Method for reinforcing transmission angle steel tower

A technology for angle steel towers and angle steels is applied in the field of reinforcement of power transmission angle steel towers, which can solve the problems of high cost, long power outage time and difficulty, etc.

Active Publication Date: 2010-10-06

CHINA ELECTRIC POWER RES INST +1

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The constant changes in the external environment and the continuous revision of the design code make most of the transmission angle steel towers in operation in my country unable to meet the actual use conditions. We have to re-evaluate the safety of the transmission lines that have been in operation. When the operating transmission angle steel towers cannot meet the actual use conditions, it will be difficult, expensive, and long-term power outages to replace the transmission angle steel towers. Under the current conditions, it is of great significance to strengthen the transmission angle steel towers that have been operated but do not meet the actual use conditions to improve the reliability of the transmission angle steel towers in our country.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

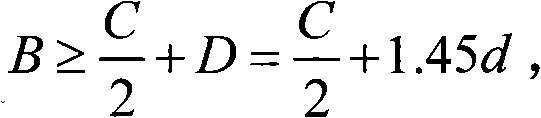

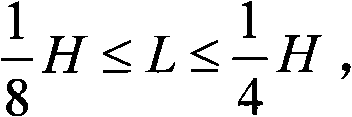

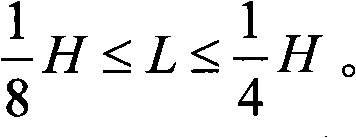

The invention relates to a method for reinforcing a transmission angle steel tower, in particular to the method for reinforcing the angle steel of a transmission line steel tower in power equipment. A layer of V-shaped section component is fixed outside the angle steel of the transmission angle steel tower and comprises smooth sections and a curved section, wherein B represents the length of the smooth section, R1 represents the inner arc radius of the curved section, R2 represents an outer arc radius, L represents a distance between the top of the curved section and an inner cross point of the smooth sections, t represents the section thickness of the V-shaped section component, and H represents the leg width of the reinforced hot-rolled angle steel. The curved section of the V-shaped section component is determined by the following conditions: R1 is equal to a difference obtained by subtracting x from t, wherein x is equal to 1 to t-1; R2 is equal to the summation of R1 and t; and a distance between the top of the curved section and the inner cross point of the smooth sections meets the condition that L is more than ore equal to one eighth of H and less than or equal to a quarter of H. Through the scheme, the steel tower can be reinforced under the condition of being electrified to guarantee the normal running of actual lines and improve the section stability of the hot-rolled angle steel.

Description

technical field The invention relates to electric power equipment, in particular to a reinforcement method for a power transmission angle steel tower in the electric power equipment. Background technique At present, my country's transmission line towers with a voltage level of 500kV and below are mostly designed with hot-rolled angle steel. The 220kV transmission line was gradually formed in the late 1970s. Many hot-rolled angle steel transmission angle steel towers have been in operation for more than 30 years. When the transmission angle steel tower When the actual use conditions cannot be met, that is, the load under the actual use conditions is applied to the transmission angle steel tower, which will cause some rods to exceed their design bearing capacity, resulting in fracture and collapse events, which will affect the safety of power transmission. Before 1990 my country's transmission line towers adopt the safety factor method, and the structural design after 1990 adopt...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04G23/02E04H12/08

Inventor 韩军科杨靖波杨风利李清华段叔宁

Owner CHINA ELECTRIC POWER RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com