Patents

Literature

34results about How to "Increase the mating surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

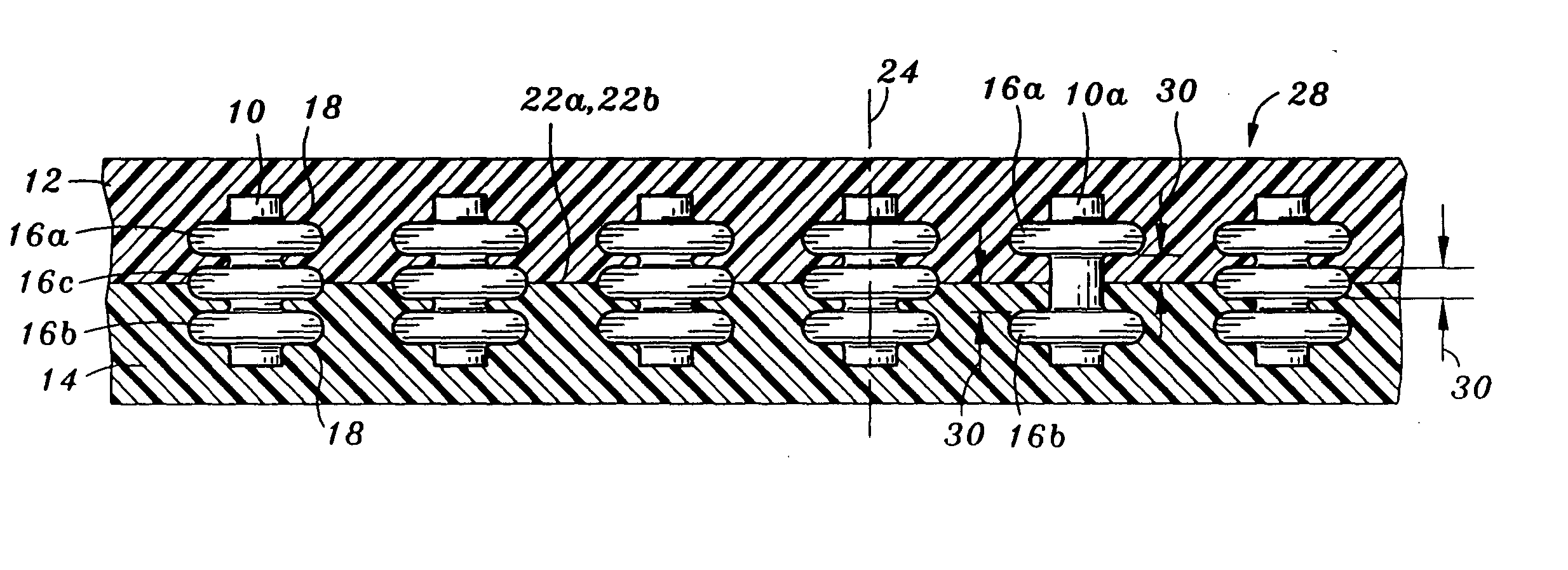

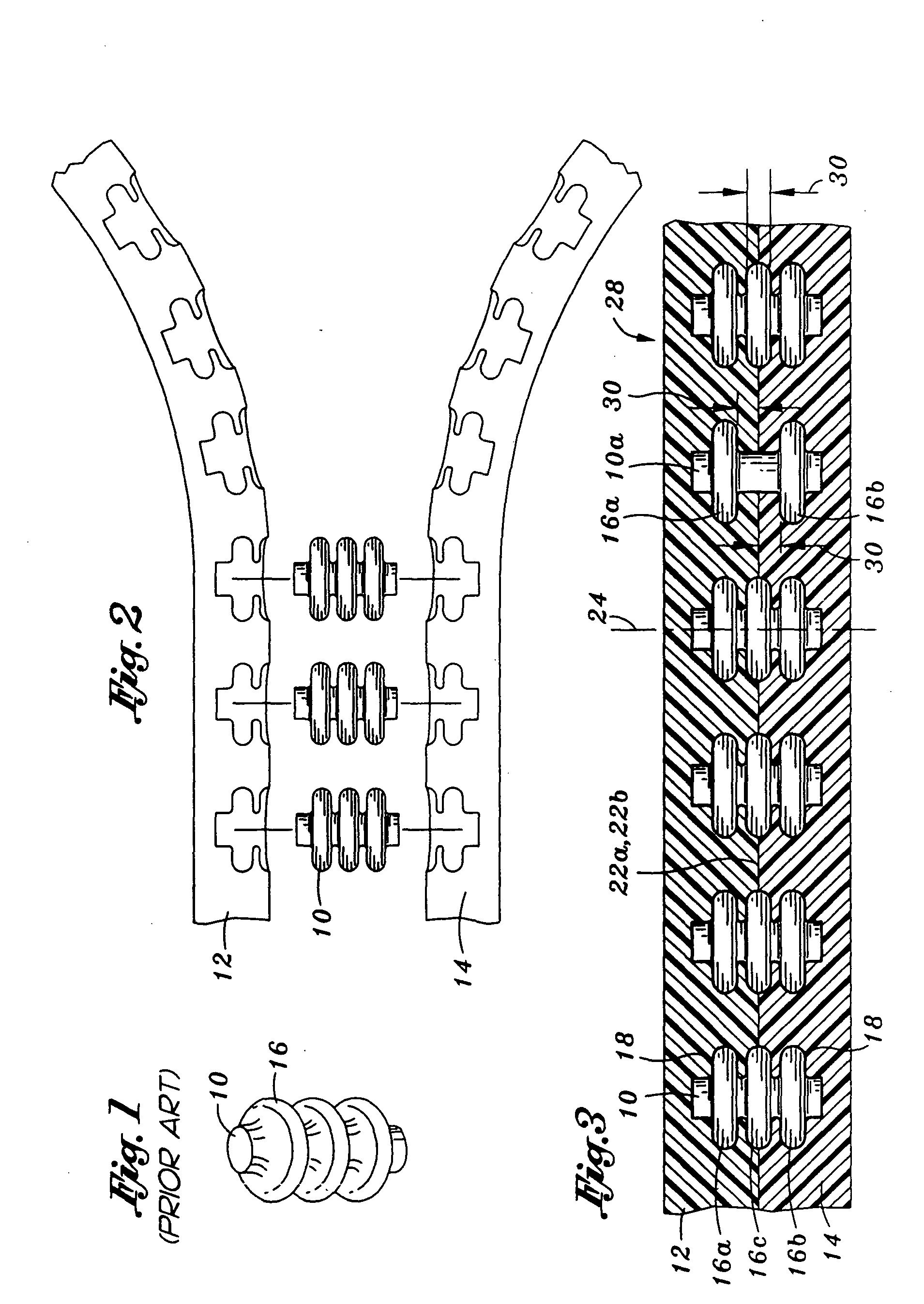

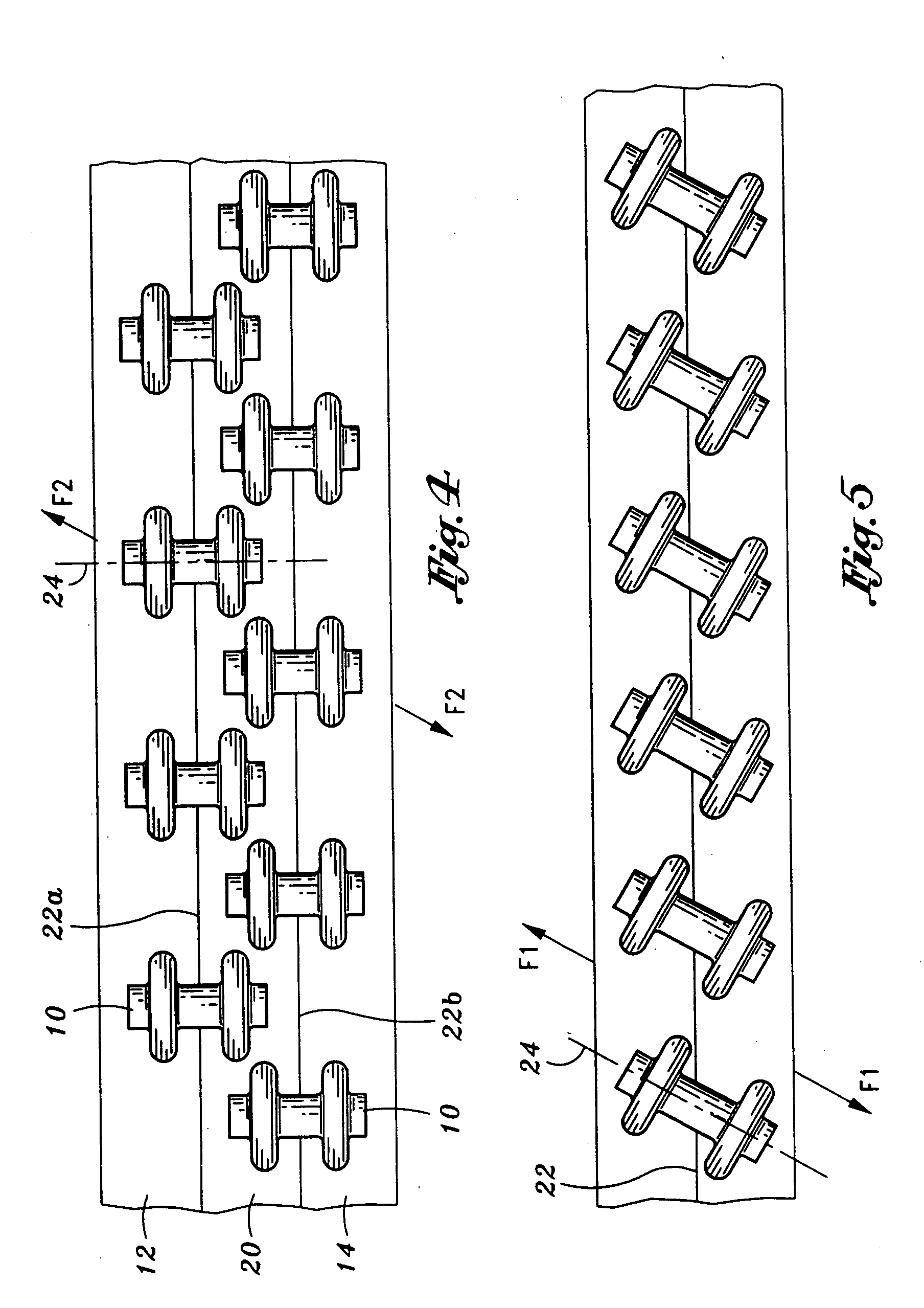

Structural assemblies using integrally molded, and welded mechanically locking z-pins

InactiveUS20050042023A1Reduce stress concentrationAbility to controlMaterial gluingSheet joiningEngineeringHardness

A structure is provided which includes first and second layers. The first and second layers are attached to each other by embedding or otherwise attaching at least one mechanically locking z pin to the first layer and then subsequently joining the protruding portion of the z pin to the second layer prior to the second layer being processed to a fully cured state. Alternatively, the z pin material is injected into a cavity formed in the first and second layer and then brought to a fully cured state. The z pin may have physical characteristics such as orientation, melting point and hardness as a function of the physical characteristics of the first and second layer and the forces subjected upon the first and second layers. For example, the z pin may define a longitudinal axis and be embedded within the first and second layers in alignment with an applied force subjected on the first and second layers. This ensures that the z-pin is subjected primarily to tensile forces which allows designs to better control the failure mode of the attached first and second layers.

