Patents

Literature

132results about How to "Effective molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

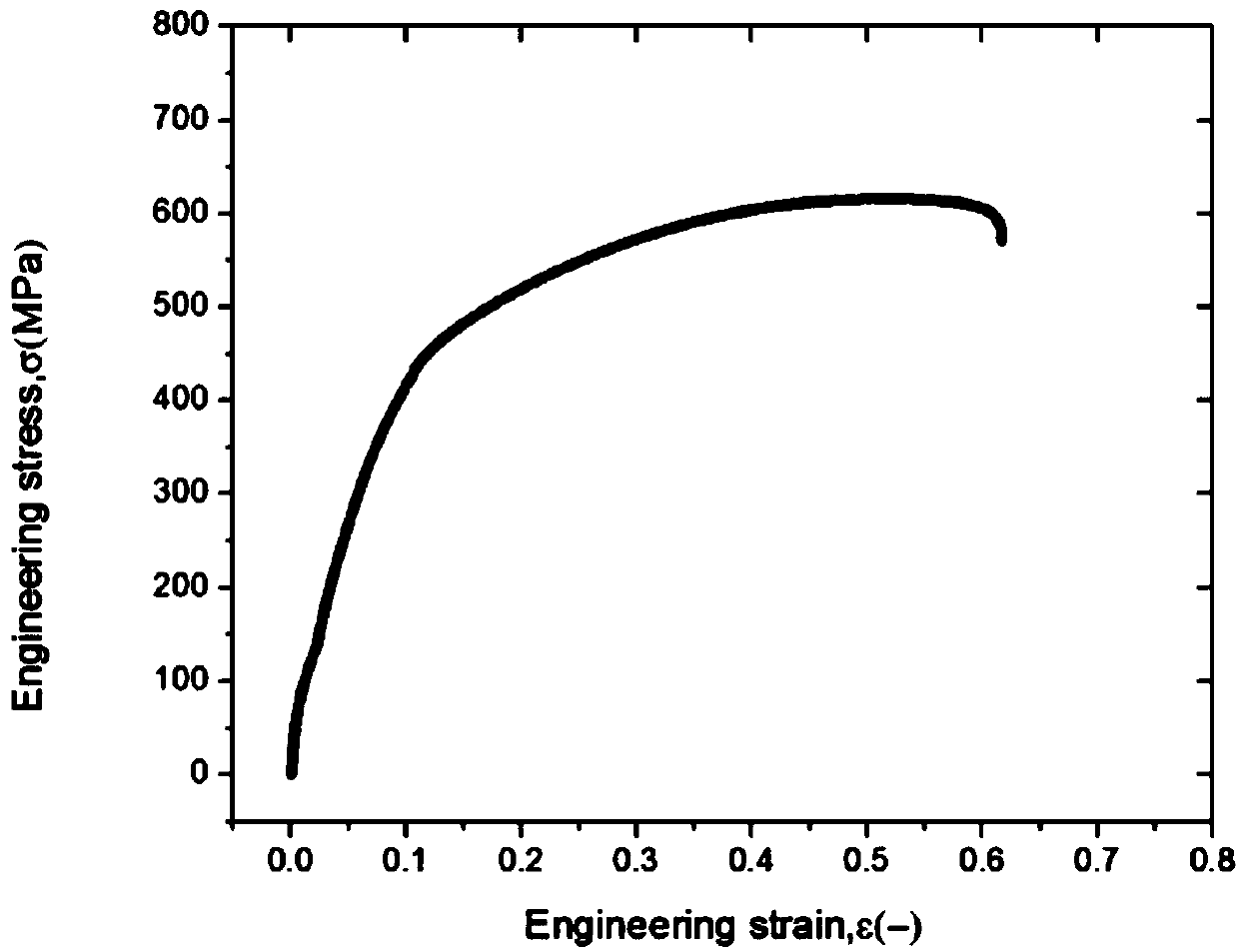

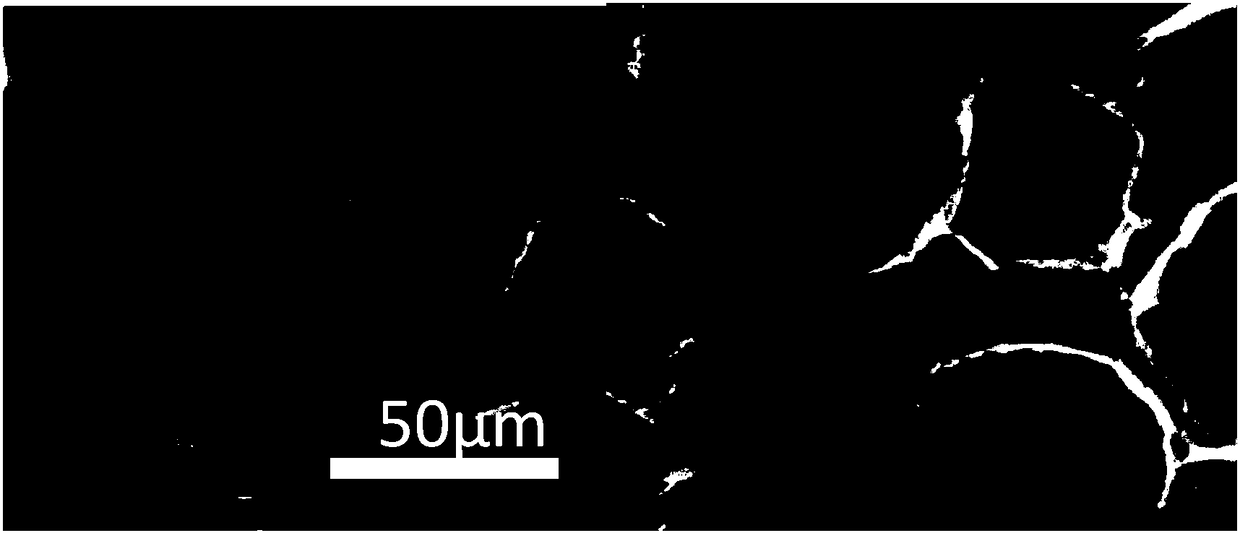

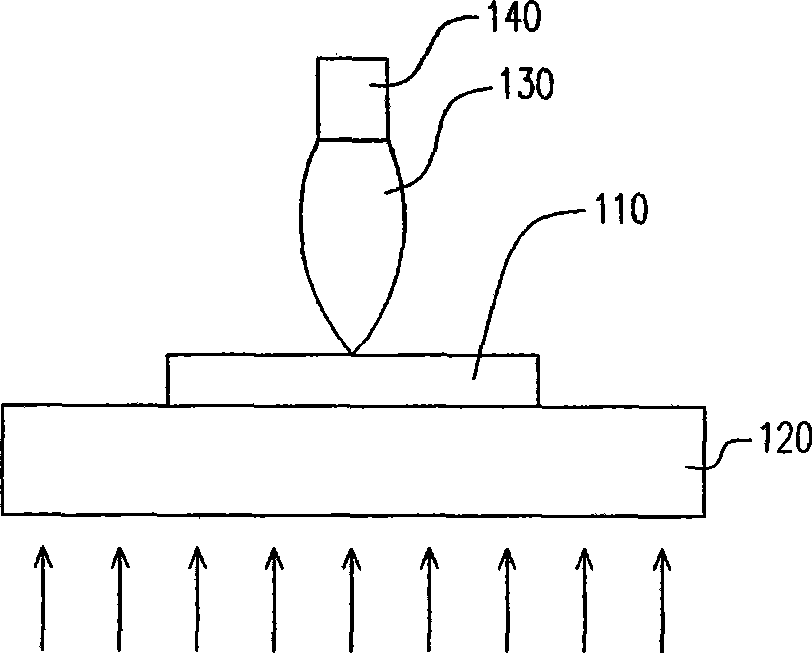

Laser 3D printing method of high-entropy alloy

InactiveCN107900335AEffective moldingLow costAdditive manufacturing apparatusIncreasing energy efficiencyMicrometerHigh entropy alloys

The invention discloses a laser 3D printing method of a high-entropy alloy. The laser 3D printing method is characterized in that high-entropy alloy powder with the particle size being 20-150 micrometers is moulded into a high-entropy alloy component in a layer-by-layer manner by employing the laser 3D printing method on the technological parameter conditions for laser 3D printing that the laser power is 200-2000 W, the scanning speed is 500-1200 mm / min, the laser spot diameter is 0.5-4 mm, the overlapping ratio is 15-50%, the thickness of a printing layer is 0.5-2 mm, the oxygen concentrationof a printing environment is lower than 50 ppm and the preheating temperature of a substrate is 0-300 DEG C; and then the obtained high-entropy alloy component is subjected to annealing at 300-1000 DEG C under inert gas shielding for 2-12 h, and then is subjected to furnace cooling, and thus manufacturing of the high-entropy alloy component is completed. By using the laser 3D printing method to mould the high-entropy alloy component, the disadvantages that the efficiency is low, the size is small and the shape is simple by adopting a casting process to mould the high-entropy alloy component are overcome, and the high-entropy alloy component in a complicated shape can be efficiently moulded with low cost.

