Novel circular double-corrugated-steel open caisson structure

A circular caisson technology, which is applied in the field of Bogang caisson foundation, can solve the problems of different pressure bearing capacity and weak bending bearing capacity, and achieve the effects of fast manufacturing speed, improved bearing capacity, and easy construction quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing by specific embodiment:

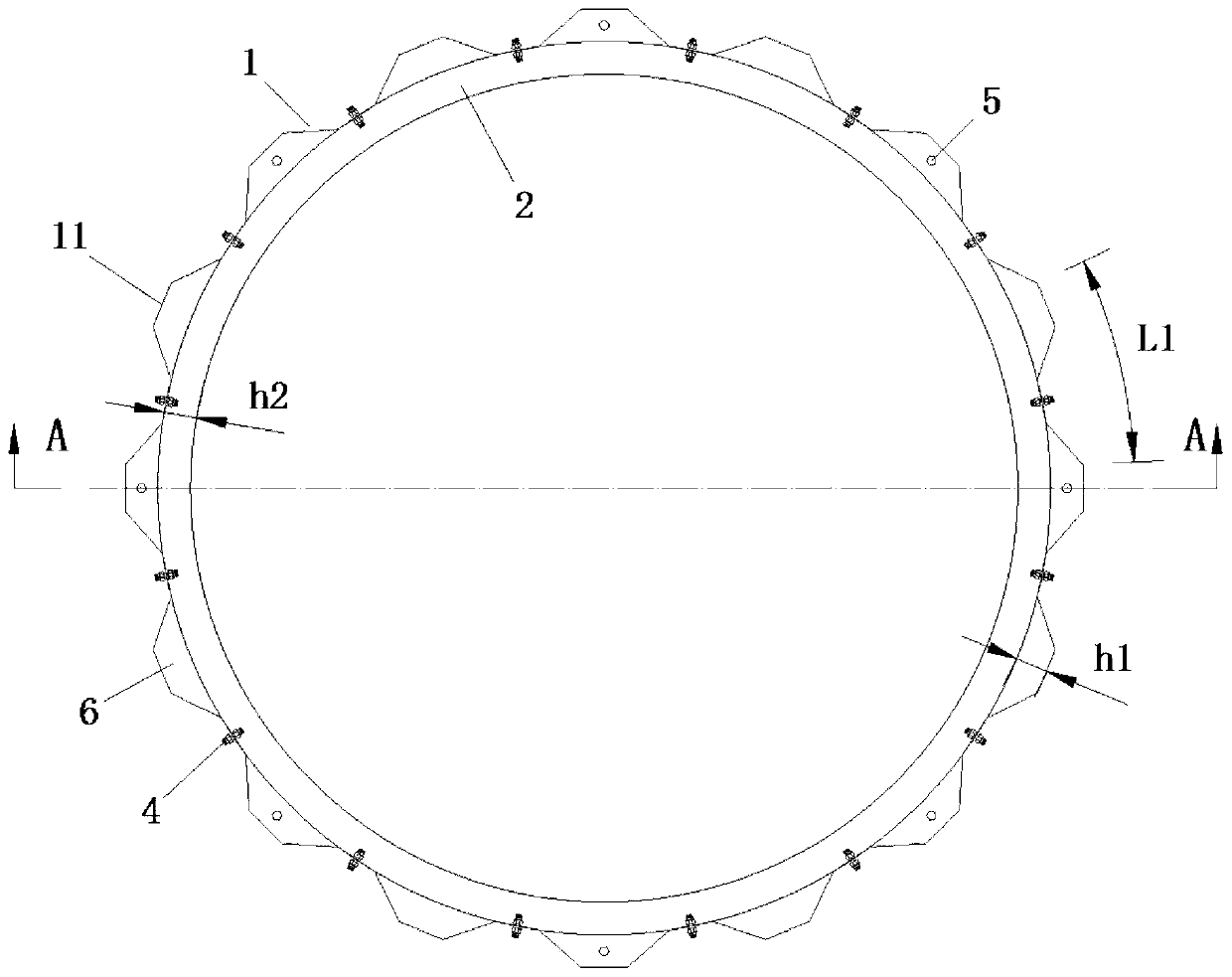

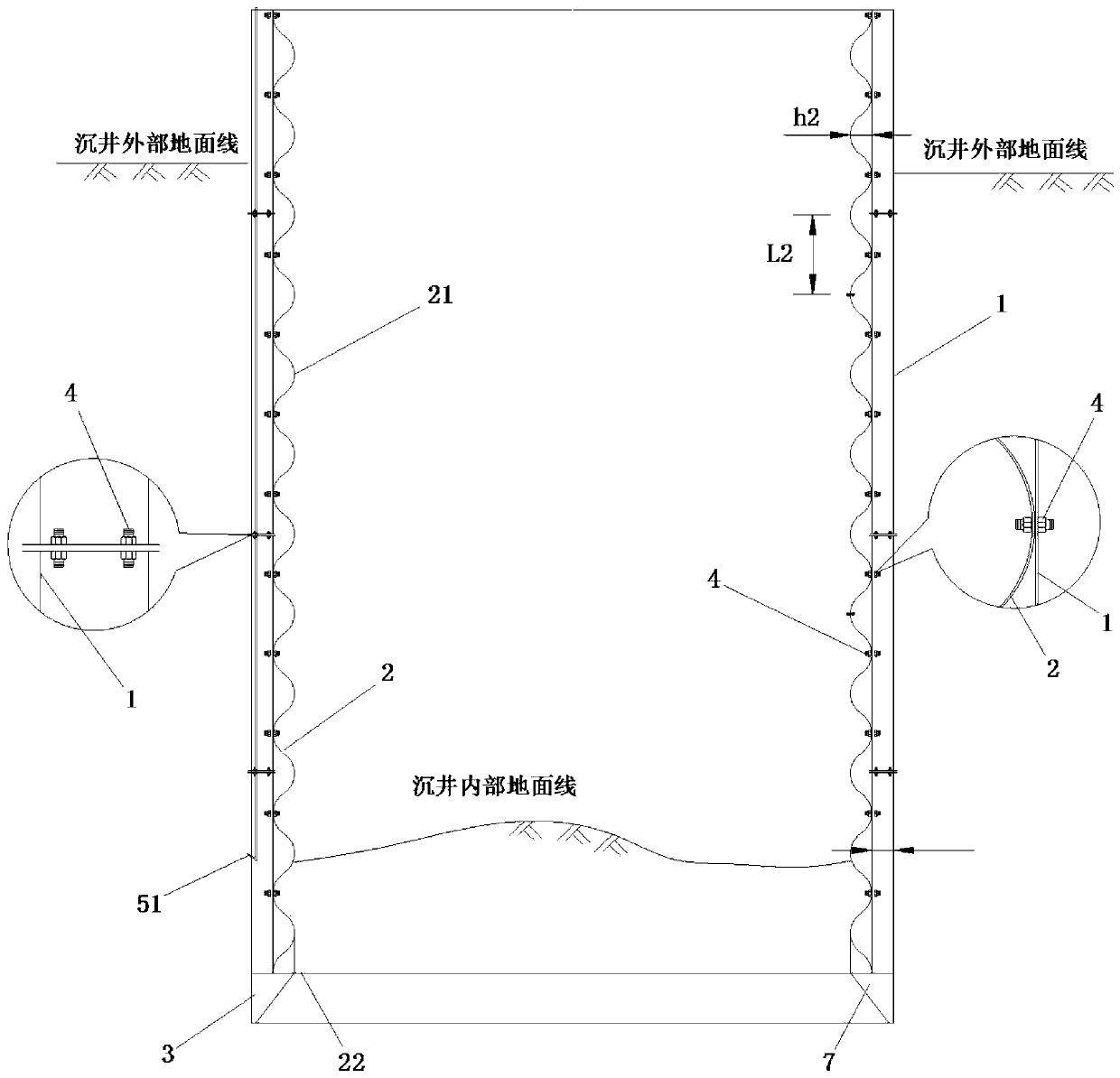

[0019] In this example, refer to figure 1 and figure 2 , the new circular double-wave steel caisson structure includes two layers of steel plates inside and outside, the cross section of the entire steel caisson is a circular structure, the steel plate positioned on the outer layer is an outer vertical corrugated steel plate 1, and the outer layer is vertical Distributed to the corrugated steel plate 1 are vertical corrugated portions 11 that extend vertically and have concavities and convexities along the horizontal direction, and several vertical corrugated portions 11 are distributed on the entire outer vertical corrugated steel plate 1; A horizontal corrugated steel plate 2, the inner horizontal corrugated steel plate 2 is distributed with a ring-shaped horizontal corrugated part 21 with a concave-convex structure on the vertical surface, and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com