Patents

Literature

43results about How to "Increased out-of-plane stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

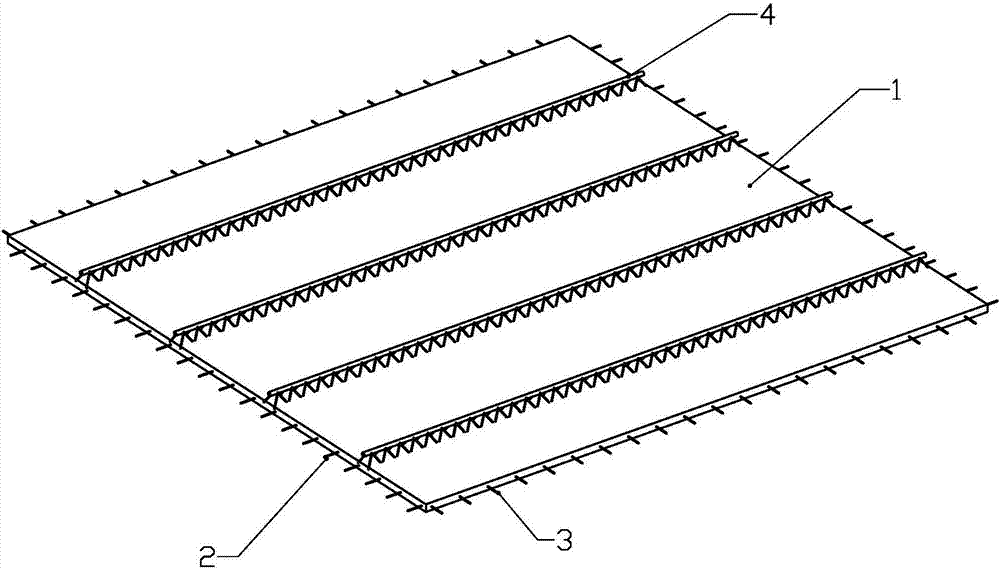

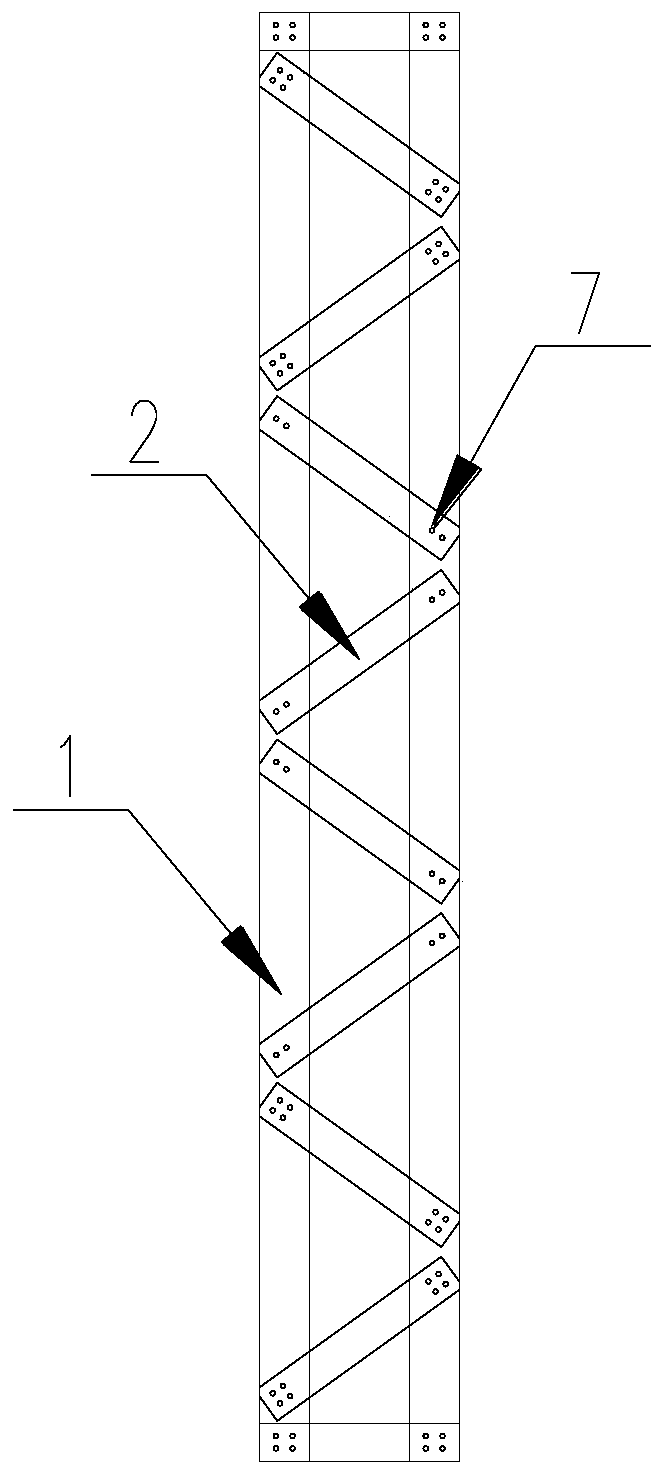

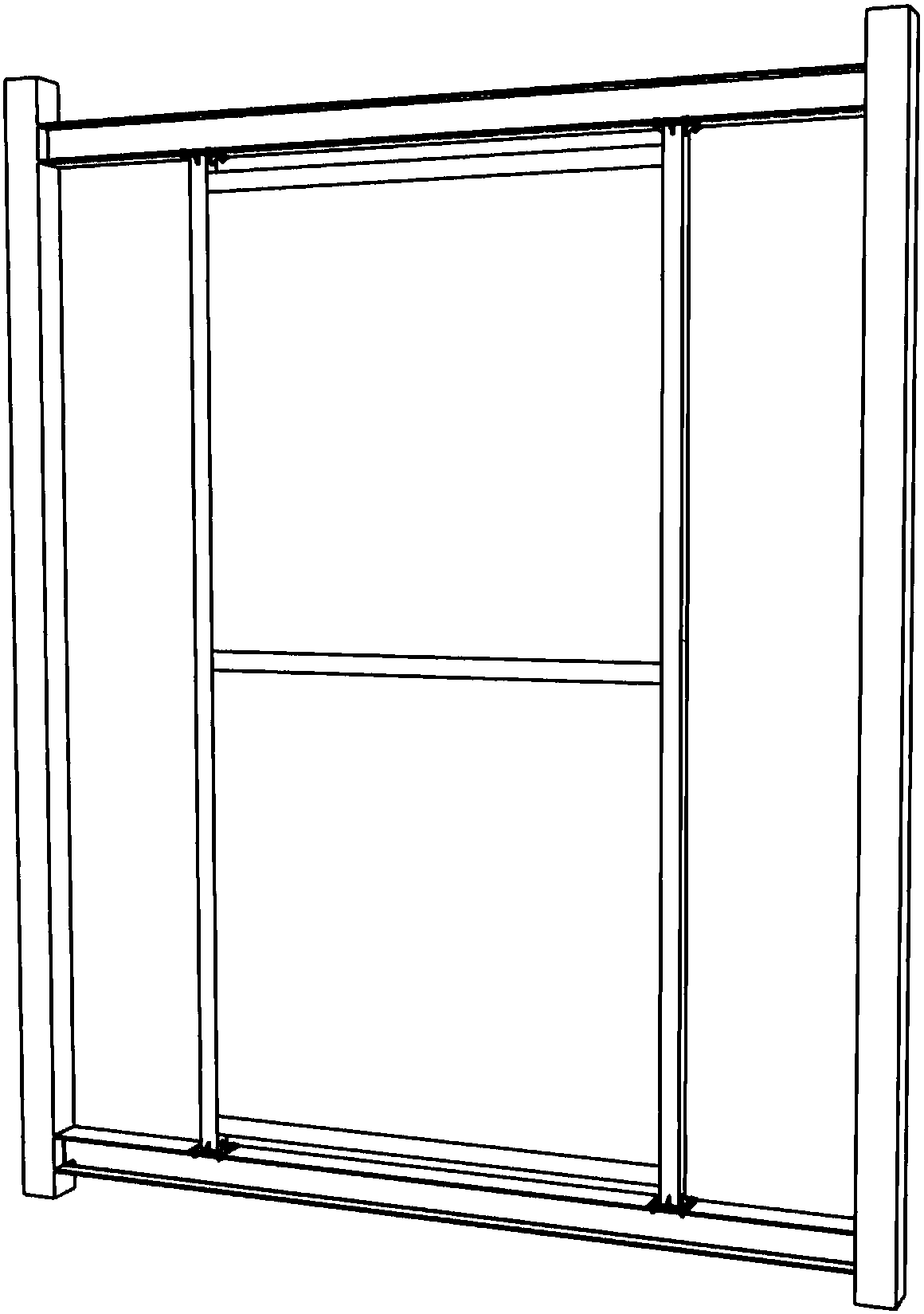

Prestressed concrete superimposed sheet with steel trusses and manufacturing method

InactiveCN106703269AIncreased out-of-plane stiffness and load carrying capacityApplicable span is largeFloorsBuilding material handlingRebarPre stress

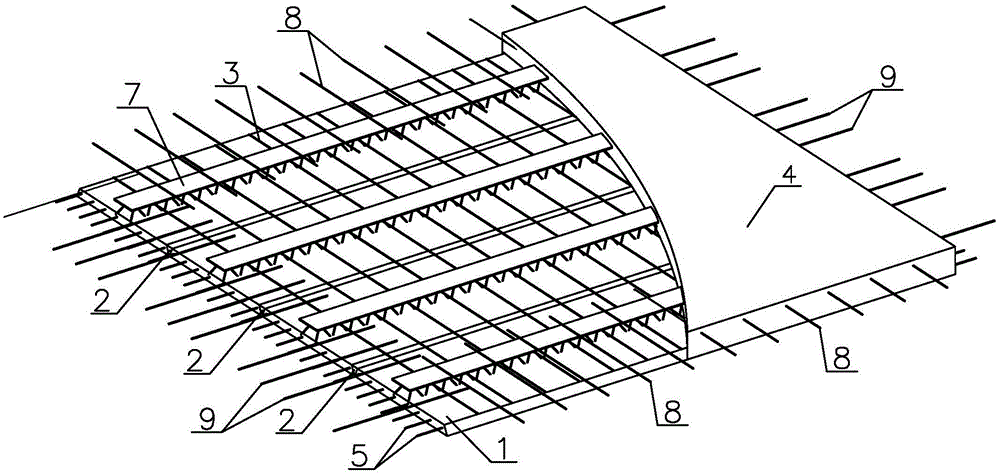

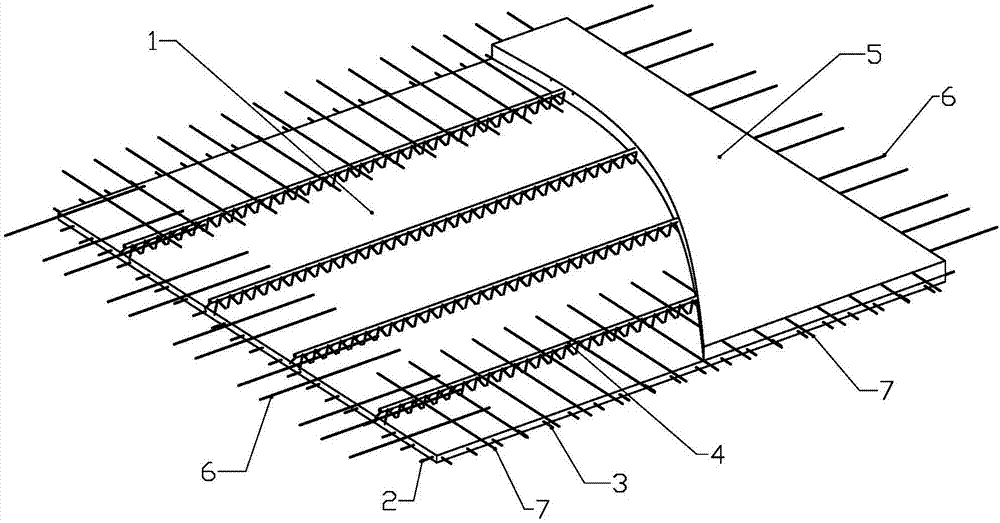

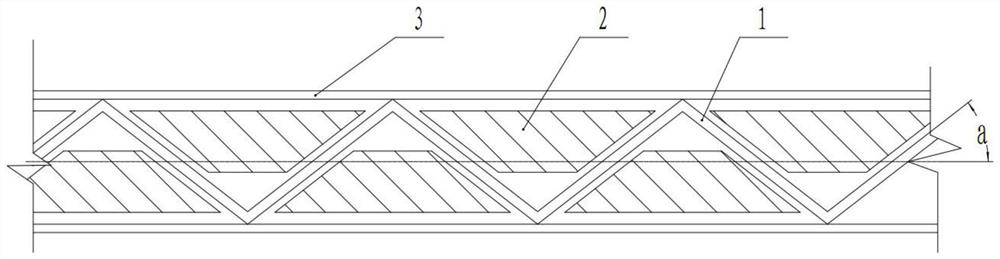

The invention discloses a prestressed concrete superimposed sheet with steel trusses and a manufacturing method, and belongs to the technical field of architectural engineering. The prestressed concrete superimposed sheet structurally comprises prefabricated bottom plates, transverse steel bars and a superimposed layer, two sides faces, in the length direction, of each prefabricated bottom plate are inclined faces, a wedge-shaped edge joint is formed between every two adjacent prefabricated bottom plates, the wedge-shaped edge joints are filled with high-strength grouting materials, longitudinal prestress steel bars are distributed in the prefabricated bottom plates in the length direction, and the transverse distribution steel bars are arranged in the width direction. The upper portion of each prefabricated bottom plate is provided with at least one steel truss in the length direction, the transverse steel bars are arranged below the steel trusses in the width direction of the prefabricated bottom plates in a penetrating mode, the prefabricated bottom plates can be connected together, the superimposed layer is poured to the prefabricated bottom plates, and superimposed layer transverse steel bars and superimposed layer longitudinal steel bars are arranged in the superimposed layer. The prestressed concrete superimposed sheet has the advantages of being good in overall stress performance, large in application span, excellent in fireproof effect and high in factory production efficiency, enabling site operation to be easy and convenient and the like.

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES

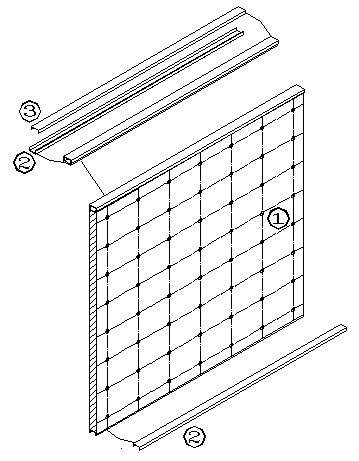

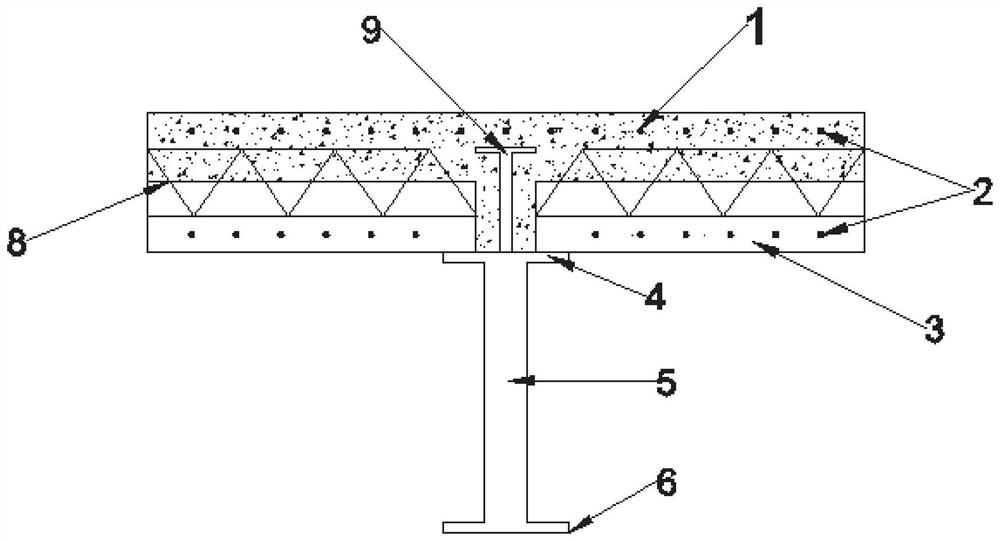

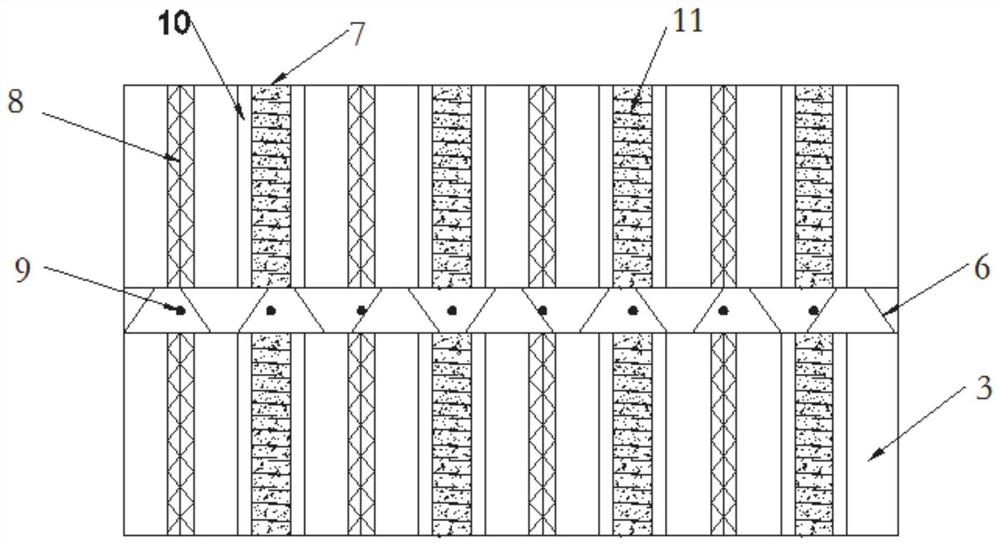

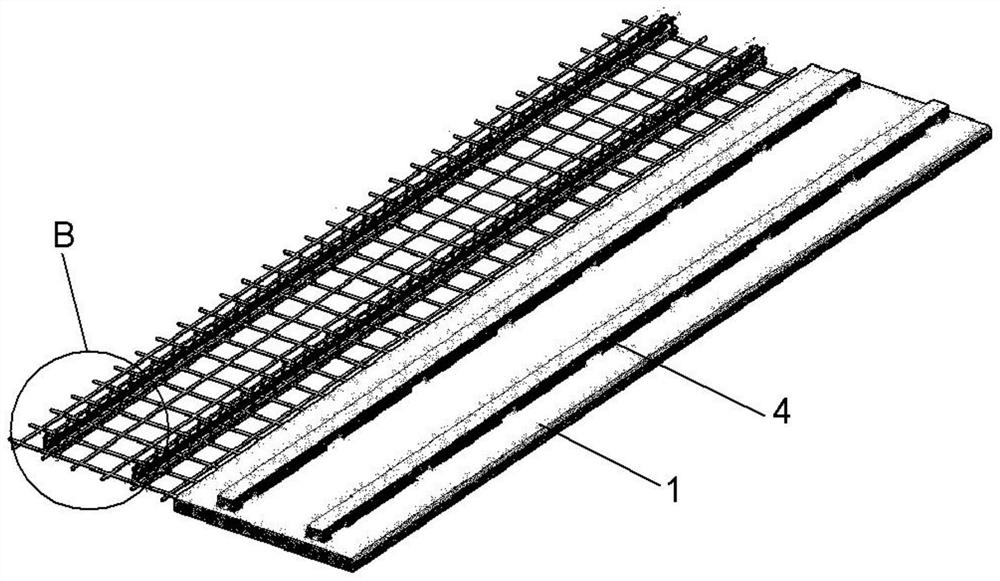

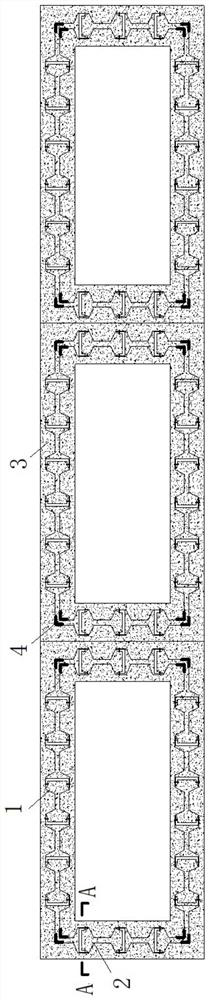

Prestressed concrete bidirectional laminated slab and manufacturing method

InactiveCN107542196AReduce support and formwork usageImprove construction efficiencyFloorsBuilding material handlingRebarPre stress

The invention discloses a prestressed concrete two-way laminated slab and a manufacturing method thereof, which belong to the technical field of construction engineering. Its structure includes a prefabricated bottom plate, a laminated layer and a steel truss. The trusses are connected, and the laminated layer transverse steel bars and laminated layer longitudinal steel bars are arranged inside the laminated layer. The laminated layer longitudinal steel bars are fixed on the upper surface of the steel truss. The transverse prestressed reinforcement is arranged at equal intervals, the longitudinal prestressed reinforcement is arranged at equal intervals along the length direction, the longitudinal prestressed reinforcement is located above the transverse prestressed reinforcement, and multiple steel trusses are arranged at equal intervals along the width direction on the upper part of the prefabricated floor. The invention also discloses a manufacturing method of the laminated board. The invention has the characteristics of high overall rigidity of the laminated slab, good force bearing performance, two-way force transmission mechanism, no joints on the prefabricated bottom plate, reduced on-site support and formwork consumption, and improved construction speed and the like.

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES

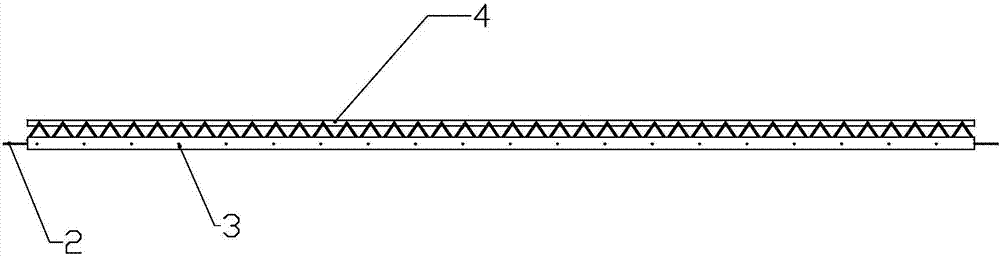

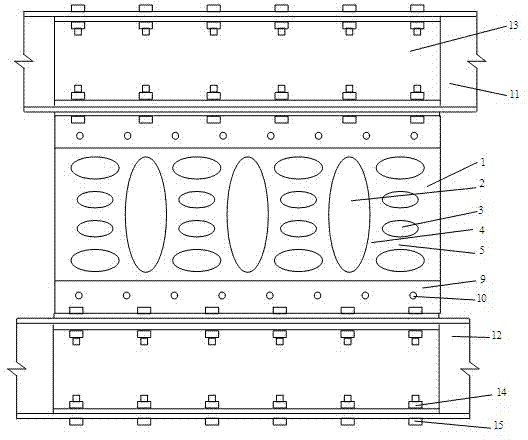

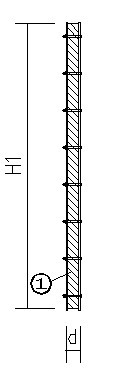

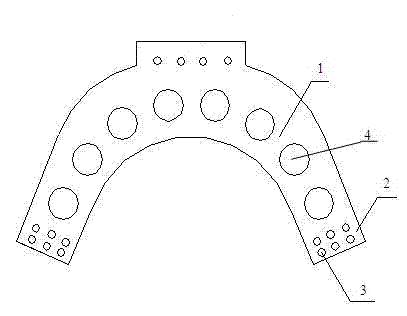

Compound mild steel damper with holes and ribs

InactiveCN102926480ALarge yield area of steelGood energy consumptionShock proofingEarthquake resistantEngineering

The invention provides a compound mild steel damper with holes and ribs. The compound mild steel damper is mainly composed of an energy dissipation portion, rib dividing holes, in-rib holes, vertical energy dissipation ribs, horizontal energy dissipation ribs, a fixing portion, a steel base plate, angle steel, a steel beam, a herringbone support top portion, U-bar and the like. The compound mild steel damper is characterized in that the energy dissipation portion is rectangular, a plurality of rib dividing holes are arranged in the energy dissipation portion, the rib dividing holes are oval, long axes of the rib dividing holes are vertically distributed, and the energy dissipation portion is divided into a plurality of vertical energy dissipation ribs. The in-rib holes are arranged in each vertical energy dissipation rib, the in-rib holes are oval, long axes of the rib dividing holes are horizontally distributed, and one vertical energy dissipation rib is divided into the plurality of vertical energy dissipation ribs and the plurality of horizontal energy dissipation ribs through the plurality of in-rib holes. The compound mild steel damper has the advantages of being big in initial stiffness, free of obvious stress concentration, big in steel surrender area, good in energy dissipation effect and high in steel utilization rate. A plane of the damper is big in outer stiffness, plane outer unstability of the damper is avoided before sufficient energy dissipation, and damage of the damper out of a big plane during stress is avoided. In addition, the compound mild steel damper with holes and ribs is simple in manufacture and installation and convenient to use, can be used for aseismic design of newly-built constructional engineering, and can be used for strengthening service of the existing engineering.

