Cast-in-place skeleton net hollow filler wall

A skeleton net and filling wall technology, applied to walls, building components, insulation, etc., can solve the problems of increased cost of the main structure, low strength of filling walls, poor integrity and other problems, and achieve quick installation on site, light weight, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

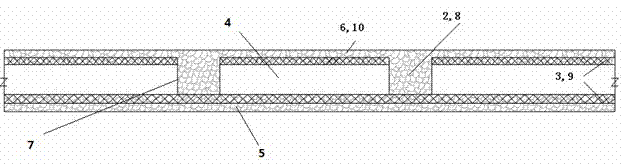

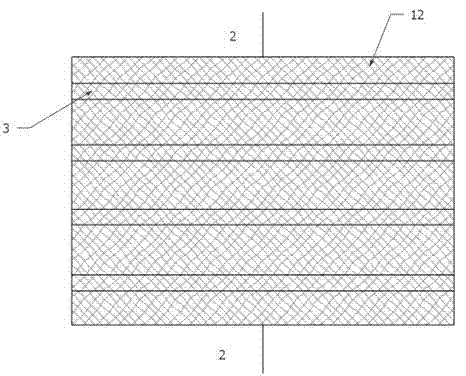

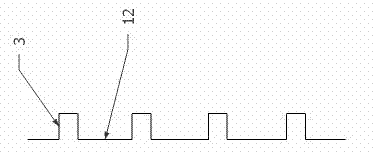

[0028] Example 1: Two-way bending skeleton net 1 (vertical rib 2 groove depth 90, width 50, middle distance 300, transverse rib 3 groove depth 20, width 20, middle distance 100) and tire net for sealing surface layer 5 (concave The groove depth is 20, the width is 20, and the middle distance is 100). After mass production in the factory, it is cut according to the size of the wall and shipped to the construction site. The two ends of the skeleton net 1 are fixed on the upper and lower floors for positioning. The pipeline is laid in the grooves in two directions. The cement sand in the ratio of 1:2 is dry-mixed and transported to the construction site in bags. After adding water and stirring well, it is now spread on the vertical rib 2 and the horizontal rib 3 to reach a certain level. After the strength, the surface layer 4 is now wiped with 15 thick vitrified microbead thermal insulation mortar, and the surface can be puttyed.

Embodiment 2

[0029] Example 2: The prefabricated core ribs (section size: thickness 40, width 90, the length according to the clear distance of the floor) are prefabricated in batches with glass fiber and desulfurized gypsum in the factory and delivered to the construction site. On the prefabricated vertical rib 2, the glass fiber mesh gypsum prefabricated panel 13 (thickness 15, width 600, length according to the floor clearance) delivered to the site and fixed on the prefabricated core rib with nails, and plaster The caulking makes it integrated with the vertical rib 2 and the skeleton net 1, and the horizontal rib 3 and the surface layer 4 are now plastered with gypsum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com