Double-pipe reinforced composite combined built pile

A technology of composite materials and combined piles, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, can solve the problems of insufficient rigidity and poor corrosion resistance of pure composite piles, and achieve wide application range, high bearing capacity, and displacement The effect of improving the ductility coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

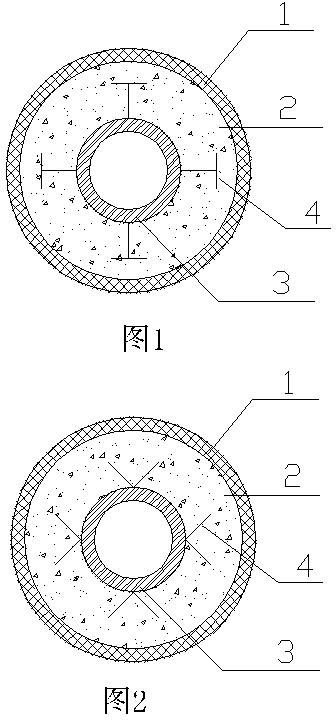

[0049] Such as figure 1 shown.

[0050] A double-tube reinforced composite pile, which is mainly composed of a cylindrical composite material outer tube 1, a cylindrical metal inner tube 3 and poured on the composite material outer tube 1 and metal inner tube 3 (generally steel pipe or stainless steel tube, the lower Concrete 2 between the same), the outer surface of the metal inner tube 3 is welded with a T-shaped metal stiffener 4, the schematic diagram of the cross section of the pile in this embodiment is as follows figure 1 shown.

[0051] The fiber layer of the composite outer tube can be unidirectionally or bidirectionally mixed with carbon fiber, glass fiber, aramid fiber and basalt fiber, and the horizontal angle of the fiber can be 0°, 45°, 55° or 90°. There can be four, or more than four, T-shaped stiffeners in the section of each member, preferably four. The sand layer can be resin-based quartz sand laid on the fiber layer to increase the strength of the pipe wa...

Embodiment 2

[0054] Such as figure 2 shown.

[0055] The difference between the present embodiment and the first embodiment is that the surface of the cylindrical metal inner tube 3 is welded with an L-shaped stiffener 4, and the rest are the same as the first embodiment, and the performance indicators are also equivalent.

Embodiment 3

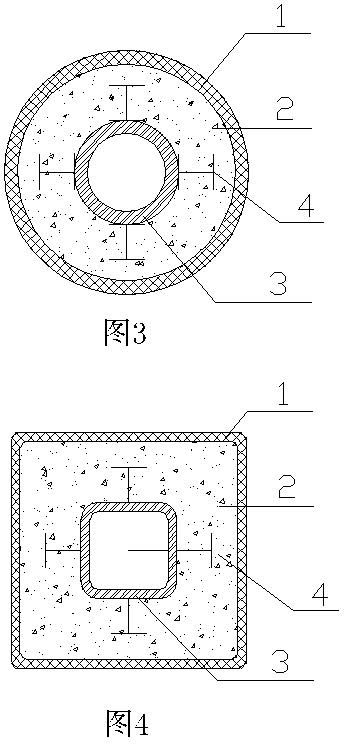

[0057] Such as image 3 shown.

[0058] The difference between this embodiment and the first embodiment is that the surface of the cylindrical metal inner tube 3 is welded with an I-shaped stiffener 4, and the rest are the same as the first embodiment, and the performance indicators are also equivalent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com