Composite steel plate shearing wall for improving stability

A technology of composite steel plate and composite plate, applied in walls, building components, buildings, etc., can solve the problems of reducing labor costs, unfavorable conditions, shortening construction time, etc., and achieve improved comfort and durability, and large shear buckling capacity , the effect of maintaining a quiet atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention is described in further detail:

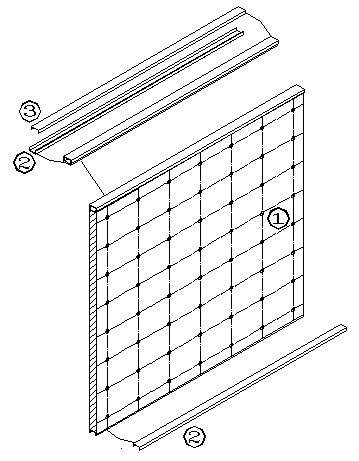

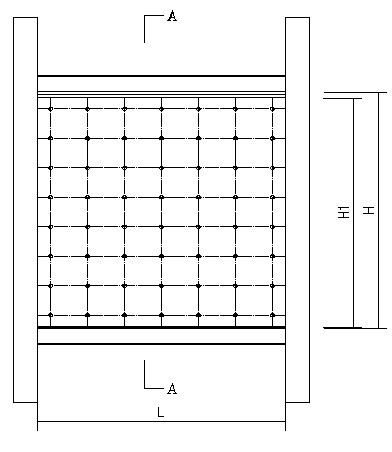

[0024] As shown in the figure: a composite steel plate shear wall with enhanced stability, including a composite plate 1 , a first channel steel connector 2 , and a second channel steel connector 3 .

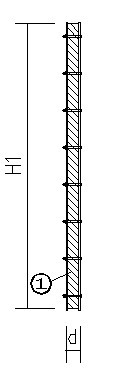

[0025] The top and bottom ends of the composite panel 1 are respectively arranged with first channel steel connectors 2, and the notches of the first channel steel connectors 2 at the top and bottom ends are outward, and the notches of the second channel steel connectors 3 are arranged inward on the composite panel. On the first channel steel connector 2 at the top of the plate 1. The composite panel 1 includes two steel plates and a rigid polyurethane foam layer; a rigid polyurethane foam layer is arranged between the two steel plates; a number of screw holes are arranged on the surface of the steel plate, and bolts pass through the screw holes to connect the steel pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com