Patents

Literature

71results about How to "Convenient pre-embedded" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

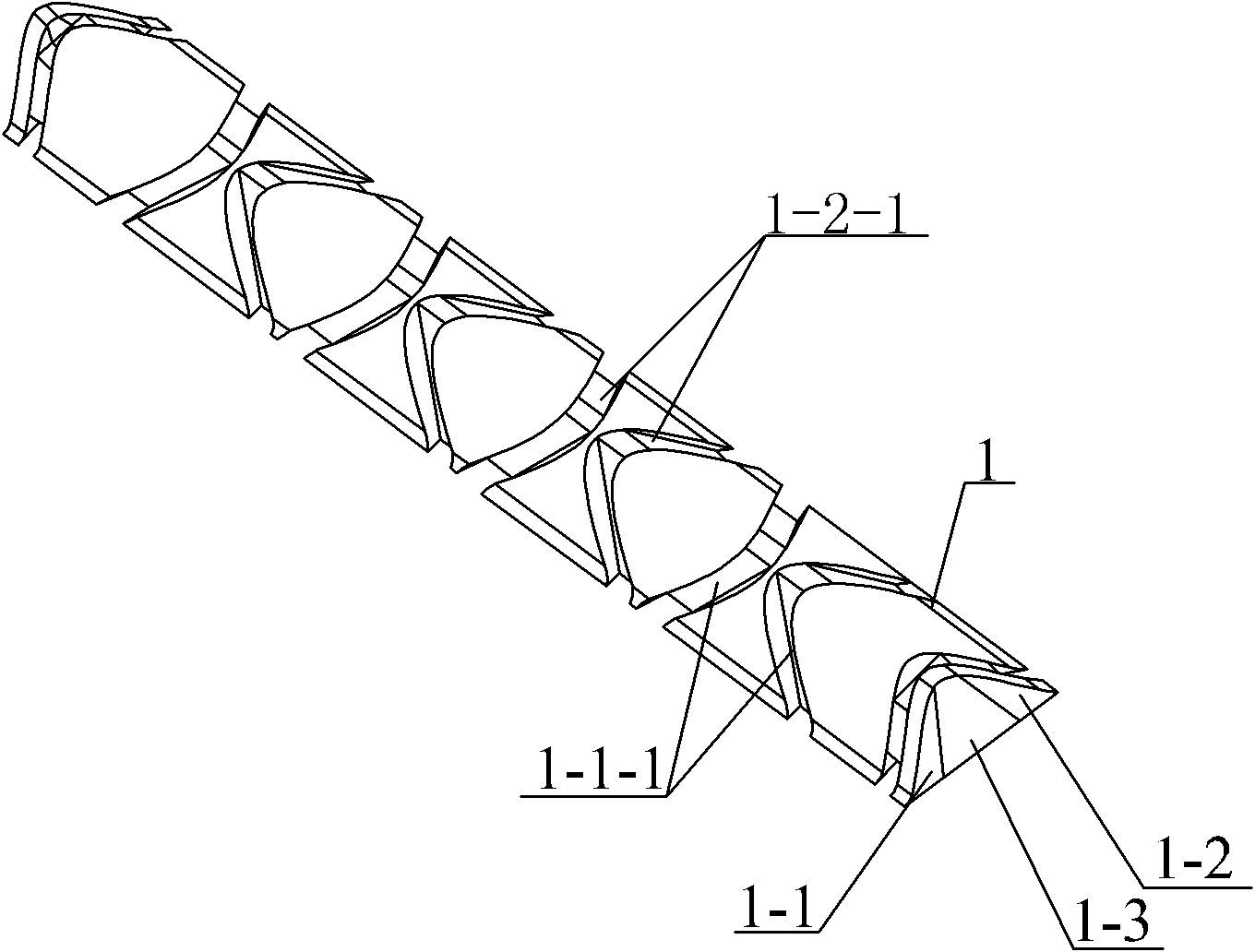

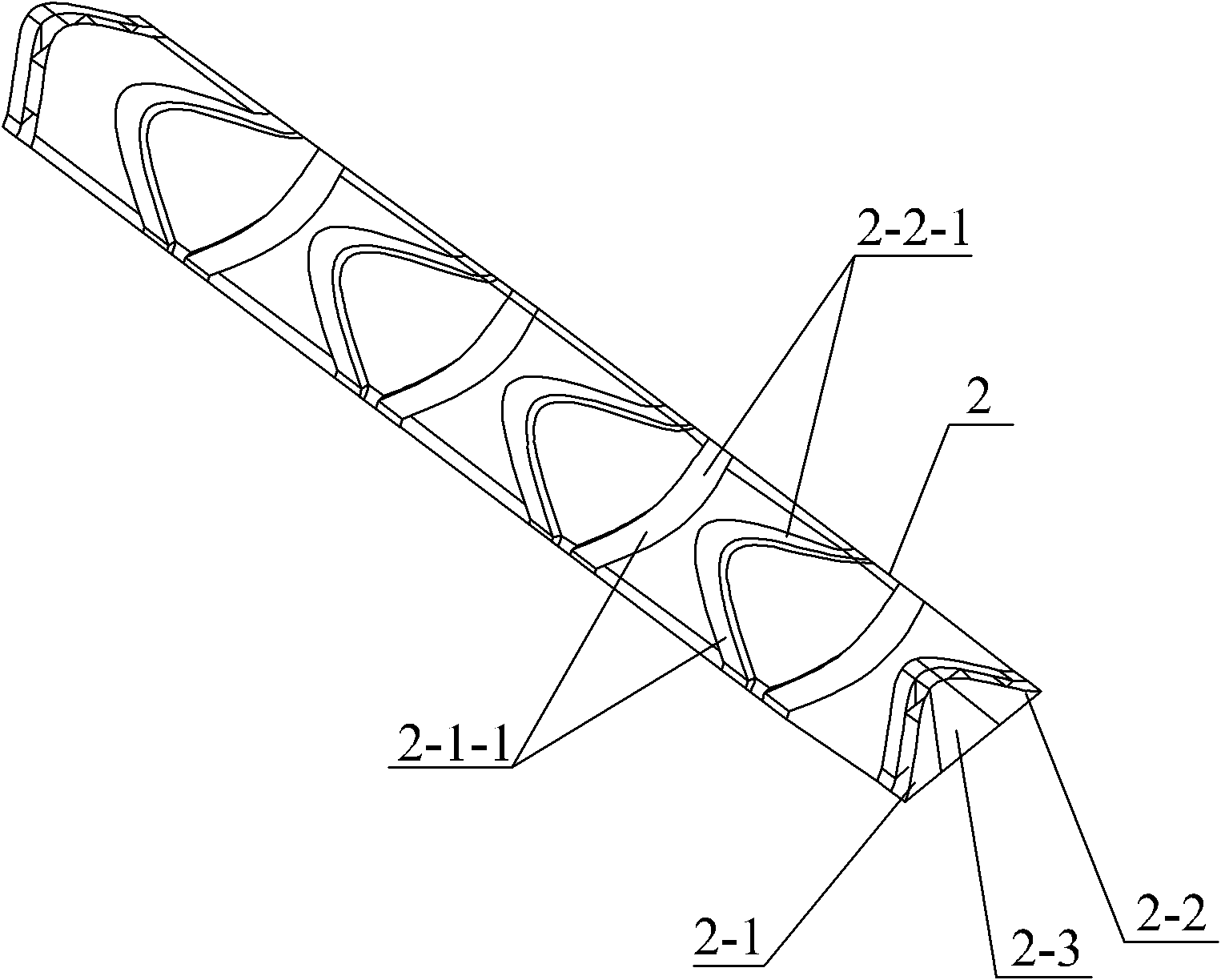

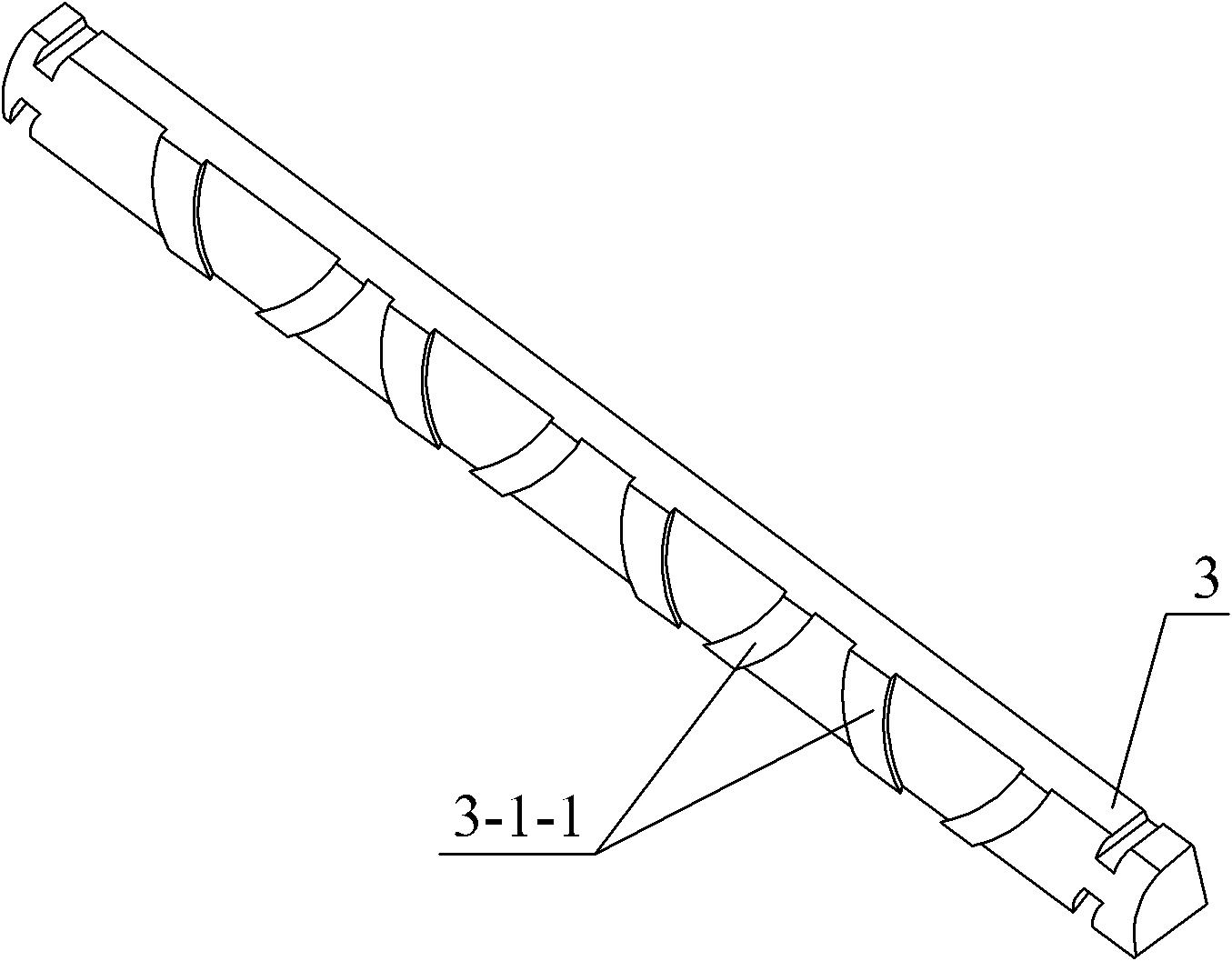

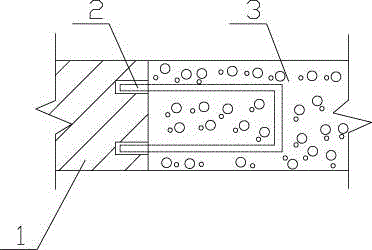

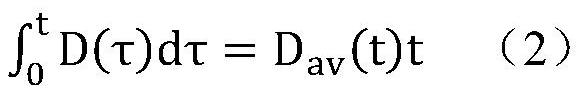

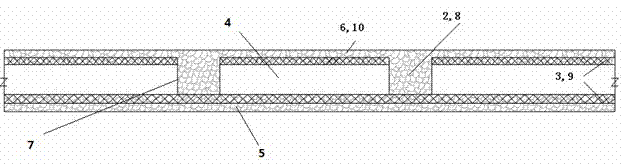

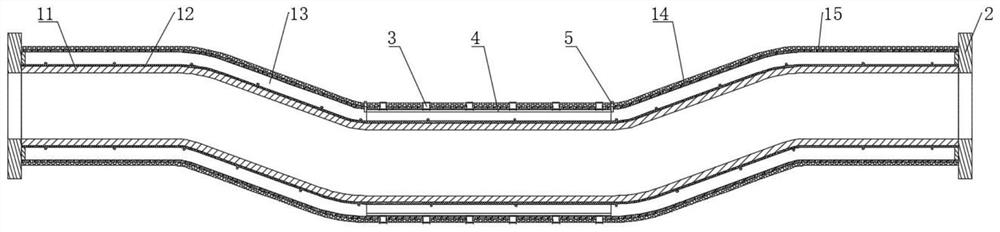

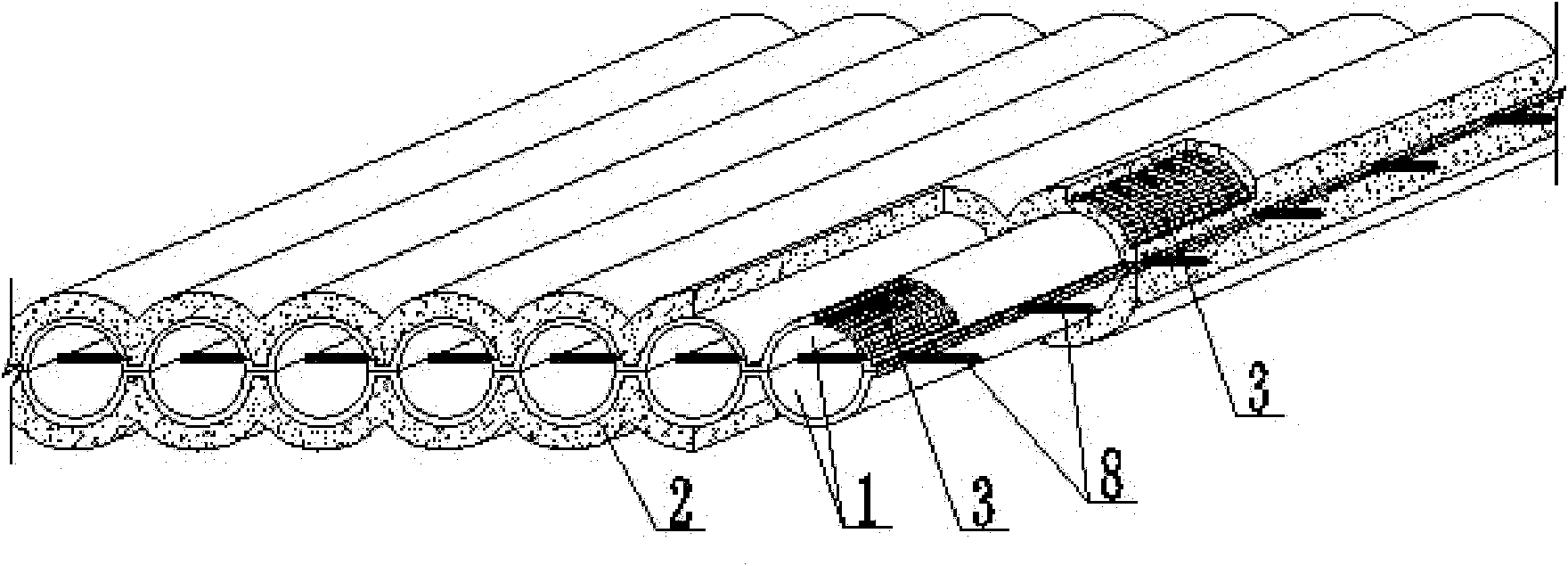

Manufacturing method of lattice core, mold and composite cylinder with lattice core

InactiveCN102275305AGood mechanical propertiesImprove performanceLayered productsFiberComposite laminates

A method for manufacturing a lattice core, a mold and a composite material cylinder with a lattice core, relating to a method for manufacturing a lattice core, a manufacturing mold and a cylinder of composite material with a lattice core. The invention solves the problems that the cylinder wall of the existing lattice core is closed, the space cannot be penetrated, and the functions of pre-embedding, heat conduction, ventilation and heat transfer are not convenient to realize. The method for preparing lattice cores is as follows: 1. Obtain multiple unidirectional prepregs; 2. Clean the mold; 3. Lay unidirectional prepregs in square grooves; 4. Lay fiber prepreg layers; 5. Lay the square silicone rubber on the surface of the prepreg layer; 6. Hot press forming; 7. Demoulding; 8. Obtain the dot matrix core. The prepared lattice core is the mold used for the wave-shaped lattice core or the pyramid-shaped lattice core. The lattice core of the composite cylinder is disposed between the outer composite laminate and the inner composite laminate. The invention is especially applicable to the field of aerospace.

Owner:HARBIN INST OF TECH

Dry-method construction method for high-performance autolaved aerated concrete block wall

InactiveCN106013509AHigh strengthAdhesive, special adhesive has strong bonding forceWallsBuilding material handlingSurface finishThermal bridge

The invention relates to the technical field of construction, and inparticular relates to a dry-method construction method for a high-performance autolaved aerated concrete block wall. The dry-method construction method comprises the following process procedures: performing construction preparation, positioning and paying off, leveling a wall foundation, erecting story poles, placing wall tie bars, constructing a block wall body, laying pipelines inside the wall body, mounting door / window hole cross beams, constructing outer wall concrete thermal bridge parts, constructing an outer wall waterproof interface agent, pasting special plaster putty on the inner wall in batch, constructing an inner wall finish coat layer, pasting wall surface heat-preservation blocks, and constructing a roof surface finish coat layer. The dry-method construction method is characterized in that a dry-method construction process is adopted for a blocking wall body, the part between the wall body and a beam top is filled with a polyurethane foamed adhesive, moreover a special construction method of an outer wall concrete thermal bridge part is adopted, the common quality problems of creep change of conventional masonry mortar and mortar joint cracks along wall surfaces are effectively solved, the overall property, the shock resistance and the heat-preservation property of the wall are improved, and the dry-method construction method can be widely applied to production construction of various buildings.

Owner:HUBEI SHENZHOU BUILDING MATERIAL

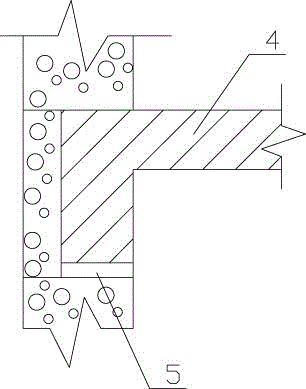

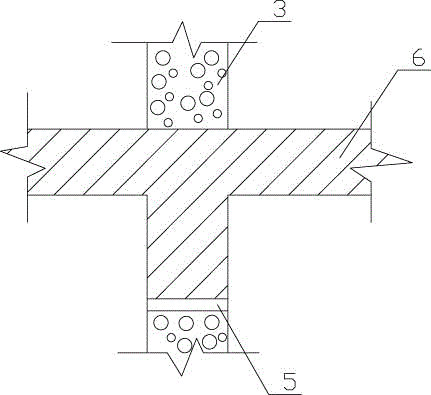

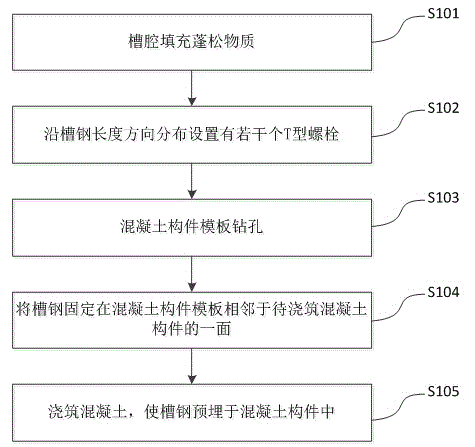

Embedding method for embedding box iron in concrete component

ActiveCN104947944AConvenient secondary adjustmentSecondary adjustment quickBuilding material handlingStructural engineeringDrill hole

The invention discloses an embedding method for embedding box iron in a concrete component. The width of a notch of the box iron is smaller than that of a groove cavity. The embedding method includes the following steps of filling the groove cavity with fluffy substances; distributing a plurality of T-shaped bolts in the length direction of the box iron, wherein bolt heads of the T-shaped bolts can be clamped in the groove cavity and can be detached out of the groove cavity, and bolt rods penetrate through the notch; drilling holes in a concrete component formwork, and making the shapes, number and intervals of drilled holes matched with those of the T-shaped bolts distributed on the box iron; fixing the box iron to the face, adjacent to the to-be-poured concrete component, of the concrete component formwork, ensuring that the bolt heads of all the T-shaped bolts distributed on the box iron are clamped in the groove cavity, and making the bolt rods of all the T-shaped bolts on the box iron penetrate through the drilled holes in the concrete component formwork respectively and then locked through locking nuts; pouring concrete, and embedding the box iron in the concrete component. By means of the embedding method, the box iron can be conveniently embedded, and exposure of the notch of the box iron conforms to the standard.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