Owner:SHENYANG JIANZHU UNIVERSITY

Corrugated steel plate confined concrete combination column and manufacturing method thereof

InactiveCN103015632AFatigue resistantImpact resistantStrutsPillarsSheet steelUltimate tensile strength

The invention discloses a corrugated steel plate confined concrete combination column which is a polygon tube formed by using a plurality of corrugated steel plates and a plurality of steel tubes as turning corners, wherein the corrugation directions of the corrugated steel plates are identical to the length direction of the polygon tube; and concrete is further filled into the polygon tube and the corners so as to manufacture the combination column. In addition to the excellent mechanical property of the conventional steel tube concrete, the combination column further has the following remarkable advantages that the load born by corrugated steel plate bears in the corrugation direction is small, so that the strength of the corrugated steel plate is mainly for providing annular restraint on the core concrete, then the compression bearing capacity of the core concrete is greatly improved, the compression bearing capacity of the combination column is improved to a large extent, the material is saved, and the engineering cost is reduced; the outer rigidity of the plane of the corrugated steel plate is large, and the corrugated steel plate is unlikely to bulge under the transverse expansion deformation action of the core concrete, so that the effective annual restraint of the corrugated steel plate to the core concrete is increased, and the compression bearing capacity of the combination column is further improved.

Owner:CHINA UNIV OF MINING & TECH

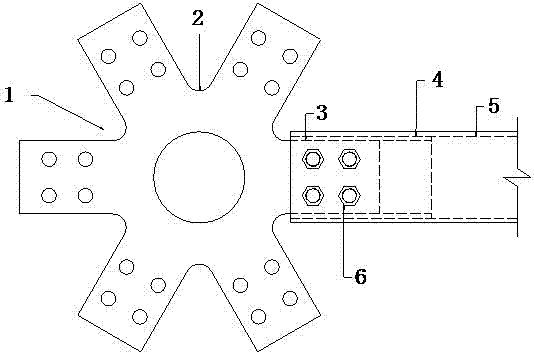

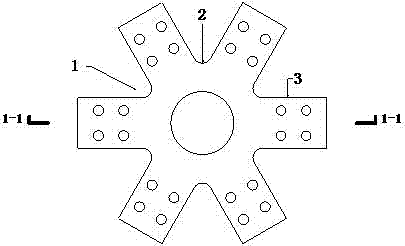

Assembled joint applicable to monolayer triangular space grid structure

InactiveCN104847015AHigh degree of prefabricationSimple on-site installationBuilding constructionsEngineeringAxial force

The invention discloses a novel assembled joint applicable to a monolayer triangular space grid structure. The novel assembled joint is mainly composed of five parts, namely a center joint, connecting sleeves, high-strength bolts, upper and lower cover plates and a center bolt. The center joint is composed of a center circular ring and six connecting arms in connection. The connecting sleeves are machined from steel tubes. Bolt holes are arranged in corresponding positions of the center joint, the sleeves and road pieces. During assembly, one end of each sleeve is sleeved with one connecting arm while the other end of the same is sleeved with one rectangular steel tube, the sleeves, the connecting arms and the rectangular steel tubes are connected through the high-strength bolts, bending moment and axial force of the rod pieces are transmitted through the bolts and friction and mechanical squeezing among the steel tubes, the sleeves, the connecting arms and the center ring, and the triangular space grid structure joint is formed by all the connections. The assembled joint is wide in application range, convenient for industrialized batch production, good in assembling capacity, convenient to construct, high in construction and assembly quality, capable of meeting the requirement of the monolayer space grid structure on joint bearing capacity and rigidity and broad in application prospect.

Owner:SOUTHEAST UNIV

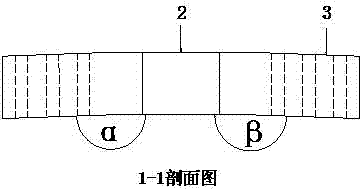

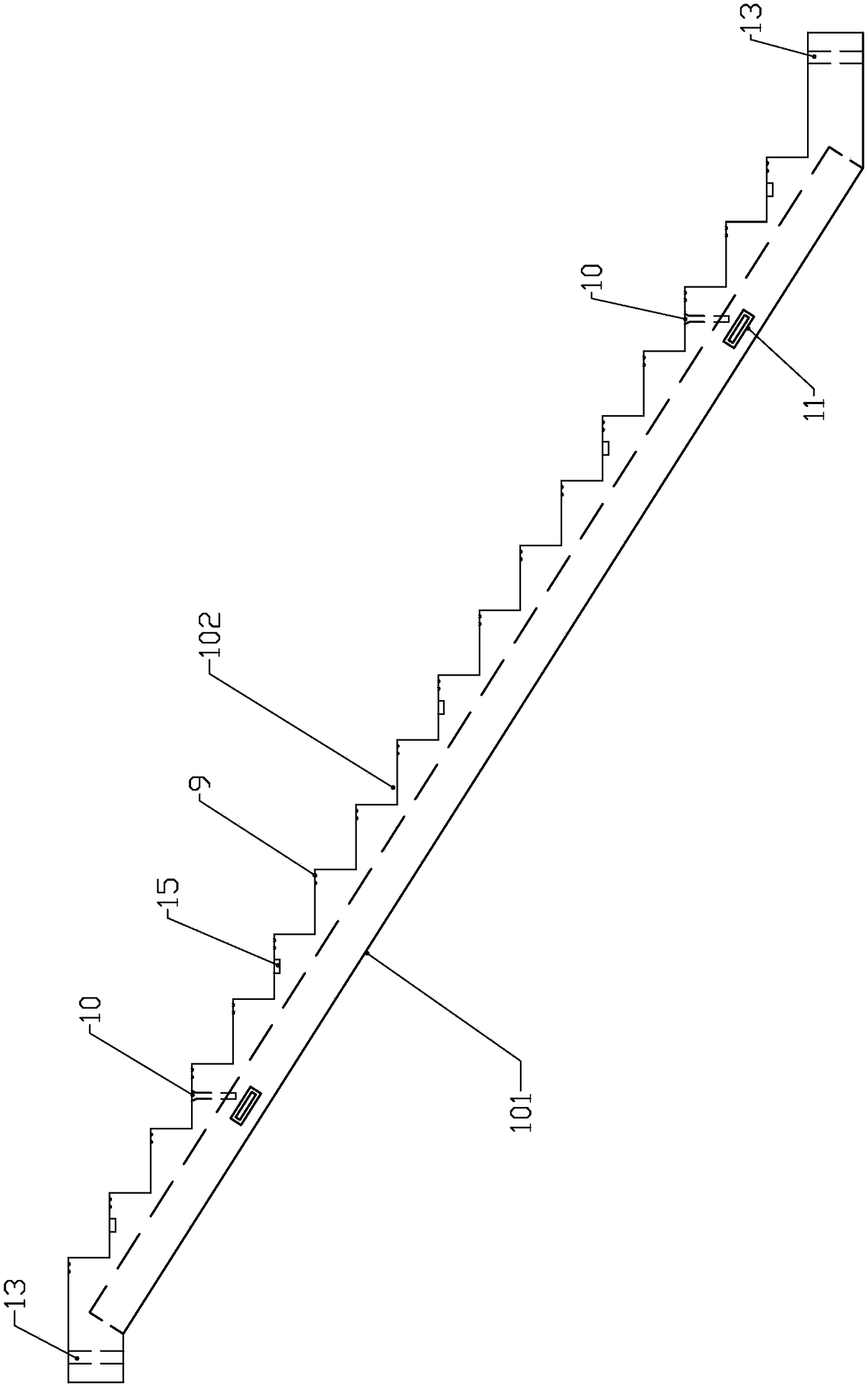

Precast prestresed-concrete beam-type stair and making construction method

PendingCN108166691AReduce difficultyIncreased out-of-plane stiffnessDischarging arrangementMouldsEarthquake resistancePrestressed concrete beam

The invention discloses a precast prestresed-concrete beam-type stair and a making construction method, and belongs to the technical field of constructional engineering. The precast prestresed-concrete beam-type stair structurally comprises a beam-type stair body, an upper stair beam and a lower stair beam, wherein the upper stair beam and the lower stair beam are used for supporting the beam-typestair body; the beam-type stair body comprises a stair-section slant beam and ladder-shaped steps, the stair-section slant beam is arranged in the length direction of the beam-type stair body, the two ends of the steps are supported on the stair-section slant beam, the two ends of beam-type stair body are connected with the upper stair beam and the lower stair beam respectively, a prestresed reinforcing steel bar is arranged at the lower portion of the stair-section slant beam in the length direction, an upper common reinforcing steel bar is arranged at the upper portion of the stair-sectionslant beam in the length direction, stirrups are arranged outside the prestresed reinforcing steel bar and the upper common reinforcing steel bar in the length direction at equal intervals, the prestresed reinforcing steel bar and the upper common reinforcing steel bar are located in the stirrups, and step distribution reinforcing steel bars are arranged in the steps. The precast prestresed-concrete beam-type stair and the making construction method have the advantages of being large in application span, good in crack resistance, light in self weight, convenient to hoist and transport, excellent in earthquake resistance and the like.

