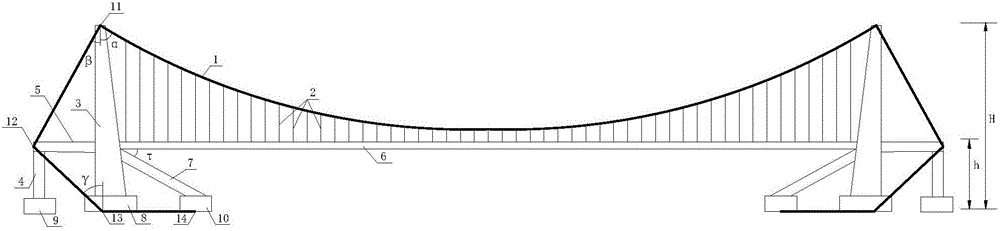

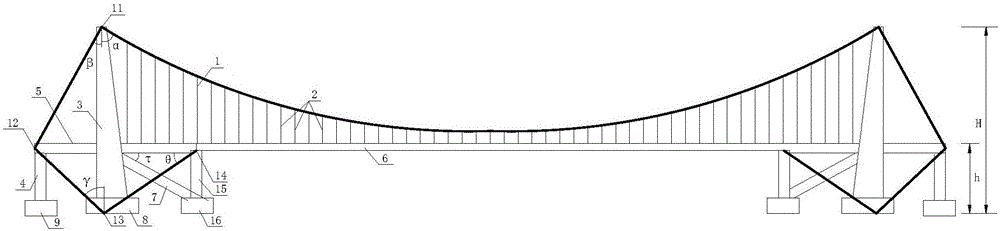

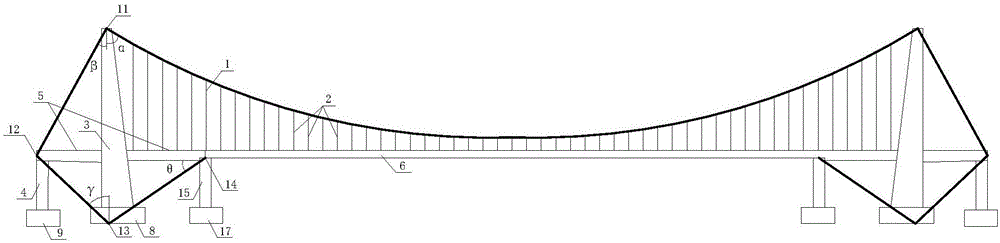

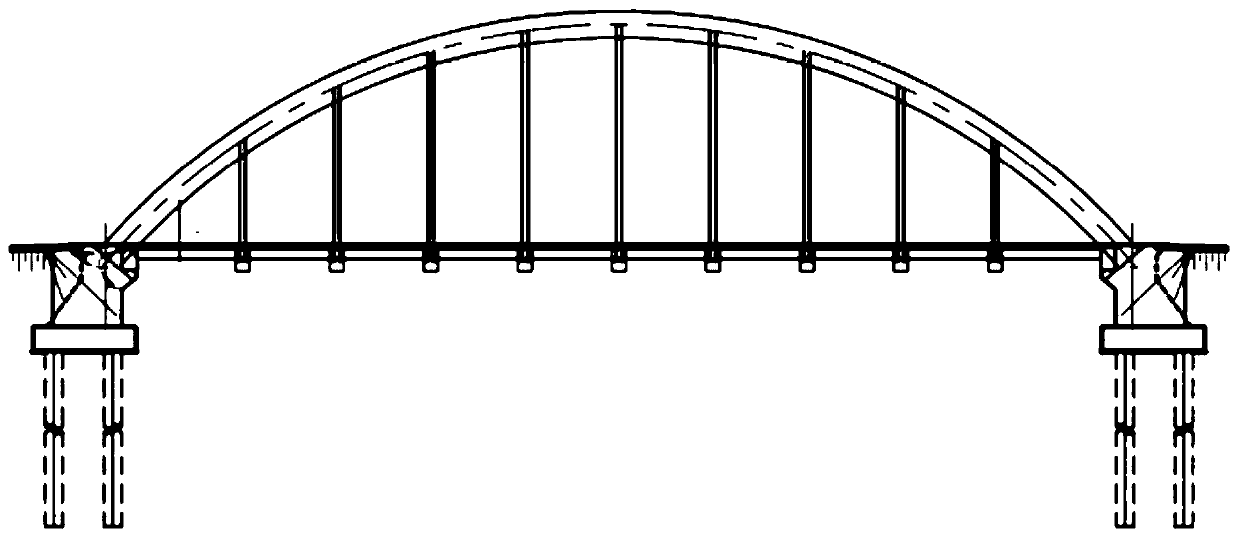

Tower-anchor combined suspension bridge

ActiveCN106284049ATake advantage ofNo bending momentSuspension bridgeBridge structural detailsAxial forceTower

The invention discloses a tower-anchor combined suspension bridge. The tower-anchor combined suspension bridge is mainly composed of a main cable, suspension cables, cable towers, horizontal rods and a main beam. The main cable is wound around the tower tops, the horizontal rods and the tower bottoms in sequence and finally anchored between the cable towers on the two sides of the suspension bridge. The cable tower form of the tower-anchor combined suspension bridge is greatly different from that of a traditional suspension bridge, the eccentric lines of the cable towers are curves, and back cables can be prevented from generating bending moment on the towers when rotating around the towers; the width lines of the cable towers are curves, and it can be guaranteed that materials are fully utilized. On the premise of keeping the span of a traditional ground anchor suspension bridge, large-size anchors can be omitted, tower foundations and anchors are combined, the calculated length of the main cable connected with the anchors is reduced, the stress and amplitude of the main cable are reduced under the dead load action, the horizontal tension of the main cable can be balanced by the counter force of the foundations and the axial force of the main beam together, and the foundations are stressed obliquely downwards. The tower-anchor combined suspension bridge is more reasonable in stress, and strength and beauty unification can be achieved more easily under the premise of guaranteeing structure safety, economy and durability.

Owner:广西恒正建设工程质量检测有限公司

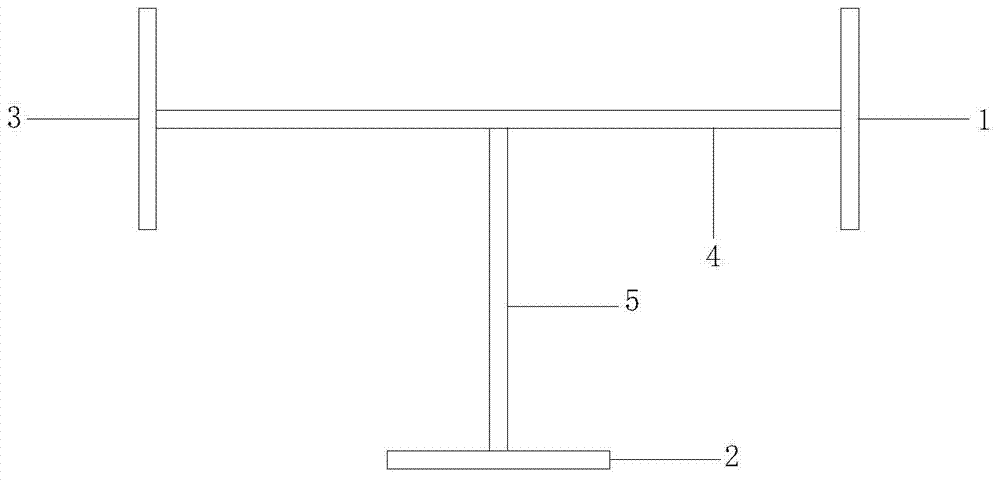

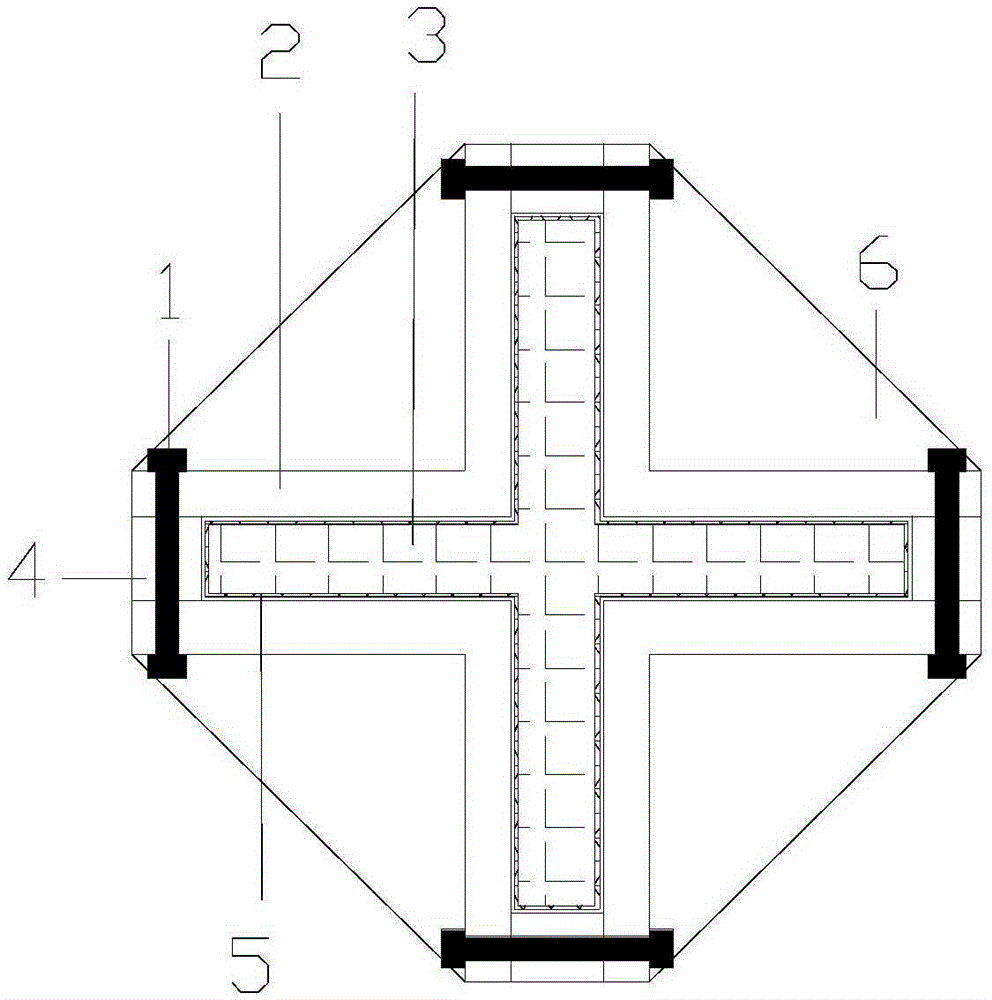

Lightweight concrete-bamboo glue-laminated panel T-shaped beam

PendingCN108316556AIncrease stiffnessChange the unfavorable situation of poor rigidityGirdersJoistsFiberShear stress