Owner:DALIAN JIAOTONG UNIVERSITY

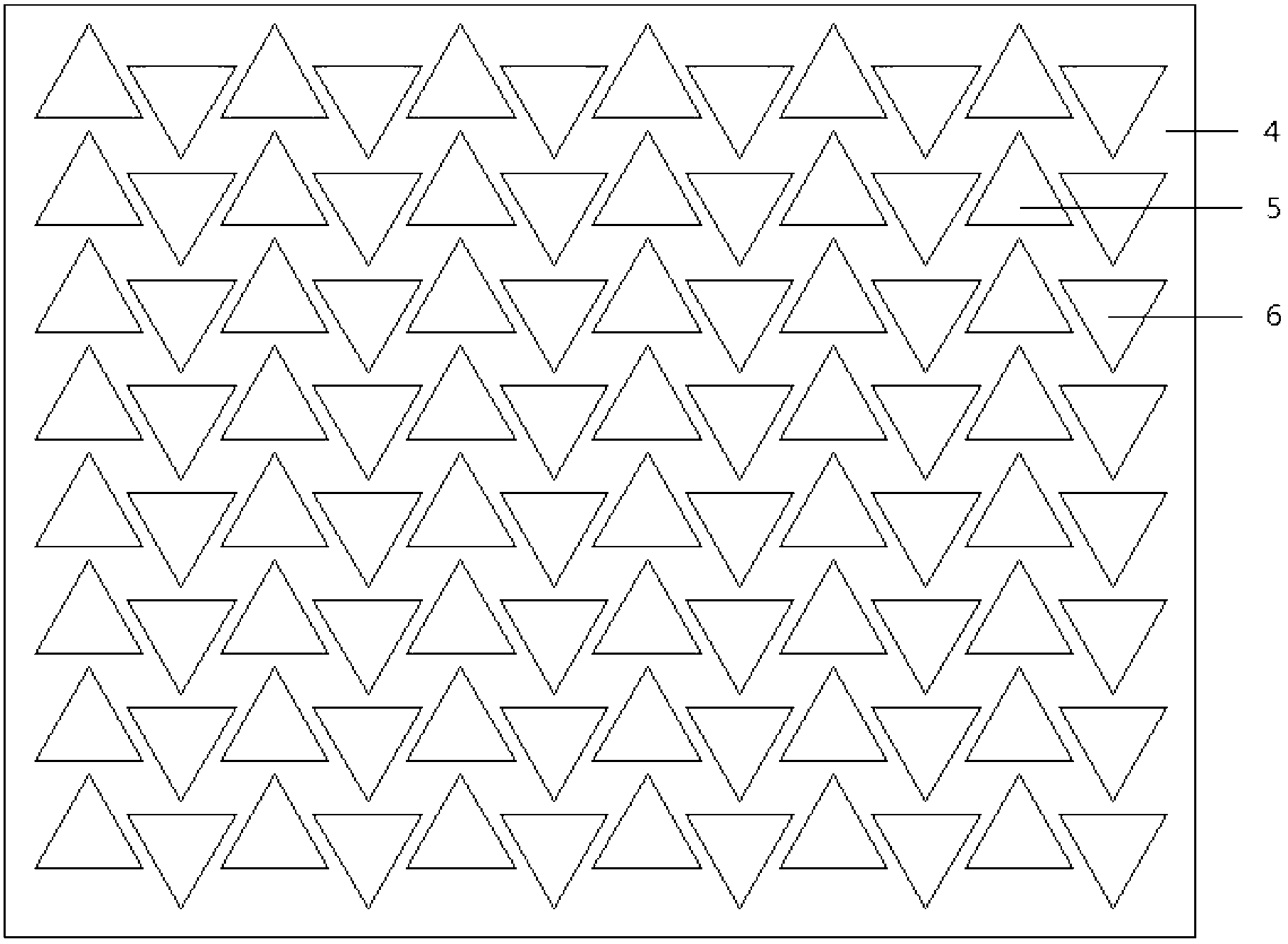

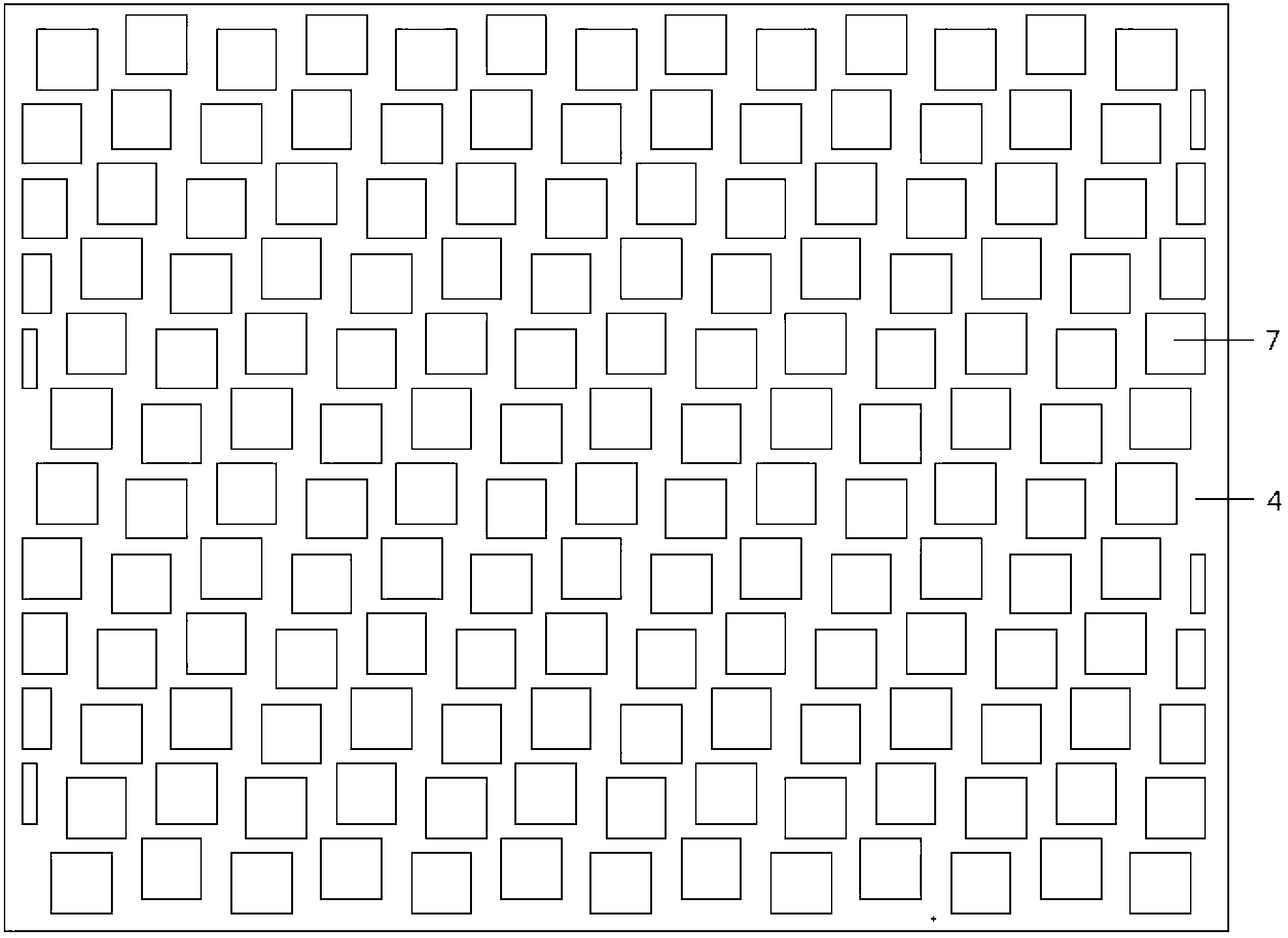

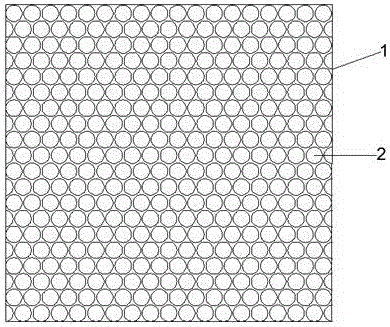

Resin-formed flexible puncture-proof fabric and preparation method thereof

The invention relates to a resin-formed flexible puncture-proof fabric and a preparation method of the resin-formed flexible puncture-proof fabric. The fabric consists of garment fabric and thermosetting resin condensates, wherein a gap exists between the thermosetting resin condensates. The preparation method comprises the following steps of: uniformly dispersing the thermosetting resin in each mesh of a screen plate so that each mesh is filled with resin; scraping residual resin on the surface of the screen plate; spreading the garment fabric on the screen plate filled with resin; applying pressure to the garment fabric, and drying; solidifying the thermosetting resin condensate on the surface of the garment fabric; and finally removing the thermosetting resin condensate from the screen plate to obtain the resin-formed flexible puncture-proof fabric. According to the invention, the thermosetting resin is a good binder before solidification, has a good binding effect with the garment fabric and relatively high strength and hardness after solidification, and can resist the puncture of a conventional tool needle tube; and the shortcomings and defects of the prior art are overcome, and the needs of the military field and civil field are met.

Owner:DONGHUA UNIV +1

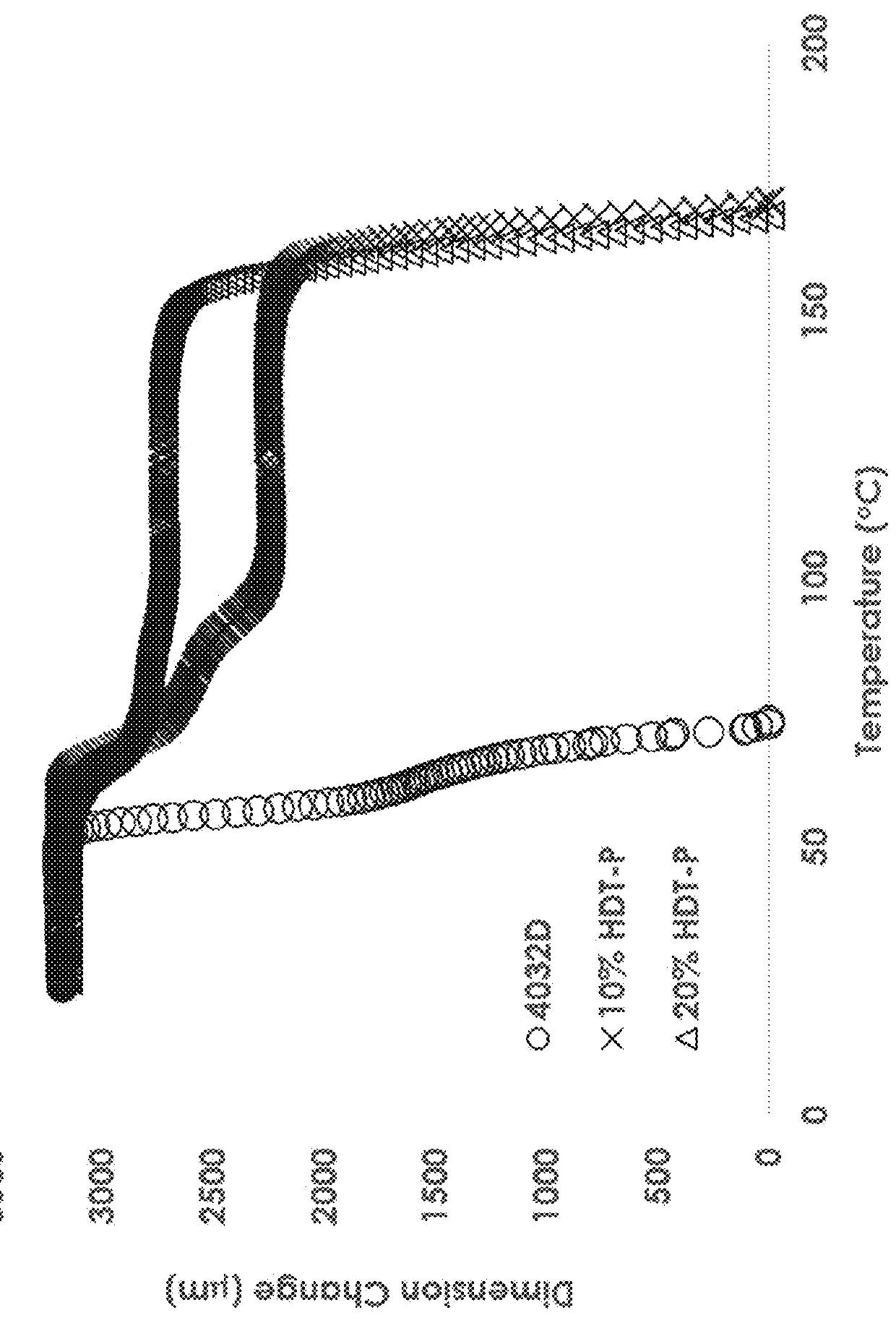

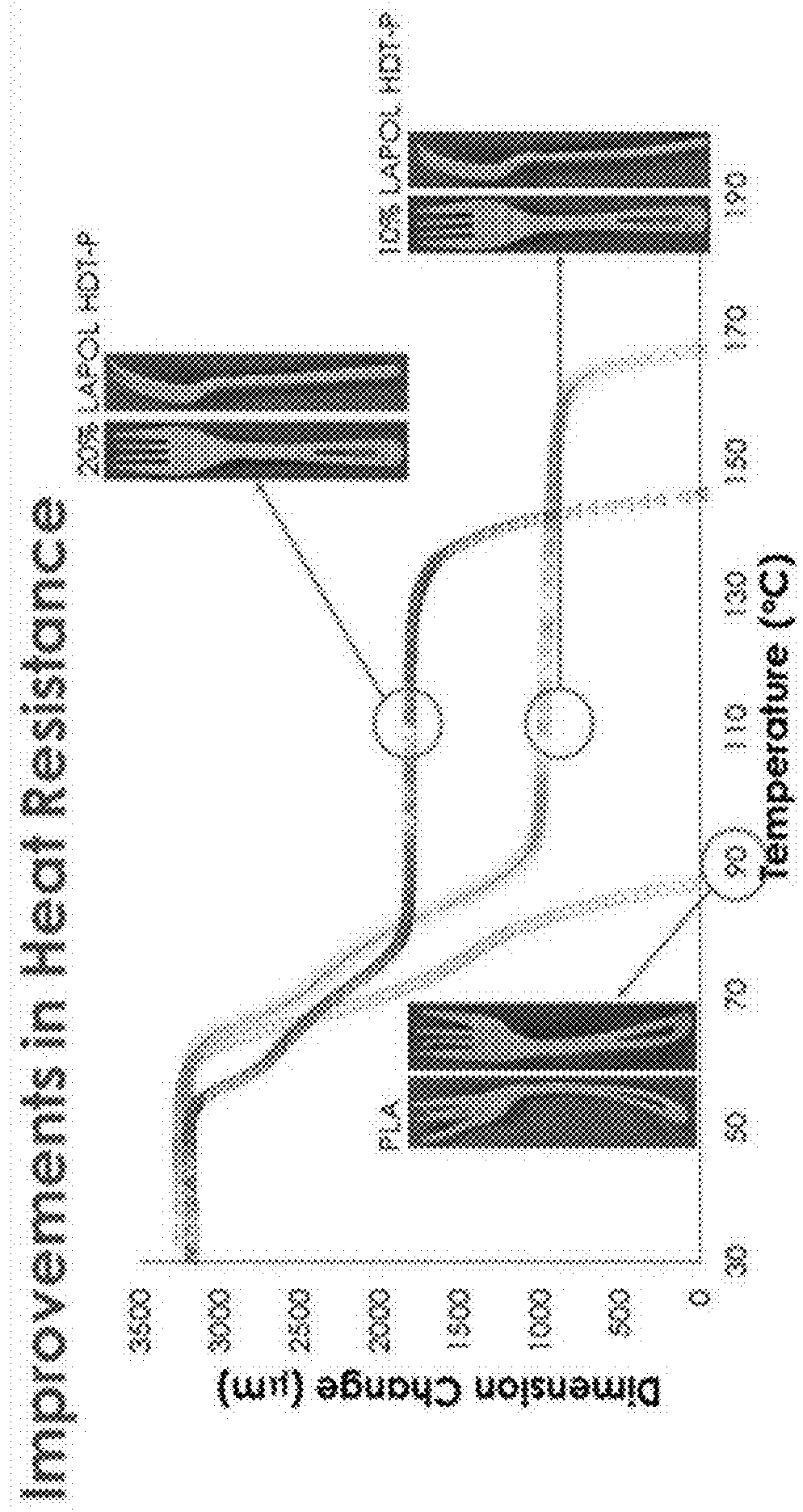

High heat deflection temperature polylactic acids with tunable flexibility and toughness

Stereocomplex biopolymer compositions having tunable and improved mechanical properties and methods of making such compositions are disclosed. The biopolymer compositions include combinations of a matrix-forming polylactic acid comprising an essentially pure enantiomer and a tough polyester to form a polylactic acid matrix. The polylactic acid matrix is further combined with a base polylactic acid comprising an essentially pure opposite enantiomer of the first essentially pure enantiomer of the matrix-forming polylactic acid to form the stereocomplex.

