Fabricating structure and method of prefabricated component

A technology of prefabricated components and assembly methods, which is applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of long preparation time period, scaffolding occupying the construction site, and prolonging the construction period, so as to shorten the construction period and simplify the assembly method , Improve the effect of connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] A method for assembling prefabricated components 2, comprising the steps of:

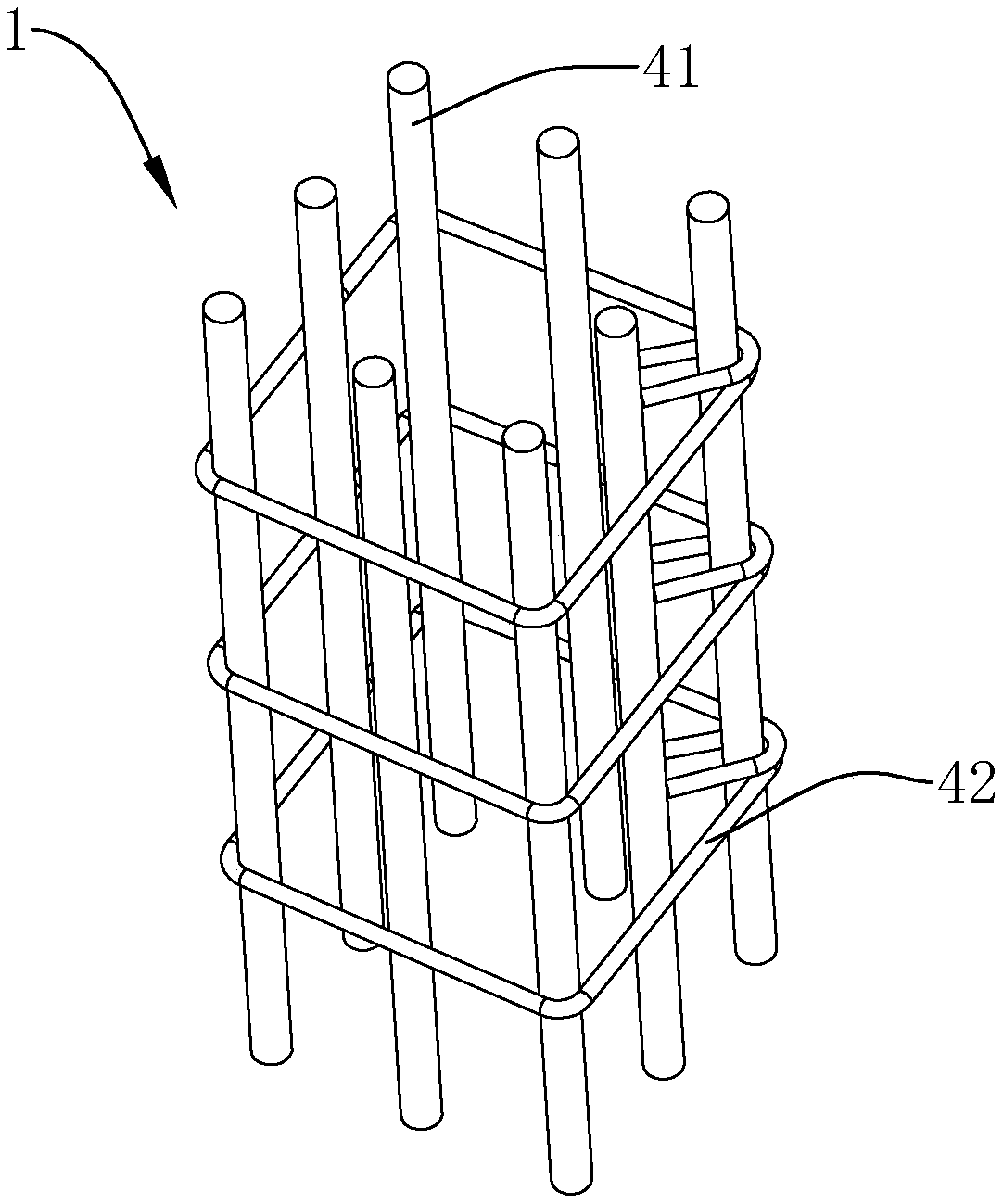

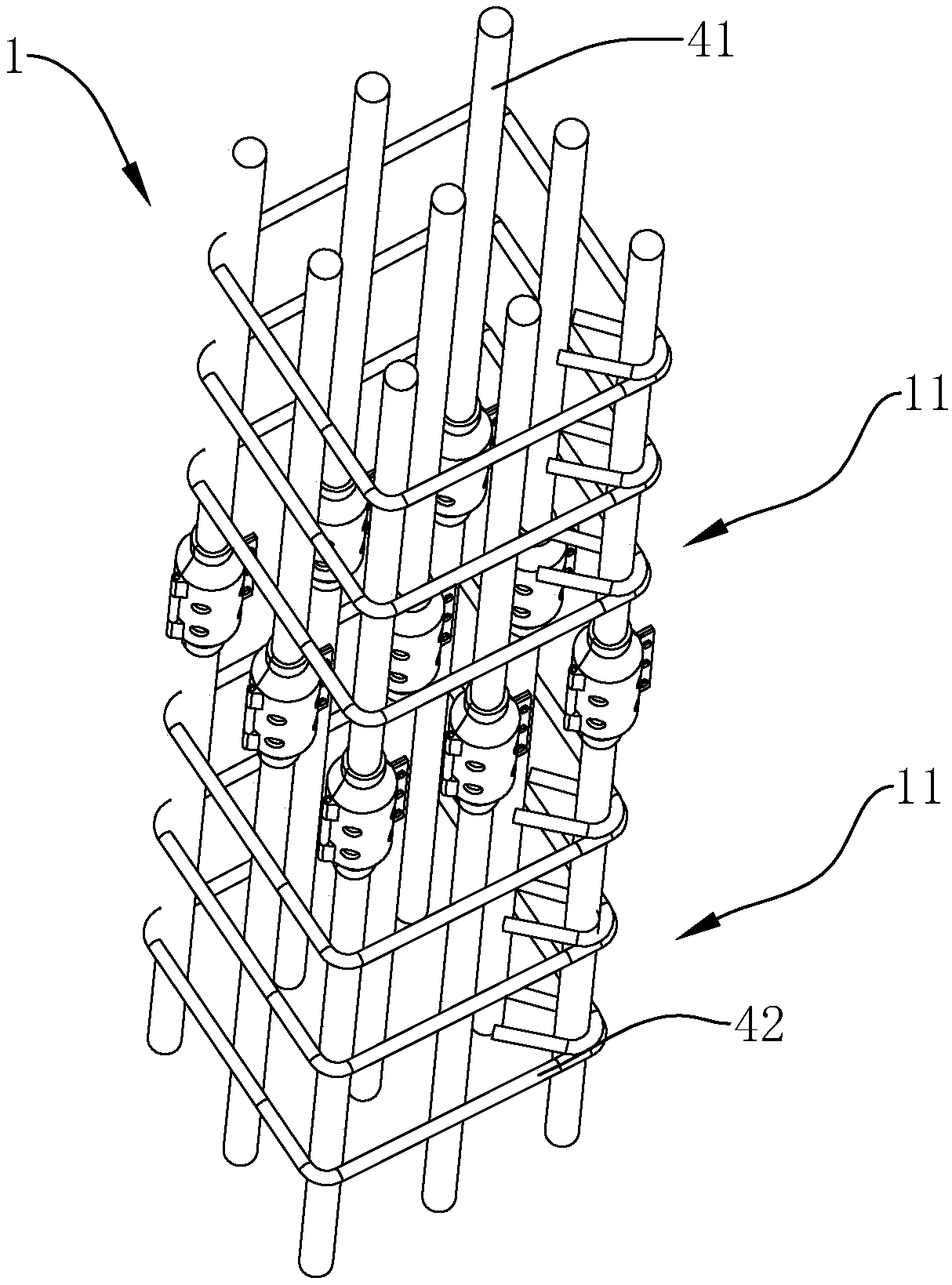

[0073] S1, see figure 1 with figure 2 , compiling the reinforcement skeleton 1 and preparing the prefabricated component 2, the end face of the prefabricated component 2 is pre-embedded with a plurality of sleeves 3 during the prefabrication process, and the opening at one end of the sleeve 3 is located on the plane where the end face is located;