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES

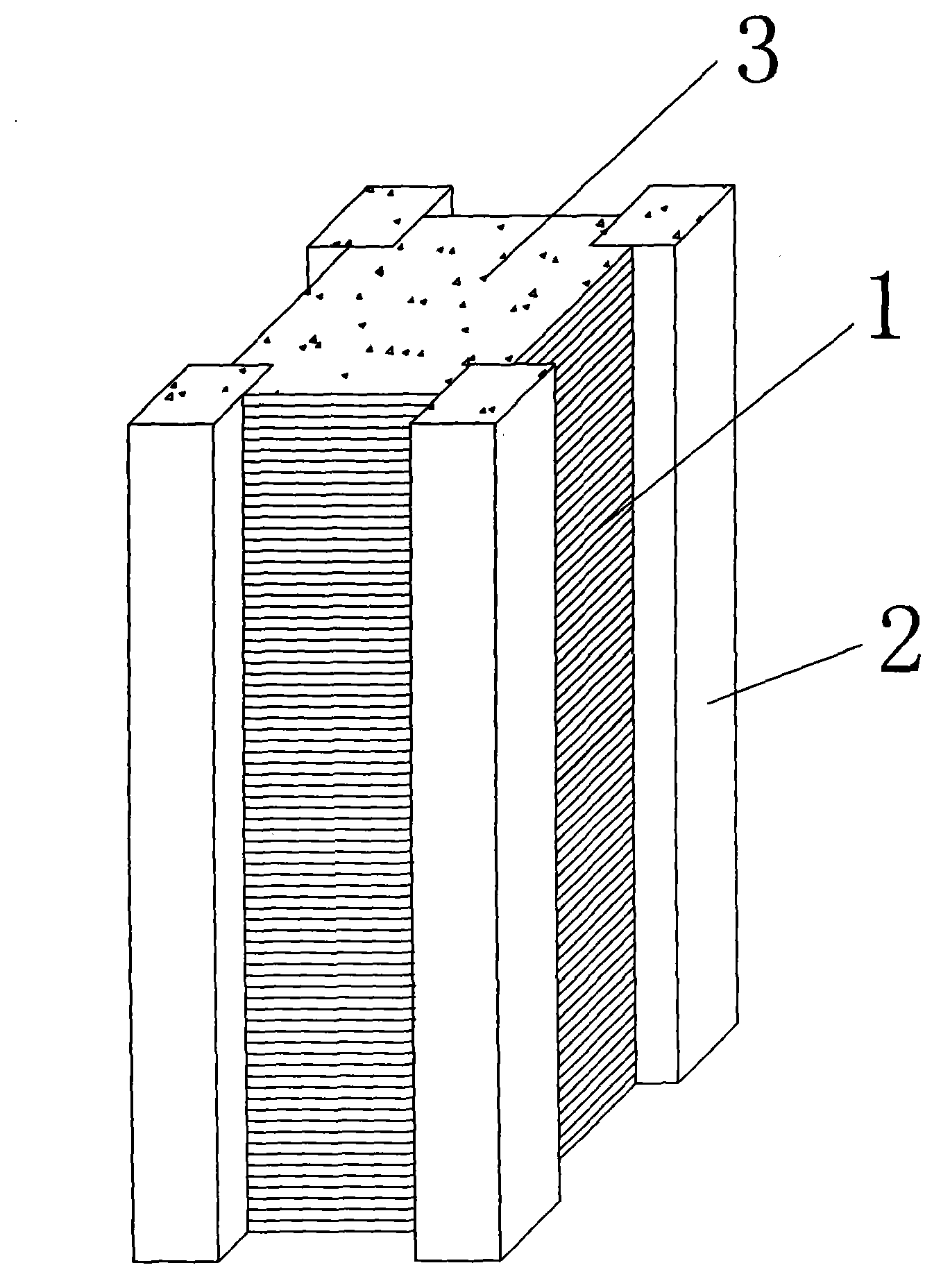

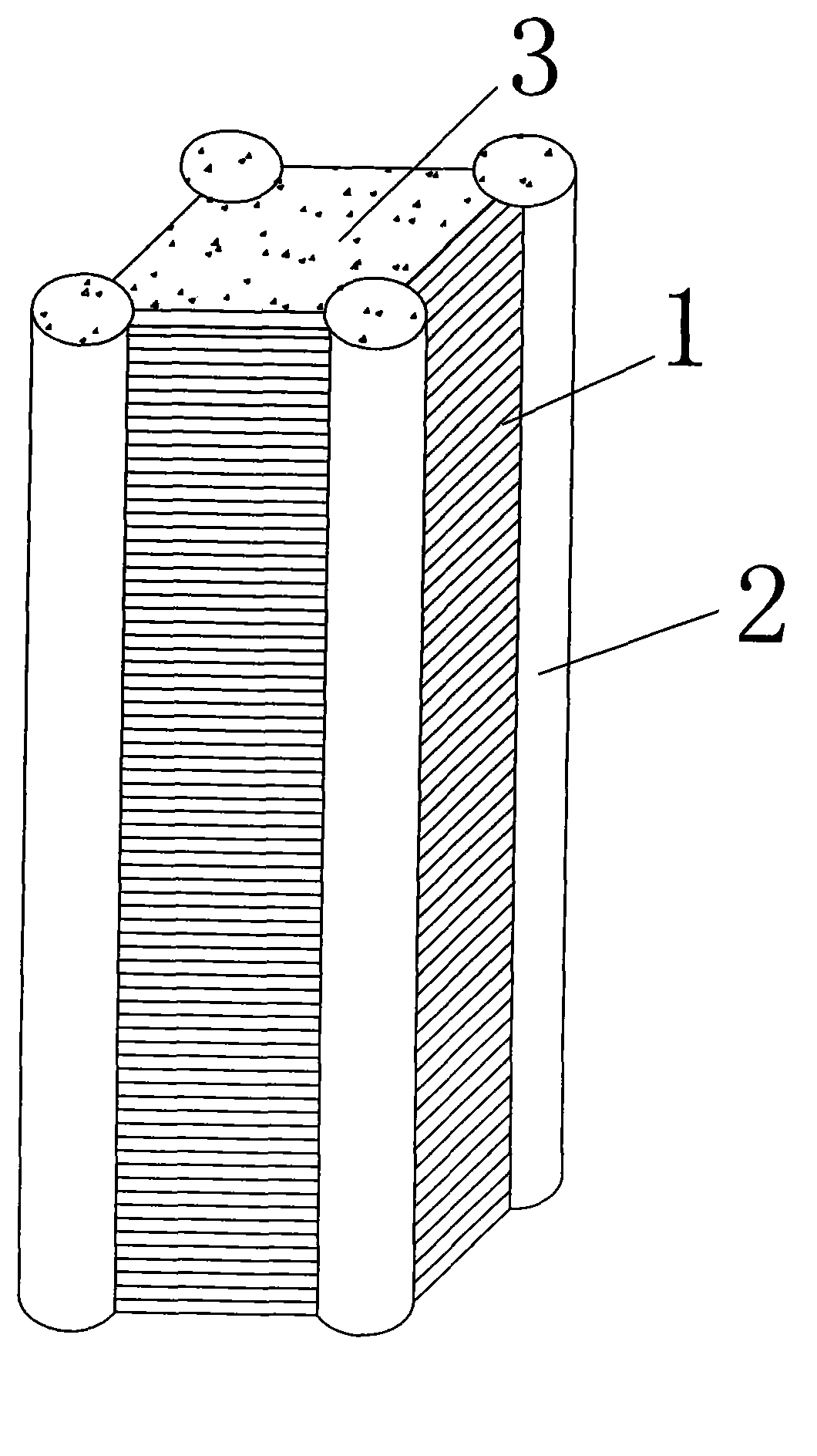

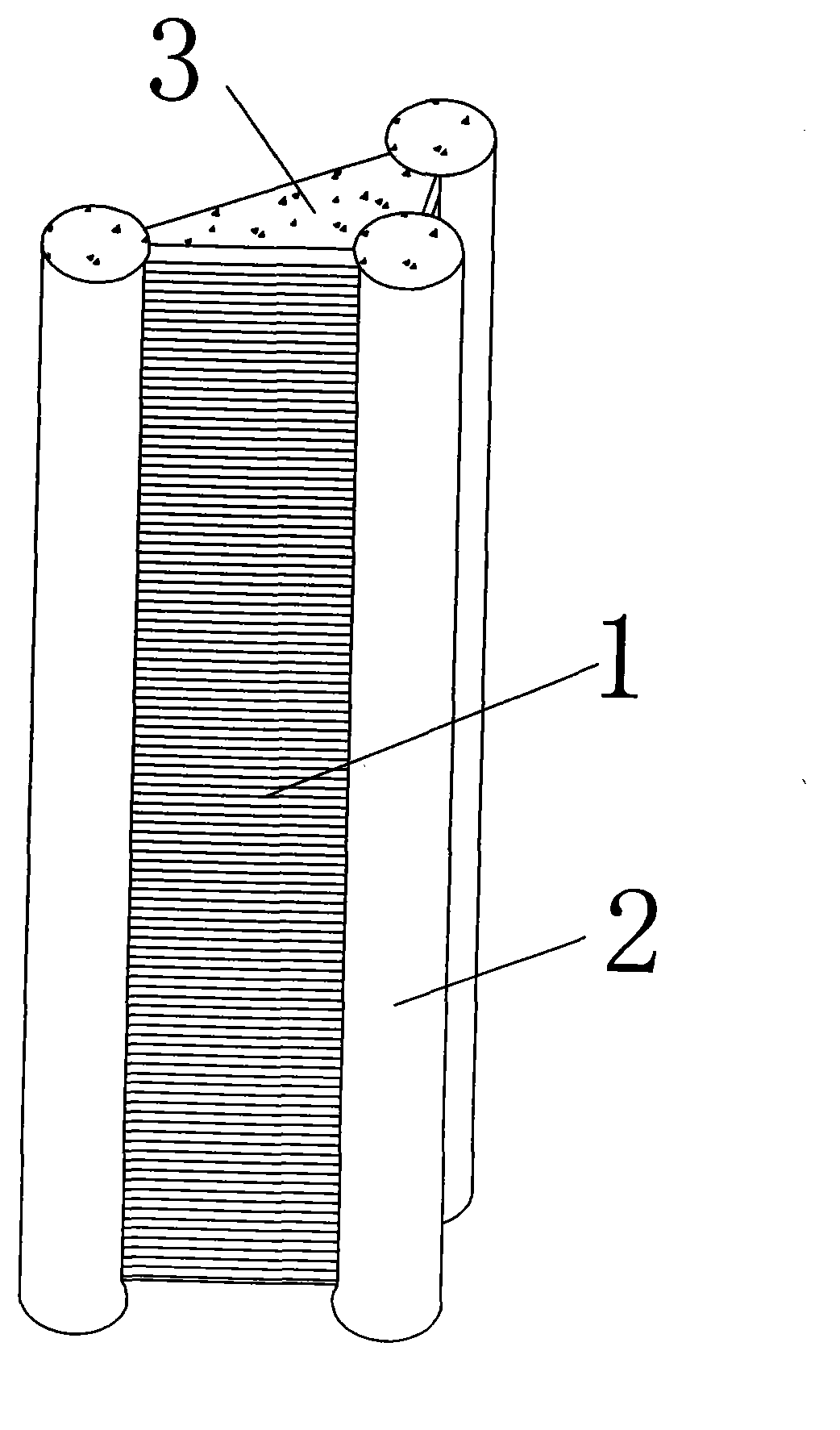

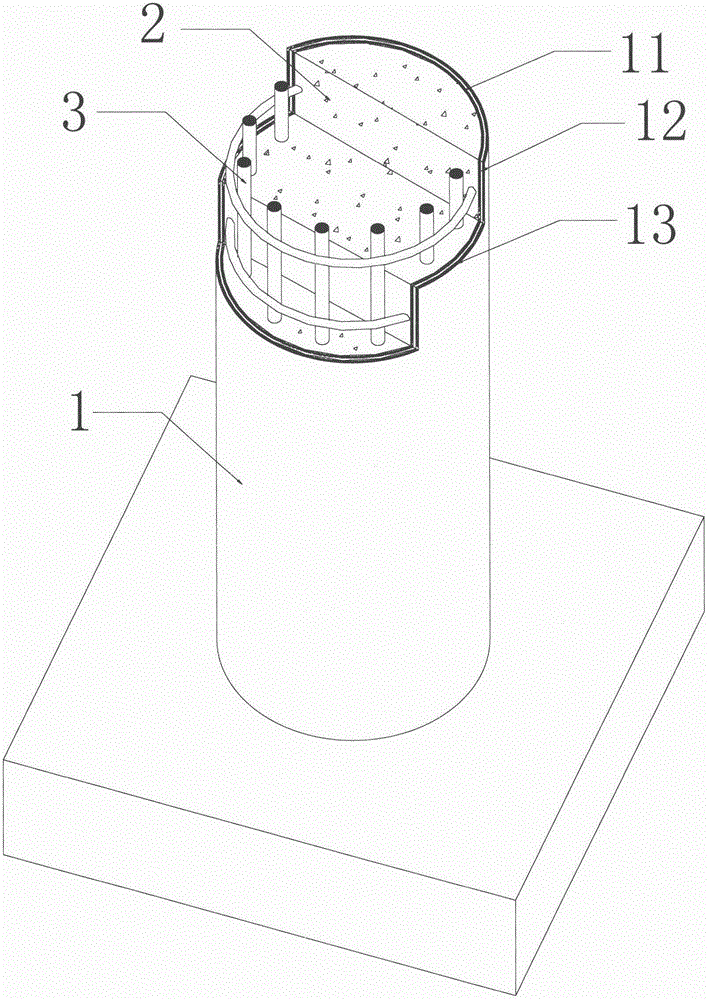

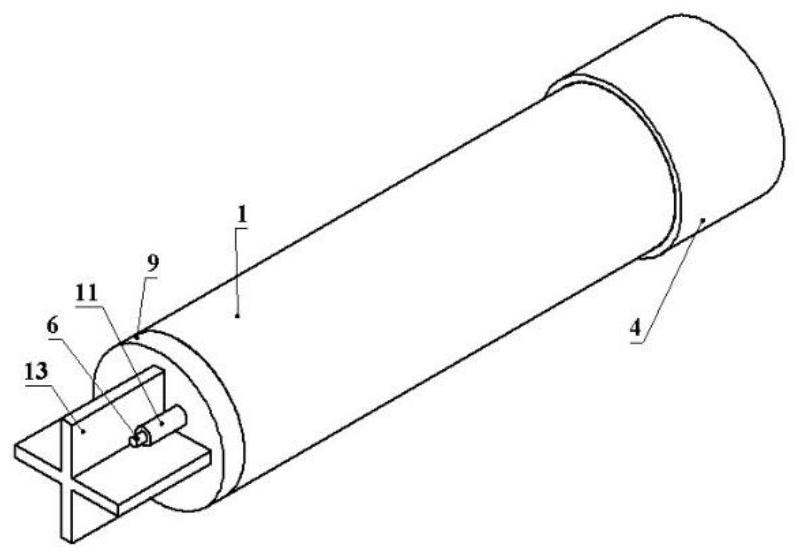

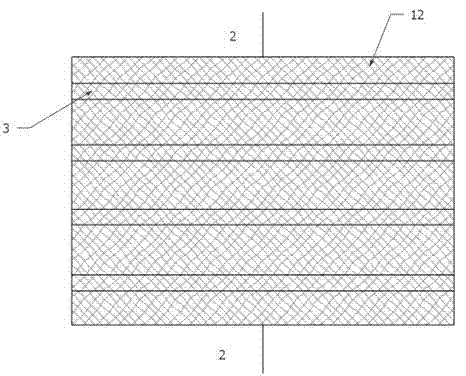

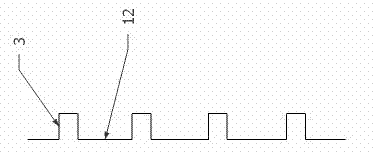

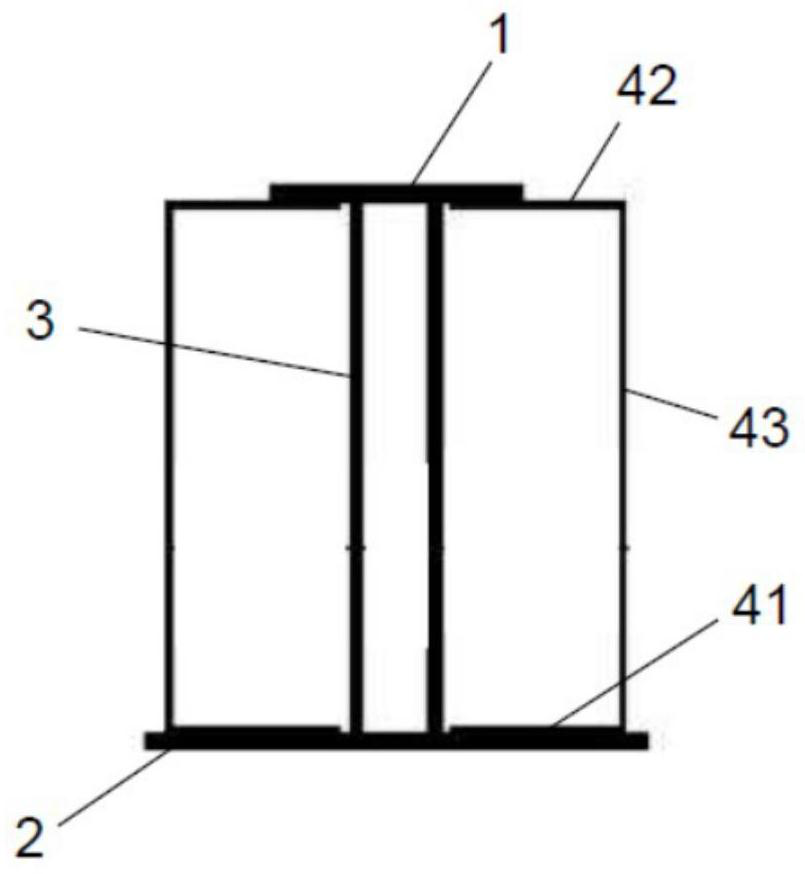

Seawater sea-sand concrete structure with corrugated composite pipe

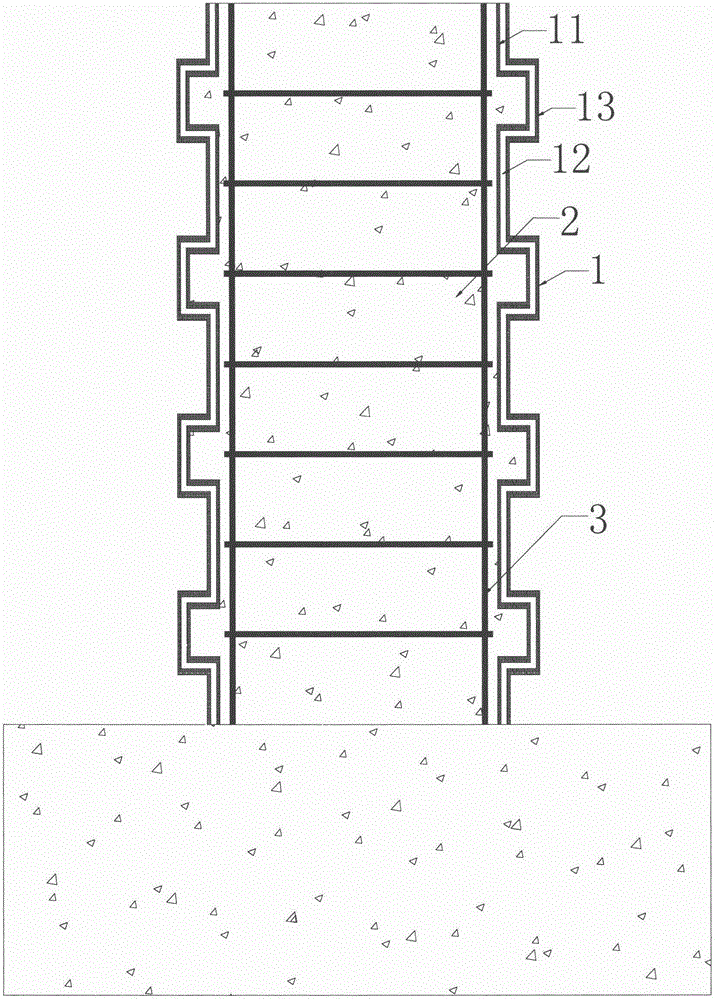

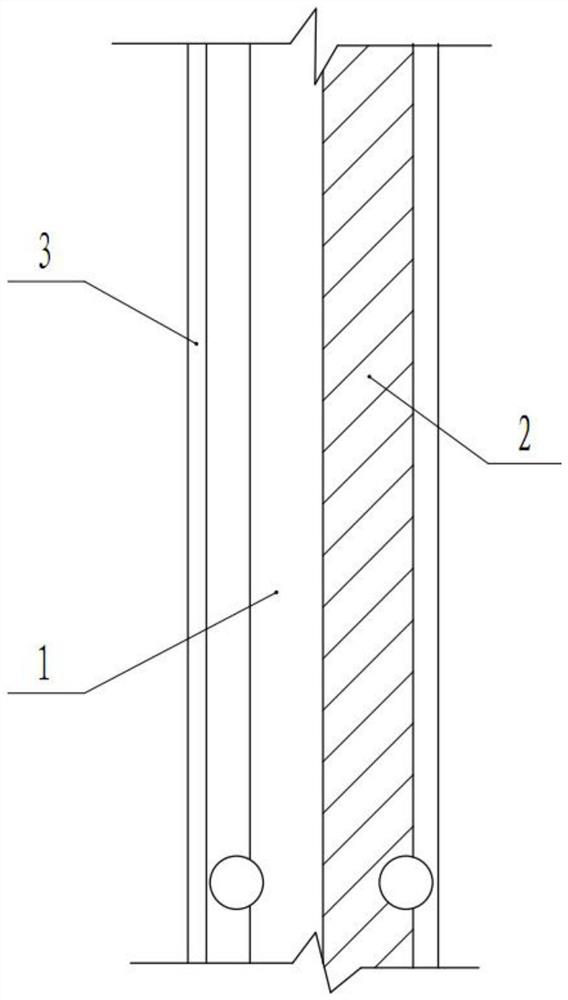

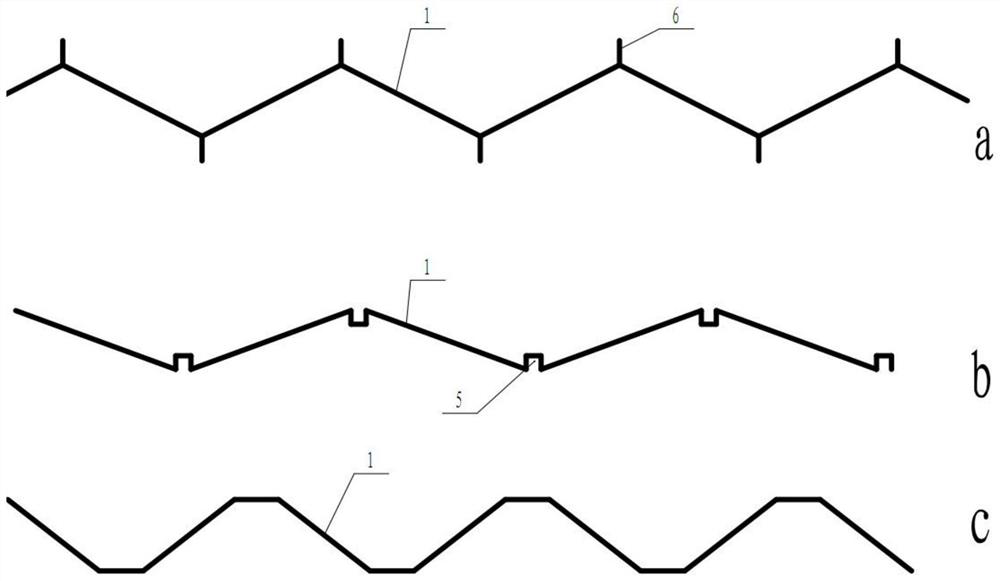

PendingCN106760212AIncreased out-of-plane stiffnessImprove restraintStrutsFoundation engineeringEngineering structuresCurve line

The invention discloses a seawater sea-sand concrete structure with a corrugated composite pipe. The seawater sea-sand concrete structure is composed of the corrugated composite pipe (1), seawater sea-sand concrete (2) and composite ribs (3). The corrugated composite pipe (1) is formed by means of the method that an inner fiber layer (11) and an outer fiber layer (13) are adhered to the inner wall and the outer wall of a corrugated steel pipe (12) correspondingly. The corrugated composite pipe (1) is in a corrugated curve line or fold line shape in the axial direction of a component. The composite ribs (3) are arranged in the corrugated composite pipe (1) in a matched mode, the seawater sea-sand concrete (2) fully fills the inside of the cross section of the corrugated composite pipe (1), and the composite ribs (3) are arranged in the seawater sea-sand concrete (2) and wrapped with the seawater sea-sand concrete (2). According to the seawater sea-sand concrete structure with the corrugated composite pipe, the defects existing in a publicly-known steel pipe concrete structure are overcome, and the seawater sea-sand concrete structure has the advantages that the bearing capacity is high, the corrosion resistance is good, materials are easy to obtain, and sustainable development is facilitated; and meanwhile, the structure has a low manufacturing cost, maneuverability is high, energy consumption is low, environment pollution is small, and the seawater sea-sand concrete structure with the corrugated composite pipe can be suitable for ocean engineering structure construction.

Owner:NANJING FORESTRY UNIV

A prefabricated assembly shear wall vertical joint connection structure and its construction method

ActiveCN105484388BDelayed local bucklingLocal buckling reinforcementWallsArchitectural engineeringPre embedding

Owner:FUJIAN UNIV OF TECH

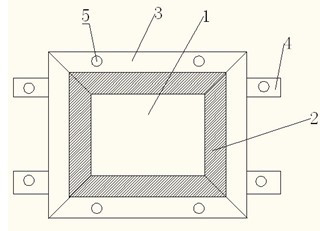

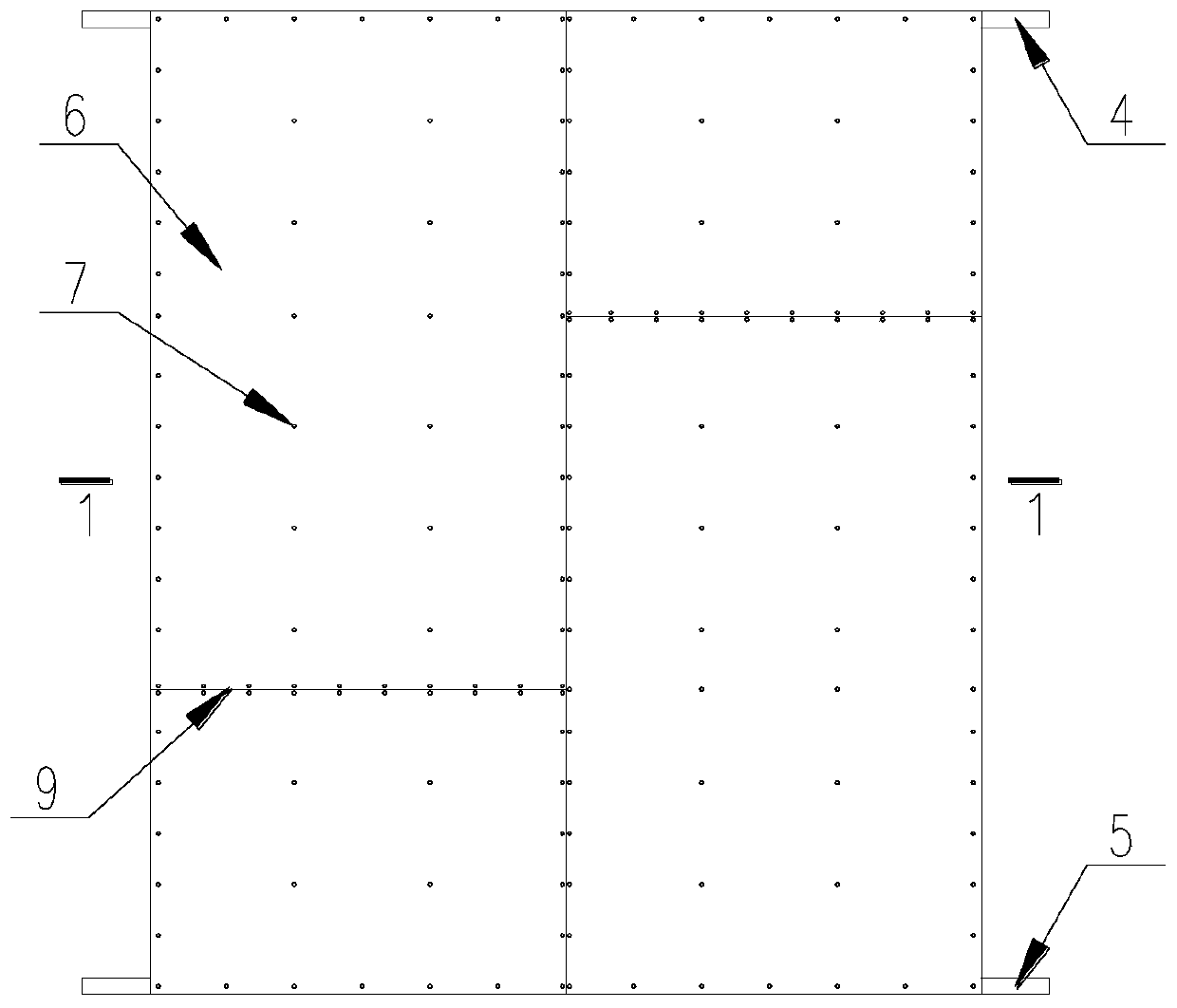

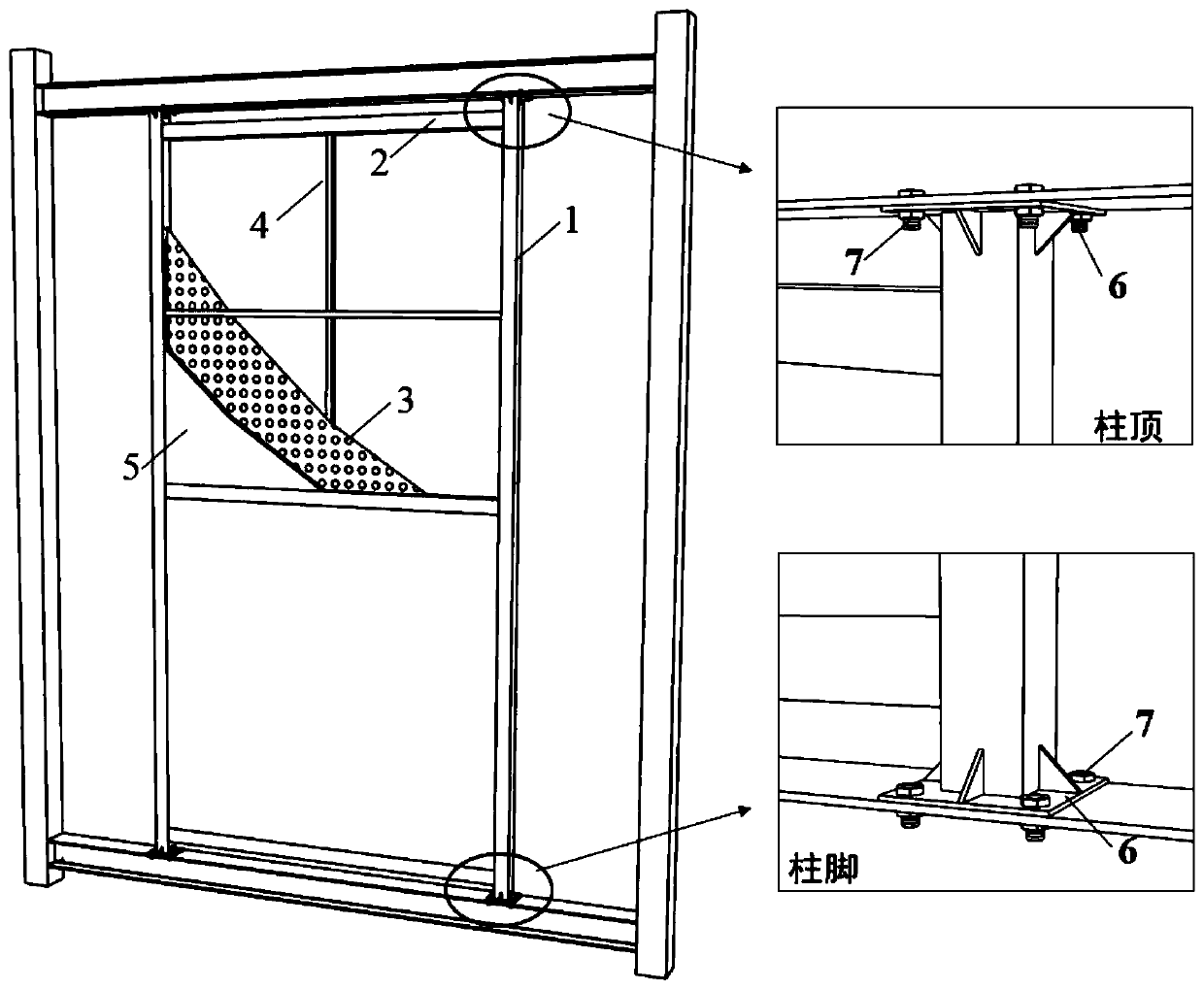

Composite steel plate shearing wall for improving stability

InactiveCN102691364ALarge shear buckling capacityGreatly increased shear buckling capacityWallsSheet steelSteel frame

The invention relates to a composite steel plate shearing wall for improving stability, which belongs to a lateral force resisting component in the technical field of structural engineering and is applied to newly construction of a frame-steel plate shearing wall and reinforcement and seismic rehabilitation of a constructed steel frame structure. Each of the top end and the bottom end of a composite plate is provided with a first channel steel connector, notches of the first channel steel connectors at the top end and the bottom end are arranged outwards, and a notch of a second channel steel connector is arranged inwards on the first channel steel connector at the top end of the composite plate. According to the composite steel plate shearing wall for improving stability, the form of clamping a hard polyurethane foam plate between two steel plates remarkably is adopted so as to increase the plane external stiffness of the cross section of the plate so that the steel plate shearing wall obtains great anti-shearing buckling bearing capacity to avoid entire buckling of the structure under the action of a larger horizontal load; and meanwhile, the steel plate is divided into small areas by dense bolts and is closely combined with the hard polyurethane foam plate to prevent partial buckling of the steel plate.