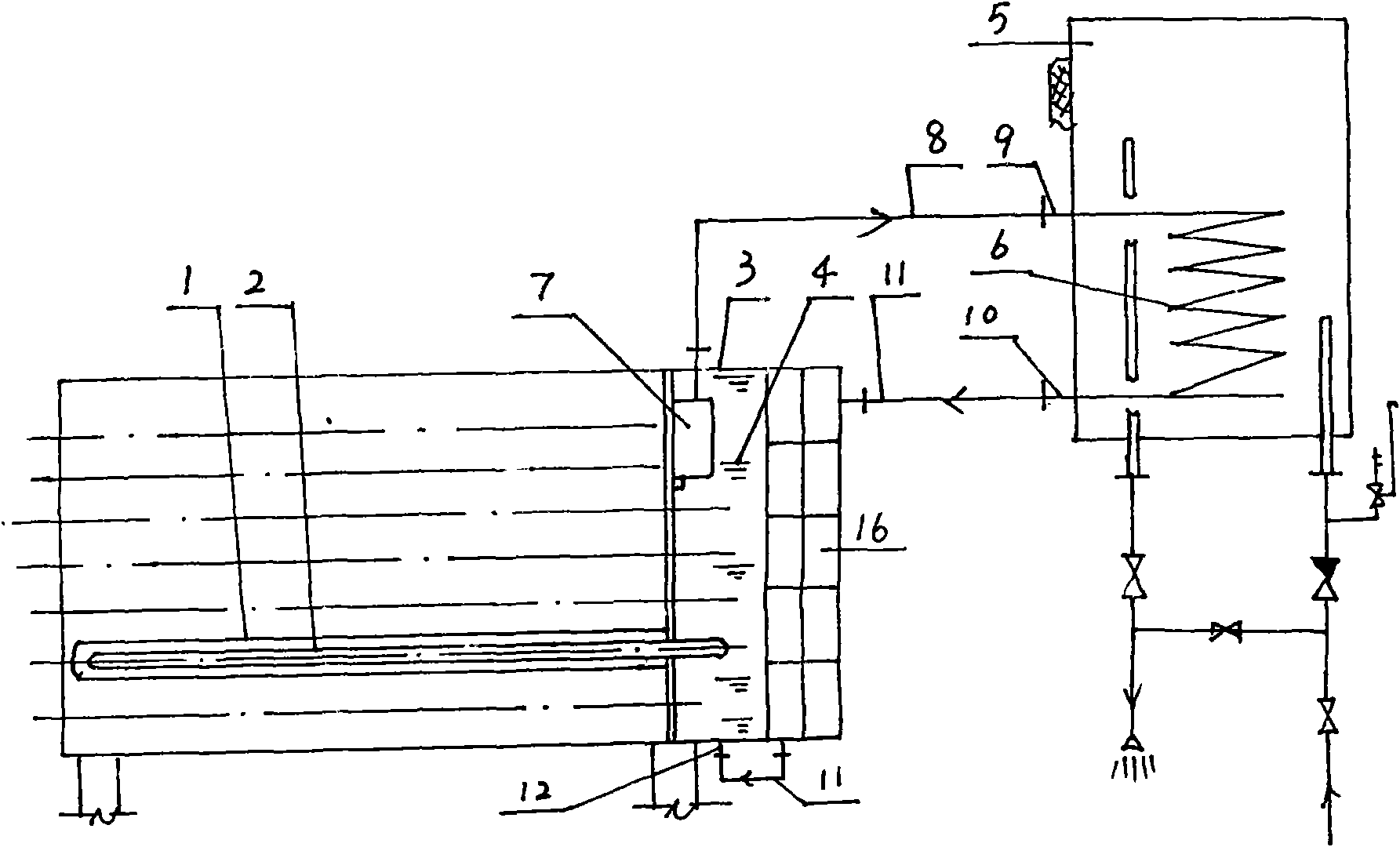

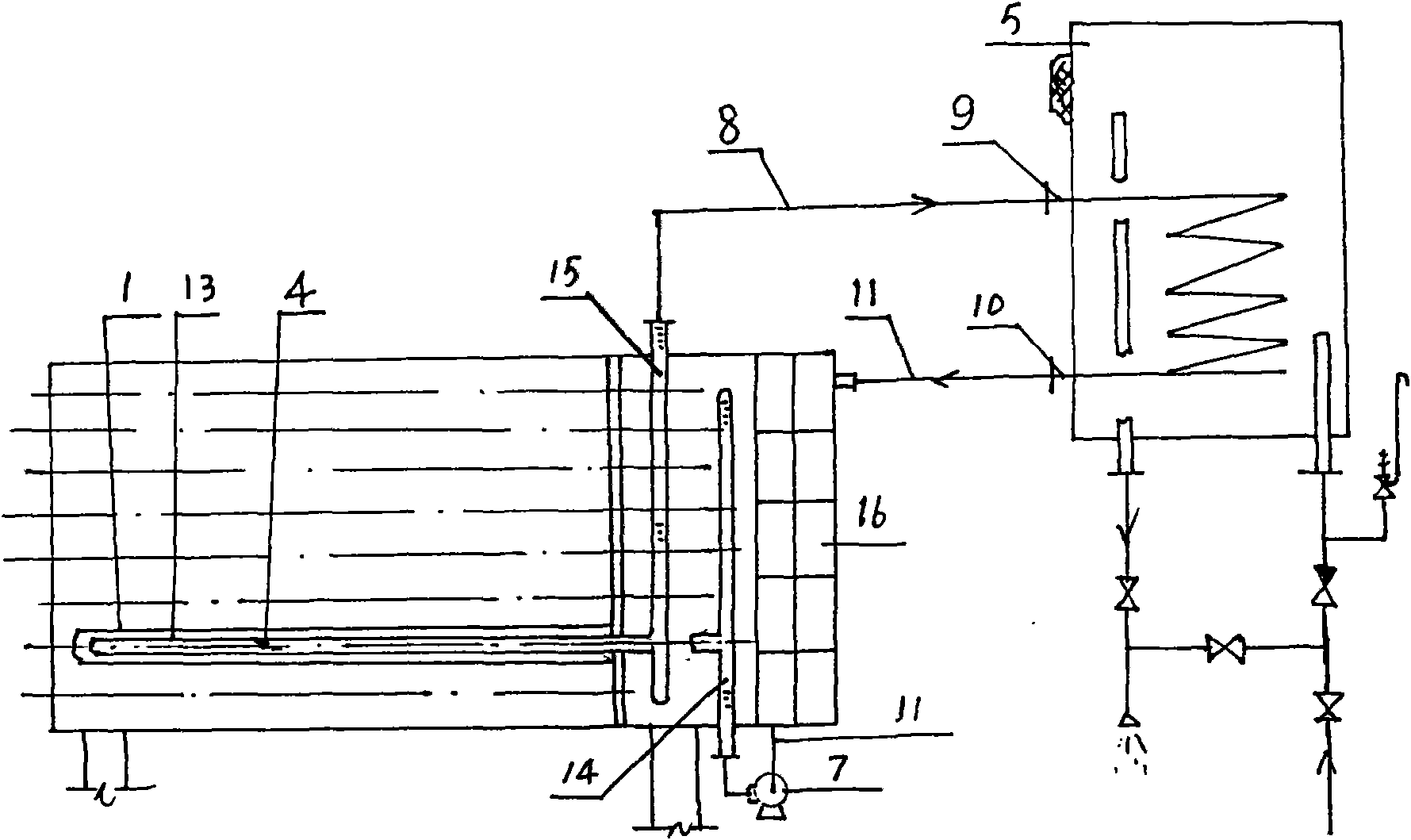

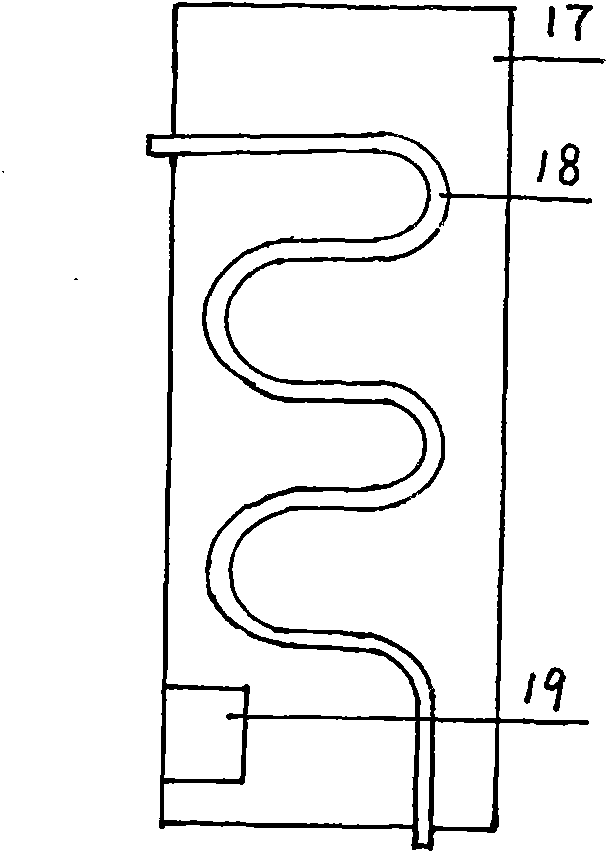

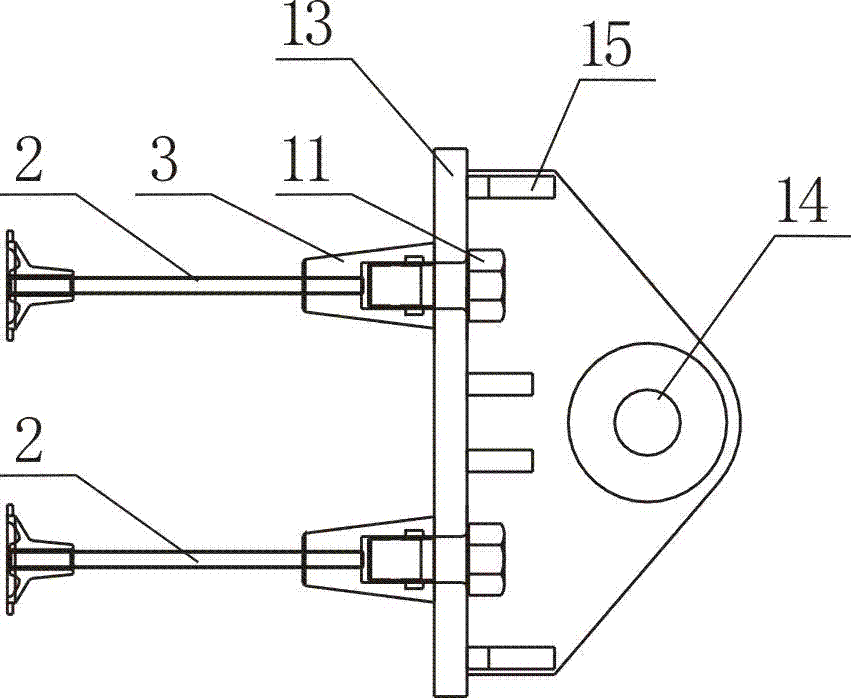

Household solar water heater with optical electromechanical integration

ActiveCN101639293AMeet needsImprove applicabilitySolar heating energySolar heat devicesWater storage tankCollector device

The invention relates to a household solar water heater with optical electromechanical integration, which belongs to the field of solar energy utilization devices and solves the problem of applicability of a household split solar water heater. The household solar water heater comprises a basic structure of the system-wide press-resistance household split solar water heater, a heat collector, a water storage tank (5) with a built-in heat exchange device (6) and a heat conductive working medium and a circulation system thereof, as well as a photovoltaic power supply (16) and a photovoltaic pump(7) driven by the photovoltaic power supply (16) which are used for forced circulation of the heat conductive working medium and form a three-in-one structure with the heat collector, and matching circuits thereof. The household solar water heater has the advantages that the household solar water heater overcomes the deficiencies of the ordinary solar water heater and the conventional household split solar water heater, improves, enriches, ensures and expands the advantages of the two; the three-in-one structure can carry out light-heat conversion and photoelectric conversion simultaneously and synchronously, and supplement collected heat while carrying out the photoelectric conversion; the automatic intelligent control of the forced circulation is safe, reliable, economic, practical and strong in applicability; and the household solar water heater facilitates standard design and mass production, is matched with the corresponding architectural design for construction and installation,is particularly applicable to multi-storey and high-rise residential buildings in cities and can meet the demands of a large number of residents.

Owner:BEIJING ENPOWER SOLAR ENERGY IND

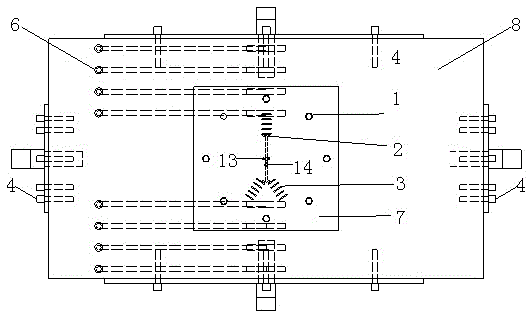

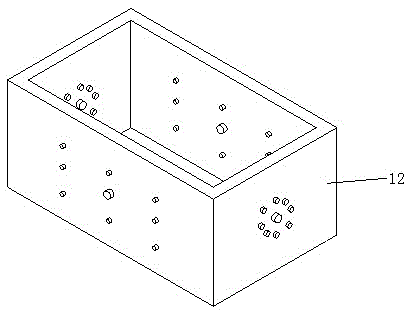

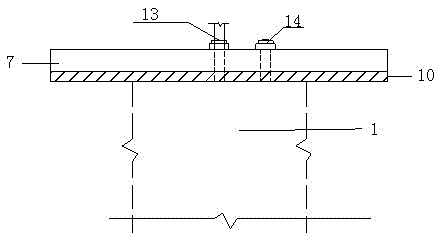

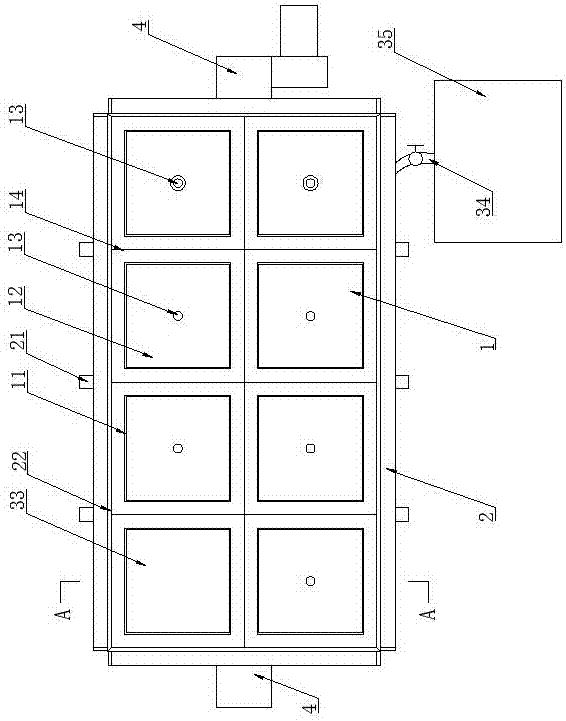

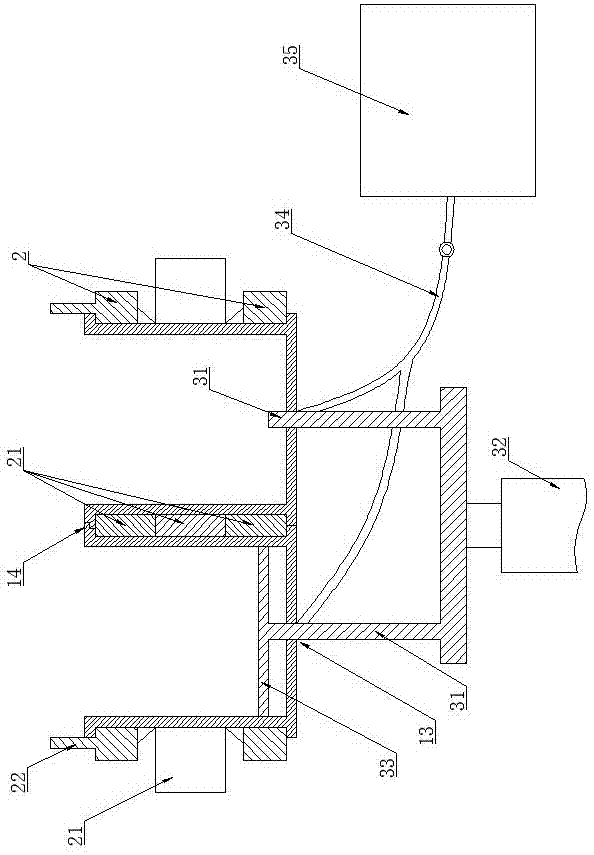

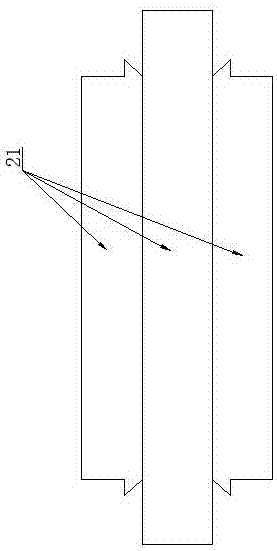

A test device for simulating hydraulic splitting of concrete members under different stress conditions

ActiveCN103698218BConvenient pre-embeddedReal-time acquisitionPreparing sample for investigationMaterial strength using tensile/compressive forcesStructural waterHigh pressure water

The invention relates to a hydraulic splitting test device for simulating concrete components under different stress conditions, and relates to the technical field of hydraulic splitting test devices for concrete components. The invention comprises a cuboid mold with an opening on one side. Concrete is poured into the mold to obtain a concrete component. Eight high-pressure resistant water bends are preset in the concrete component, and a water pressure sensor joint is arranged at the end of each high-pressure resistant water bend; the steel is pulled out from the concrete component. The initial cracks are prefabricated on the sheet, and a certain range of grooves are ground around the cracks, strain gauges and clip-type extensometers are arranged, filled and ground with water-proof insulating glue; water-sealed steel plates are arranged on the components, and water inlets and belt Seal the exhaust port of the cap. Based on the invention, the hydraulic splitting test research of the concrete structure under the combined working conditions of different stress conditions and different initial crack inclination angle conditions can be carried out.

Owner:HOHAI UNIV

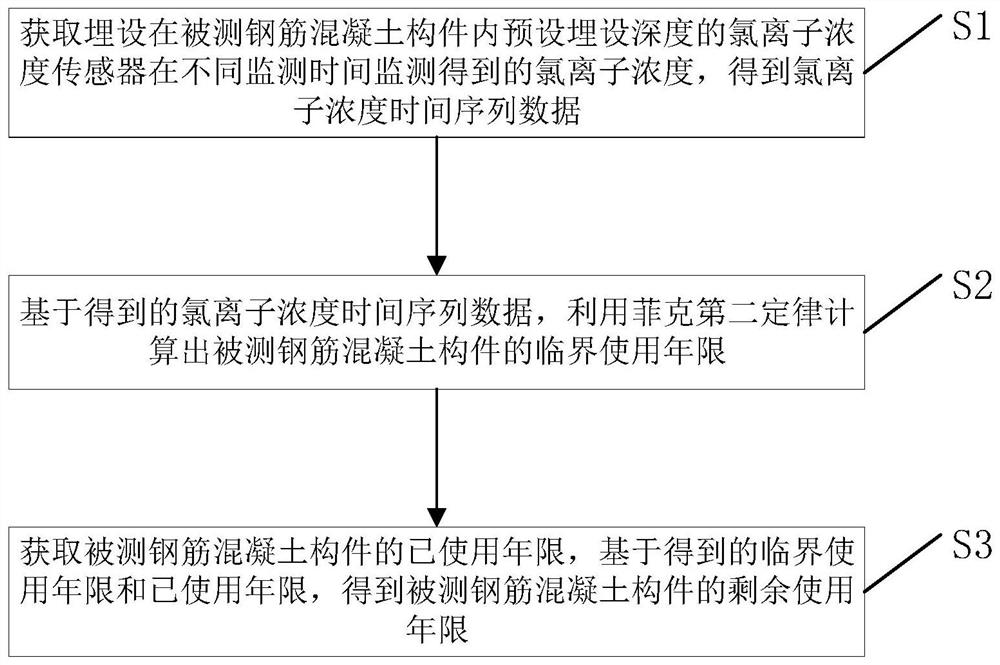

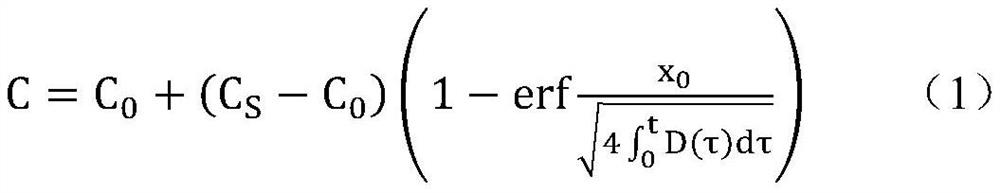

Reinforced concrete member service life prediction method based on chloride ion concentration monitoring

ActiveCN112529255AConvenient pre-embeddedEasy to installForecastingDesign optimisation/simulationReinforced concreteChloride

The invention provides a reinforced concrete member service life prediction method based on chloride ion concentration monitoring, and the method comprises the following steps: obtaining chloride ionconcentrations monitored by a chloride ion concentration sensor with a preset burying depth in a measured reinforced concrete member at different monitoring times, and obtaining chloride ion concentration time series data; based on the obtained chloride ion concentration time series data, calculating the critical service life of the measured reinforced concrete member by utilizing a Fick second law; and obtaining the service life of the tested reinforced concrete member, and obtaining the remaining service life of the tested reinforced concrete member based on the obtained critical service life and the obtained service life. The invention aims to overcome the defects of the existing reinforced concrete member service life prediction method based on chloride ion concentration monitoring.

Owner:CCCC FOURTH HARBOR ENG INST +2

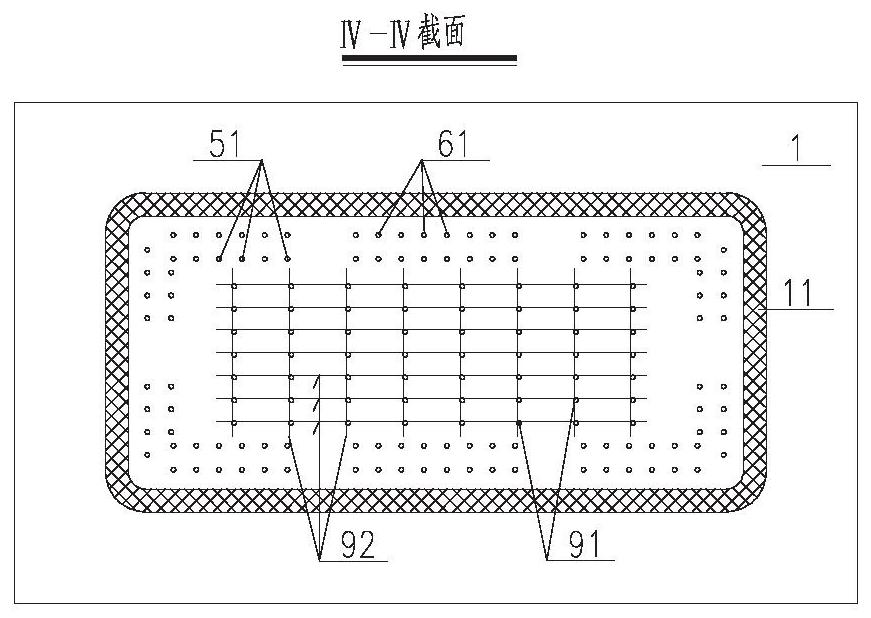

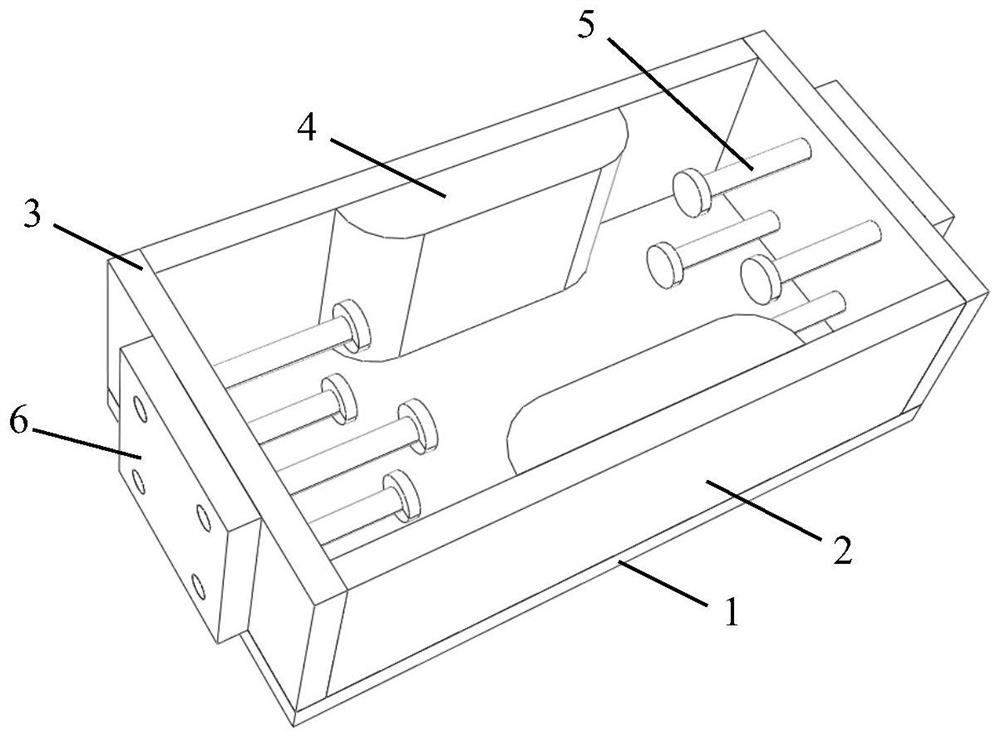

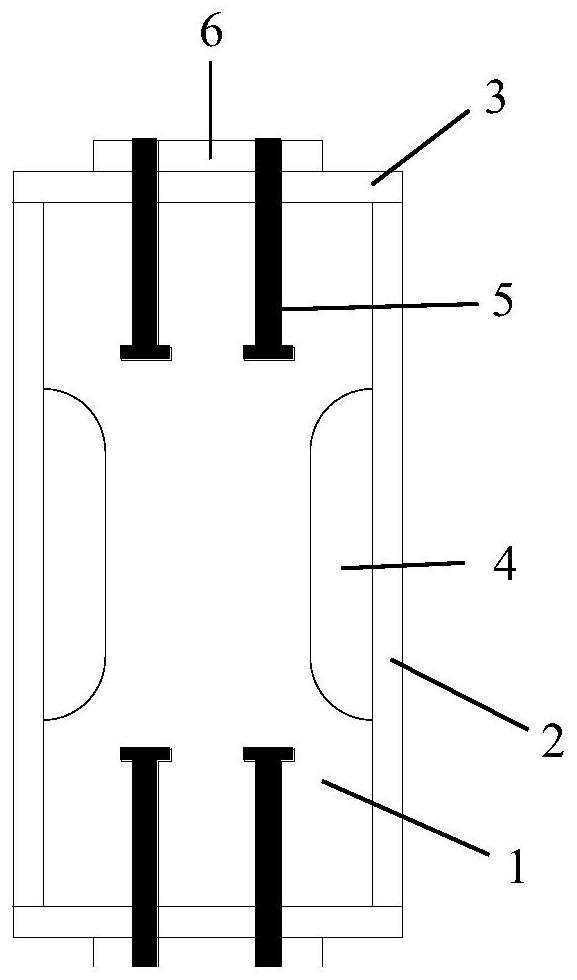

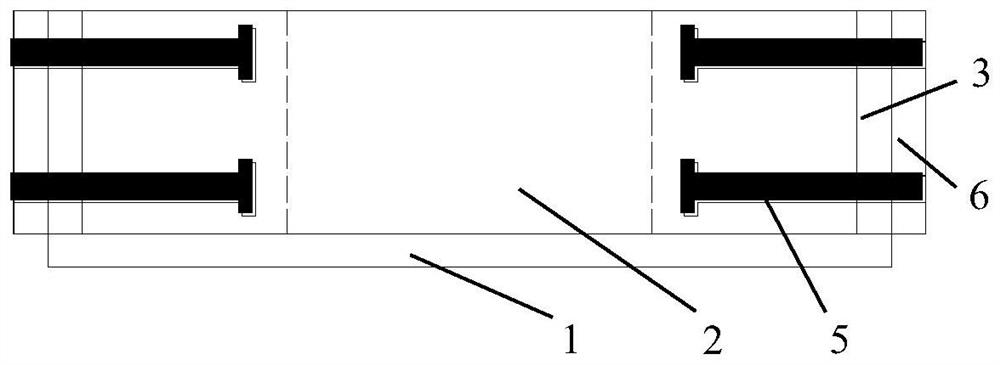

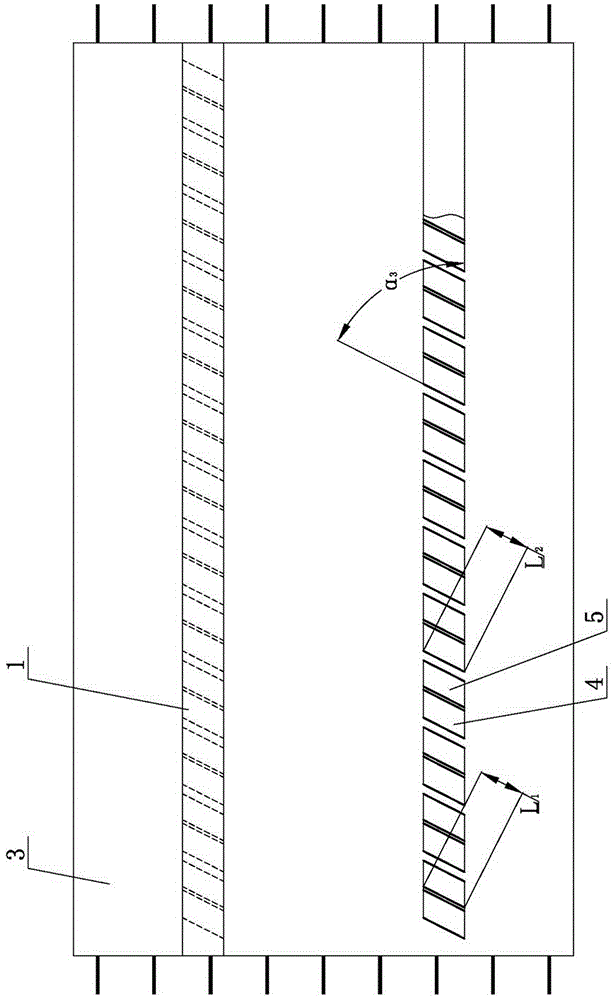

Cast-in-place skeleton net hollow filler wall

InactiveCN102758492AIncreased out-of-plane stiffnessLess materialWallsHeat proofingStructural engineeringMaterials science

The invention discloses a cast-in-place skeleton net hollow filler wall which comprises a skeleton net (1). A cast-in-place surface layer (4) and a seal surface layer (5) are arranged at outer ends of two sides of the skeleton net (1) respectively, and vertical ribs (2) and horizontal ribs (3) are sequentially arranged between the skeleton net (1) and the cast-in-place surface layer (4). According to integration of economic indicators and construction periods, the cast-in-place skeleton net hollow filler wall has an advantage over an existing air-entrapping concrete building block filler wall and a hollow internal mold metal net cement internal partition wall, has the advantages of being high in industrialized production degree and simple in site operation process, and overcomes the shortcomings in the prior art.

