Forming tool for locking flanging-riveting nut

A technology for forming tooling and nuts, applied in the directions of forming tools, nuts, manufacturing tools, etc., can solve the problems of low production efficiency and high production cost of stop turning rivet nuts, and achieve the effects of improving convenience, efficiency and high forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

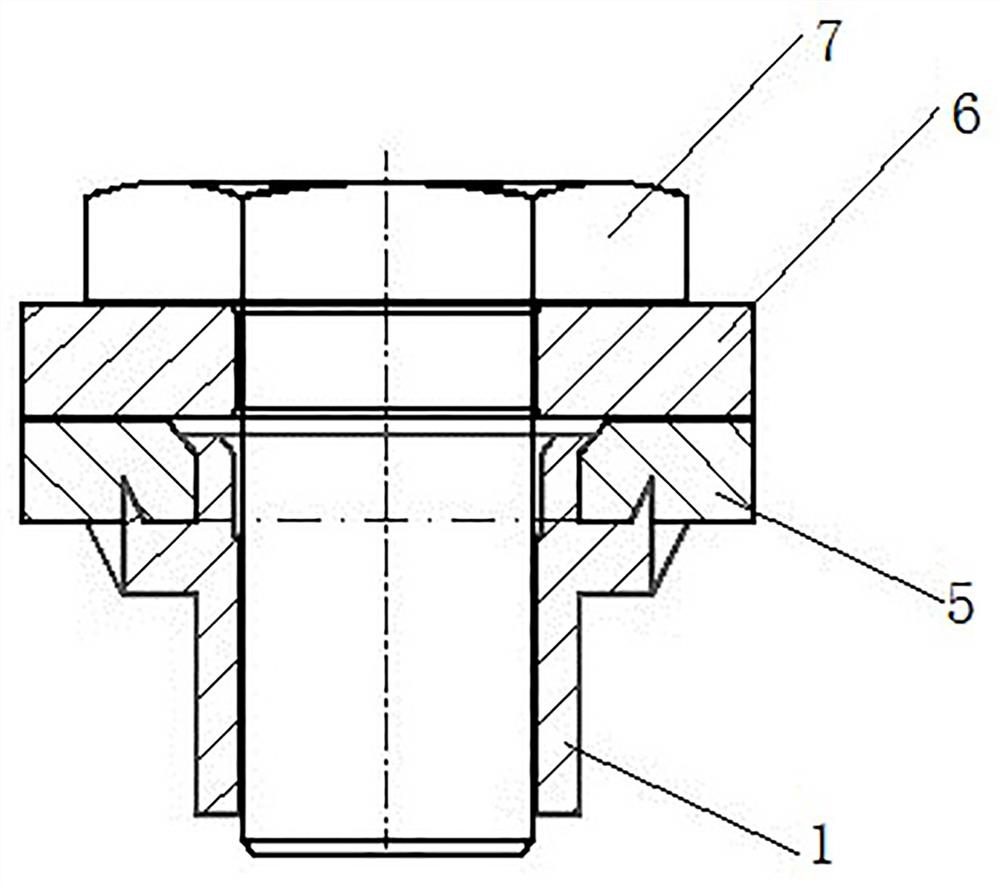

[0042] The structure of the stop turning rivet nut forming tooling is as follows: Figure 4 As shown, including base 9 and punch 10.