Owner:NORTHROP GRUMAN CORP

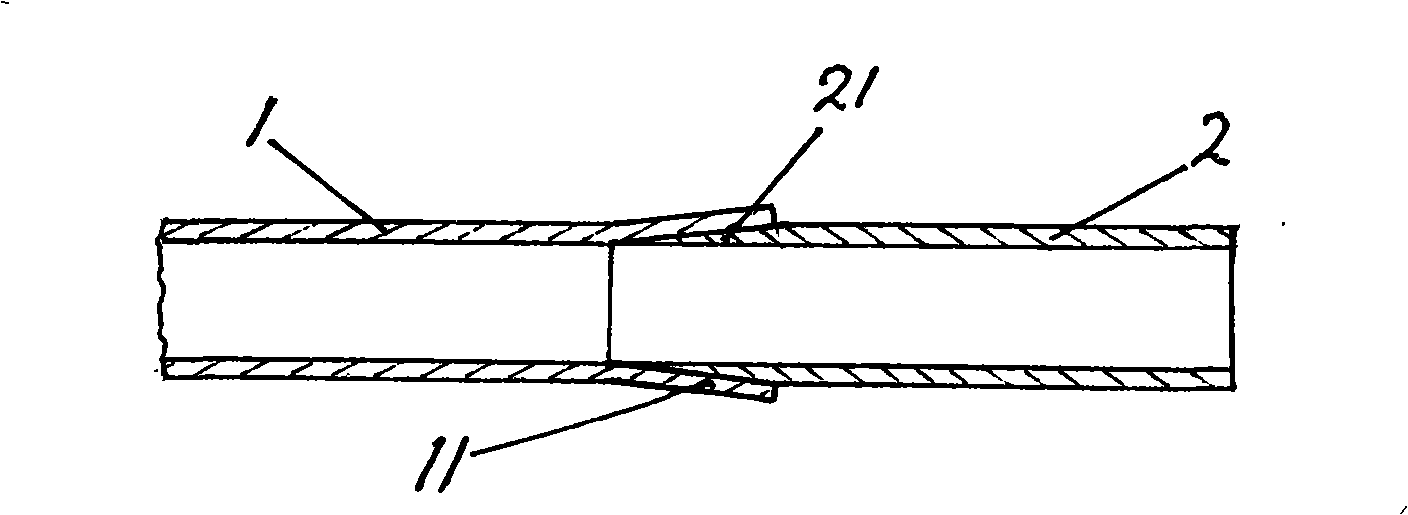

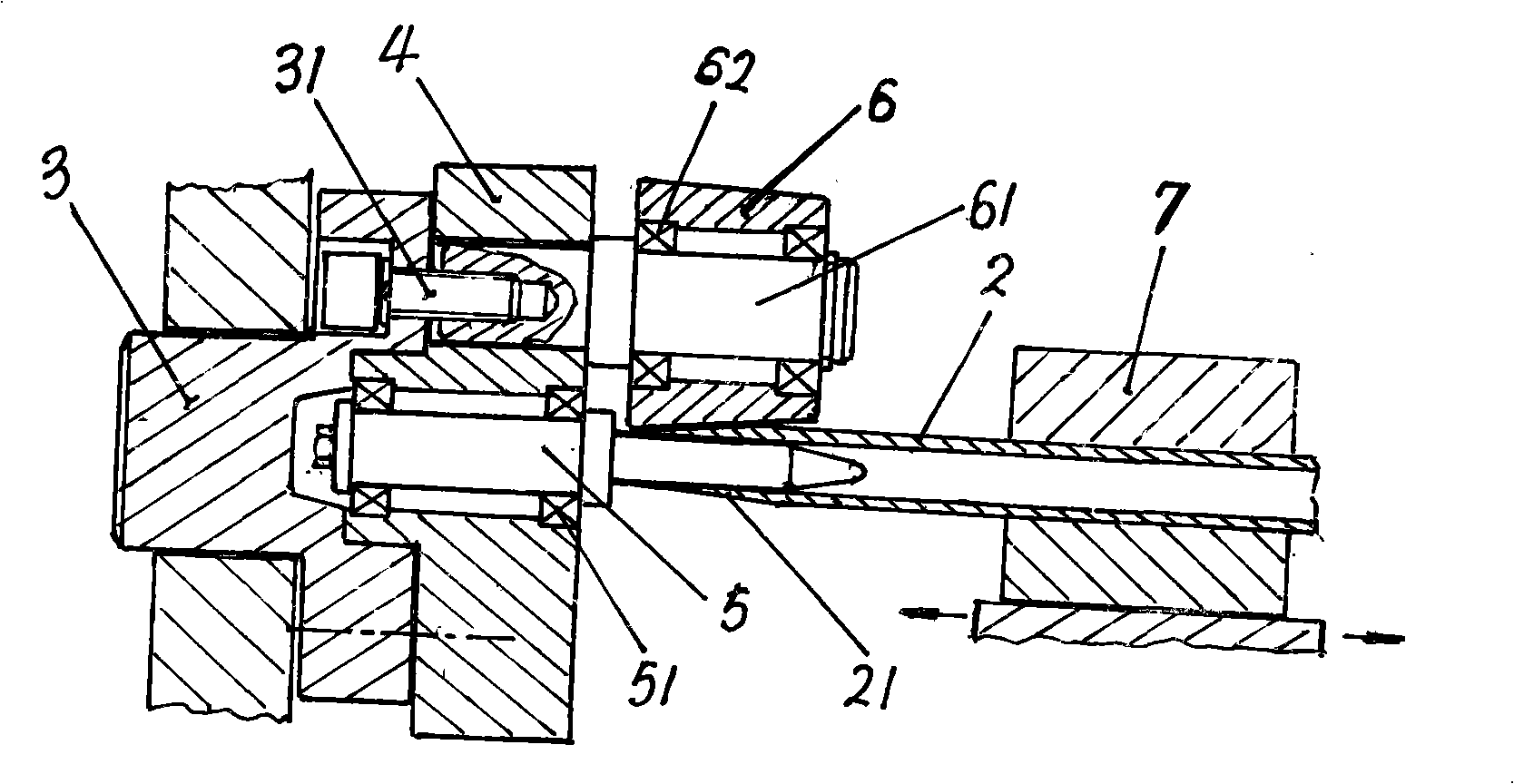

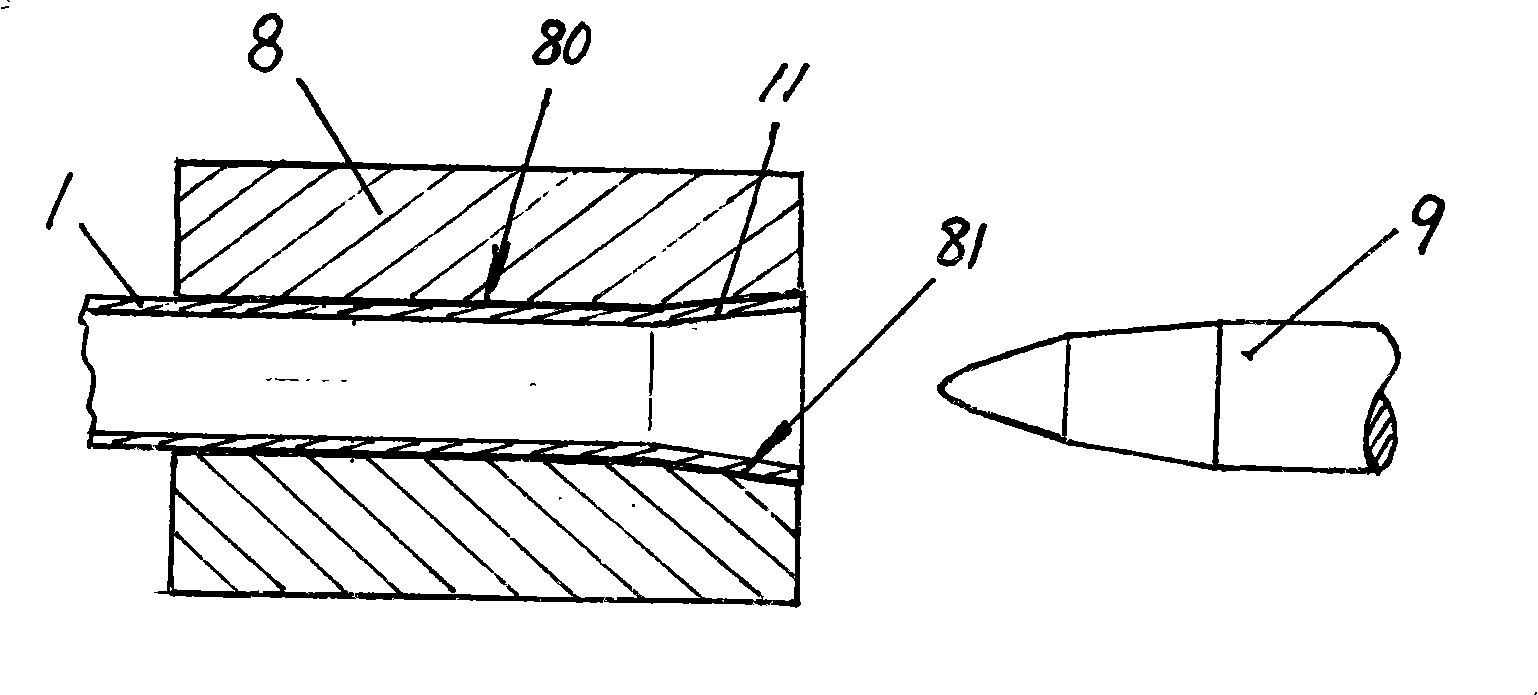

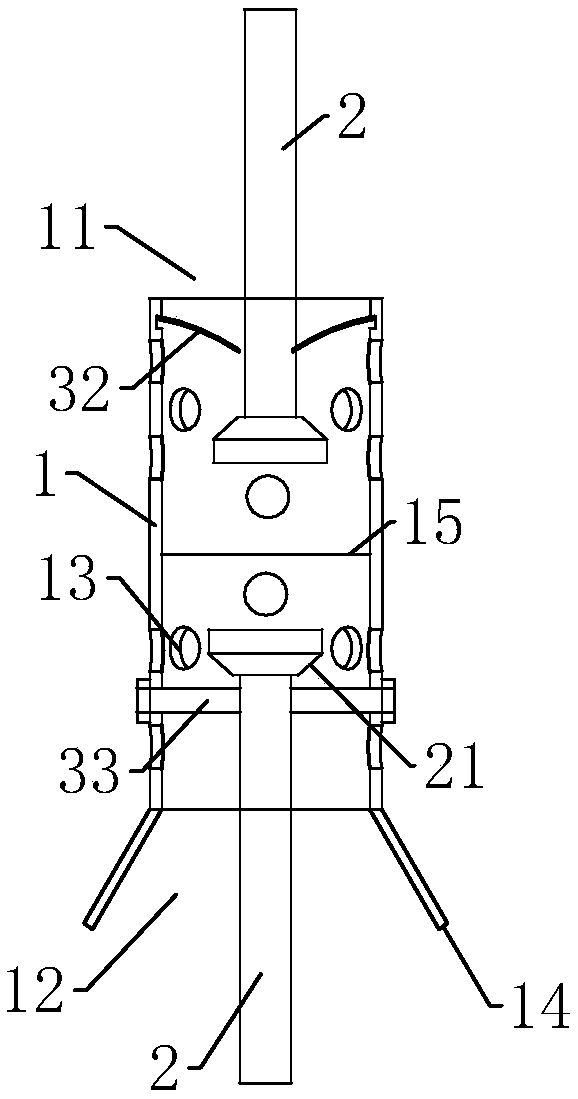

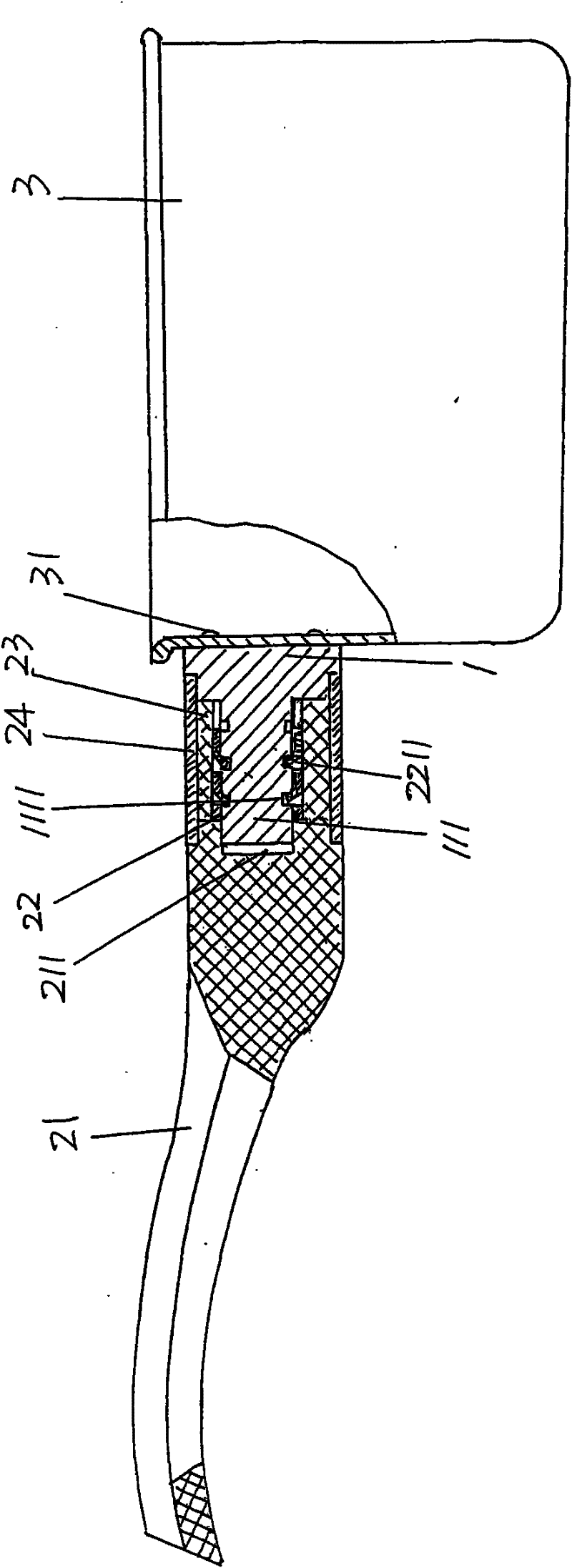

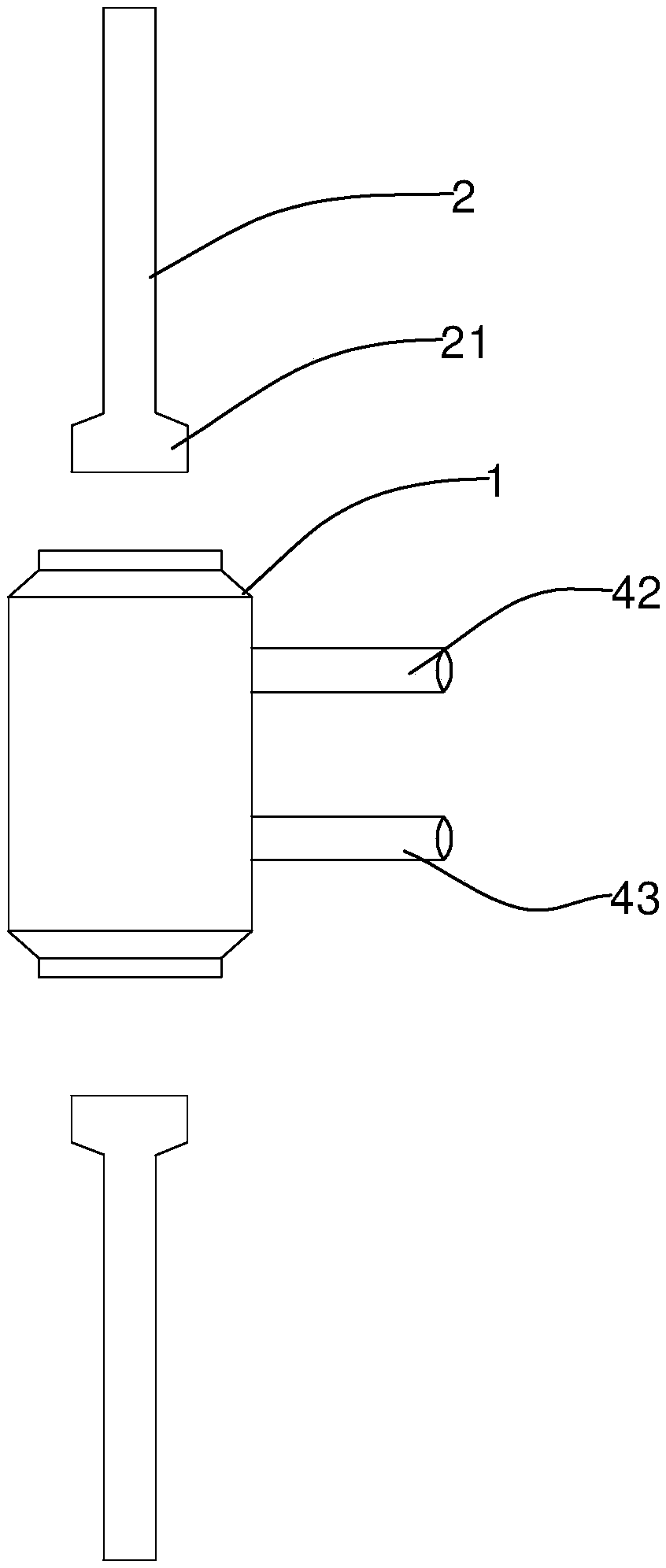

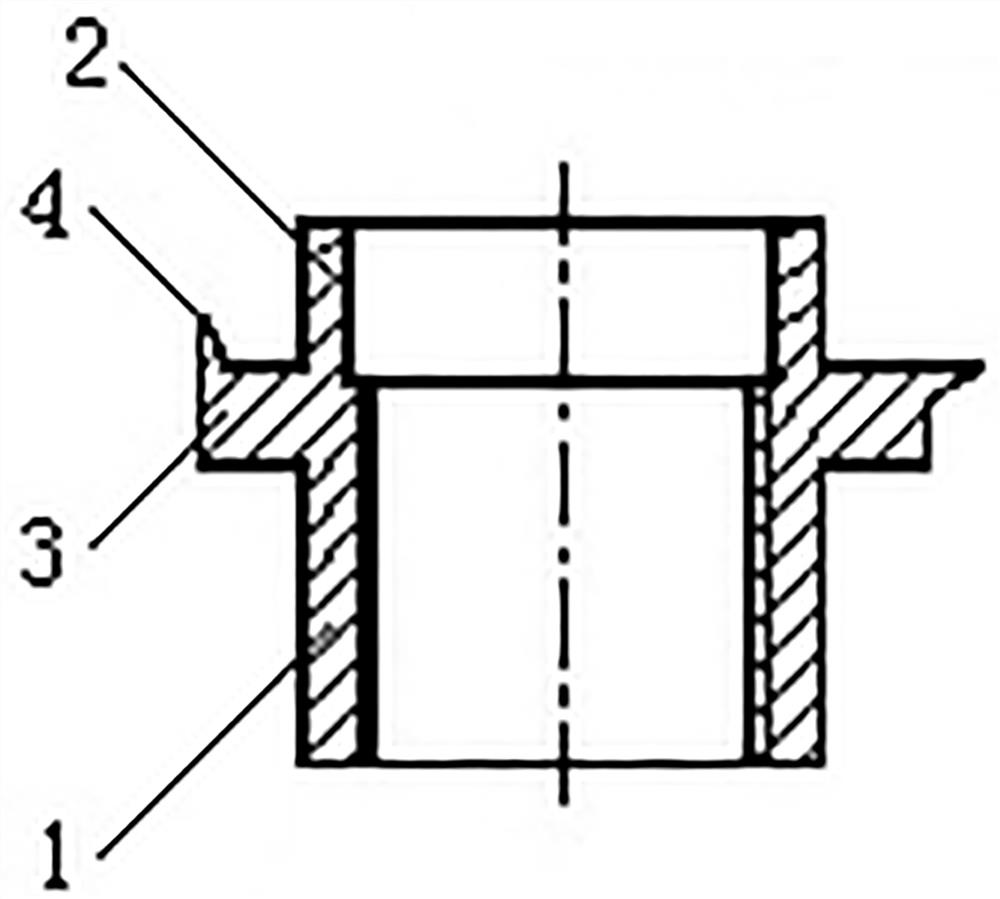

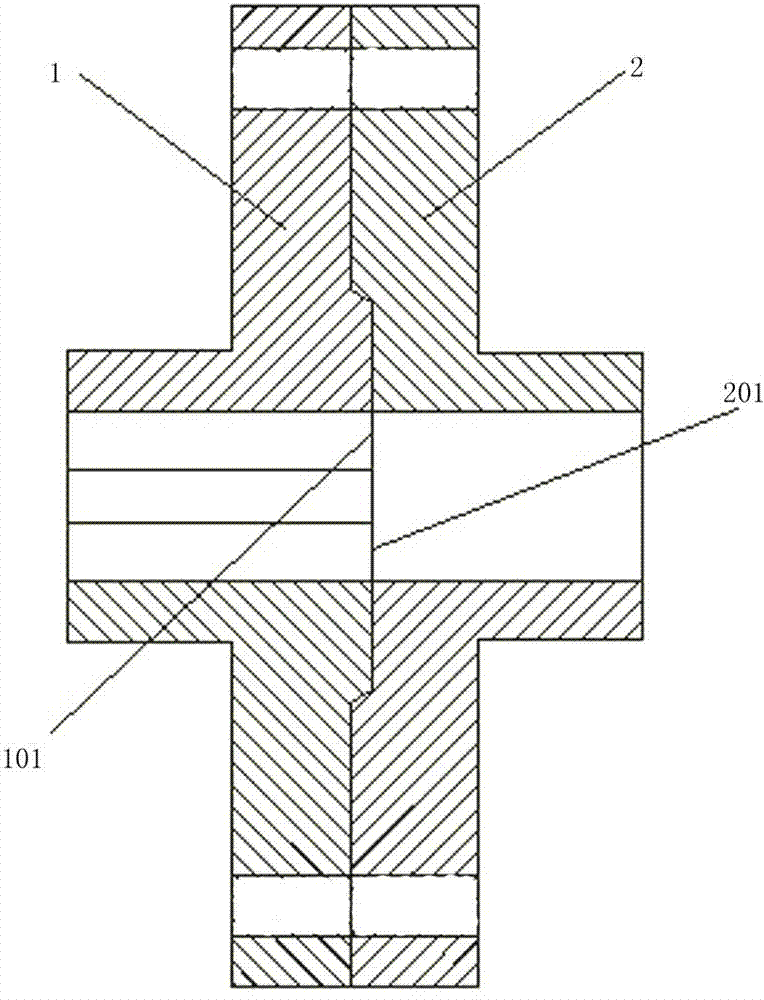

Tube used for refrigerating device and its processing method

InactiveCN101324293AInner diameter does not shrinkGood welding and sealing connectionRigid pipesNon-disconnectible pipe-jointsElectrical resistance and conductanceRefrigeration

The invention relates to a pipe used for a refrigeration device. The pipe is formed by connecting two ends of an aluminum pipe (1) with a joint of a copper pipe(2); the pipe wall of the splicing terminal (21) of both the copper pipe (2) and the aluminum pipe (1) is in the shape of a cone, through the shaping of a cone extruding machine, the copper pipe (2) is spliced with the aluminum copper (1), and the copper pipe (2) is connected with the aluminum copper (1) through resistance welding; and the inner diameter of the splicing terminal part of both the copper pipe and the aluminum pipe does not draw down, so as not to influence flow and efficiency. The refrigeration device has the advantages of good contact of splicing fitting surface, solid and uniform welding, good sealing performance, simple processing technology and reliable and stable quality.