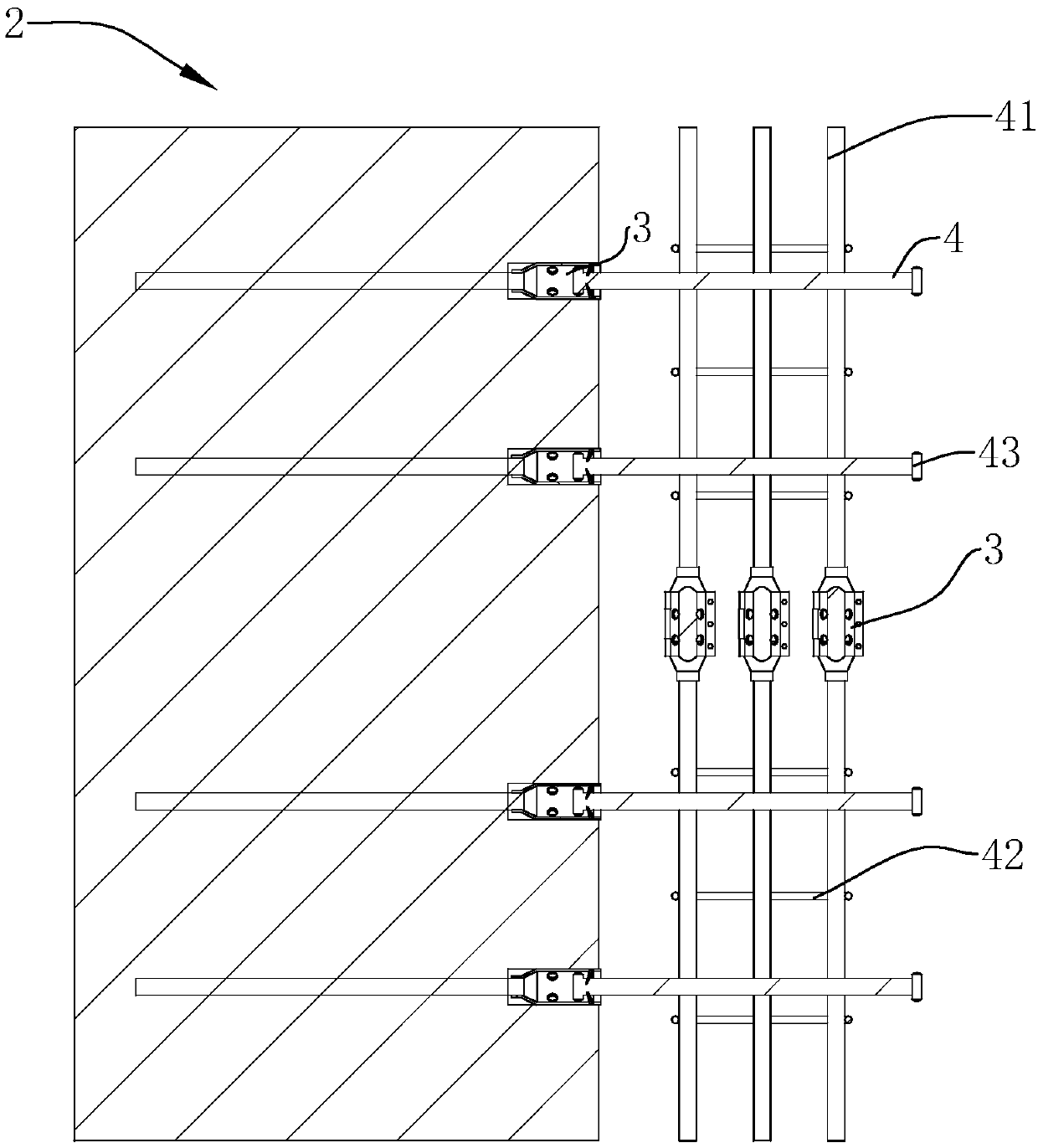

[0074] S2, see image 3 , the end face of the prefabricated component 2 is set facing the reinforcement frame 1, the sleeve 3 of the reinforcement frame 1 corresponding to the end face of the prefabricated component 2 crosses the reinforcement bar 4, and the reinforcement bar 4 passes through the reinforcement frame 1;

[0075] S3, see Figure 4 Push the prefabricated component 2 to abut against the reinforcement frame 1, and insert the end of the reinforcement bar 4 that crosses the reinforcement frame 1 into the sleeve 3;

[0076] S4 , grout...

Embodiment 2

[0089] Embodiment two: the difference with embodiment one is that in the above steps, the reinforcement frame 1 is a circular reinforcement frame 12 in the section surrounded by several longitudinal bars 41, and the outer side of the reinforcement frame 1 is provided with circular stirrups 42, and the longitudinal bars 41 and stirrups 42 constitute the cylindrical reinforcement skeleton 1.

[0090] The prefabricated component 2 is a rectangular prefabricated slab 21. The end surface of the prefabricated slab 21 faces the arc surface of the steel frame 1 that matches the cylindrical steel frame 1. A sleeve 3 is pre-embedded on the arc surface, and the sleeve 3 is far away from the prefabricated slab 21. Elastic slips 32 are provided at one end.

[0091] The assembly form of the assembly formed by the above steps can be found in Figure 7 with Figure 8 , can be two prefabricated panels 21, each prefabricated panel 21 has a semicircular end face facing the cylindrical steel fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com