The invention provides a lightweight concrete-bamboo glue-laminated panel T-shaped beam which comprises a concrete (1), an upper flange (2), a lower flange (3), a side web (4), a middle web (5), a reinforcing steel bar (6), FRP (Fiber Reinforced Plastic) (7) and a shear key (8). The lightweight concrete-bamboo glue-laminated panel T-shaped beam is characterized in that the concrete (1) is locatedon the top part of the T-shaped beam and is used for bearing the pressure; the side web (4) and the middle web (5) are located on the middle parts of the upper flange (2) and the lower flange (3) andare used for bearing the shear stress; the upper flange (2) is located on the upper part of a box beam; the lower flange (3) is located on the lower part of the box beam; the upper flange and the lower flange are used for bearing the pulling stress; the reinforcing steel bar (6) is located in the lower flange (3); the FRP (7) is adhered to the bottom part of the lower flange (3); the reinforcing steel bar (6) and the FRP (7) are used for bearing the pulling stress; the concrete (1) and the upper flange (2) are connected through the shear key (8). By fully utilizing the characteristics of the eight materials, the lightweight concrete-bamboo glue-laminated panel T-shaped beam provided by the invention has the characteristics of light weight, high strength and great rigidity, and can be applied to bending members in the field of civil construction.

Owner:NANJING FORESTRY UNIV

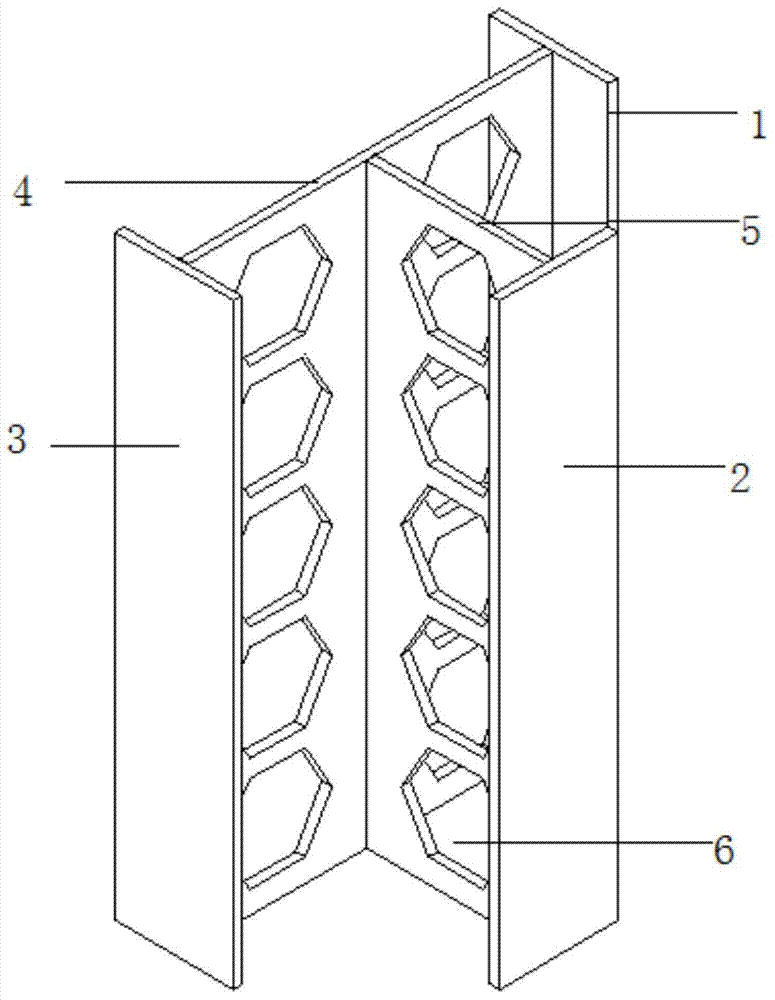

Honeycomb-shaped web special-shaped steel column with T-shaped section

InactiveCN104234309AReasonable section compositionImprove mechanical propertiesStrutsPillarsSheet steelResidence

The invention discloses a honeycomb-shaped web special-shaped steel column with a T-shaped section. The honeycomb-shaped web special-shaped steel column with the T-shaped section comprises a first plain steel plate flange, a second plain steel plate flange, a third plain steel plate flange, a first steel web, a second steel web and holes; one side edge of the second steel web is perpendicularly connected with the middle part of the first steel web, and the other side edge of the second steel web and two side edges of the first steel web are respectively connected with the first plain steel plate flange, the second plain steel plate flange, the third plain steel plate flange together to form the special-shaped steel column with the T-shaped section; the first steel web and the second steel web are honeycomb-shaped webs of which the middles are provided with the holes; each of the first steel web and the second steel web respectively consists of steel plates of which the edges are provided with notches; the steel plates are welded by butt-jointed seams to form the honeycomb-shaped webs. According to the invention, the structural behavior of the special-shaped steel column is improved without obviously increasing comprehensive cost of the construction, so that the special-shaped column structure is more widely applied to multi-storey and high-rise residences.

Owner:NANJING UNIV OF TECH

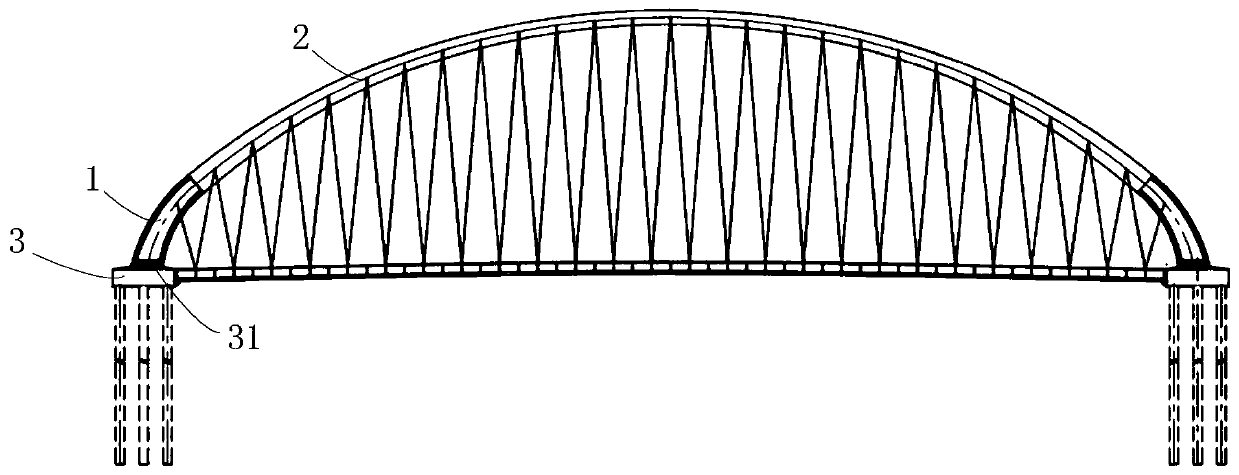

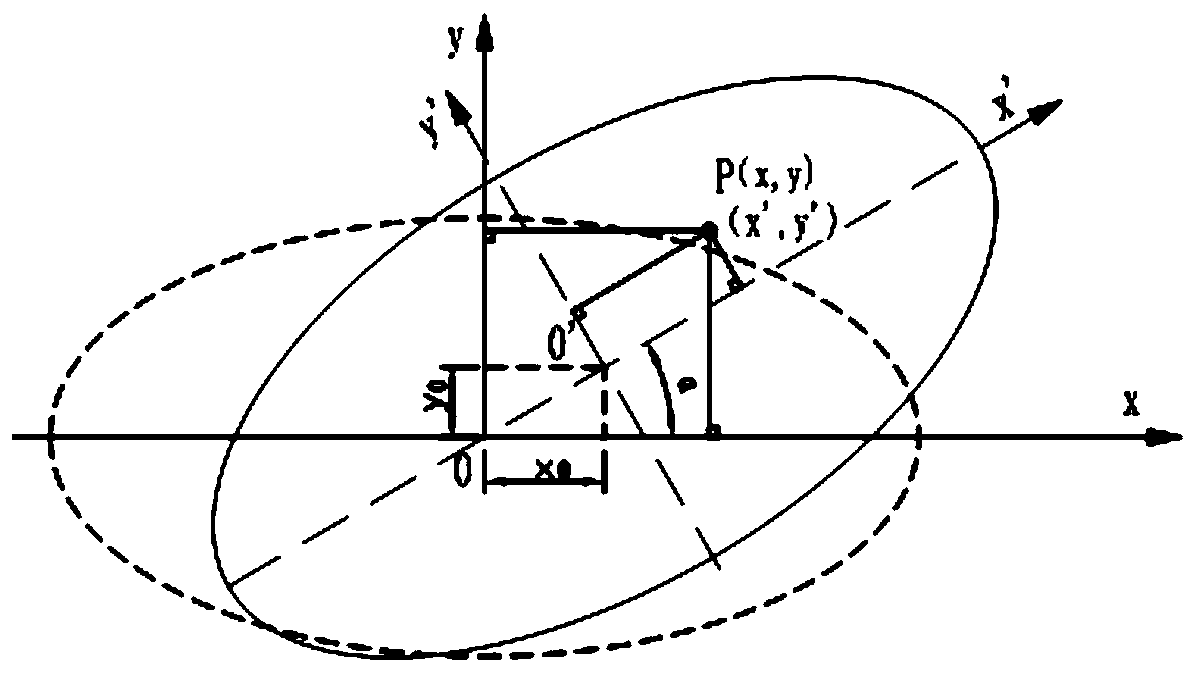

Large-span combined arch bridge based on bending pressure design theory and design and construction method thereof