Owner:李东泽 +1

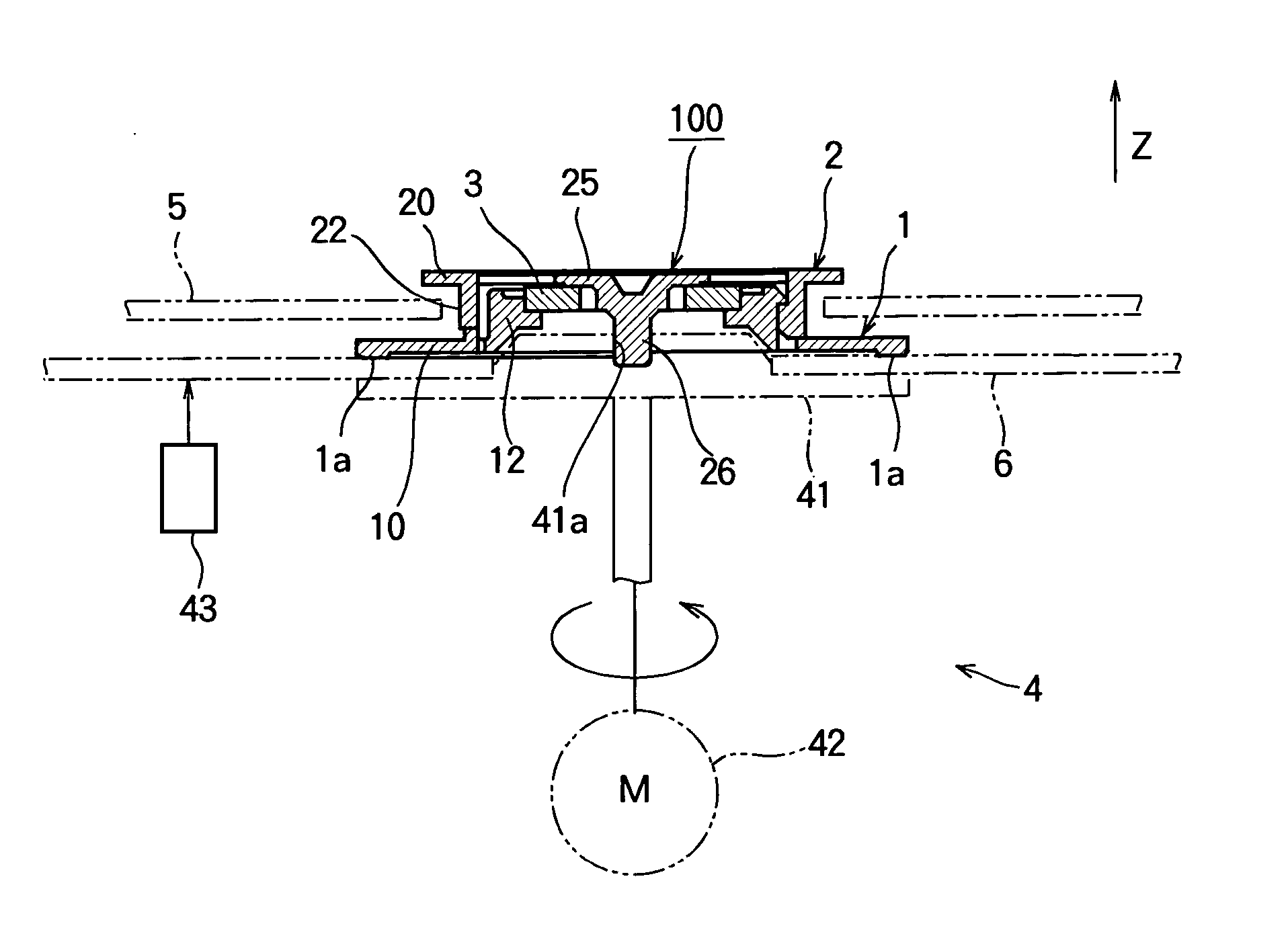

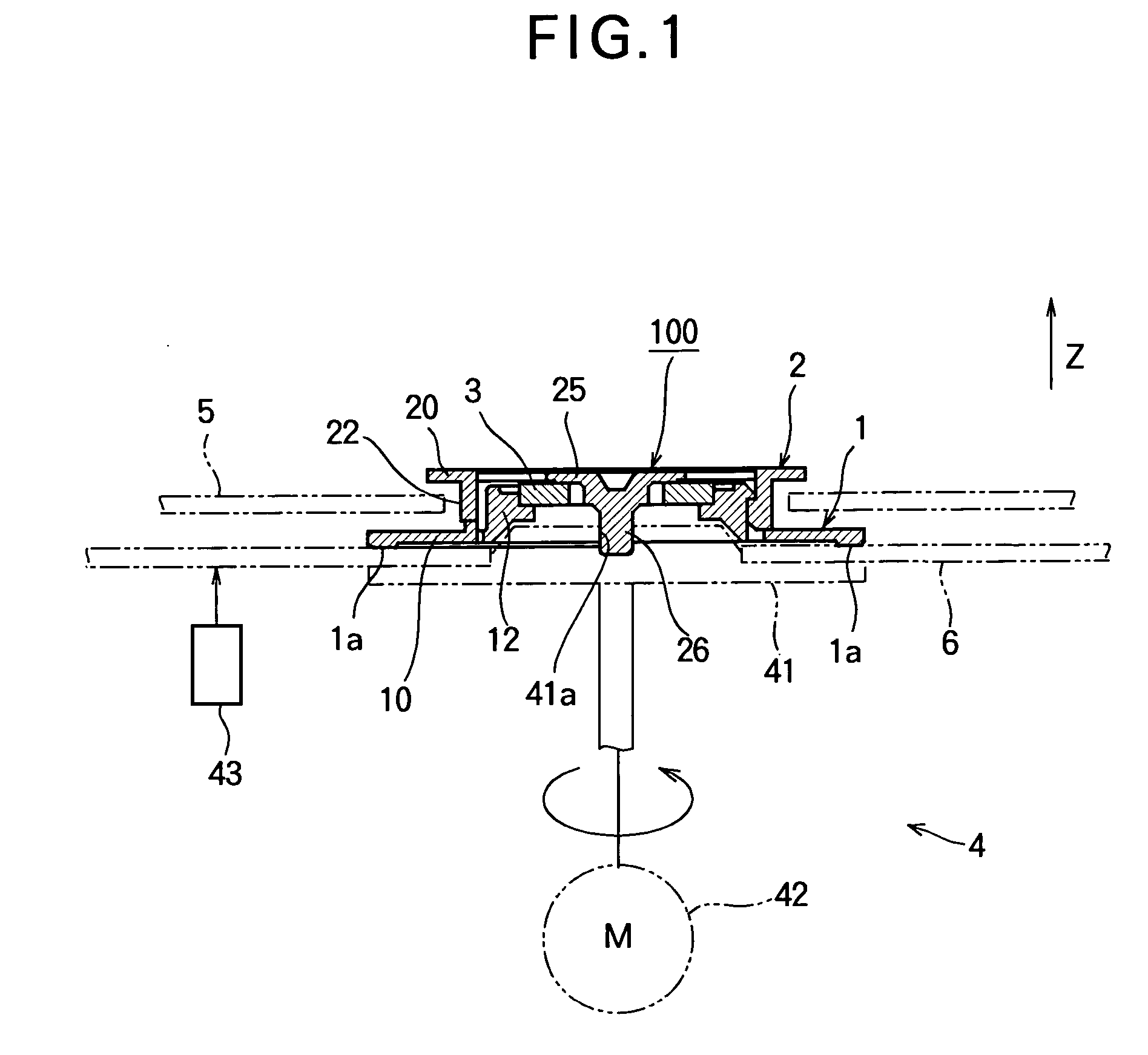

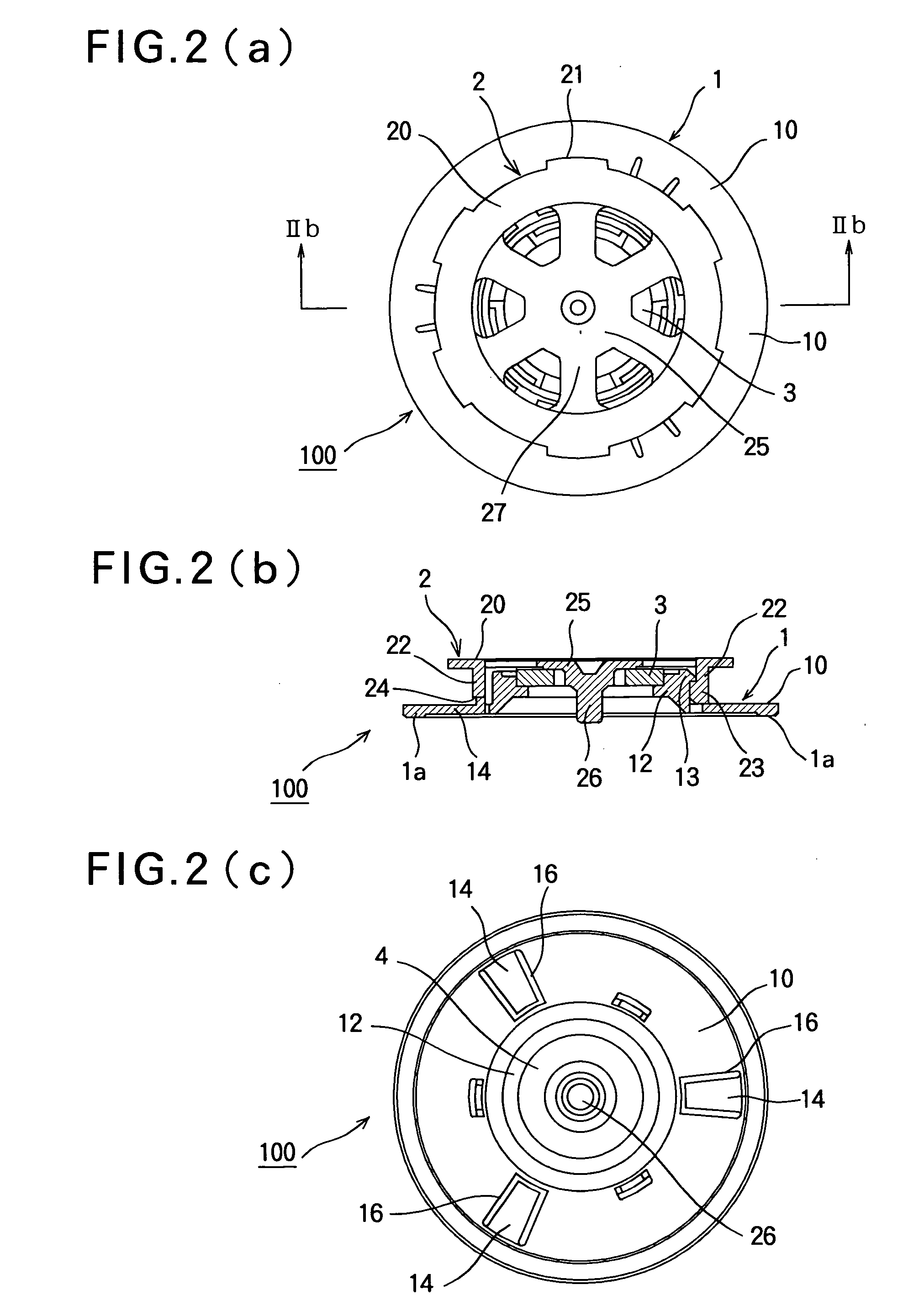

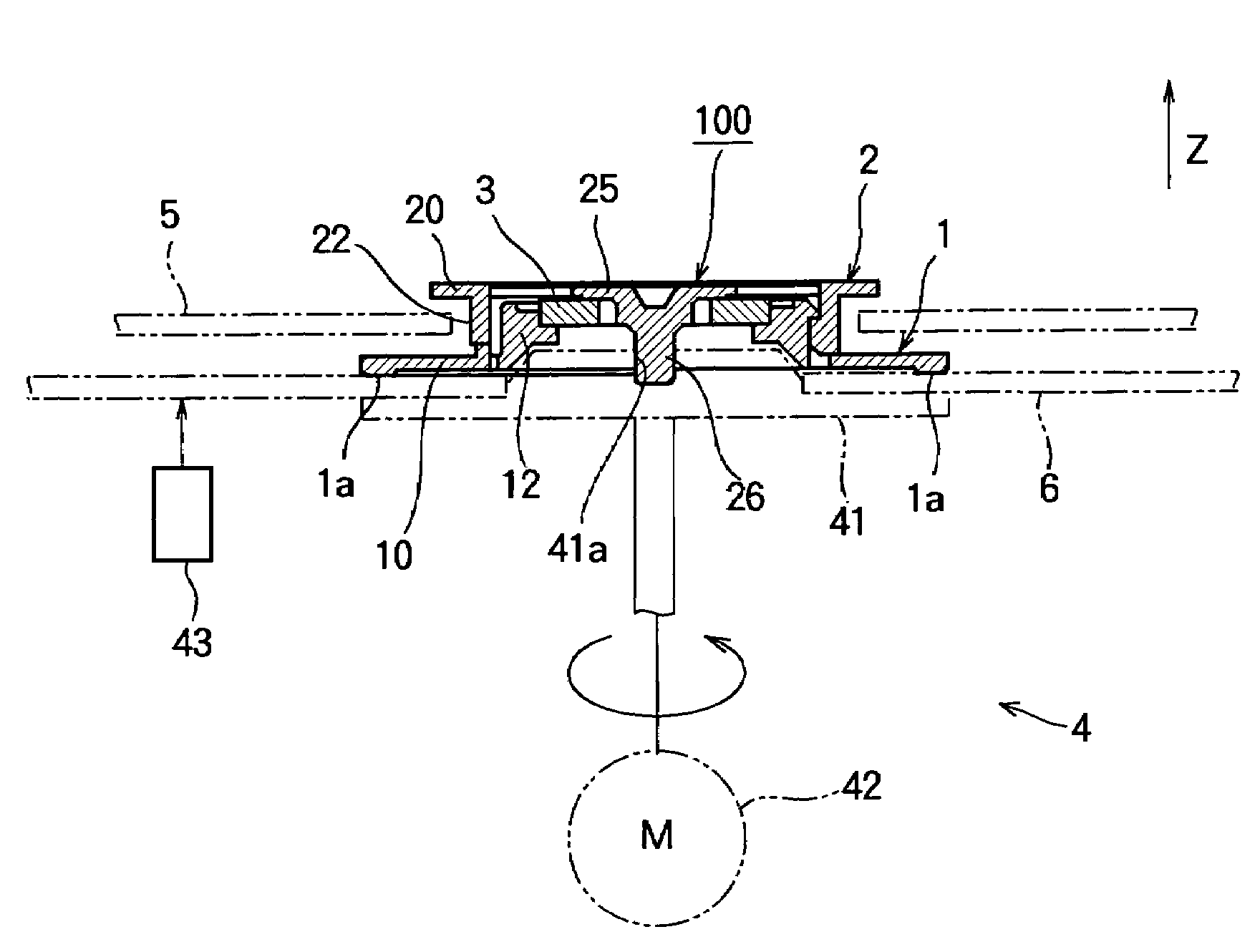

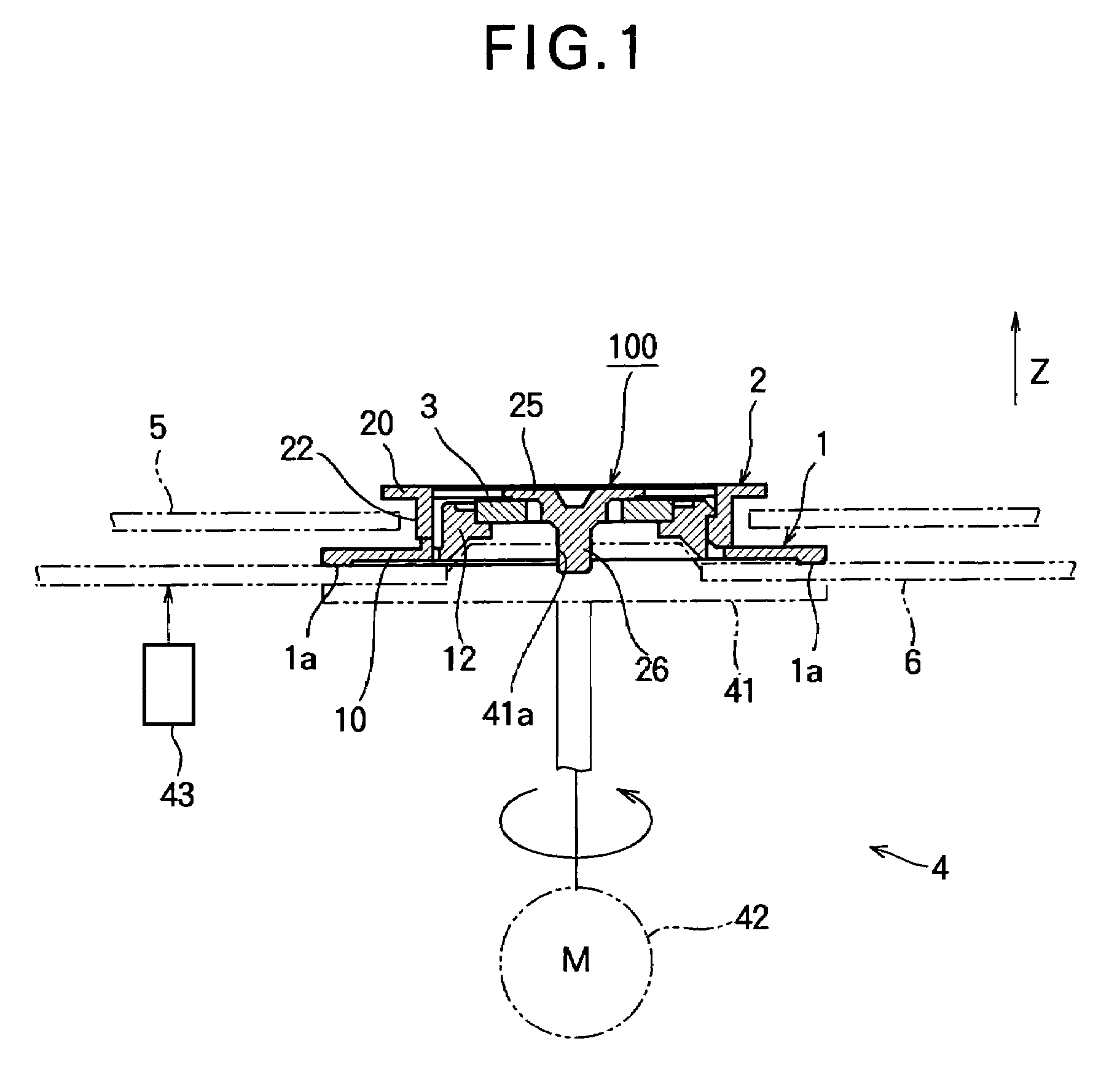

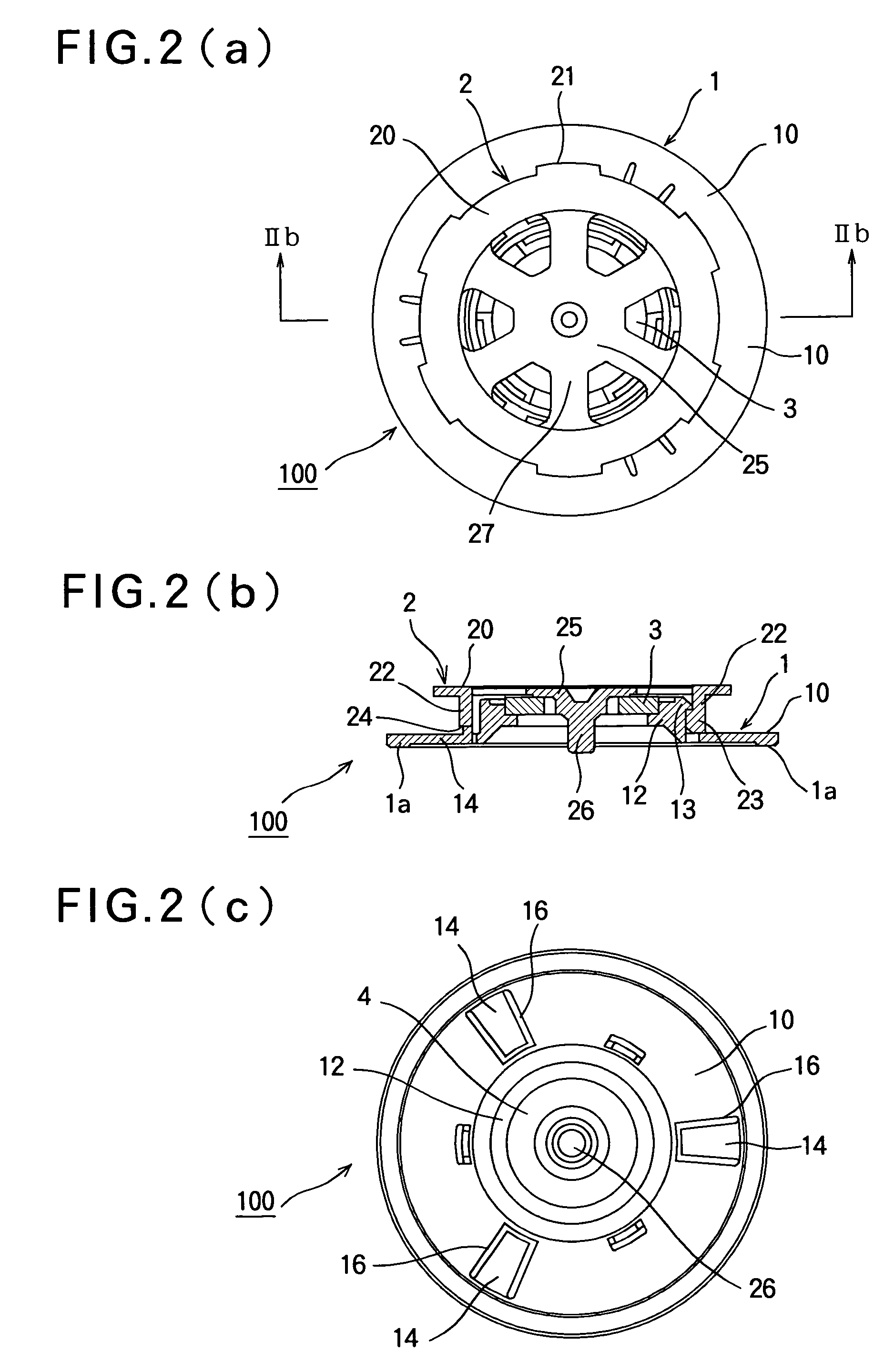

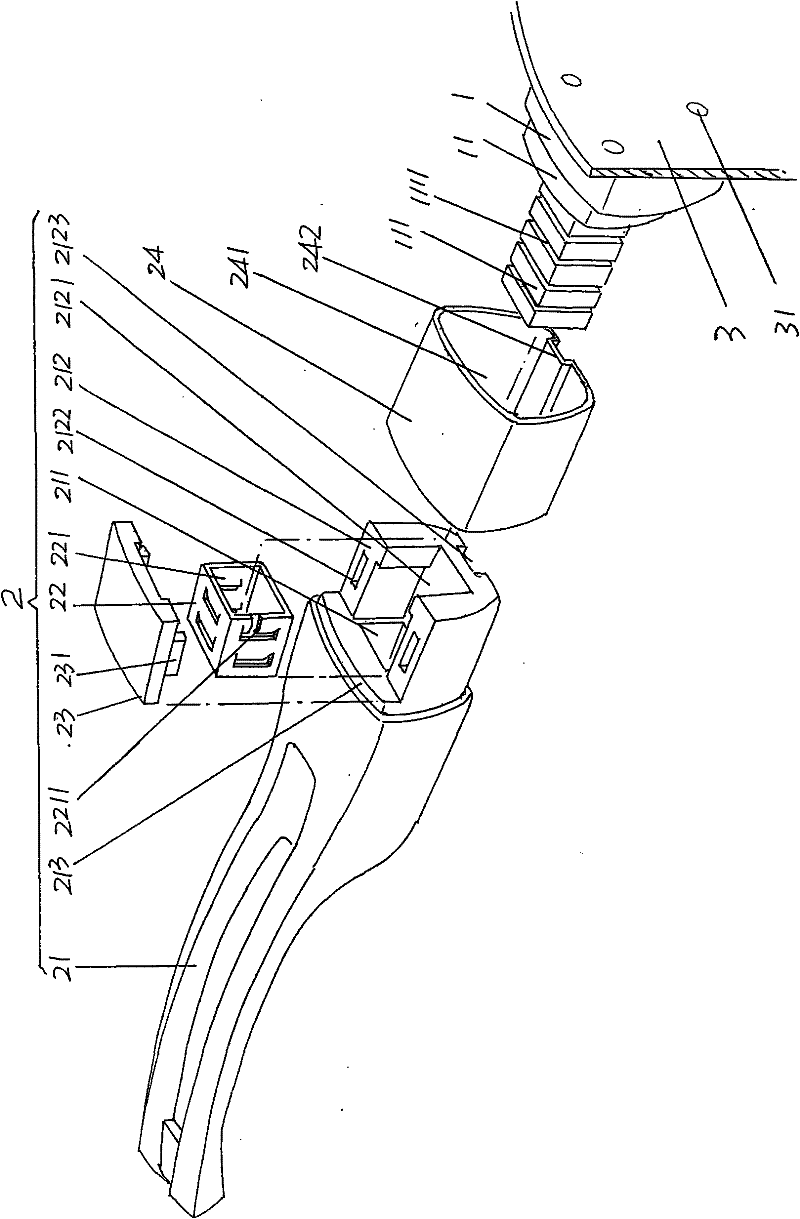

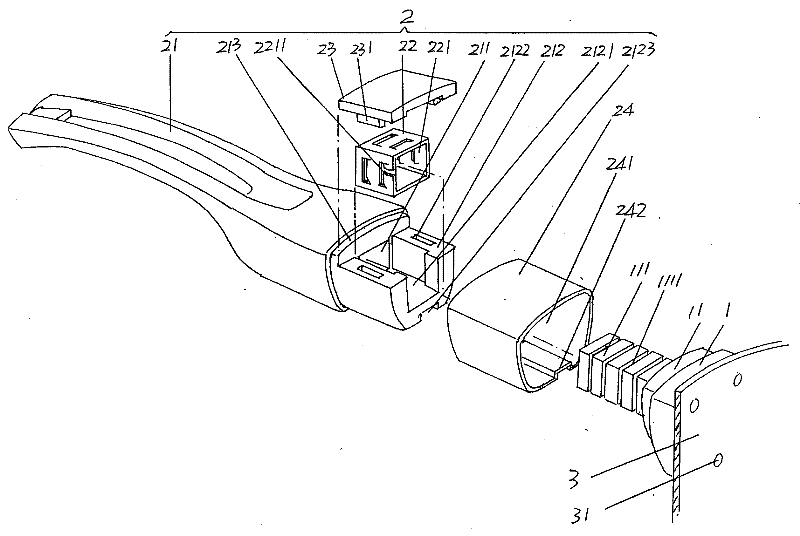

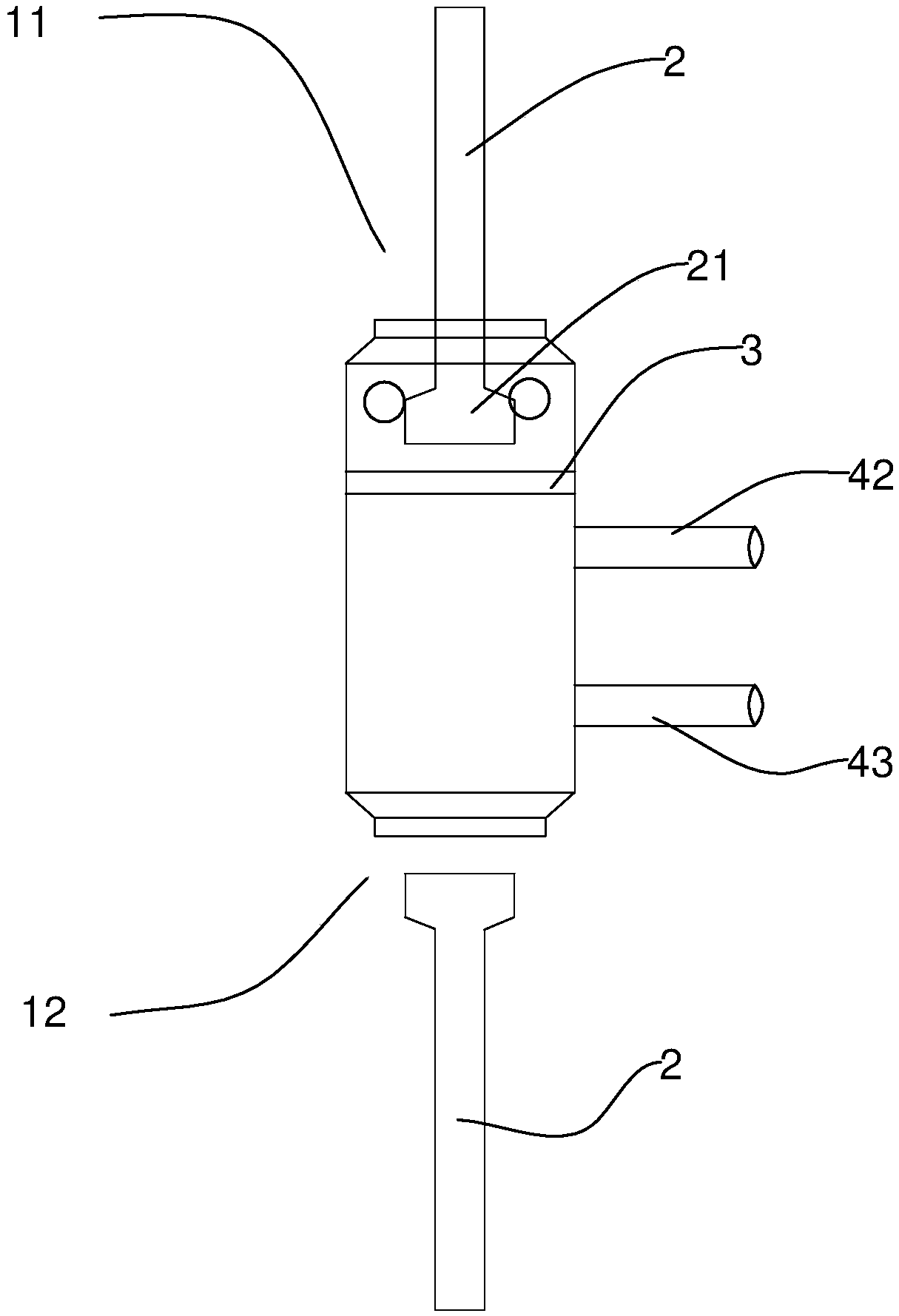

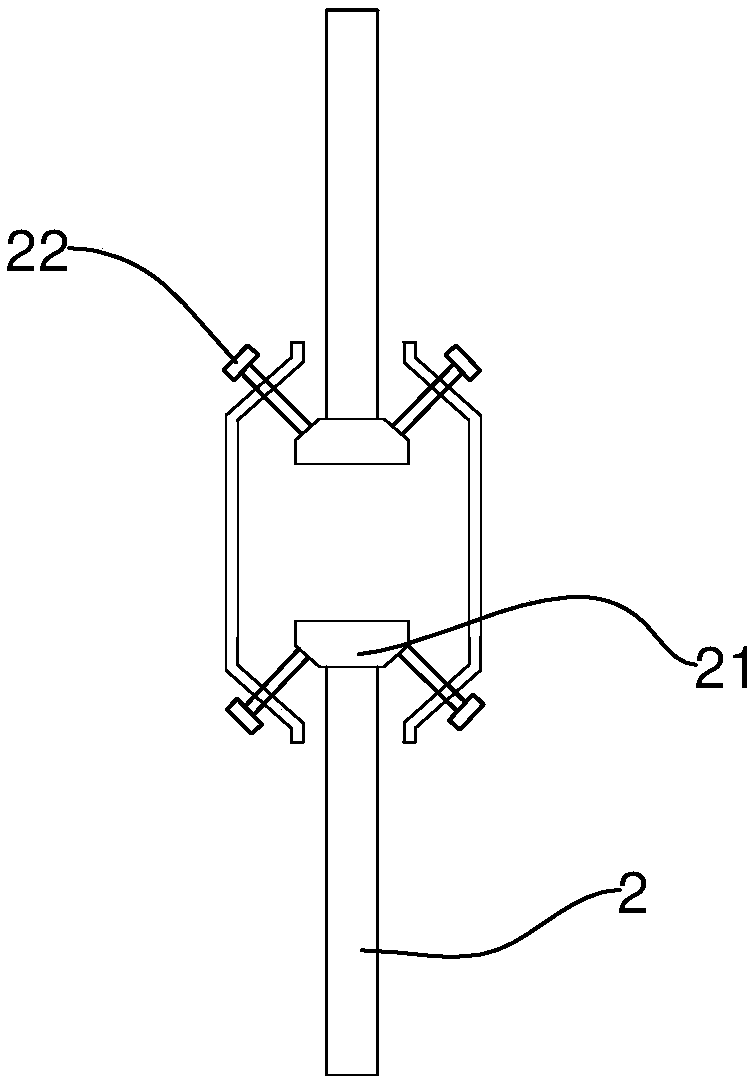

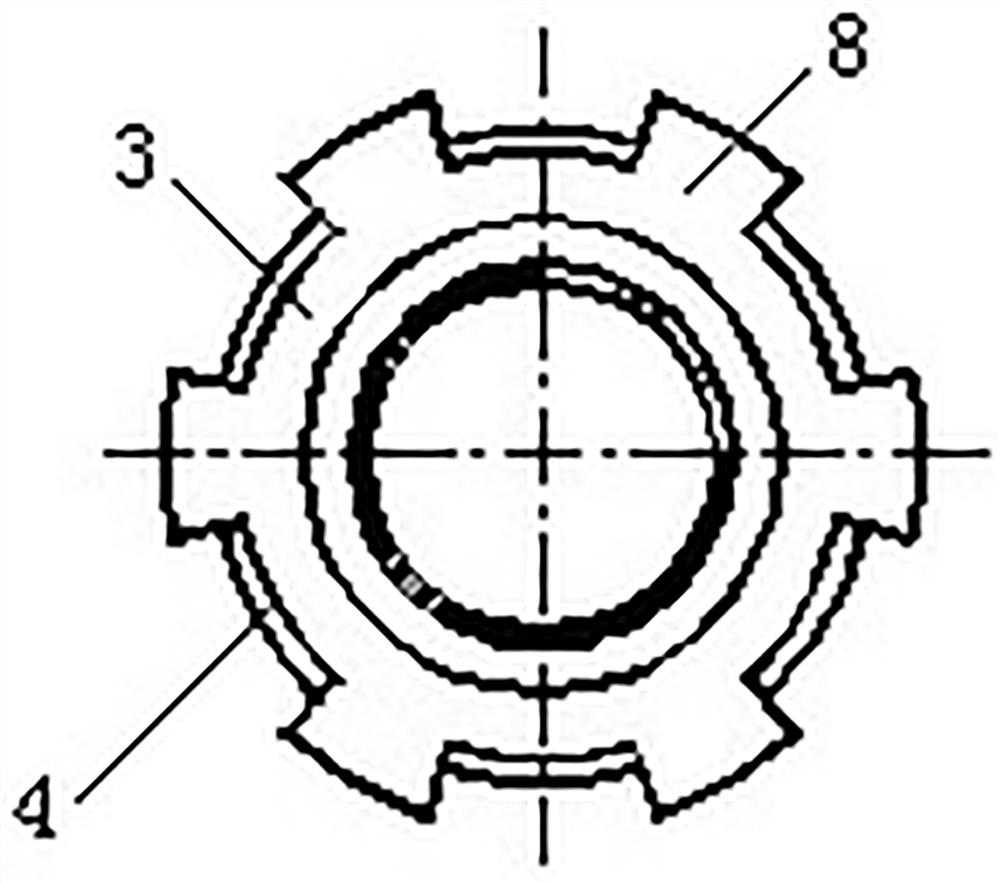

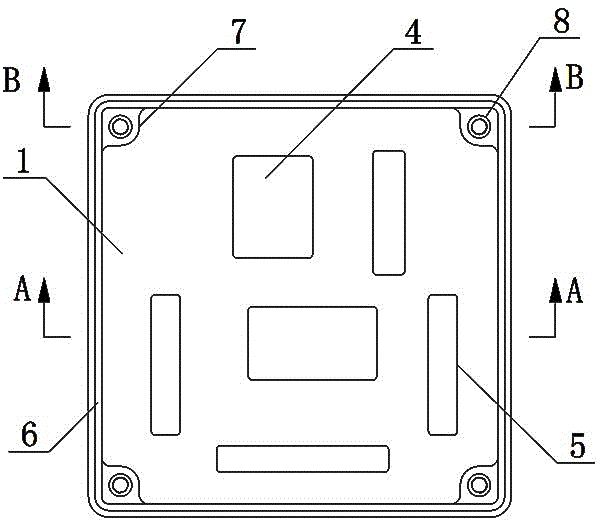

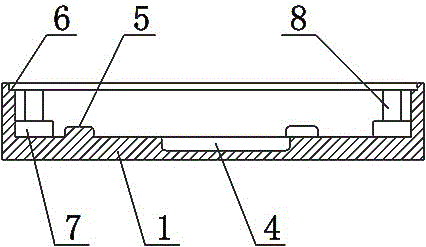

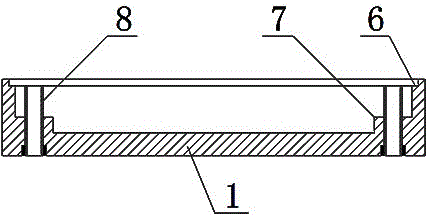

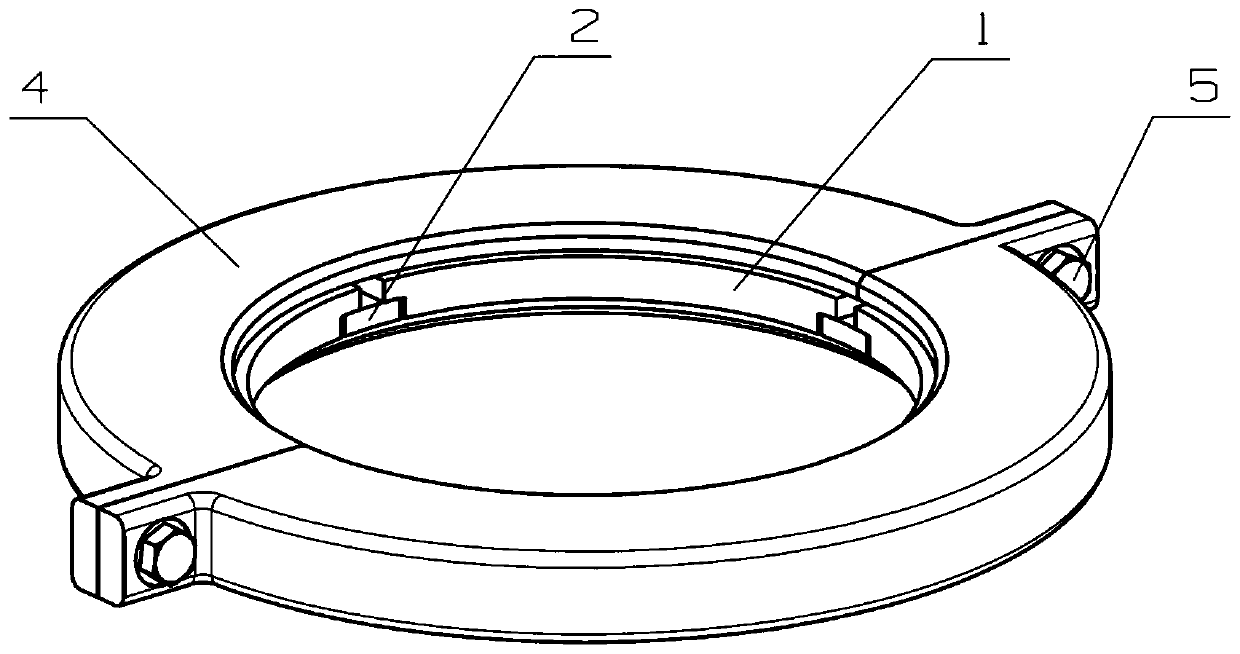

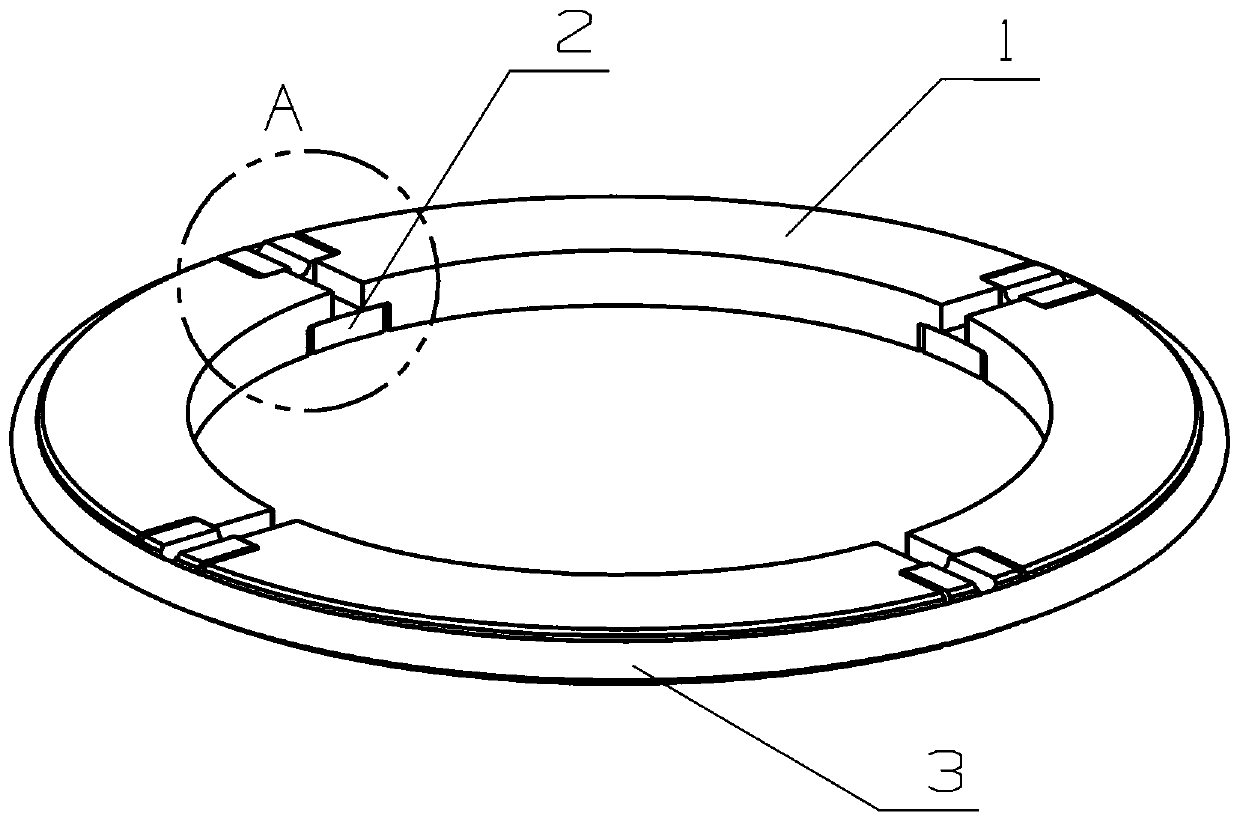

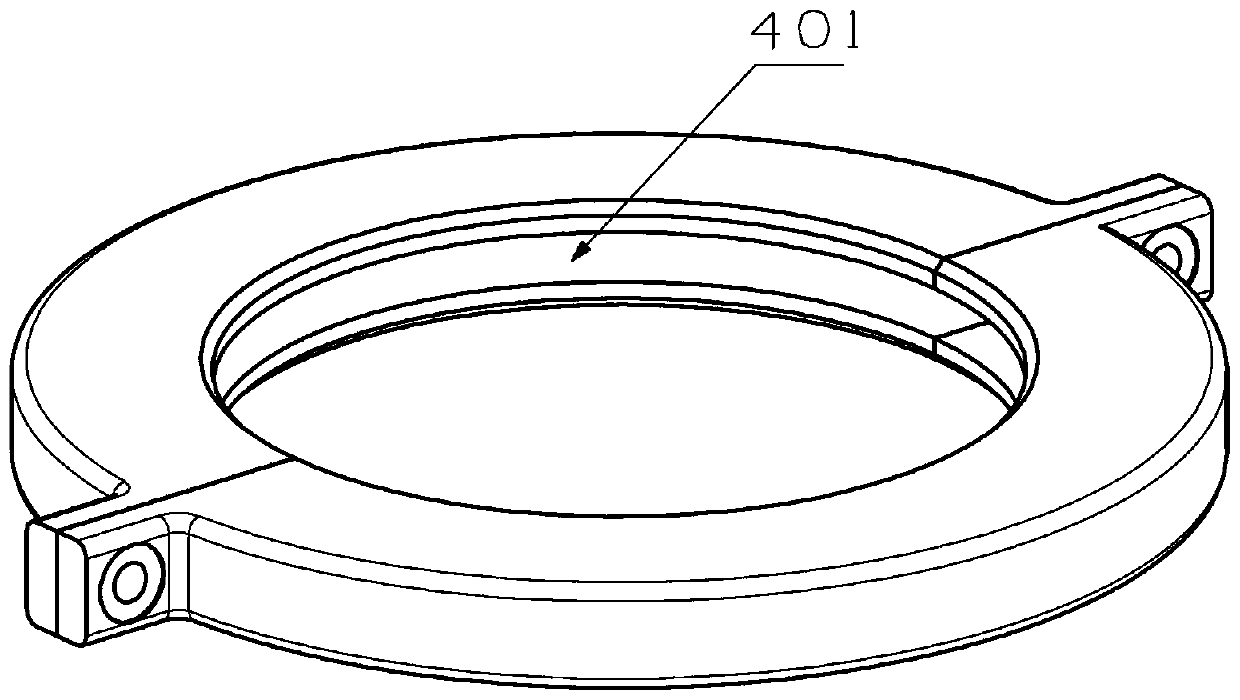

Disk clamper and method of assembling the same

ActiveUS20050223401A1Increase the mating surfaceControl deformationRecord information storageRecording on magnetic disksBiomedical engineeringMagnet

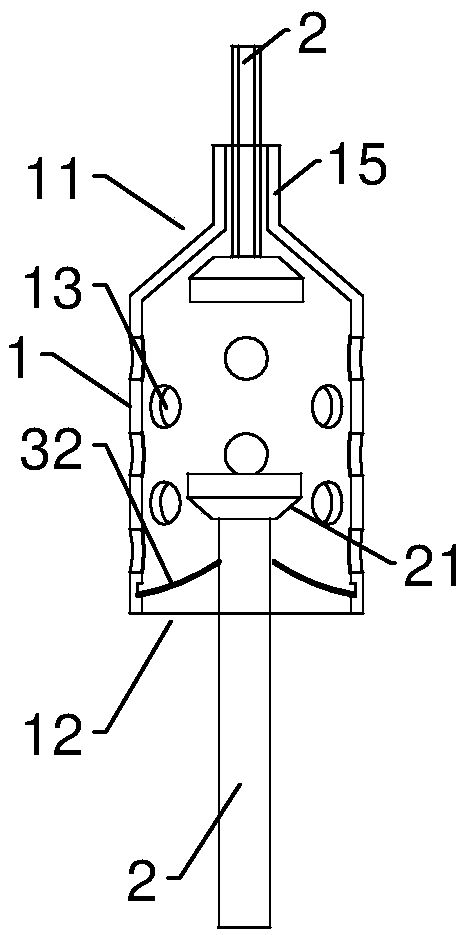

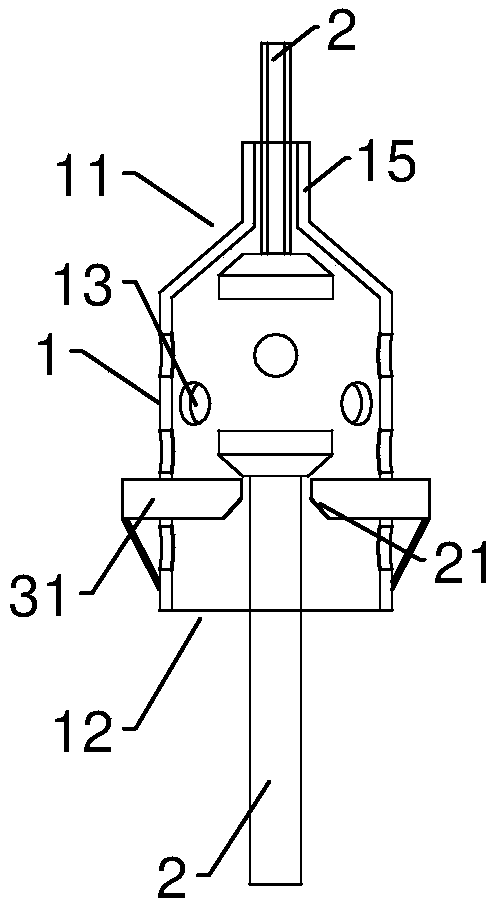

A disk clamper (100) includes a clamper main body (1) and a lid body (2) that holds an attraction member (3) such as a magnet or the like between the clam main body (1) and the lid body (2). The clamper main body (1) includes a peripheral wall (12) whose outer peripheral surface constitutes a cylindrical surface. The lid body (2) includes a peripheral wall (22) fitted on the outside of the peripheral wall (12) of the clamper main body (1). Engaging claws (13) are formed on and protruded from the outer peripheral surface of the peripheral wall (12). Engaging claws (23) are formed on the inner peripheral surface of the peripheral wall (22). The clamper main body (1) and the lid body (2) can be integrated by fitting the peripheral wall (22) to the outside of the peripheral wall (12) in a state where the circumferential positions of the engaging claws. (13, 23) are different from each other, and by rotating the peripheral walls (12, 22) relative to each other until the engaging members (13, 23) engage each other in the axial direction.