Owner:贵州皆盈科技开发有限公司

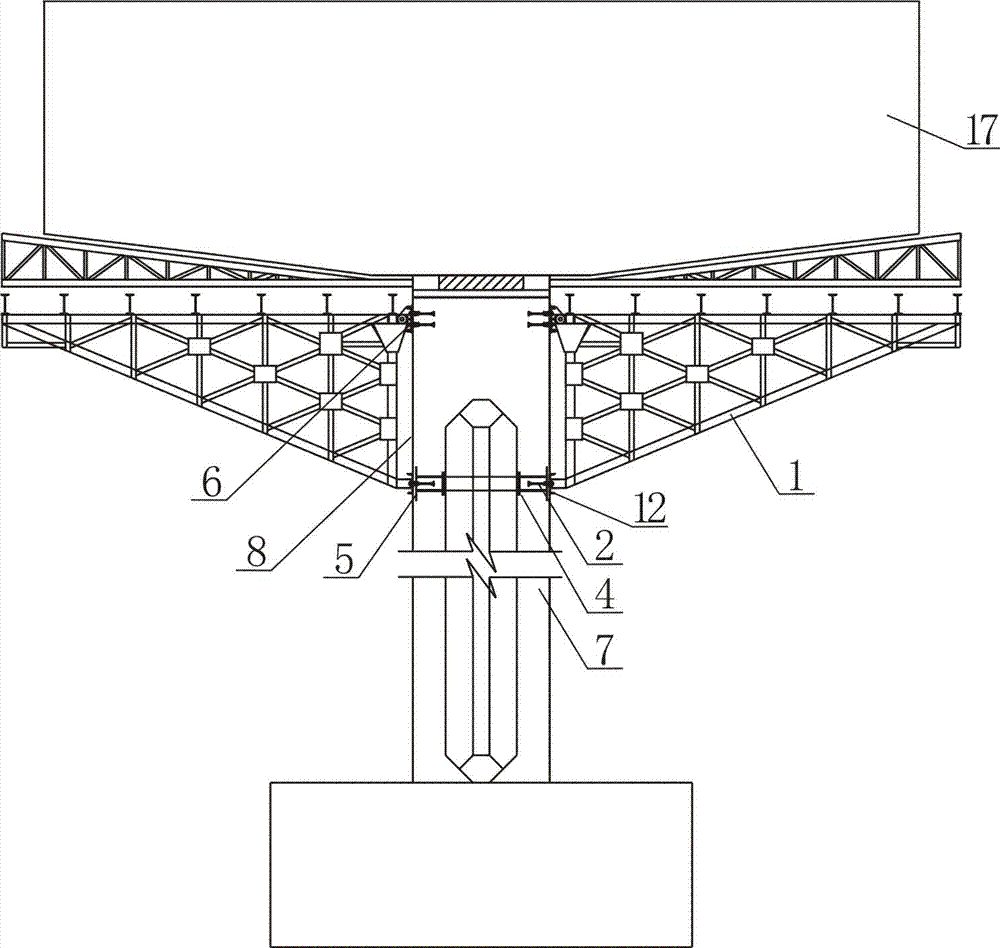

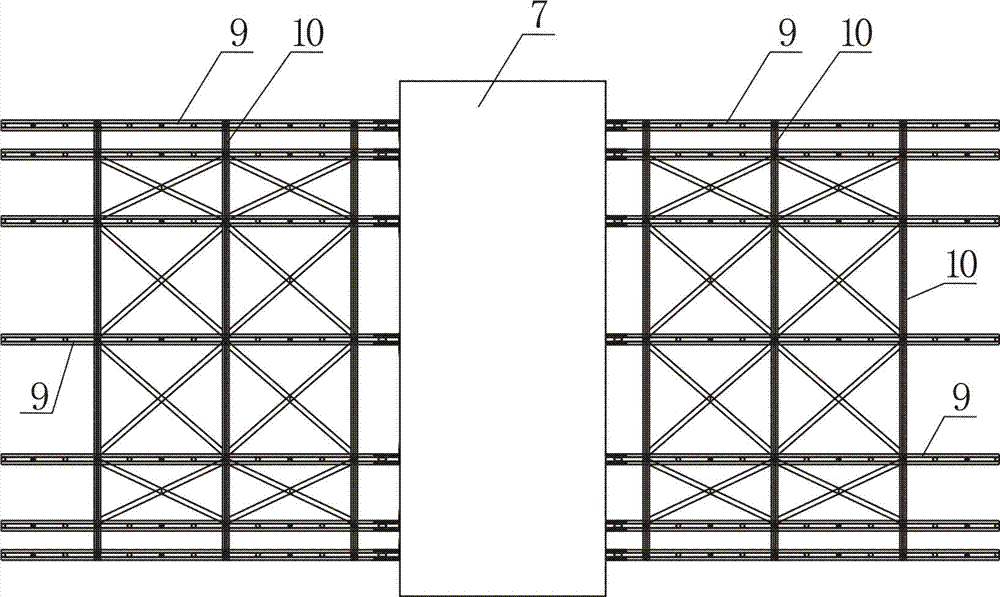

Climbing cone type triangular cantilever bracket

The invention discloses a climbing cone type triangular cantilever bracket which consists of a triangular bracket, a climbing cone bolt, a cone-shaped nut, a steel plate, a steel mesh and a permanent seat. The permanent seat is fixedly arranged on the side face of a pier body through match of a screw and the cone-shaped nut. The upper end on one side of the triangular bracket is hinged with the permanent seat while the lower end on another side is fixedly arranged on the side face of the pier body through the screw. The use level of materials of the whole bracket is small and the pier bodyloss rate is low, and the bracket can be repeatedly used, so that the construction cost is lowered. The bracket is in a split mounting type pin joint structure, so that the bracket is erected and detached in a short time and high is construction efficiency, and the process step transfer time can be shortened. The cone-shaped nut is adopted, so that the pier body can be repaired after the bracket is detached, the a pre-buried hole is small, the pier body is convenient to repair, and the shape of the pier body is less affected. Particularly, the steel plate and the steel mesh are pre-buried in the pier body, so that crack of the pier body bearing the bracket is effectively prevented, the anti-shearing force and anti-pressure ability of the pier body are improved, and meanwhile, the riveting property of the climbing cone bolt is further enhanced to provide the probability of supporting the cantilever of a cast-in-place box beam.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

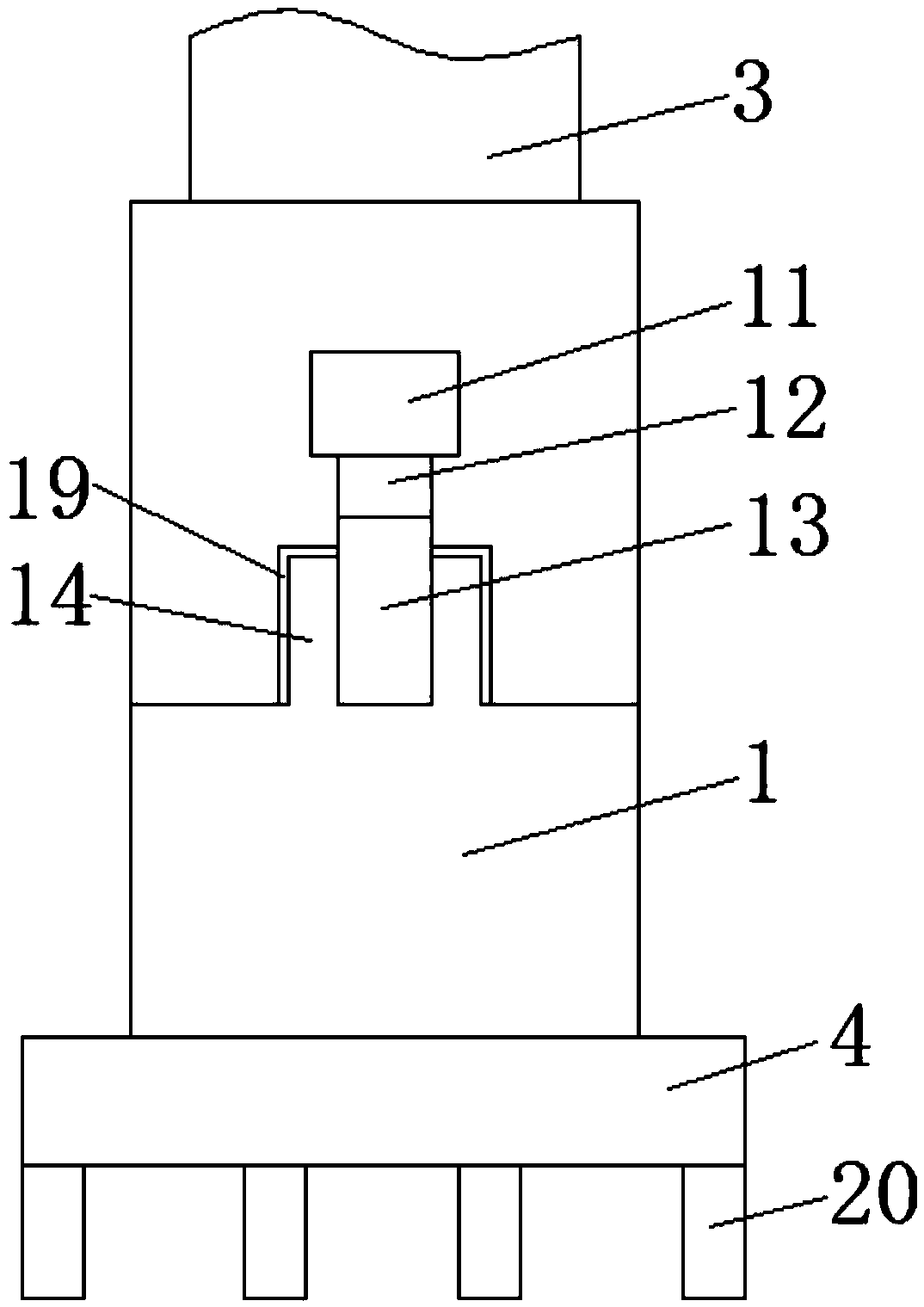

Foam concrete demoulding equipment

PendingCN107415042AIncrease production speedHigh speedDischarging arrangementMould auxillary partsFoam concretePre embedding

The invention provides foam concrete demoulding equipment, and belongs to the technical field of foam concrete construction equipment. The foam concrete demoulding equipment comprises a plurality of moulds and a demoulding device; each mould comprises a side mould and a bottom mould; each side mould has draft taper; each bottom mould is provided with a through hole; each bottom mould is connected with the lower part of the corresponding side mould; a splicing structure which is used for splicing with an adjacent side mould is arranged at the upper part of each side mould; the demoulding device comprises a frame body which is used for holding the plurality of the moulds and pressure mechanisms which are used for removing formed foam concrete from the moulds; and the pressure mechanisms are connected with the through holes of the bottom moulds. The foam concrete demoulding equipment is beneficial to pre-embedding reinforcement structures and pre-embedding pieces into the foam concrete; meanwhile, the appearance quality is higher; the quality of the foam concrete is improved; the demoulding efficiency is improved; and the production speed of foam concrete building blocks is increased.

Owner:HEBEI SANSHAN BUILDING MATERIALS TECH

Prestress sheet assembling type prefabricated composite floor slab

The invention provides a prestress sheet assembling type prefabricated composite floor slab which comprises a lower bottom board, side stop modules, support components, an upper bottom board and string columns. By the adoption of the prestress sheet assembling type prefabricated composite floor slab, the problems that in the manufacturing process of an existing composite floor slab, side edges ofthe existing composite floor slab need to be enclosed by wooden boards so as to prevent poured cement from overflowing, however, plenty of the cement still can overflow through the bottom ends of thewooden boards adopted for enclosing, thus the cement is wasted, furthermore, the cement can be bonded to the wooden boards after setting, a worker needs to use a hammer or other tools for separating the wooden boards from the manufactured composite floor slab, the cement of the composite floor slab cracks in the separation process of the wooden boards, and the strength of the composite floor slabis further affected can be solved.

Owner:山东富海材料科技有限公司

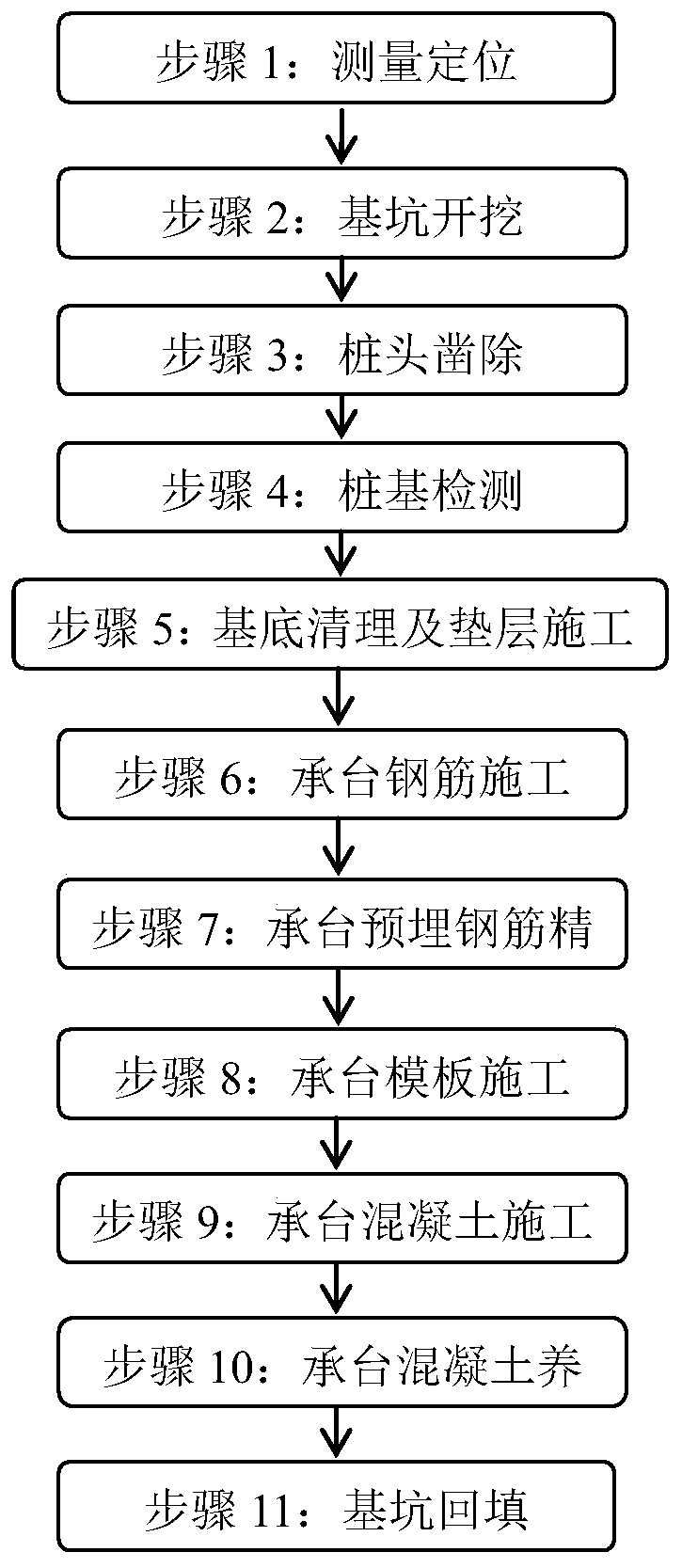

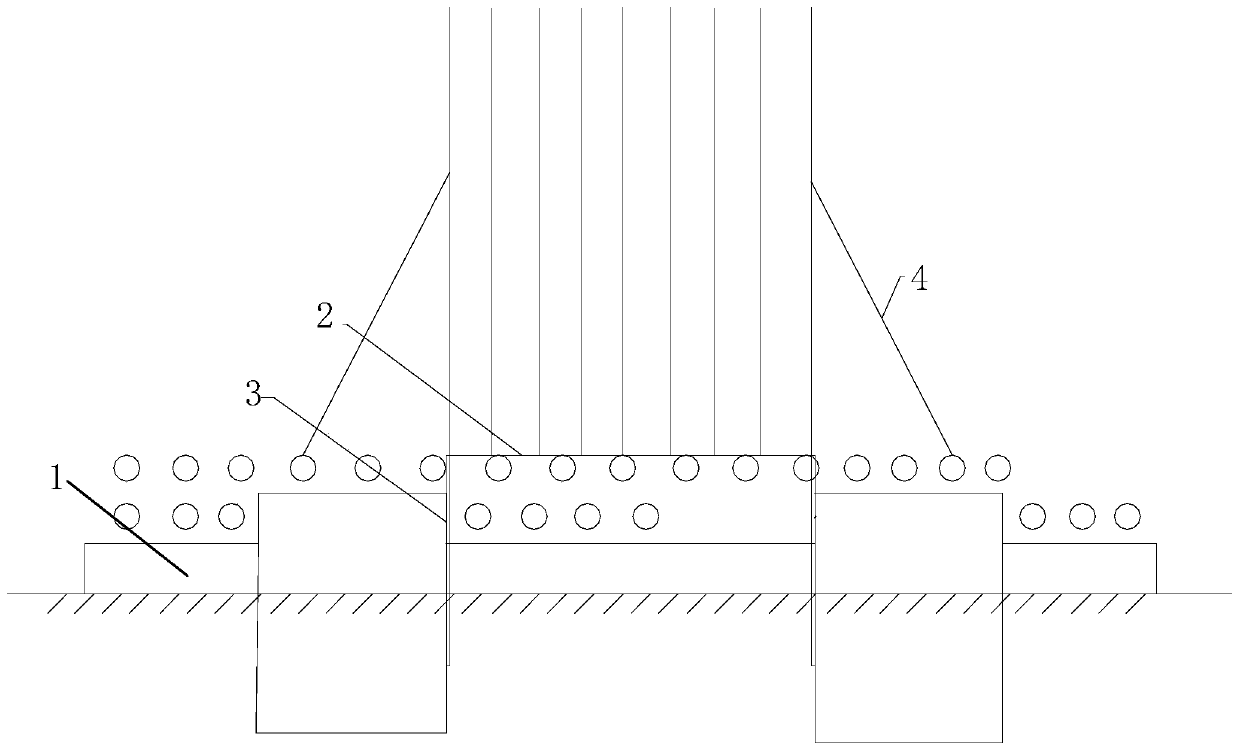

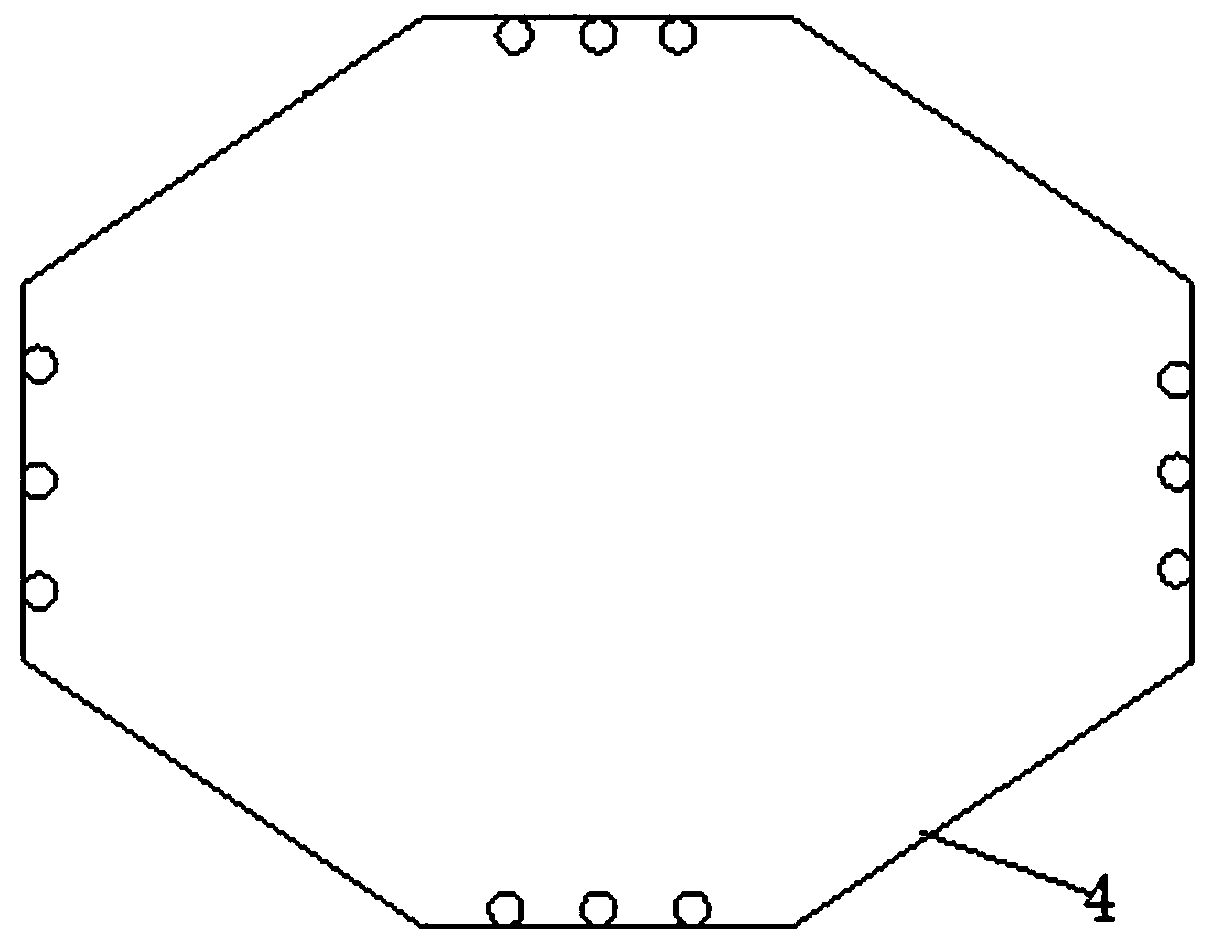

Bearing platform construction process method within prefabricated vertical column range

ActiveCN110453592AGuaranteed one-time castingGuaranteed integrityBridge structural detailsBridge erection/assemblyBridge engineeringCable stayed

The invention discloses a bearing platform construction process method within a prefabricated vertical column range, and relates to the field of bridge engineering construction. The method includes the following steps of S1, base cleaning and cushion layer construction, wherein a prefabricated vertical column embedded reinforcement cage sideline is positioned and paid off, multiple anchor bolts are evenly distributed on the outer side of the sideline in an embedded manner, and the anchor bolts are poured into a cushion layer; S2, bearing platform rebar construction, wherein an octagonal rebarpositioning device is welded through angle steel, a bound reinforcement cage is hoisted above the rebar positioning device, and the periphery of the embedded reinforcement cage is welded and fixed through cable-stayed rebars; and S3, precision control of bearing platform embedded rebars, wherein the relative positions of the embedded rebars are controlled through limiting formworks on the top faces of the prefabricated vertical column embedded rebars, multiple steel pipes and jacks are used below the limiting formworks for supporting the limiting formworks, and the tail ends of the steel pipesare supported on a steel formwork erected on the outer side of a bearing platform. The construction method has the beneficial effects that the construction process is simple, a construction verticalcolumn is convenient to determine, the stability is good, the economic cost is reduced, and the influence on surrounding environments is low.