ActiveCN111041969AAvoid attenuationAvoid the problem of arch rib crackingArch-type bridgeBridge materialsWeb structureArchitectural engineering

The invention discloses a large-span combined arch bridge based on a bending pressure design theory and a design and construction method thereof. The arch bridge comprises an arch springing section capable of bearing the action of tension or pressure and an arch web-arch crown section of an open web structure. The arch axis part of the arch foot section is a convergent composite curve; the curvature is changed, the arch foot section is rigidly connected with the arch web-arch crown section; the structure is continued, the tangent slopes of connecting points between the two are consistent, thecurvature of the arch foot section is gradually increased to be close to 90 degrees, only vertical component force exists, the horizontal component force is close to 0, the horizontal thrust of the main arch is reduced by 30%-64%, and the transverse stability is improved by 35%-55%; and horizontal tie bars required for overcoming horizontal thrust are reduced or canceled, so that the manufacturingcost is saved, the mechanical advantage that the composite structure material can be pressed and can be tensile and the economic spanning capacity of the large-span arch bridge can be fully exerted,and the section efficiency is improved.

Owner:SHENZHEN UNIV +1

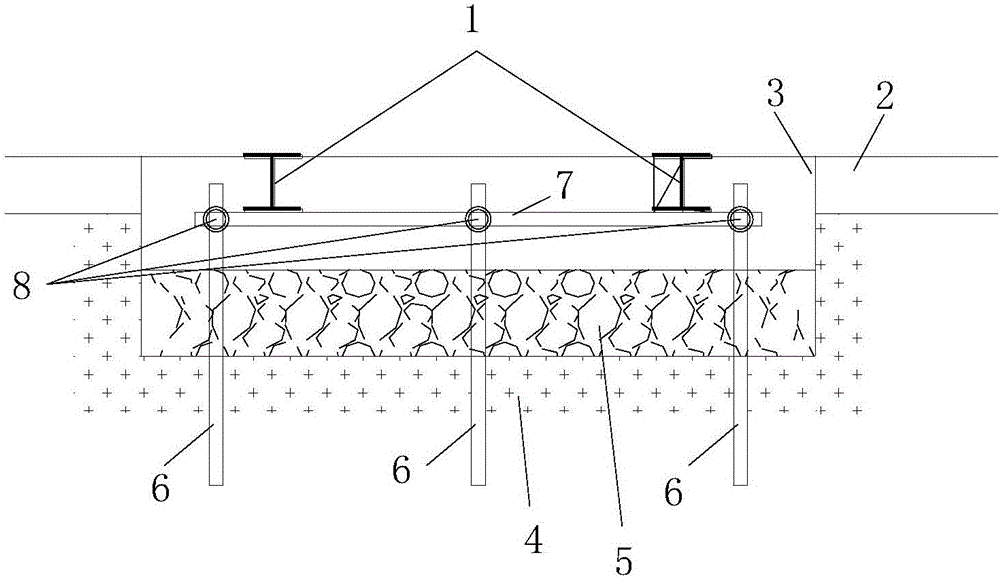

Scaffolding equipment foundation embedded part construction method

InactiveCN106703072AEasy and stable installationEasy to installFoundation engineeringRebarSteel tube

The invention discloses a scaffolding equipment foundation embedded part construction method. The scaffolding equipment foundation embedded part construction method comprises the following steps of excavating a foundation trench of an equipment foundation to a set depth; tamping plain soil at the bottom of the foundation trench of the equipment foundation; paving gravels on the plain soil, and tamping the paved gravels; binding transverse reinforcing bars and vertical reinforcing bars on the tamped gravels; vertically tamping multiple columns of steel tube stand pipes so that the steel tube stand pipes penetrate through the gravels and the plain soil; separately mounting one steel tube cross arm along the longitudinal direction on the corresponding one of the steel tube stand pipes which are located at the same transverse position in the columns of steel tube stand pipes; connecting the crossed positions of the steel tube cross arms and the corresponding steel tube stand pipes through cross-shaped buckles; mounting a left H-shaped steel embedded part and a right H-shaped steel embedded part on each steel tube cross arm; fixing two sides of the lower bottom of each H-shaped steel embedded part to the corresponding steel tube cross arm in a welding manner; and pouring concrete in the foundation trench of the equipment foundation, so that the top surface of the concrete is consistent with the ground level of a factory building. According to the method disclosed by the invention, each whole H-shaped steel beam can be well mounted by adopting a small number of the steel tube stand pipes and the steel tube cross bars.

Owner:CHINA CONSTR SIXTH ENG BUREAU CIVILENG +1

Bent groove-shaped steel plate type laminate member

ActiveCN105822012AImprove overall stabilityGood stabilityConstruction materialSteel platesDistortion

The invention discloses a bent groove-shaped steel plate type laminate member which comprises a base plate and concrete ribs, wherein a steel plate is arranged on the base plate; the bottom of the steel plate in a height direction is embedded in the base plate; the top of the steel plate in the height direction is embedded in the concrete ribs; the steel plate is bent in a length direction to form a number of grooves; opening directions of every two adjacent grooves are opposite; a number of through holes are formed in the middle of the steel plate. The base plate of the laminate member provided by the invention can be equal to smaller than 30 mm; the weight of the laminate member is reduced by 50% or higher while achieving excellent supporting, compression resistance and other conditions and properties; the weights of beams, columns, walls and foundation members are reduced; the clear height of each building storey is increased; the bent groove-shaped steel plate type laminate member provided by the invention further has advantages of being high in overall strength, good in fastness and free of distortion, and improves the quality of buildings.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

Cross four-angle-steel type bending constraint support

InactiveCN105386530AEasy to handleDoes not affect the main constructionShock proofingBuckling-restrained braceEngineering

The invention discloses a cross four-angle-steel type bending constraint support, and belongs to the technical field of building structures. The cross four-angle-steel type bending constraint support can preferably transfer axial tension and compression loads, fully exerts the performance of dissipating the seismic energy, can save the steel cost and the production period, and is easy to construct and industrially produce. The cross four-angle-steel type bending constraint support comprises a cross core material, wherein a non-bonding material layer is coated at the outer side of the cross core material; the core core material is arranged in four angle steels; the two ends of the cross core material extend outside the angle steels; friction type high-strength bolt holes are formed in the cross core material outside the angle steels; rectangular steel blocks having through holes are arranged at the outer end of the cross core material between two angle steels; bolts penetrate through the through holes of the rectangular steel blocks and the angle steels at two sides to fixedly connect the rectangular steel blocks with the angle steels to form a constraint mechanism; gaps are left between the cross core material and the angle steels; and stiffened rib plates are fixed at the outer sides of the angle steels.

