Construction method of a high-fill corrugated steel pipe culvert

A technology of corrugated steel pipes and construction methods, applied in the construction field of culverts, can solve the problems of increasing construction difficulty and construction period, increasing construction engineering volume, increasing culvert cost, etc., achieving improved transportation capacity and transportation volume, short construction period, and occupied space small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

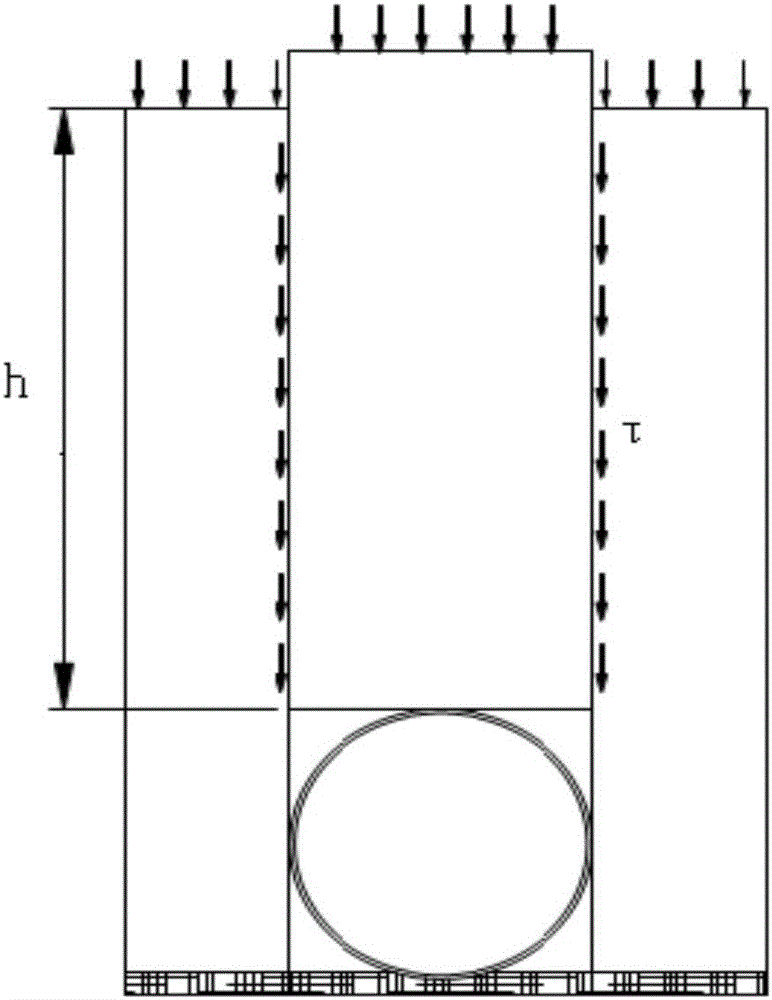

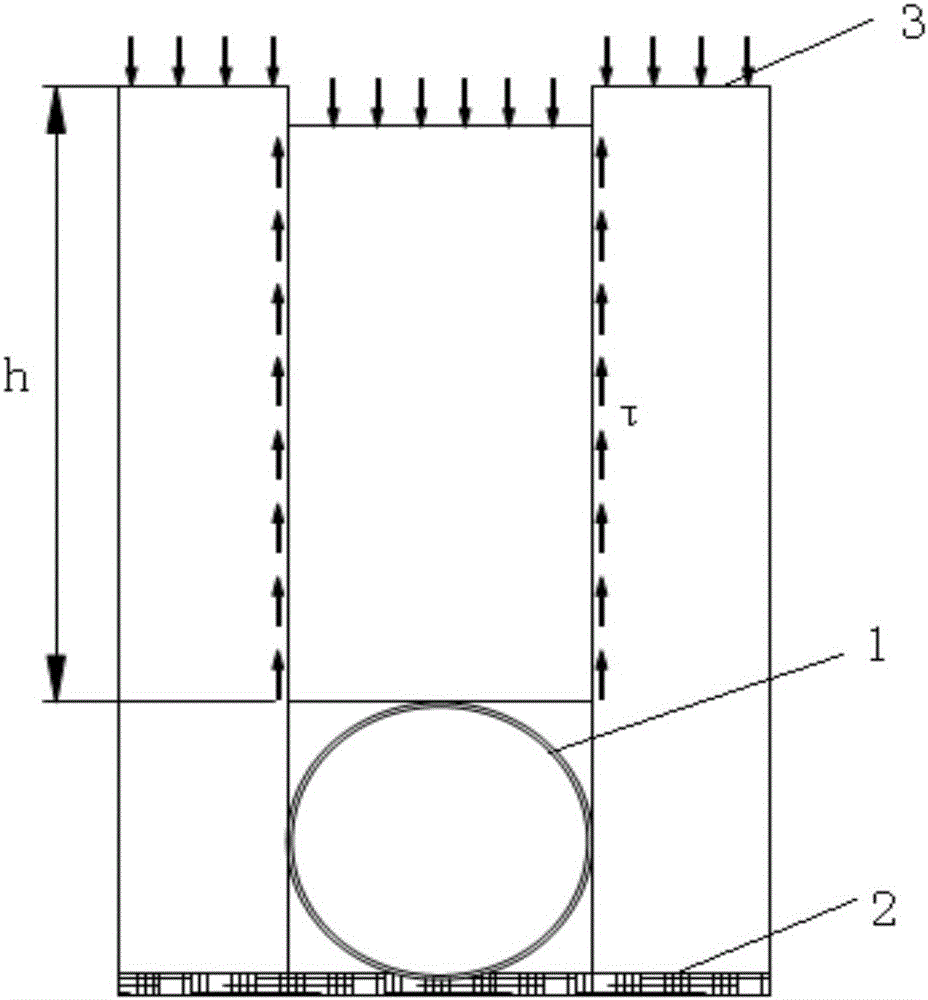

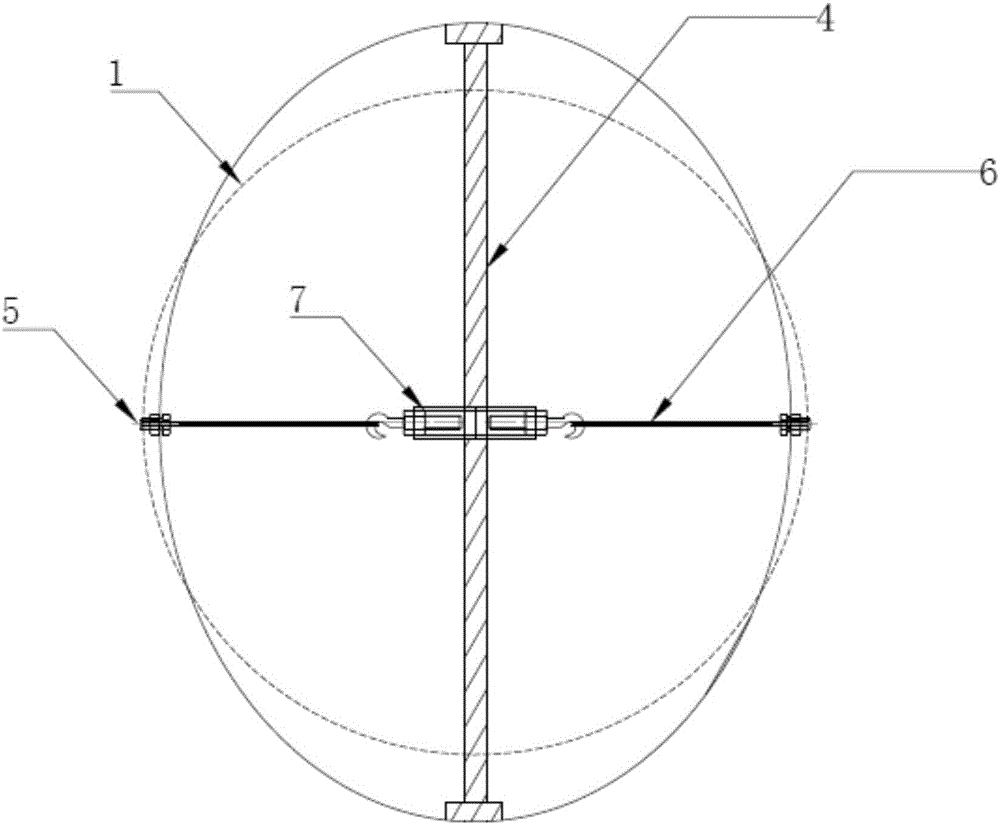

[0017] Figure 1(a) is a schematic diagram of the settlement of a rigid culvert soil column, and Figure 1(b) is a schematic diagram of the settlement of a flexible culvert soil column, where τ represents the friction force generated by the outer soil column on the inner soil column, and the direction of τ in Figure 1(a) is Below, the τ direction in Figure 1(b) is upward, h is the filling height, 1 is the culvert, 2 is the foundation, below the foundation is the subgrade, and 3 is the filling plane.

[0018] First of all, Q345 or higher-grade hot-rolled steel plates are selected. After processing large waves, the surface of the steel plates should be galvanized and anti-corrosion treated. The corrugated steel pipe culverts are assembled at the construction site according to the construction of corrugated steel pipes. Next, carry out foundation treatment on culvert 1, so that the foundation bearing capacity on both sides of the projection area of the culvert is 30-50KPa greater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com