Owner:BEIJING MUNICIPAL CONSTR +1

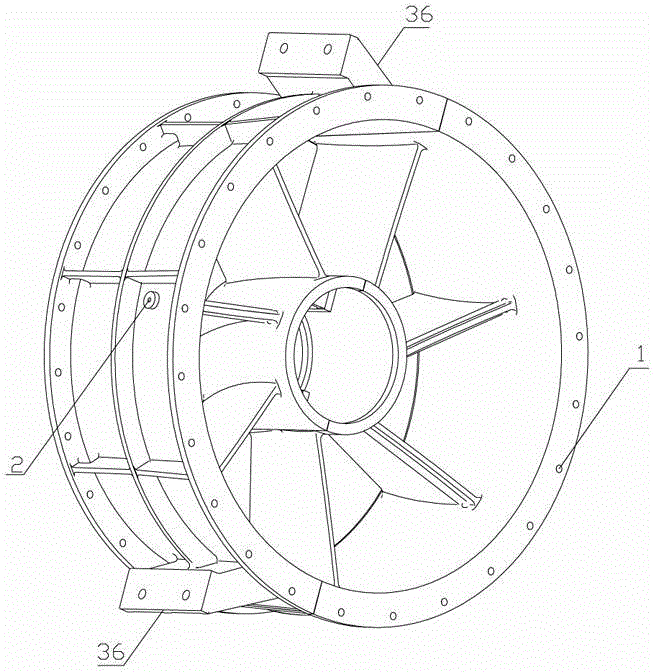

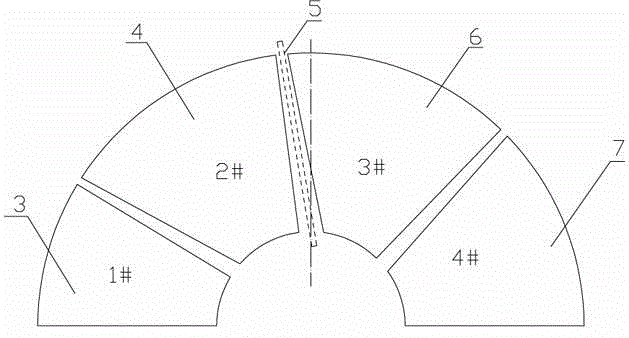

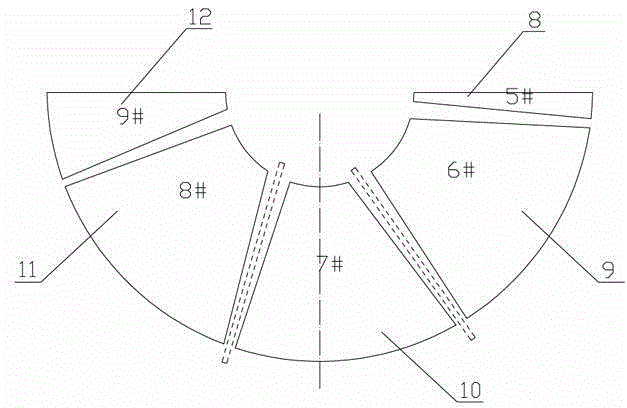

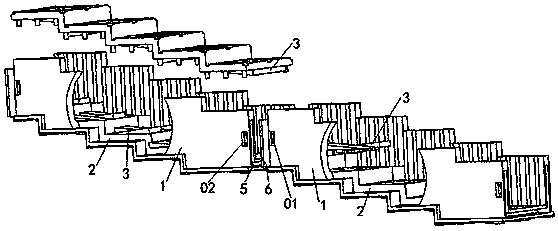

Large horizontal axial flow pump split guide vane casting method

InactiveCN104001864AIngenious designSimple structureFoundry mouldsFoundry coresAxial-flow pumpThick wall

The invention relates to a large horizontal axial flow pump split guide vane casting method. The method is characterized by comprising the steps of: (1) employing a foam module to make an upper half guide vane outer die and a lower half guide vane outer die; (2) designing the upper guide vane into four sand cores, designing the lower guide vane into five sand cores, and specially making a set of molding wood die universal to 1#-9# sand cores; (3) employing the upper half guide vane outer die and the lower half guide vane outer die and the universal molding wood die to manufacture sand molds, and placing coke in the sand cores; (4) pre-embedding a thick-walled seamless steel pipe at the molding position of a guide vane oil pipe hole, and inserting the seamless steel pipe into a foam outer die to fix it; (5) brushing an ISOMOL type special alcohol-based coating on a molding sand casting wall surface twice; (6) carrying out molten iron casting; and (7) controlling the heat preservation time of a casting in the sand mold over 48h. The method provided by the invention adopts the special universal molding wood die, and arranges coke in the sand cores, and employs heat preservation time prolonging and other measures, thus greatly saving the manufacturing cost of the guide vane body and improving the product quality. The method is mainly used for production of large horizontal axial flow pump guide vanes.

Owner:黄石新兴管业有限公司

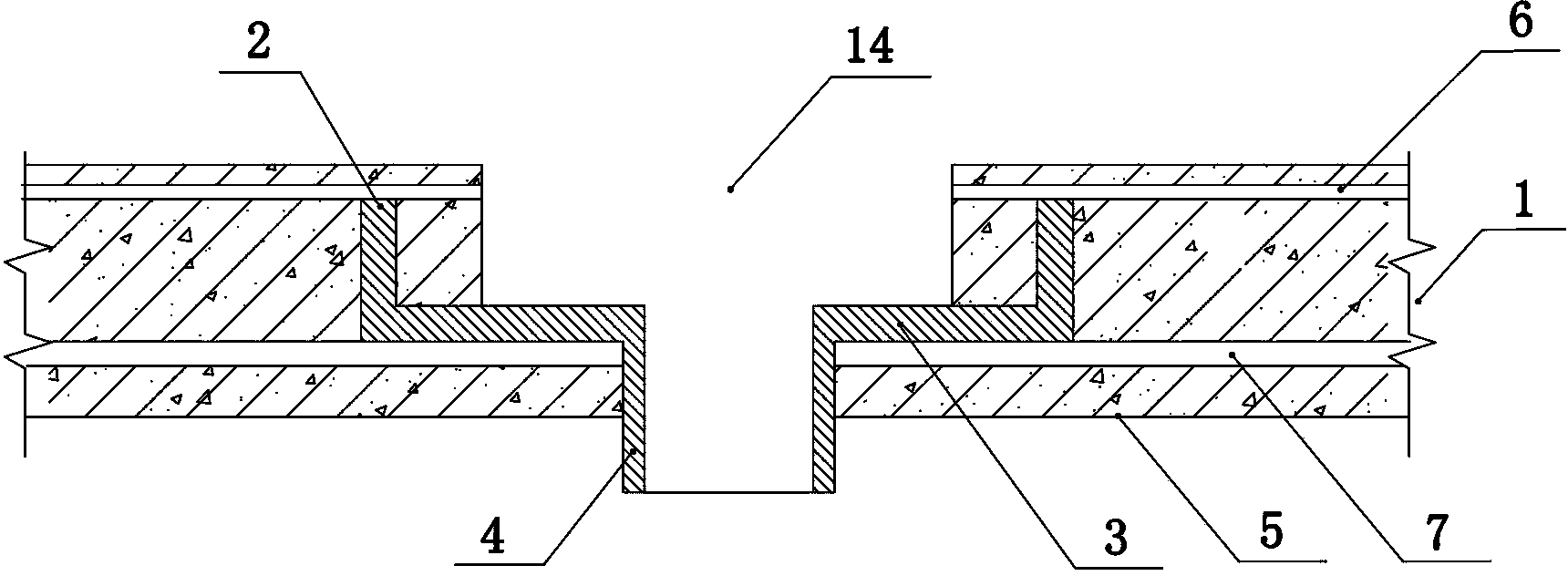

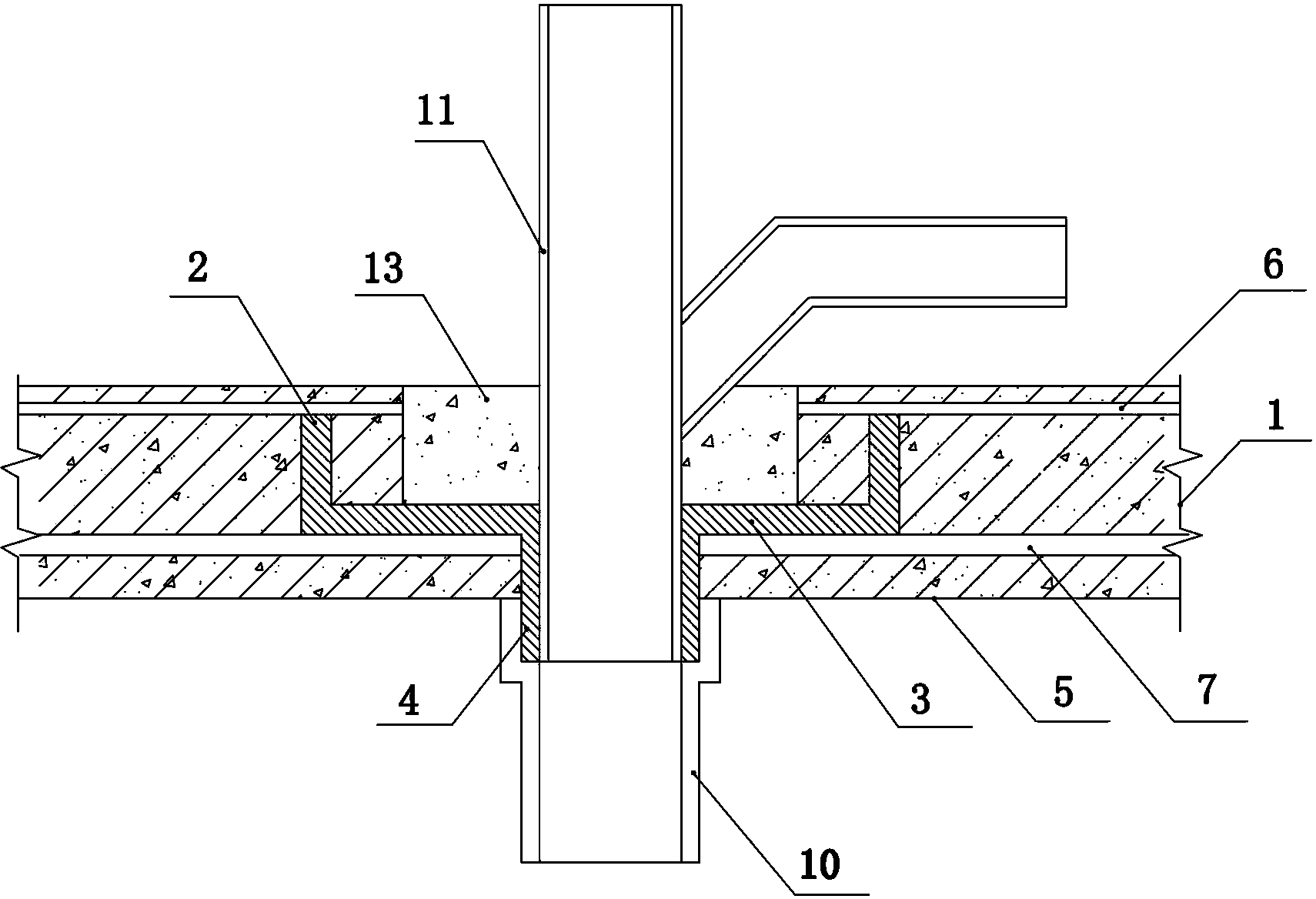

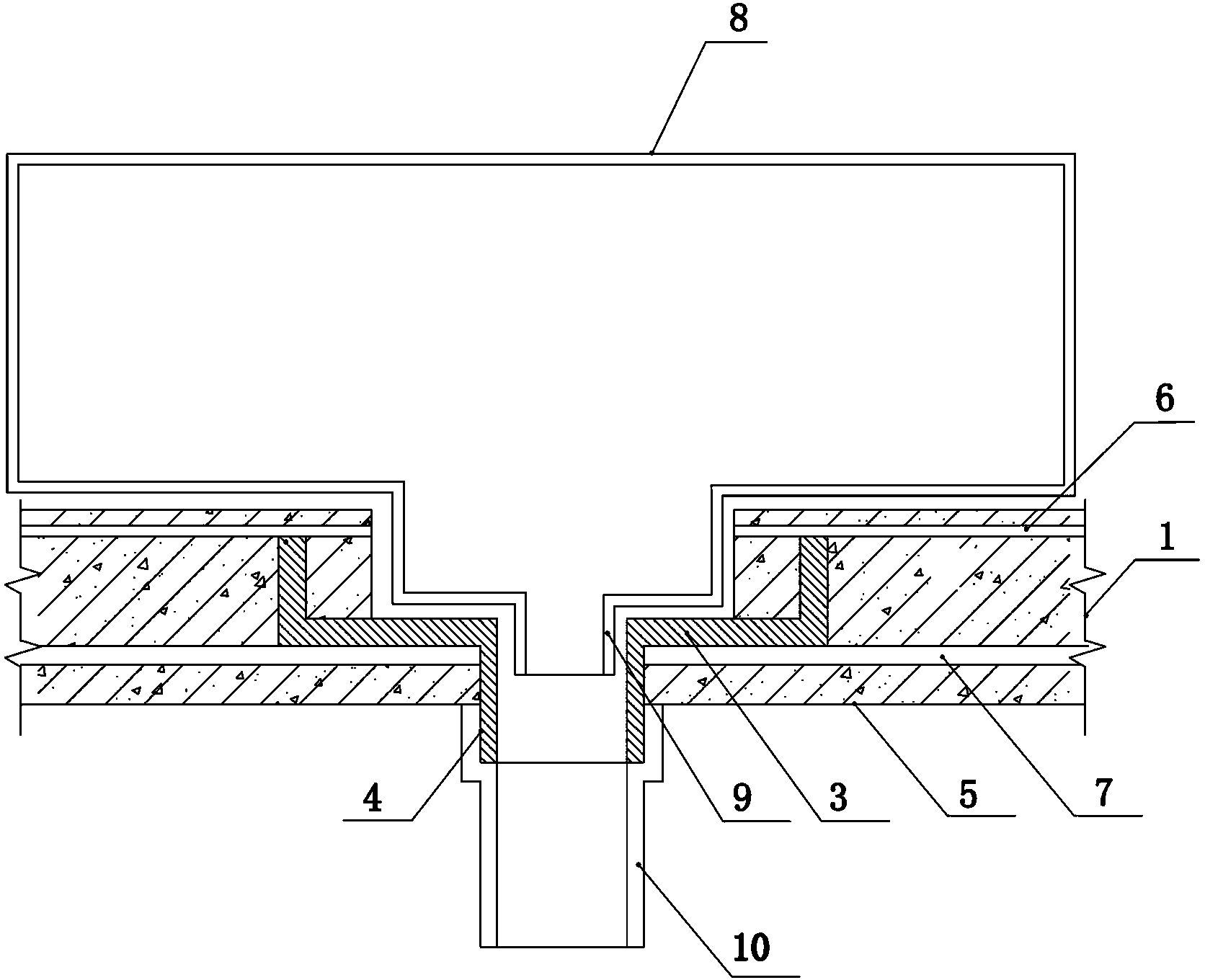

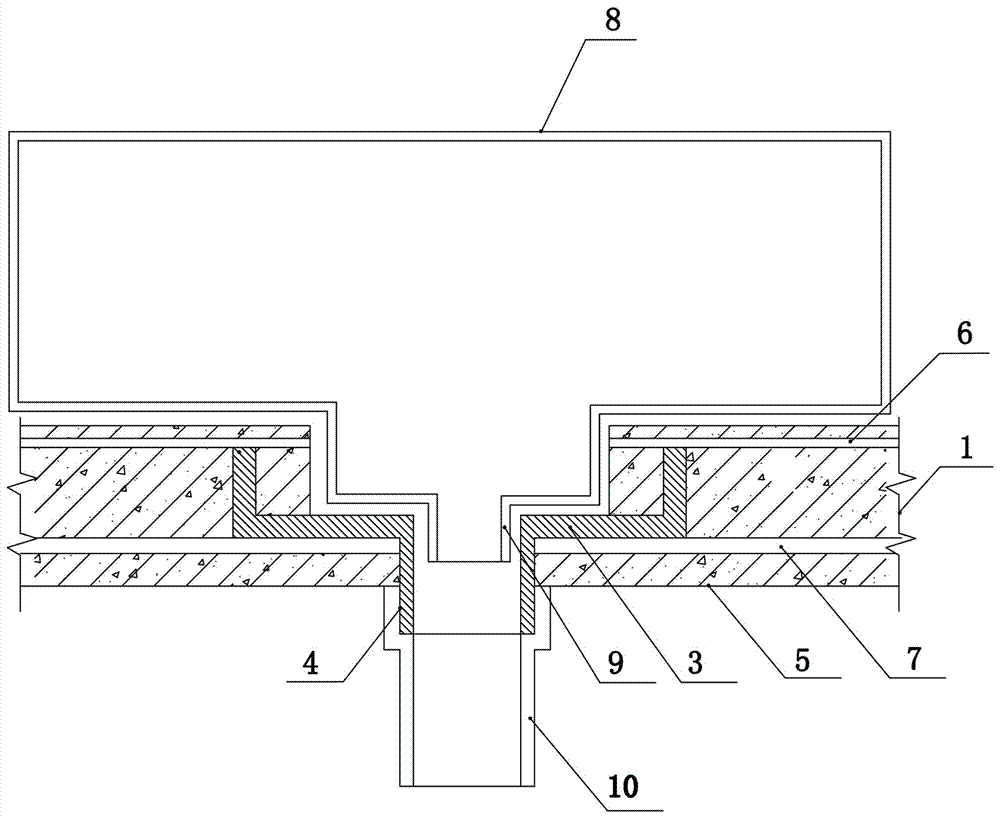

Anti-seepage floor slab and anti-seepage construction method

ActiveCN103835421ASimple structureHigh degree of standardizationPipesFloorsFloor slabStructural engineering

The invention provides an anti-seepage floor slab and an anti-seepage construction method of the anti-seepage floor slab. The anti-seepage floor slab comprises a floor slab body and a waterproof connecting piece embedded into the floor slab body. The waterproof connecting piece comprises an anti-seepage cylinder and a connecting pipe arranged at the bottom end of the anti-seepage cylinder. The top and the side wall of the anti-seepage cylinder are embedded into the floor slab body. The lower end of the connecting pipe extends out of the lower surface of the floor slab body. The invention further provides the anti-seepage construction method. Compared with the prior art, the anti-seepage floor slab and the anti-seepage construction method have substantive features and improvements. According to the structure of the anti-seepage floor slab, seepage is fundamentally eradicated, the installation requirement and difficulty are reduced, the anti-seepage floor slab is quite convenient to use, meanwhile, the structure is simple, waterproof materials are saved, and the cost is low; the anti-seepage construction method is ingenious in concept and easy to implement.