Owner:US SEC AGRI +1

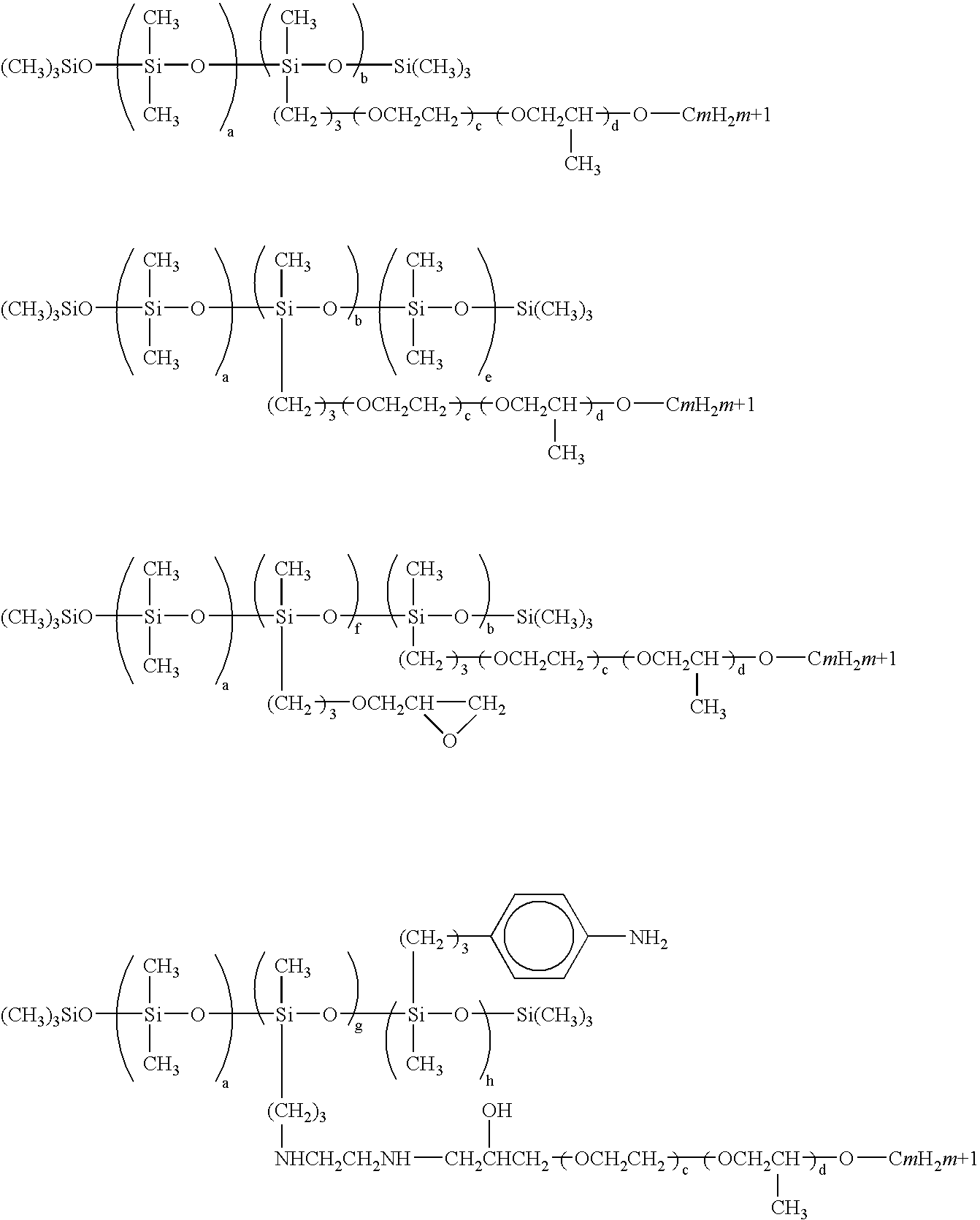

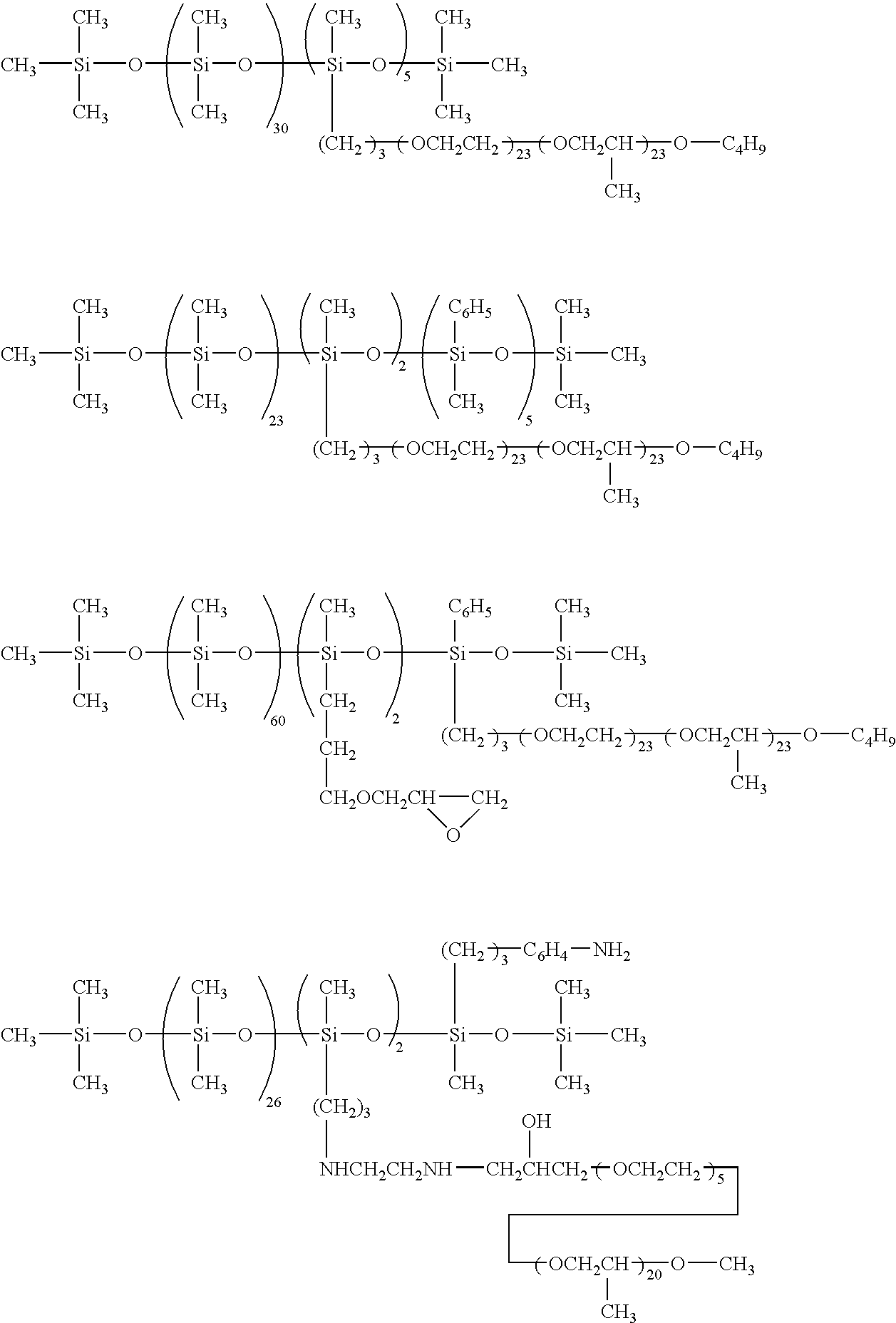

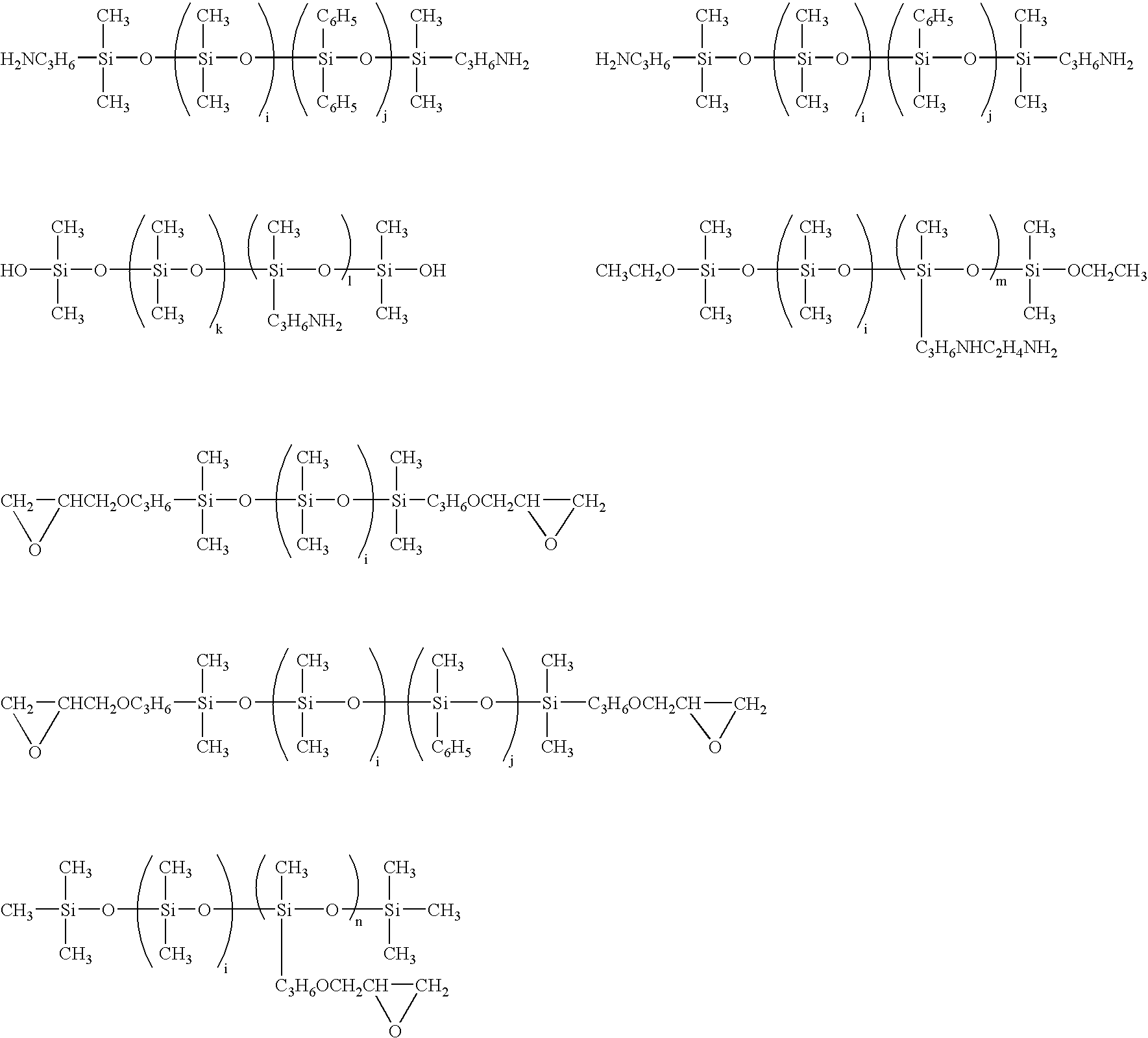

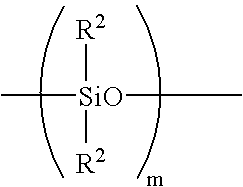

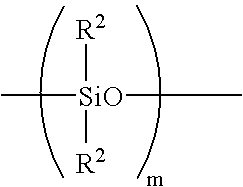

Silicone composition and cured product

A silicone composition is provided comprising (A) an organopolysiloxane of resin structure consisting of R1SiO1.5, R22SiO, and R3aR4bSiO(4−a−b) / 2 units, wherein R1, R2, and R3 are methyl, ethyl, propyl, cyclohexyl or phenyl, R4 is vinyl or allyl, a is 0, 1 or 2, b is 1 or 2, a+b is 2 or 3, the number of recurring R22SiO units being 10 to 300, (B) an organohydrogenpolysiloxane of resin structure consisting of R1SiO1.5, R22SiO, and R3cHdSiO(4−c−d) / 2 units, wherein R1, R2, and R3 are as defined above, c is 0, 1 or 2, d is 1 or 2, c+d is 2 or 3, the number of recurring R22SiO units being 10 to 300, and (C) a platinum catalyst. The silicone composition cures into a product exhibiting flexibility and minimized surface tack, and can be effectively molded on the existing molding machines.

