Tower-anchor combined suspension bridge

A suspension bridge and anchoring technology, which is applied in the direction of suspension bridges, bridges, bridge construction, etc., can solve the problems of large amount of foundation engineering, affecting the economical efficiency of the suspension bridge structure, and the negative impact on the beautiful environment, so as to achieve short construction period, reduce the calculation length, and save back cables long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

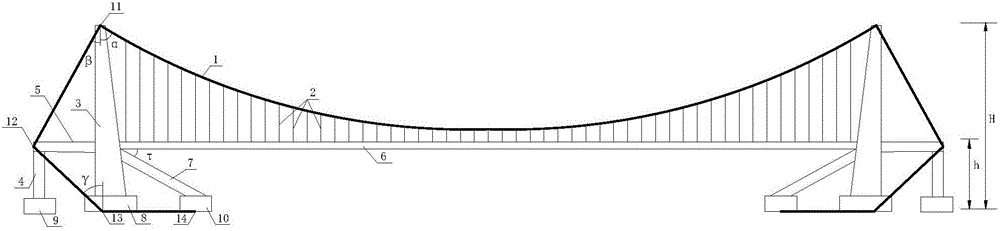

[0135] The span arrangement of the tower-anchor integrated suspension bridge in this embodiment is the same as that of the Runyang Yangtze River Bridge. Such as figure 1 As shown, a tower-anchor integrated suspension bridge is mainly composed of a main cable 1, a sling 2, a cable tower 3, a horizontal bar 5, a main girder 6 and an inclined column 7; Between the main beam 6; the horizontal bar 5 intersects vertically with the cable tower 3; the horizontal bar 5 and the inclined column 7 are respectively arranged on both sides of the cable tower 3, and the inclined column 7 is a two-force bar, and the horizontal The pole 5, the cable tower 3 and the slanted column 7 have a common intersection; the bottom of the slanted column 7 is poured with a slanted column foundation 10; the end of the horizontal bar 5 is added with an auxiliary pier II4, and the bottom of the auxiliary pier II4 is poured with an auxiliary pier II Foundation 9; the bottom of the cable tower 3 is poured with ...

Embodiment 2

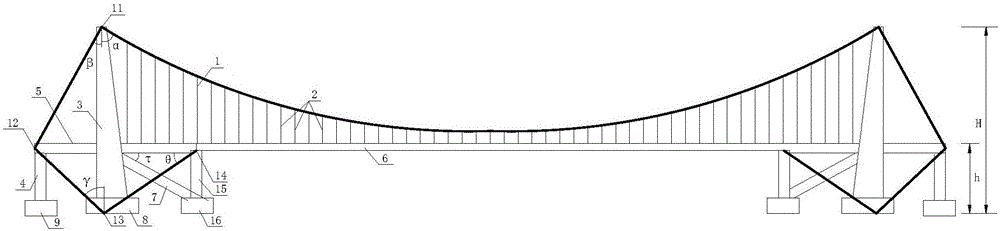

[0139] The span arrangement of the tower-anchor integrated suspension bridge in this embodiment is the same as that of the Wufengshan Yangtze River Bridge. Such as figure 2 As shown, a tower-anchor integrated suspension bridge is mainly composed of a main cable 1, a sling 2, a cable tower 3, a horizontal bar 5, a main girder 6 and an inclined column 7; between the main beam 6; the horizontal bar 5 intersects the cable tower 3 vertically; the horizontal bar 5 is connected to the cable tower 3 and connected to the main beam 6, and auxiliary piers are respectively added at both ends of the horizontal bar 5 II4. Auxiliary pier I15; the slanting column 7 is a two-force rod, which is located inside the cable tower 3, and the horizontal bar 5, cable tower 3 and slanting column 7 have a common intersection point; the bottom of the auxiliary pier II4 is poured to assist Pier II foundation 9; the bottom of the inclined column 7 intersects with the bottom of the auxiliary pier I 15, an...

Embodiment 3

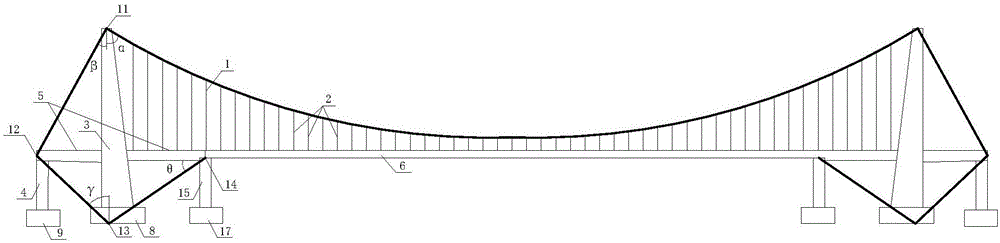

[0143] The span arrangement of the tower-anchor-integrated suspension bridge in this embodiment is the same as that of the Nanjing Fourth Yangtze River Bridge. Such as image 3 As shown, a tower-anchor integrated suspension bridge is mainly composed of a main cable 1, a sling 2, a cable tower 3, a horizontal bar 5 and a main girder 6; between; the horizontal bar 5 intersects vertically with the cable tower 3; the horizontal bar 5 is connected to the cable tower 3, and is connected with the main beam 6; I15; the bottoms of the auxiliary pier II4 and auxiliary pier I15 are respectively poured with the auxiliary pier II foundation 9 and the auxiliary pier I foundation 17; A steering block II13 is provided at the bottom; a cable saddle 11 is provided on the top of the cable tower 3; a steering block I12 is provided at the end of the horizontal bar 5; The cable saddle 11, the steering block I12 at the end of the horizontal rod 5, and the steering block II13 at the bottom of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com