Owner:王凤蕊

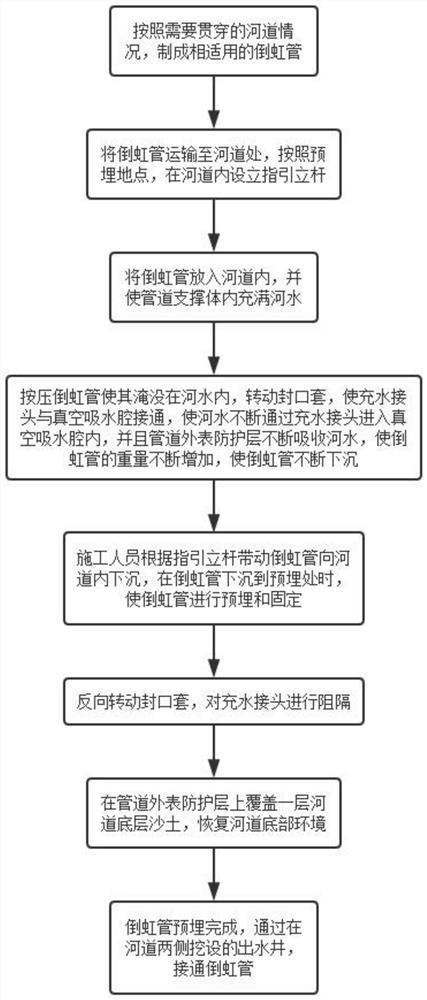

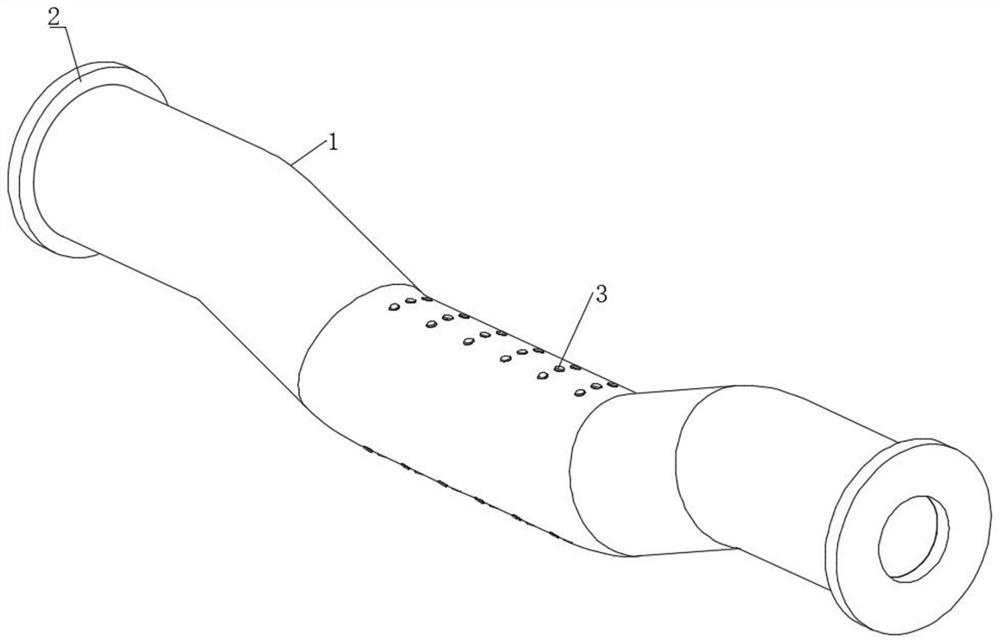

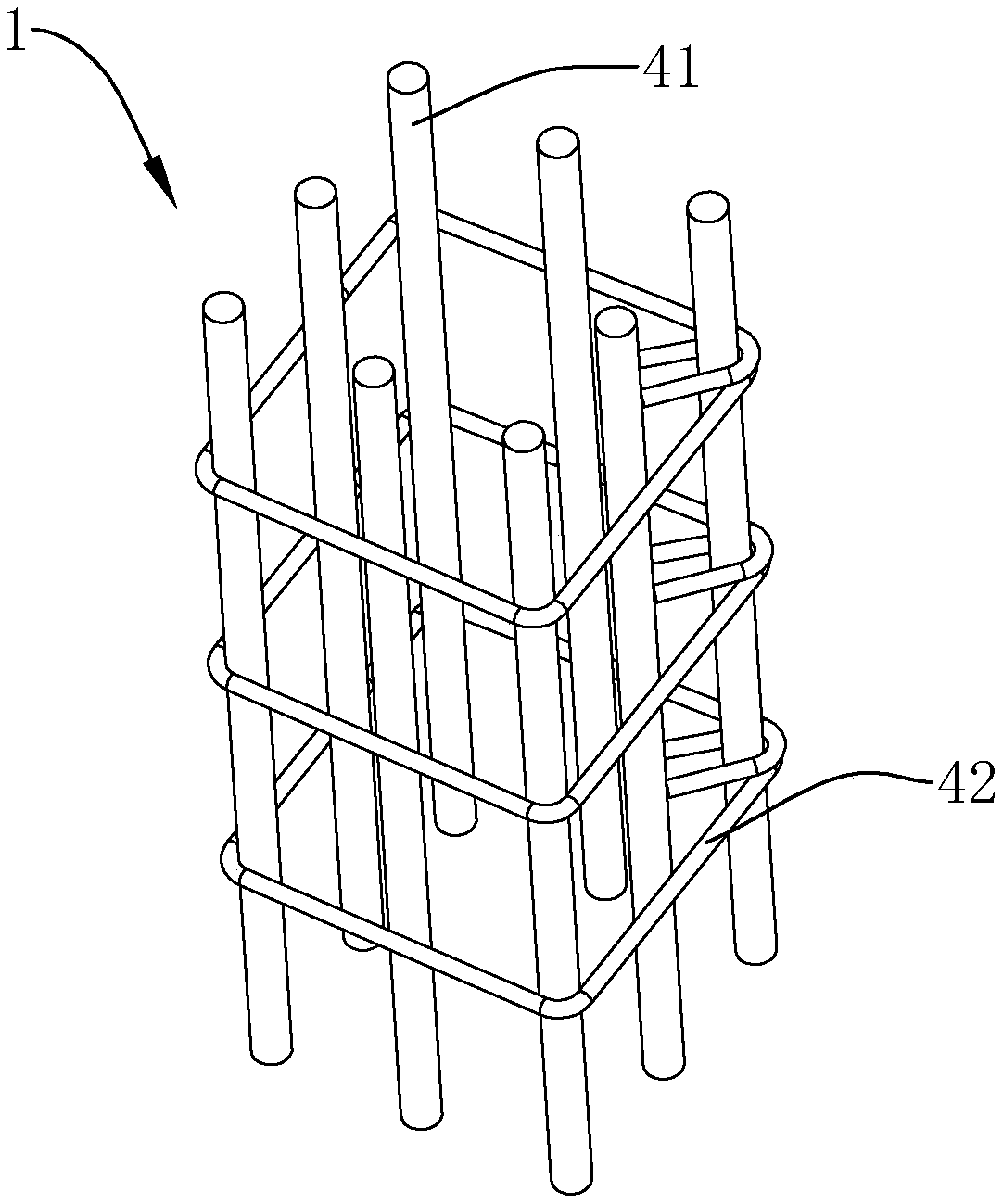

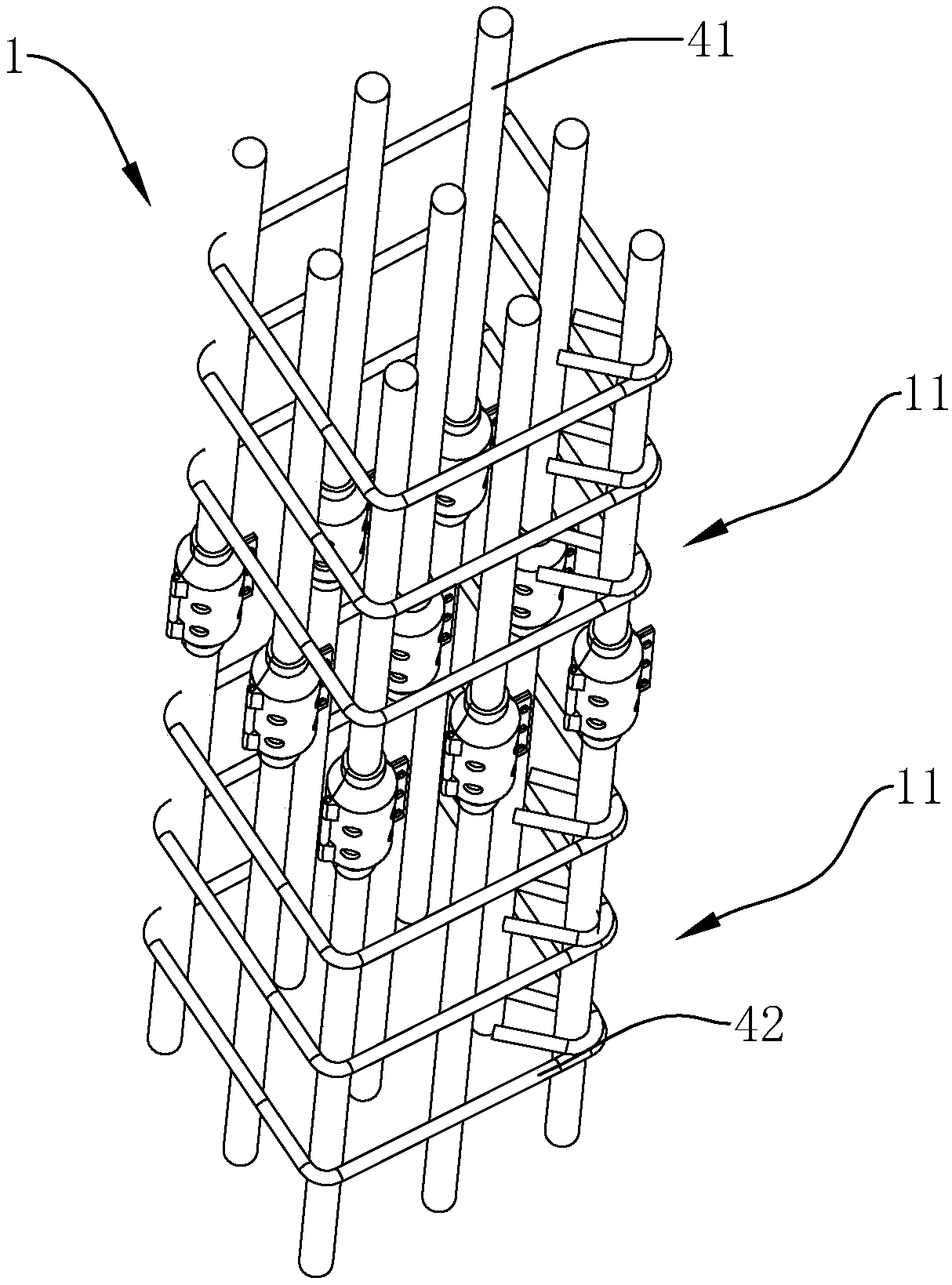

Buoyancy self-control type inverted siphon and construction process thereof

InactiveCN112682576AWeight increaseRealize autonomous sinkingArtificial islandsPipe laying and repairSiphonPipe support

The invention discloses a buoyancy self-control type inverted siphon and a construction process thereof, and belongs to the field of pipelines. The buoyancy self-control type inverted siphon comprises a pipeline body, the pipeline body comprises a pipeline support body, the outer end of the pipeline support body is coated with a pipeline protection interlayer, and the outer end of the pipeline protection interlayer is fixedly connected with a vacuum water suction cavity; the outer end of the vacuum water suction cavity is fixedly connected with a waterproof protective layer, the outer end of the waterproof protective layer is fixedly connected with a pipeline outer surface protective layer, and the vacuum water absorption cavity is matched with the pipeline outer surface protective layer, so that the inverted siphon effectively absorbs water in a self-service manner in the construction process, the self-weight is increased, and therefore the blocking of buoyancy is reduced; and automatic sinking of the inverted siphon is effectively realized, the operation is simple and convenient, the construction efficiency is improved, the construction of constructors is effectively facilitated, the use of auxiliary parts is effectively reduced, the construction cost is reduced, and the economic benefit of the inverted siphon is effectively improved.

Owner:刘谦明

Fabricating structure and method of prefabricated component

PendingCN110258769AEasy to operateEasy assemblyBuilding reinforcementsRebarUltimate tensile strength

The invention discloses a fabricating structure and method of a prefabricated component, and belongs to the field of fabricated buildings. According to the fabricating method, prefabricated plates and rebar concrete are fixedly fabricated into the unified whole through rebar sleeves and concrete. Through stress cooperation generated among the sleeve, the concrete and rebars, the connecting strength of the finally-formed fabricating structure is greatly enhanced, the prefabricated component fabricated through the method is easy to assembly during construction, the prefabricated plates can be quickly fabricated, and the construction period is greatly shortened.

Owner:李藏柱

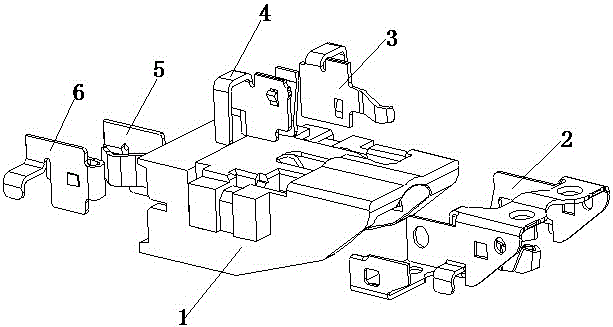

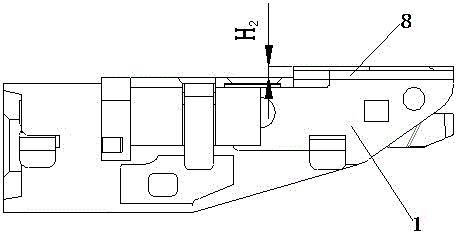

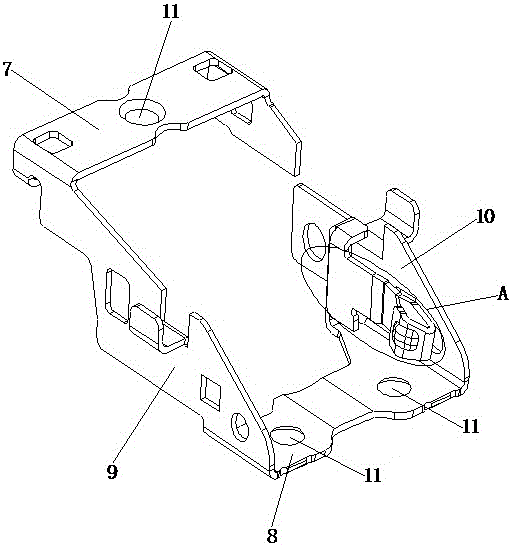

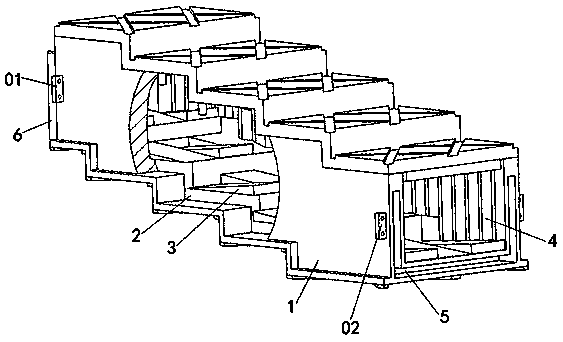

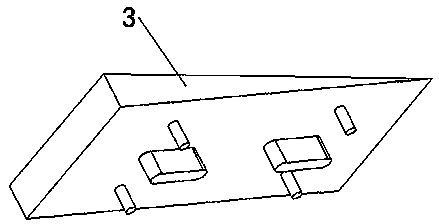

Novel earphone base

ActiveCN105049974AHigh strengthConvenient pre-embeddedEarpiece/earphone attachmentsEngineeringPre embedding

Owner:鸿日达科技股份有限公司

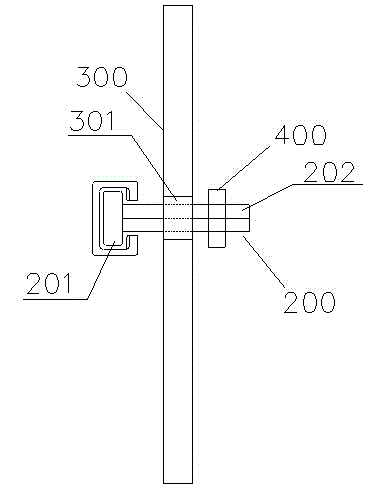

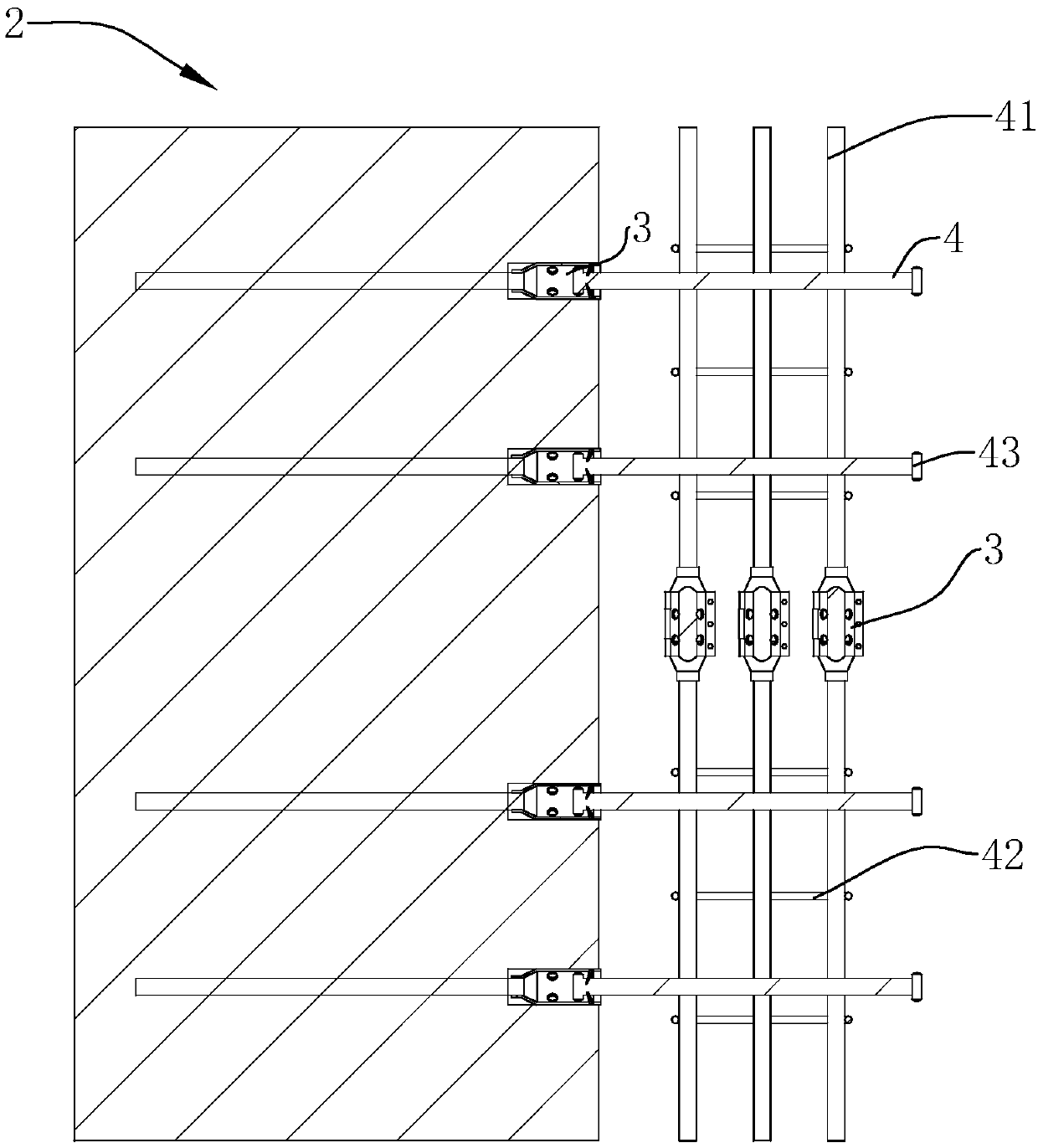

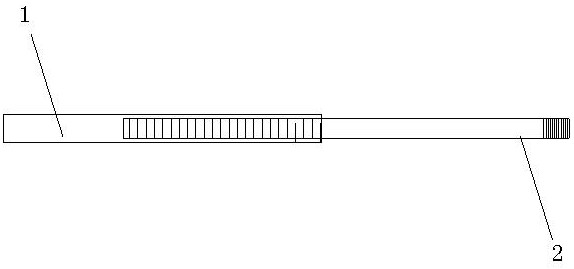

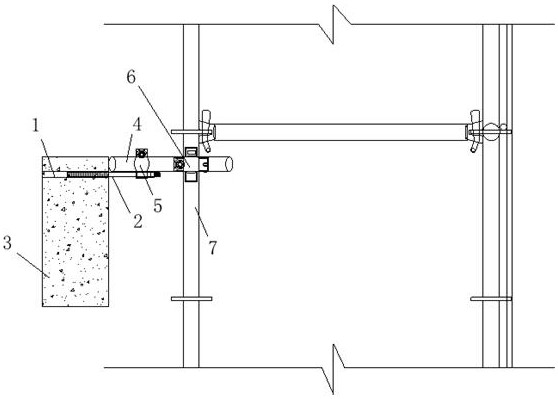

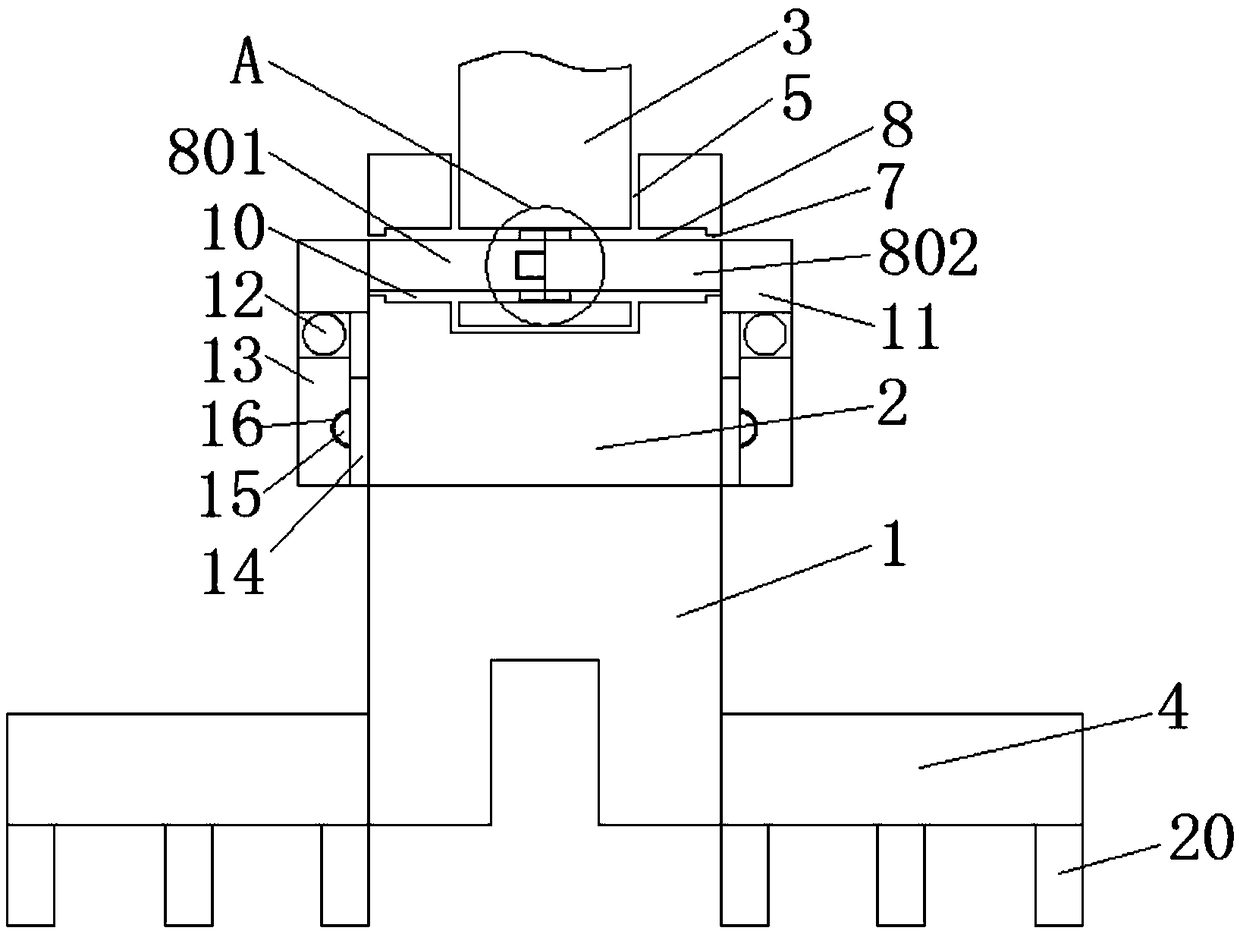

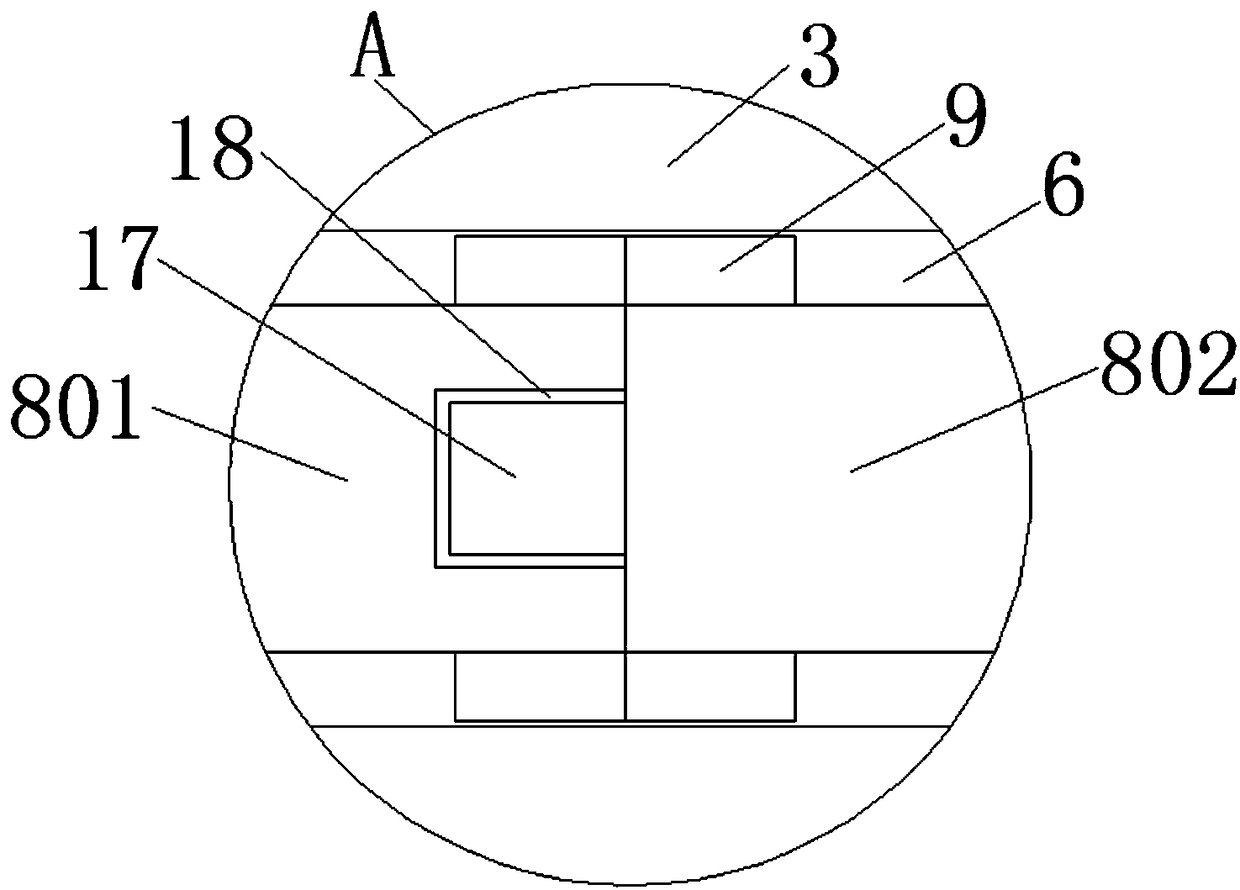

Novel wall connecting piece setting method

PendingCN114737744ASimple structureEasy to manufactureScaffold accessoriesThreaded rodIndustrial engineering

A novel wall connecting piece arranging method is characterized by comprising the following steps that a, a wall connecting piece is manufactured, b, the wall connecting piece is installed, c, a threaded rod is inserted into a sleeve, d, the wall connecting piece is fixedly connected with a scaffold, and the end, exposed out of the sleeve and a wall body, of the threaded rod is fixedly connected with a scaffold vertical rod through a connecting steel pipe and a scaffold fastener. The novel wall connecting piece setting method has the advantages that the wall connecting piece is simple in structure, convenient to manufacture, convenient to pre-embed, high in safety index, stable in structural stress and convenient to dismantle in the later period, and scaffold holes do not need to be blocked.

Owner:MCC5 GROUP CORP SHANGHAI

Foundation embedded component applied to corn planting greenhouse

InactiveCN108775082AEasy to buildAvoid accidentsBuilding constructionsManufacturing technologyGreenhouse

The invention discloses a foundation embedded component applied to a corn planting greenhouse and relates to the technical field of agricultural greenhouse manufacturing. The component comprises an embedded part, wherein fixing plates are fixedly mounted on two sides of the lower end of the embedded part, a connecting block is movably mounted at the upper end of the embedded part, a first groove is formed in the middle of the lower end of the connecting block, a boss is fixedly mounted in the middle of the upper end of the embedded part and movably mounted in the first groove, and a fixing rodis movably mounted in the upper end of the connecting block. The foundation embedded component applied to the corn planting greenhouse can be connected with a fixing rod conveniently to be fixed effectively, the fixing property of the fixing rod is improved, the structure is simple, accidents in the setting up process of the greenhouse are avoided, resource waste is effectively reduced, setting up is facilitated, manpower and material resources are saved, connection with the embedded part is facilitated, shaking of the connecting block is effectively avoided, and the embedded component is simple in structure, convenient to use, large in contact area and firm in fixation and facilitates embedment.