Owner:SHENYANG JIANZHU UNIVERSITY

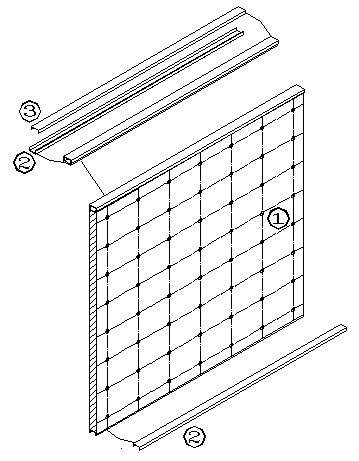

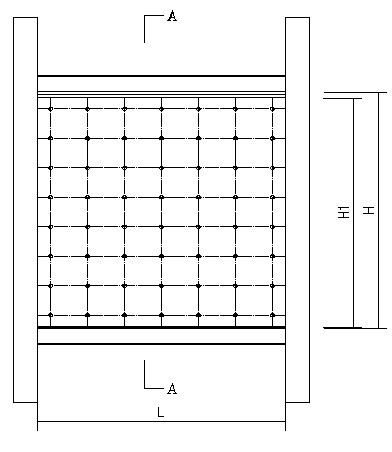

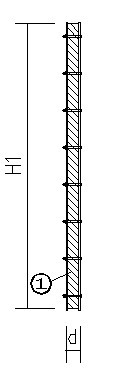

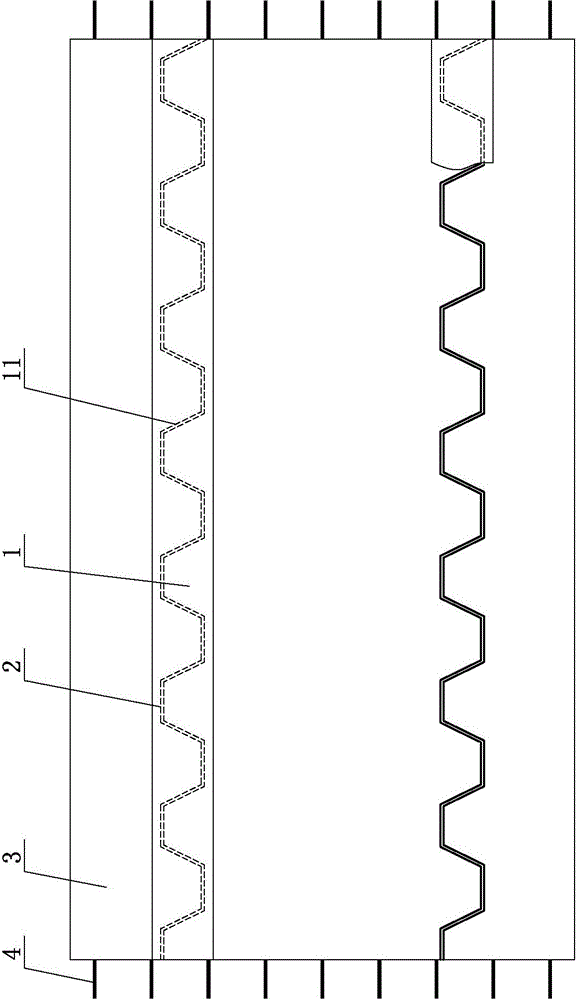

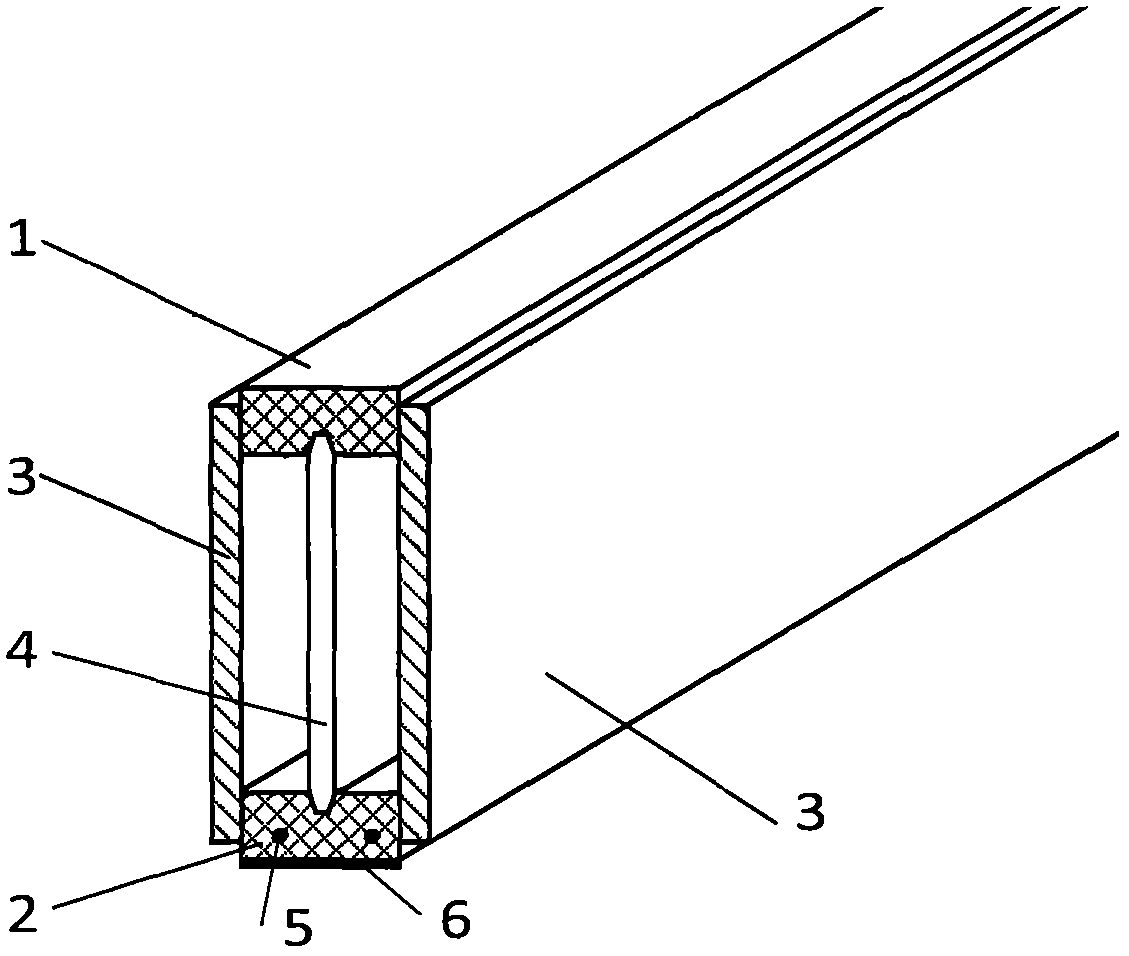

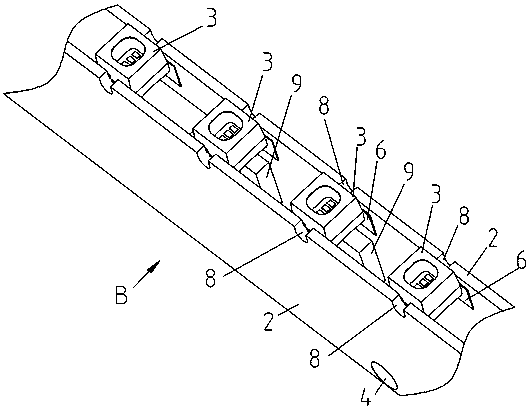

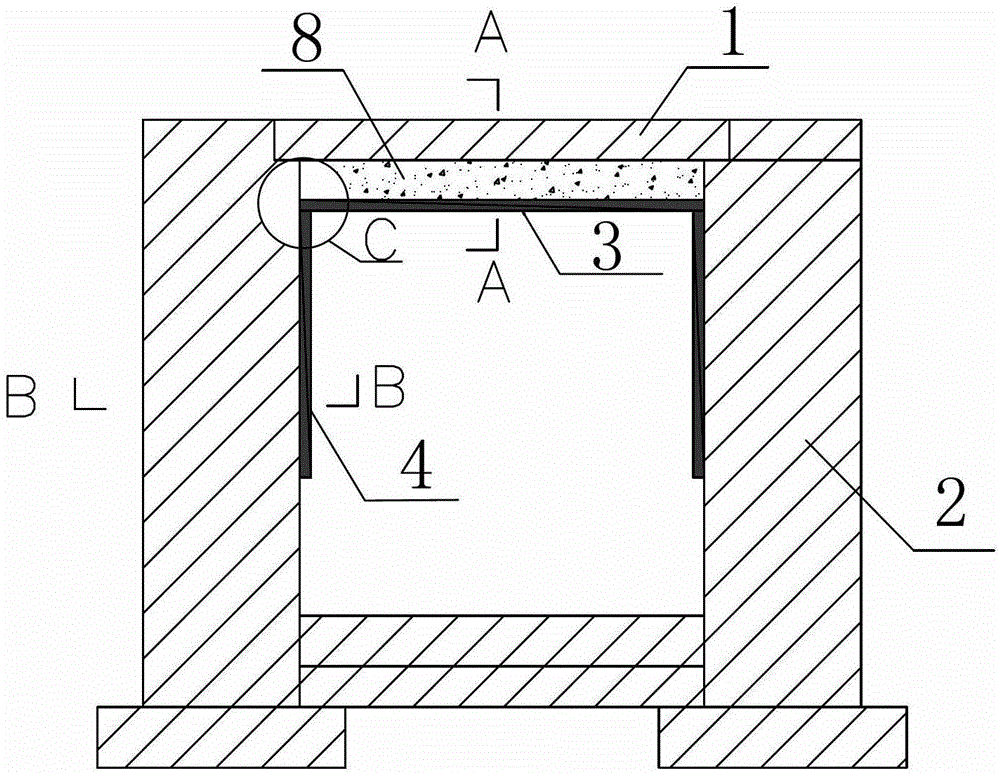

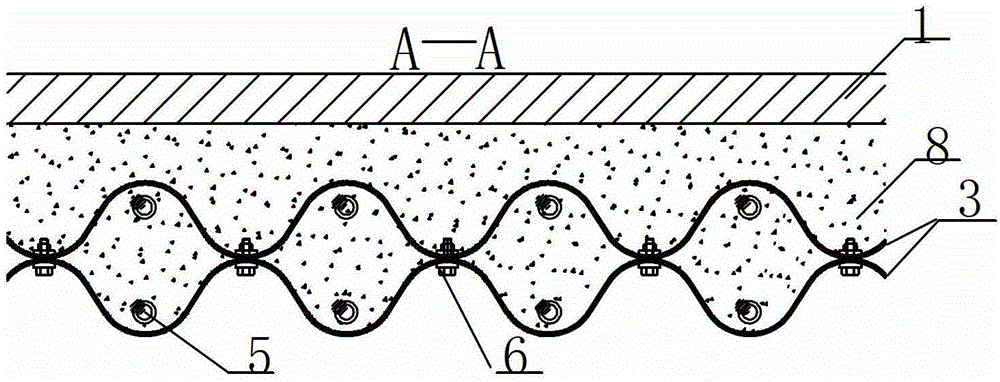

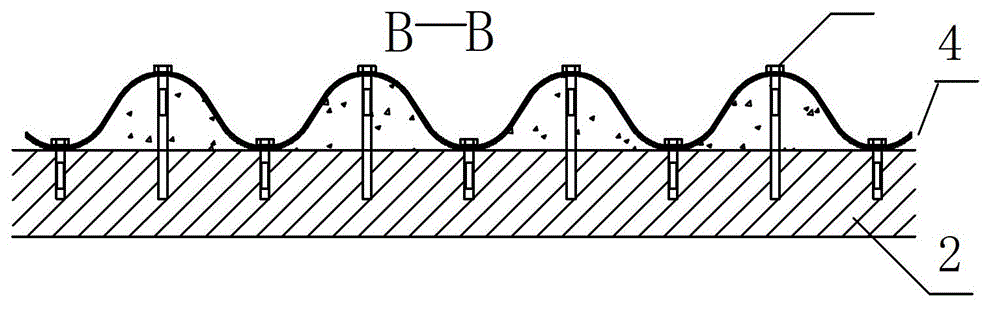

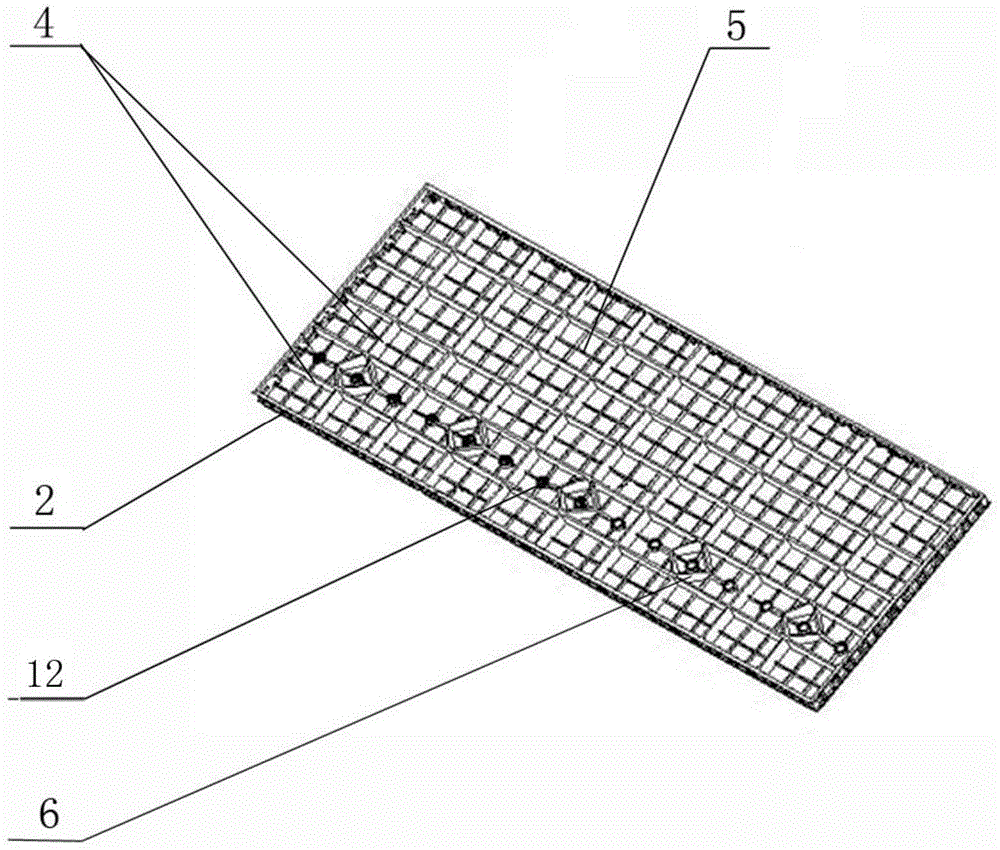

FRP-rebar-bamboo laminated wood combined box girder

PendingCN108412123AIncrease the moment of inertia of the sectionIncrease stiffnessGirdersJoistsAdhesiveEngineering

The invention provides an FRP-rebar-bamboo laminated wood combined box girder, which comprises a top flange (1), a bottom flange (2), side webs (3), a middle web (4), rebar (5) and FRP (6), wherein the side webs (3) are arranged at two sides of the top flange (1) and the bottom flange (2), and used for bearing shearing strength; the middle web (4) is in mortise joint with the top flange (1) and the bottom flange (2) and is bounded by an adhesive, and is used for bearing shearing strength; the top flange (1) is located at the upper part of the box girder, and is used for bearing pressure stress; the bottom flange (2) is located at the lower part of the box girder, and is used for bearing tensile stress; the rebar (5) is wrapped in the bottom flange (2), the FRP (6) is pasted at the bottom of the bottom flange (2), and the rebar (5) and the FRP (6) are used for bearing tensile stress. An anticorrosive coating is sprayed on the surface of the box girder, and is used for bearing the function of moistureproofing and corrosion prevention. The FRP-rebar-bamboo laminated wood combined box girder solves the difficult problems that the original bamboo beam is low in bearing capacity, small in rigidity and difficult in material selection, and can be applied to flexural members in a bamboo structural building.

Owner:NANJING FORESTRY UNIV

Concrete-filled steel tube bundle composite shear wall with internally-arranged composite confined concrete columns

PendingCN112127512AImprove carrying capacityImprove shear resistanceWallsFiber-reinforced compositePipe

The invention discloses a concrete-filled steel tube bundle composite shear wall with internally-arranged composite confined concrete columns. The concrete-filled steel tube bundle composite shear wall comprises a composite shear wall body formed by steel tube bundles, the steel tube bundles comprise a plurality of steel tubes, and fiber reinforced composite tubes are fixedly arranged in the steeltubes at the end parts of the composite shear wall body; and when the wall body of the composite shear wall is provided with