Owner:SHIN ETSU CHEM IND CO LTD

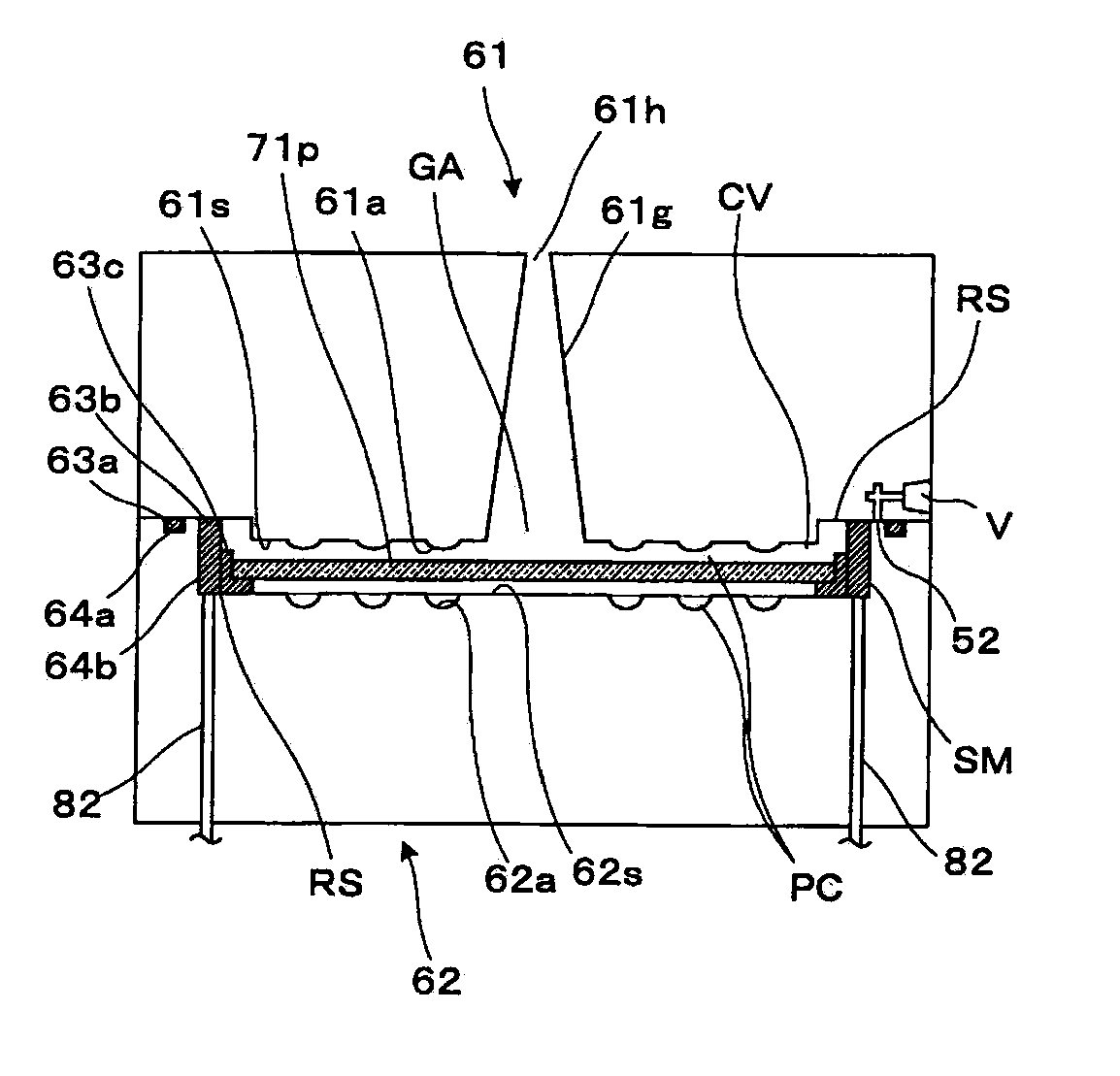

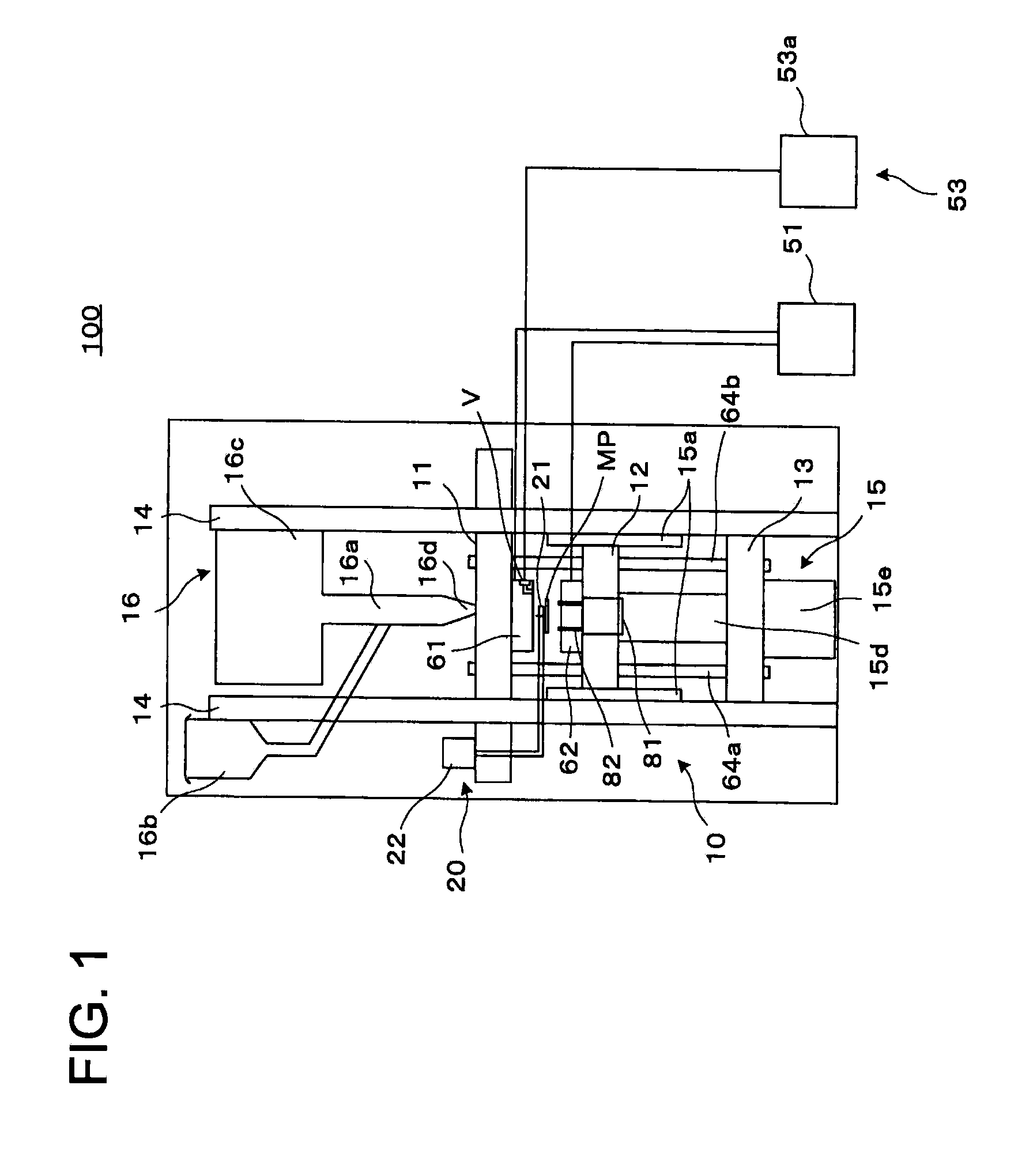

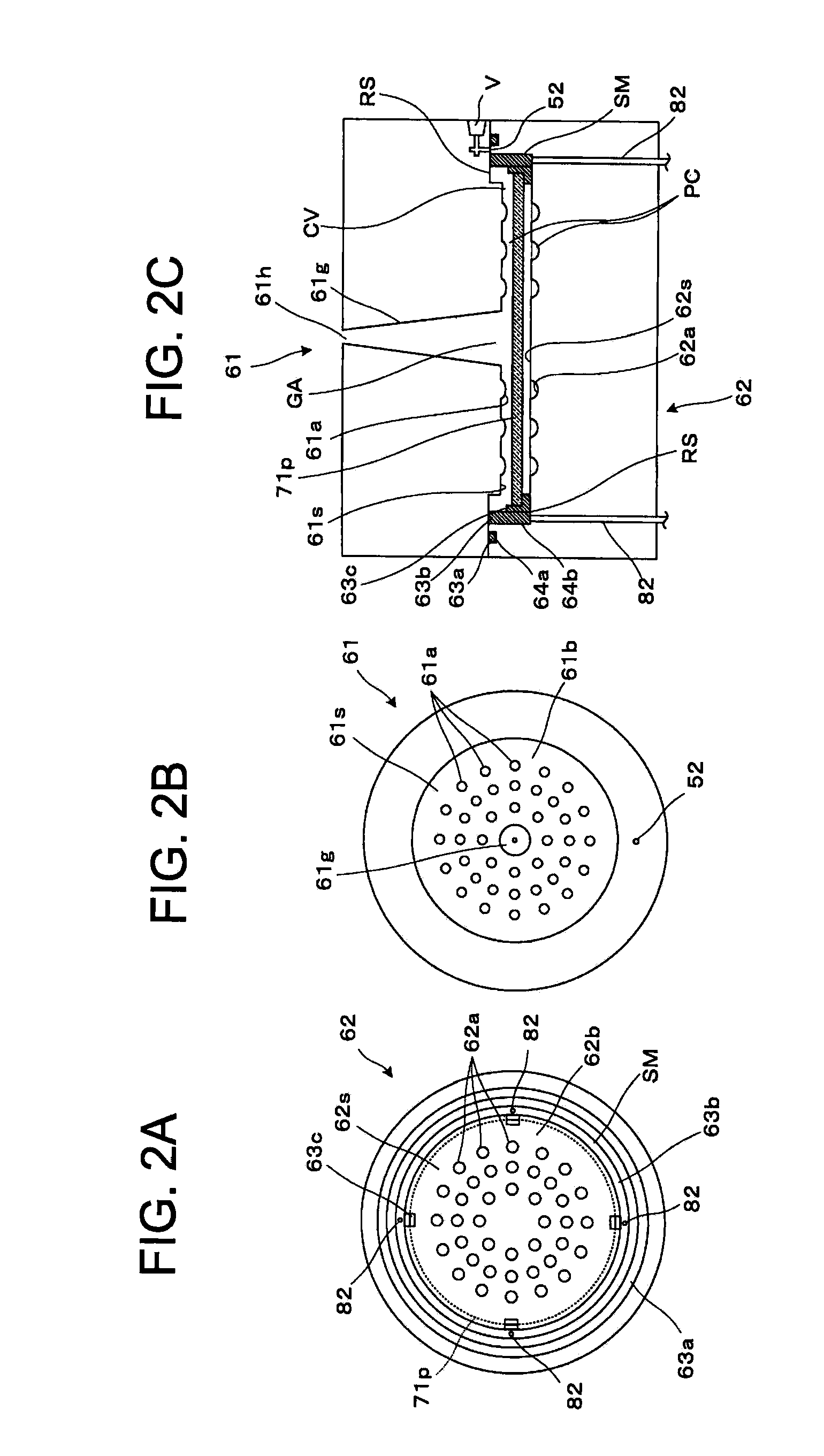

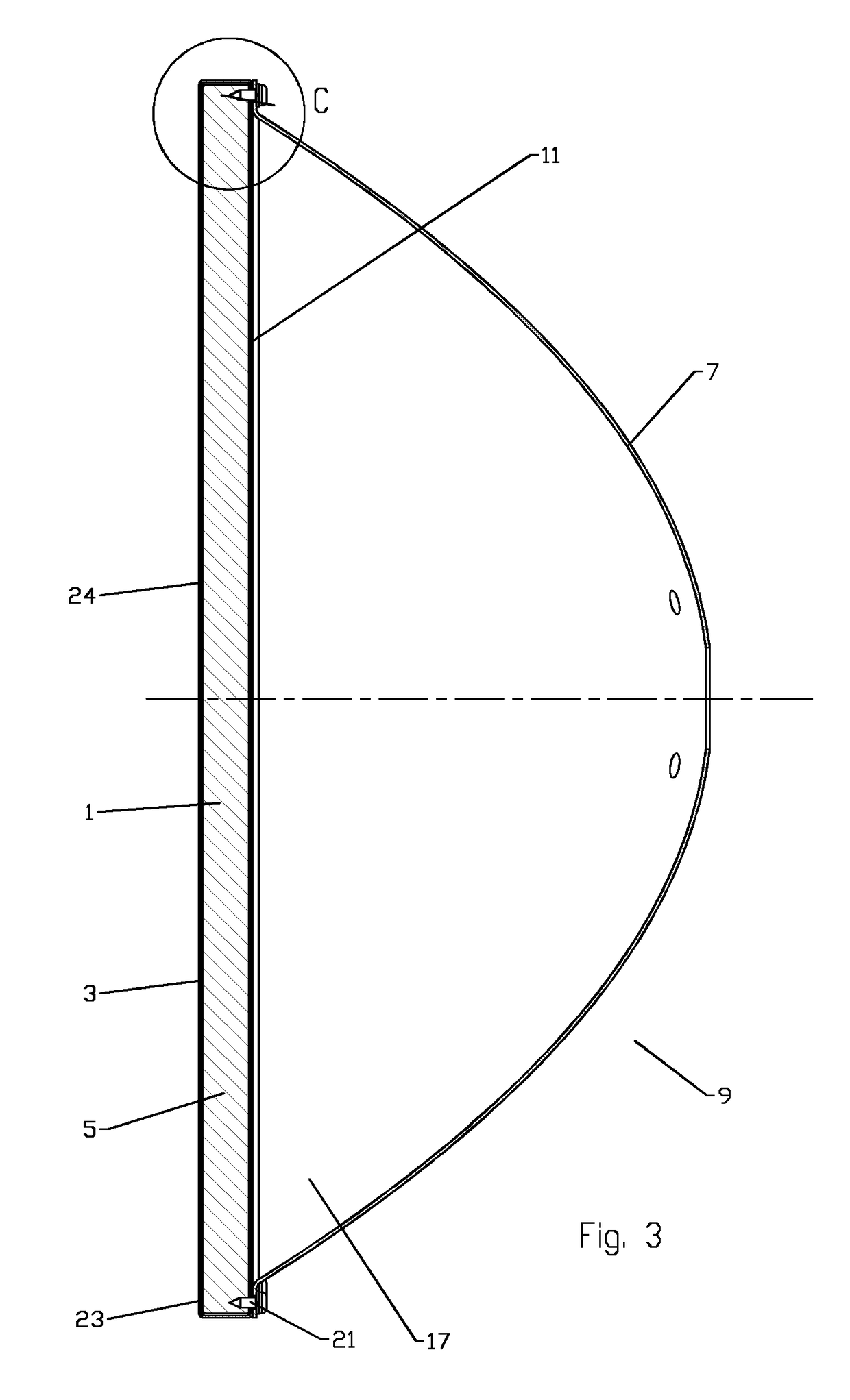

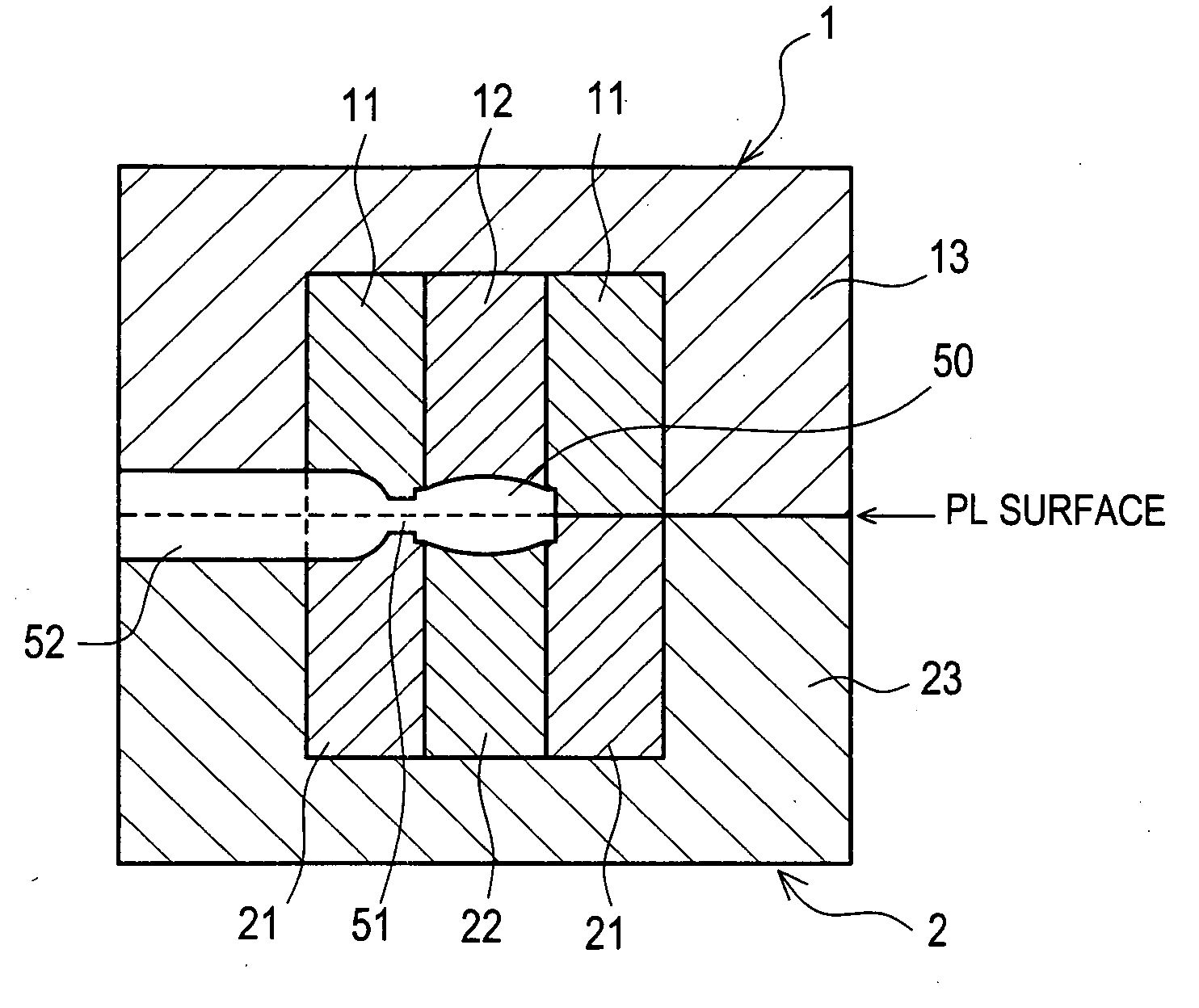

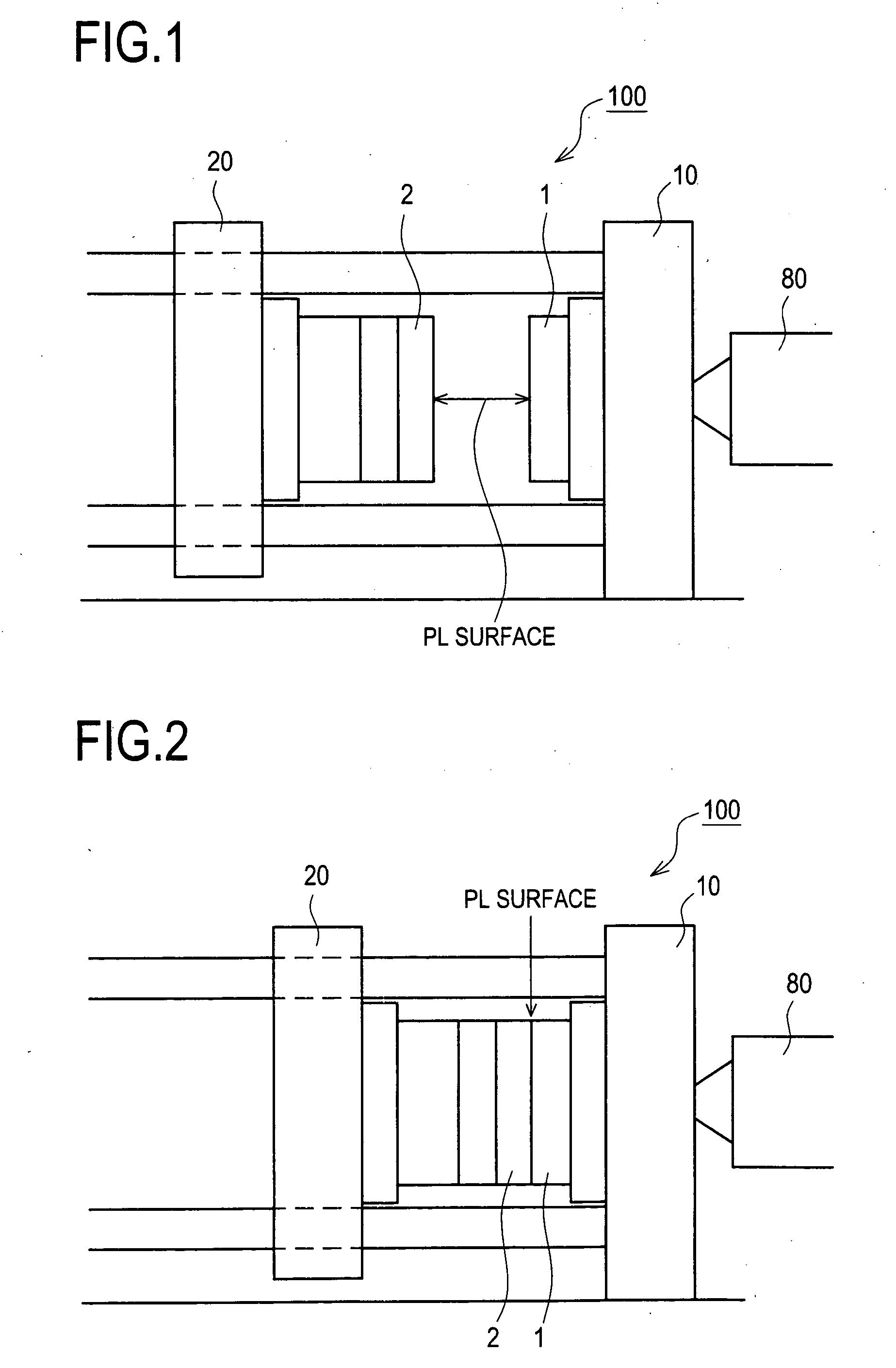

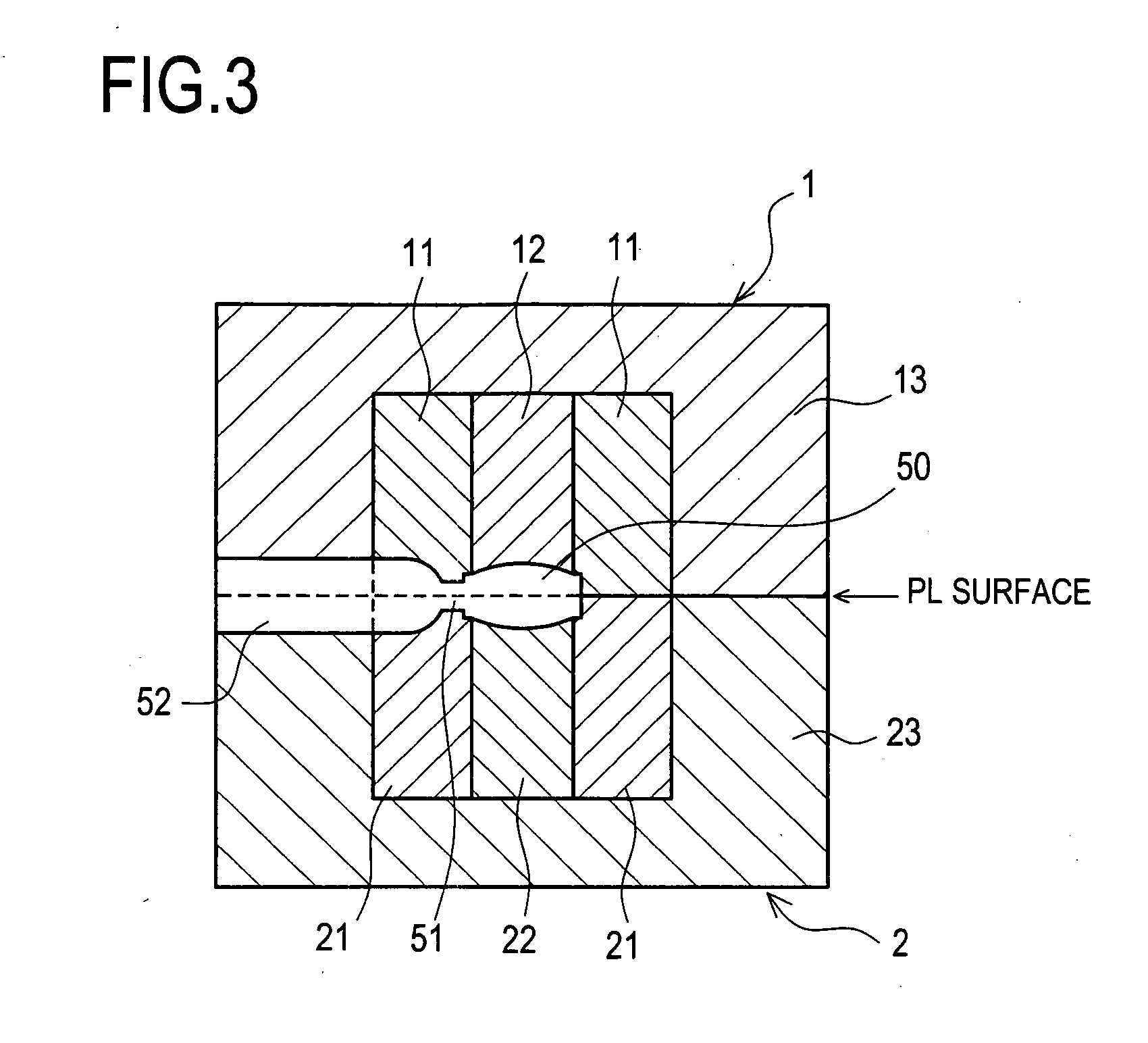

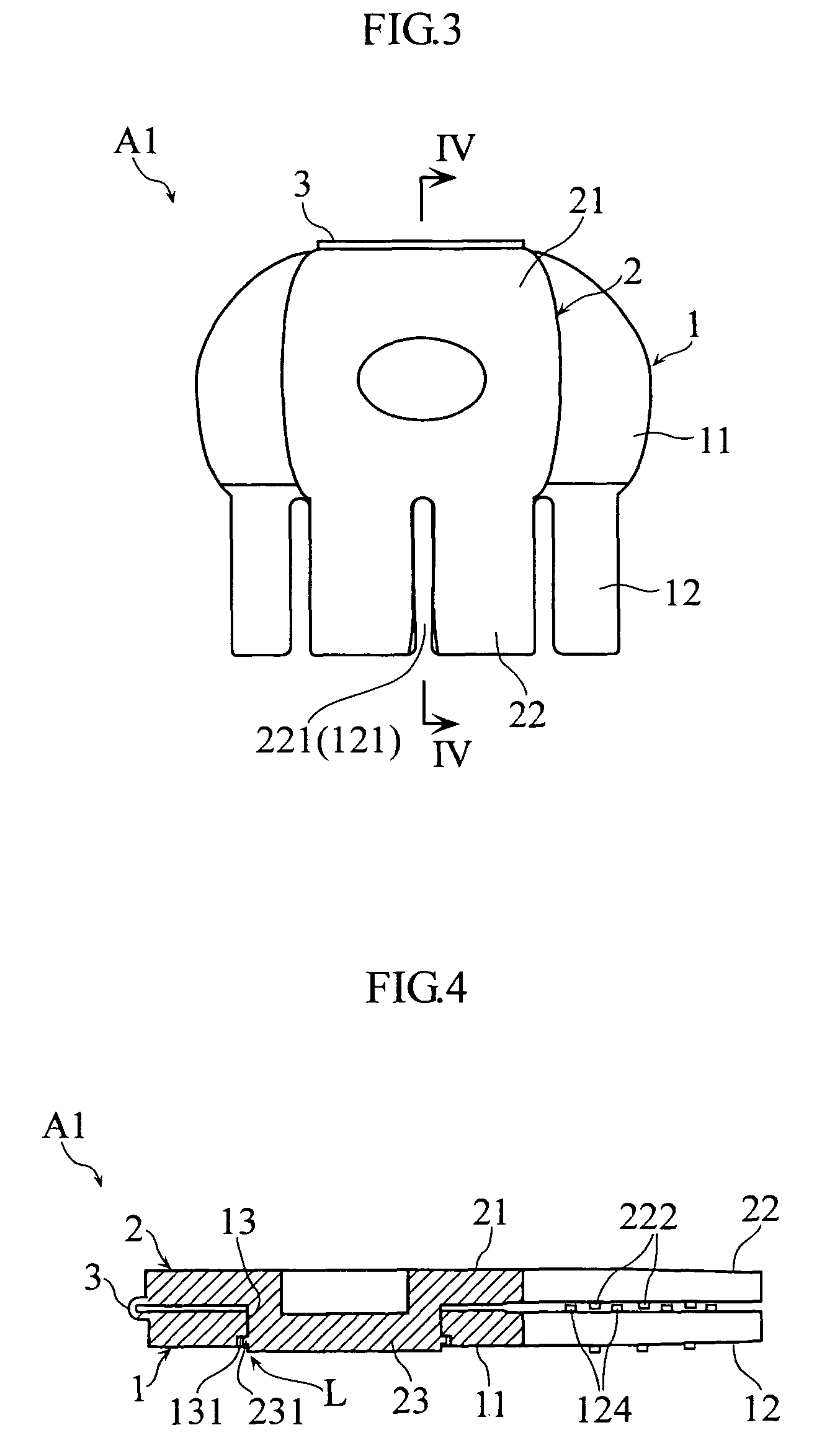

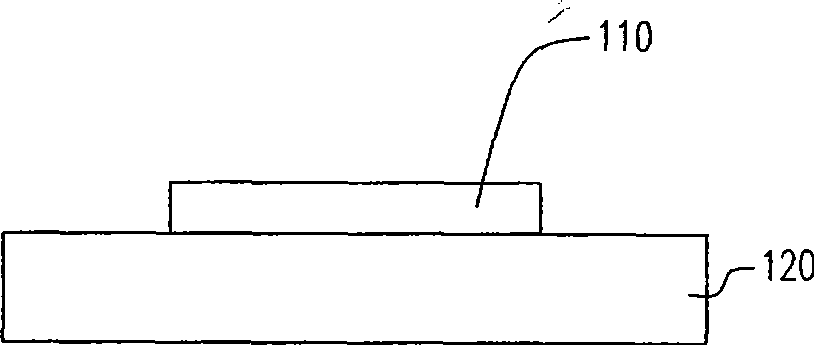

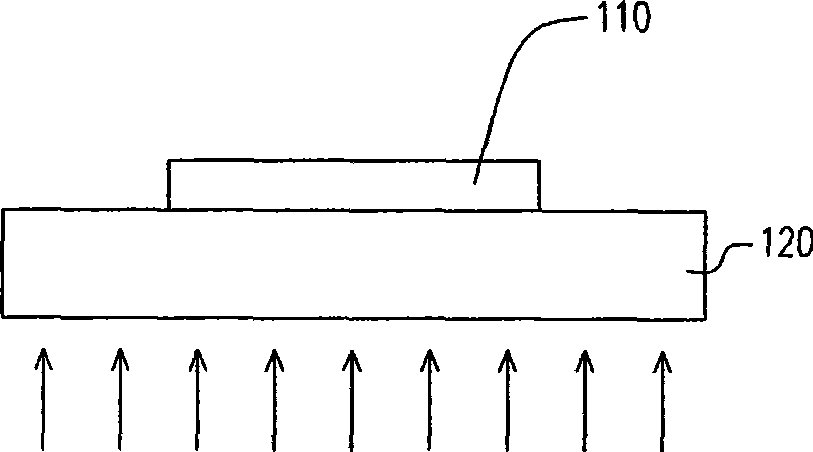

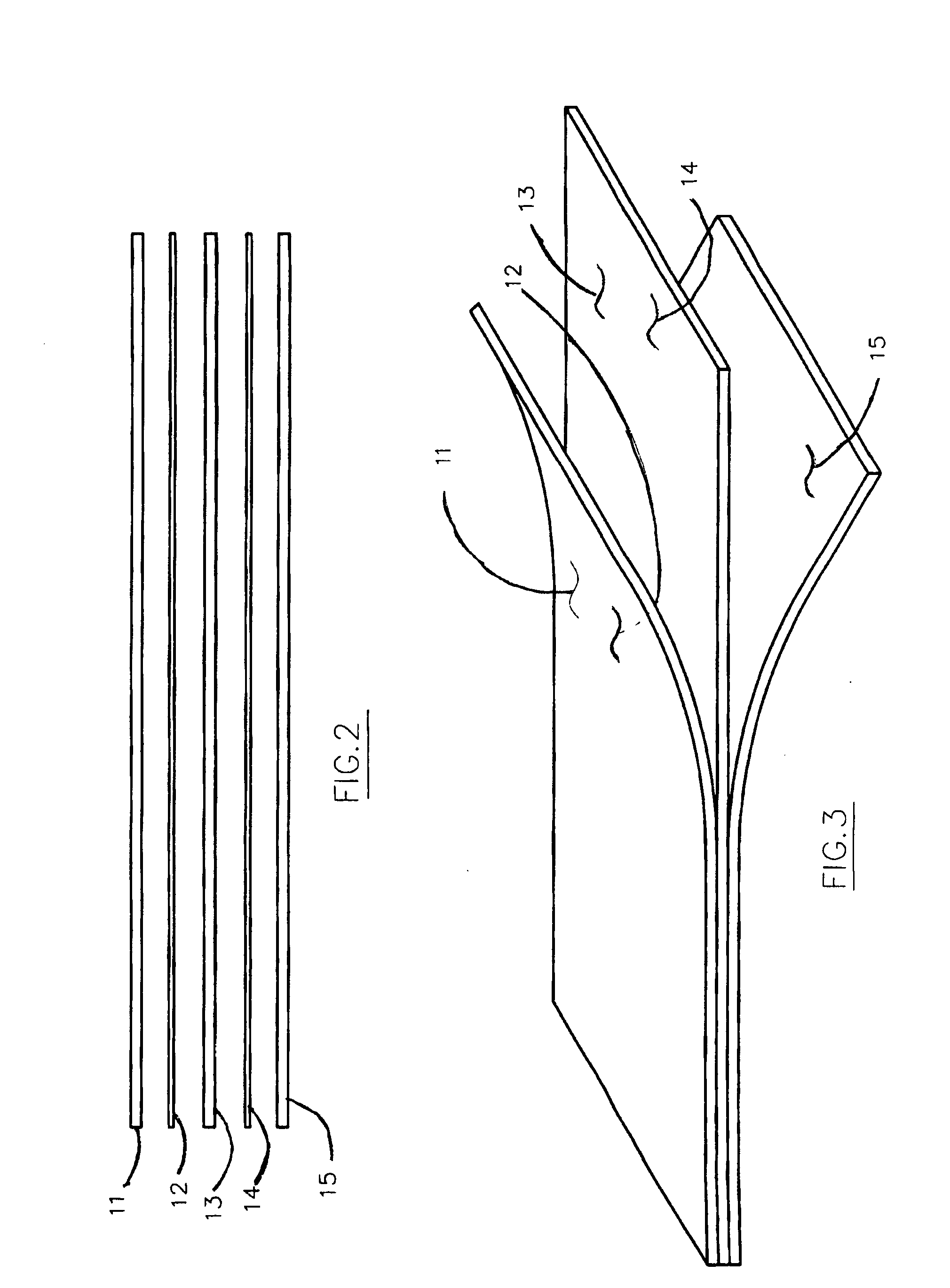

Molding method, optical element manufacturing method, and arrayed optical element

InactiveUS20100323105A1Reduce workloadEasy to assembleOptical articlesCoatingsOptical propertyOptical surface

There is provided a high-efficient molding method for realizing an inexpensive optical element exhibiting environmental stability of optical performance approximately equivalent to glass optical elements. Optical plate 71p which is a transparent inorganic material with stable optical property in the environment, is inserted in molding cavity CV. Then, molds 61 and 62 are closed and optical plate 71p is unitedly molded with energy curable resin to obtain molded body MP. Thereby, optical path length of the energy curable resin is shortened, and the optical property of the molded body MP is hardly affected by environmental change. A highly accurate molding transferability of the shape of optical surfaces 71j and 71k formed by injection molding, simultaneous molding of the opposing optical surfaces 71j and 71k, and securing alignment of the double-molded optical surfaces 71j and 71k are easily realized. Therefore, inexpensive optical element 71a can be molded with high efficiency.