Owner:MITSUBISHI ELECTRIC CORP

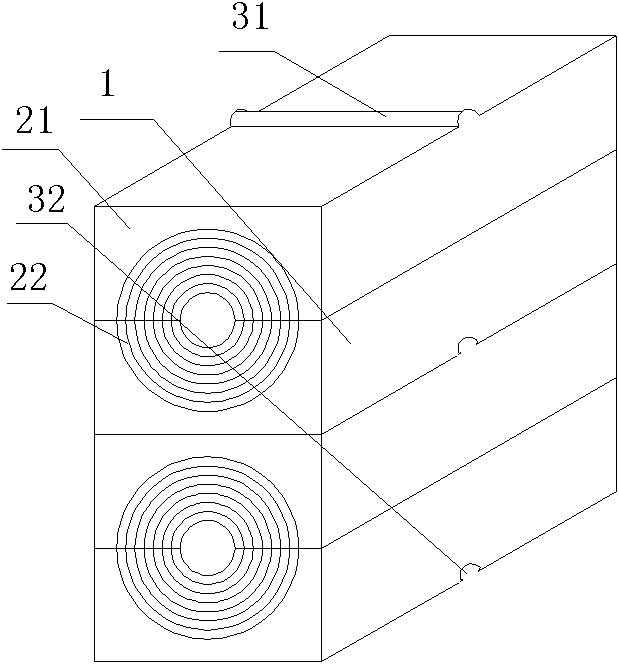

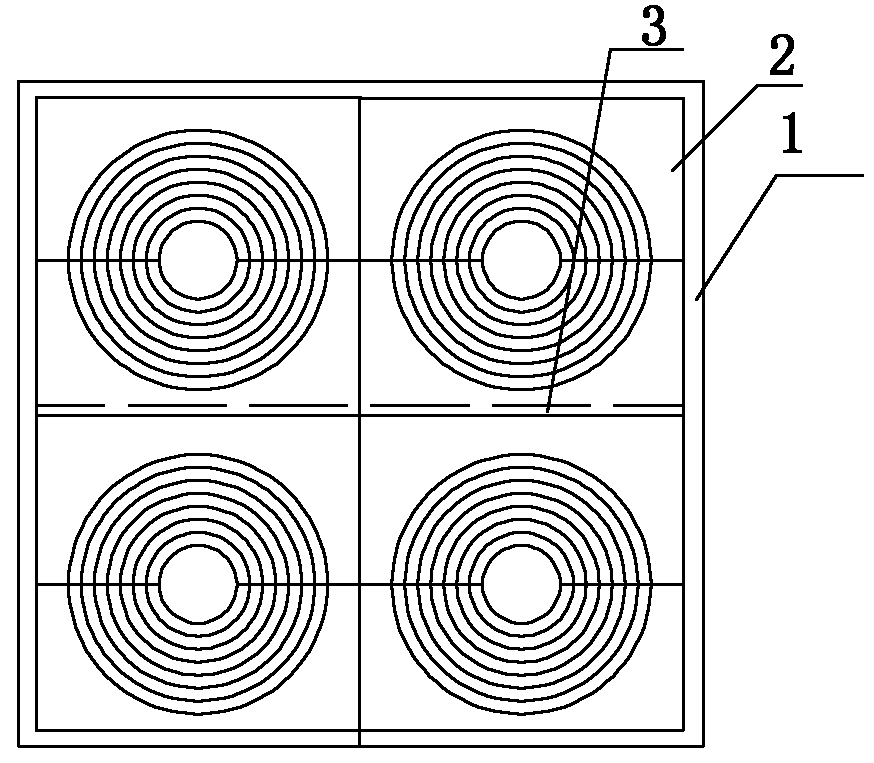

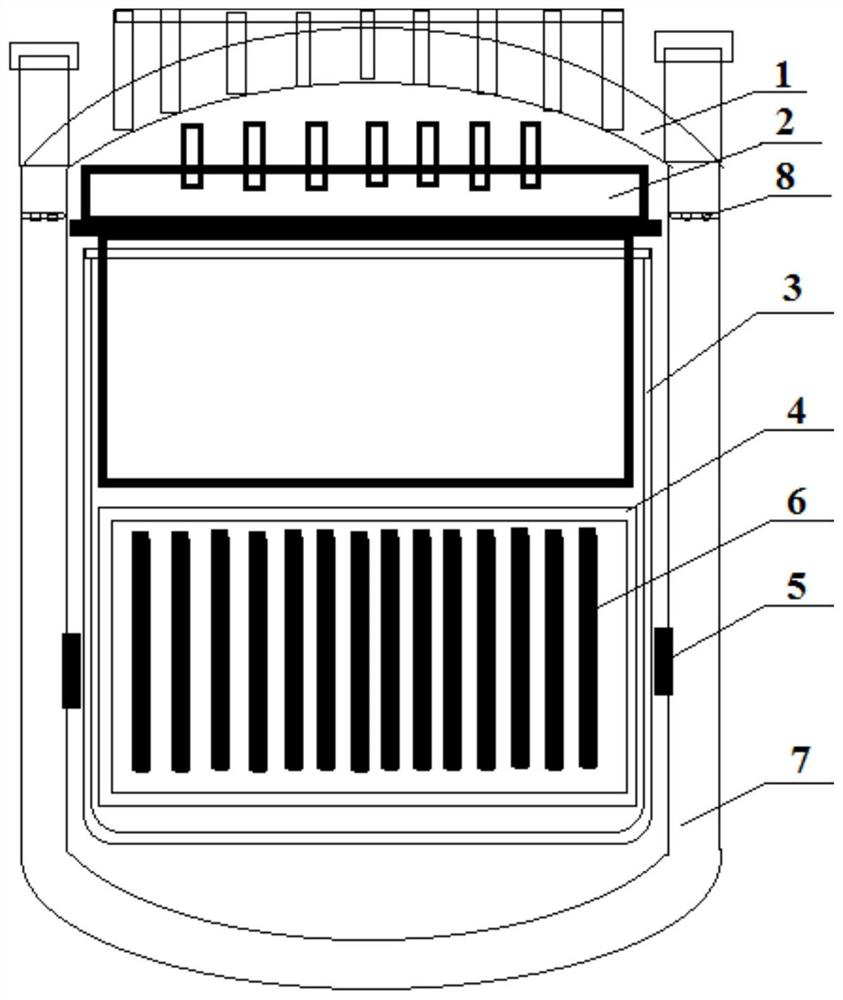

Well-radiating module power supply

ActiveCN104377940AIncrease contact areaImprove cooling effectCasings/cabinets/drawers detailsModifications for power electronicsEngineeringHeating element

Owner:SICHUAN SHENGHUA POWER TECH CO LTD

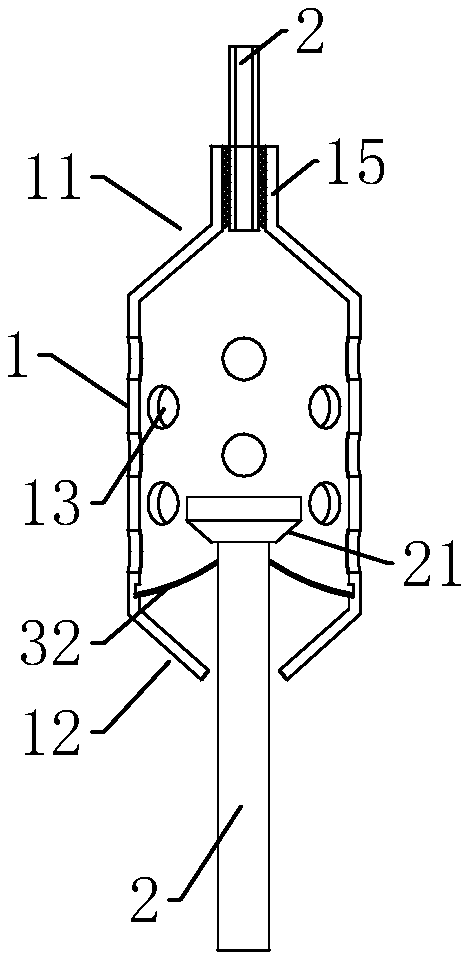

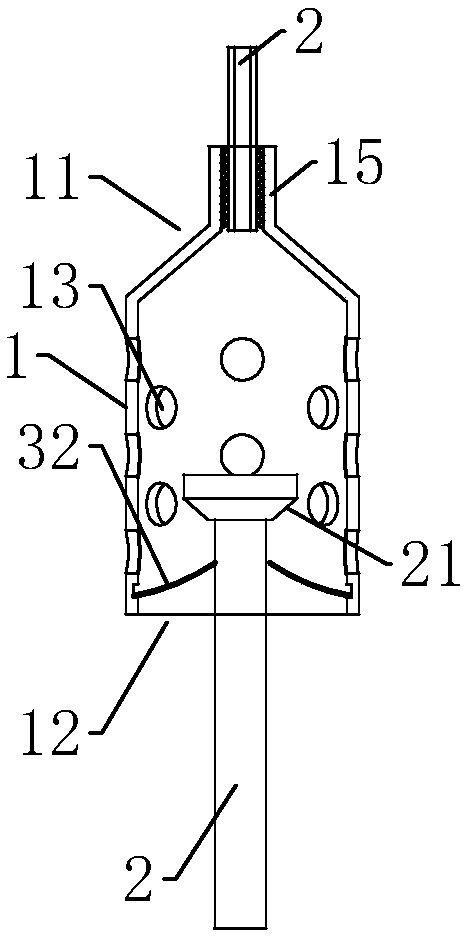

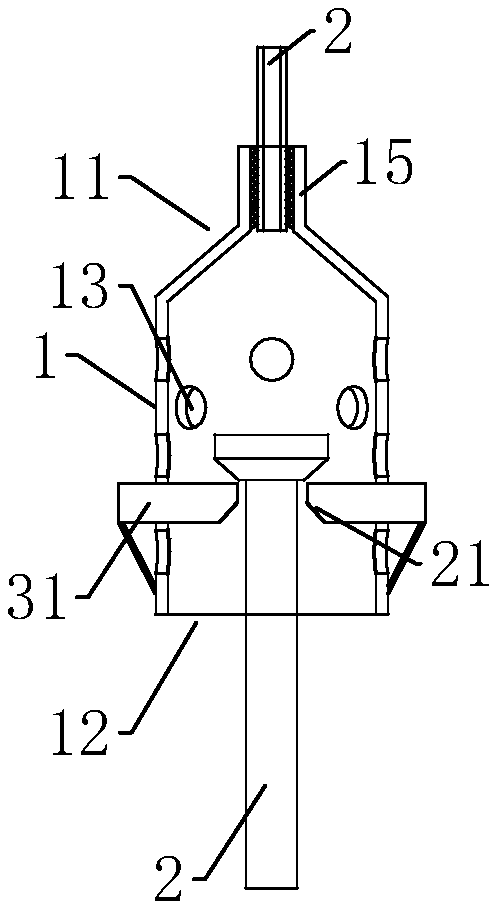

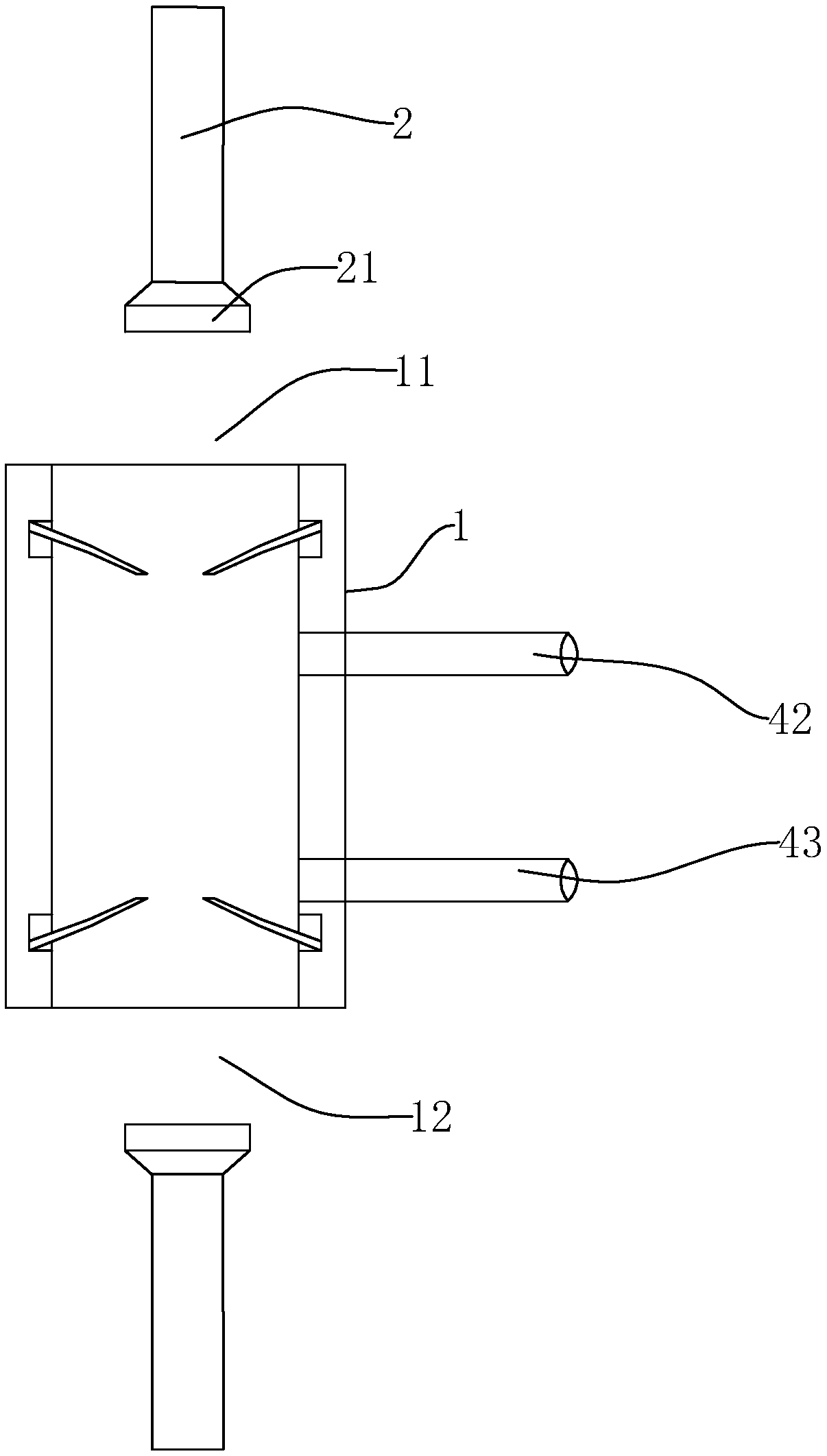

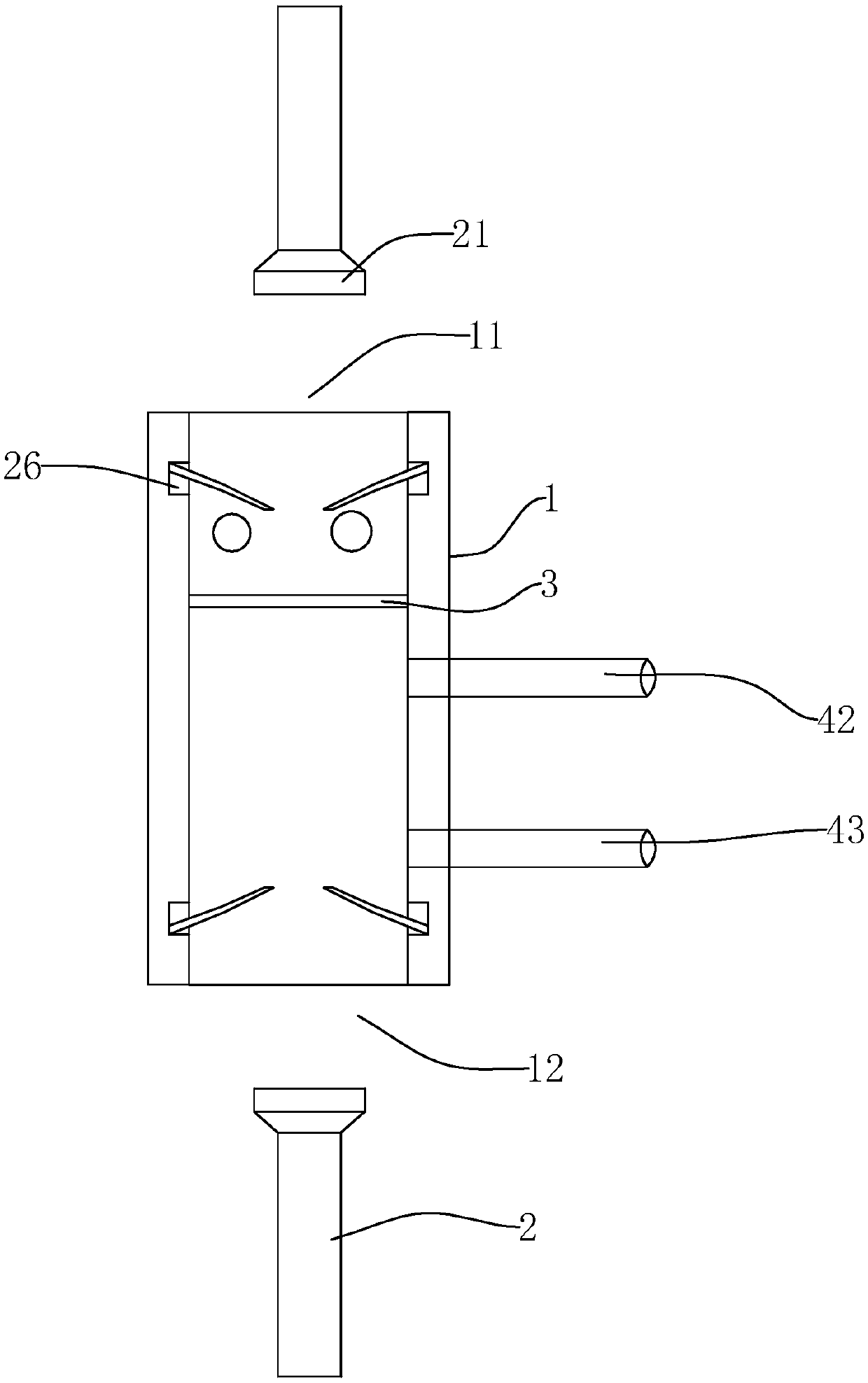

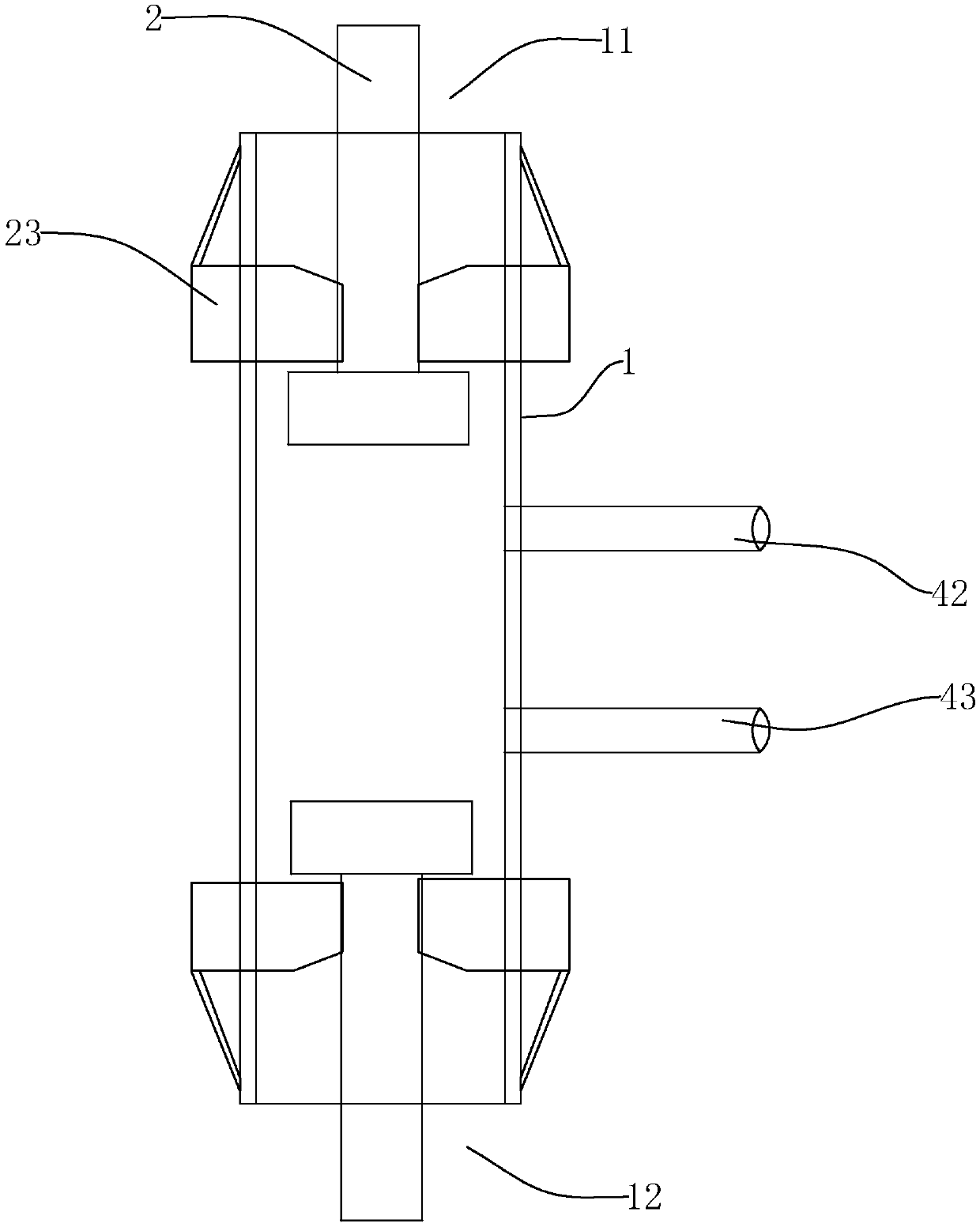

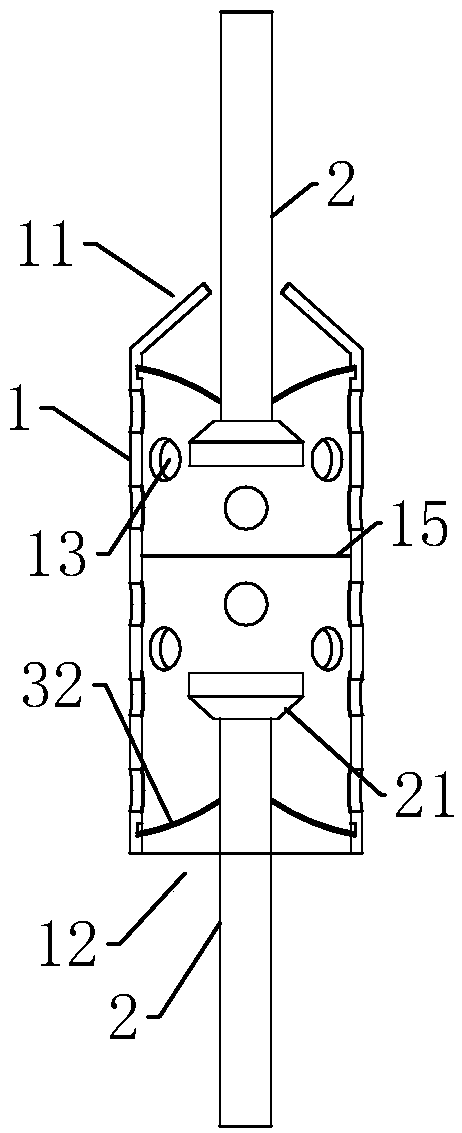

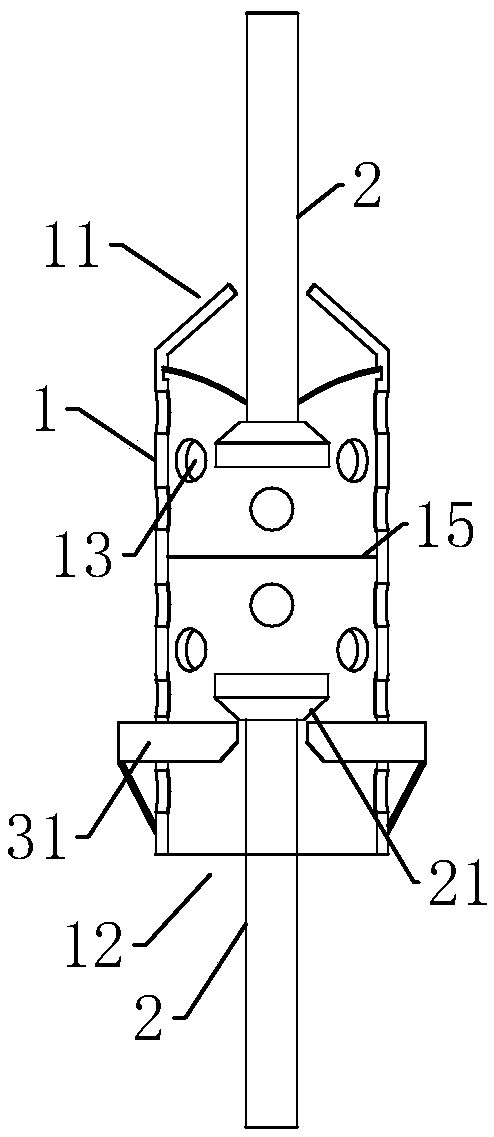

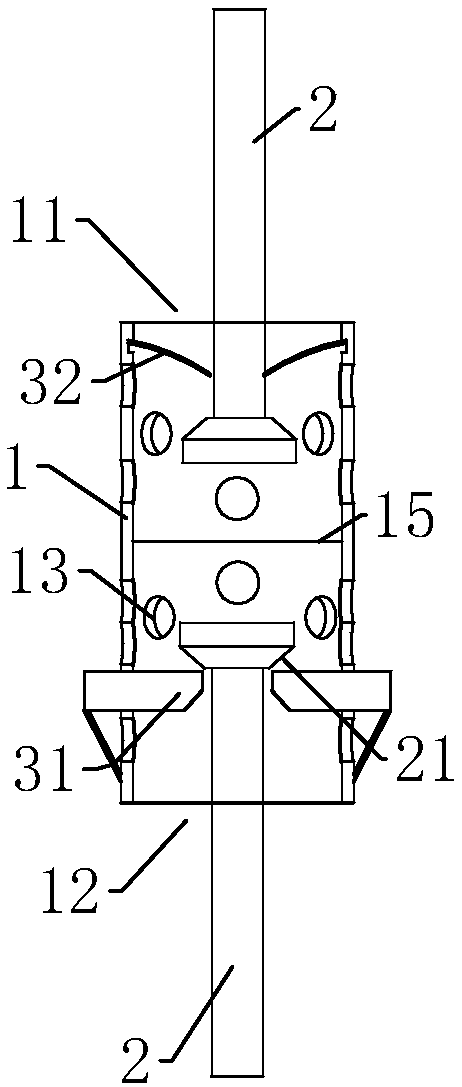

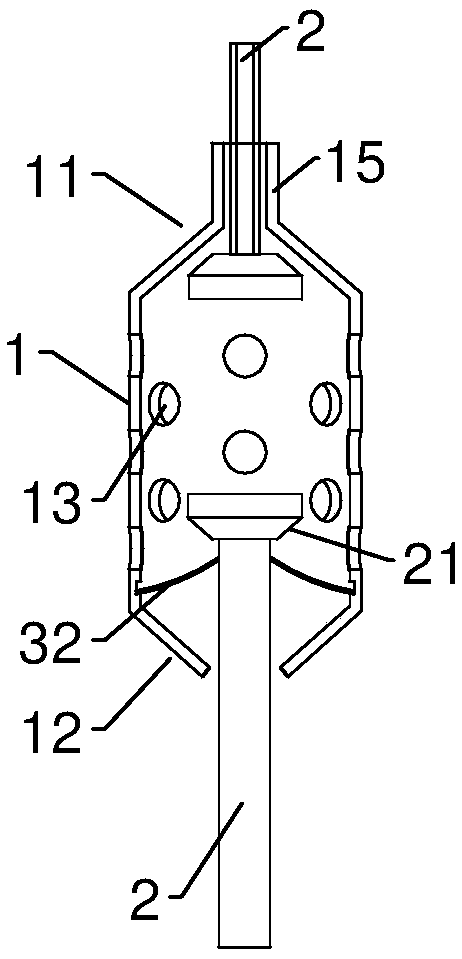

Sleeve, prefabricated part connector, prefabricated part and prefabricated part assembly

PendingCN108678145AIncrease contact surfaceImprove connection strengthConstruction materialThreaded pipeAgricultural engineering

The invention discloses a sleeve, a prefabricated part connector constructed on the basis of the sleeve, a prefabricated part and a prefabricated part assembly and belongs to the field of prefabricated buildings. The sleeve comprises a basic port and a matched port, wherein the basic port is a closing port which outwards extends in the axial direction of the sleeve to form a threaded pipe; the matched port is a closing port or an opening with the same inner diameter as the sleeve. The contact area of a rebar and concrete and the contact area of the sleeve and the concrete are increased throughassembly of a port structure of an embedded part and a rebar inserted into the port, fixed connection of the rebar and the sleeve by concrete pouring, construction of the sleeve port and the shape ofthe end part of the rebar, meanwhile, the connection strength of the connector formed by the sleeve is greatly enhanced by changing the stress plane produced among the sleeve, the concrete and the rebar, the prefabricated part assembled through the sleeve is simple to assemble, assembling of a prefabricated plate can be rapidly completed, and the construction period is greatly shortened.

Owner:李藏柱

Sleeve, prefabricated part connector, prefabricated part and prefabricated part assembly

PendingCN110485647AImprove connection strengthIncrease the mating surfaceBuilding reinforcementsAgricultural engineeringRebar

The invention discloses a sleeve, and a prefabricated part connector, a prefabricated part and a prefabricated part assembly which are constructed on the basis of the sleeve, and belongs to the fieldof assembly type buildings. The sleeve comprises a sleeve body and open ends positioned at two ends of the sleeve body, clamping pieces are arranged at the two open ends, and one ends of a grouting channel and an exhaust channel communicate with the through holes formed in the sleeve body. By assembling a port structure of an embedded part and a steel bar inserted into the port of the embedded part, fixing the steel bar and the sleeve by concrete or grouting material, and by the structure of the port of the sleeve and the shape of the end part of the steel bar, the contact surface between thesteel bar and the concrete or grouting material and between the sleeve and the concrete or grouting material is increased; meanwhile, the connection strength of the connector formed by the sleeve is enhanced by changing the stress surface generated between the sleeve, the concrete or grouting liquid and the steel bar; and the prefabricated part assembled through the sleeve is simple to assemble during construction, the assembly between the prefabricated plates can be completed quickly, and the construction period is shortened greatly.