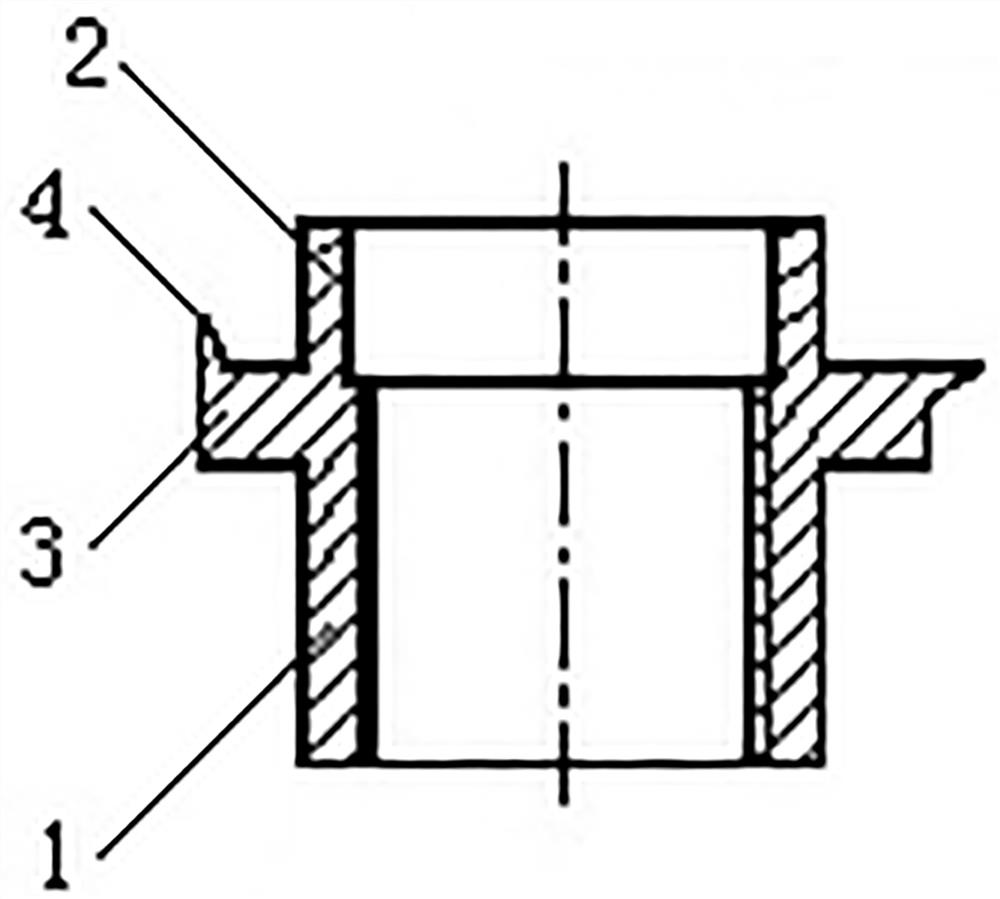

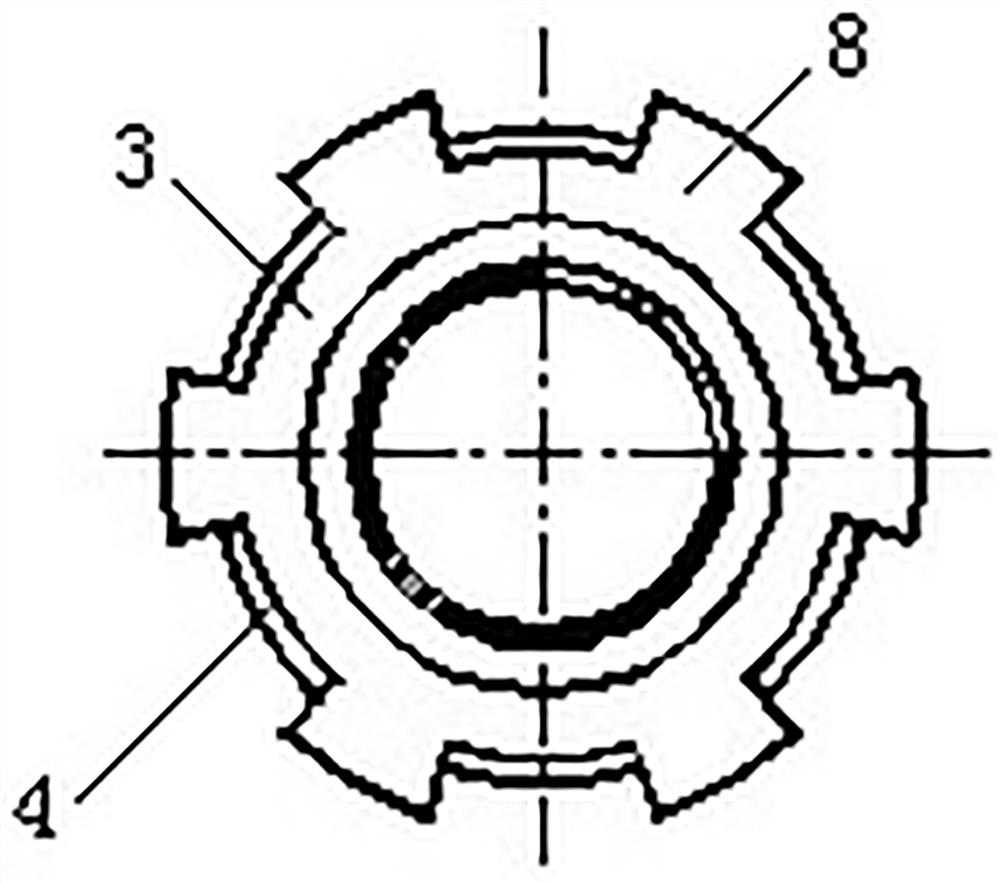

[0043] Base 9 is used to be installed on the workbench of press, and its structure is as Figure 5 As shown, the base 9 includes a positioning cylinder 11 and a stopper 12 located on the outer peripheral surface of the positioning cylinder 11. The diameter of the inner cavity 13 of the positioning cylinder 11 is not smaller than the outer diameter of the threaded section 1 of the nut blank, which can make the threaded section of the nut blank 1 is inserted to avoid the threaded section 1, and the upper end surface of the positioning cylinder 11 is used as a stop fitting surface, which can stop and cooperate with the end surface of the annular boss 3 of the nut blank facing the threaded section 1 side, such a positioning cylinder 11 acts as a nut The installation structure enables the nut blank to be installed on the base 9 .

[0044] A plural...

Embodiment 2

[0052] Embodiment 2 of the stop turning rivet nut forming tool in the present invention, the difference between this embodiment and embodiment 1 is that the stop turning rivet nut forming tool in embodiment 1 includes a punch and a base. In this embodiment, Stop rivet nut forming tooling has punches only.

Embodiment 3

[0053] Embodiment 3 of the stop turning riveting nut forming tool in the present invention, the difference between this embodiment and Embodiment 1 is that the lower end surface of the pressing block in Embodiment 1 is a plane perpendicular to the axis of the nut blank. Among them, the lower end surface of the pressing block is a slope that gradually slopes upward from the inside to the outside along the radial direction of the nut blank, so as to ensure that the part of the annular protrusion that is stamped and deformed by the stamping surface is deformed outward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com