Owner:KONICA MINOLTA OPTO

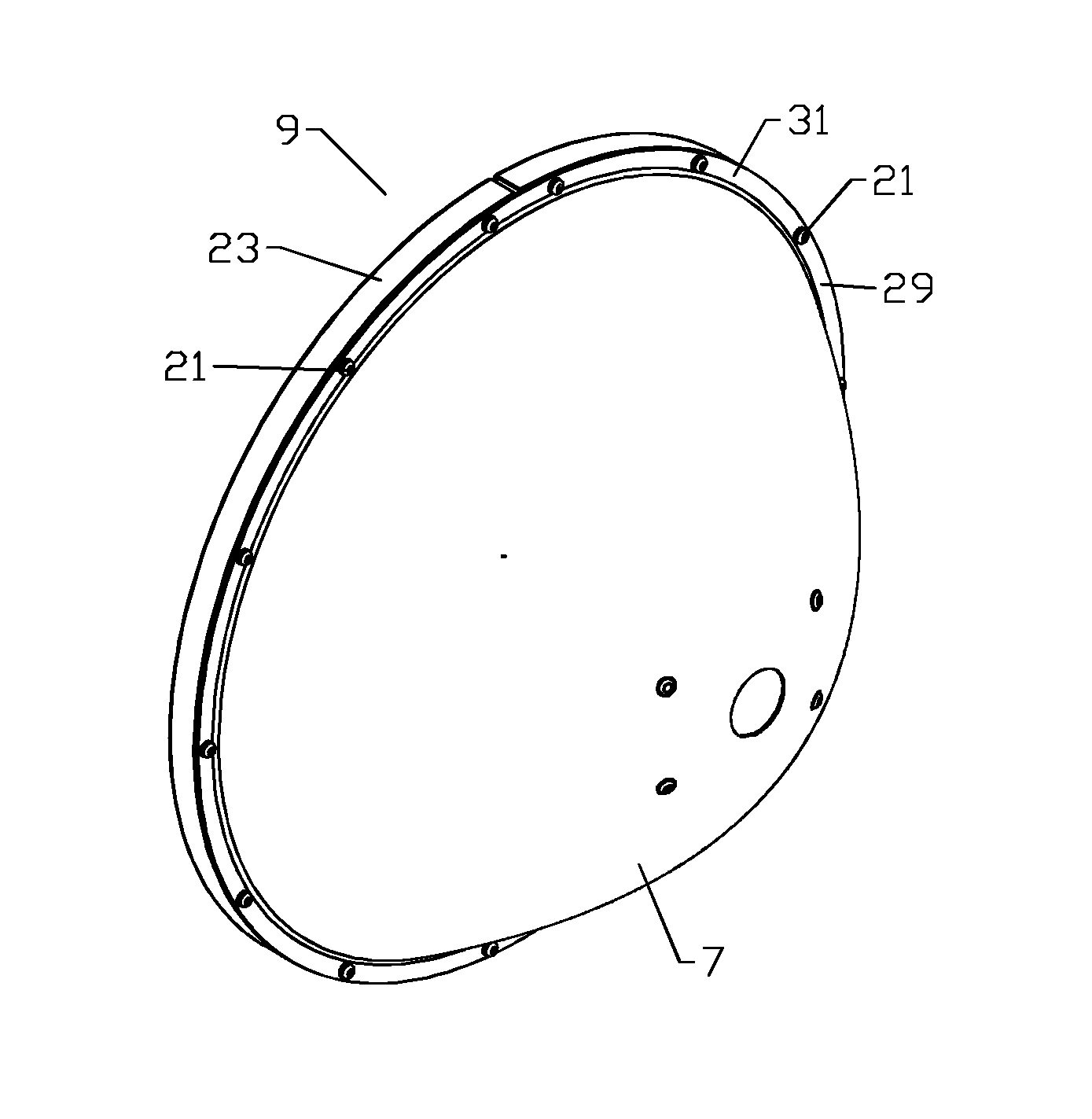

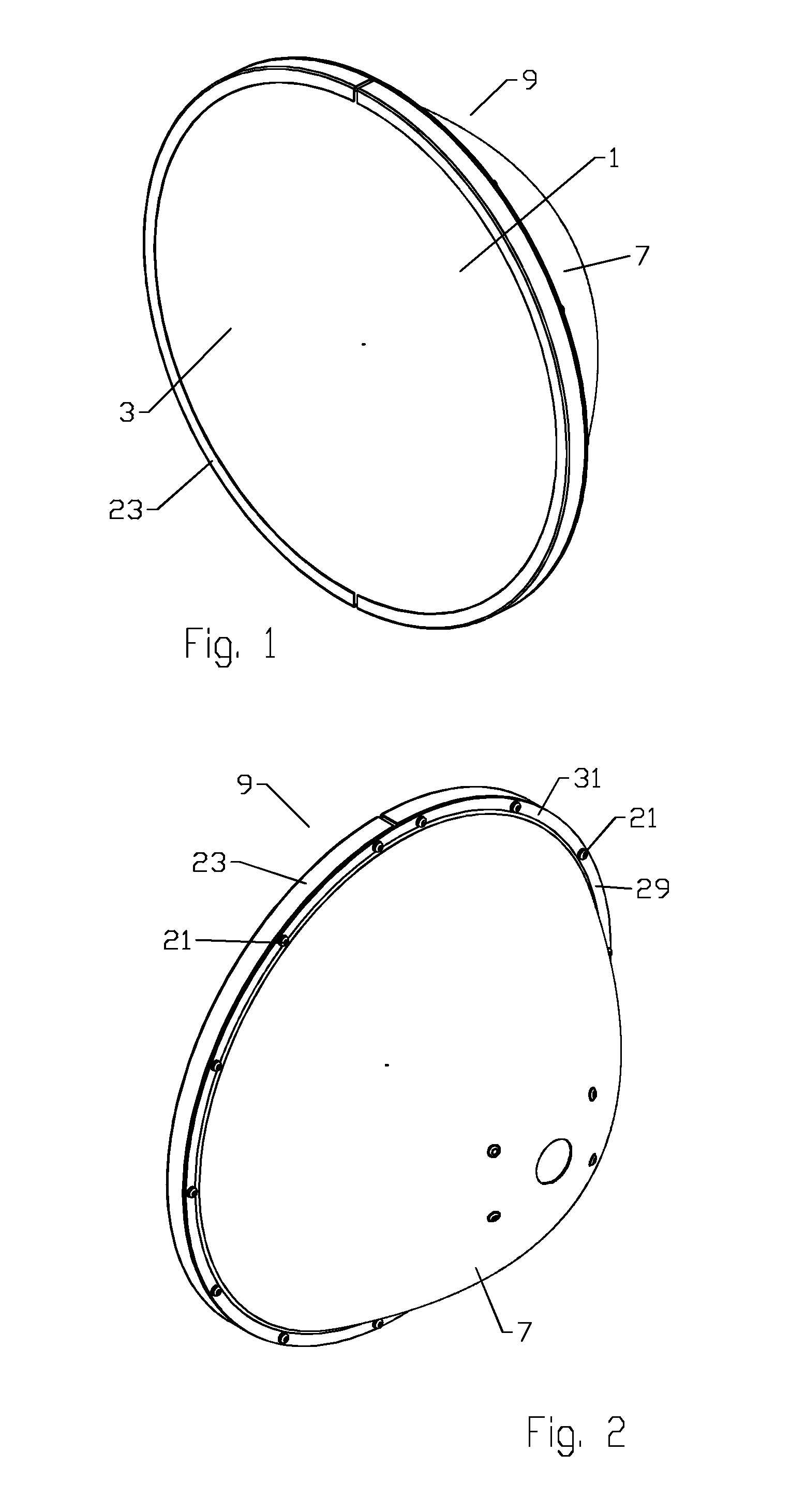

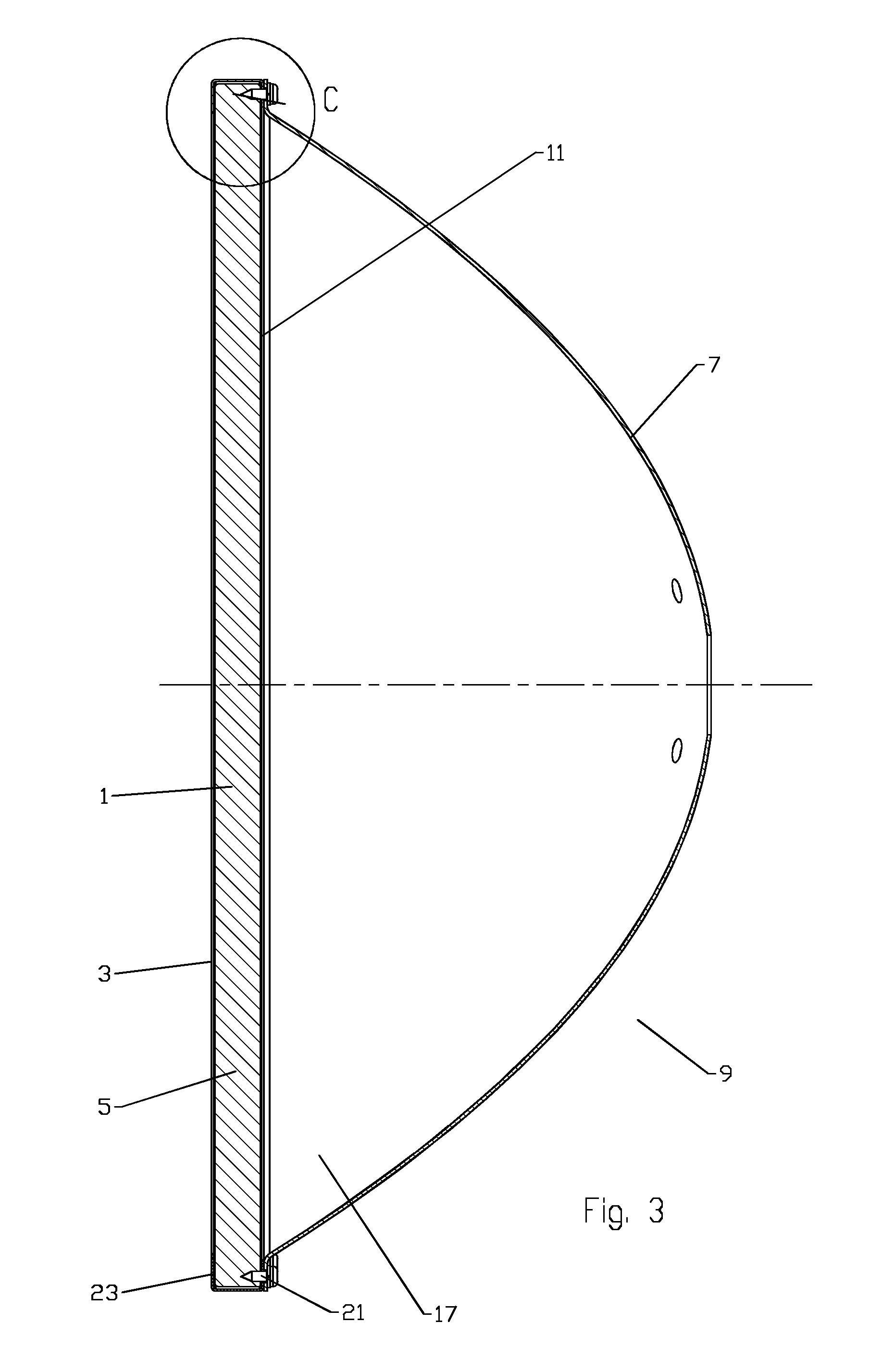

Broad band radome for microwave antenna

ActiveUS20150116184A1High strengthHigh precisionRadiating element housingsDomestic articlesFastenerEngineering

A radome for an antenna is provided as a composite of an isotropic outer layer and a structural layer of foamed polymer material. The composite is dimensioned to enclose an open end of the antenna. The radome may be retained upon the antenna by a retaining element and fasteners. The outer layer may be a polymer material with a water resistant characteristic.