Owner:李藏柱

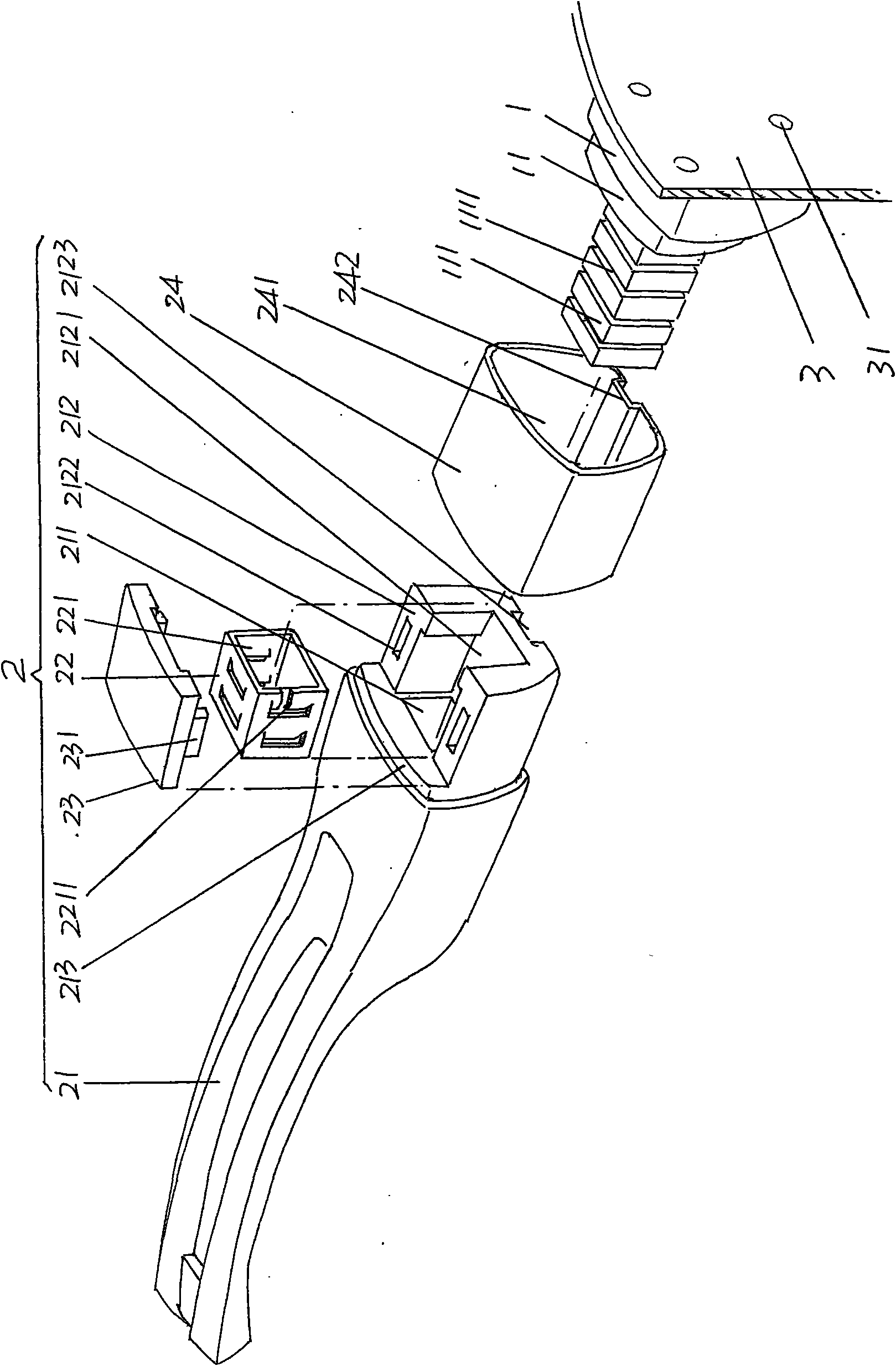

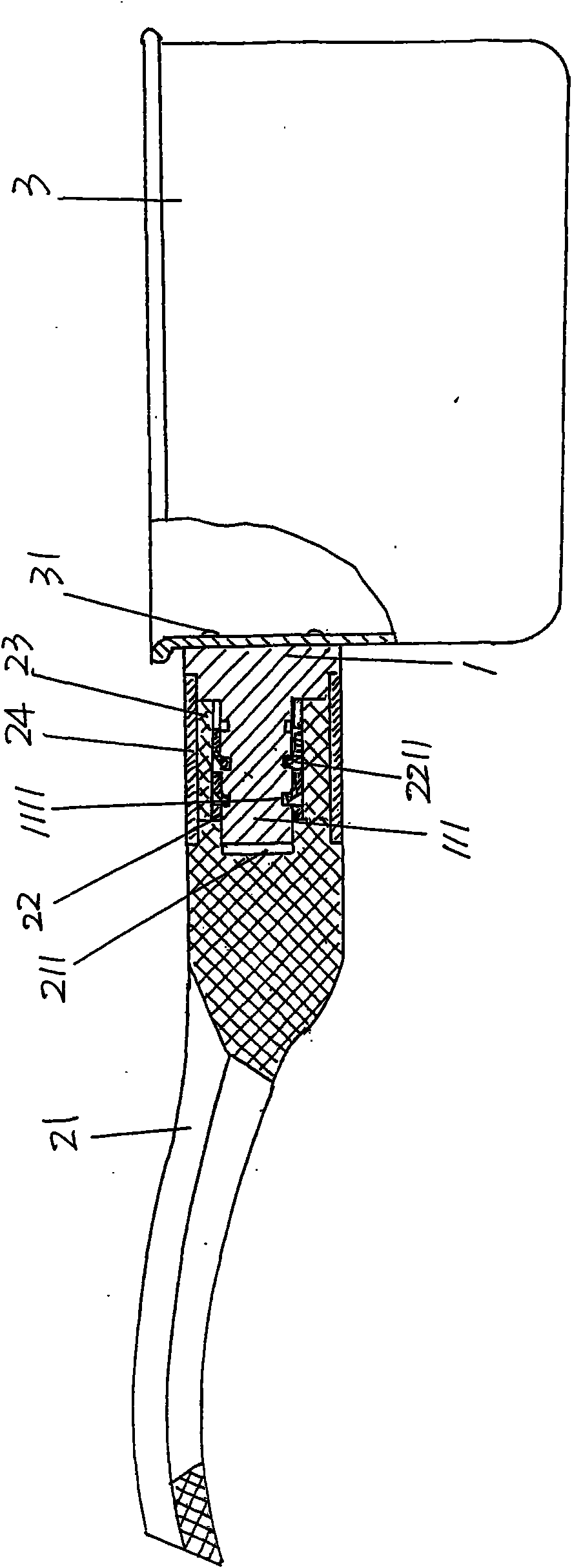

Disk clamper and method of assembling the same

InactiveUS7263704B2Improve coupling strengthAvoid separationRecord information storageRecording on magnetic disksBiomedical engineeringMagnet

A disk clamper (100) includes a clamper main body (1) and a lid body (2) that holds an attraction member (3) such as a magnet or the like between the clam main body (1) and the lid body (2). The clamper main body (1) includes a peripheral wall (12) whose outer peripheral surface constitutes a cylindrical surface. The lid body (2) includes a peripheral wall (22) fitted on the outside of the peripheral wall (12) of the clamper main body (1). Engaging claws (13) are formed on and protruded from the outer peripheral surface of the peripheral wall (12). Engaging claws (23) are formed on the inner peripheral surface of the peripheral wall (22). The clamper main body (1) and the lid body (2) can be integrated by fitting the peripheral wall (22) to the outside of the peripheral wall (12) in a state where the circumferential positions of the engaging claws. (13, 23) are different from each other, and by rotating the peripheral walls (12, 22) relative to each other until the engaging members (13, 23) engage each other in the axial direction.

Owner:MITSUBISHI ELECTRIC CORP

Sleeve, prefabricated component connector, prefabricated component and prefabricated component assembly

PendingCN110485552AIncrease contact surfaceImprove connection strengthConstruction materialRebarUltimate tensile strength

The invention discloses a sleeve and a prefabricated component connector, a prefabricated component and a prefabricated component assembly which are constructed based on the sleeve, and belongs to thefield of fabricated buildings. The sleeve includes a base port and a matching port. The base port is a closing port. The matching port is an opening port. A clamping member is arranged on the side wall of the matching port. The clamping member can reciprocate in the radial direction of the sleeve. The port structure of an embedded part is fabricated with steel bars inserted into the port of the port structure, and then the steel bars and the sleeve are fixedly connected together by pouring concrete. Through the structure of the ports of the sleeve and the shape of the end parts of the steel bars, the contact surface between the steel bars and the concrete and between the sleeve and the concrete is enlarged, meanwhile, by changing the stress surface generated between the sleeve, the concrete and the steel bars, the connection strength of the connector formed by the sleeve is greatly enhanced, the prefabricated component which is fabricated through the sleeve is easy to assemble duringconstruction, the fabrication between prefabricated panels can be quickly completed, and the construction period is greatly shortened.

Owner:李藏柱

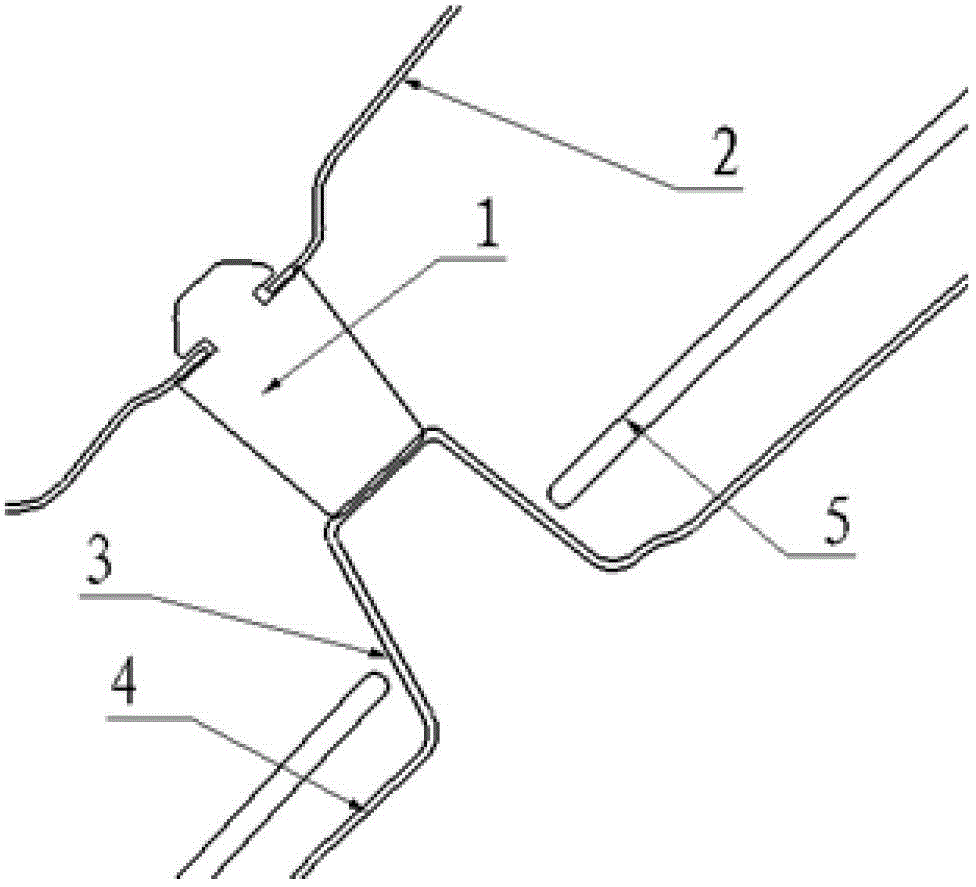

Fireproof plugging member for cable

InactiveCN102003574APrevent popupImprove securityPipesFire resistanceElectrical and Electronics engineering

The invention provides a fireproof plugging member for a cable. The fireproof plugging member comprises a clamping frame and a plurality of block bodies filled in the clamping frame, wherein at least one matching mechanism is arranged between adjacent block bodies which are matched with each other; and the matching mechanism comprises convex blocks which are transversely arranged on the peripheral region of the block bodies and grooves which are transversely formed on the peripheral region of the adjacent block bodies and matched with the convex blocks. During installation, the convex blocks are matched with the corresponding grooves. During the occurrence of fire, the fireproof plugging member is expanded at high temperature so that the convex blocks are closely matched with the grooves to avoid the block bodies from jumping out of the wall and prevent damage to the human body. Therefore, the security of the fireproof plugging member is greatly improved and the fire resistance of the fireproof plugging member is ensured. In addition, the fireproof plugging member is simple in structure.

Owner:江苏华兴防火材料有限公司

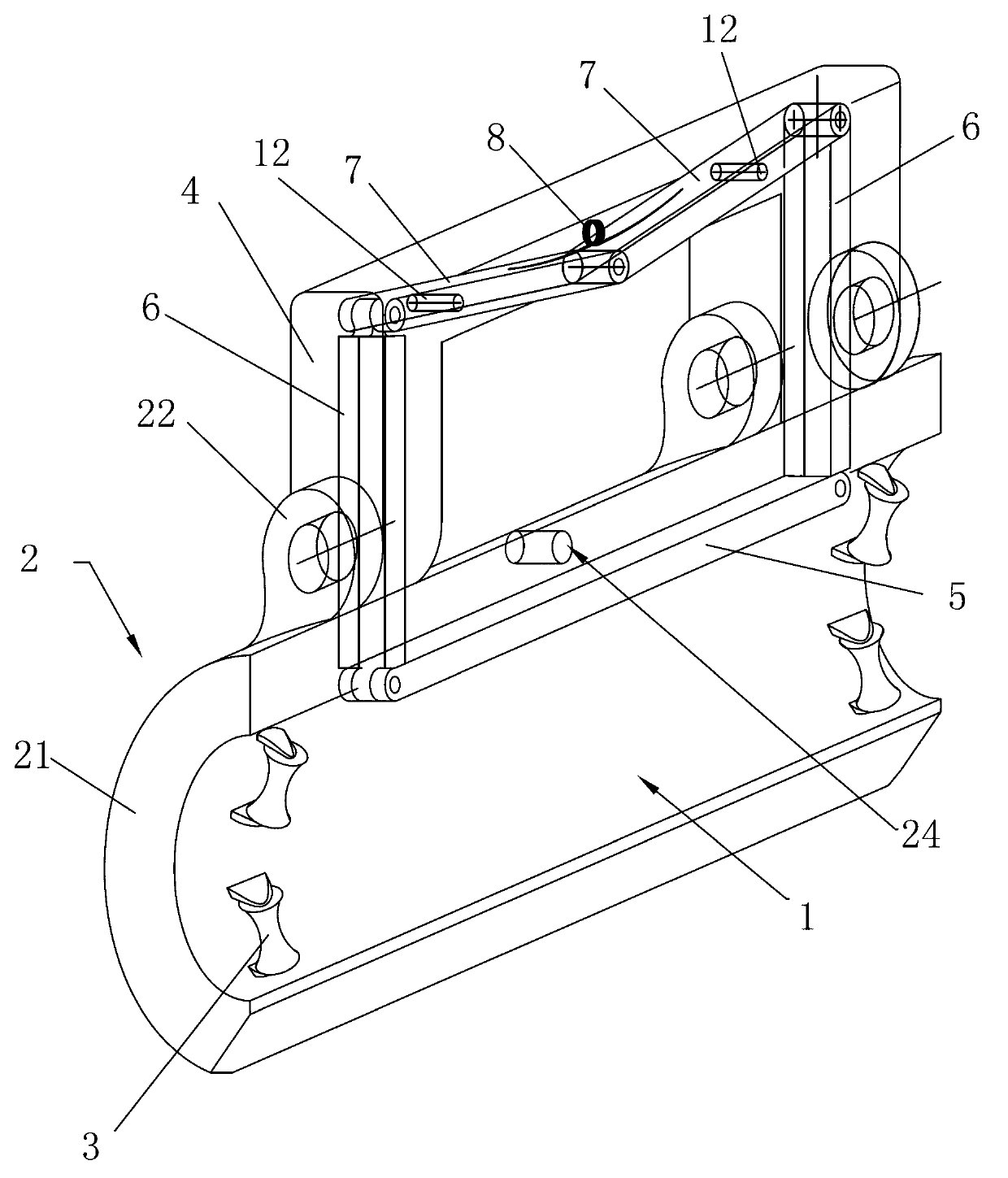

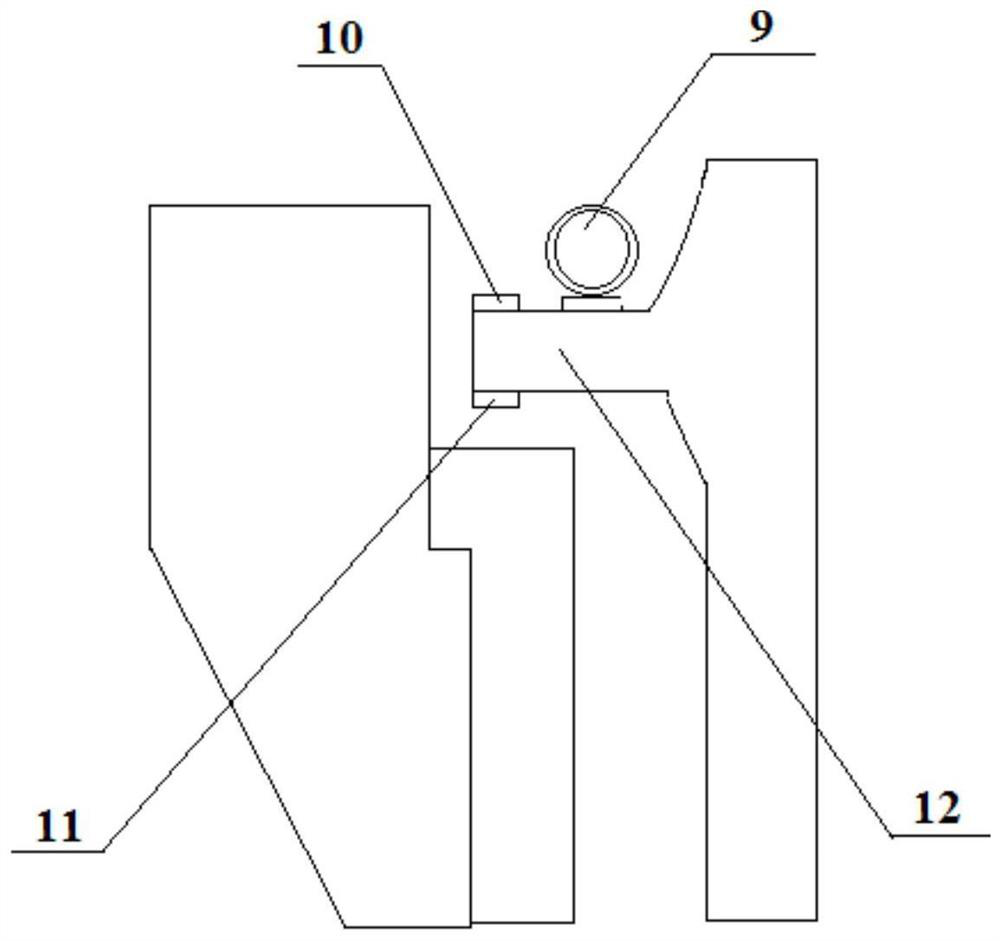

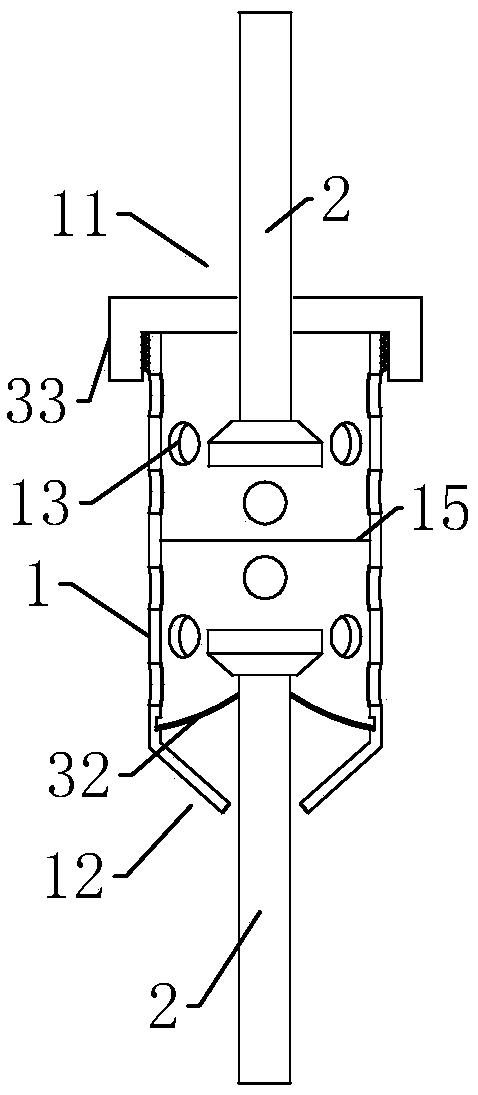

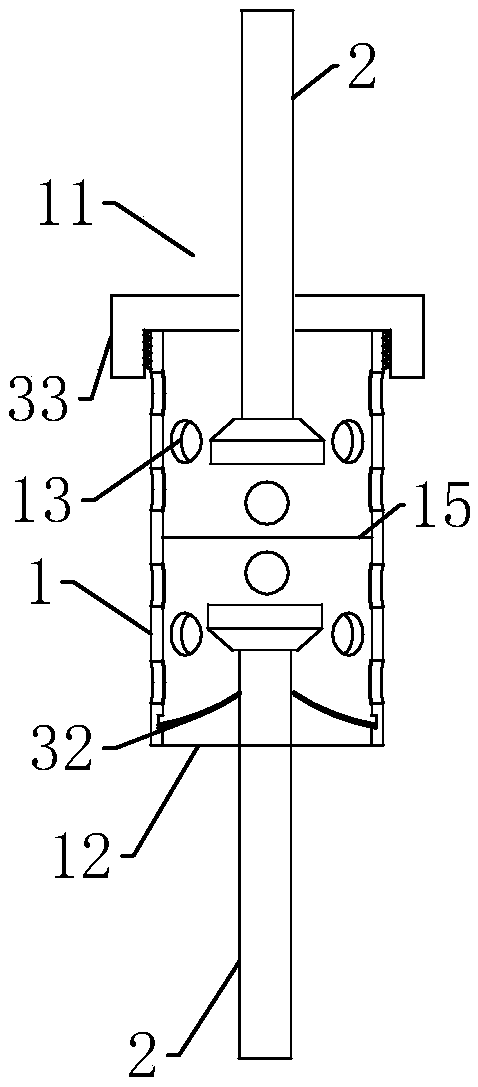

Hand wheel used for wire arrangement of electric transmission line

ActiveCN103138203AAvoid consumptionEasy to use with one handApparatus for overhead lines/cablesStructural engineeringMechanical engineering

The invention relates to a hand wheel used for wire arrangement of an electric transmission line. The hand wheel comprises a wire holding part provided with a wire passing cavity, a plurality of wire arranging wheels arranged on the inner wall of the wire passing cavity, a handle arranged above the wire holding part, and a locking component arranged on the handle and stretching into the wire passing cavity. The hand wheel used for the wire arrangement of the electric transmission line has the advantages that a wire is held by the wire holding part, sliding fit between the wire holding part and the wire is controlled through the locking component and the wire can be grasped firmly without sliding under the control of the locking component according to walking requirements of work staff, and therefore consumption of a large amount of labor protection appliance is avoided, physical output is reduced due to the fact that manual holding is replaced with firm mechanical holding, working intensity is relieved, and safety of operation is improved; and as the wire holding part is of a two-piece type, grasping of the wire and separating of the wire holding part from the wire are enabled to be convenient. Opening and closing of the two wire holding pieces are controlled by the wheel opening handle, convenience of the operation is improved, and operation with one hand can be achieved easily.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER COMPANY TAIZHOU POWER SUPPLY +1

