FRP-rebar-bamboo laminated wood combined box girder

A technology of glulam and combined boxes, applied in the direction of joists, girders, truss beams, etc., can solve the problems of poor ductility, low bearing capacity of original bamboo beams, poor deformation performance, etc., and achieve good ductility, good ductility and self-recovery ability , the effect of large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

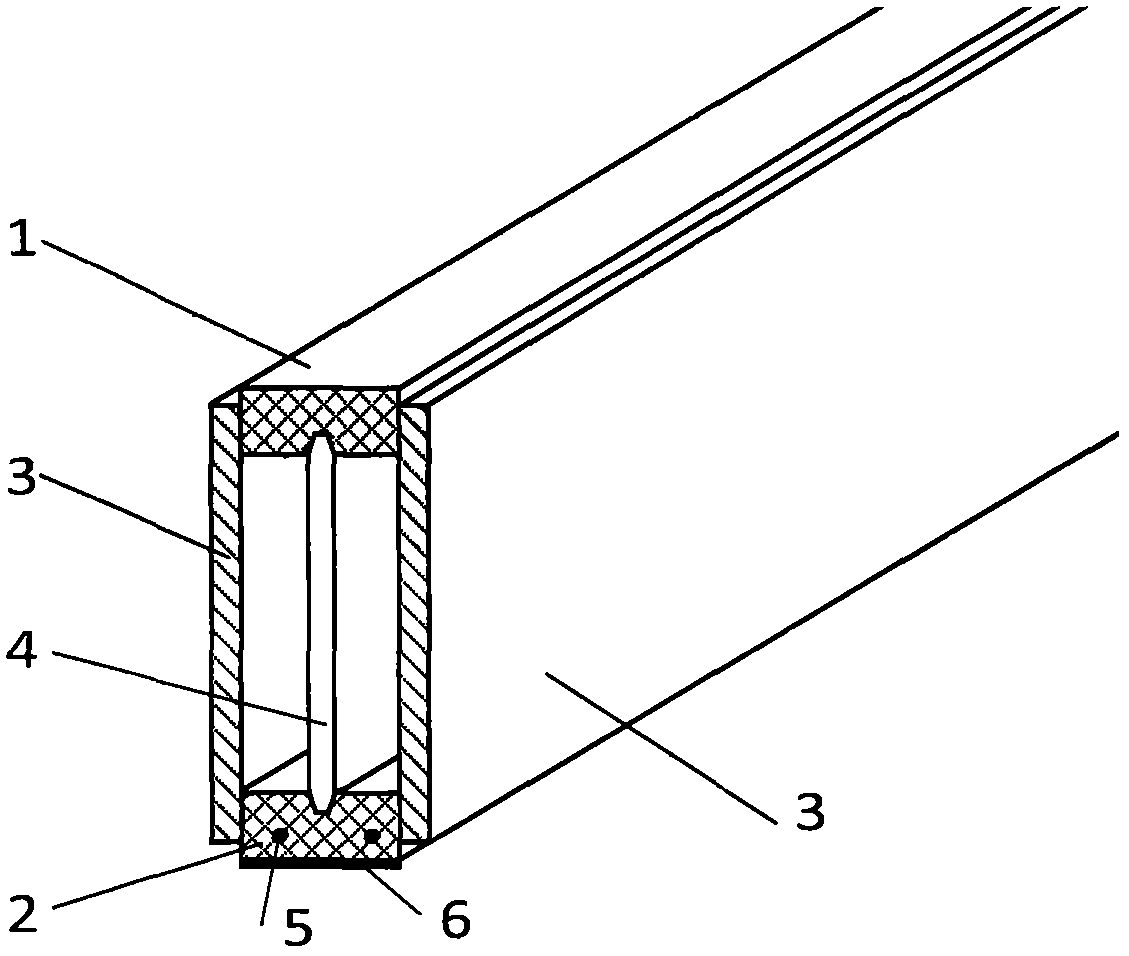

[0028] Example 1: Bamboo curtain plywood is selected as the side web and middle web, and bamboo glulam is used as the upper and lower flanges. The specifications of the side web and the middle web are 12mm×330mm and 12mm×300mm respectively; the height×width of the upper and lower flanges are 40mm×80mm, the width of the card groove is 11mm, and the depth is 15mm; the threaded steel bar is FRP uses two layers of CFRP. The finished box girder has a height of 350mm and a length of 4800mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com