Ribbed net rack superimposed wall structure and construction method

A technology of superimposed walls and net frames, which is applied in the direction of building structures, walls, and building components, can solve problems such as easy to break, hidden dangers of overall structural safety and insecurity, and low flexural strength, and achieve the goal of improving flexural performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

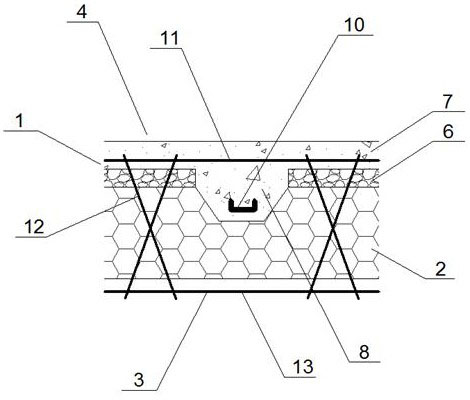

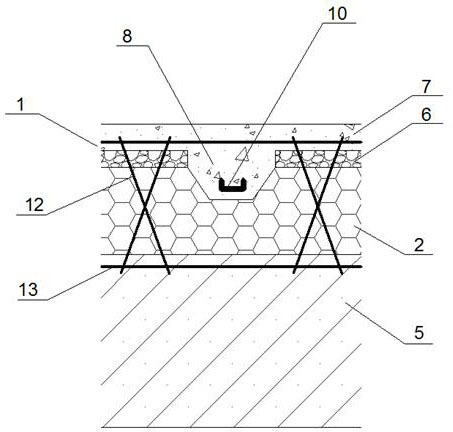

[0032] see Figure 1~2 , in an embodiment of the present invention, a structure and construction method of a ribbed network frame laminated wall, including a prefabricated unit 4, the prefabricated unit 4 includes a concrete prefabricated construction layer 1, an insulation layer 2 and a welded steel grid panel 3, and the concrete prefabricated structure Layer 1 has concrete ribs 8 embedded in the insulation layer 2 vertically or horizontally and vertically. Anti-deformation parts are placed inside the concrete ribs 8 close to the insulation layer 2. A reinforced concrete cast-in-place unit is arranged on the side of the insulation layer 2. 5. The concrete prefabricated structure layer 1 is composed of a layer of lightweight aggregate concrete layer 6 close to the insulation layer 2 and an outer fine stone concrete layer 7. The concrete prefabricated structure layer 1 is composed of a single layer of concrete layer. The anti-deformation part is thin-walled steel 10, the wall t...

Embodiment 2

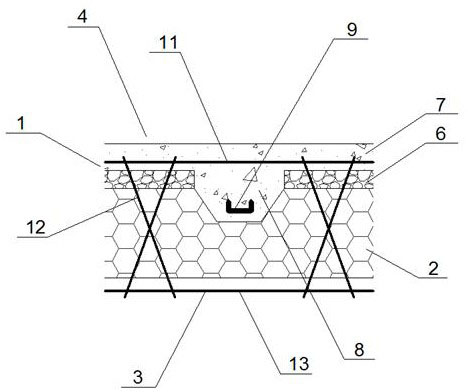

[0034] see image 3 , In an embodiment of the present invention, a structure and a construction method of a ribbed grid laminated wall, the deformation-resistant member is a bending-resistant steel bar 9, and the diameter of the bending-resistant steel bar 9 is 3mm-12mm.

[0035] The construction process steps are as follows:

[0036] S1: welding and combining the insulation board with grooves, the first steel mesh 11, the second steel mesh 13 and the obliquely inserted web bars 12 to form a steel bar welded grid plate 3;

[0037] S2: place bending steel bars 9 or thin-walled section steel 10 in the groove of the insulation board;

[0038] S3: Pouring the concrete layer of the prefabricated structural layer or successively pouring lightweight aggregate concrete and fine stone concrete to form prefabricated unit 4;

[0039] S4: Binding the steel bars of the reinforced concrete cast-in-place unit 5;

[0040] S5: install the prefabricated unit 4 on one side of the reinforced c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com