at least two wall limbs, fiber reinforced composite material tubes are fixedly arranged in the steel tubes located at the intersections of the wall limbs, and each steel pipe and each fiber reinforced composite material tube are filled with concrete. Fiber reinforced composite material confined concrete has good deformation performance and ductility and has the characteristic of obvious later-period rigidity at the same time, the fiber reinforced composite material confined concrete is arranged at one or more positions, such as the wall end, the intersection of two wall limbs and the intersection of the multiple wall limbs, of a deformed or heavily stressed part inthe steel tube bundle composite shear wall; and the fiber reinforced composite material tube is filled with the concrete, so that the composite material tube has the characteristics of high bearing capacity and good ductility.

Owner:SOUTH CHINA UNIV OF TECH +1

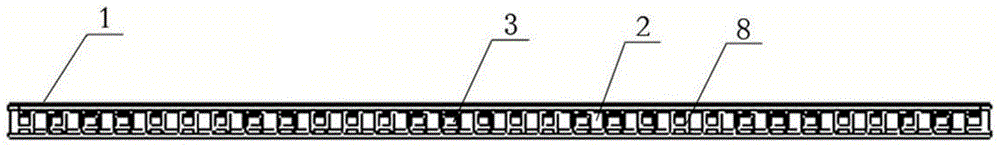

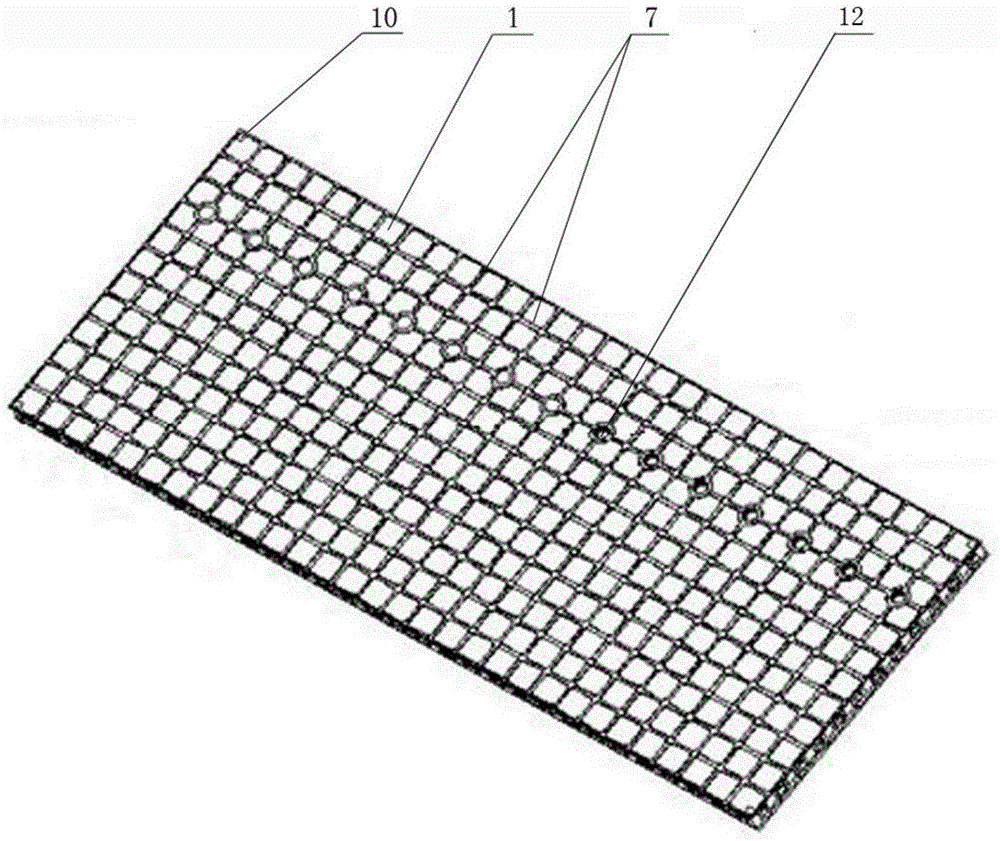

LED light bar clamped and welded between double PCBs and light bar screen

PendingCN108307583AIncrease the moment of inertia of the sectionImprove bending abilityPrinted circuit assemblingPrinted circuit aspectsEngineeringElectronic component

The invention provides an LED light bar clamped and welded between double PCBs and a light bar screen composed of the LED light bar. The LED light bar is composed of two bar-shaped PCBs with or without electronic components, SMD packaged LEDs and supporting and connecting pieces; the sides with the electronic components of the two bar-shaped PCBs face the inward and are opposite to each other, arealigned in one edge, and are fixed by the supporting and connecting pieces; an interval for clamping and welding pins in the side surface of the LED is left between the PCBs, each side-surface pin ofthe LED is welded to a pad close to the aligned edge of each PCB, the light bar is formed, and the light bars are combined to form the light bar screen. The LED is welded into the interval between the bar-shaped PCBs from the side surface, the light bar is narrowed, the hollow area is increased, and the hollow area in a position without LED in the internal between the PCBs is also increased; thesides welded with the electronic components of the bar-shaped PCBs are inwards and opposite to each other, so that the electronic components are hidden in the interval between the PCBs, and the electronic components except the light surface are not exposed; and the LED is clamped and welded between the PCBs in the hollowed way, the sectional inertia moment of the light bar is increased, and the bending resistance of the light bar is improved greatly.