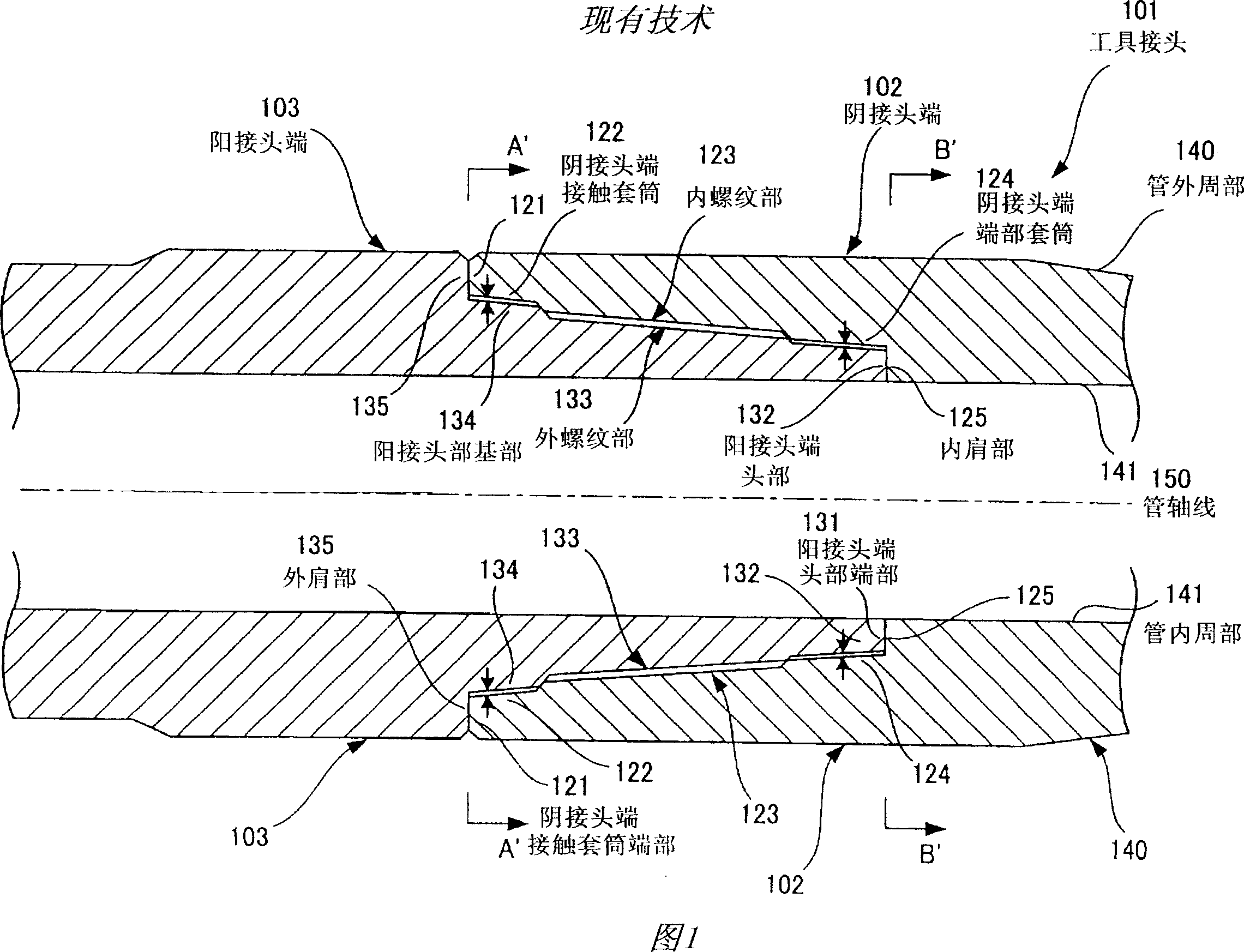

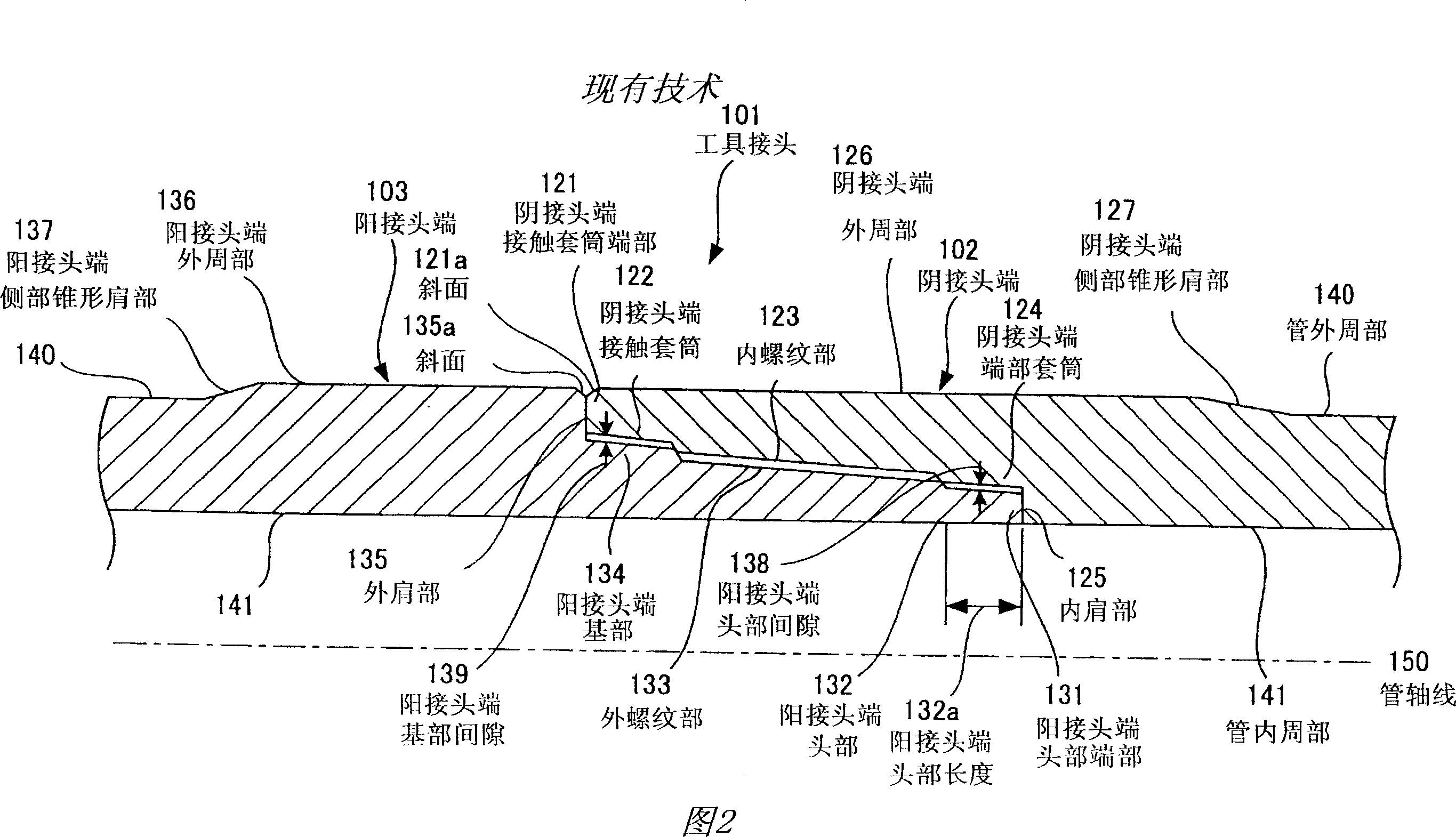

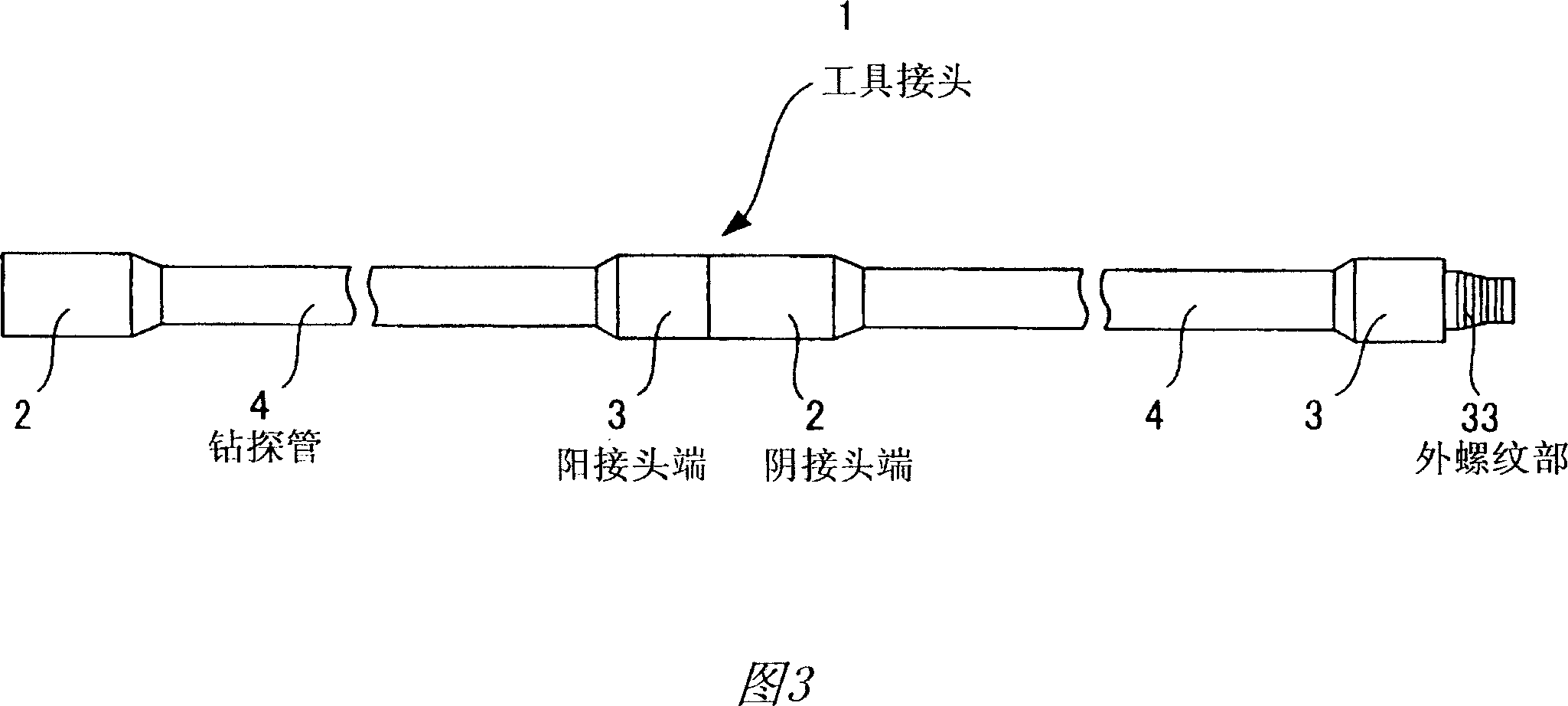

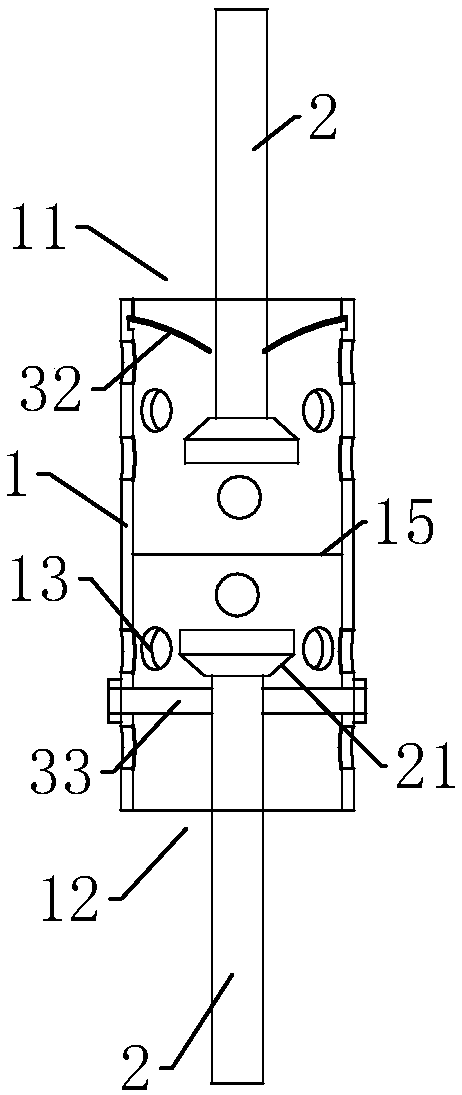

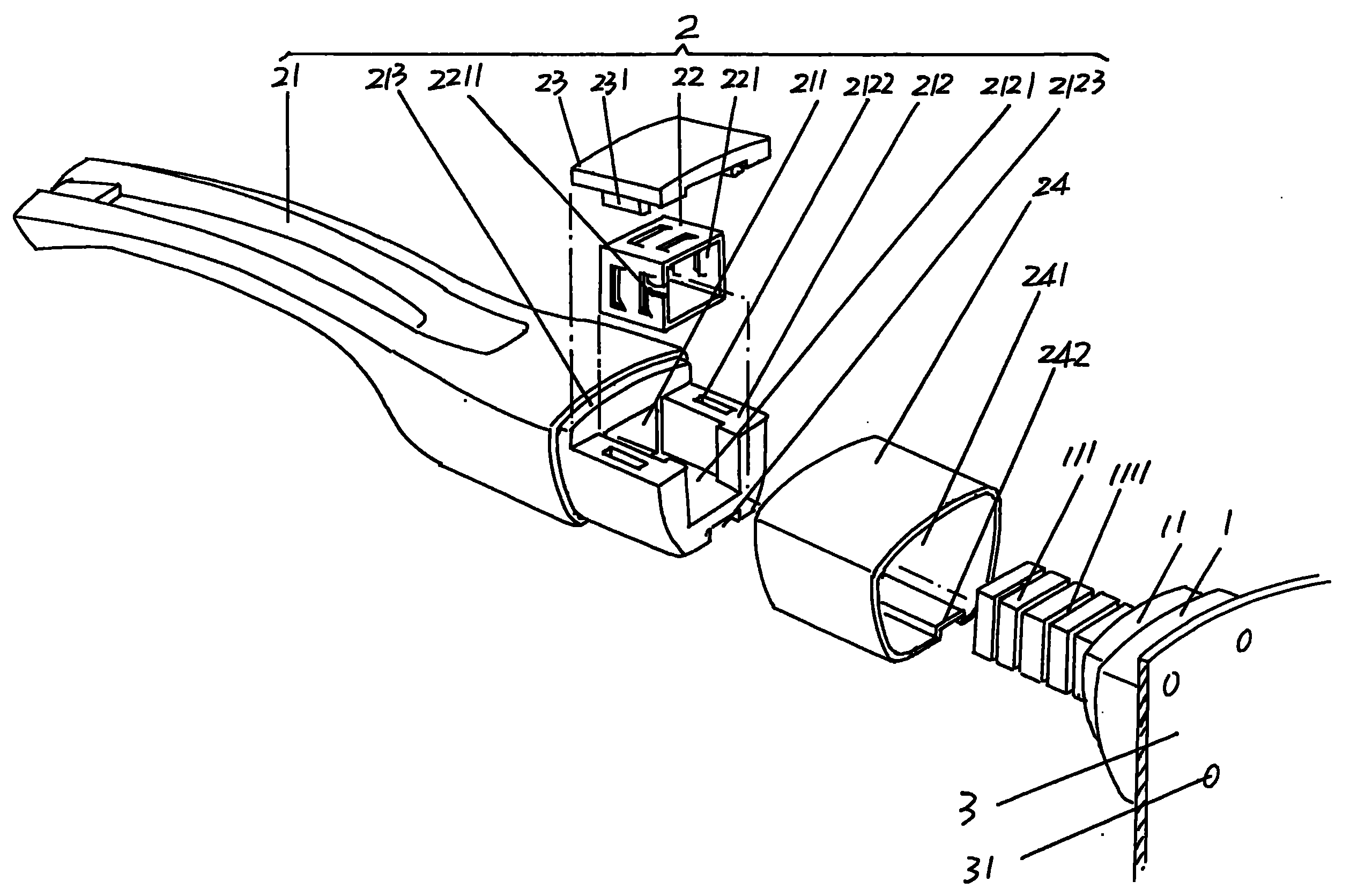

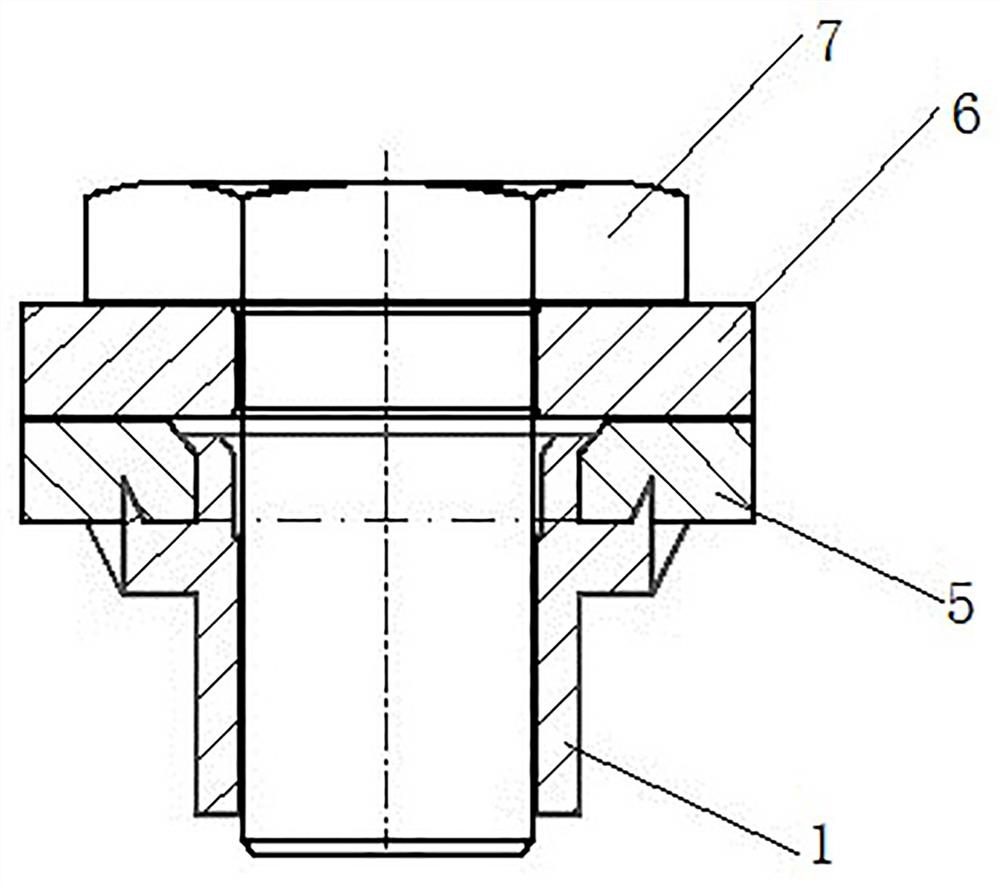

Double shoulder tool joint

InactiveCN1934386AImprove operabilityExtended service lifeDrilling rodsDrilling casingsHigh torqueDrill pipe

The tool joint 1 for drill pipe used for boring oil or gas well. The pin 3 is provided with an outside shoulder 35, a pin base 34 having an outer periphery surface parallel with the pipe axis 50, a male threaded part 33 having a predetermined taper to the pipe axis 50, and a pin nose 32 having an outer periphery surface parallel with the pipe axis 50. The box 2 is provided with a box access sleeve 22 having an inner periphery surface parallel with the pipe axis 50, a female threaded part 23 engaging by thread with the male threaded part 33, a box end sleeve 24 having an inner periphery surface corresponding to the outer periphery surface of the pin nose 32, and an inside shoulder 25. By increasing a total of a mating surface between the outside shoulder 35 and a box access sleeve end portion 21 and a mating surface between the inside shoulder 25 and a pin nose end portion 31, higher torque characteristics is realized without reducing the operativity.

Owner:NKKTUBES

Sleeve, prefabricated component connector, prefabricated component and prefabricated component assembly

PendingCN110485640AIncrease contact surfaceImprove connection strengthBuilding reinforcementsEngineeringRebar

The invention discloses a sleeve as well as a prefabricated component connector, a prefabricated component and a prefabricated component assembly which are constructed on the basis of the sleeve, andbelongs to the field of assembly type buildings. The sleeve comprises a base port and a matching port, the base port and the matching port are both openings, a plurality of elastic slips are uniformlydistributed in the circumferential direction of the inner side wall of the base port, and the elastic slips are obliquely arranged on the inner side wall of the base port; a small circular opening formed by a plurality of annular slips is close to the matching port, and a large circular opening is away from the matching port; and a plurality of through holes are formed in the side wall of the matching port in the radial direction thereof, and a clamping piece is arranged in each through hole. According to the structure of the sleeve, stress surfaces generated among the sleeve, concrete and steel bars are effectively changed, so that the connection strength of the connector formed by the sleeve is greatly enhanced, the prefabricated component assembled by the sleeve is simple to assemble during construction, assembling of prefabricated plates can be quickly completed, and the construction period is greatly shortened.

Owner:李藏柱

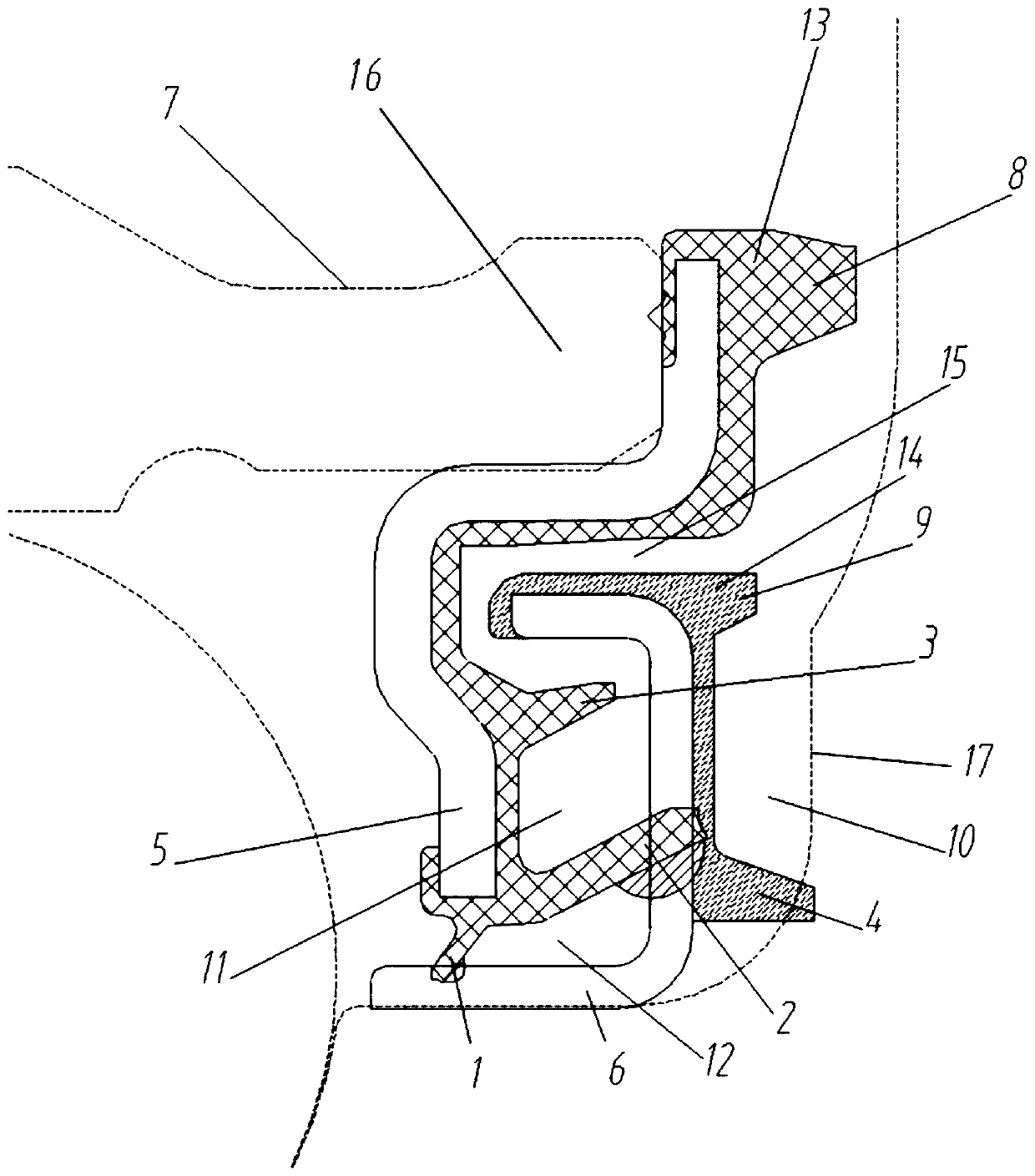

Seal assembly for hub bearing unit

PendingCN111271381AAvoid direct accessAvoid enteringEngine sealsBearing componentsFriction torqueMetal framework

The invention discloses a seal assembly for a hub bearing unit. The seal assembly for the hub bearing unit mainly comprises a static framework arranged on an outer ring and a rotating framework arranged on a flange plate, a roller path is formed between the outer ring and the flange plate, and a cavity is formed in the outer side of the roller path. The seal assembly has the following beneficial effects that only two lips of the static framework make contact with the rotating framework, and large friction torque is avoided; meanwhile, a large gap is formed between the rotating framework and aflange, muddy water is prevented from directly entering a sealing cavity, and it is ensured that a large amount of muddy water can be accumulated and discharged in time through centrifugation and gravity; through additionally arranging a lip D, the purposes of protecting the matching surface of the rotating framework and the flange and preventing a metal framework at the position from being corroded to generate matching failure can be achieved; and according to the internal structure design of the seal assembly, the difficulty of the muddy water invading a path is increased through the labyrinth effect, non-contact lips are added, muddy water is prevented from invading the sealing cavity, and efficient dynamic sealing is generated through combined action.

Owner:ZHEJIANG WANXIANG PRECISION IND +1

Embedded fixed type lifting handle structure of pot

ActiveCN102113841BReduce the intensity of installation workImprove installation efficiencyKitchen equipmentUltimate tensile strengthMechanical engineering

The invention discloses an embedded fixed type lifting handle structure of a pot, and belongs to the field of cooking instruments. The lifting handle structure comprises a lifting handle seat and a lifting handle body, wherein an internal shrinkage step is formed on one side of the lifting handle seat; connecting blocks on which a group of barb grooves are formed are extended on the internal shrinkage step; the lifting handle body comprises a grip, a barb sleeve, a cover plate and a sheath; one end of the grip is provided with a connecting block compensation cavity; an adapter and a supporting step are extended at the one end of the grip; the adapter is provided with a barb sleeve cavity; the barb sleeve is provided with a connecting block accommodating cavity; the inner wall of the connecting block accommodating cavity is provided with barbs which are matched with the barb grooves; the cover plate is matched with the adapter; one end of the sheath is matched with the internal shrinkage step, and the other end of the sheath is matched with the supporting step; the adapter and the cover plate are positioned in a sheath cavity; and the connecting blocks are arranged in the connecting block accommodating cavity and also extend into the connecting block compensation cavity. The lifting handle structure has the advantages that: the mounting efficiency is improved and the working intensity of mounters is relieved; loosening is avoided during use so as to guarantee safety; a neatness effect is achieved; and any tool is not required to be used during assembly.

Owner:CHANGSHU KASMAIN

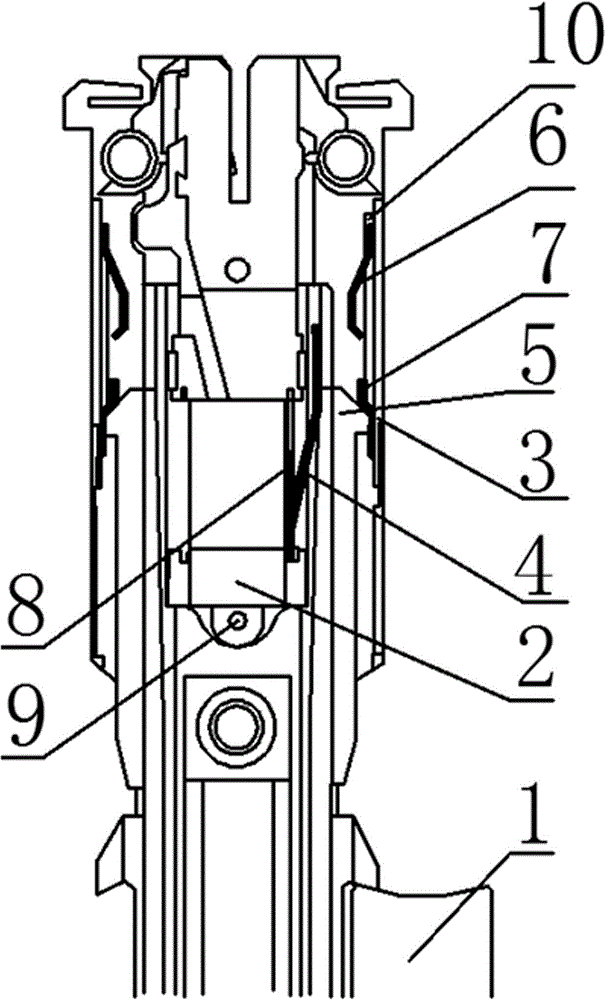

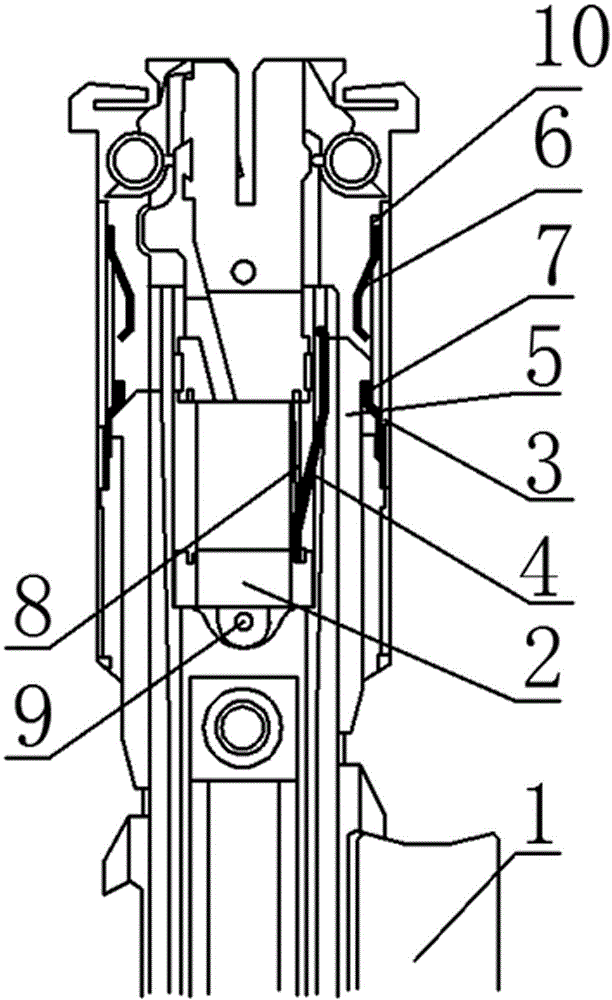

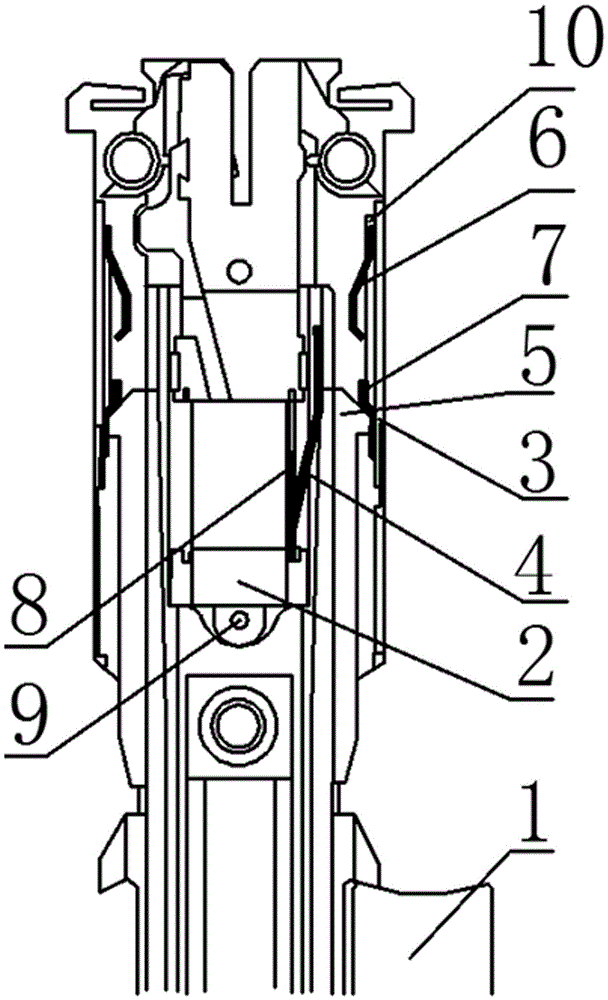

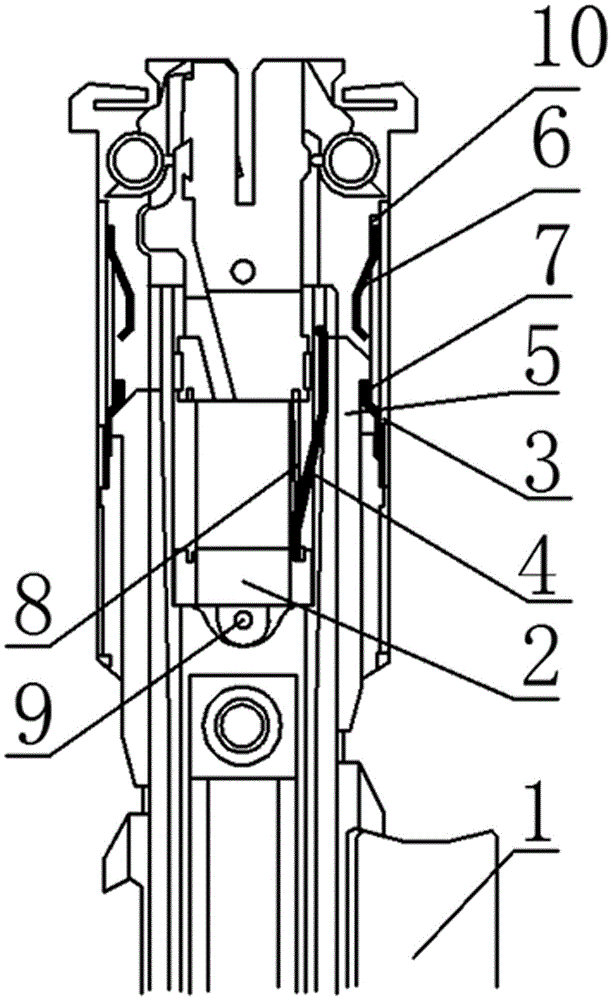

Jacquard machine assembly device

The invention relates to the technical field of textile machinery, in particular to a jacquard machine assembly device. The jacquard machine assembly device comprises a broach, electromagnets, clamping plates, a reset spring piece, a moving iron vertical hook, suction assistance spring pieces and reset spring hooks. The broach is arranged on a jacquard machine, the electromagnets are arranged on the clamping plates, the reset spring is arranged on the electromagnet, and the vertical moving iron hook is arranged between the two clamping plates. The vertical moving iron hook is driven by the broach to slide in a T-shaped groove formed by the two clamping plates. A soft magnetic insert is arranged in the vertical moving iron hook. The reset spring hooks are arranged on the clamping plates, and the suction assistance spring pieces are arranged above the reset spring hooks. By means of the jacquard machine assembly device, a moving iron shaft, a moving iron pressure spring, moving iron and a tongue spring which are prone to abrasion are omitted, so that component failures caused by abrasion of the moving iron shaft, the moving iron pressure spring, the moving iron and the tongue spring are eliminated, the component structure is changed, the service lives of the components are prolonged, the machining and assembling difficulty of all components is reduced, production cost is reduced, the failure occurrence rate and maintenance cost are reduced, and the production efficiency of the jacquard machine is improved.