Owner:HOHAI UNIV

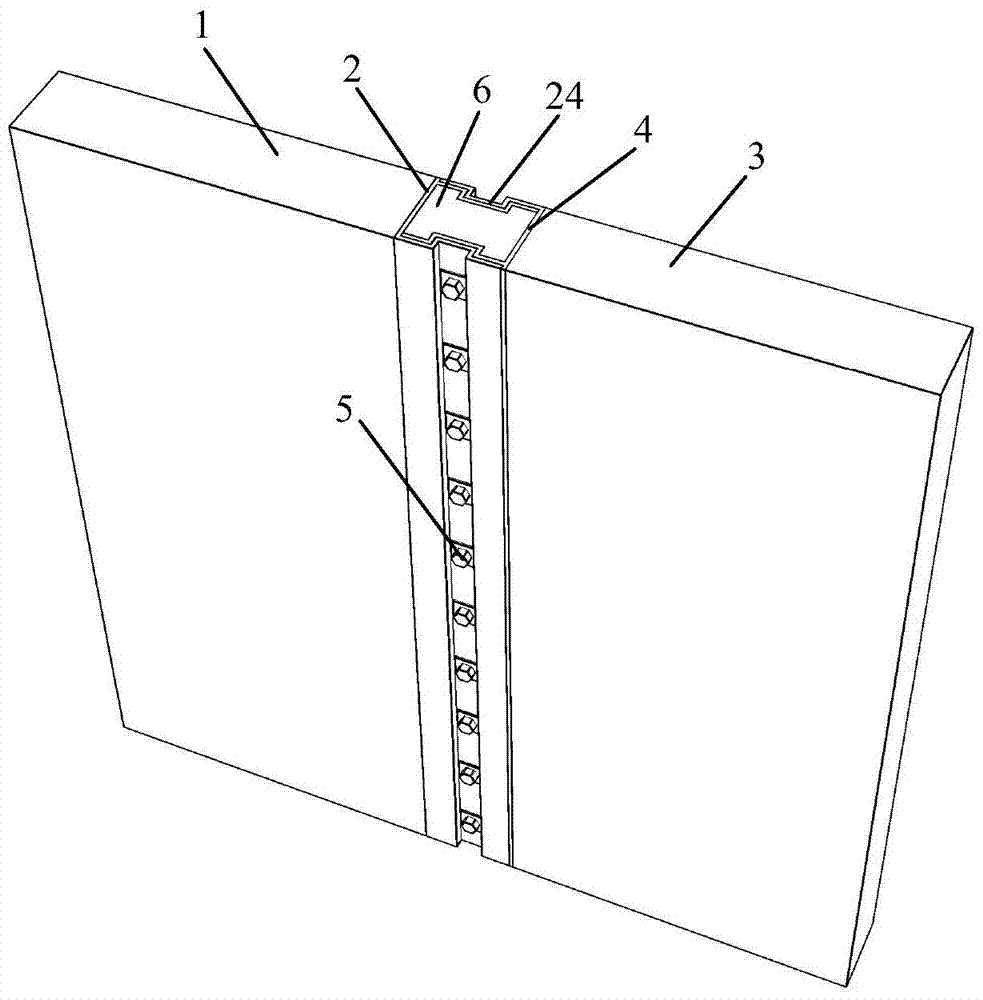

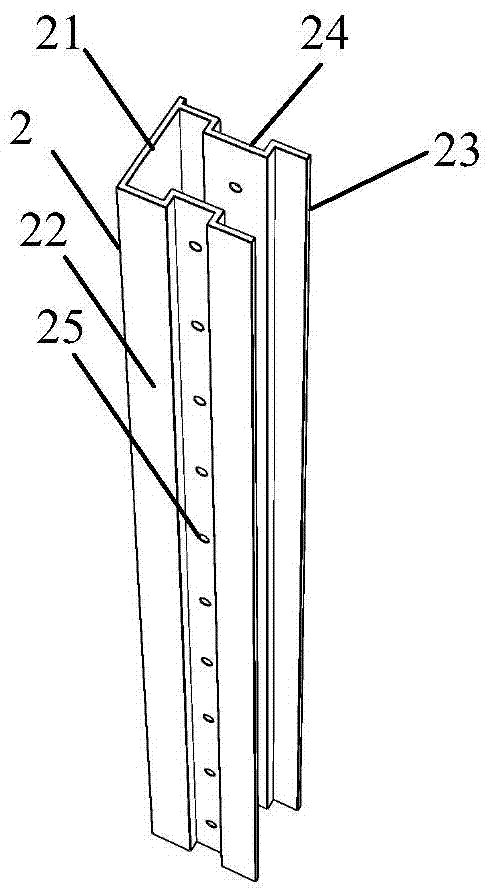

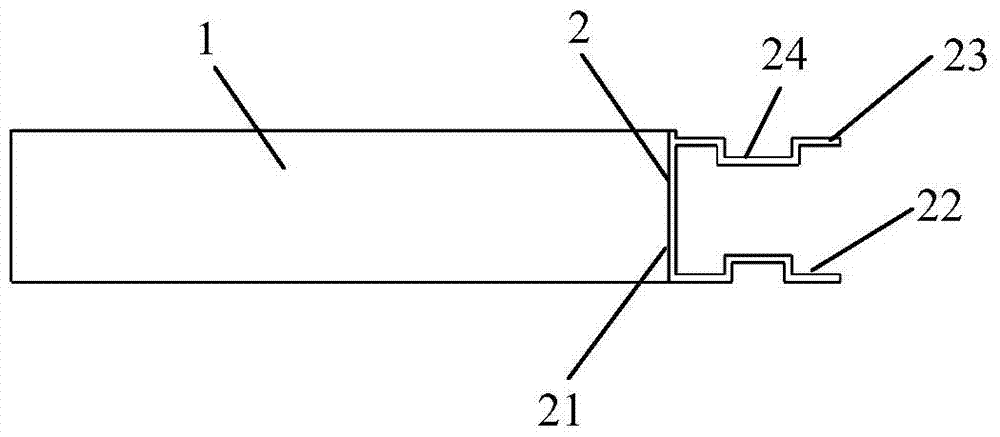

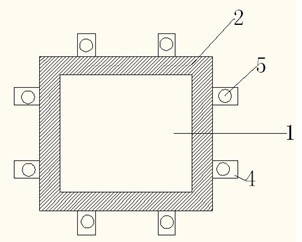

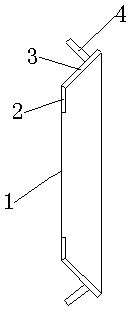

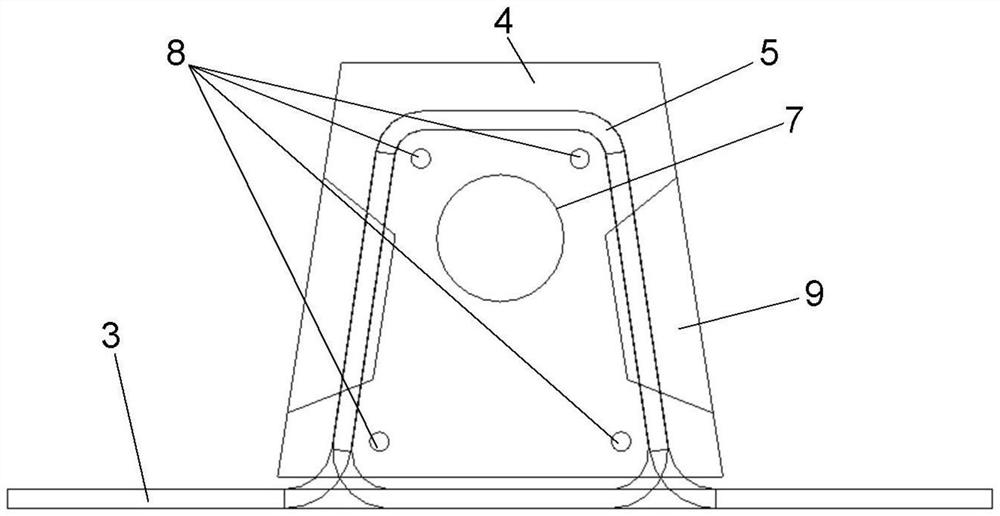

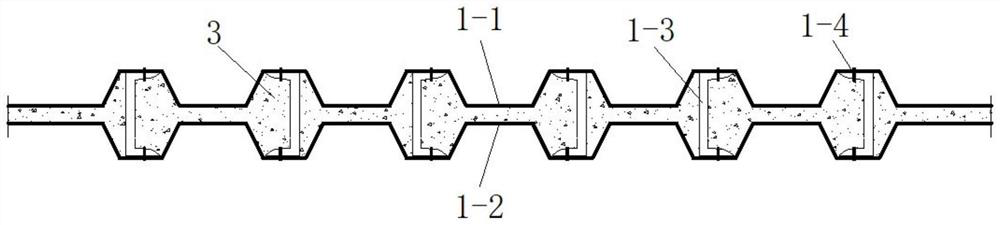

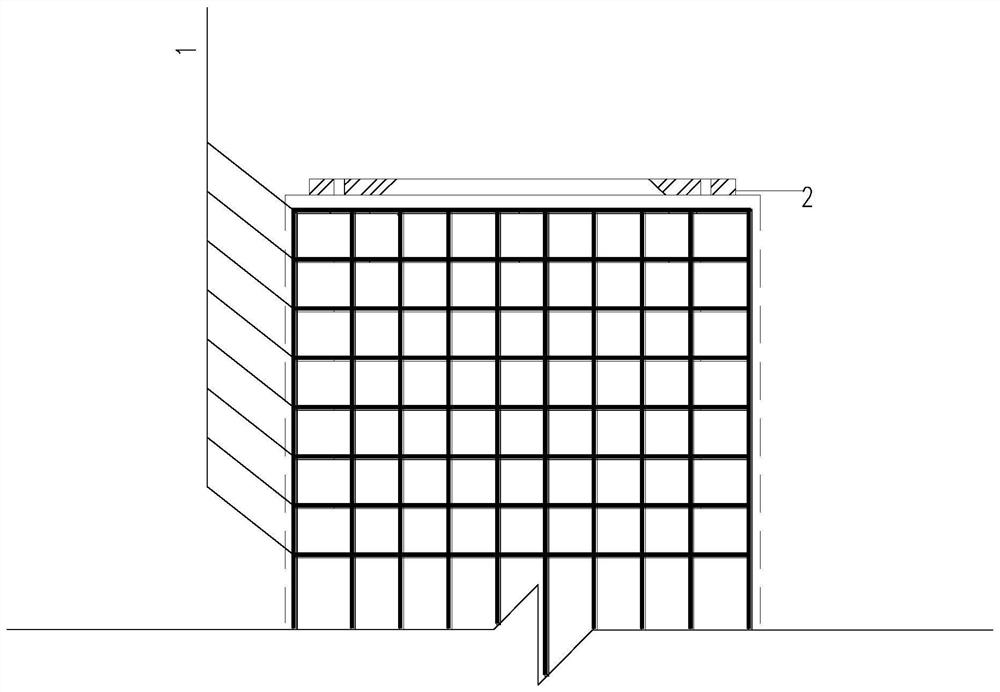

Combined filling mold

InactiveCN102359270ASimple production processFacilitate factory mass productionFloorsForms/shuttering/falseworksMechanical engineeringThin walled

The invention discloses a combined filling mold. The mold is enclosed by a thin wall plate type member, wherein the thin wall plate type member comprises a panel (1), a stiffening plate (2), a counter force plate (3) or a counter force key (4); the periphery of the panel (1) is connected with the stiffening plate (2); the periphery of the stiffening plate (2) is connected with the counter force plate (3) or the counter force key (4); and at least one connecting hole (5) is formed in the counter force key (4). Novel filling mold combination members which are assembled on site and are connected with one another are convenient for industrial mass production, contribute to improvement on production efficiency and reduction in production cost and contribute to sufficient quantity transportation and reduction in transportation cost; because of light weight, the mold can be conveniently assembled, disassembled and mounted manually and contributes to reduction in construction and mounting cost; and due to the adoption of a combined structure, requirements on product diversification are convenient to meet, the defects of the conventional various filling molds are overcome, and the mold has low cost and is easy to operate.

Owner:谢孟

Novel four-casing-pipe buckling restrained brace

PendingCN111677141APrevent bucklingImprove recoverabilityProtective buildings/sheltersShock proofingBuckling-restrained bracePre stress

The invention discloses a novel four-casing-pipe buckling restrained brace. The novel four-casing-pipe buckling restrained brace comprises an inner restrained steel pipe. The outer side of the inner restrained steel pipe is sleeved with an energy-consumption core material pipe. The outer side of the energy-consumption core material pipe is sleeved with an outer restrained steel pipe. The energy-consumption core material pipe and the inner restrained steel pipe are connected with a first force transmission plate. The first force transmission plate is fixedly connected with a first connecting part. The energy-consumption core material pipe is fixedly connected to the inner side of the outer restrained pipe. The outer side of the outer restrained pipe is fixedly connected with an outer sleeving force transmission steel pipe. The outer side of the first force transmission plate is closely attached to the inner side of a first sliding plate. The edges of the first force transmission plate and the first sliding plate are closely attached to the outer restrained steel pipe. The outer restrained pipe, the energy-consumption core material pipe and the inner restrained steel pipe are closelyattached to the inner side of a second sliding plate. A prestress material is arranged between the second sliding plate and the first sliding plate. The prestress material sequentially penetrates thefirst sliding plate and the second sliding plate and is anchored to a first anchorage device and a second anchorage device. The inner side of a second force transmission plate is fixedly connected with the outer sleeving force transmission steel pipe, and the outer side of the second force transmission plate is fixedly connected with a second connecting part. The novel four-casing-pipe buckling restrained brace is reliable, reasonable and great in practicability.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

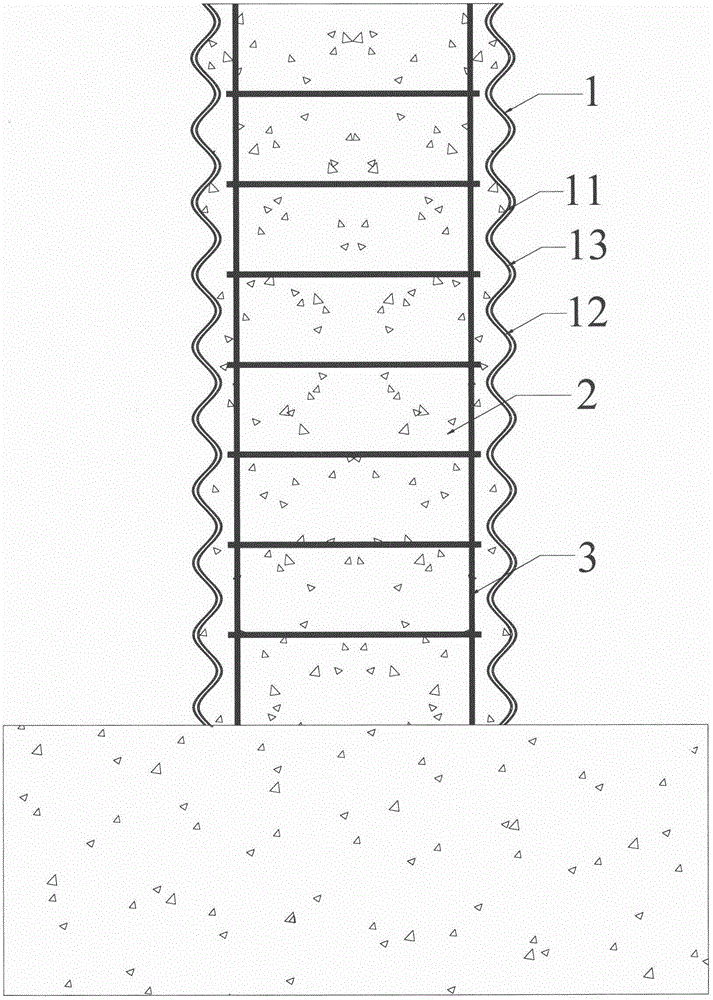

Cast-in-place skeleton net hollow filler wall

InactiveCN102758492AIncreased out-of-plane stiffnessLess materialWallsHeat proofingStructural engineeringMaterials science

The invention discloses a cast-in-place skeleton net hollow filler wall which comprises a skeleton net (1). A cast-in-place surface layer (4) and a seal surface layer (5) are arranged at outer ends of two sides of the skeleton net (1) respectively, and vertical ribs (2) and horizontal ribs (3) are sequentially arranged between the skeleton net (1) and the cast-in-place surface layer (4). According to integration of economic indicators and construction periods, the cast-in-place skeleton net hollow filler wall has an advantage over an existing air-entrapping concrete building block filler wall and a hollow internal mold metal net cement internal partition wall, has the advantages of being high in industrialized production degree and simple in site operation process, and overcomes the shortcomings in the prior art.

Owner:贵州皆盈科技开发有限公司

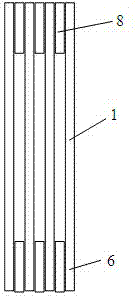

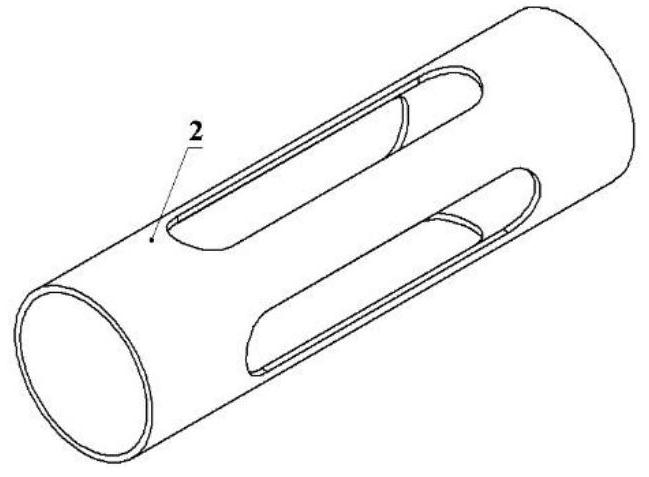

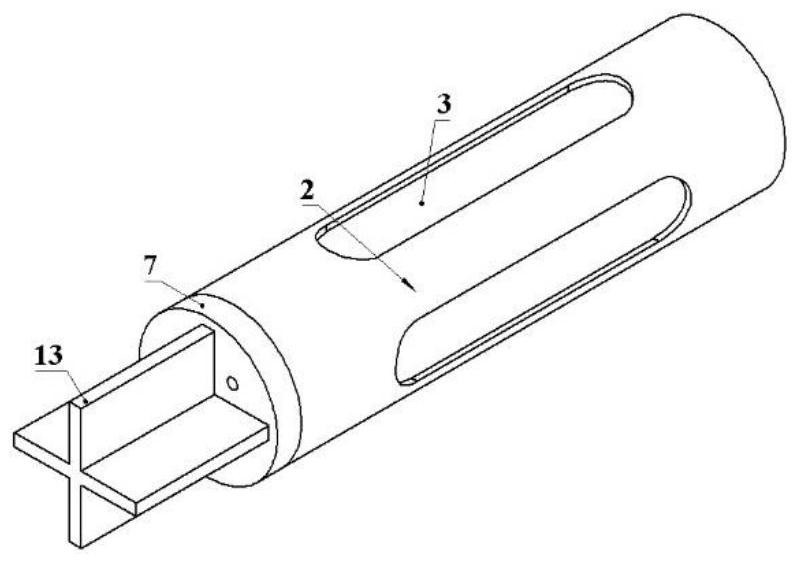

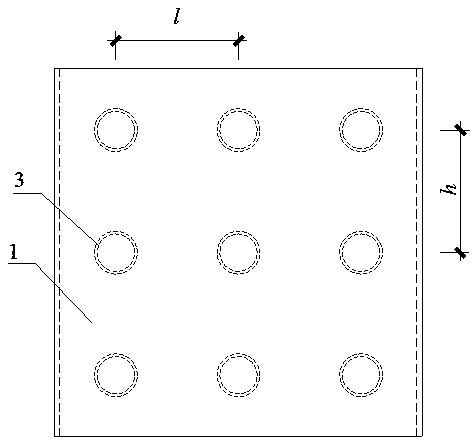

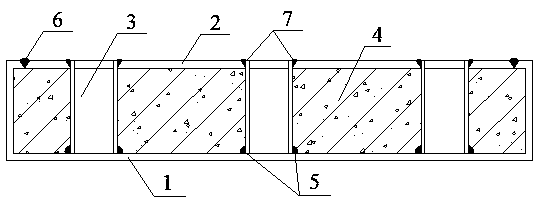

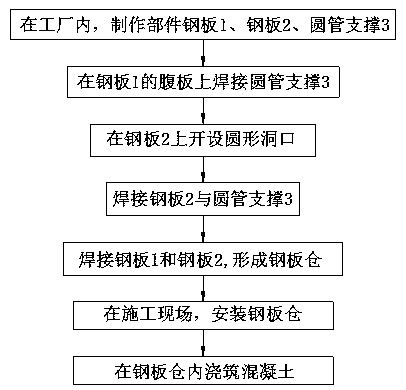

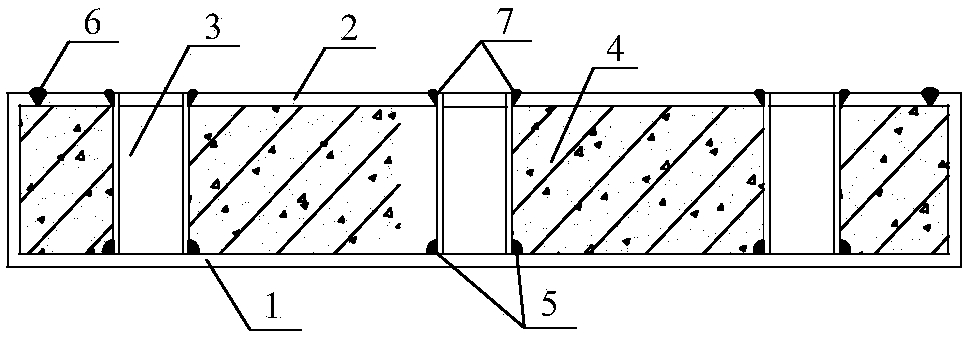

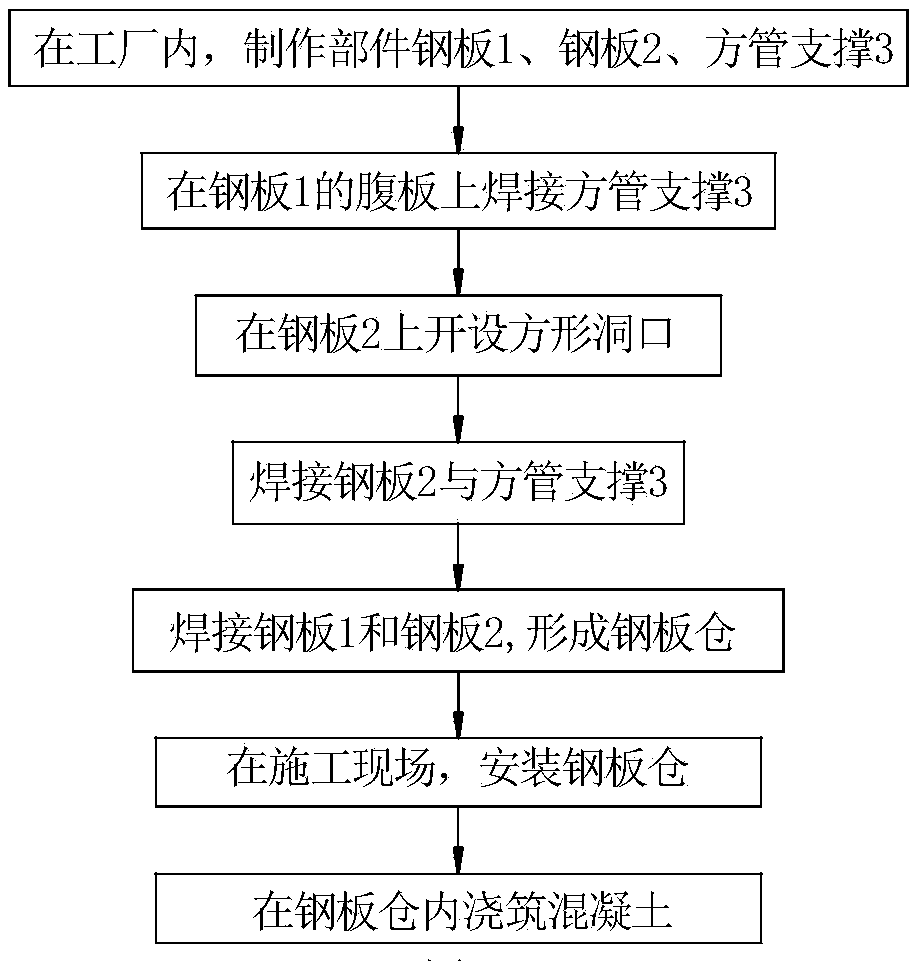

Circular tube support steel plate silo and manufacture method

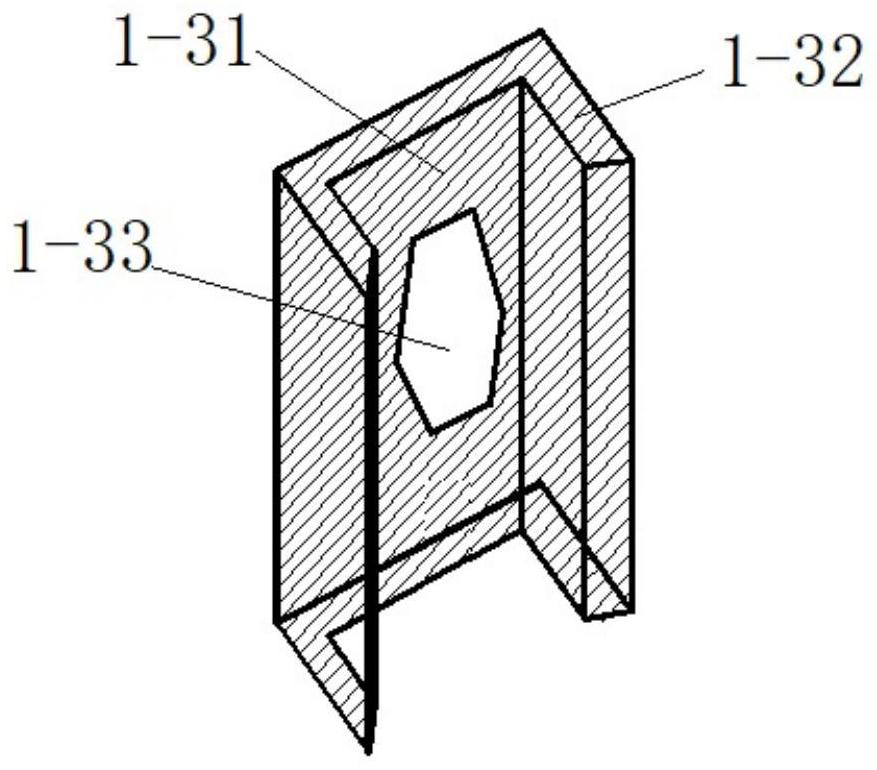

InactiveCN108149835AIncreased out-of-plane stiffnessGuaranteed Out-of-Plane StiffnessConstruction materialSheet steelSilo

The invention belongs to the field of shear wall structures, and relates to a circular tube support steel plate silo and a manufacture method thereof. A basic unit is composed of a steel plate 1 and asteel plate 2, and two sides of the basic unit are the steel plate 1 and the steel plate 2; and the middle of the two steel plates are welded with circular tube supports 3, the steel plate 1 and thesteel plate 2 form a steel plate silo, and concrete is poured into the steel plate silo. The manufacture method of the circular tube support steel plate silo comprises the steps that in a factory, thesteel plate 1 is bent to a groove shape with roll rims, and the circular tube supports 3 are welded on the steel plate 1; a circular hole is formed in the steel plate 2; the steel plate 1 and the steel plate 2 are welded; and at the construction site, the concrete is poured into the steel plate silo formed by the steel plate 1 and the steel plate 2. The circular tube supports are welded on the middle of the two steel plates, so that the rigidity outside steel plate planes is increased; a penetrating hollow silo is formed by the two steel plates and the circular tube supports, so that the compactness of the concrete is easy to ensure; and the large-scale steel plate silo can be formed by the basic unit, so that steel can be saved, the welding quantity can be reduced and the splicing efficiency can be improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

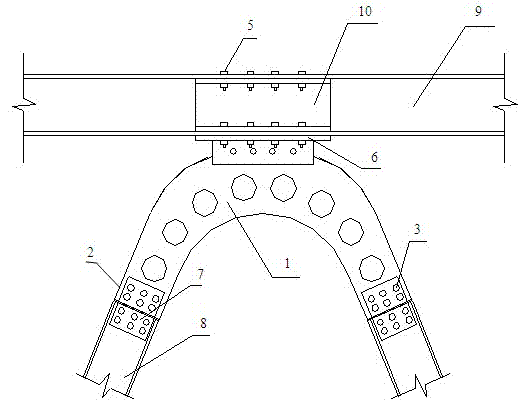

Multiple arched porous metal damper

InactiveCN102505769ALarge yield area of steelGood energy consumptionShock proofingSteel platesSheet steel

The invention provides a multiple arched porous metal damper, and relates to a shake controller for a building structure. The multiple arched porous metal damper comprises an energy consumption part, fixation parts, bolt holes, internal circular holes, an I-shaped sway brace and an I-shaped steel beam, wherein the energy consumption part of the damper is arched in outline, the energy consumption part is internally provided with a plurality of circular holes, and the circular holes are regularly arranged according to an arched trend. The fixation parts are rectangular, and are internally provided with the bolt holes, the fixation parts and the energy consumption part are mild and tangent to transit, two or more mild steel dampers are assembled together, the two lower fixation parts are connected with the I-shaped sway brace by virtue of the rectangular steel plate, and the upper fixation part is connected with the I-shaped steel beam. The steel material of the damper is larger in yield surface, good in energy consumption effect and high in steel material use ratio, the whole rigidity of the building structure can be increased when the damper is used under a normal status, in the earthquake, the earthquake reaction of the building structure can be reduced due to the yield energy consumption of the steel plate damper, and the building structure can be well protected.

