LED light bar clamped and welded between double PCBs and light bar screen

A light bar and strip technology, which is applied in the structural connection of printed circuits, printed circuits connected with non-printed electrical components, printed circuits, etc., can solve the problems of increasing cost and manufacturing difficulty, and reducing the hollow area of light bar screens. , to achieve the effect of enhancing the bending resistance, increasing the moment of inertia of the section, and increasing the hollow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the present invention more comprehensible, preferred embodiments are described below with accompanying drawings. It should be noted that the embodiments and the features in the embodiments can be combined with each other under the condition of no conflict.

[0018] figure 1 It is a structural schematic diagram of an embodiment of the present invention. See figure 1 , Light bar 1 is a light bar with double PCB clip-welded LEDs. Since the light bar is relatively long, there are more LEDs installed, and the structure is similar, so figure 1 Only a section of the light bar is shown.

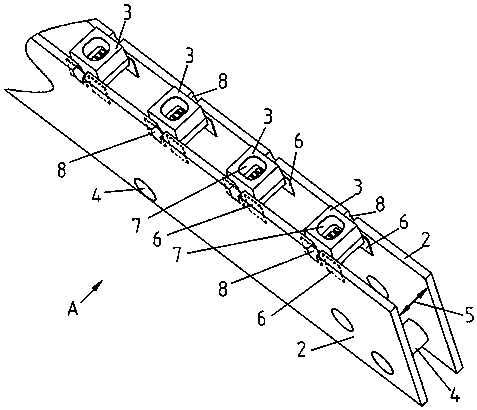

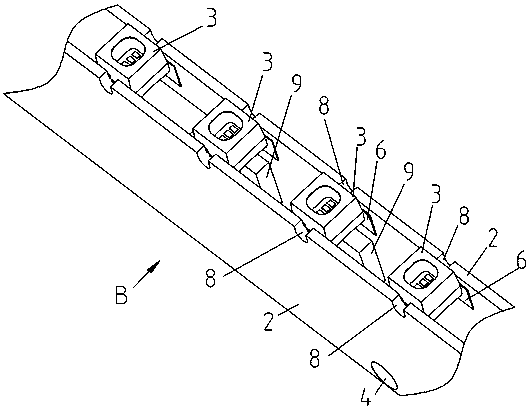

[0019] figure 2 with image 3 respectively figure 1 Schematic diagram of the structure of part A and part B. See figure 2 with image 3 , the two strip PCBs 2 are respectively provided with pads 6 for soldering LED side pins ( figure 2 Indicated by a dotted line on the front PCB), and according to the requirements of the light bar, the electronic components 9 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com