Owner:安吉富民生态农业开发有限公司

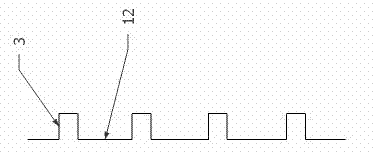

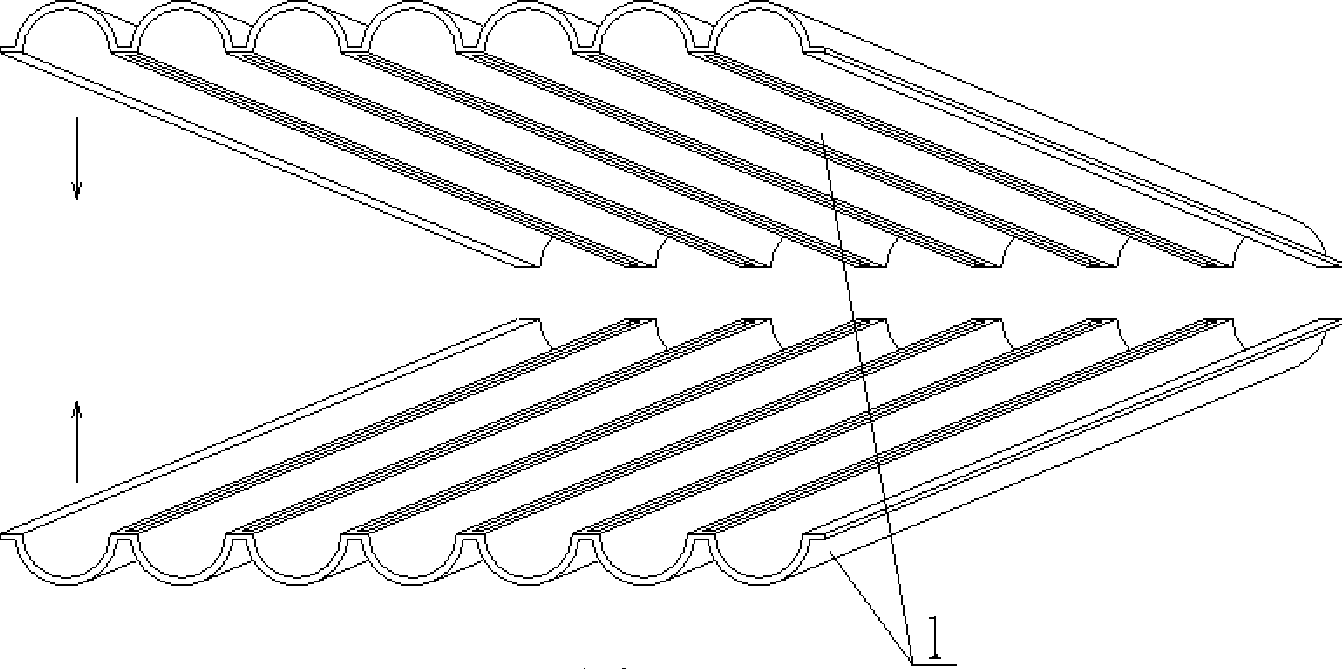

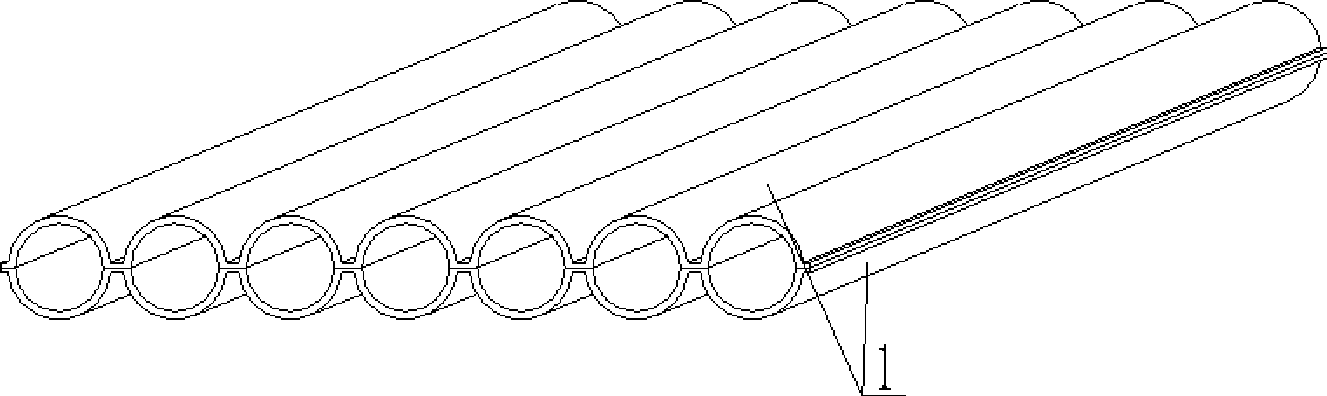

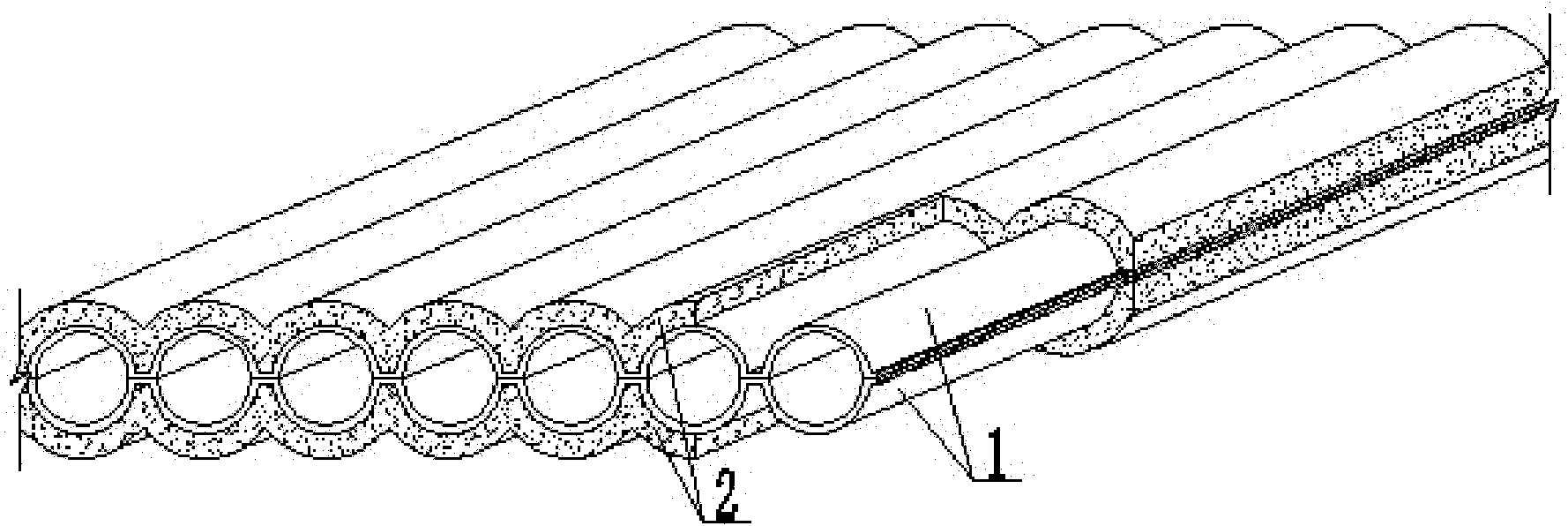

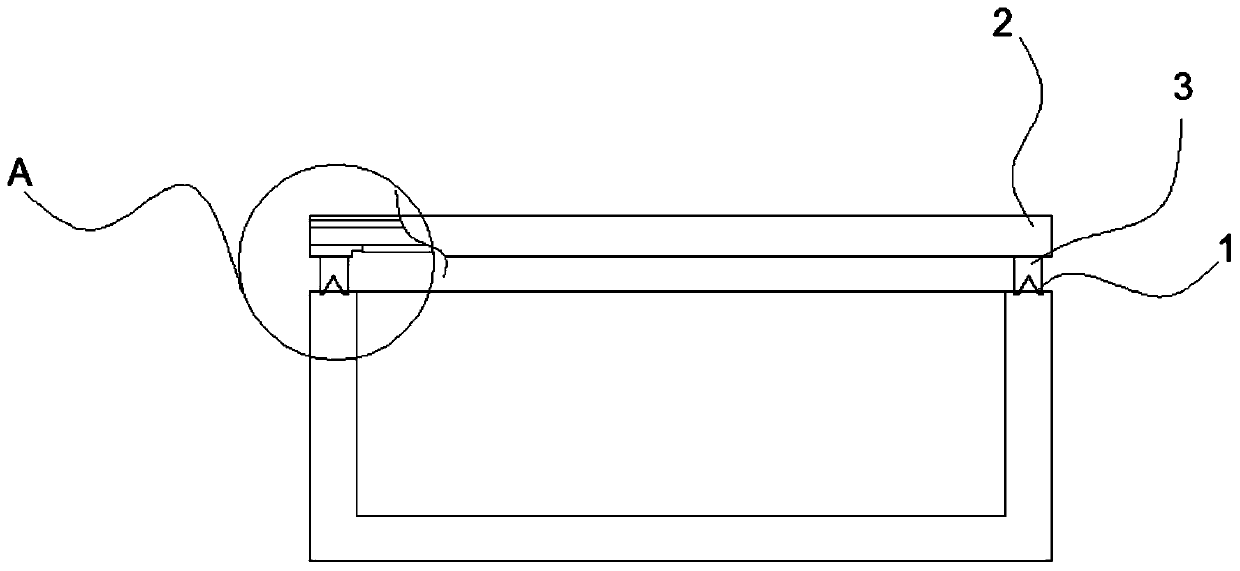

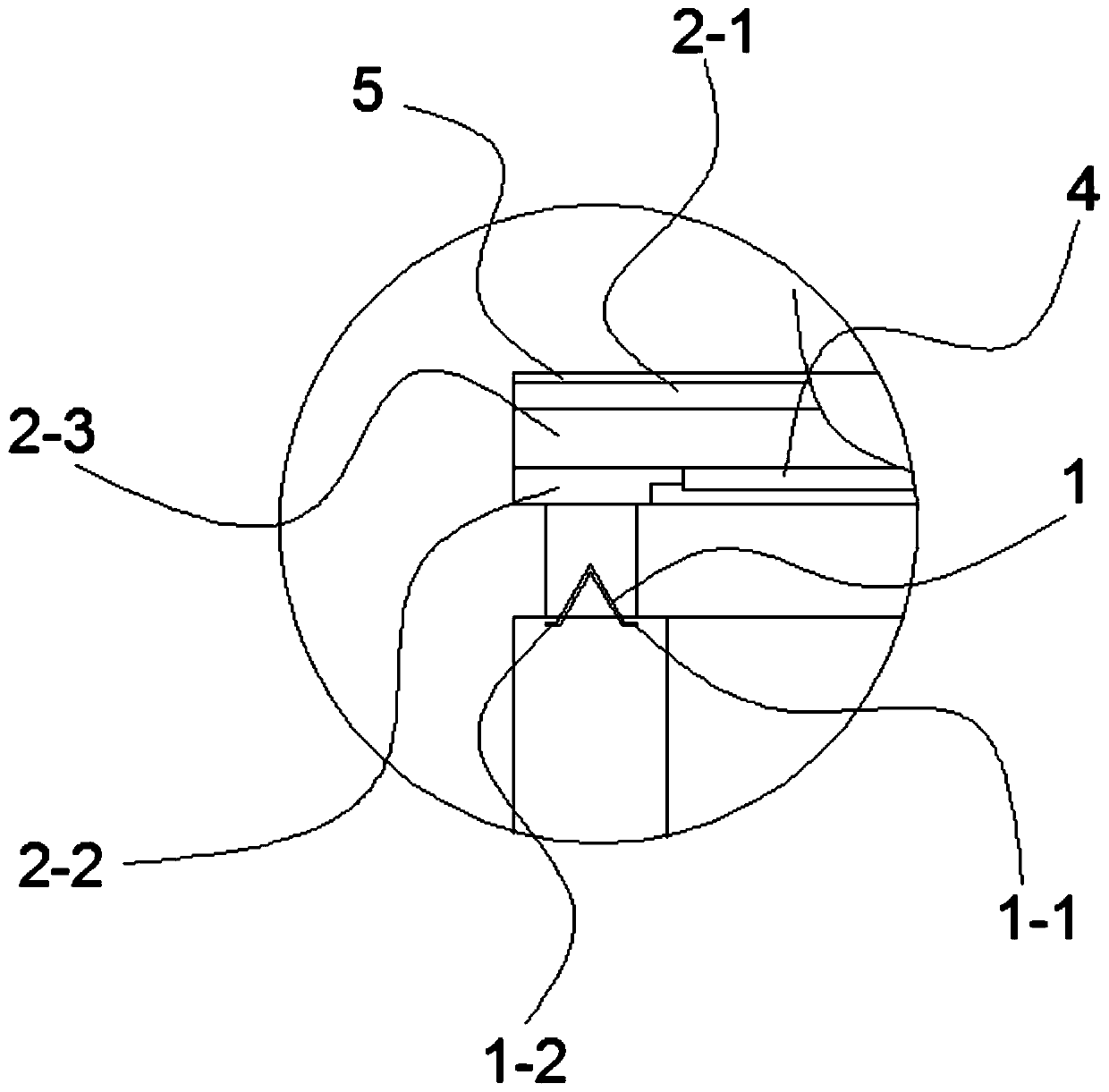

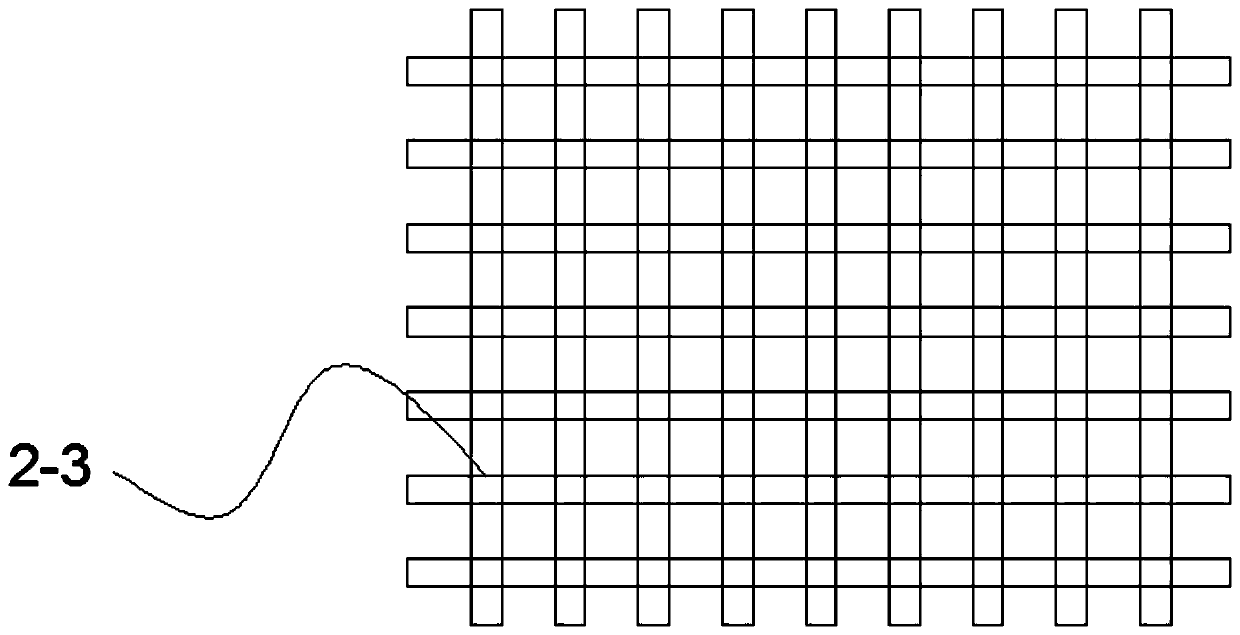

Light wall board drying plate

The invention relates to a light weight wallboard core plate which comprises core plate parts (1), and the light weight wallboard core plate is characterized in that the core plate parts (1) are correspondingly buckled. Therefore, the core plate has simple manufacture and simple and convenient construction technology, and can be applied to a light weight wallboard; an air layer which is sealed and still and is formed in the core plate has good sound insulation and heat preservation effects, and is light in self weight, so that the building load is greatly reduced, the basic construction cost is lowered, the transportation is convenient, and the labor intensity of the installation workers is lightened. Before the core plate is positioned and plastered, the construction of the pipeline and the pre-buried of a hanger are both convenient, so that the cost is reduced; furthermore, the core plate parts can be produced by flow process by adopting automation special equipment, thus ensuring the product quality. The needs of the project can be met by manufacturing the core plate parts with various cross sectional shapes and diameters according to the construction design requirements. The light weight wallboard core plate is suitable for the wallboard of cast in place reinforced concrete, prestressed reinforced concrete or sand pulp, and is applicable to the overlong wall, the overhigh wall and the polygonal line wall.

Owner:邱则有

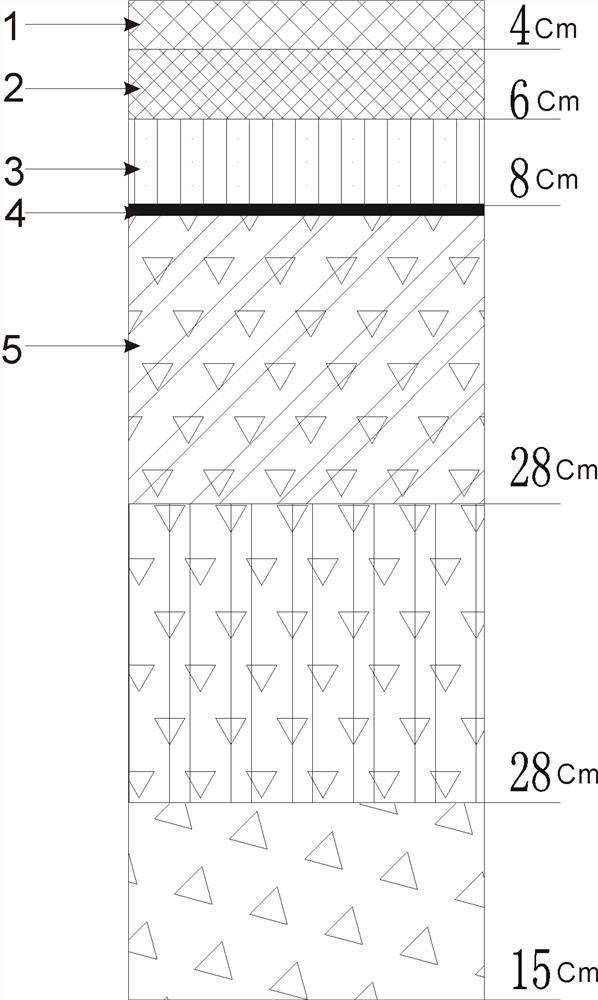

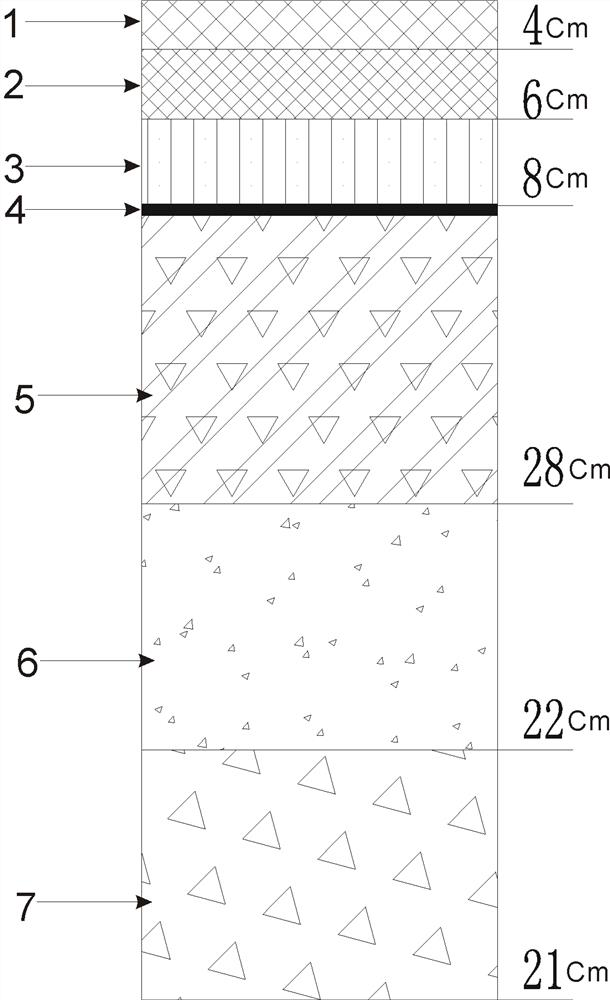

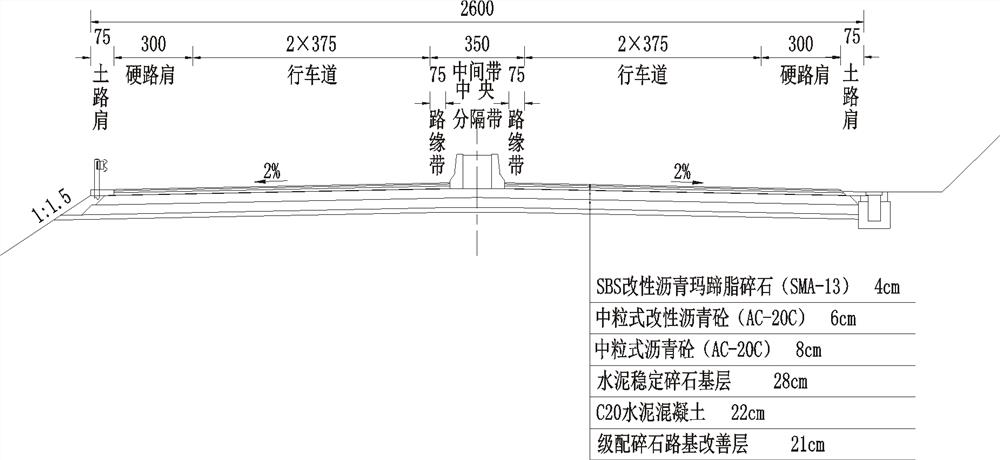

Asphalt pavement structure for expressway precast beam field pavement permanent and temporary structure conversion

InactiveCN113089410AExtended service lifeFulfil requirementsIn situ pavingsStructural engineeringRoad surface

The invention discloses an asphalt pavement structure for expressway precast beam field pavement permanent and temporary structure conversion. The structure is characterized in that: the asphalt pavement structure comprises an asphalt pavement and a modified asphalt synchronous gravel seal coat; a cement stabilized macadam base layer; a prefabricated beam yard concrete pavement; and a prefabricated beam field graded broken stone base layer; wherein the asphalt pavement is divided into an asphalt pavement upper surface layer, an asphalt pavement middle surface layer, and an asphalt pavement lower surface layer. The invention particularly relates to a pavement structure for arranging a precast beam yard in a main line or a service area of an expressway, in particular to a pavement structure for arranging a precast beam yard in a main line or a service area of the expressway, which is characterized in that after the beam yard is used, an original pavement is fully utilized, permanent and temporary structure conversion is performed, a corresponding structure is paved on the original pavement after the original pavement is correspondingly treated, and a new permanent pavement structure for expressway driving is formed.