Owner:SHENYANG JIANZHU UNIVERSITY

Cold-bending thin-walled steel lattice column composite wall with built-in straw grass brick

PendingCN109944365AHas viscoelastic propertiesWith thermal insulationWallsProtective buildings/sheltersBrickThermal insulation

The invention discloses a cold-bending thin-walled steel lattice column composite wall with a built-in straw grass brick. The wall comprises a composite wall skeleton formed by a cold-bending thin-walled steel lattice column and a top guide rail and a bottom guide rail, the composite wall skeleton is filled with the straw grass brick, and cover panels are fixed to both sides of the composite wallskeleton. The wall has high shear resistance and compression bearing capacity and large out-of-plane stiffness, provides convenience for the combination wall to absorb and dissipate seismic energy, has the advantages of green environmental protection, thermal insulation, sound insulation and noise reduction, and achieves structural heat insulation integration. In a low-rise and multi-story steel structure building, the strength, stiffnes and ability to absorb and dissipate the seismic energy of the structure can be significantly improved, it is convenient to manufacture and process, the wall can be prefabricated and produced in a plant, and on-site assembly and construction are achieved; waste is turned into a treasure, which can produce good social and economic benefits, help to protect the environment, promote the sustainable development of green buildings and has broad application prospects.

Owner:TIANJIN UNIV

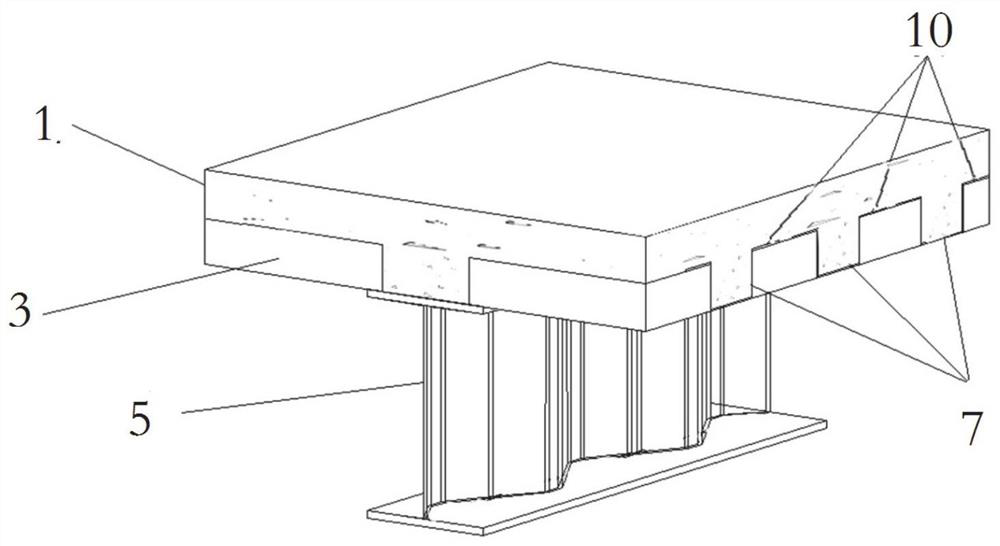

Steel-concrete composite beam structure, building and construction method

Owner:SHANDONG JIANZHU UNIV +2

Square tube support steel silo

InactiveCN108316516AIncreased out-of-plane stiffnessSave steelWallsSheet steelArchitectural engineering

The invention belongs to the technical field of construction engineering, and relates to a square tube support steel silo. A basic unit is composed of two steel plates and square tube supports. Two sides of the basic unit are provided with the steel plate 1 and the steel plate 2, wherein the cross section of the steel plate 1 is in a curled edge groove shape, the square tube supports are welded onthe steel plate 1, and square holes are formed in the positions, corresponding to the square tube supports, of the steel plate 2. The curled edges of the steel plate 1 are welded to the steel plate 2, and the square tube supports welded to the steel plate 1 are welded to the steel plate 2. Concrete is poured into an empty silo formed by the steel plate 1 and the steel plate 2. The square tube supports are arranged in the middle of the two steel plates, so that the out-of-plane stiffness of the steel plates is increased; the two steel plates and the square tube supports form the through emptysilo, so that the compactness of concrete pouring can be ensured; and the basic unit can form a large-sized composite shear wall, so that steel is saved, the welding quantity is less, and the splicingefficiency is high.

Owner:QINGDAO TENGYUAN DESIGN ACCOUNTANTS CO LTD

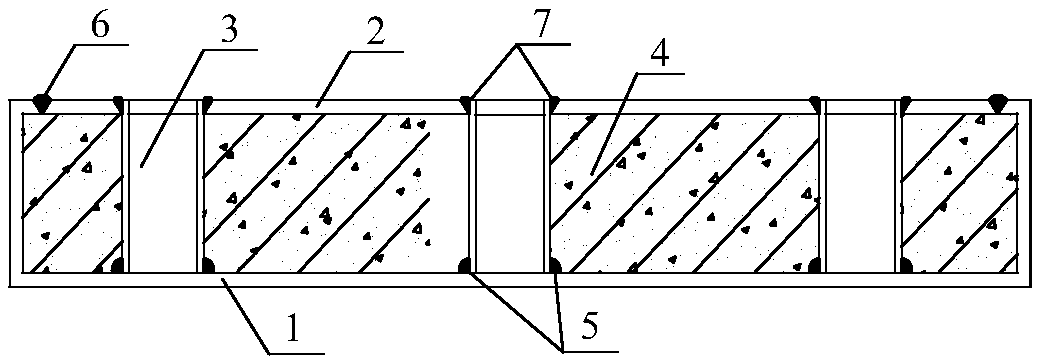

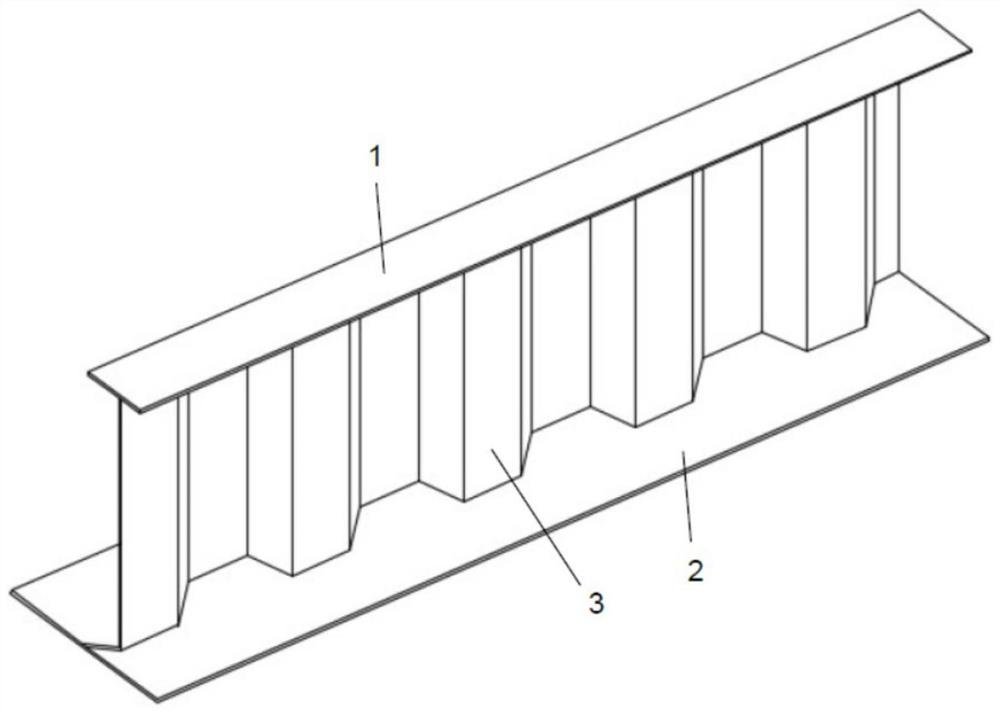

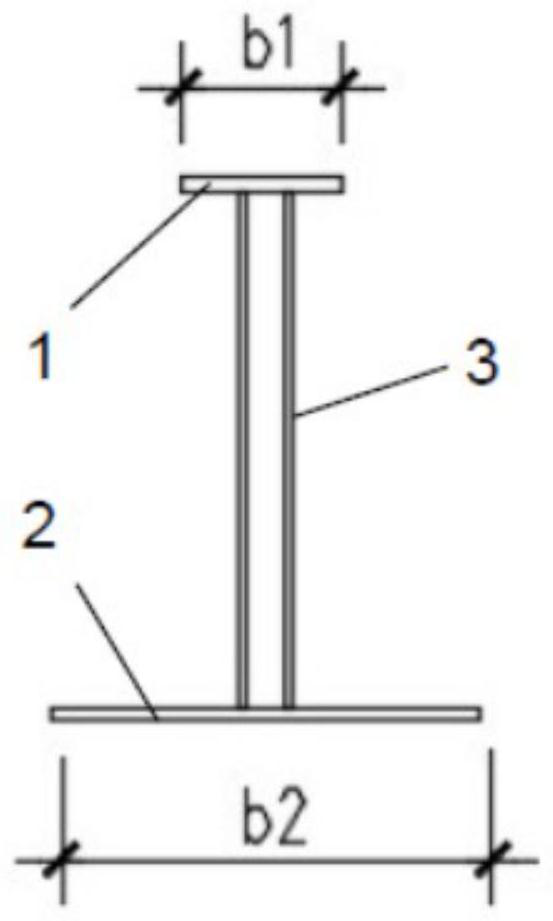

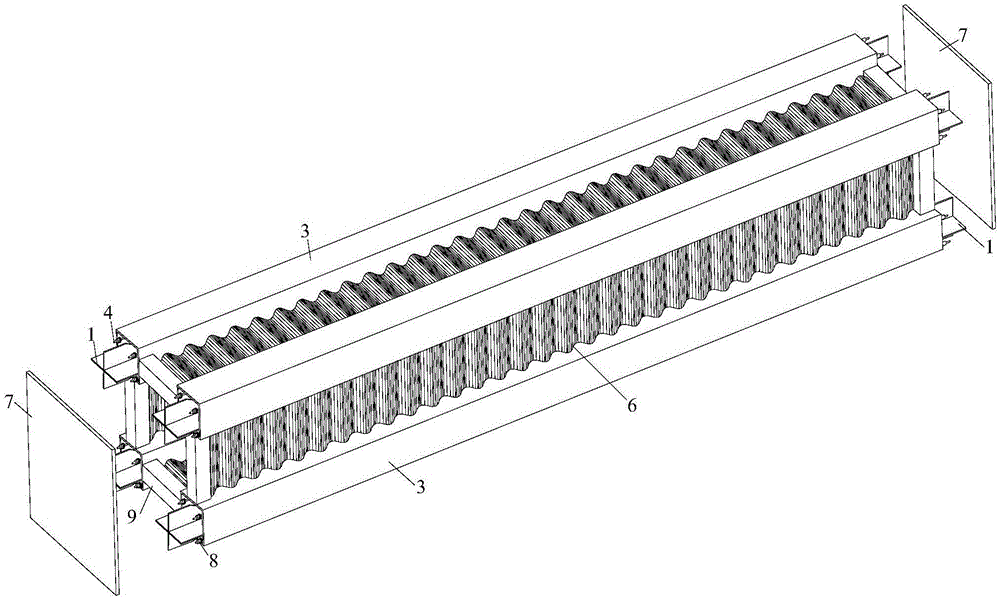

Construction method of novel unequal-flange steel-concrete combined corrugated web H-shaped beam

InactiveCN112982987AAvoid stiffenersIncreased out-of-plane stiffnessFloorsGirdersFloor slabShaped beam

The invention discloses a construction method of a novel unequal-flange steel-concrete combined corrugated web H-shaped beam. The construction method comprises the following steps that firstly, an upper flange plate, a lower flange plate, a corrugated web, a tie stirrup, concrete, a formwork and an arch-shaped clamp are provided; secondly, the upper flange plate, the lower flange plate and the corrugated web are welded to form an H-shaped steel framework, and then the tie stirrup is welded to the H-shaped steel framework; thirdly, the H-shaped steel framework is installed on a floor slab, then the formwork and the H-shaped steel framework are fixed together through the arch-shaped clamp to form a composite beam, and a pouring opening is reserved in the composite beam; and fourthly, the composite beam and the floor slab are integrally poured through the pouring opening. The construction method has the beneficial effects that the steel consumption and the welding workload are reduced, so that steel is saved, and the economic benefit is improved; construction is easy and convenient, the integrity of the beam and the floor slab is enhanced, pouring of a large number of post-pouring sections is avoided, and the construction efficiency is greatly improved.

Owner:湖南嘉晟住建科技有限公司

Ribbed net rack superimposed wall structure and construction method

The invention discloses a ribbed net rack superimposed wall structure and a construction method. The ribbed net rack superimposed wall structure comprises a concrete precast structural layer, a heat insulation layer and a reinforced concrete cast-in-place unit, the concrete precast structural layer is provided with a concrete rib protrusion embedded in the heat insulation layer in the vertical direction or the horizontal and vertical directions, an anti-deformation part is placed in the position, close to the heat insulation layer, in the concrete rib protrusion, and the reinforced concrete cast-in-place unit is arranged on one side of the heat insulation layer; the concrete precast structural layer is composed of a light aggregate concrete layer close to the heat insulation layer and an outer fine aggregate concrete layer, the concrete precast structural layer is composed of a single concrete layer, and the anti-deformation part is thin-walled steel; and the concrete precast structural layer contains reinforcing meshes, and a first reinforcing mesh is welded with an oblique-cutting web bar penetrating through the heat insulation layer and a second reinforcing mesh on the other side of the heat insulation layer to form a space net rack. The concrete rib protrusion can increase the stiffness out of plane of the structural layer, and ensure that the precast unit cannot be brokenin the hoisting process.