Owner:潘尚法

Reinforced culvert

The invention discloses a reinforced culvert. The reinforced culvert comprises a culvert top and side walls. A prestress top plate which is composed of a symmetrically fastened double-layer corrugated steel is arranged at the bottom of the culvert top, single-layer corrugated steels are arranged on the inner sides of left and right side walls, the top plate is installed on the single-layer corrugated steels of the side walls, reinforcing steel bars are arranged in a cavity cylinder formed by the double-layer corrugated steel, the cavity cylinder is filled with concrete, and simultaneously, concrete is filled between the culvert top and the prestress top plate as well as between left and right side walls and the single-layer corrugated steels. The reinforced culvert has the advantages that a corrugated steel rigid support is added on the basis of the original culvert structure, and further expansion of cracks is prevented, so that the internal force and deformation of the original culvert structure are reduced greatly, simultaneously, the original structure is fully utilized, and shared force bearing of new and old structures is guaranteed with the using function of the original culvert unchanged.

Owner:NANJING LIANZHONG CONSTR ENG TECH

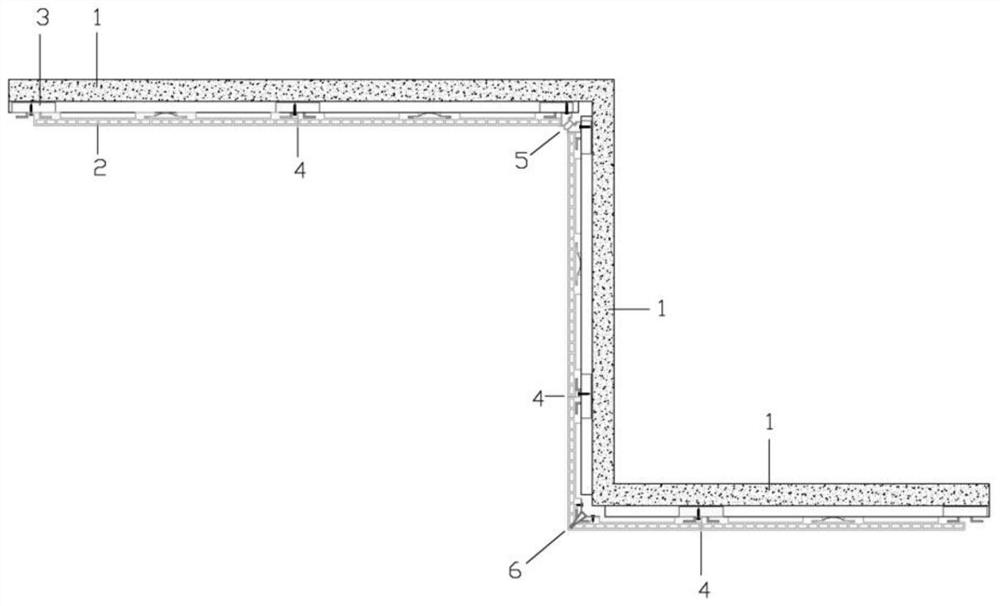

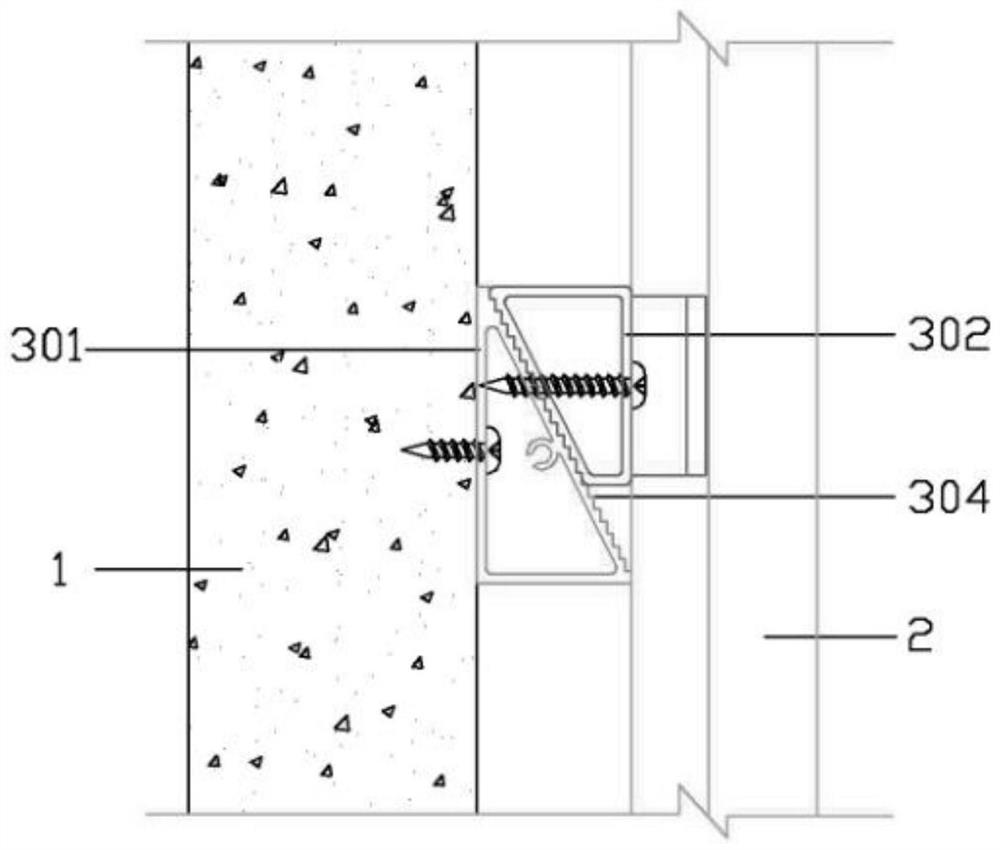

Assembly type wall surface system and mounting method thereof

PendingCN113137023AImprove mechanical propertiesPlay the role of sound insulationCovering/liningsHeat proofingClassical mechanicsMechanical engineering

The invention discloses an assembly type wall surface system and a mounting method thereof. The assembly type wall surface system comprises an original wall surface, modular wallboards, a triangular keel leveling system and a wallboard butt joint system, wherein the modular wallboards are arranged on the original wall surface through the triangular keel leveling system, the modular wallboards are connected through the wallboard butt joint system, a magnetic attraction skirting line system is arranged at the bottom of the original wall surface, a top edge closing system is arranged at the top of the original wall surface, a detachable internal corner system is arranged at the internal corner position of the original wall surface, an integral external corner system is arranged at the external corner position of the original wall surface, and a door side plate system is arranged at a doorway of the original wall surface. The assembly type wall surface system has the beneficial effects that through the combined action of the modular wall boards, the magnetic attraction skirting line system, the triangular keel leveling system, the wall plate butt joint system, the overall external corner system, the detachable internal corner system, the door edge plate system and the top edge closing system, rapid leveling and mounting of the building wall surface are achieved.

Owner:ZHEJIANG YASHA DECORATION

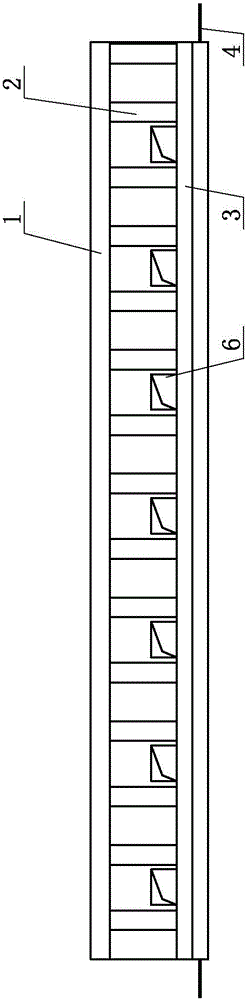

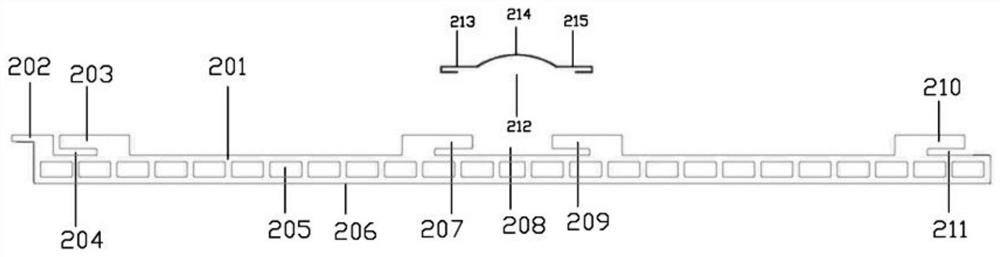

Flat plastic formwork for construction

ActiveCN104763140BReduce weightIncrease the moment of inertia of the sectionAuxillary members of forms/shuttering/falseworksForming/stuttering elementsMolecular materialsSquare Shape

The invention provides a plastic formwork for a building slab. The plastic formwork comprises a front plate and a frame, wherein the frame is vertical to the surface of the front plate; a plurality of connecting holes for connecting with other formworks are formed in the frame; a ribbed plate vertical to the surface of the front plate is arranged on the back of the front plate; the ribbed plate comprises a main ribbed plate and a secondary ribbed plate; the back of the front plate is divided into a plurality of rectangular partitioning areas, which are arranged longitudinally and transversely, by the main ribbed plate; the back of the front plate in the rectangular partitioning areas is partitioned into a plurality of longitudinal and transverse square blocks by the secondary ribbed plate in the rectangular partitioning area; plug-in type protective corners are respectively installed at four corners of the front plate. The plastic formwork overcomes the disadvantage that the whole plastic formwork is scraped because of the damage of the corners; the breaking rate of the plastic formwork for the slab is reduced; advantages of high-molecular material can be utilized and disadvantages are overcome; a plate design effectively matches with a support and reinforcing system, thus a scientific and effective formwork engineering system is finished.