Owner:JIANGSU S&S INTELLIGENT SCI & TECH CO LTD

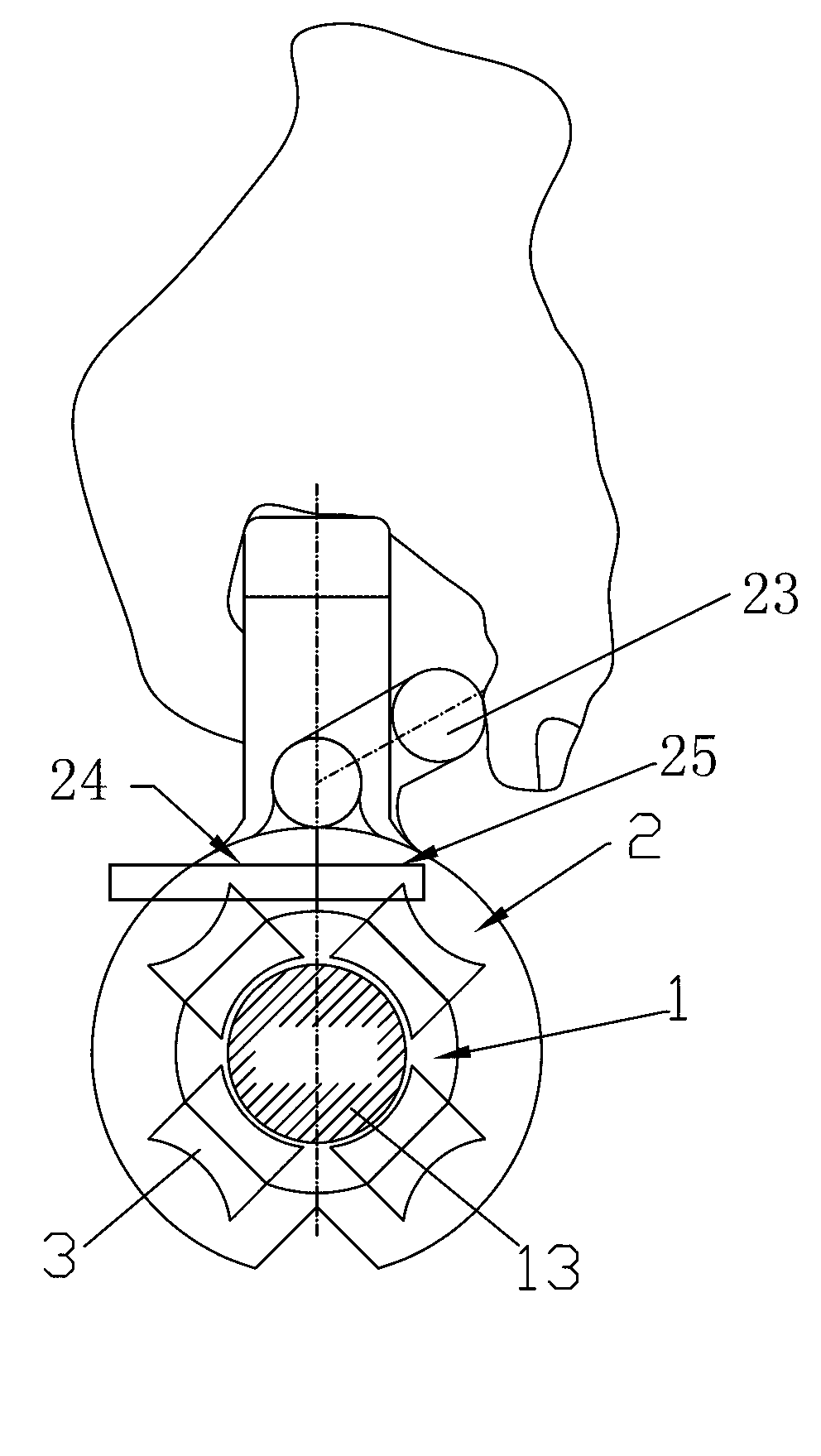

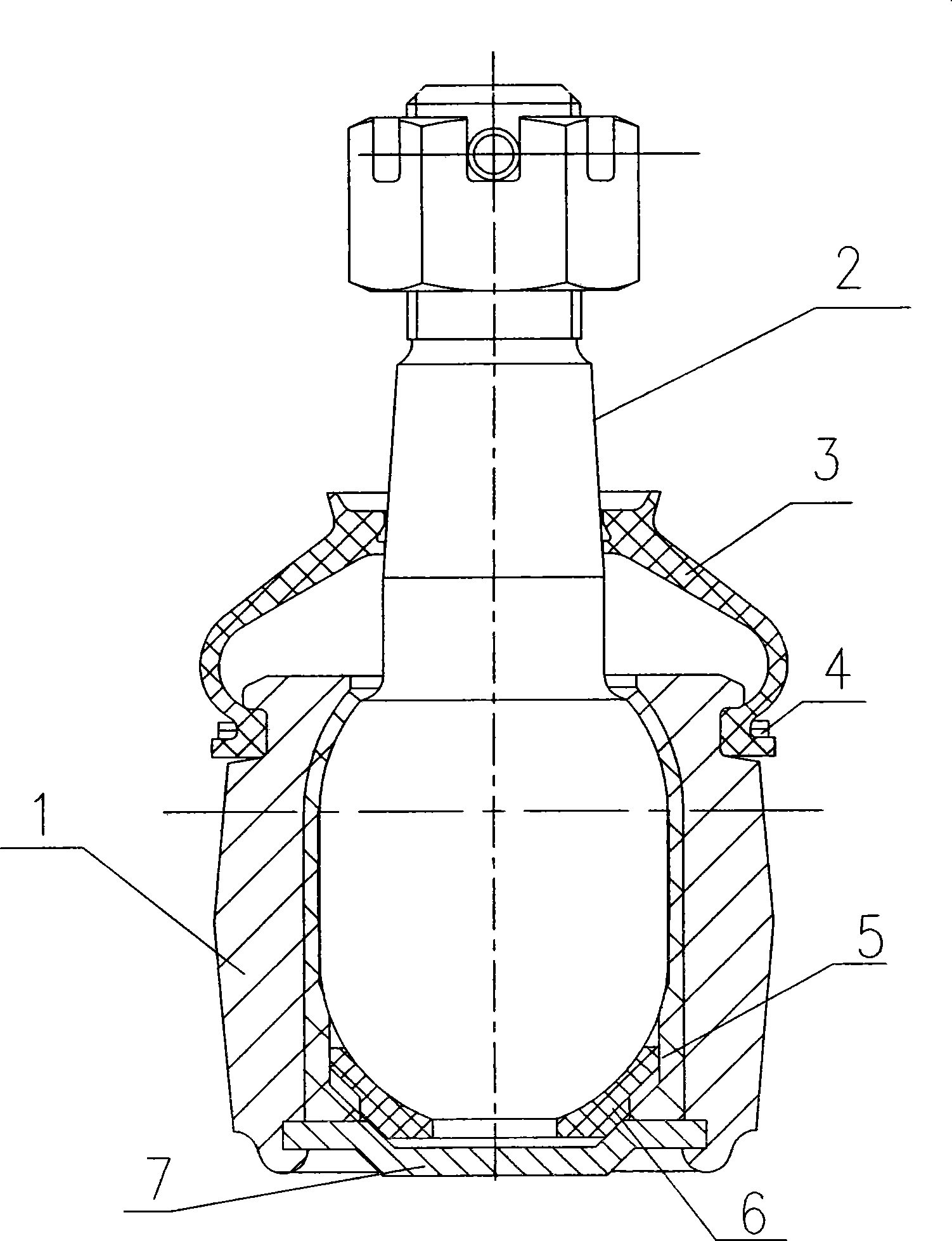

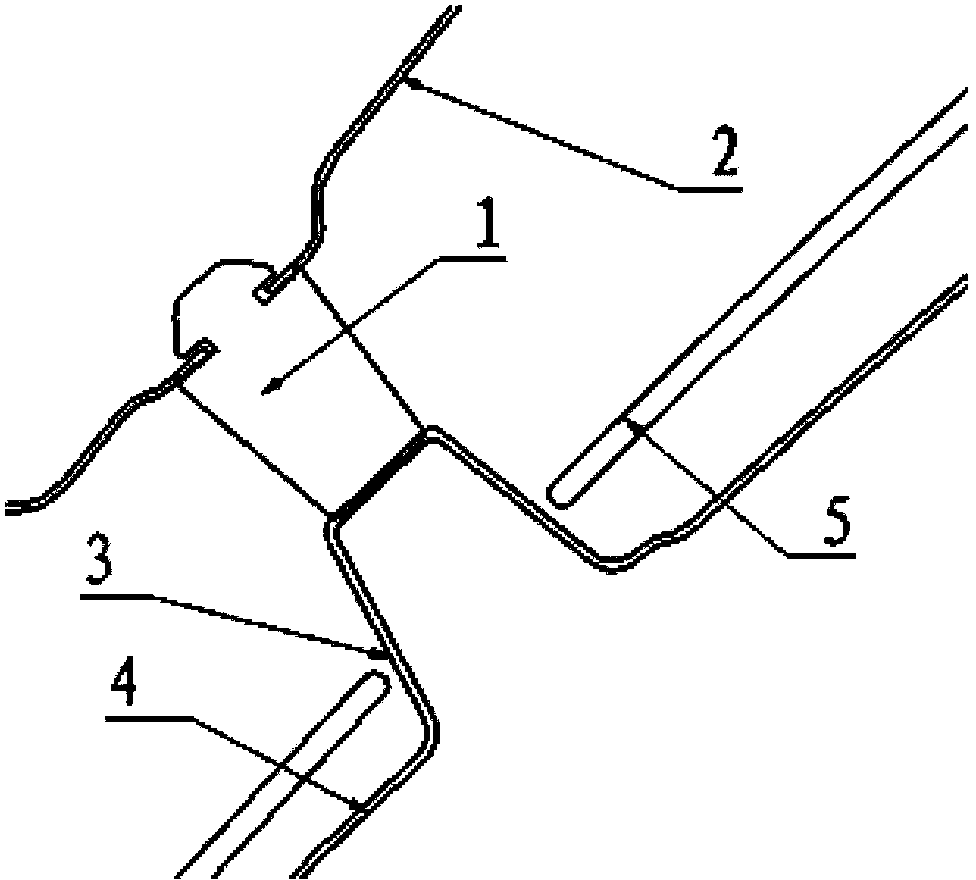

Guide ball-pin assembly

InactiveCN101380968AImprove handling stabilityEasy rideSteering linkagesEngineeringOperational stability

The invention discloses a guidance ball pin assembly which comprises a casing body, a ball seat which is arranged in the casing body and a guidance ball pin which is arranged in the ball seat, wherein, the ball seat consists of a big ball seat that is arranged in the casing body and a small ball seat that is arranged on the bottom of the big ball seat; a spherical hollow cavity which is matched with the guidance ball pin comprises the big ball seat and the small ball seat; a cover plate is arranged below the small ball seat; dustproof covers are respectively arranged at both sides of the guidance ball pin; other ends of the dustproof covers are arranged on the casing body through a clamp ring; the guidance ball pin adopts a ball pin of column jacket type, wherein, both ends of the column jacket type ball pin are spherical and the middle part of the column jacket type ball pin is a cylinder tube; and synthetic resin is adopted as the raw material of the small ball seat. The invention has double excellences of excellent rotation resistance and tensile pressure resistance and can guarantee the good operational stability and the ride comfort of a whole vehicle.

Owner:沈百庆

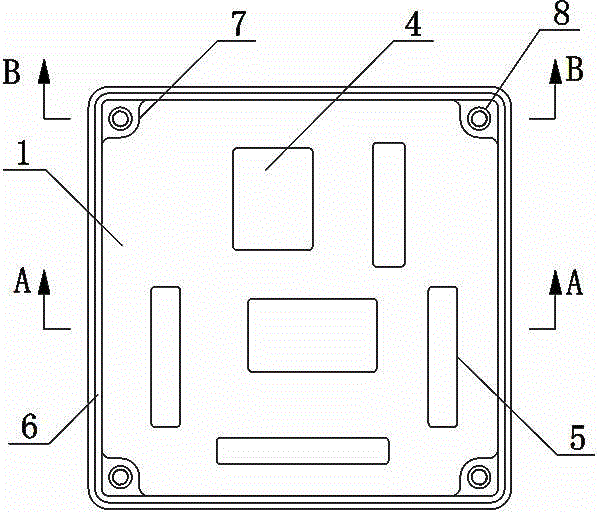

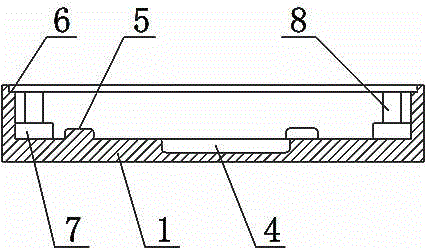

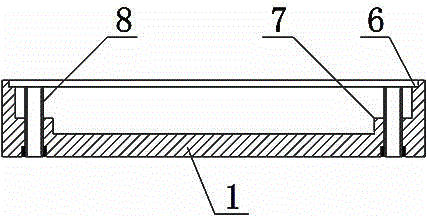

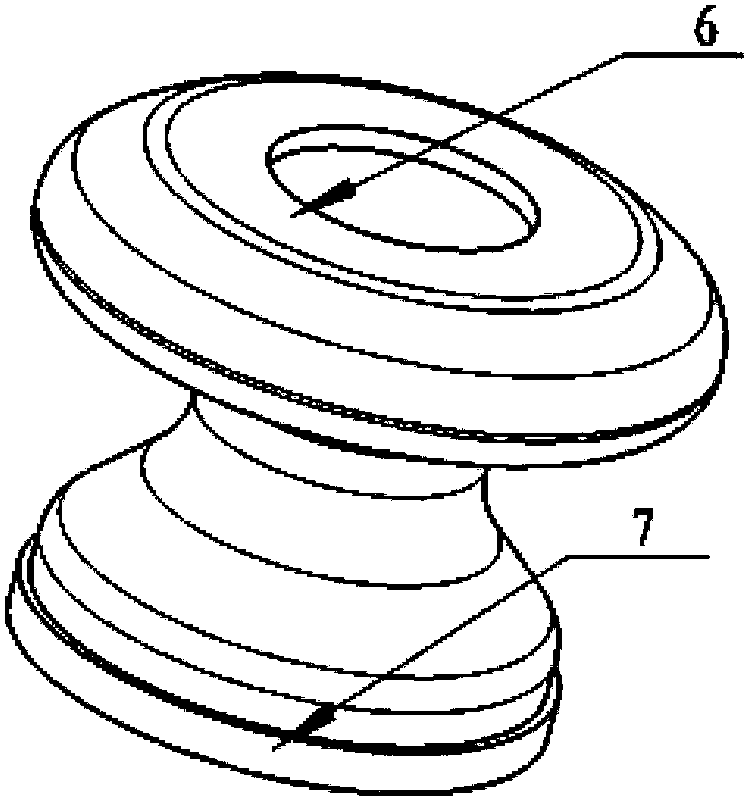

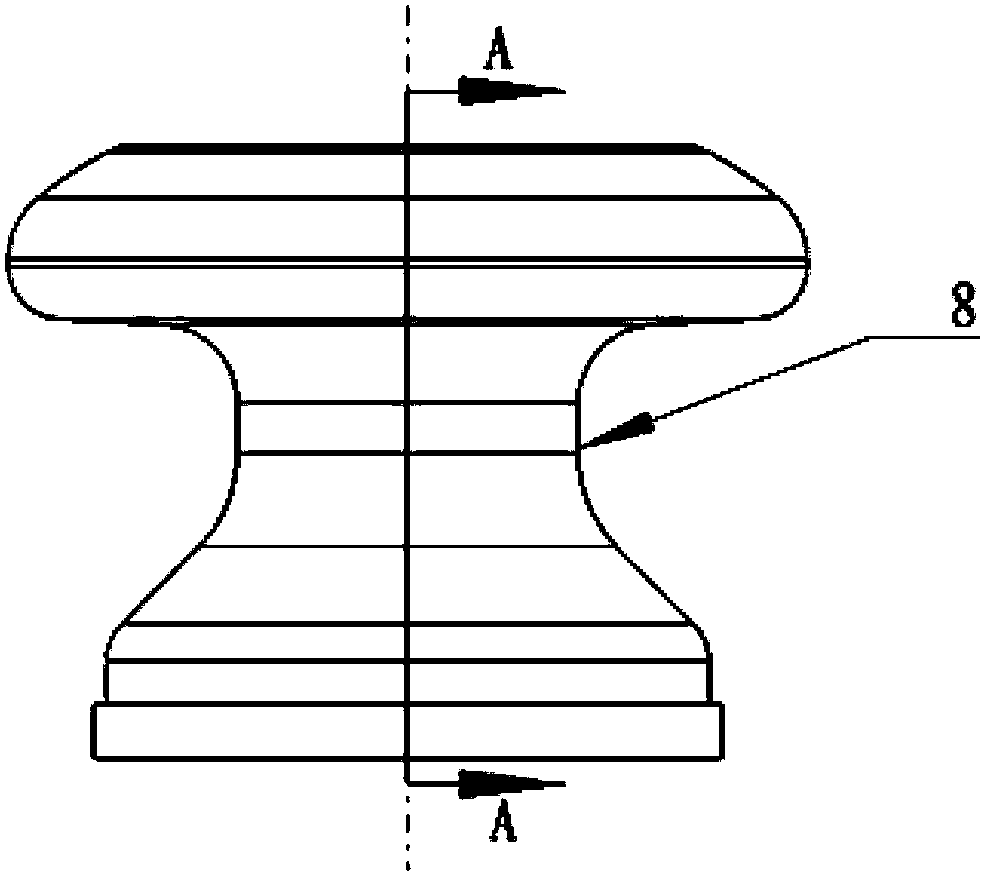

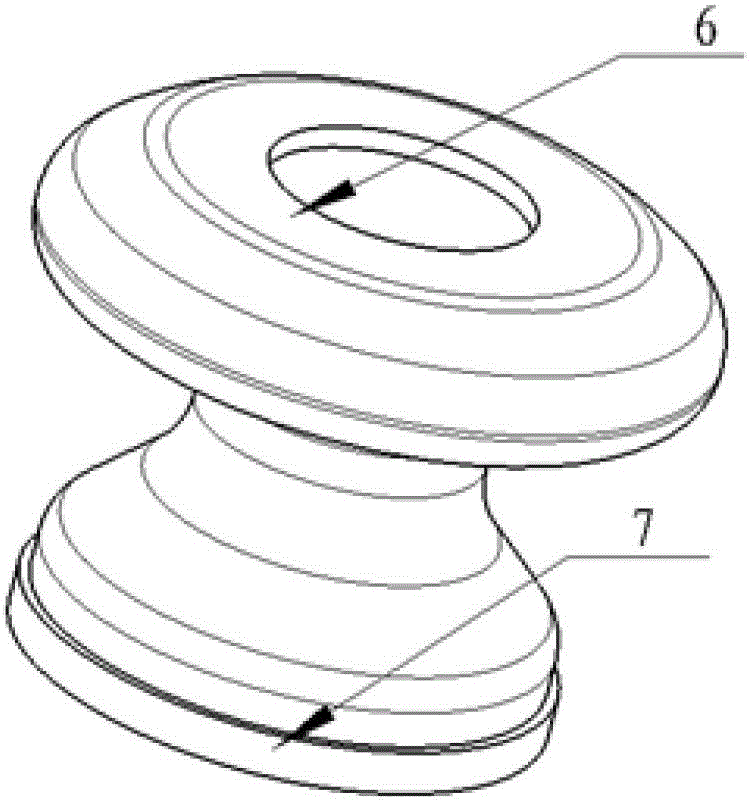

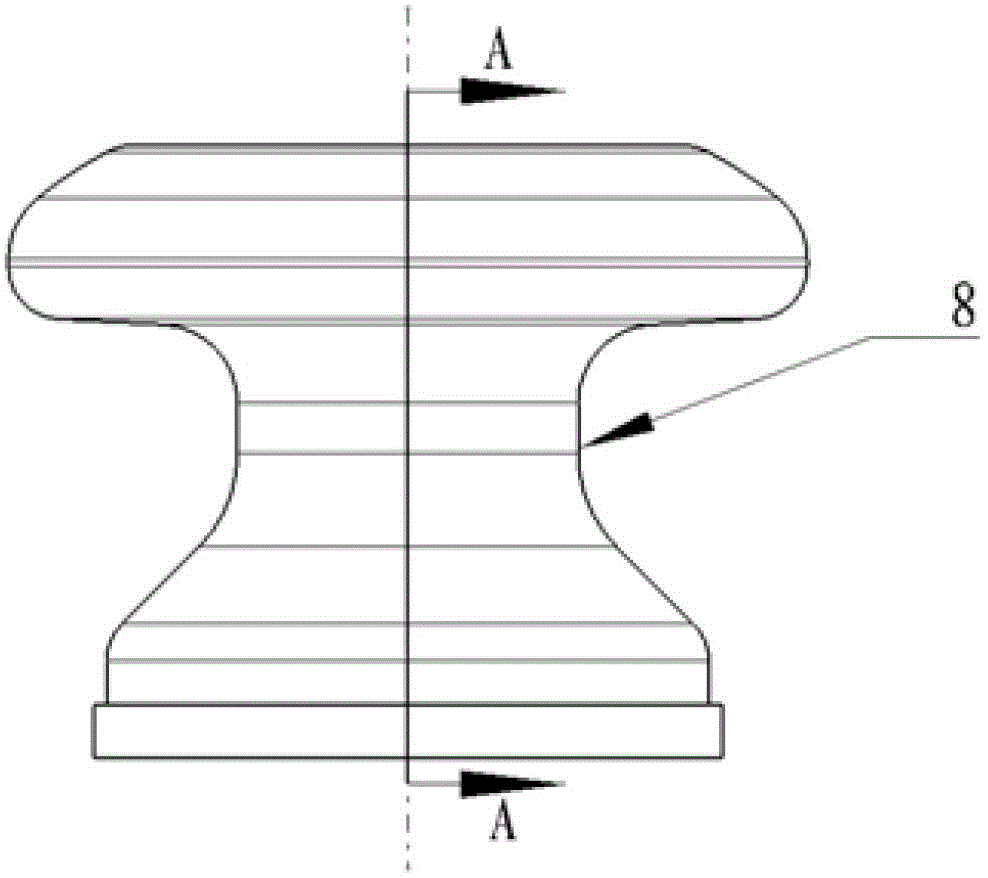

Cushion pad support assembly suitable for passenger car back door

ActiveCN103863069AIncrease the mating surfaceAchieve a buffering effectNon-rotating vibration suppressionDoorsEngineeringBack door

The invention relates to a cushion pad support assembly suitable for a passenger car back door. The assembly is in a waist drum structure and comprises a cushion pad support and a support water-proof pad, wherein the lower part of the cushion pad support is stuck and connected with the support water-proof pad; the center of the cushion pad support assembly is provided with a through bolt hole; the top of the bolt hole is in a countersink structure; the depth of the countersink is consistent with the thickness of the pan head of the bolt; after the bolt is installed, the upper surface of the cushion pad support assembly is level with the top of the pan head of the bolt. According to the cushion pad support assembly, the defect of the cushion pad that the cushion pad can not be favorably cooperated with the car body is solved. The cushion pad support assembly suitable for the passenger car back door has the advantages of simpleness in processing, convenience in installation and exquisite appearance and can be favorably cooperated with the cushion pad.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Sleeve, prefabricated component connector, prefabricated component and prefabricated component assembly

PendingCN110485646ASimplify or clarify stress relationshipsDefined tensile strengthBuilding reinforcementsAgricultural engineeringSteel bar

The invention discloses a sleeve and a prefabricated component connector, a prefabricated component and a prefabricated component assembly which are constructed based on the sleeve, and belongs to thefield of fabricated buildings. The sleeve includes a cylinder body and ports in both ends of the cylinder body. The ports are closed openings, and the sleeve further includes a grouting channel and an exhaust channel. One end of the grouting channel and one end of the exhaust channel communicate with a through hole formed in the cylinder body. A port structure of an embedded part is fabricated with steel bars inserted into the ports, and then the steel bars and the sleeve are fixedly connected together by pouring concrete or grouting materials. Through the structure of the ports of the sleeveand the shape of the end parts of the steel bars, the connection strength of the connector formed by the sleeve is greatly enhanced, the prefabricated components fabricated through the sleeve is easyto assemble during construction, the fabrication between prefabricated panels can be quickly completed, and the construction period is greatly shortened.

Owner:李藏柱

Sleeve, prefabricated component connector, prefabricated component and prefabricated component assembly body

PendingCN110485641AIncrease contact surfaceImprove connection strengthBuilding reinforcementsEngineeringRebar

The invention discloses a sleeve as well as a prefabricated component connector, a prefabricated component and a prefabricated component assembly body which are constructed on the basis of the sleeve,and belongs to the field of assembly type buildings. The sleeve comprises a basic port and a matching port; the basic port is a nosing; the nosing is formed into a cold-pressed pipe through a cold pressing process; and the matching port is a nosing or an opening with the same inside diameter as the sleeve. According to the sleeve, by means of assembly of a port structure of an embedded part and asteel bar inserted into the port of the embedded part, fixed connection of the steel bar and the sleeve by pouring concrete and construction of the ports of the sleeve and the shape of the end part of the steel bar, the contact surfaces between the steel bar and concrete as well as between the sleeve and the concrete are increased; meanwhile, by changing the stress surface generated among the sleeve, the concrete and the steel bar, the connecting strength of a connecting head formed by the sleeve is greatly enhanced; and in addition, the prefabricated component assembled on the basis of the sleeve is simple in assembly during construction, assembly between two prefabricated plates can be rapidly completed, and the construction period is greatly shortened.