Owner:COMMSCOPE TECH LLC

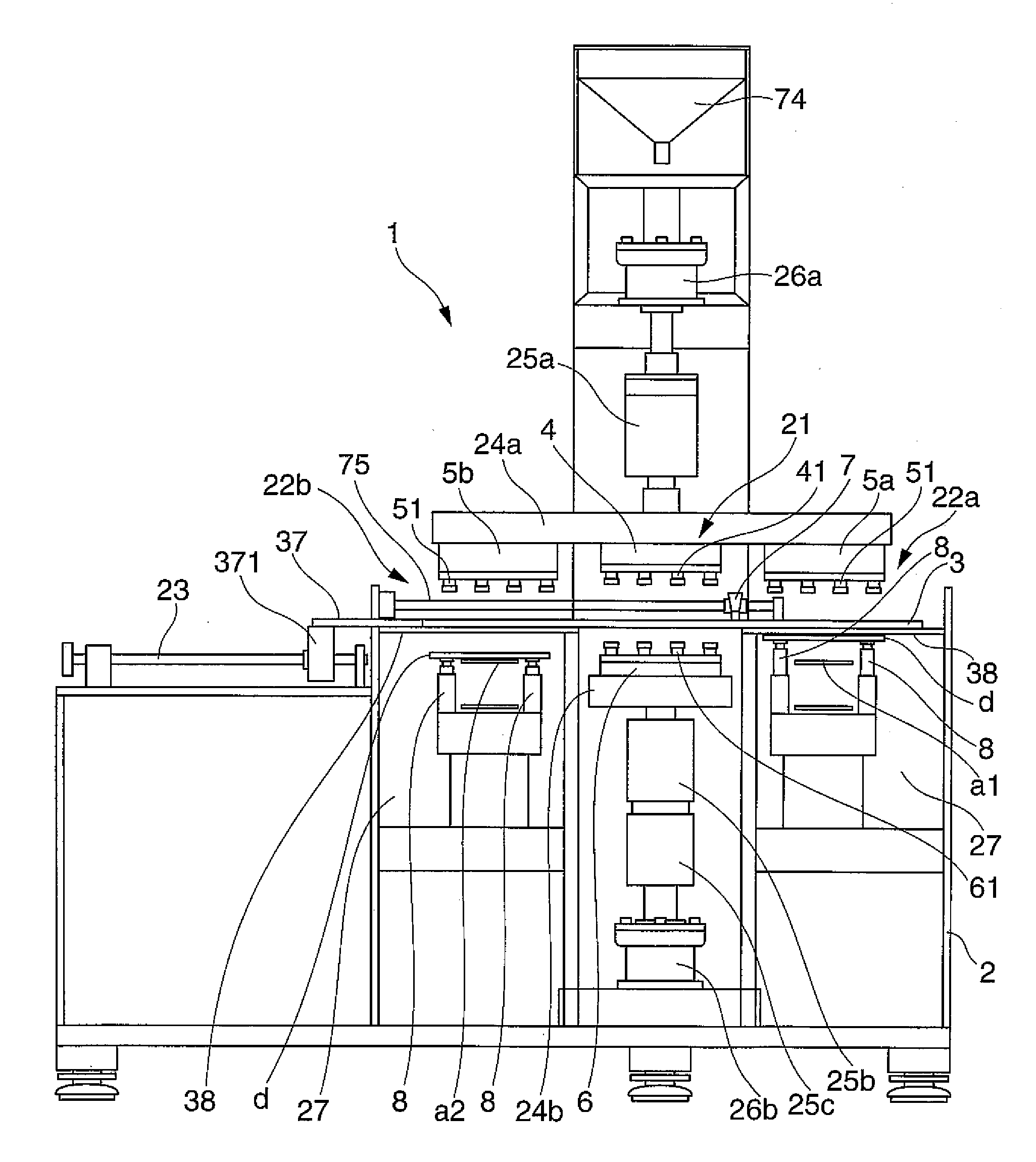

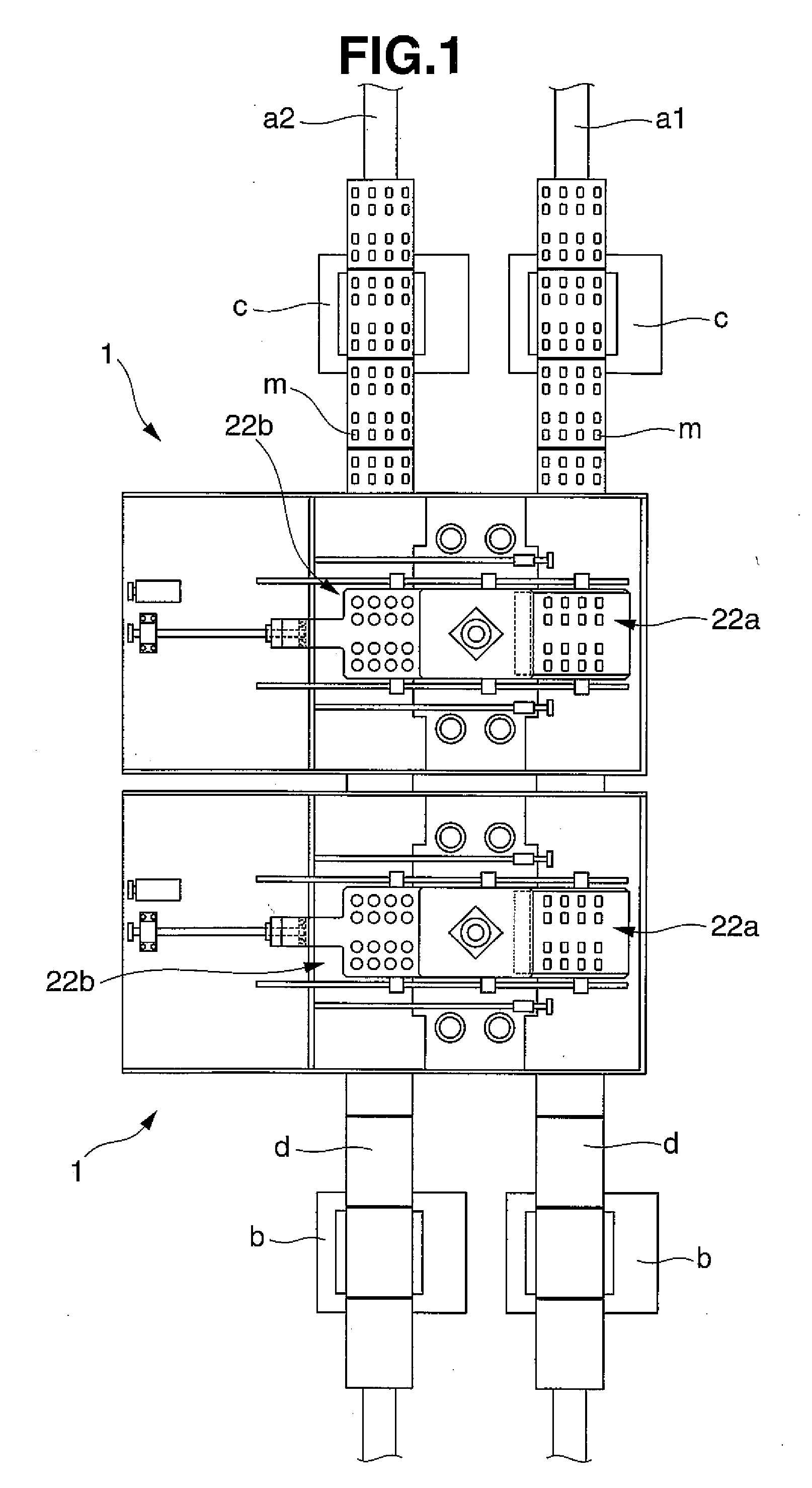

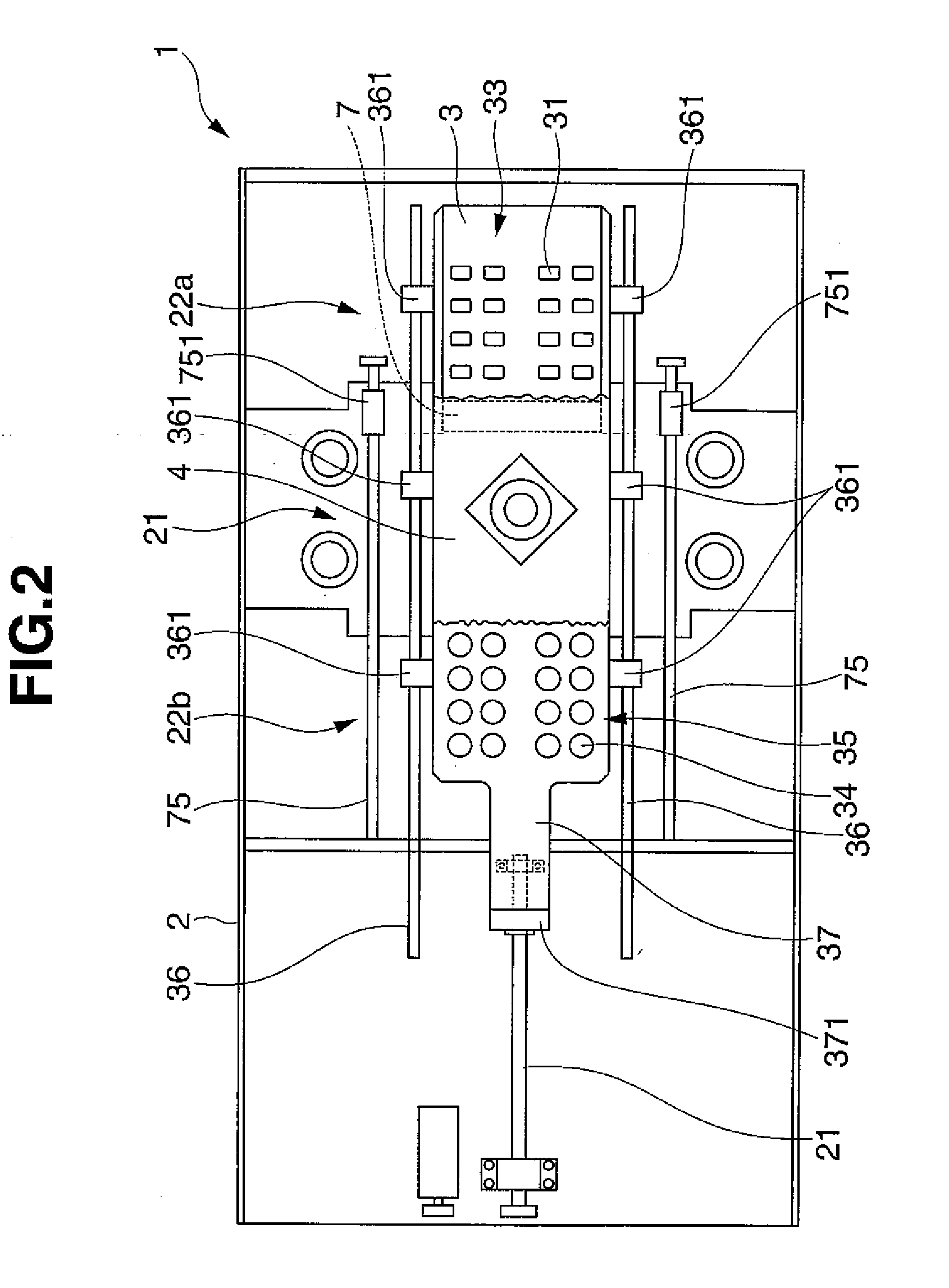

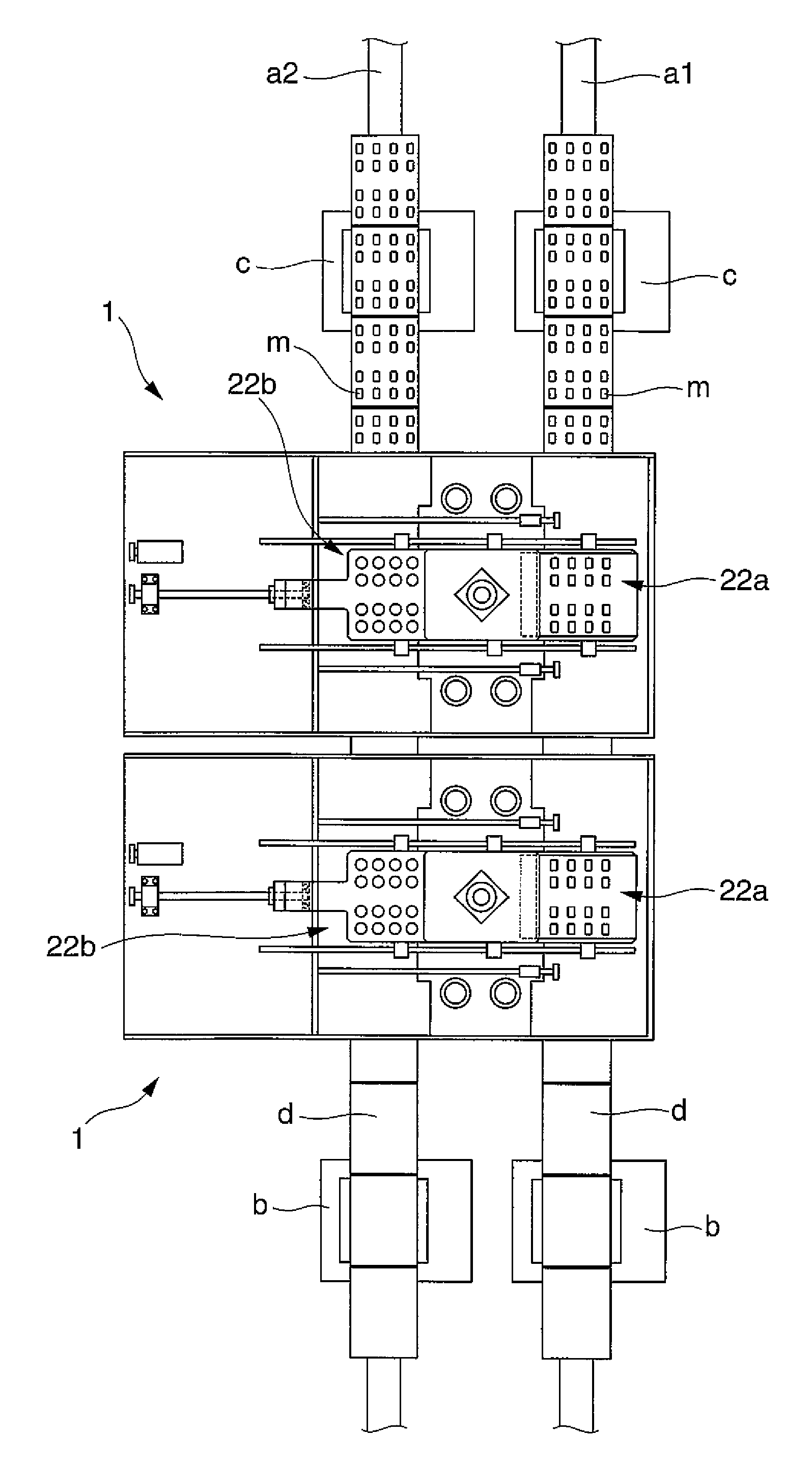

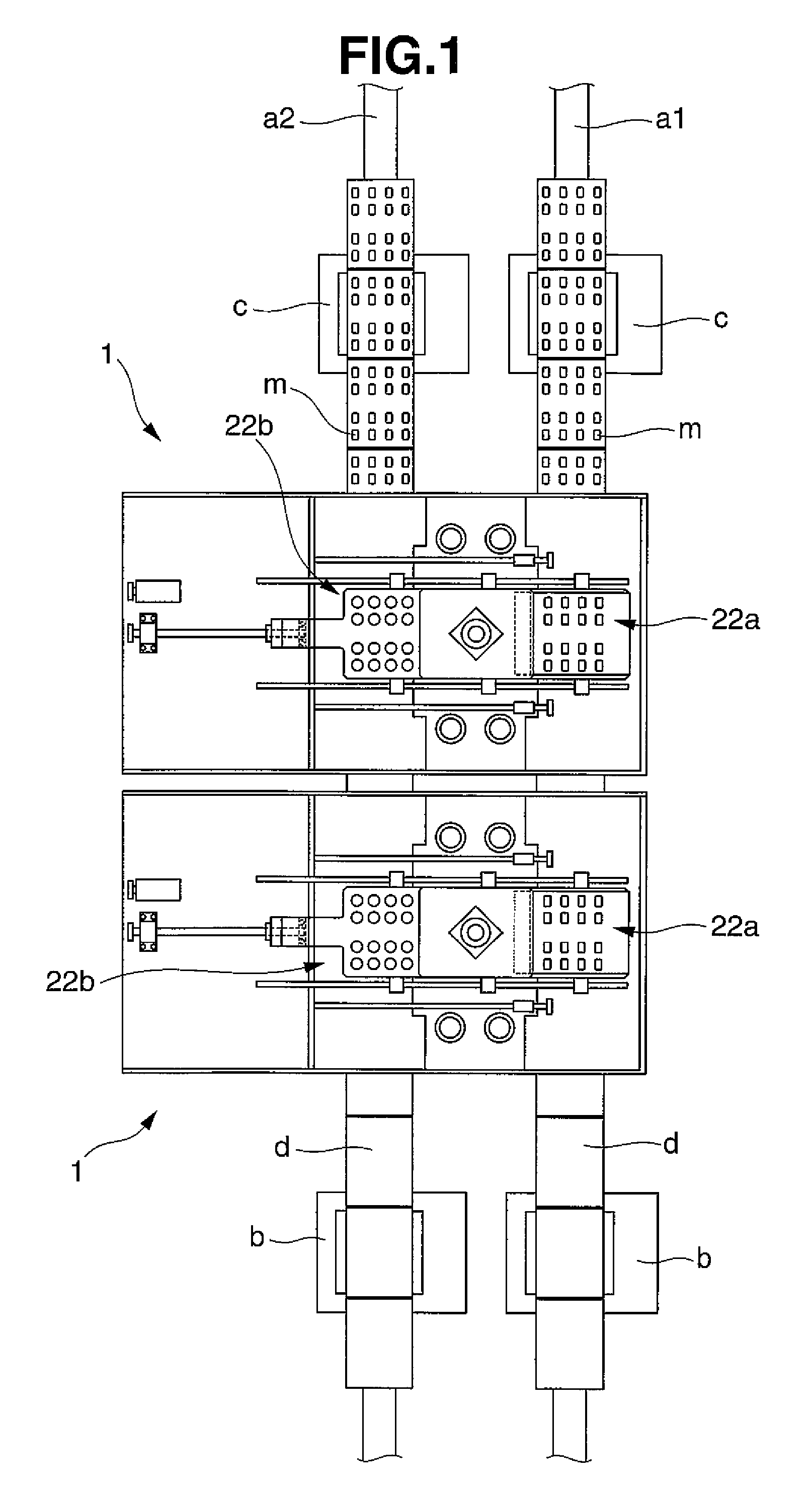

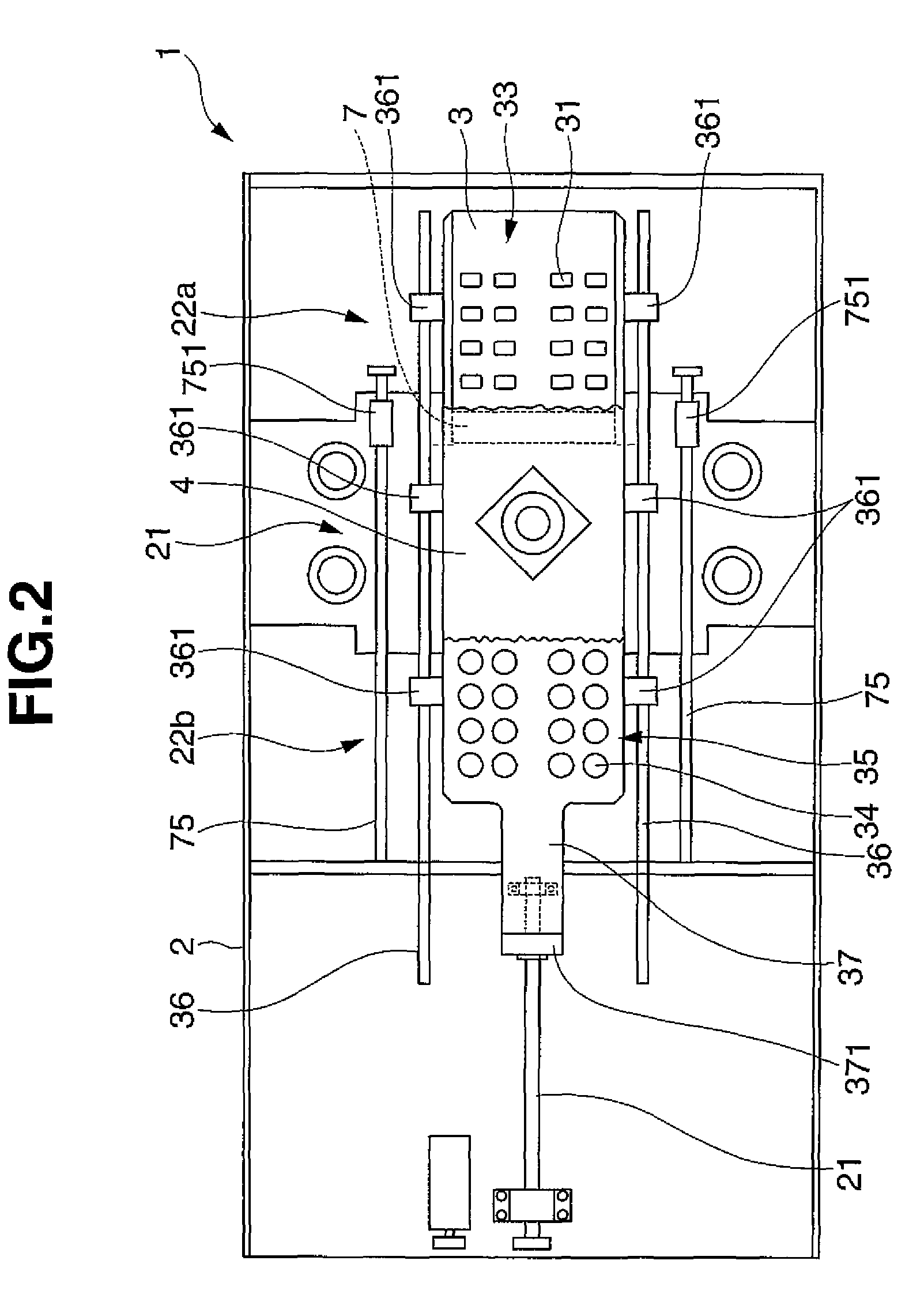

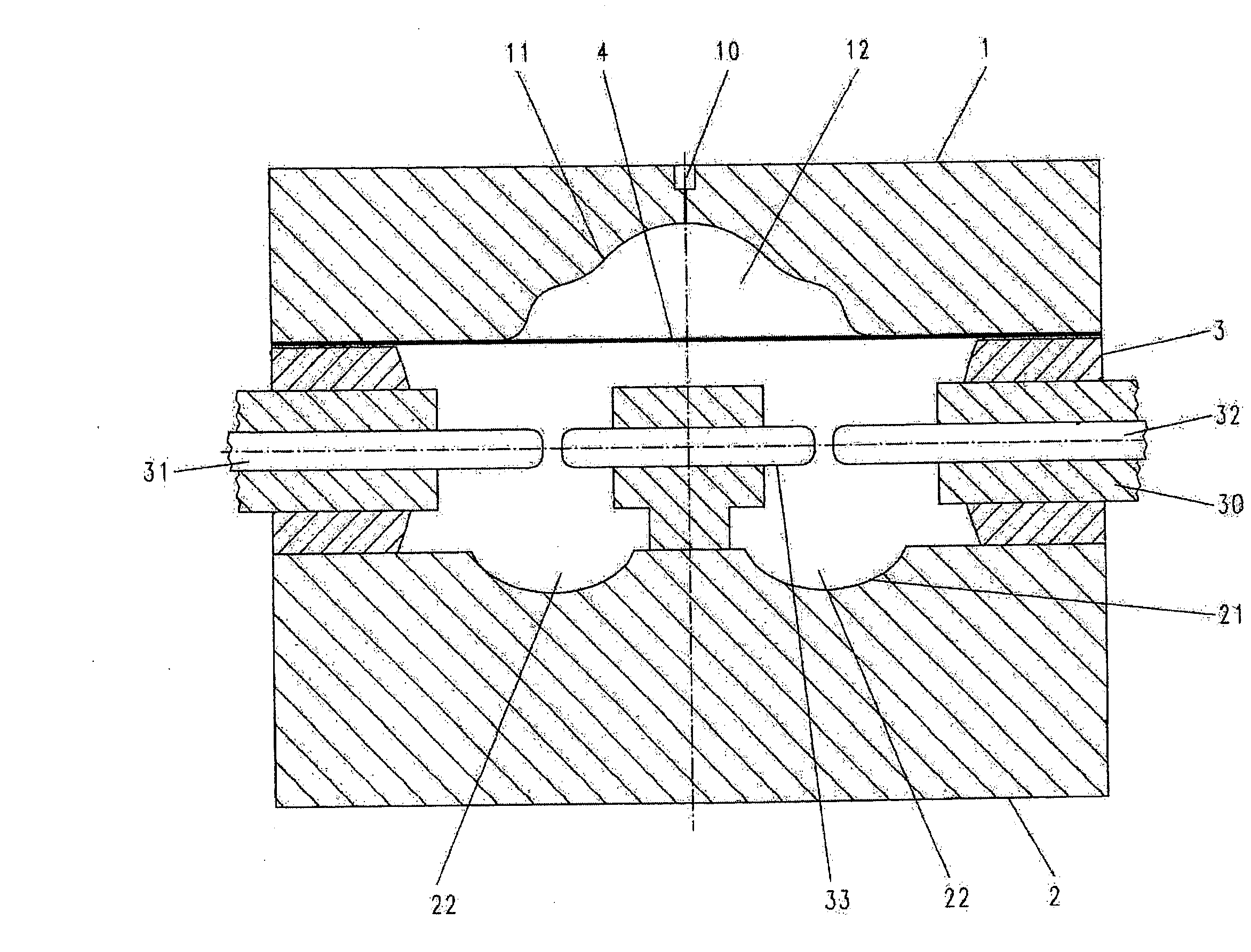

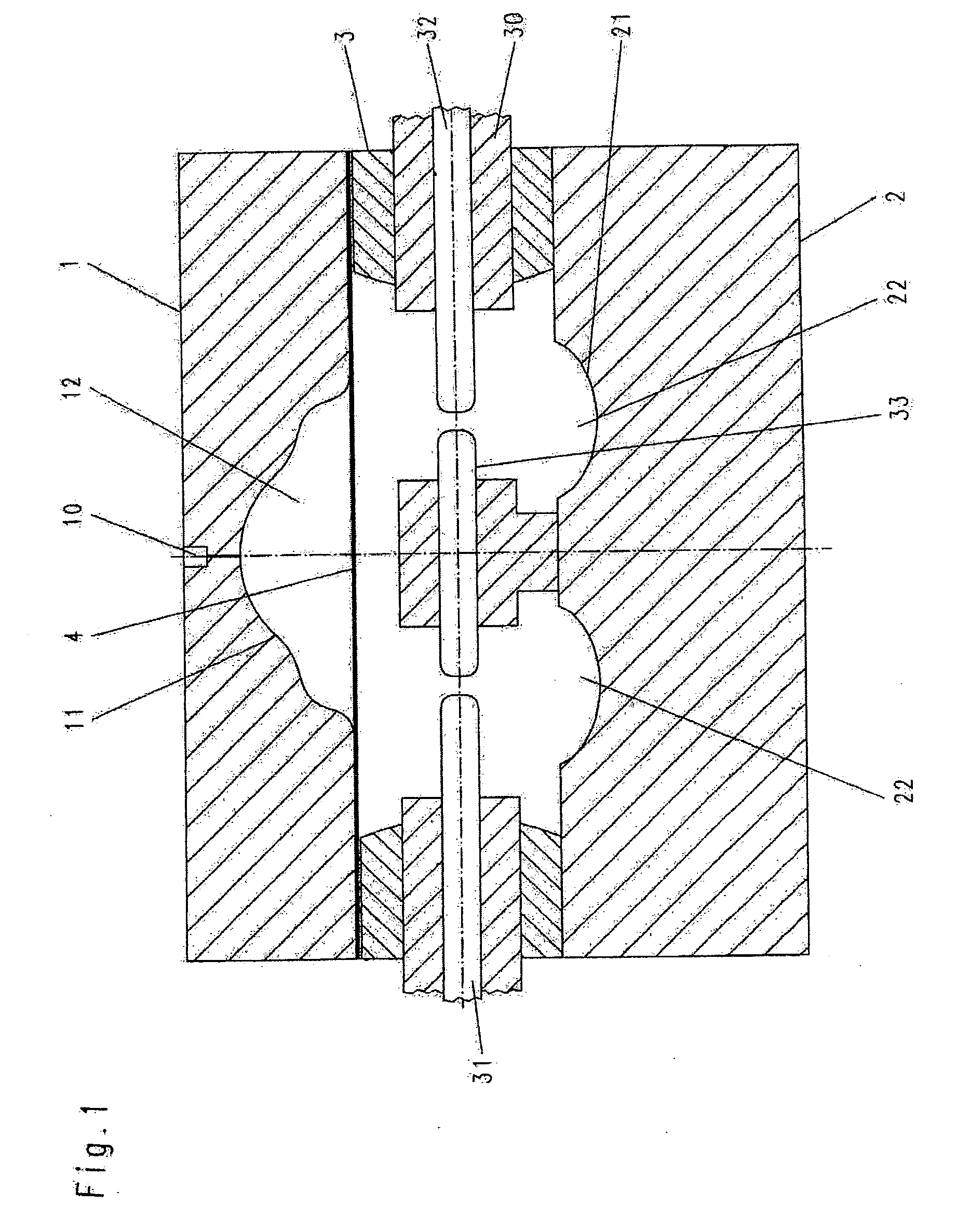

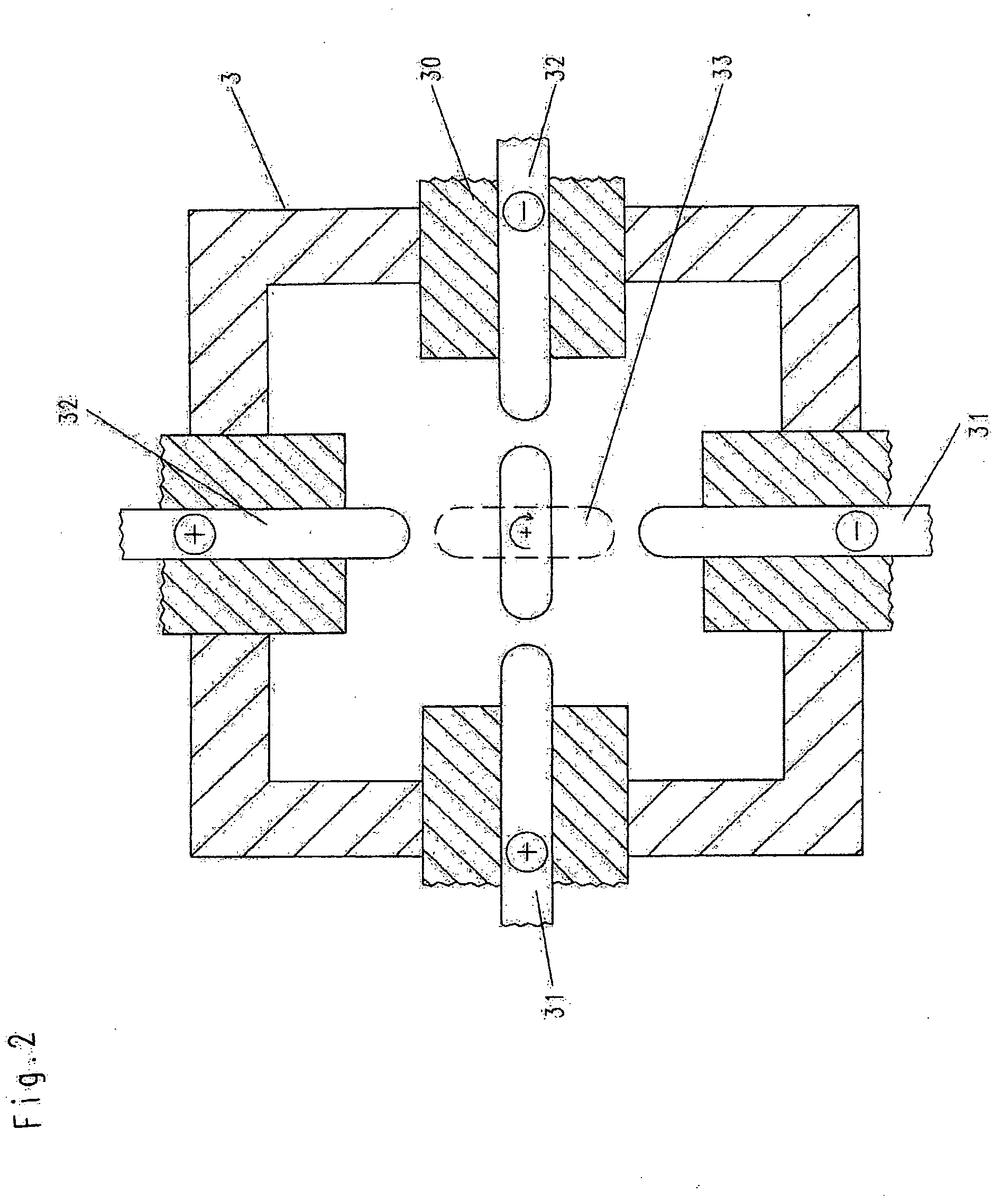

Powder compression molding machine and apparatus for continuous production of powder compression molded item using the machine

ActiveUS20090130243A1High porosityReduce compressionConfectioneryPharmaceutical product form changePorosityCompression molding