Owner:河北新农建节能科技有限公司

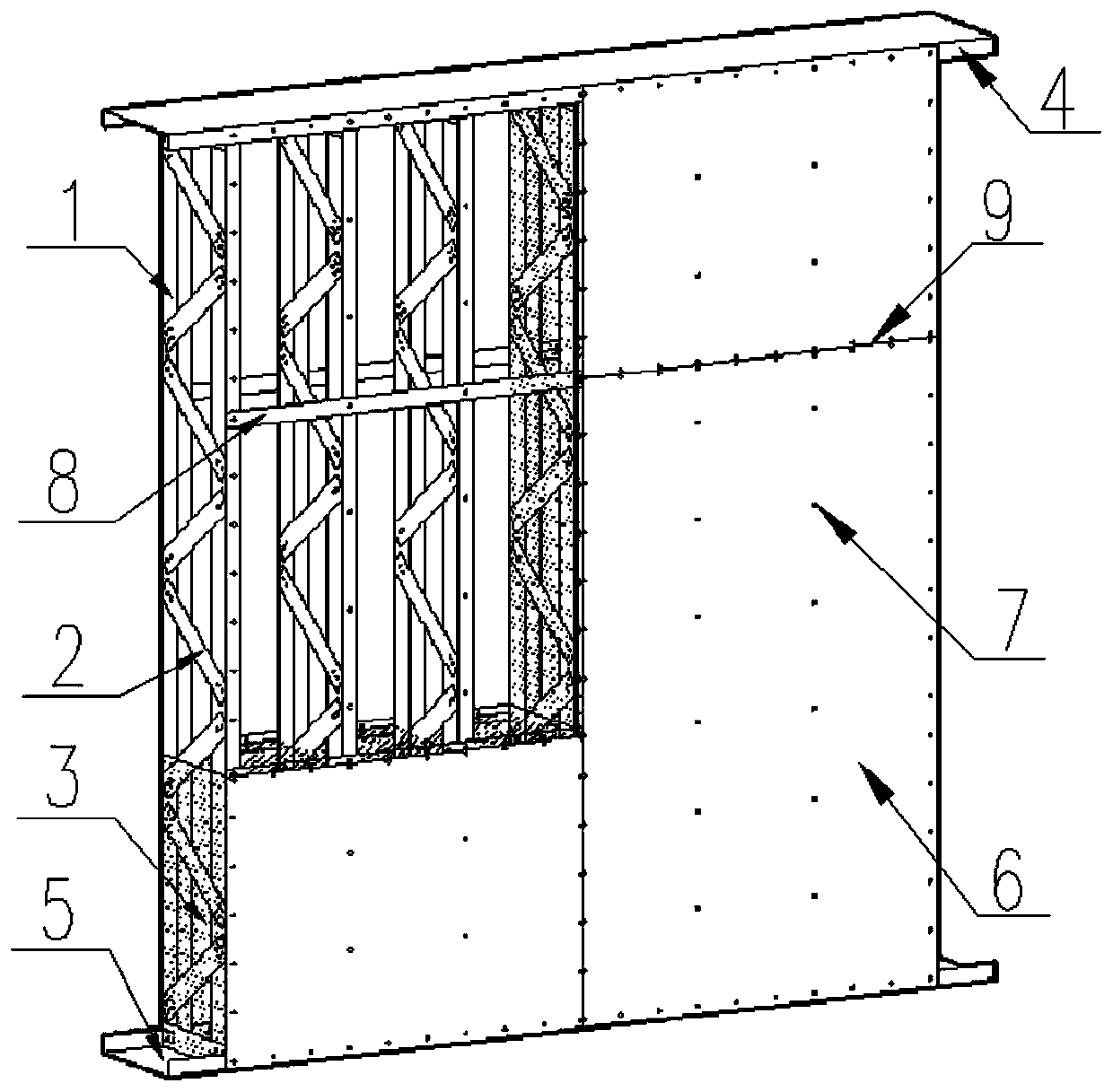

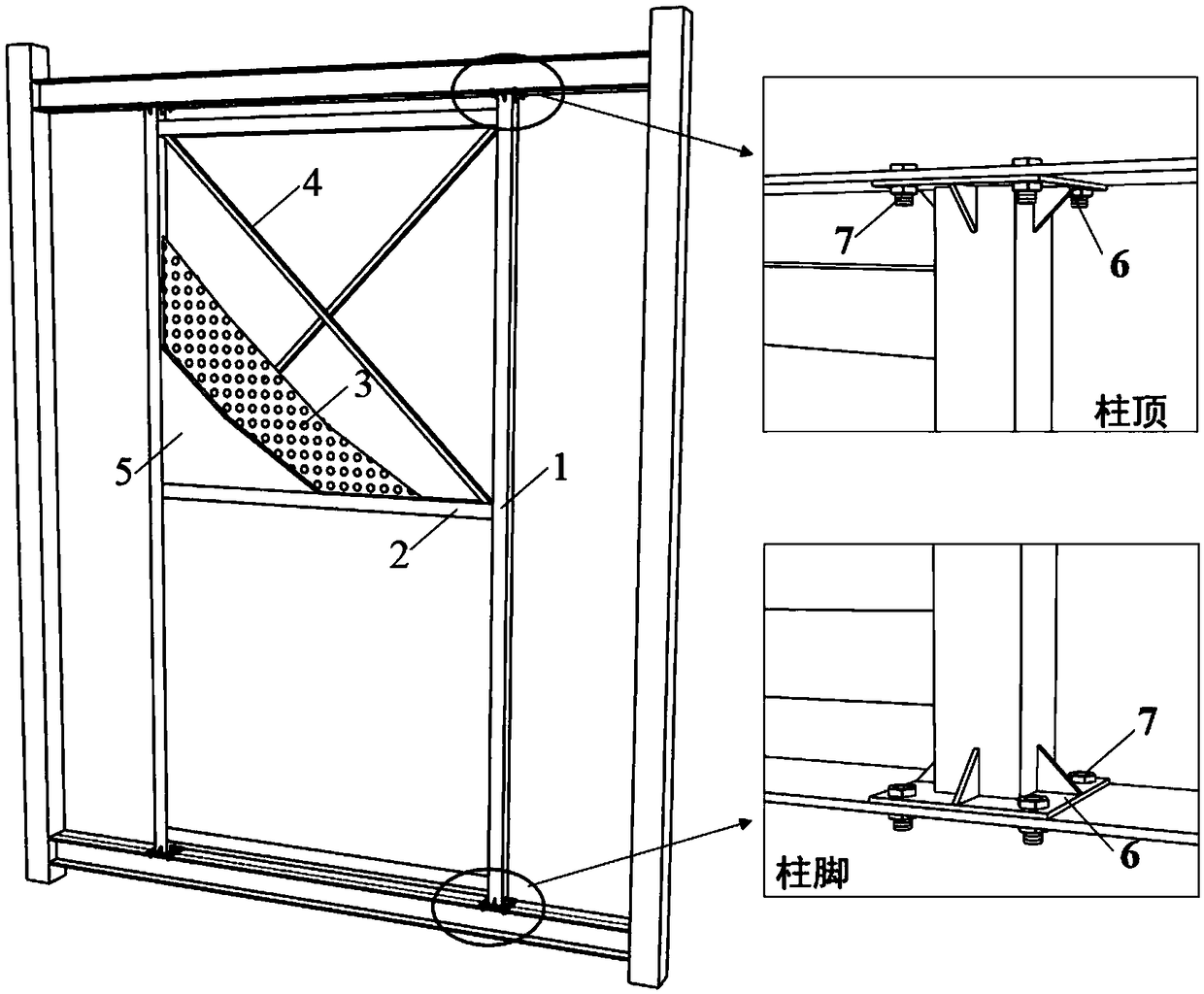

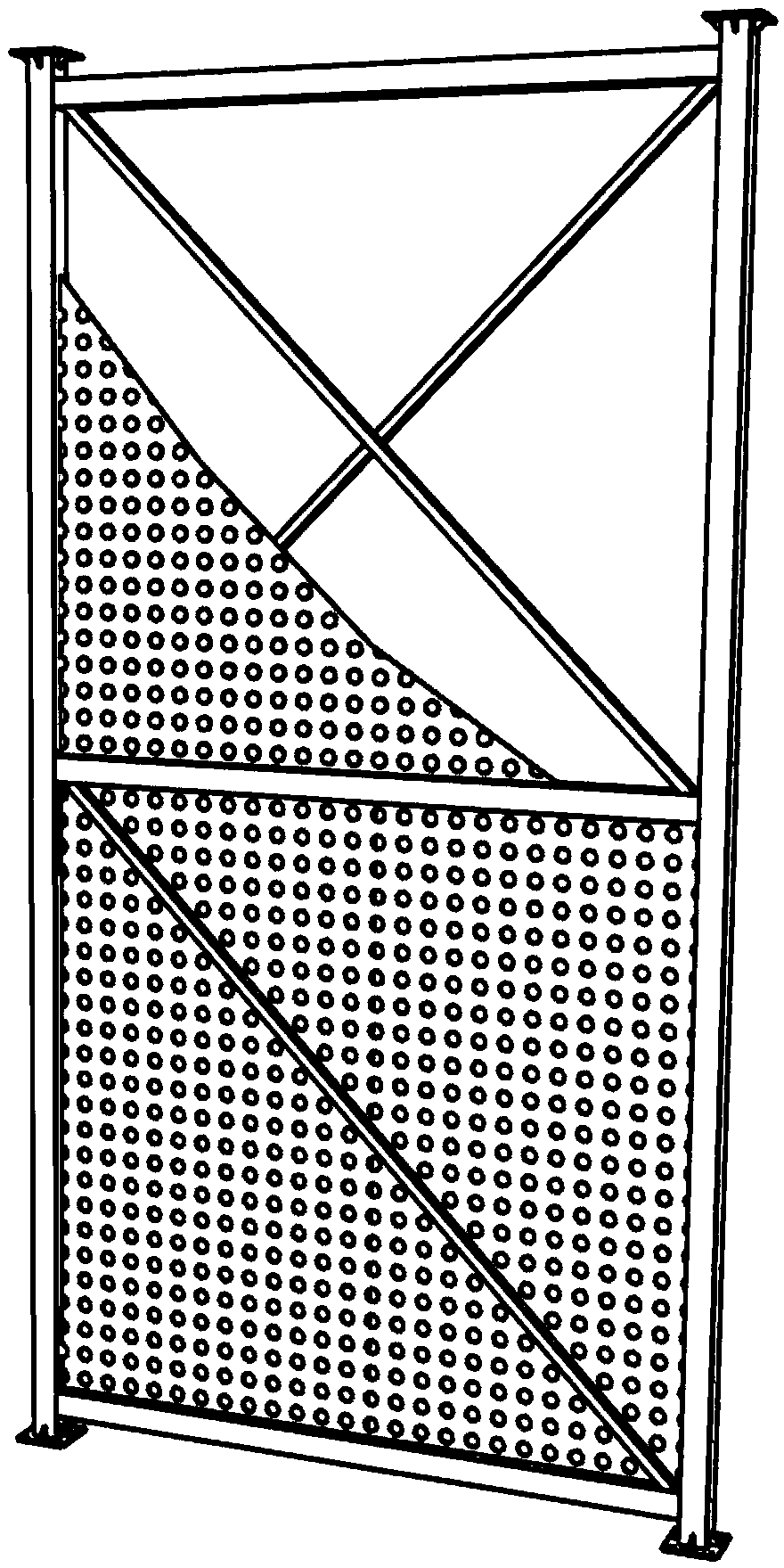

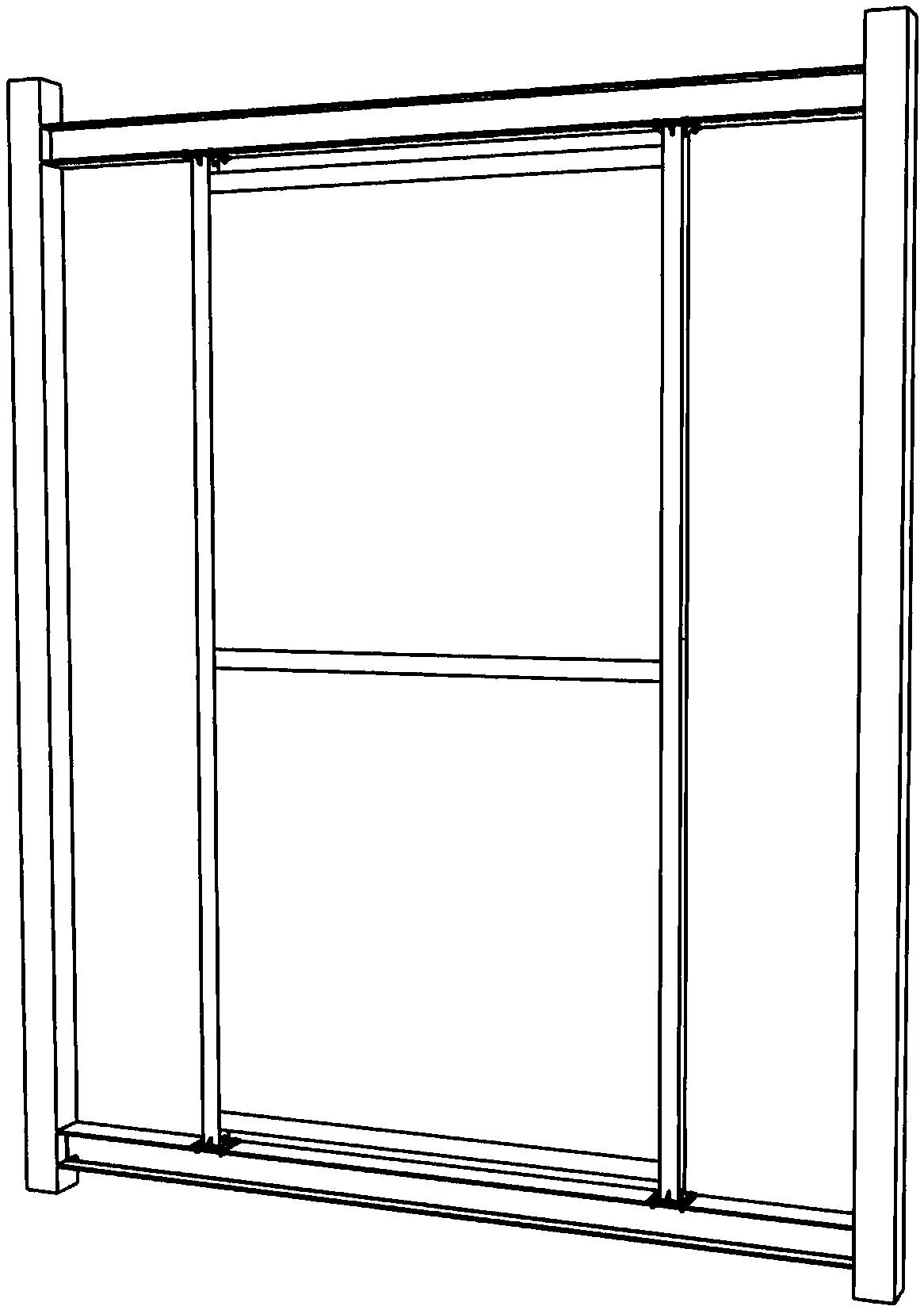

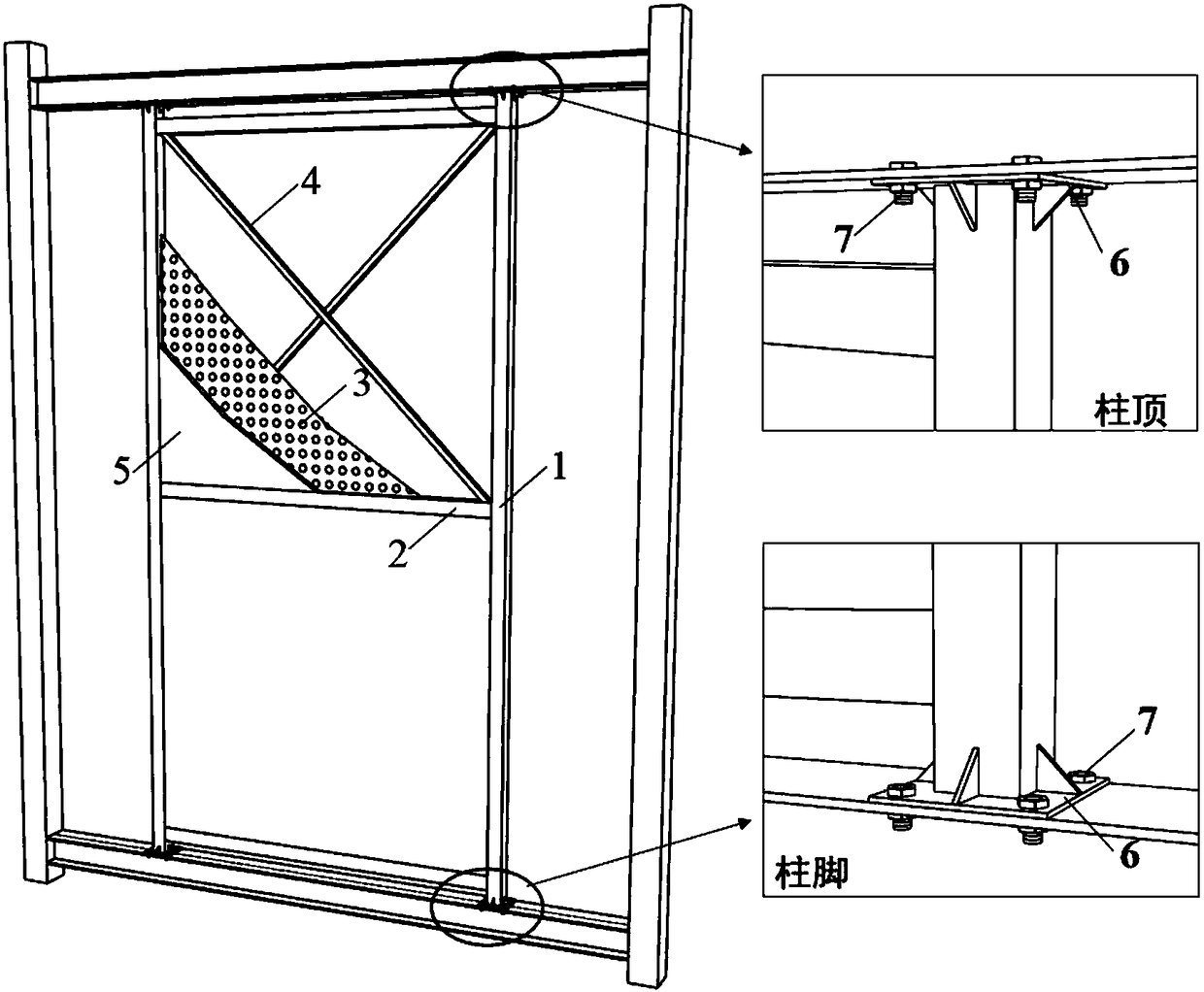

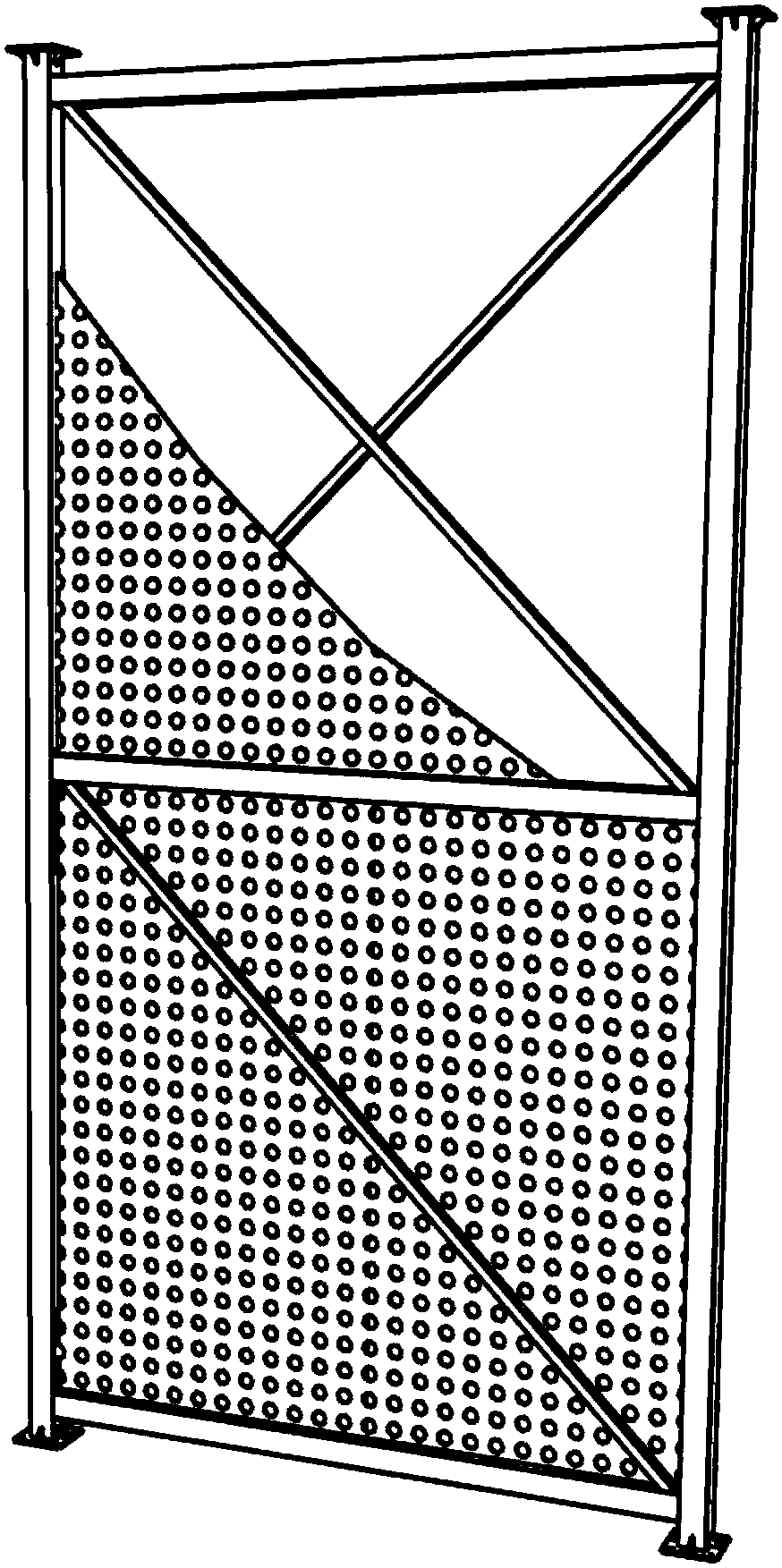

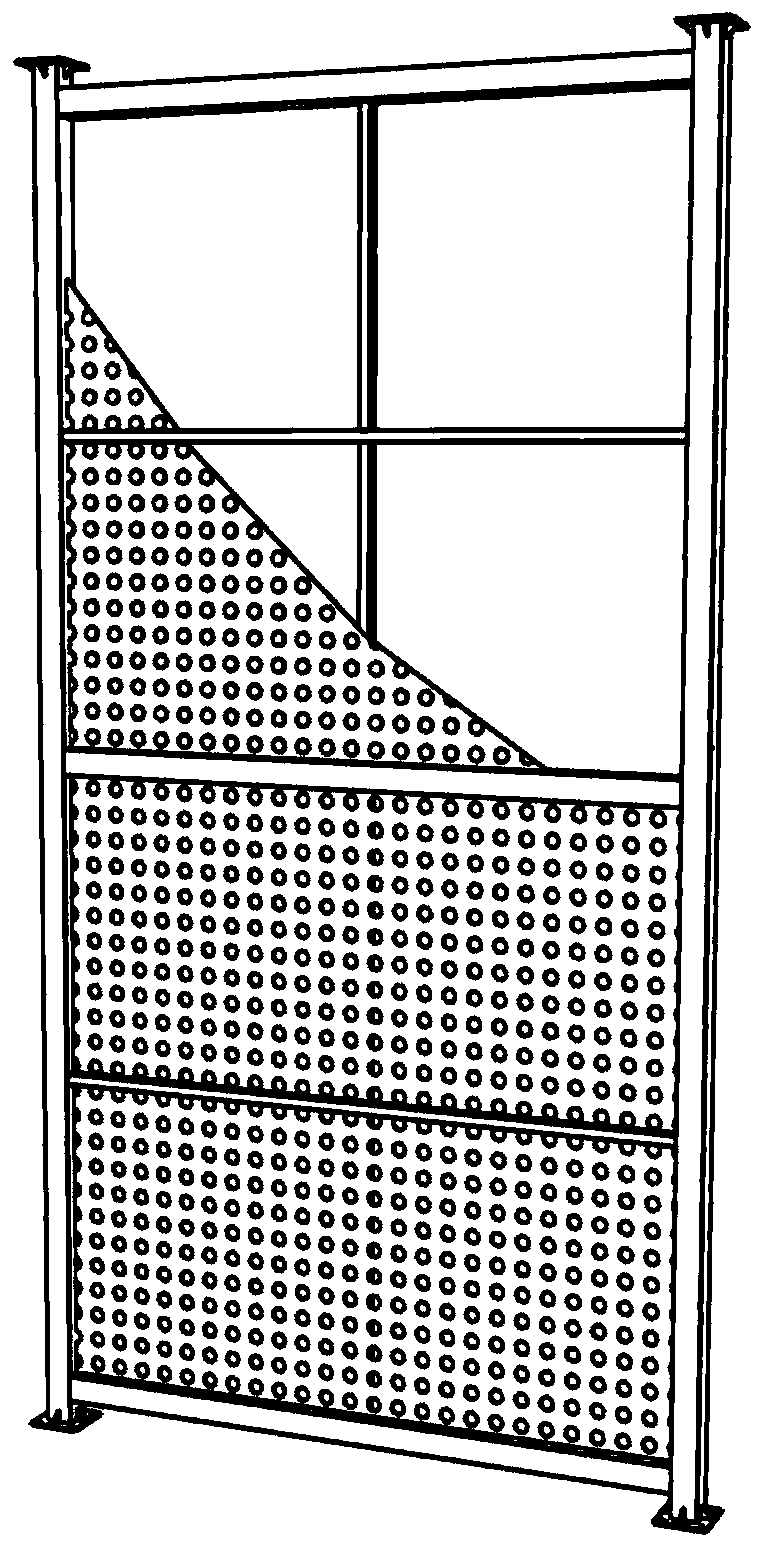

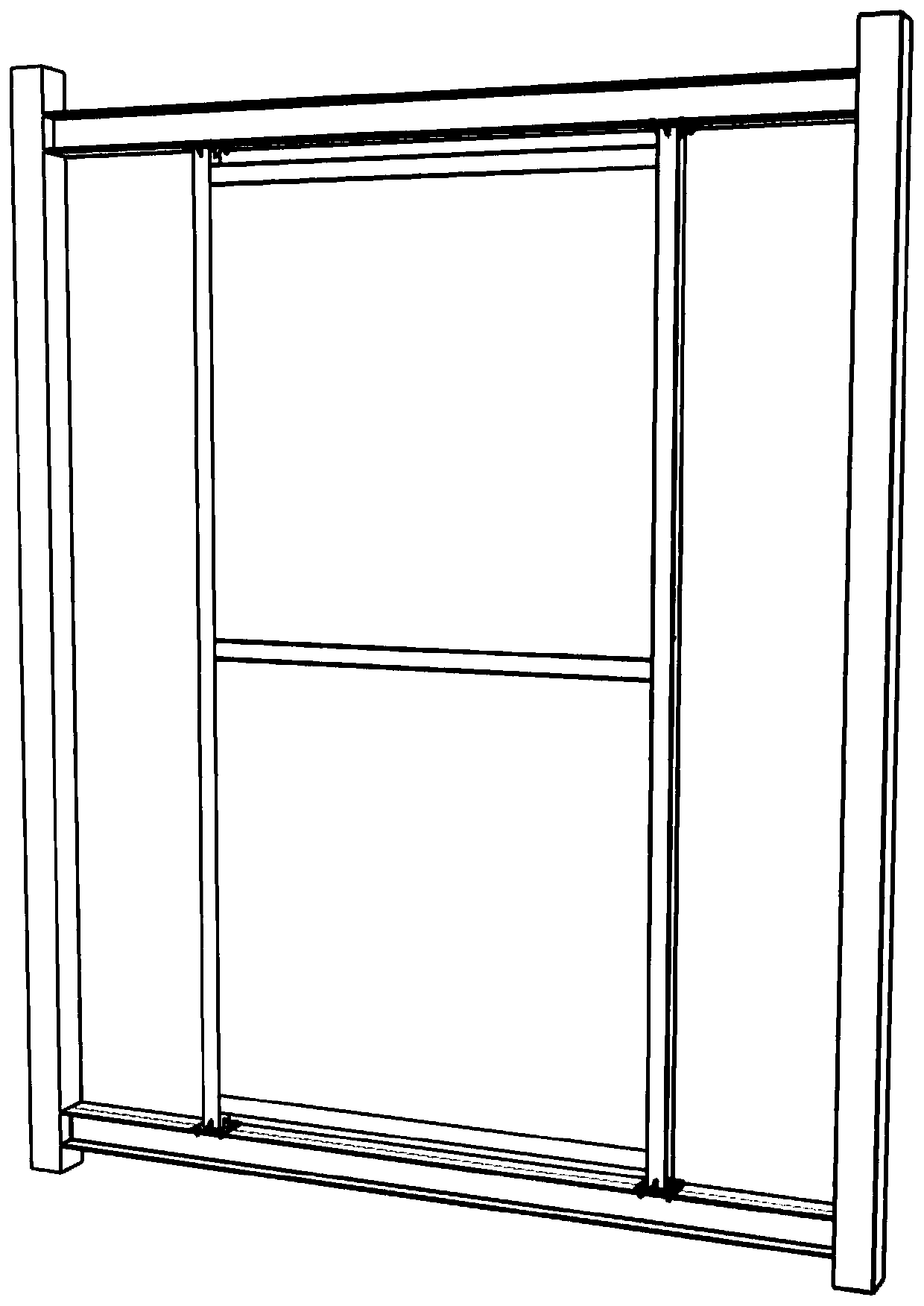

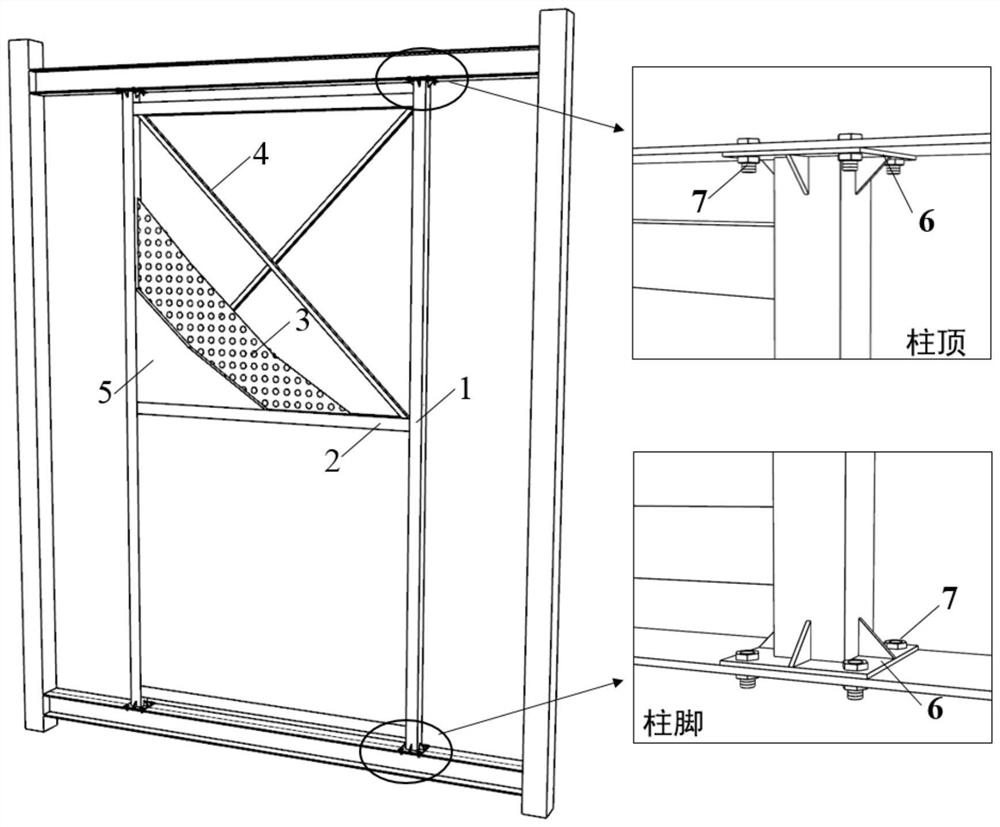

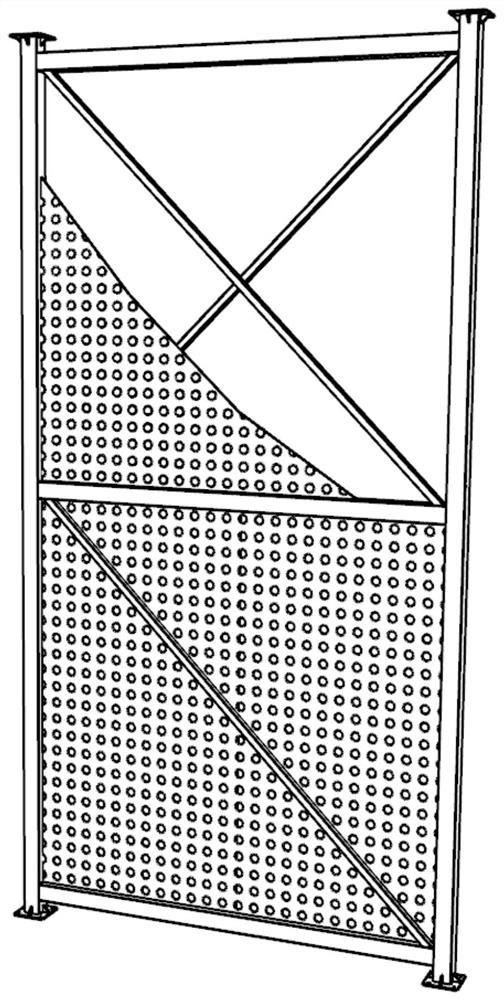

Prefabricated truss type light steel frame-punching thin steel plate-foamed concrete composite wall

ActiveCN108643390ASolve the current situation of lack of anti-seismic measures and weak anti-seismic abilityImprove carrying capacityWallsSteel tubeOut of plane

The invention relates to a prefabricated truss type light steel frame-punching thin steel plate-foamed concrete composite wall. A concrete filled steel tube frame column, a concrete filled steel tubeframe beam and concrete filled steel tube truss ribs together form a wallboard concrete filled steel tube truss stress system, a composite wall steel skeleton is formed by the wallboard concrete filled steel tube truss stress system and a punching thin steel plate, and the integrality of a wallboard is improved. Novel light insulation material foamed concrete is used for pouring the wallboard, theprefabricated truss type light steel frame-punching thin steel plate-foamed concrete composite wall is formed after maintenance, and the composite wall can be assembled to an external structure onlyby connecting bolts. The prefabricated truss type light steel frame-punching thin steel plate-foamed concrete composite wall is integrated in heat preservation, has good bending resistance, shear capacity and out of plane stiffness, the anti-seismic property is good, meanwhile, the wallboard is manufactured in a factory and assembled on site, the common quality problems caused by site constructioncan be effectively resolved, the construction efficiency of the project is greatly improved, the amount of labor used of engineering is reduced, and the prefabricated truss type light steel frame-punching thin steel plate-foamed concrete composite wall is suitable for wide application in the structure of low-rise multi-storey rural houses in villages and towns.