Owner:SICHUAN ROAD & BRIDGE GRP

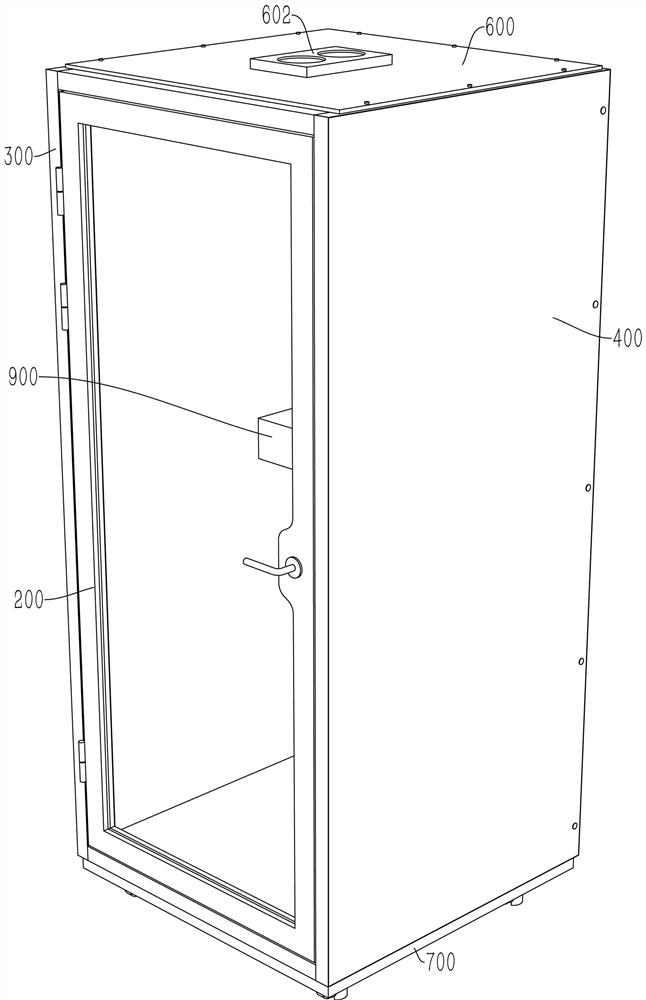

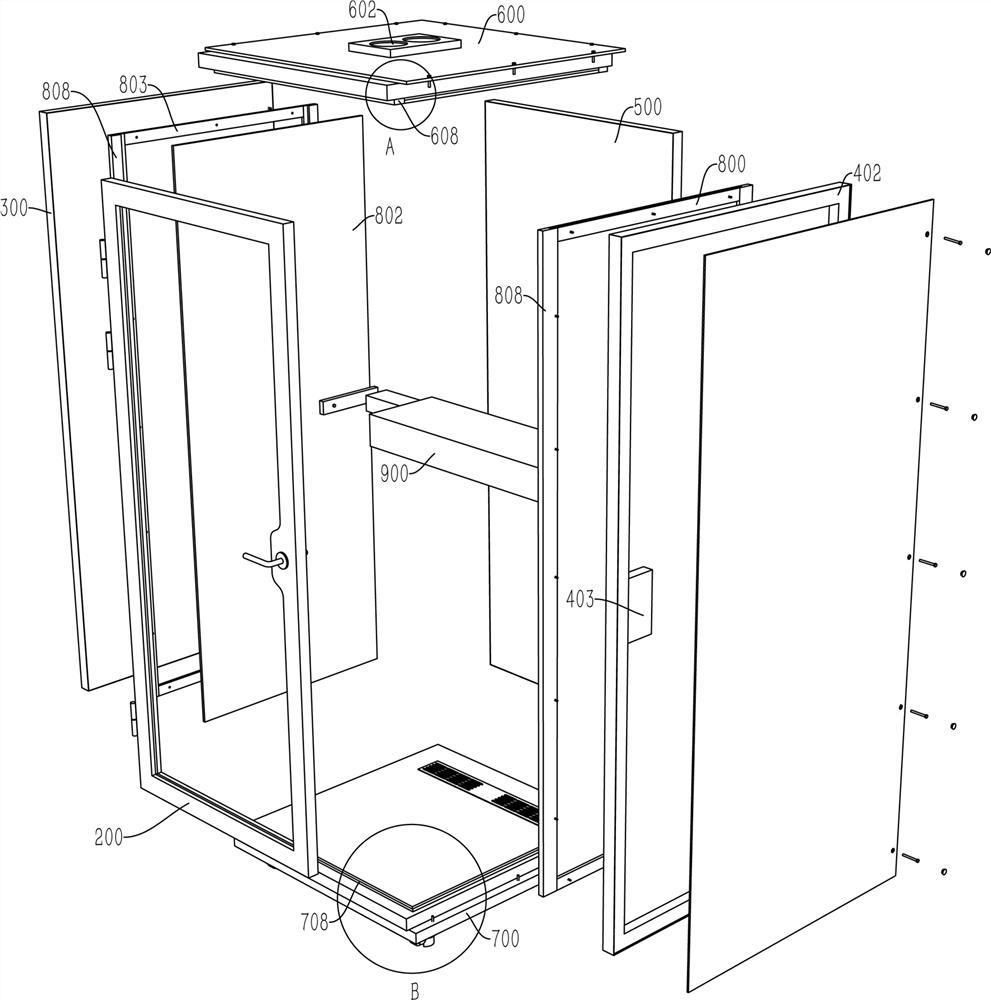

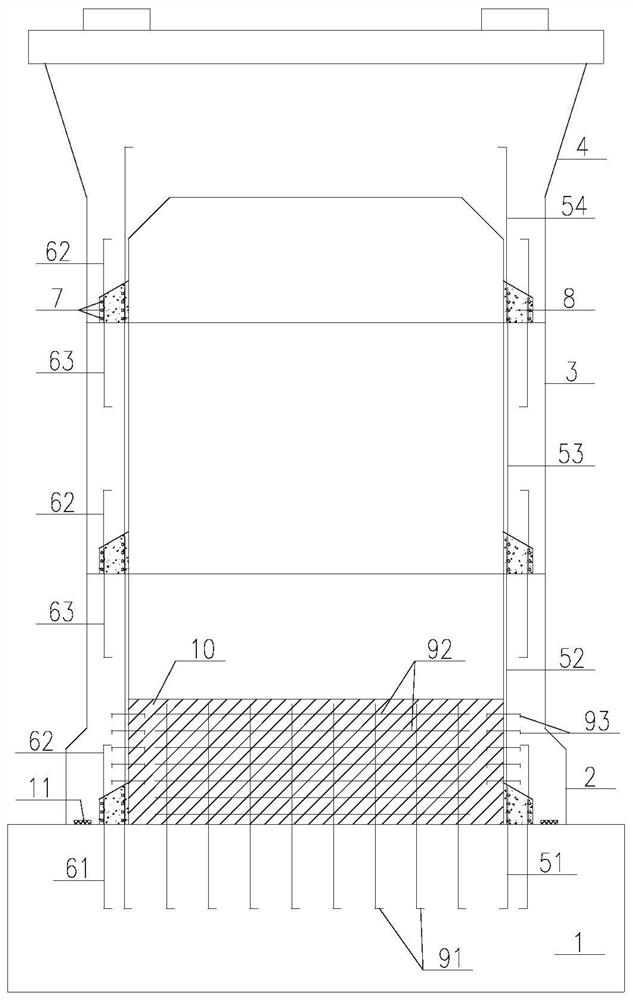

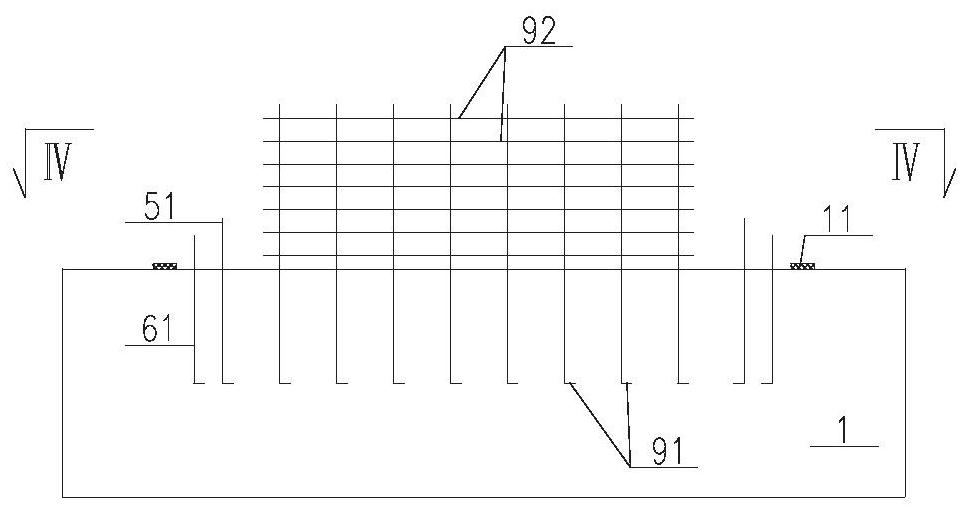

Indoor sound insulation structure

PendingCN111764697ASimple preparation processReduce the difficulty of productionWallsSpecial buildingStructural engineeringMechanical engineering

The invention discloses an indoor sound insulation structure. The indoor sound insulation structure comprises a wall assembly, a door assembly, a top assembly and a bottom assembly; a door leaf is adopted as the wall assembly; the door leaf comprises a door leaf frame and a door plate; the door leaf frame is connected with other door leaf frames, the door assembly, the top assembly and the bottomassembly; embedded nuts are arranged in the door leaf frame to serve as connecting parts; and the door leaf frames are connected through bolts and embedded nuts when the door assembly, the top assembly and the bottom assembly are connected with the door leaf frames. According to the indoor sound insulation structure, the door leaf is adopted for manufacturing the wall assembly, the manufacturing process of the door leaf is simple, and the door leaf can be manufactured by a common furniture factory, so that the production difficulty of the wall assembly is reduced, the indoor sound insulation structure is easier to produce, and a closed room can be conveniently manufactured by cooperation of different manufacturers; and the industrial chain of small closed room production can be integratedmore easily, the production cost of the wall assembly can be greatly reduced, and then the production cost of the whole indoor sound insulation structure is reduced.

Owner:3DS ENG PROCUREMENT CONSTR SUZHOU CO LTD

Prefabricated assembled hollow pier based on UHPC joints and construction method

PendingCN113123221AConvenient pre-embeddedPre-buried connection is reliableBridge structural detailsBridge erection/assemblyArchitectural engineeringRebar

The invention discloses a prefabricated assembled hollow pier based on UHPC joints and a construction method of the pier, the prefabricated assembled hollow pier comprises a pier column and a base, the pier column is a hollow pier column, the pier column is sequentially composed of a pier bottom section, a middle section and a top cap section from bottom to top, the pier bottom section is located at the top of the base, steel bar connectors are embedded between the pier bottom section and the base, between the pier bottom section and the middle section and between the middle section and the top cap section, reinforcing stirrups are arranged outside the steel bar connectors, and connection is achieved through post-pouring of UHPC joints. According to the invention, the steel bar connectors between the sections are easy to position and connect, the height of the joints is remarkably reduced, and the using amount of joint concrete is small; the segment construction tolerance is large, and the precision requirement is low; joints are free of vibration, self-compaction is achieved, pouring is convenient, and construction is simple; and the assembled pier is excellent in overall performance, high in joint durability, rapid to assemble, short in field operation time and high in efficiency.

Owner:CHINA RAILWAYS CORPORATION +1

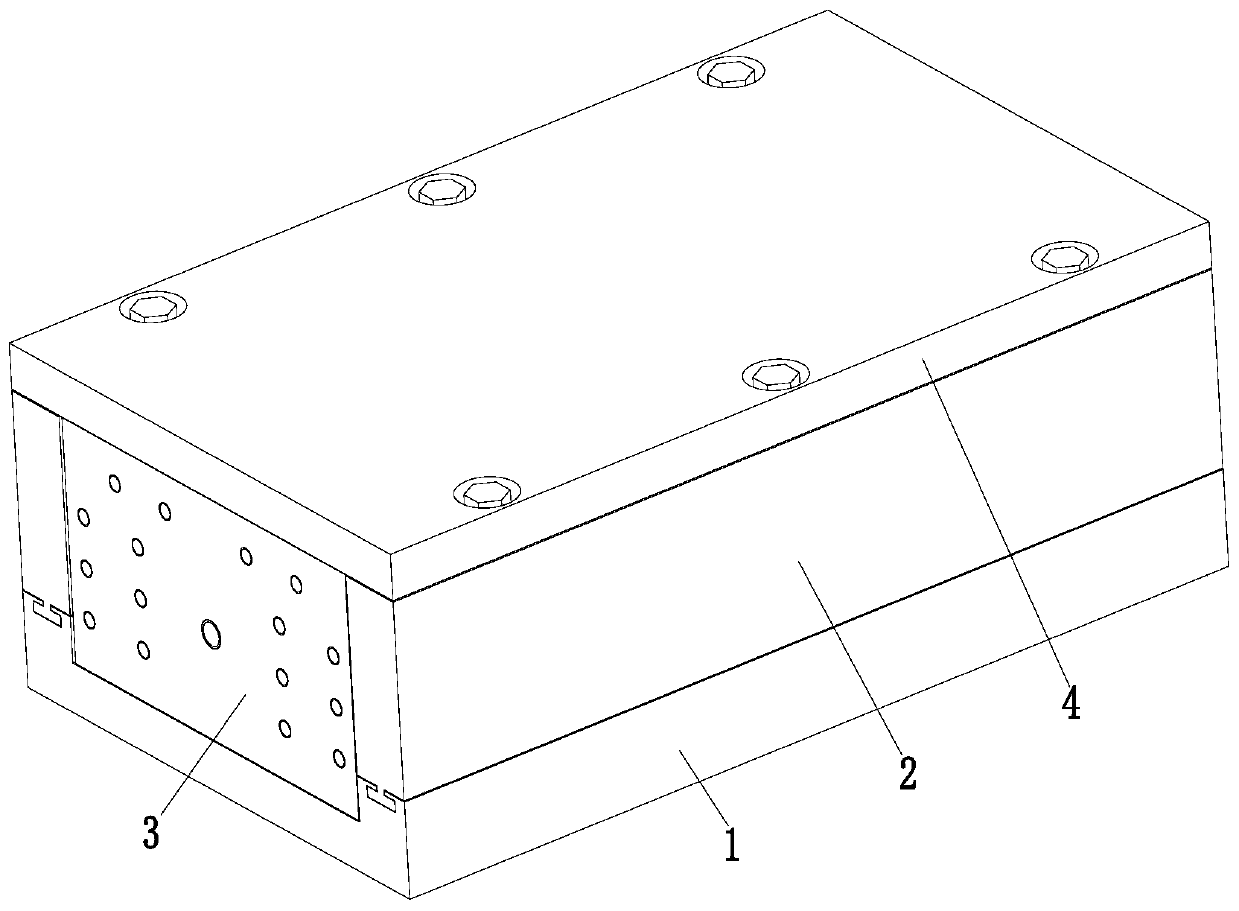

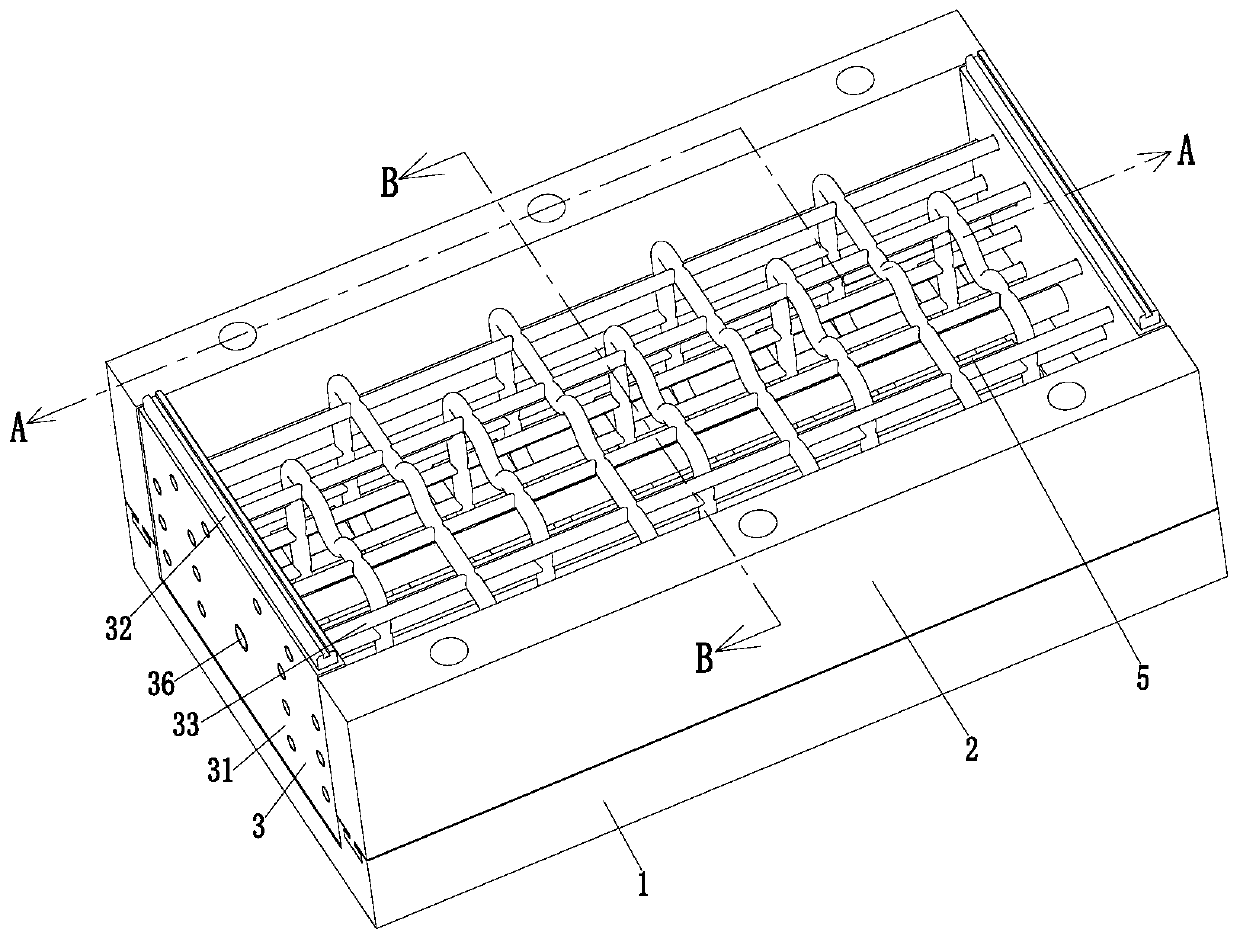

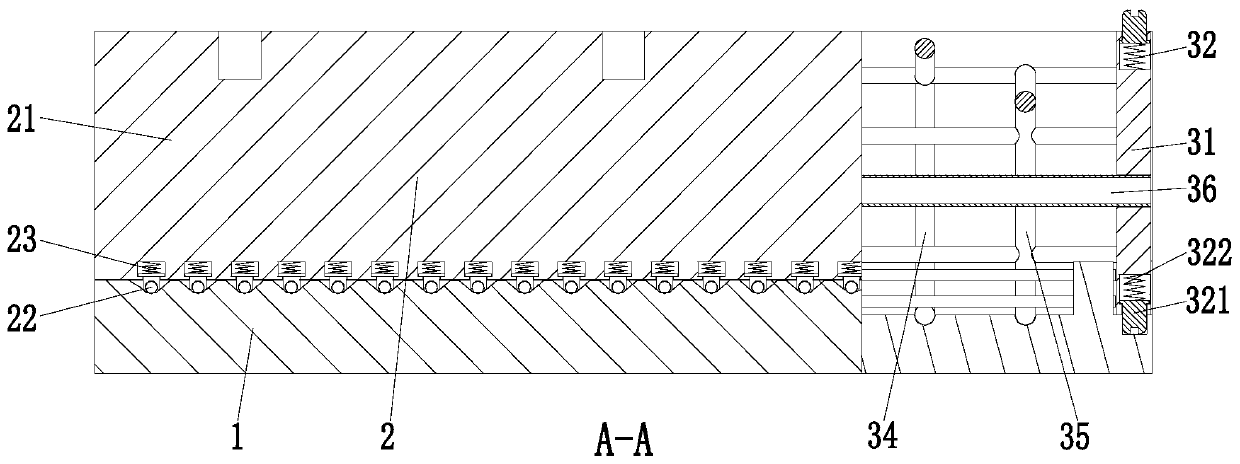

Method for manufacturing and testing pre-embedded screw type steel fiber reinforced concrete uniaxial tensile test piece

PendingCN114279783APrecise positioningConvenient pre-embeddedPreparing sample for investigationMaterial strength using tensile/compressive forcesTotal thicknessMechanical engineering

The invention provides a manufacturing and testing method for a pre-embedded screw type steel fiber reinforced concrete uniaxial tensile test piece. The mold is composed of a cuboid wood mold, a foam piece, an embedded screw and a screw positioning base plate. The foam piece is attached to the wood mold side plate after being processed into a specified shape, so that the transition between the end part of the tensile test piece and the middle test section is realized. The screw positioning base plate is connected with the wood mold end plate, the hole corresponds to the embedded screw in size and position and is used for embedding the screw during pouring, and the exposed length of the embedded screw of the test piece is controlled by adjusting the total thickness of the two plates. The step of manufacturing the test piece comprises pouring and demolding. The test method comprises the steps of tensile test preparation and test flow. The tensile test piece mold provided by the invention can conveniently realize the forming of a tensile test piece in a special shape and the positioning and embedding of screws, is economical, flexible and high in operability, is easily processed into a multi-connected mold, and can conveniently realize the test of the direct tensile property of the steel fiber reinforced concrete by combining with the test method.

Owner:TONGJI UNIV

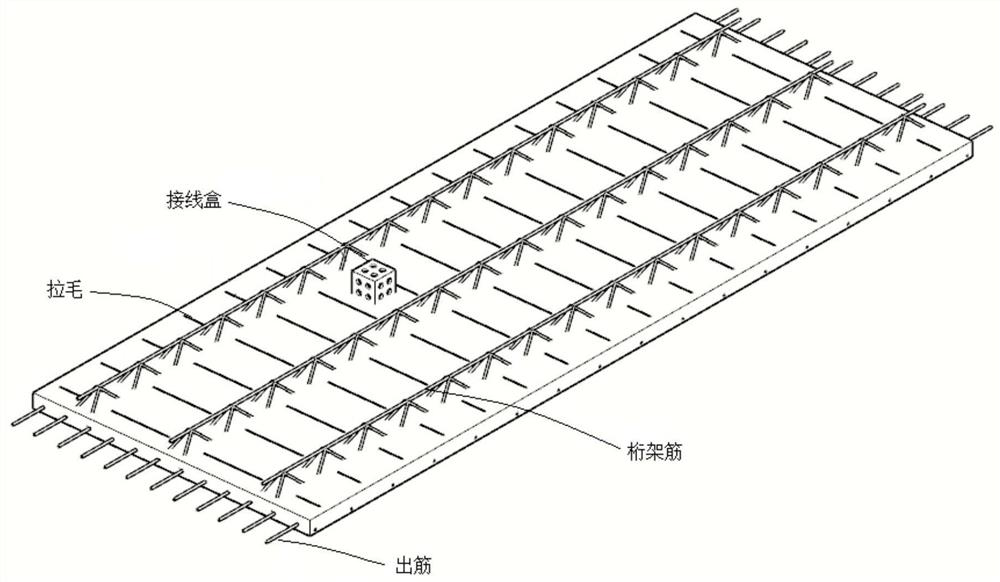

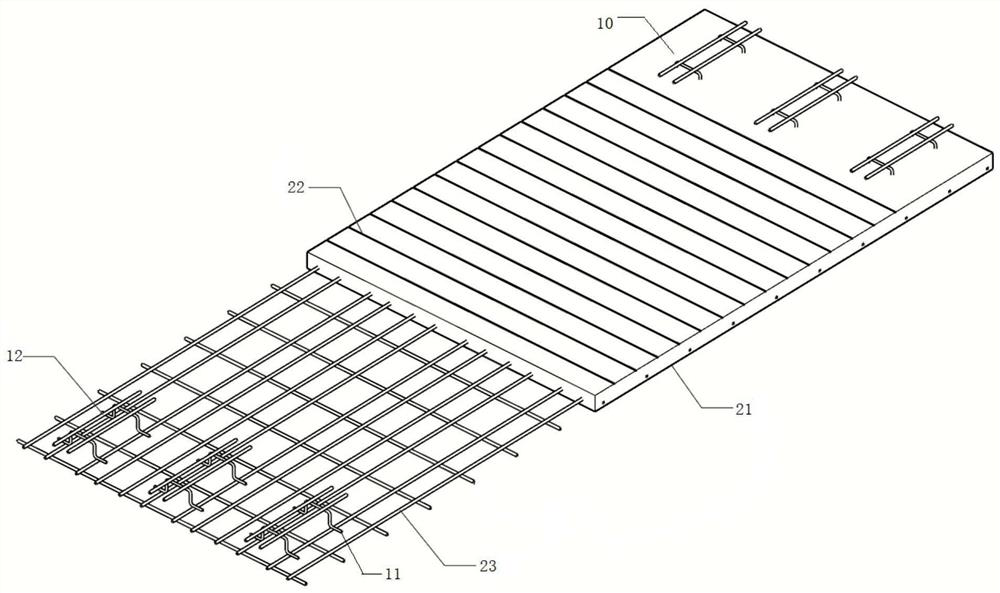

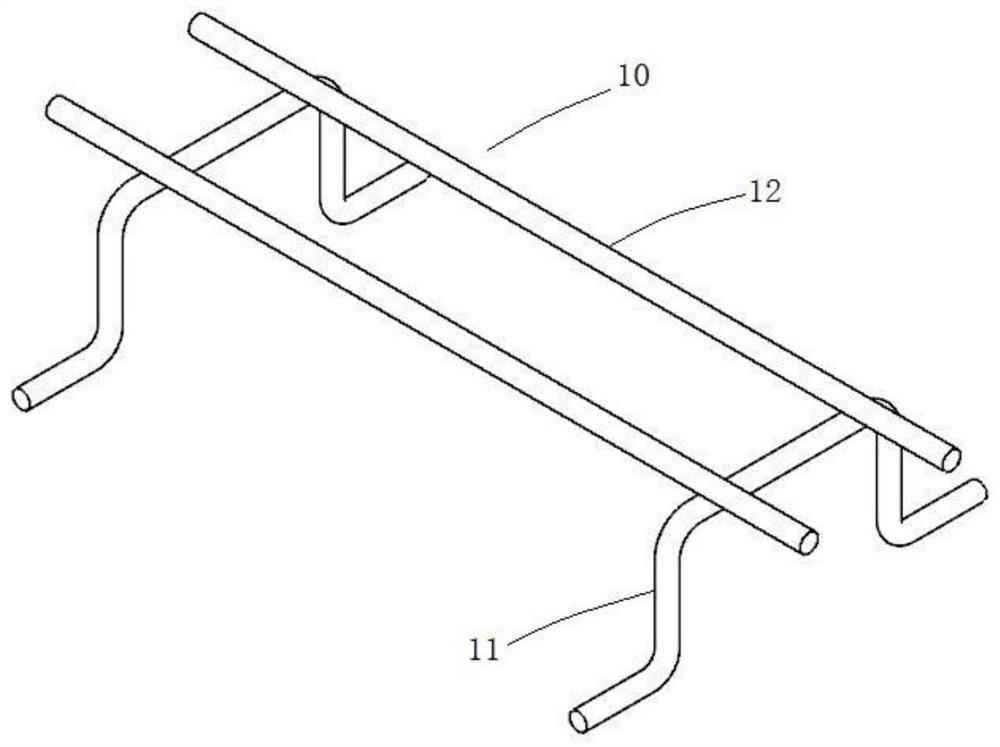

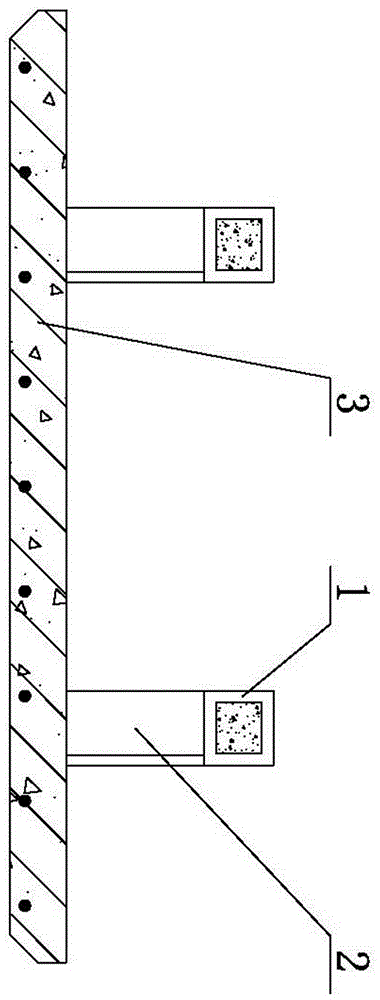

Prefabricated bottom plate preparation method, prefabricated bottom plate structure and construction method of prefabricated bottom plate structure

ActiveCN112942658AReduce labor costsConvenient pre-embeddedFloorsCeramic shaping apparatusArchitectural engineeringMesh reinforcement

The invention discloses a prefabricated bottom plate preparation method, a prefabricated bottom plate structure and a construction method of the prefabricated bottom plate structure. The prefabricated bottom plate preparation method comprises the following steps that a bottom plate mold is assembled, and rib outlet holes do not need to be formed in a side mold of the mold; longitudinal stress steel bars and transverse distribution bars are welded to form a steel bar mesh according to the size of the mold; steel bar trusses are arranged in a segmented mode in the longitudinal bar direction of the steel bar mesh, and the bottoms of the steel bar trusses are bound and fixed to the steel bar mesh; concrete is poured; and when the concrete is close to initial setting, galling treatment is carried out on the surface of the concrete. According to the prefabricated bottom plate preparation method, the prefabricated bottom plate structure prepared through the method can prevent the prefabricated bottom plate structure and beam stirrups from abutting against each other without checking the relative positions of the prefabricated bottom plate outlet bars and the beam stirrups one by one, and standardized design of the mold can be achieved. The invention further aims to provide the construction method.

