X-shaped precast reinforced concrete pile mould

A reinforced concrete and mold technology, applied in the direction of molds, manufacturing tools, mold auxiliary parts, etc., can solve the problems of small specific surface and low material utilization rate, and achieve enhanced deformation resistance, low pouring pressure, and simple and compact mold overall structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

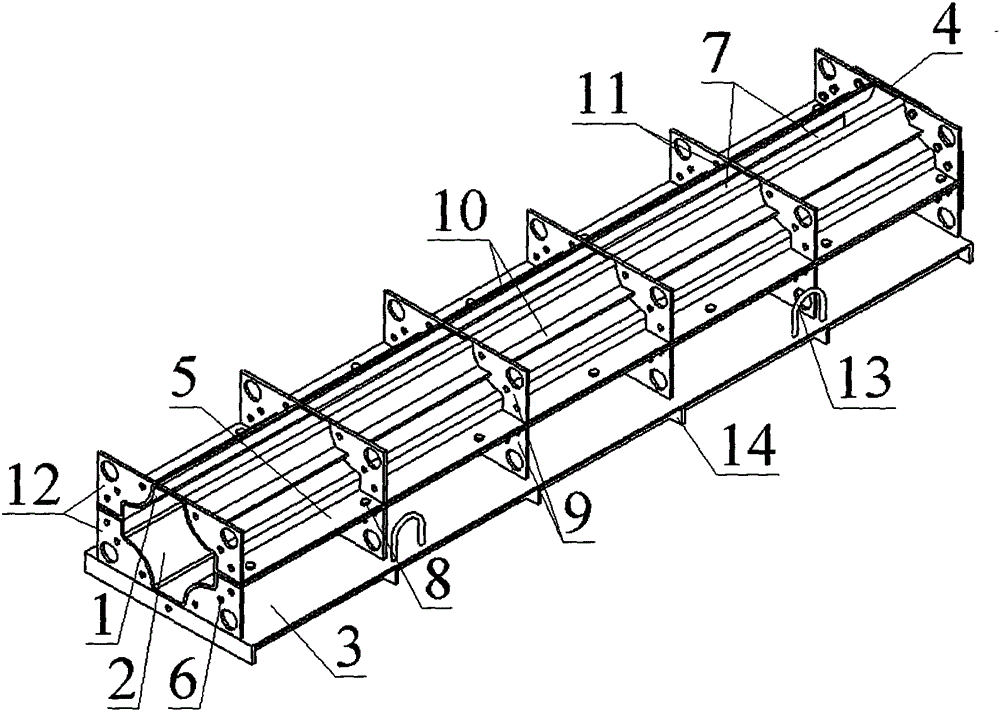

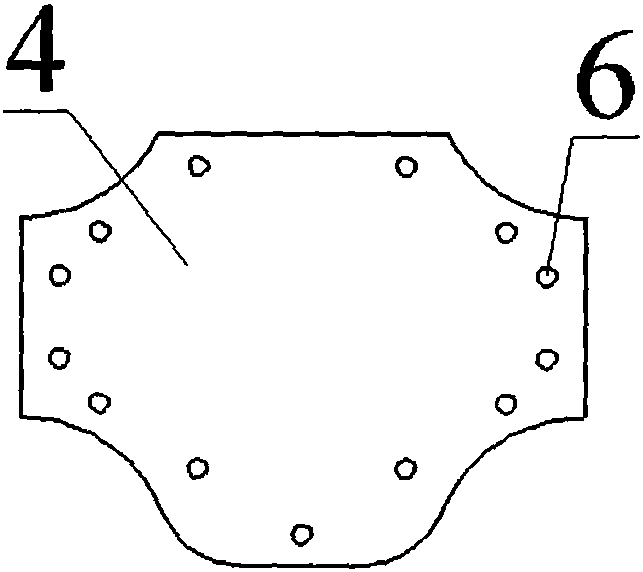

[0023] like figure 1 as shown, figure 1 It is a three-dimensional structure diagram of a X-shaped prefabricated reinforced concrete pile mold proposed by the present invention; figure 2 as shown, figure 2 It is a schematic diagram of the end plate of an X-shaped prefabricated reinforced concrete pile mold; from figure 1 and figure 2 It can be seen that the mold includes a positive V-shaped shaping template 1 , an inverted V-shaped shaping template 2 , a base plate 3 , and an end plate 4 . The positive V-shaped formwork 1 is made of steel plates, and the two side panels constituting the V-shaped opening are all made of concave arc-shaped panels with a horizontal attachment plate 5 at one end, and bolt holes 6 are set on the horizontal attachment plate 5. The intersection of concave arc-shaped panels is made into a platform or rounded corners,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com