Owner:BEIJING UNIV OF TECH

Square pipe supporting steel plate bunker and manufacturing method

InactiveCN108222361AIncreased out-of-plane stiffnessSave steelConstruction materialMetallurgyPipe support

The invention belongs to the field of shear wall structures, and relates to a round pipe supporting steel plate bunker and a manufacturing method thereof. A basic unit is formed by a steel plate 1 anda steel plate 2, the steel plate 1 and the steel plate 2 are arranged on the two sides of the basic unit, round pipe supports 3 are arranged between the two steel plates in a welding mode, a steel plate bunker is formed by the steel plate 1 and the steel plate 2, and concrete is poured into the steel plate bunker. The manufacturing method of the round pipe supporting steel plate bunker comprisesthe following steps that in a factory, the steel plate 1 is bent to form a groove shape with a roll rim, and the round pipe supports 3 are connected with the steel plate 1 in a welding mode; square openings are formed in the steel plate 2; the steel plate 1 and the steel plate 2 are welded; and the concrete is poured into the steel plate bunker formed by the steel plate 1 and the steel plate 2 atthe construction site. The round pipe supports 3 are arranged between the two steel plates, and the external stiffness of steel plates is increased; an empty bunker is formed by the two steel plates and the round pipe supports, and the compactness of the concrete can be easily ensured; and the basic unit can form a large size steel plate bunker, steels can be saved, the welding quantity is reduced, and the efficiency of splicing is improved.

Owner:QINGDAO TENGYUAN DESIGN ACCOUNTANTS CO LTD

Fabricated truss type light steel frame-punched thin steel plate-concrete composite wall

ActiveCN108277903AImprove carrying capacityImprove seismic performanceWallsCeramic shaping apparatusSheet steelSteel frame

The invention relates to a fabricated truss type light steel frame-punched thin steel plate-concrete composite wall and a manufacture method thereof. Concrete-filled steel tube frame columns, concrete-filled steel tube frame beams and wall concrete-filled steel tube truss ribs together form a wall plate concrete-filled steel tube truss stress system and then form a composite wall steel frame together with punched thin steel plates, so that the integrity of wall panels is improved, concrete is poured in a formwork, and after maintenance, the fabricated truss type light steel frame-punched thinsteel plate-concrete composite wall is formed and is fabricated to an external structure simply by connecting bolts. The fabricated truss type light steel frame-punched thin steel plate-concrete composite wall has good bending resistance, shear bearing capacity and stiffness out of panel, and good anti-seismic performance; and at the same time, wall panels are manufactured by a factory and fabricated on site to effectively solve the common quality problems caused by on-site construction, the efficiency of engineering construction is improved greatly, the amount of labor used in construction isreduced, and the fabricated truss type light steel frame-punched thin steel plate-concrete composite wall is suitable for wide popularization and application in low-storey agricultural house structures of villages and towns.

Owner:BEIJING UNIV OF TECH

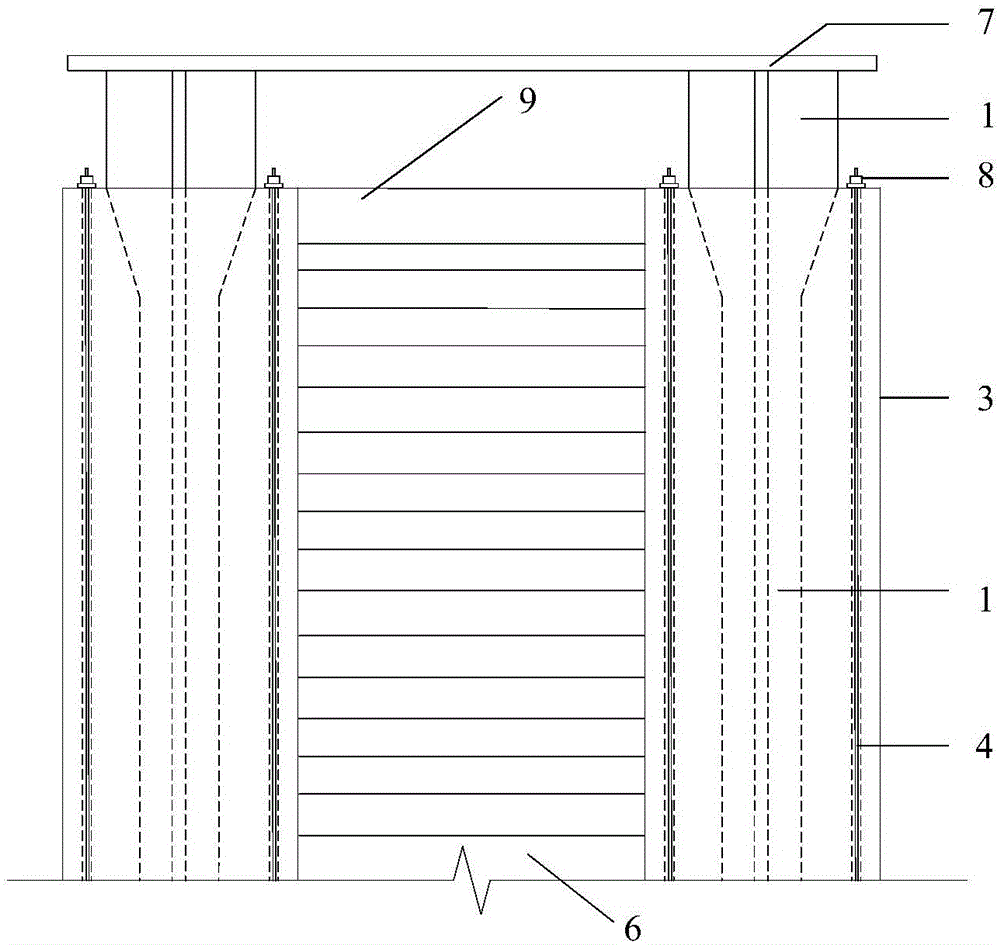

Four-limb pre-stressed anti-buckling member connected through wavy webs

InactiveCN105155713AIncreased bending stiffnessIncreased out-of-plane stiffnessBuilding repairsShock proofingSquare cross sectionPre stress

A four-limb pre-stressed anti-buckling member connected through wavy webs is characterized in that the anti-buckling member comprises four cross core prestressed concrete filled steel pipe constraint type anti-buckling support limbs, four wavy webs, two end part end plates and eight end part reinforcing square steel pipes; each of the four cross core prestressed concrete filled steel pipe constraint type anti-buckling support limbs in the member comprises a cross core energy consumption member, a nonbonded material, a peripheral constraint square steel pipe, a prestressed rope and concrete; and the four limbs are distributed in the axis direction in parallel and sequentially connected through the four wavy webs in a welding manner so as to form a lattice type anti-buckling member with a square cross section. The four-limb pre-stressed anti-buckling member adopting the lattice type cross section can greatly improve the anti-bending rigidity and the bearing capability of the peripheral constraint member and is suitable for structures with large-tonnage shock absorbing energy consumption requirements. The wavy webs can be made high and thin, the steel usage of the webs is greatly saved under the condition of meeting peripheral rigidity requirements, and the economic benefit is improved.

Owner:TSINGHUA UNIV

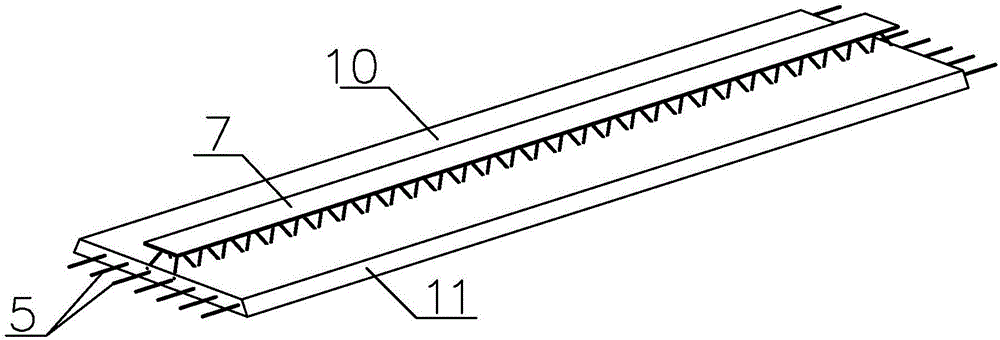

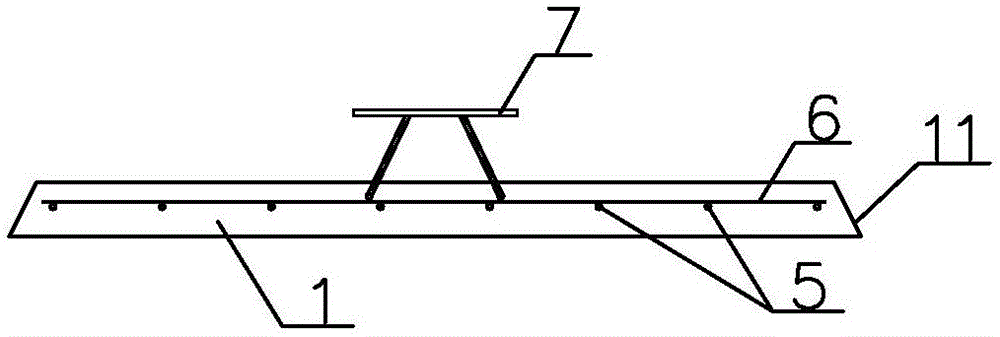

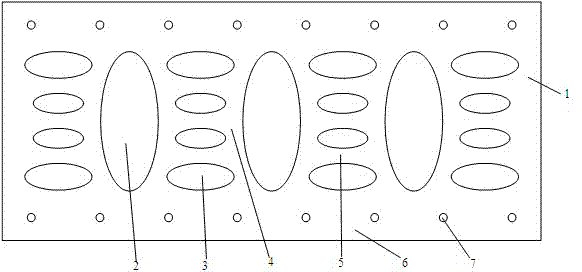

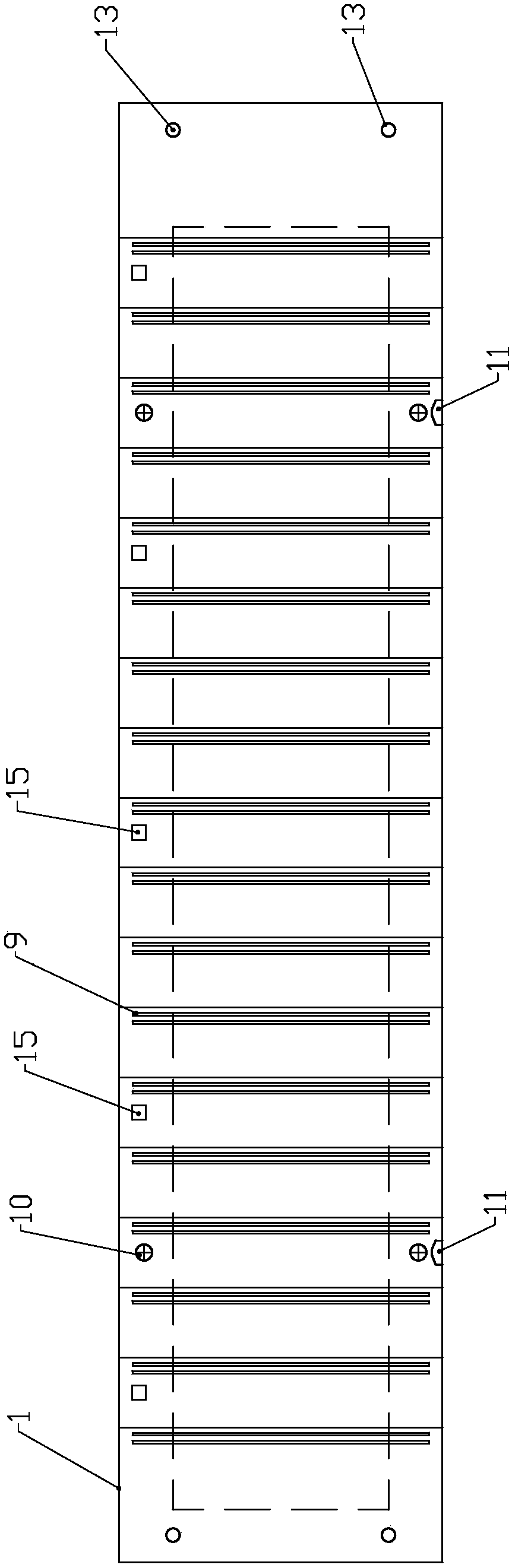

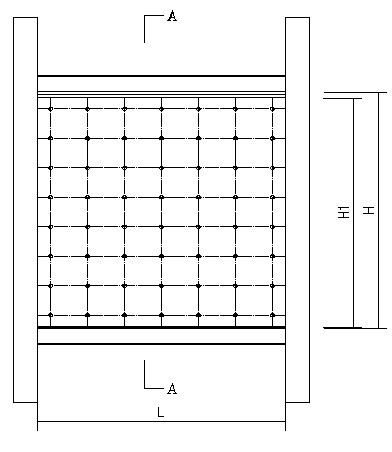

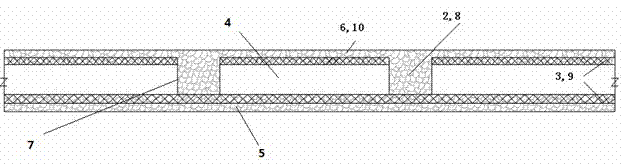

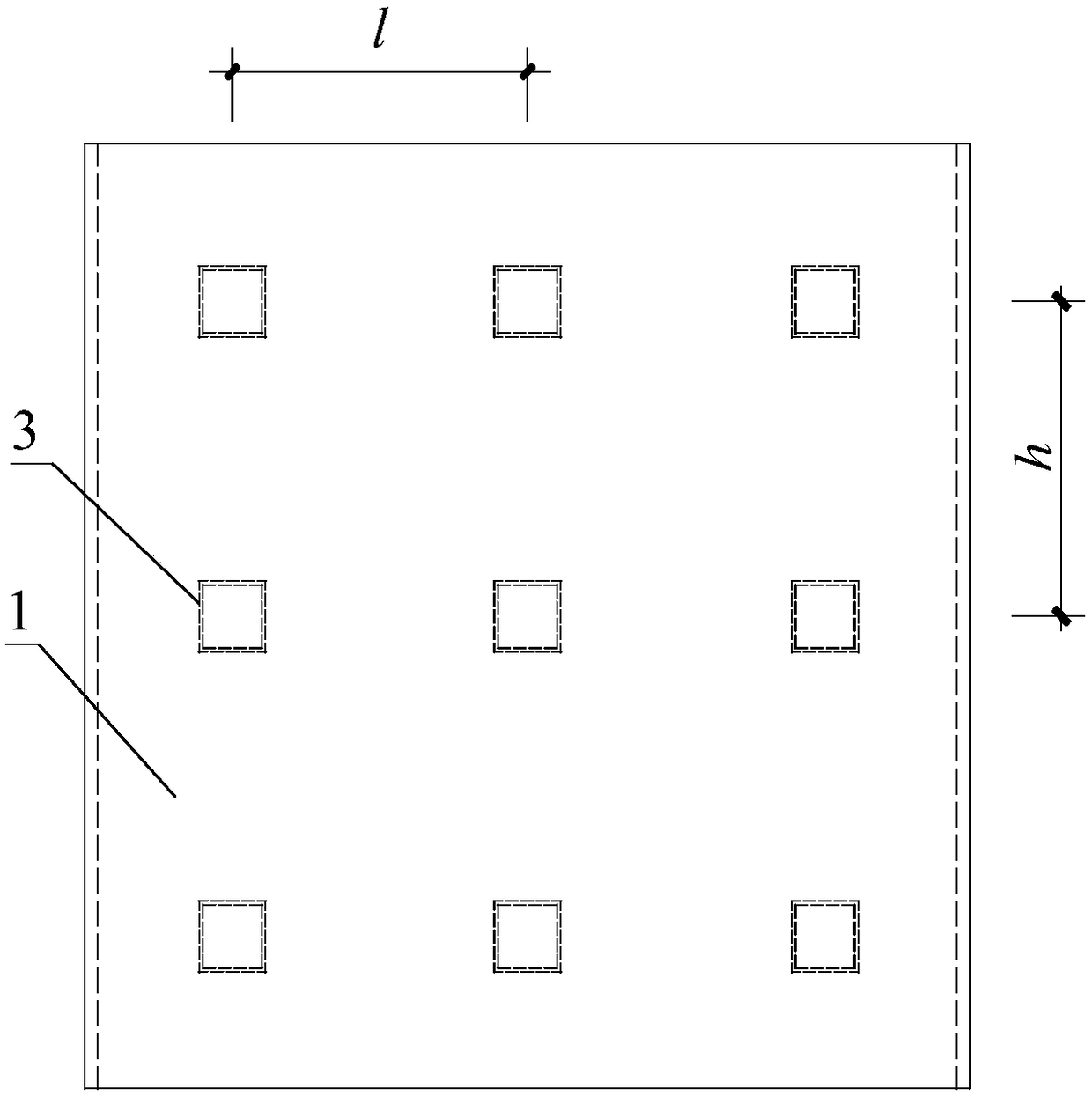

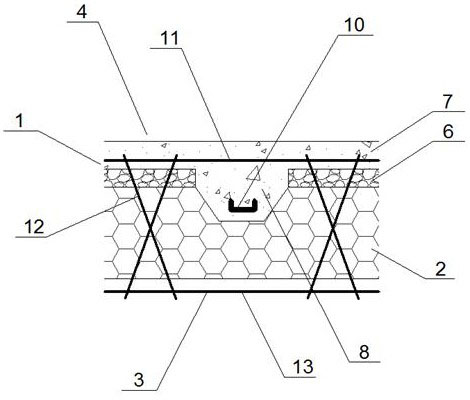

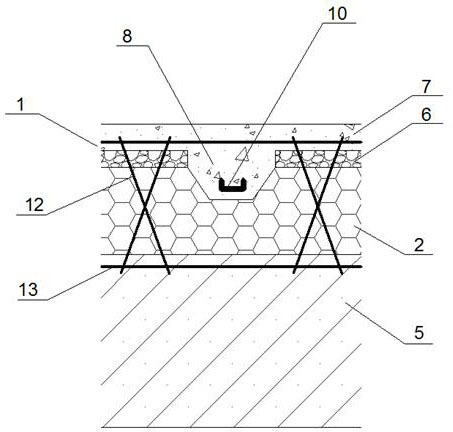

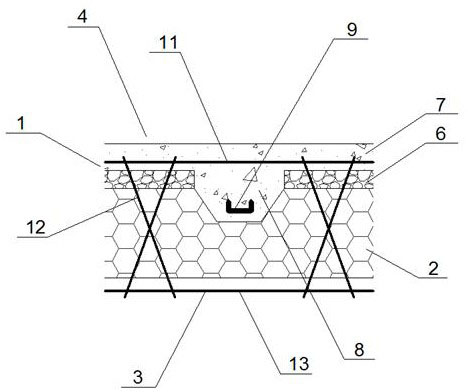

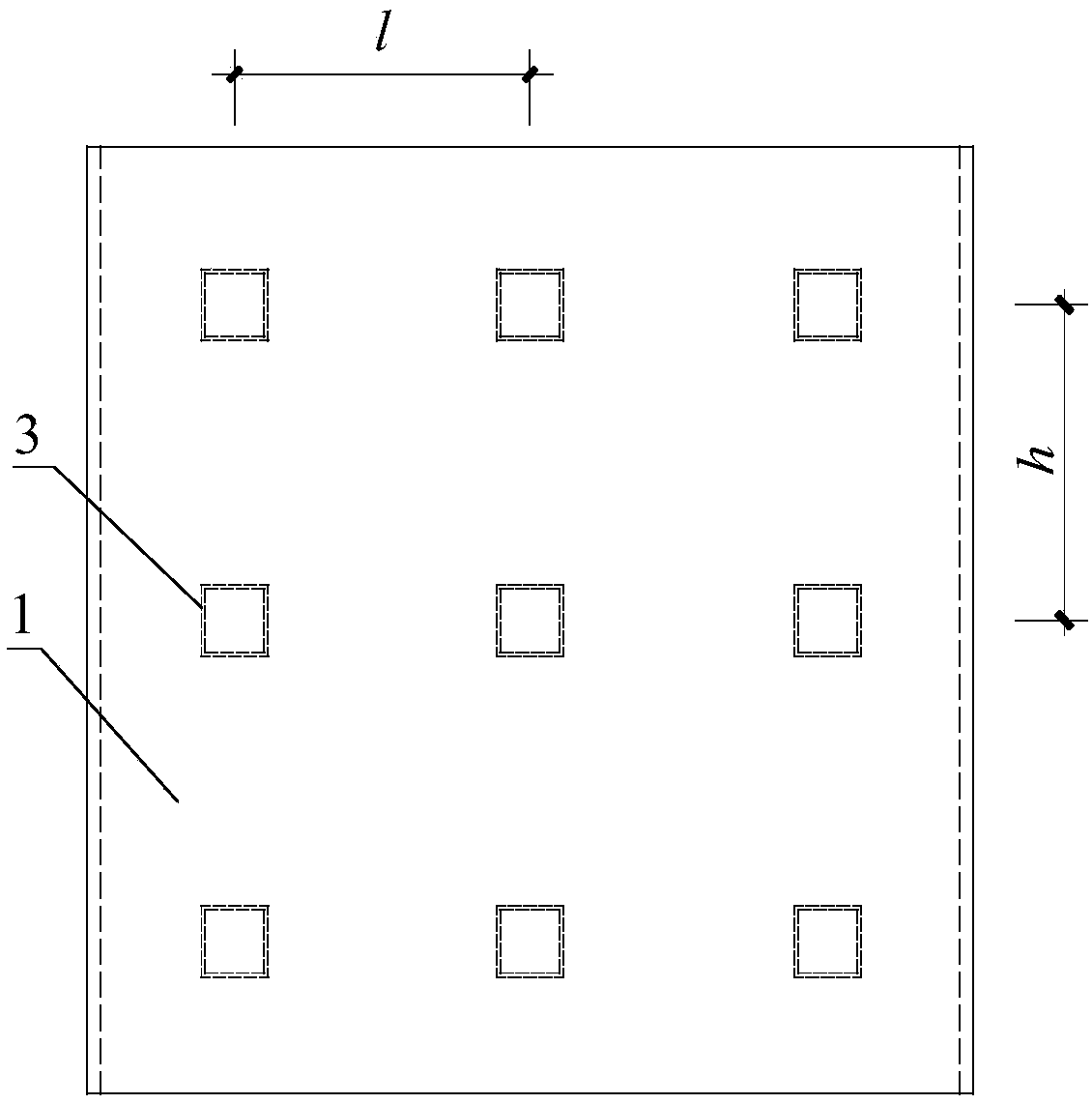

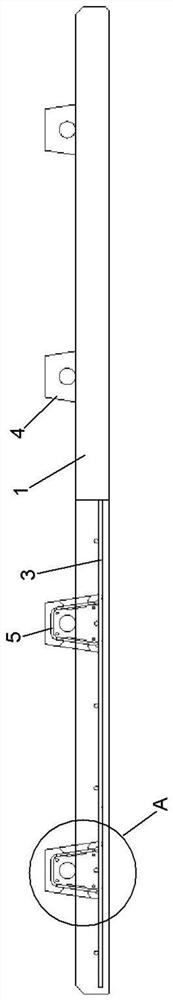

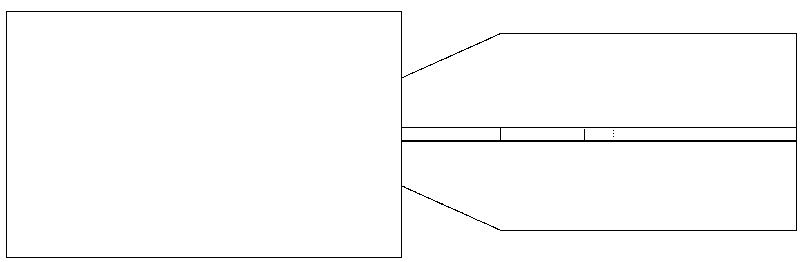

Non-stretching bar combined laminated slab with prefabricated prestressed concrete ribs