Owner:河北润林新材料科技有限公司

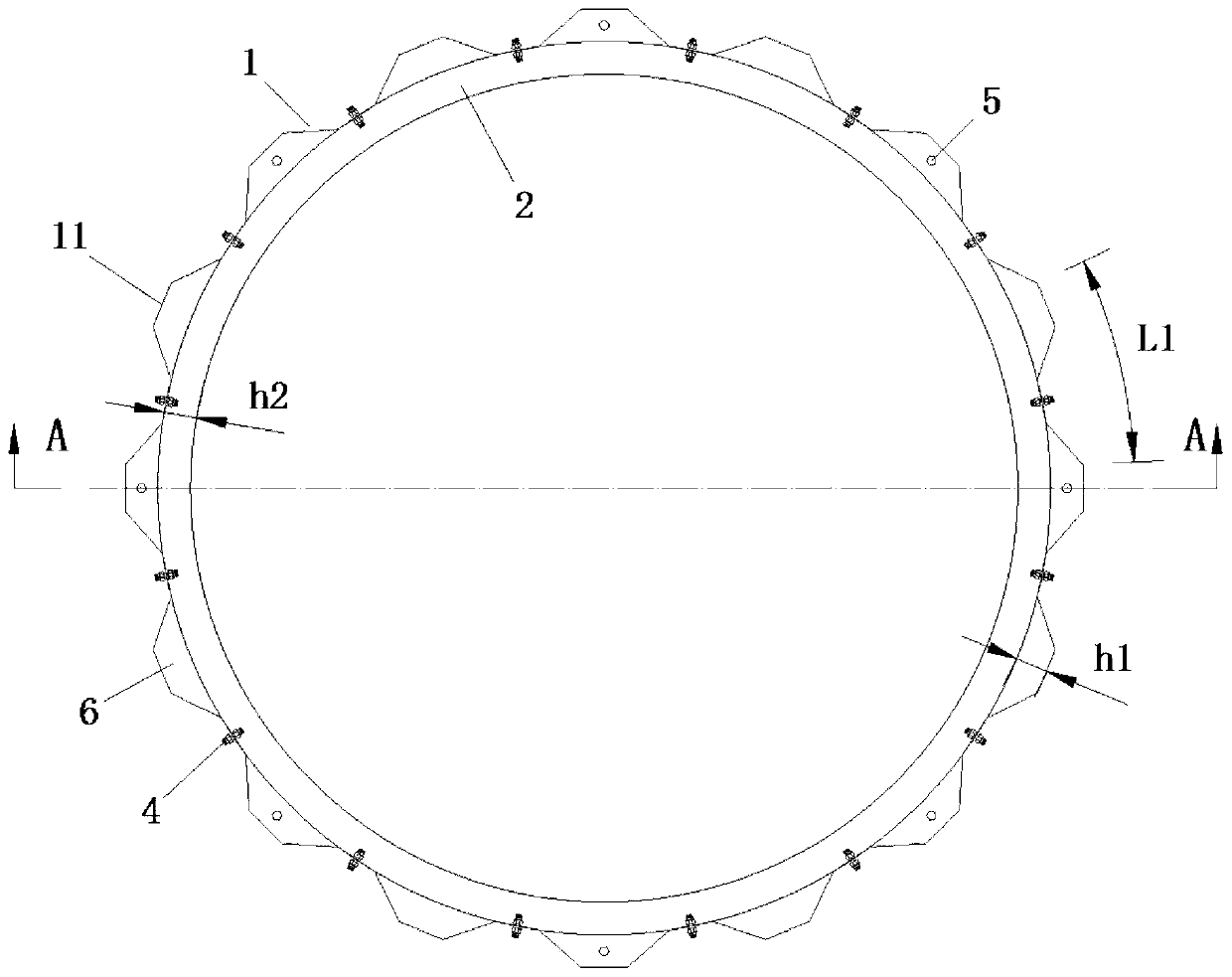

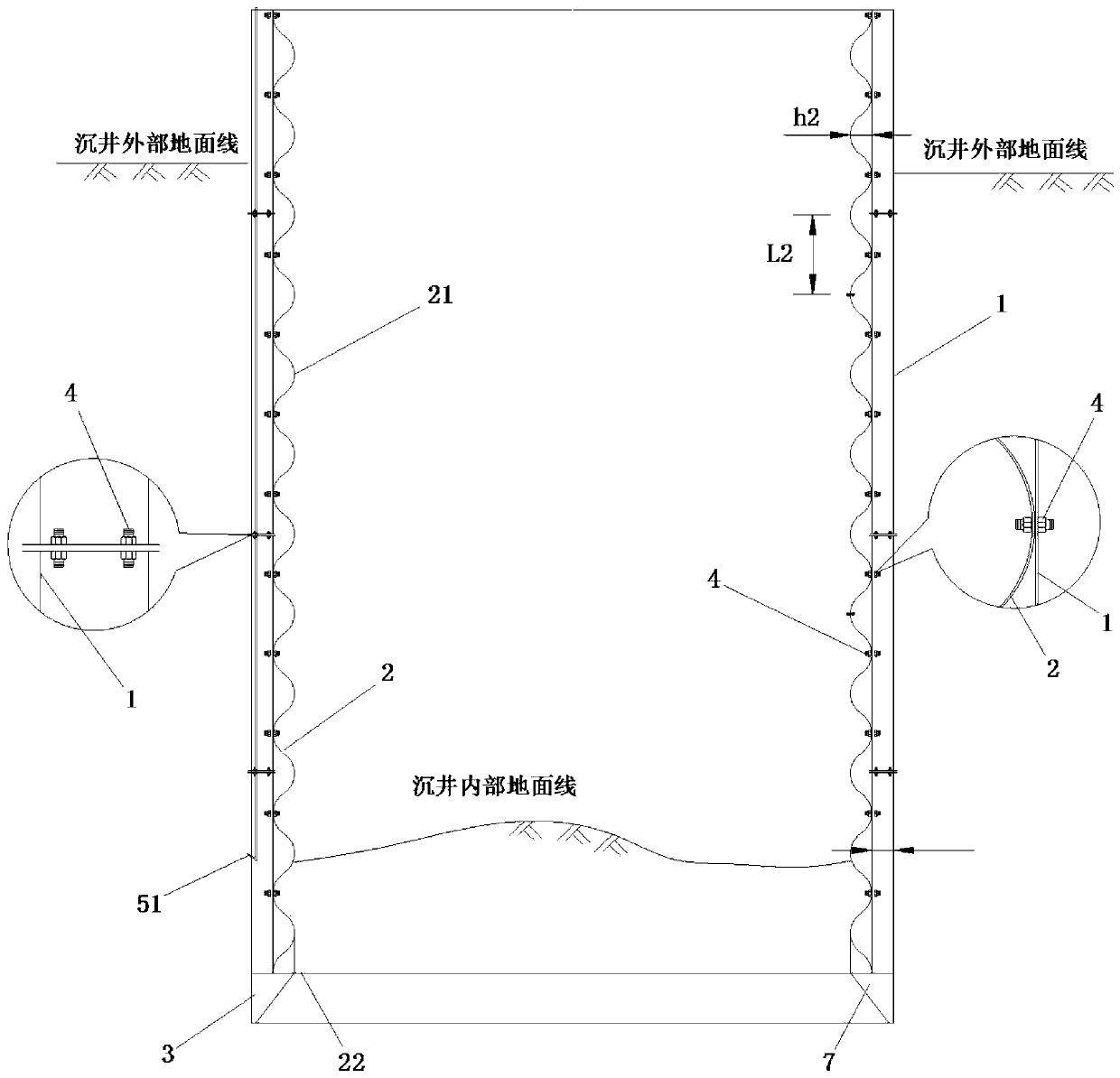

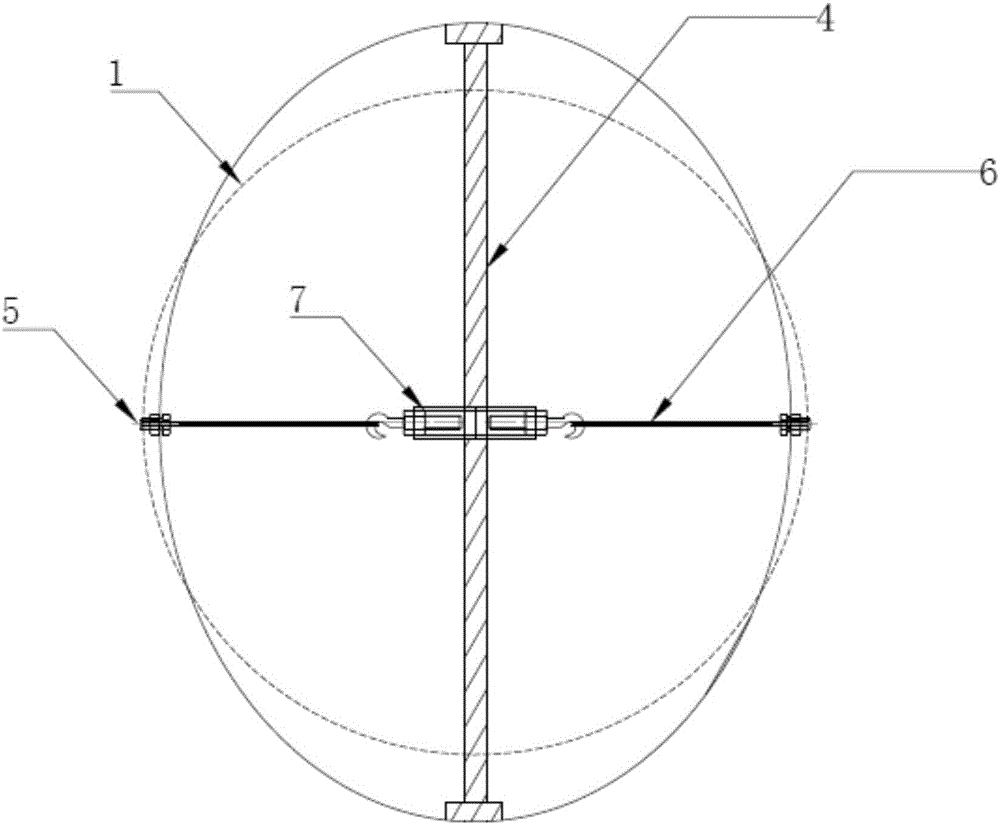

Novel circular double-corrugated-steel open caisson structure

PendingCN111197316AImprove carrying capacityIncrease the moment of inertia of the sectionCaissonsConvex structureCaisson