Owner:李藏柱

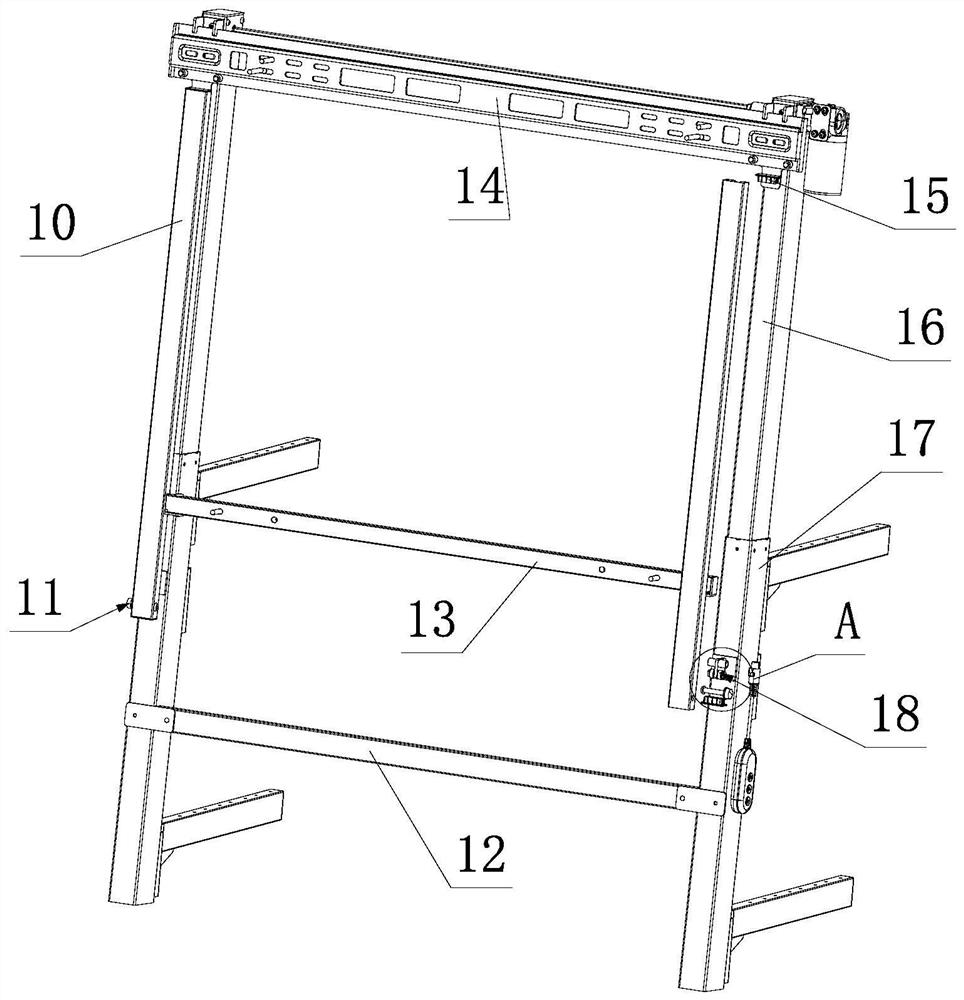

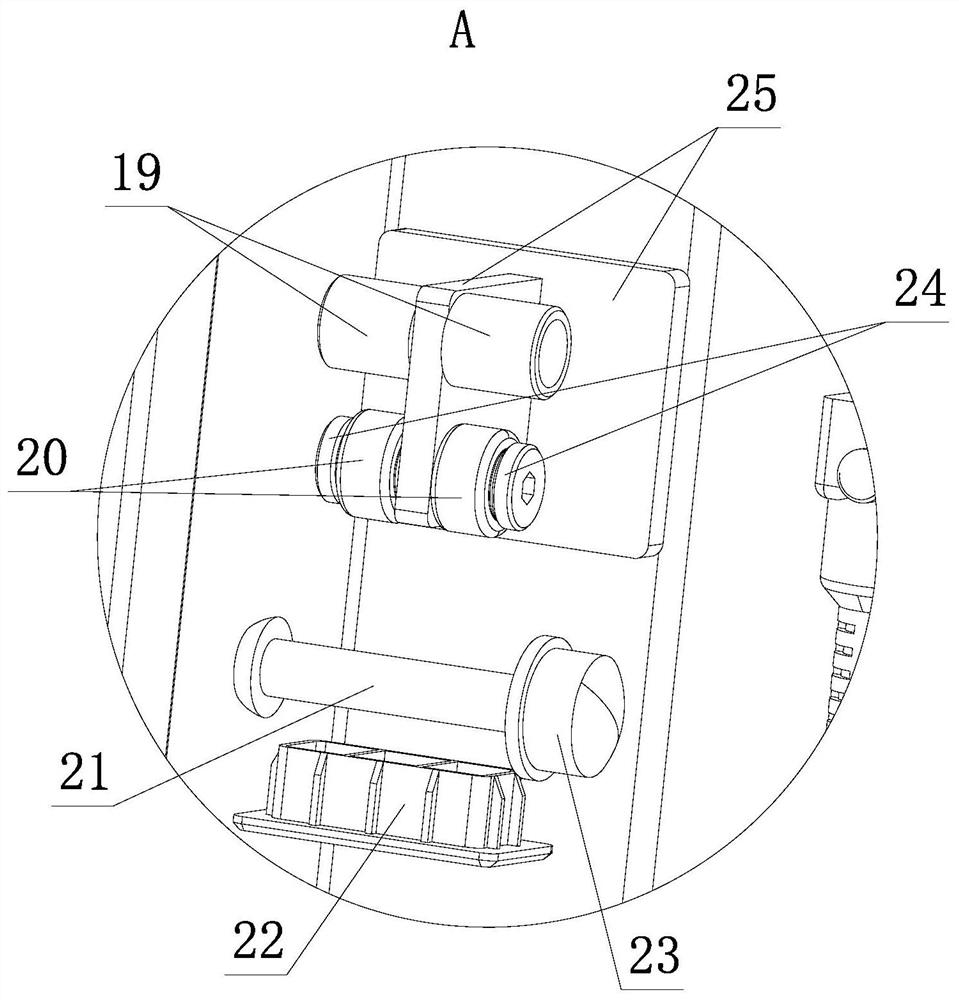

Wall-mounted lifting storage rack

ActiveCN113618695ASmooth liftReliable and efficient lifting processWork tools storageRolling-element bearingEngineering

The invention discloses a wall-mounted lifting storage rack, which comprises a transverse fixed plate used for being fixed to a wall surface, at least two guide rails serving as fixed stand columns are fixed to the transverse fixed plate, fixed parts of at least two lifting stand columns are fixed to the transverse fixed plate, the lifting part of each lifting stand column is provided with a supporting and rolling assembly which supports and is in rolling fit with a corresponding guide rail; the lifting stand columns are located on the outer side of the guide rail, and carrying plate supporting rods are arranged on the lifting parts of the lifting stand columns; the guide rail is a rectangular steel pipe, an opening penetrating through the whole length of the guide rail is arranged at the middle of a front side plate of the rectangular steel pipe, a connecting block of the supporting and rolling assembly is fixed to the lifting part of each lifting stand column, a shaft is arranged at the front end, penetrating into the opening of the guide rail, of the connecting block, and two first rolling bearings in rolling fit with a rear side plate of the rectangular steel pipe are arranged on the shaft; and a transverse limiting guide rod is arranged at the front end of the connecting block. The wall-mounted lifting storage rack provided by the invention is low in noise, good in mechanical property, smooth in lifting, stable and reliable.

Owner:LOCTEK ERGONOMIC TECH CORP

Embedded fixed type lifting handle structure of pot

ActiveCN102113841AReduce the intensity of installation workImprove installation efficiencyKitchen equipmentEngineeringUltimate tensile strength

The invention discloses an embedded fixed type lifting handle structure of a pot, and belongs to the field of cooking instruments. The lifting handle structure comprises a lifting handle seat and a lifting handle body, wherein an internal shrinkage step is formed on one side of the lifting handle seat; connecting blocks on which a group of barb grooves are formed are extended on the internal shrinkage step; the lifting handle body comprises a grip, a barb sleeve, a cover plate and a sheath; one end of the grip is provided with a connecting block compensation cavity; an adapter and a supporting step are extended at the one end of the grip; the adapter is provided with a barb sleeve cavity; the barb sleeve is provided with a connecting block accommodating cavity; the inner wall of the connecting block accommodating cavity is provided with barbs which are matched with the barb grooves; the cover plate is matched with the adapter; one end of the sheath is matched with the internal shrinkage step, and the other end of the sheath is matched with the supporting step; the adapter and the cover plate are positioned in a sheath cavity; and the connecting blocks are arranged in the connecting block accommodating cavity and also extend into the connecting block compensation cavity. The lifting handle structure has the advantages that: the mounting efficiency is improved and the working intensity of mounters is relieved; loosening is avoided during use so as to guarantee safety; a neatness effect is achieved; and any tool is not required to be used during assembly.

Owner:CHANGSHU KASMAIN

A cushion support assembly suitable for passenger car back doors

ActiveCN103863069BIncrease the mating surfaceAchieve a buffering effectNon-rotating vibration suppressionDoorsEngineeringBack door

The invention relates to a cushion pad support assembly suitable for a passenger car back door. The assembly is in a waist drum structure and comprises a cushion pad support and a support water-proof pad, wherein the lower part of the cushion pad support is stuck and connected with the support water-proof pad; the center of the cushion pad support assembly is provided with a through bolt hole; the top of the bolt hole is in a countersink structure; the depth of the countersink is consistent with the thickness of the pan head of the bolt; after the bolt is installed, the upper surface of the cushion pad support assembly is level with the top of the pan head of the bolt. According to the cushion pad support assembly, the defect of the cushion pad that the cushion pad can not be favorably cooperated with the car body is solved. The cushion pad support assembly suitable for the passenger car back door has the advantages of simpleness in processing, convenience in installation and exquisite appearance and can be favorably cooperated with the cushion pad.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

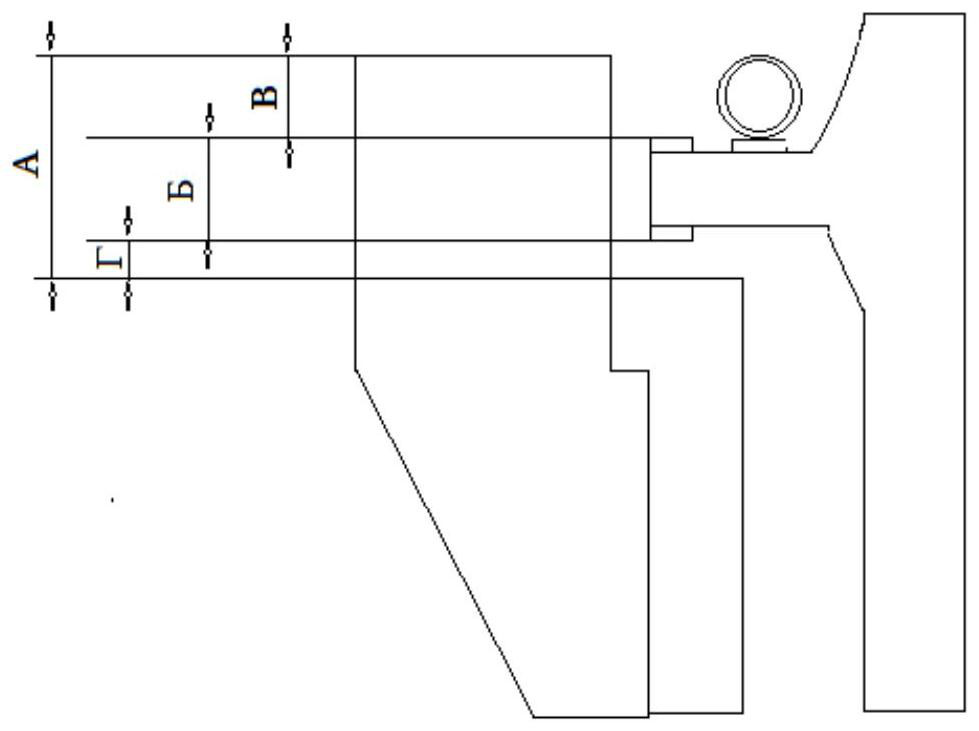

Nuclear power station reactor protection tube assembly position measuring tool

PendingCN114353617AReduce the number of measurementsReduced effectivenessError compensation/eliminationNuclear engineeringNuclear power

The invention belongs to the field of nuclear power station reactor maintenance, and particularly relates to a nuclear power station reactor protection tube assembly position measuring tool which comprises a measuring tool body, a measuring pawl, a digital display measuring instrument and a vernier caliper. A sliding groove is formed in the middle position, corresponding to the vernier caliper, of the measuring tool body, the digital display measuring instrument is installed in the sliding groove of the measuring tool body, the measuring pawl is installed on the measuring tool body in a sliding mode, and the digital display measuring instrument is correspondingly connected with the measuring pawl. The problem that an existing tool interferes with an on-site overhaul space object in the using process is solved, the measurement accuracy is improved, the measurement time is shortened, the staying time of personnel in a high-temperature environment is shortened, and the physical consumption of the personnel is reduced.

Owner:JIANGSU NUCLEAR POWER CORP

Forming tool for locking flanging-riveting nut

ActiveCN112845868AReduce manufacturing costEffective moldingShaping toolsNutsPunchingStructural engineering

The invention relates to a forming tool for a locking flanging-riveting nut. The forming tool comprises a punch used for being arranged on a pressing head of a press machine and provided with a punching end, wherein the punching end is provided with two or more pressing blocks annularly distributed at intervals, and the lower end face of each pressing block is a punching face used for punching an annular protrusion of a nut blank; in the radial direction of the nut blank, the radial size of each punching face is not smaller than the height of the annular protrusion; a flanging-riveting section receding structure for receding the flanging-riveting section of the nut blank is arranged in the area defined by the pressing blocks annularly arranged at intervals; and a plurality of notches are directly punched in the annular protrusion of the nut blank in a punching mode, so that locking teeth can be rapidly and efficiently formed on the side face, facing the flanging-riveting section, of the annular protrusion of the nut blank, the manufacturing efficiency of the locking flanging-riveting nut is improved, and then the production cost of the locking flanging-riveting nut is reduced.

Owner:河南航天精工制造有限公司

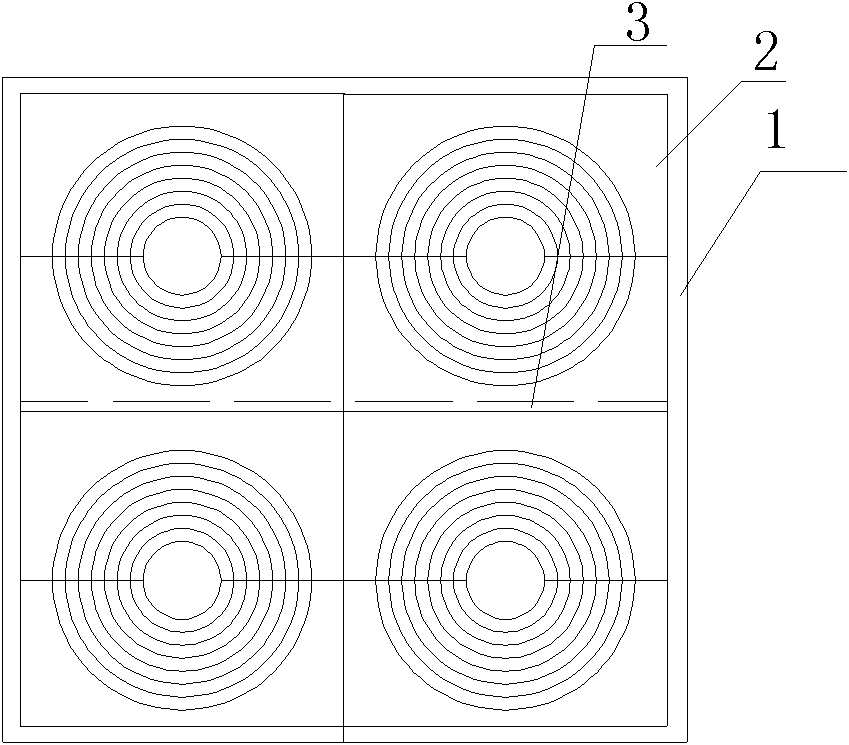

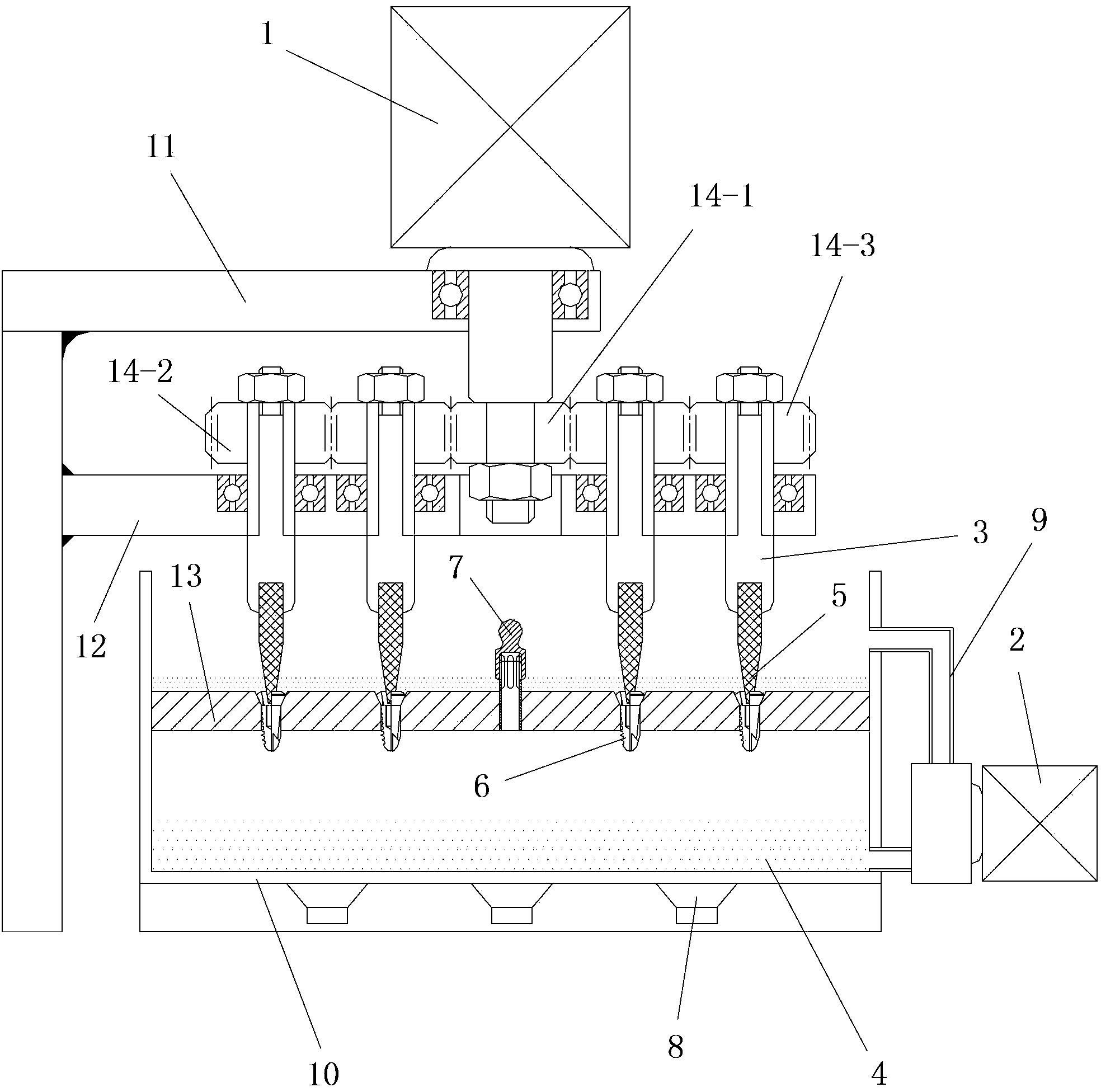

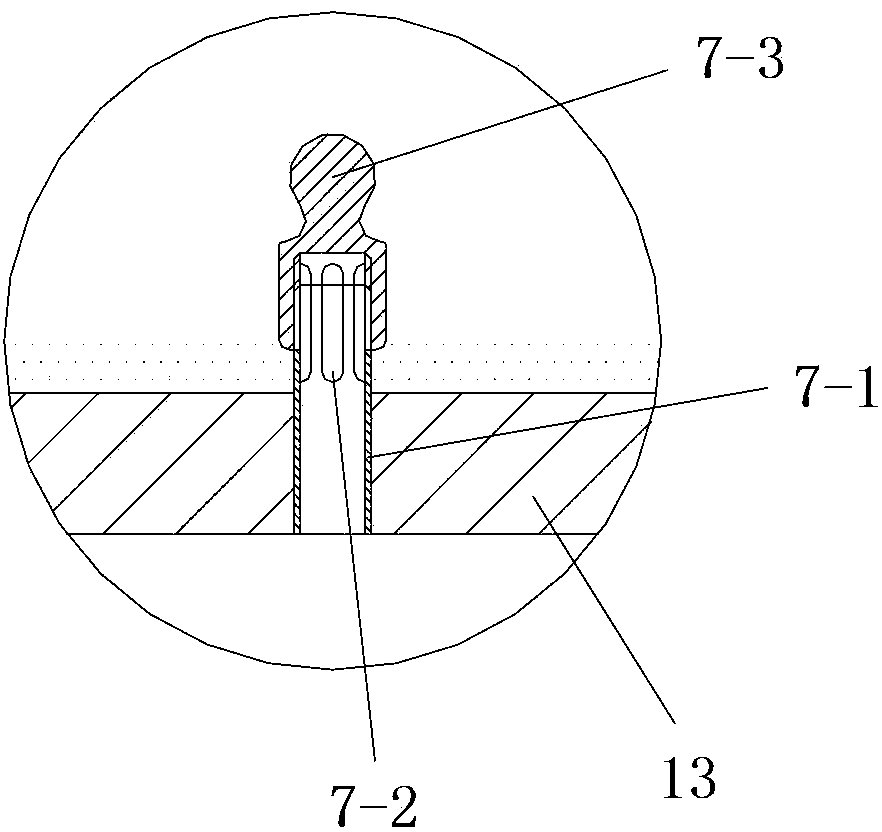

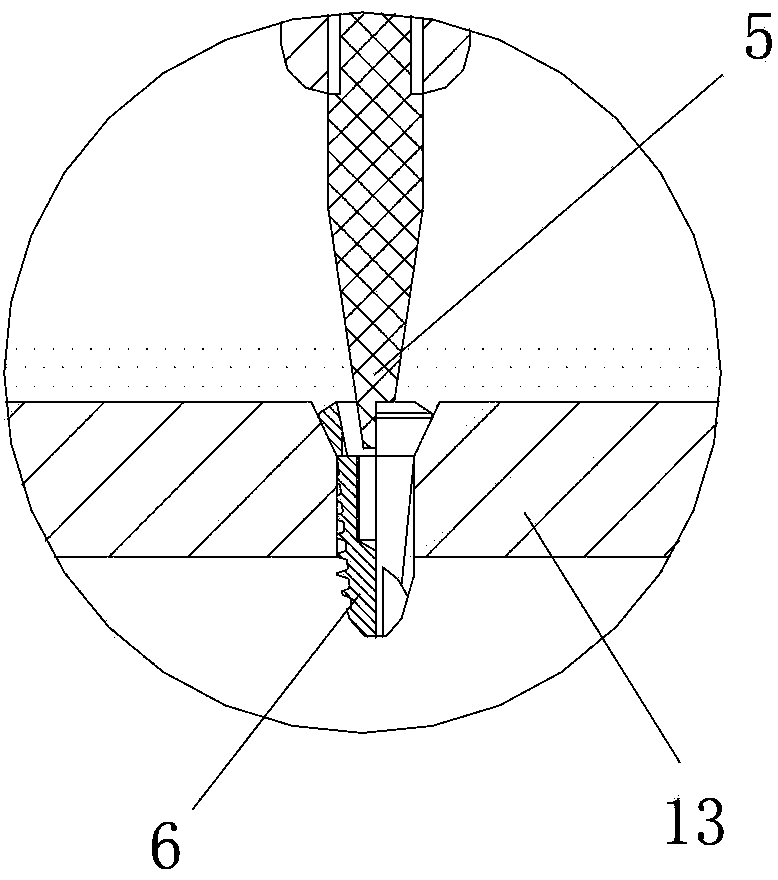

Blind hole polishing device for dental implants

ActiveCN102962755BReasonable structural designEasy installation and layoutPolishing machinesGrinding drivesDrive shaftDrive motor

The invention discloses a blind hole polishing device for dental implants. The blind hole polishing device for the dental implants comprises a polishing groove, a polishing platform, a plurality of polishing heads, a driving motor and a fixing bracket, wherein the polishing platform is horizontally arranged at the middle upper part of the inner side of the polishing groove; the driving motor is used for synchronously driving the plurality of polishing heads; the fixing bracket is arranged above the polishing platform and is used for mounting the plurality of polishing heads; a plurality of vertical polishing holes for mounting a plurality of processed dental implants are formed on the polishing platform; a plurality of transmission shafts are arranged on the fixing bracket; the plurality of polishing heads are coaxially arranged under the plurality of transmission shafts respectively; the plurality of transmission shafts are in transmission connection with the driving motor through a transmission mechanism; a circulating pipeline for conveying polishing liquid to the polishing platform continuously from bottom to top is arranged on the outer side of the polishing groove; and a liquid level regulating valve is arranged on the polishing platform. The blind hole polishing device for the dental implants is reasonable in structural design, simple and convenient to use and control, low in input cost, good in using effect and high in polishing precision and polishing efficiency, and can effectively improve precision of the fitting surfaces of the implants and a base on the premise of not influencing the sizes of the dental implants.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Coupling

InactiveCN104776126AGuaranteed coaxiality requirementsImprove matchCouplings for rigid shaftsLeft halfCoupling

The invention relates to a coupling, which comprises a left half coupling and a right half coupling. The coupling is characterized in that: the left half coupling is provided with a boss, and the right half coupling is provided with a socket which is matched with the boss of the left half coupling. Since the boss and socket matching form is adopted by the coupling, the coupling is easy to center and assemble, the fitting surface is big, abrasions cannot be easily produced, moreover, the coupling is easy to manufacture, the cost is low, and the requirement of the coaxiality of the left half coupling and the right half coupling can be effectively ensured.

Owner:SUZHOU FURUN MACHINERY

A modular power supply with good heat dissipation

ActiveCN104377940BIncrease contact areaImprove cooling effectCasings/cabinets/drawers detailsModifications for power electronicsEngineeringHeat power

Owner:SICHUAN SHENGHUA POWER TECH CO LTD

A jacquard machine component device

The invention relates to the technical field of textile machinery, in particular to a jacquard machine component device, which includes a broach, an electromagnet, a splint, a return spring piece, a moving iron vertical hook, an auxiliary suction spring piece and a return spring piece hook, and the broach is installed on the jacquard On the machine, the electromagnet is installed on the splint, the return spring is installed on the electromagnet, the moving iron vertical hook is installed between the two splints, and the moving iron vertical hook is driven by the broach to slide in the T-shaped slot formed by the two splints. The internal injection molding soft magnetic insert of the movable iron vertical hook is provided with a reset spring hook on the splint, and an auxiliary suction spring is installed above the reset spring hook. And the reed, eliminate the component failure caused by the wear of the above parts, change the structure of the component, improve the service life of the component, reduce the processing and assembly difficulty of each component, reduce the production cost, reduce the failure rate and maintenance cost, and improve the production of the jacquard machine efficiency.

Owner:JIANGSU S&S INTELLIGENT SCI & TECH CO LTD

A low-speed diesel engine stuffing box internal sealing ring structure

ActiveCN106640405BReduce the overall heightSmall mating surface areaSealing arrangements for enginesMachines/enginesDieselingMachining process

The invention discloses an inner sealing ring structure for a stuffing box of a low-speed diesel engine. The inner sealing ring structure comprises four sealing rings, four compensation blocks, a spring and a shell, wherein the four sealing rings, the four compensation blocks and the spring are arranged in the shell; the four compensation blocks are inserted among the four sealing rings respectively and connected into an integrated ring in a manner of being spaced one by one; and the spring is arranged at the peripheries of the four sealing rings and the four compensation blocks in an encircling manner and tensioned, thus the inner rings of the four sealing rings and the four compensation blocks are in close contact with a piston rod of the low-speed diesel engine to play a sealing role. According to the inner sealing ring structure disclosed by the invention, the height of the whole sealing ring structure is reduced, and the difficulty of a machining process is lowered; and the inner sealing ring structure has the advantages of being simple in structure, reliable in sealing and low in manufacturing cost.

Owner:HUDONG HEAVY MACHINERY +1

Sleeve, prefabricated component connector, prefabricated component and prefabricated component assembly

PendingCN110485645AIncrease contact surfaceImprove connection strengthBuilding reinforcementsAgricultural engineeringRebar

The invention discloses a sleeve and a prefabricated component connector, a prefabricated component and a prefabricated component assembly which are constructed based on the sleeve, and belongs to thefield of fabricated buildings. The sleeve includes a base port and a matching port. The base port is an opening port with the same inner diameter as the sleeve. An end cap is fabricated at the opening port in a threaded mode and a hole is formed in the center of the end cap. The matching port is a closed port or an opening port with the same inner diameter as the sleeve. The port structure of anembedded part is assembled with steel bars inserted into a port of the port structure, and then the steel bars and the sleeve are fixedly connected together by pouring concrete. Through the structureof the ports of the sleeve and the shape of the end parts of the steel bars, the contact surface between the steel bars and the concrete and between the sleeve and the concrete can be enlarged, meanwhile, by changing the stress surface generated between the sleeve, the concrete and the reinforcing steel, the connection strength of the connector formed based on the sleeve is greatly enhanced, and the prefabricated component fabricated through the sleeve is easy to assemble during construction, the assembly between prefabricated panels can be quickly completed, and the construction period is greatly shortened.

Owner:李藏柱

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com