InactiveCN112160478AIncreased out-of-plane stiffnessLarge spanFloorsPre stressArchitectural engineering

The invention discloses a non-stretching bar combined laminated slab with prefabricated prestressed concrete ribs. The non-stretching bar combined laminated slab comprises a bottom plate (1), longitudinal bars (2) and transverse bars (3) are arranged in the bottom plate (1), a plurality of concrete ribs (4) are arranged on the bottom plate (1), the concrete ribs (4) are arranged in the direction of the longitudinal bars (2), a plurality of stirrups (5) are arranged in the concrete ribs (4), and the bottoms of the stirrups (5) are fixedly arranged on the transverse bars (3). According to the scheme of the non-stretching bar combined laminated slab with the prefabricated prestressed concrete ribs, the span of the bottom plate can be increased, and the production process is simplified.

Owner:CHONGQING ZHONGKE CONSTR GROUP

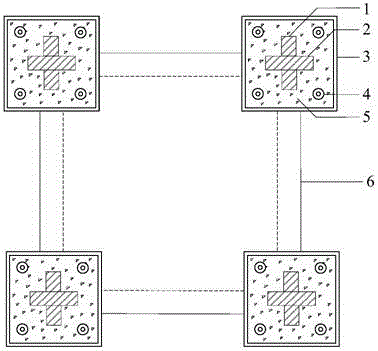

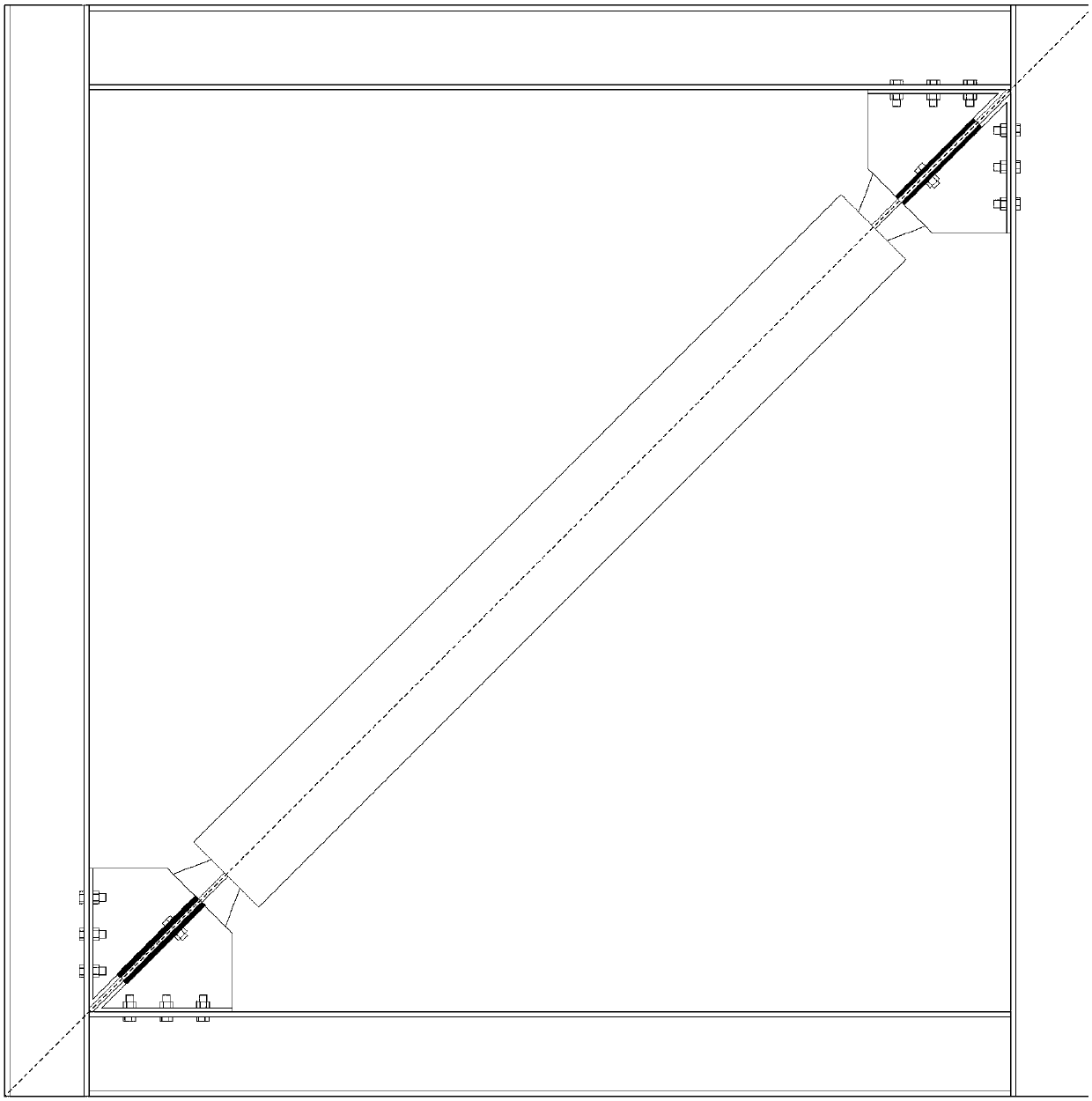

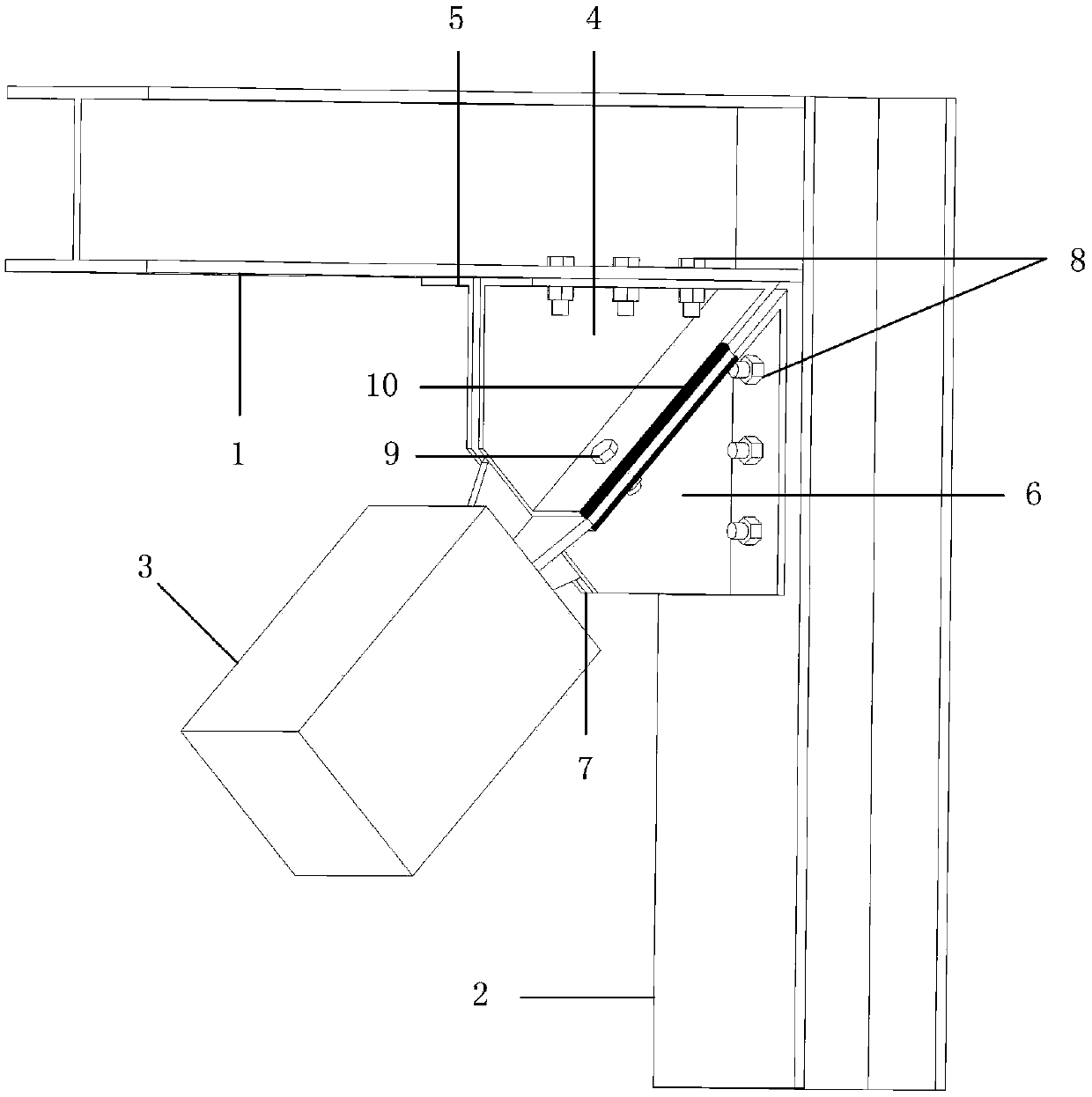

Precast modular buckling-restrained brace bolting and welding mixed connection joint

ActiveCN108222286ANode link length is shortIncreased out-of-plane stiffnessProtective buildings/sheltersShock proofingOut of planeBuckling-restrained brace

The invention discloses a precast modular buckling-restrained brace bolting and welding mixed connection joint, and belongs to the field of energy dissipation and seismic reduction of a building structure. The precast modular buckling-restrained brace bolting and welding mixed connection joint comprises precast steel joint modules, buckling restrained braces, connecting high-strength bolts, fixedhigh-strength bolts and attachment welds. The buckling restrained braces are laid in the diagonal direction of frame structures formed by structural beams and structural columns. The precast steel joint modules comprise first precast steel joint modules, second precast steel joint modules, third precast steel joint modules, and fourth precast steel joint modules. The precast modular buckling-restrained brace bolting and welding mixed connection joint has the advantages that the length of the joint connection is short, the stiffness out of plane is high, the installation and construction are simple, and the post-earthquake replacement is convenient. The length of the traditional bolt connection is greatly reduced by adopting a method of assembling the four precast steel joint modules and supporting connecting sections, at the same time, the length of energy consumption sections can be increased according to the design proportion, and the energy consumption performance of the buckling restrained braces can be improved under the same engineering conditions.

Owner:BEIJING UNIV OF TECH

A prefabricated corrugated steel plate lattice enclosure structure and construction method thereof

ActiveCN112983116BPlay the role of tension reinforcementIncrease contact surfaceFencingClassical mechanicsAxial force

The invention discloses a prefabricated corrugated steel plate lattice-type enclosure structure and a construction method thereof. The structure includes a number of frame-structured enclosure units, each enclosure unit includes a transverse enclosure portion and a longitudinal enclosure portion filled with concrete, and a truss as a bending component is arranged inside the transverse enclosure portion. The interior of the enclosure is provided with a lattice column as an axial force-bearing member. The truss and the lattice column are connected to each other and bonded with the concrete to form a whole. It is composed of channel steel, a channel steel is arranged in the cavity formed by each peak-to-peak part, the flange of the channel steel is connected with the wave crest in the cavity, and the opening direction of the channel steel in the adjacent cavity is opposite. The invention solves the problem that the envelope structure is only regarded as a non-structure in the traditional building form, is convenient for timely replacement when damaged, and ensures that the structure has good mechanical properties.

Owner:CHANGZHOU INST OF TECH

Prefabricated sash light steel frame-perforated thin steel plate-concrete composite wall

InactiveCN108625507BImprove carrying capacityImprove seismic performanceWallsProtective buildings/sheltersEarthquake resistanceSheet steel

The invention relates to a fabricated sash type frame type light steel frame-punching thin steel plate-concretecomposite wall. A concrete-filled steel tube frame column, a concrete-filled steel tube frame beam and a concrete-filled steel tube frame rib together form a light steel frame sash of a wall board, and form a compositewall steel skeleton with a punching thin steel plate to improve integrity of the wall board. A framework is erected and the concrete is poured; after maintenance, the fabricated sash type frame type light steel frame-punching thin steel plate-concretecomposite wallis formed, and only connection bolts are needed for assembling the composite wall onto an external structure. The fabricated composite wall has good bend-resisting and shear-resisting capacities, out-of-plane stiffness, and good anti-seismic performance; and meanwhile, the wall board is manufactured in a factory, and is assembled on-site, and therefore the common quality problem caused by site construction is effectively solved; construction efficiency of a project is greatly improved; and work amount of the project is lowered. The fabricated composite wall is suitable for being widely popularized and used in the structure of low and multi-storey rural house structures in villages and towns, and plays an important role in promoting improvement of the traditional rural house structure technology.

Owner:BEIJING UNIV OF TECH +1

Fabricated partition wall and construction method

PendingCN113338493AMeet performance requirementsConducive to dark applicationWallsEngineeringStructural engineering

The invention discloses a fabricated partition wall and a construction method. The fabricated partition wall comprises a partition wall body, a performance partition wall body and a facing partition wall body; the partition wall body is formed by arranging a plurality of prefabricated partition core plates along the longitudinal axis of the partition wall body according to a certain rule and fixing and assembling the upper ends and the lower ends of the prefabricated partition core plates; the performance partition wall body is formed by additionally connecting prefabricated filling strip plates with the partition wall body as a carrier in an assembled mode; the facing partition wall body is formed by additionally connecting prefabricated facing strip plates with the partition wall body as a carrier or additionally connecting prefabricated filling strip plates and prefabricated facing strip plates in an assembled mode; the horizontal axis of the partition wall body is not parallel to the horizontal axis of at least one section of main body of each partition core plate; and the wall surface of the partition wall body is in a non-planar shape. According to the fabricated partition wall and the construction method, fabricated partition wall bodies in different states are assembled in different time periods according to the requirements of different main bodies, concave cavities in the two faces of the partition wall body are filled with the filling strip plates, the filling strip plates can be assembled easily so as to meet the performance requirements of the partition wall body, and the partition wall body is made of folded plates or curved plates, so that the out-of-plane rigidity of the partition wall body is improved easily.

Owner:贵州皆盈科技开发有限公司

Prefabricated truss-type light steel frame-perforated thin steel plate-foamed concrete composite wall

ActiveCN108643390BIncrease lateral stiffnessImprove seismic performanceWallsFoam concreteEarthquake resistance

The invention relates to a prefabricated truss type light steel frame-punching thin steel plate-foamed concrete composite wall. A concrete filled steel tube frame column, a concrete filled steel tubeframe beam and concrete filled steel tube truss ribs together form a wallboard concrete filled steel tube truss stress system, a composite wall steel skeleton is formed by the wallboard concrete filled steel tube truss stress system and a punching thin steel plate, and the integrality of a wallboard is improved. Novel light insulation material foamed concrete is used for pouring the wallboard, theprefabricated truss type light steel frame-punching thin steel plate-foamed concrete composite wall is formed after maintenance, and the composite wall can be assembled to an external structure onlyby connecting bolts. The prefabricated truss type light steel frame-punching thin steel plate-foamed concrete composite wall is integrated in heat preservation, has good bending resistance, shear capacity and out of plane stiffness, the anti-seismic property is good, meanwhile, the wallboard is manufactured in a factory and assembled on site, the common quality problems caused by site constructioncan be effectively resolved, the construction efficiency of the project is greatly improved, the amount of labor used of engineering is reduced, and the prefabricated truss type light steel frame-punching thin steel plate-foamed concrete composite wall is suitable for wide application in the structure of low-rise multi-storey rural houses in villages and towns.

Owner:BEIJING UNIV OF TECH

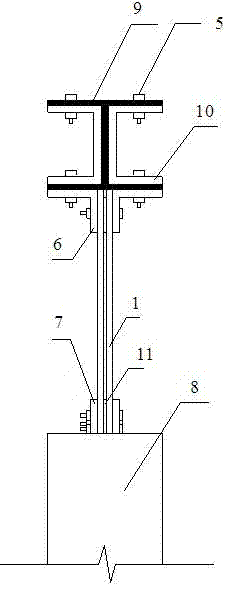

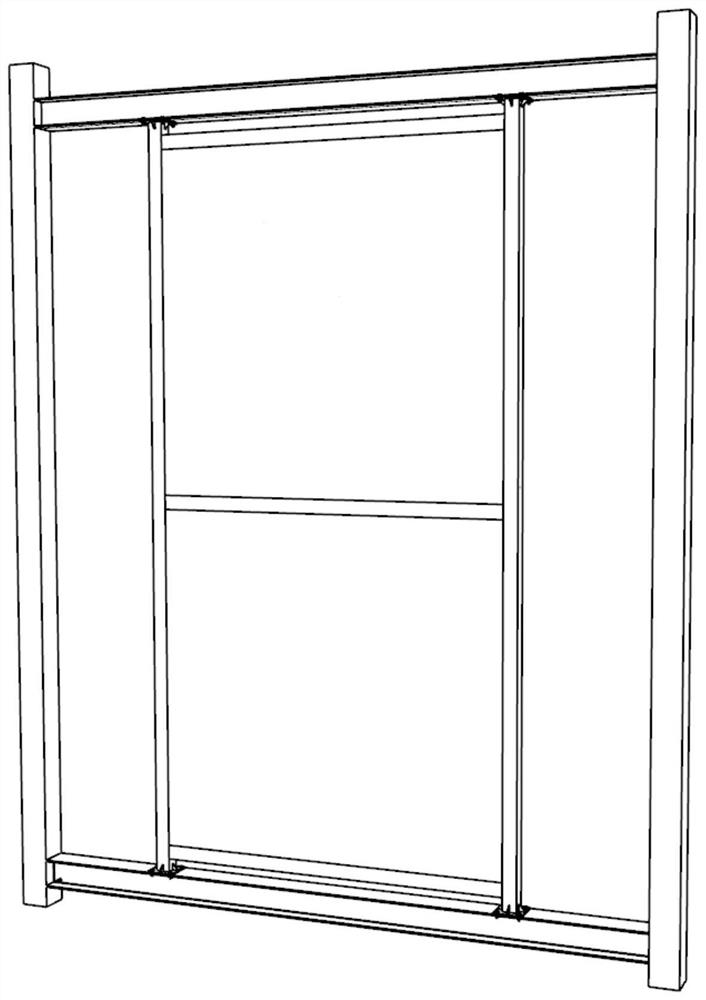

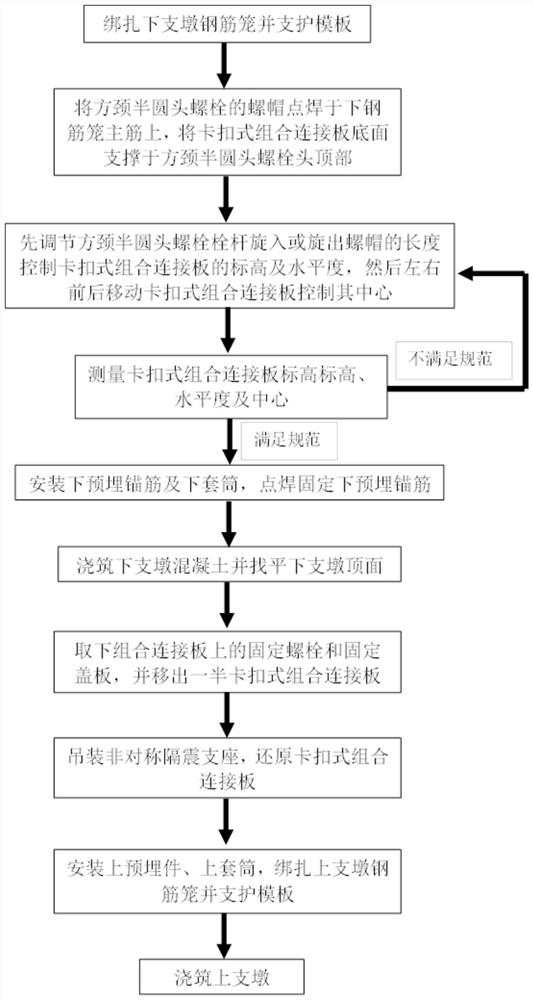

Mounting method of seismic isolation support

PendingCN112681852AImprove construction efficiencyImprove installation accuracyProtective buildings/sheltersShock proofingOut of planeEarth quake

The invention discloses a mounting method of a seismic isolation support. According to the mounting method, bolts are adopted for control, the construction efficiency is high, the mounting precision is high, and the phenomenon that the mechanical property of the seismic isolation support deviates greatly in all directions due to the mounting precision problem can be also avoided; a buckle type combined connecting plate is used to replace a positioning embedded plate, so that a conventional positioning embedded plate is omitted, steel can be saved, and the cost can be reduced; a concrete pouring opening reserved in the buckle type combined connecting plate is larger, so that pouring and vibrating are very convenient when concrete of a lower buttress is poured, the compactness of the lower buttress is easy to control, the construction quality of the lower buttress is guaranteed to a great extent, and potential safety hazards caused by earthquakes are reduced; and meanwhile, the out-of-plane rigidity of the buckle type combined connecting plate is large, and compared with the conventional positioning embedded plate, the buckle type combined connecting plate is not prone to deformation in the transportation process, and therefore, the support mounting precision is further guaranteed.

Owner:云南省设计院集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com