The invention discloses a novel circular double-corrugated-steel open caisson structure. The novel circular double-corrugated-steel open caisson structure comprises an inner-layer steel plate and an outer-layer steel plate, wherein the steel plate located on the outer layer is an outer-layer vertical corrugated steel plate, a vertical corrugated portion which extends in the vertical direction andis concavo-convex in the horizontal direction is arranged on the outer-layer vertical corrugated steel plate, the steel plate located on the inner layer is an inner-layer horizontal corrugated steel plate, and a horizontal corrugated portion which is in a circular shape and is provided with a concave-convex structure on the vertical surface is arranged on the inner-layer horizontal corrugated steel plate. According to the novel circular double-corrugated-steel open caisson structure, firstly, a smooth steel plate is machined into the horizontal corrugated shape to form the inner-layer corrugated steel, so that the cross-sectional moment of inertia of the novel circular double-corrugated-steel open caisson structure is greatly increased, and the bearing capacity of the steel plate is greatly improved; secondly, the structure is considered to need to have the strong vertical pressure-bearing capacity and the water and soil pressure of transmitting the outer side of an open caisson, so that the smooth steel plate is machined into the vertical corrugated shape to form the outer-layer corrugated steel; and the novel circular double-corrugated-steel open caisson structure can adapt to elastic restraint and deformation of a surrounding soil body of the open caisson structure, the redistribution of the non-uniform soil pressure around the open caisson is achieved, the bearing capacityof the structure is improved, and the structure economy is improved.

Owner:CCCC FHDI ENG

Construction method of a high-fill corrugated steel pipe culvert

ActiveCN103541311BHigh compressive strengthIncrease the moment of inertia of the sectionGround-workEngineeringCulvert

Owner:NANJING LIANZHONG CONSTR ENG TECH

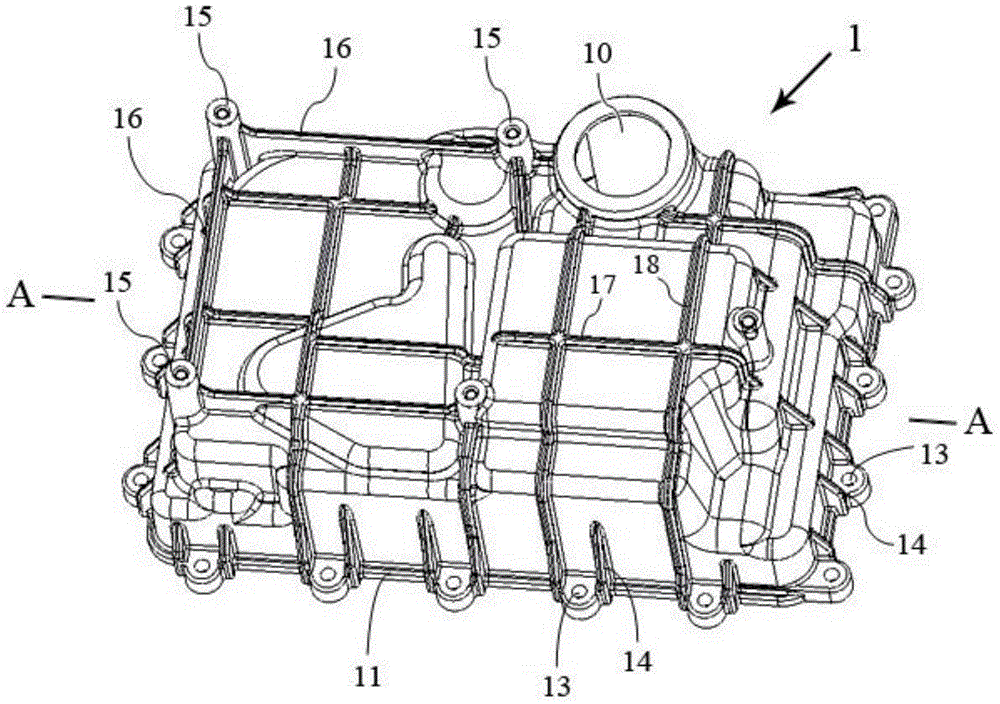

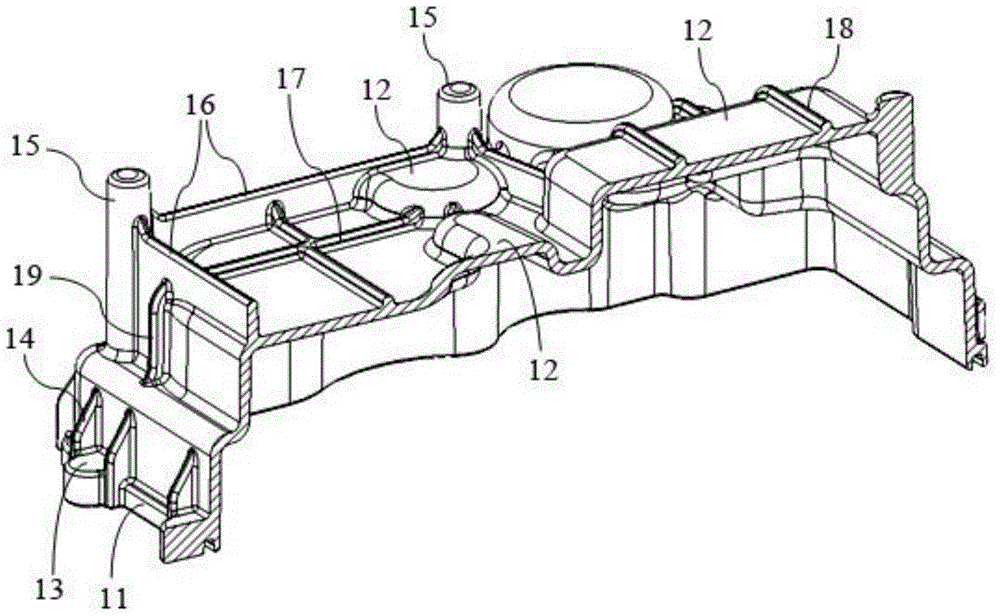

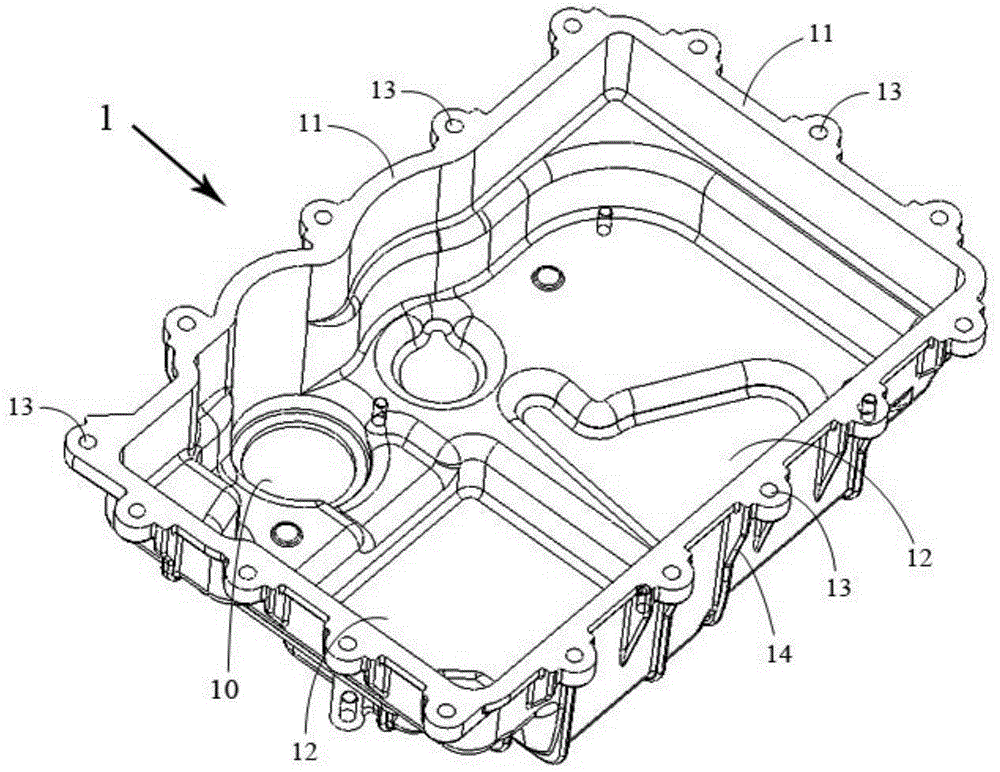

Hydraulic mechanism cover of automobile dual-clutch transmission

ActiveCN104235330BHigh strengthIncrease stiffnessGearboxesGearing controlVibration amplitudeNoise, vibration, and harshness

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com