Owner:重庆恒昇大业建筑科技集团有限公司

Anti-slip multistage-drop box culvert

The invention discloses an anti-slip multistage-drop water box culvert. The anti-slip multistage-drop water box culvert comprises a hollow box culvert body; the outer top and outer bottom of the box culvert body are both in a step shape; a plurality of drop water steps are arranged on the inner bottom face of the box culvert body in a water flow direction; and inclined energy-buffering abrupt slopes are arranged on the step faces of the drop water steps. According to the anti-slip multistage-drop water box culvert of the invention, the outer top and outer bottom of the box culvert body are both arranged to be in a step shape, so that the weight of the box culvert body acts on a soil body below the box culvert body in a vertical direction, meanwhile, covering soil is forwards pressed on thetop of the box culvert body, and the box culvert body and the covering soil on the top of the box culvert body can be effectively prevented from sliding without additional anti-sliding supporting facilities required; water flow is impacted and subjected to energy dissipation through the water drop steps and the energy buffering abrupt slopes in the box culvert body; energy dissipation is furtherconducted on the water flow with energy dissipation protrusions on the upper face of the inner side face of the box culvert body; and water flow speed can be effectively decreased with no additional adopting energy dissipation facilities required.

Owner:中恒工程设计院有限公司

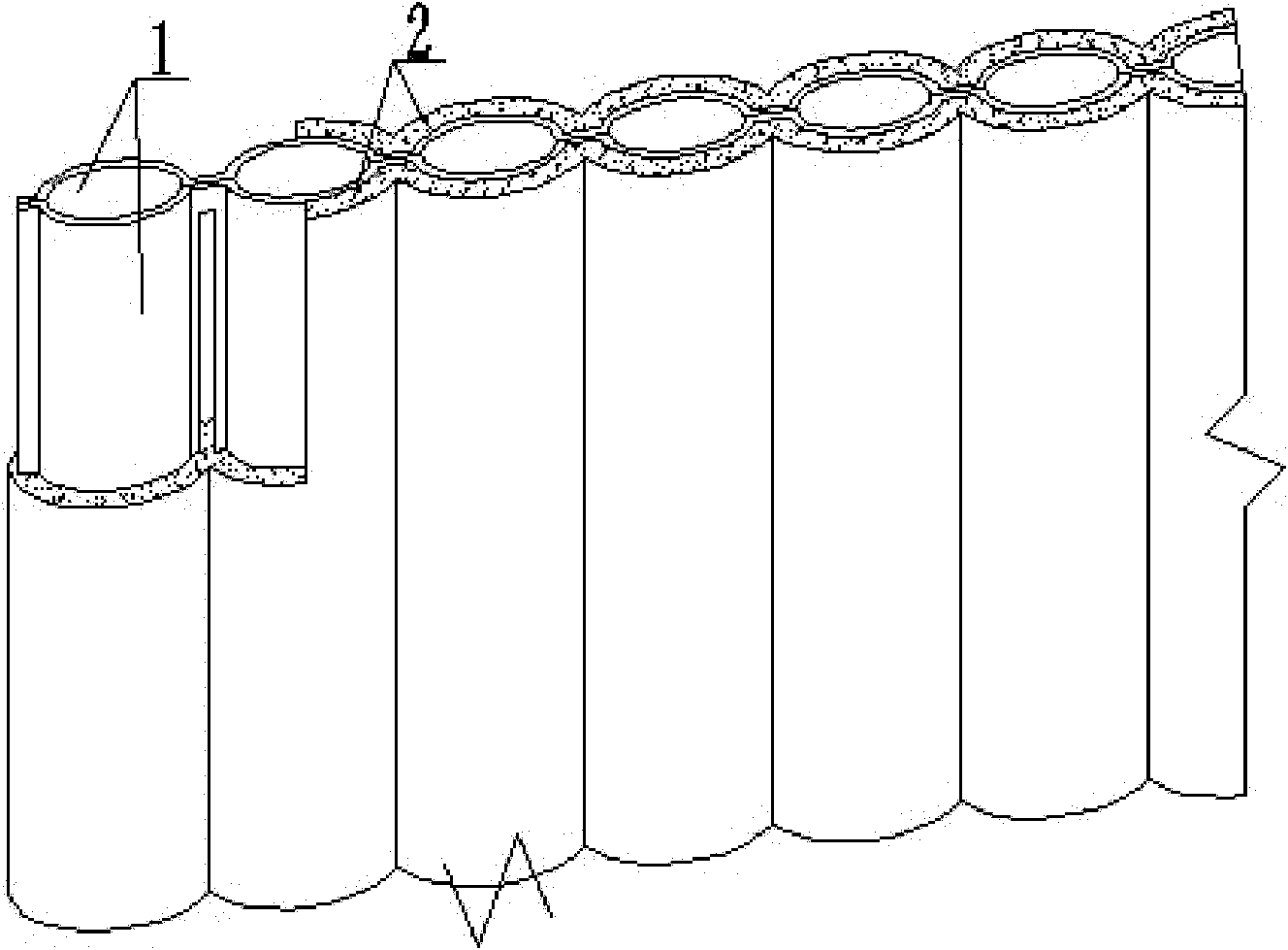

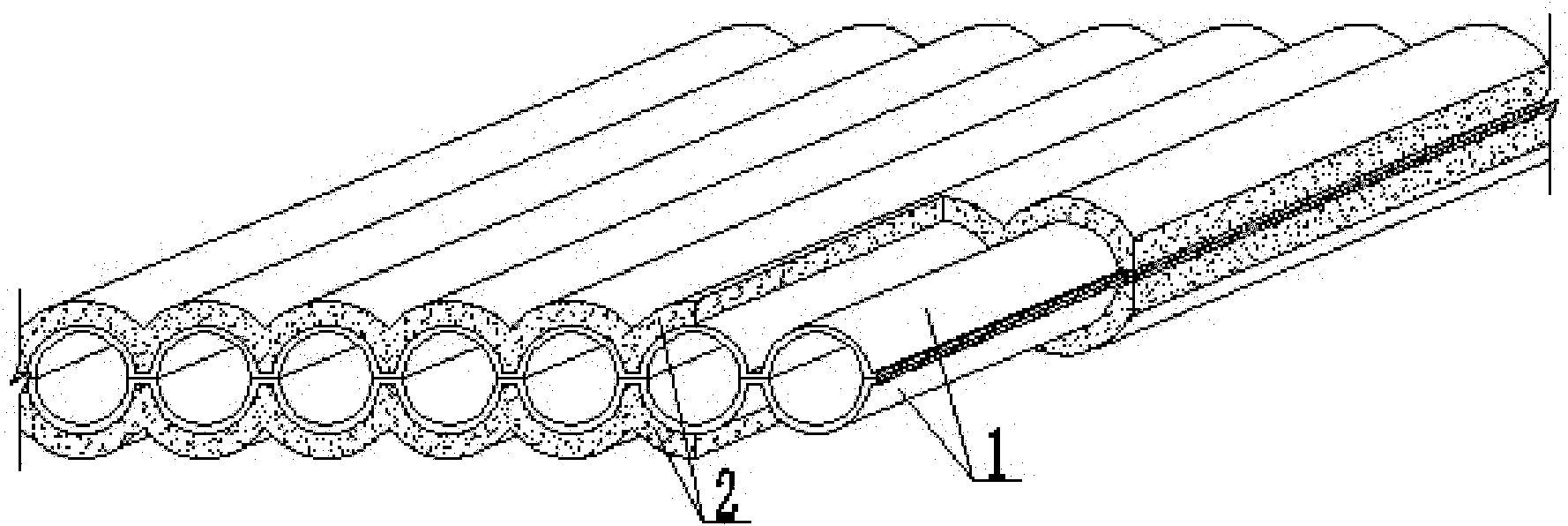

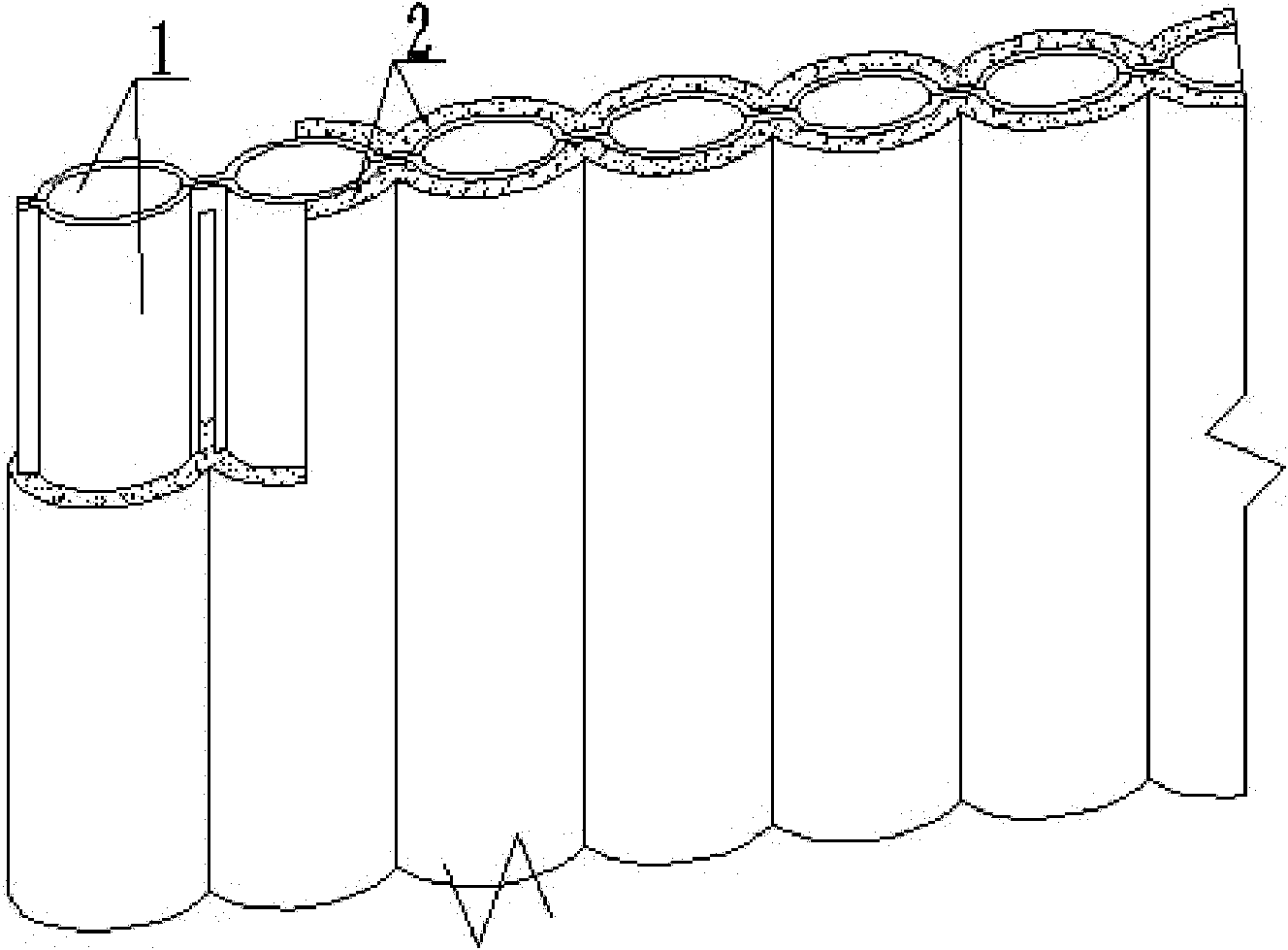

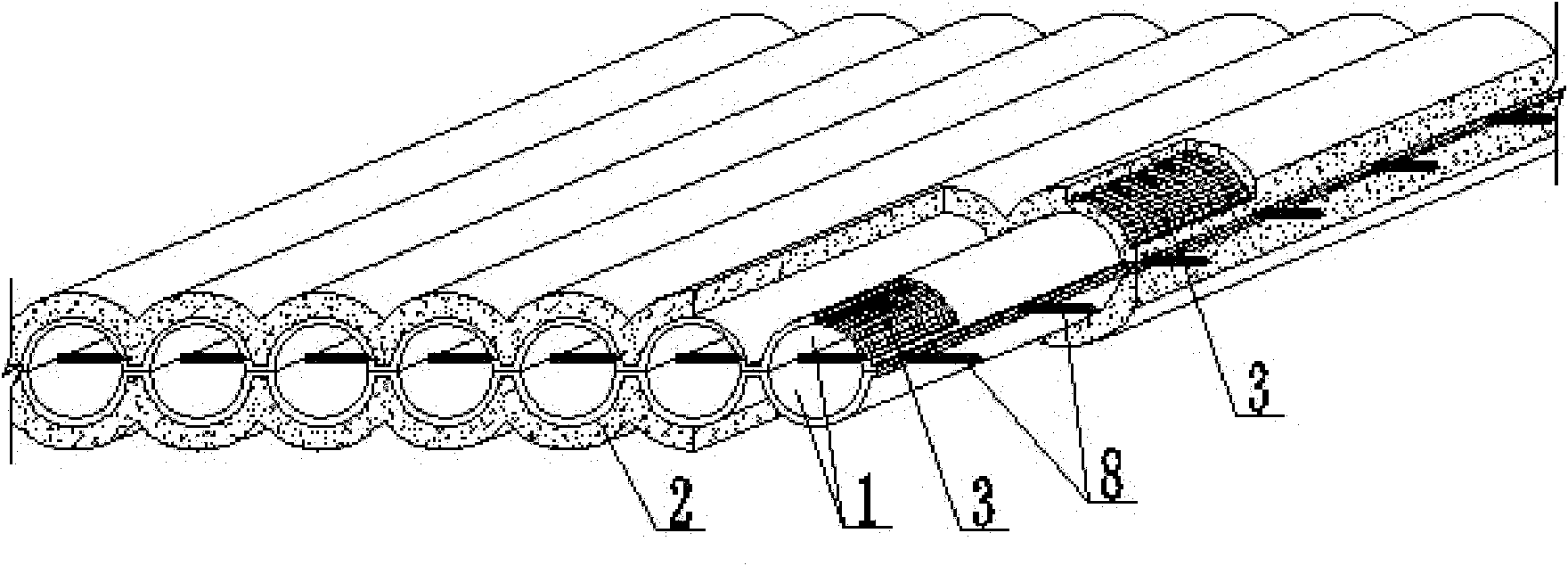

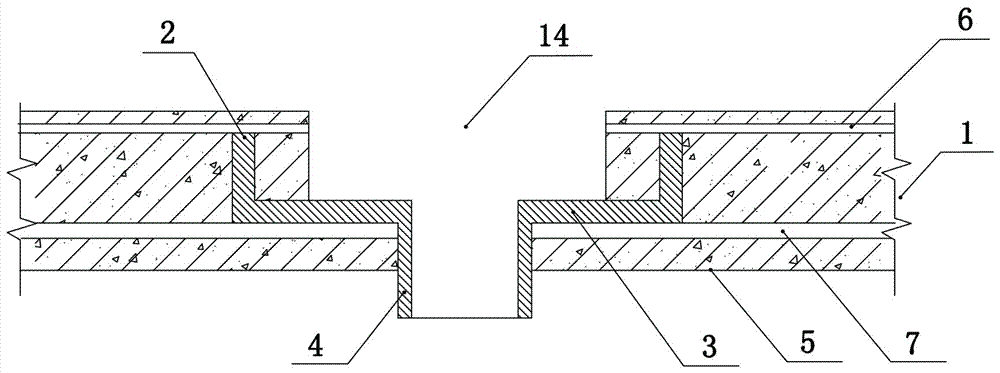

Light wallboard

A light wallboard includes core board parts (1), and is characterized in that two core board parts (1) are correspondingly buckled and coated with external mortar (2), wherein the external mortar (2) passes through seams, and the external mortar (2) is applied onto the external surfaces of the core board parts (1) to form plane mortar layers (4). Therefore, the light wallboard is manufactured simply and the construction technology is simple and convenient; an inner cavity formed inside the light wallboard has excellent sound insulation and heat preservation effects; moreover, the wall body has light deadweight, the construction costs are reduced, the light wallboard can be transported and moved conveniently, and the work intensity of installation workers is reduced; the pipeline construction and the pre-embedment of pendants before the core board are positioned and coated with the mortar are very convenient, and the cost can be reduced; the size of the wall body can be manufactured freely according to the requirements of actual design and application, and can be dismounted and moved conveniently; in addition, the core board parts can be produced by a flow using automatic special equipment, the quality of the product is ensured, and the core board parts having various section shapes and diameters can be manufactured to meet the engineering requirements; and the wallboard is suitable for cast-in-place reinforced concrete, or prestressed reinforced concrete, or mortar, and is suitable for ultra-long walls, ultra-high walls, and broken-line walls.

Owner:湖南邱则有专利战略策划有限公司

Underground pump room inlet sealing device and pouring method thereof

InactiveCN111005654AGood water permeabilityExtended service lifeCeramic shaping apparatusDoor/window applicationsMechanicsPulley

Owner:四川中至耀辉建设有限公司

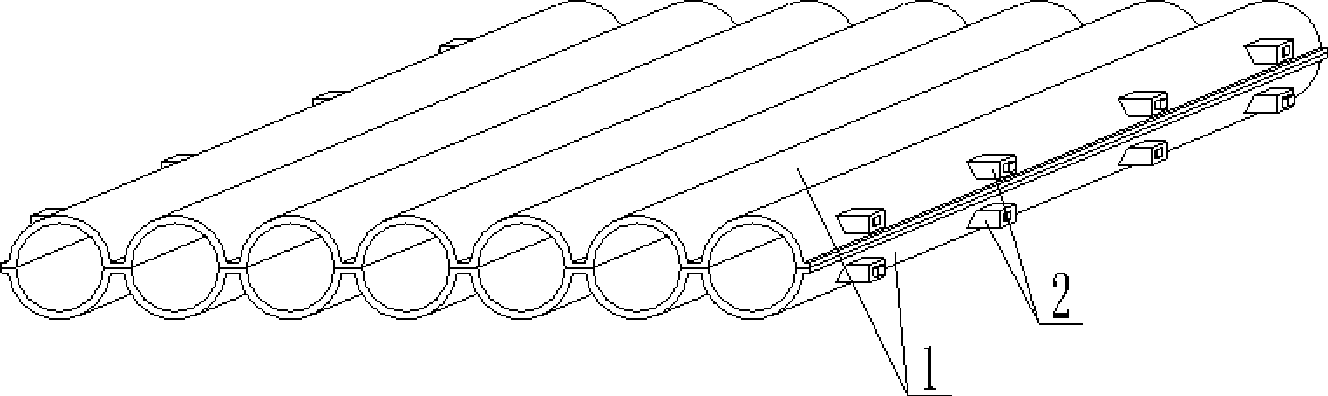

Light wall plate

The invention relates to a light wall plate comprising core plate components (1). The light wall plate is characterized in that both core plate components (1) are oppositely buckled; external plastering mortar (2) is plastered outside the core plate components (1) and penetrates through a through seam; each core plate component (1) is provided with a transverse connector (5), and the two core plate components (1) are buckled into whole by the transverse connectors (5); and each core plate component (1) is further provided with a U-shaped groove (10) in which a flat notch rib plate (22) is arranged. Thus, the light wall plate is simple to produce and is simple and convenient to construct; a cavity formed inside the wall plate has favorable sound insulation and heat insulation effects; besides, the wall body has light self weight, reduces the engineering cost and the labor intensity of workers, is convenient to transport and carry, and is suitable for wall plates of cast-in-situ reinforced concrete or pres-stress reinforced concrete or mortar as well as super-long walls, super-high walls and line walls.

Owner:湖南邱则有专利战略策划有限公司

Anti-leakage floor slab and anti-leakage construction method

The invention provides an anti-seepage floor slab and an anti-seepage construction method thereof, wherein, an anti-seepage floor slab includes a floor slab body and a waterproof connector pre-buried in the floor slab body, and the waterproof connector includes an anti-seepage A leakage cylinder and a connecting pipe provided at the bottom of the anti-leakage cylinder, the top and side walls of the anti-leakage cylinder are pre-embedded in the floor panel body, and the lower end of the connection pipe protrudes from the floor panel body The lower surface; the present invention also provides an anti-leakage construction method. Compared with the prior art, the present invention has substantial characteristics and progress. The structure of the anti-leakage floor slab of the present invention fundamentally eliminates the occurrence of leakage, reduces the requirements and difficulty of installation, is very convenient to use, and has a simple structure and saves waterproof materials. , low cost; the anti-leakage construction method is ingeniously conceived, simple and easy to implement.

Owner:王凤蕊

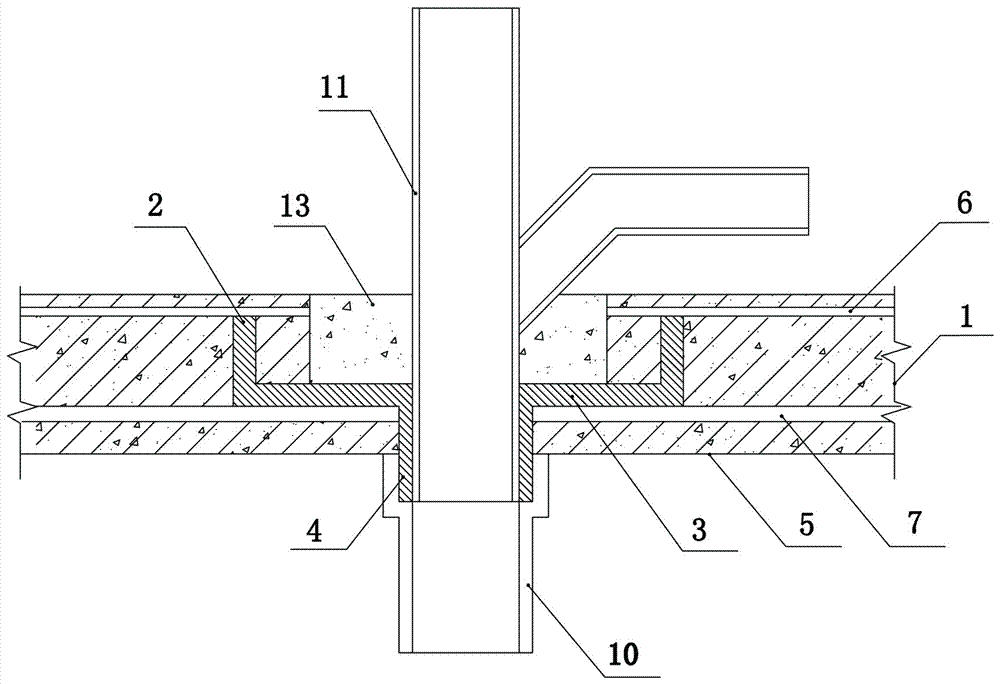

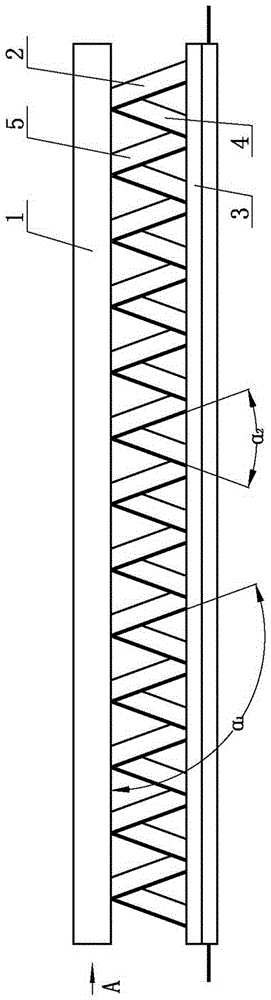

Folded-plate truss concrete assembly

A folded-plate truss concrete assembly comprises a bottom plate.Protruding rebars are arranged on the two sides of the bottom plate, a folded-plate truss is arranged on the surface of the bottom plate and composed of a connecting rod and multiple folded plates, one end of each folded plate is connected with the surface of the bottom plate, and the other end of each folded plate is connected with the connecting rod; each folded plate is composed of multiple first inclined plates and multiple second inclined plates, the first inclined plates are distributed in parallel, the second inclined plates are distributed in parallel, and a second included angle alpha<2> is formed between each first inclined plate and the corresponding second inclined plate.According to the folded-plate truss concrete assembly, the defects in the prior art can be overcome, the thickness of the bottom plate can be greatly reduced, loads of other components in engineering are reduced, and the construction cost of a main structure is reduced; the inertia moment of the section is large, stress is uniform and reasonable, and in the engineering construction process, the safety of hoisting and construction processes is high, rebars do not need to be arranged, and meanwhile the engineering construction cost is reduced.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com