A powder compression molding machine is configured such that a plurality of lower and upper punches 61, 41 are allowed to enter a plurality of through-die holes 31 provided in first and second molding die sections 32, 33 of a slide plate 3 in a compression molding zone 21 to compressively mold powder and the slide plate 3 is slid to push out compacts downward and collect them in compact discharge zones 22a, 22b. Even when powder is compressively molded at a low compression force into solids having high porosity, compacts can satisfactorily be molded and collected without crumblingness, the compacts having sufficient high porosity and being dissolvable in water or the like.

Owner:QUALICAPS CO LTD +1

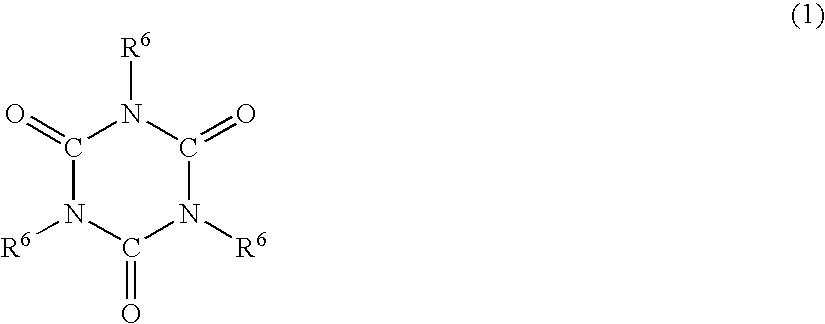

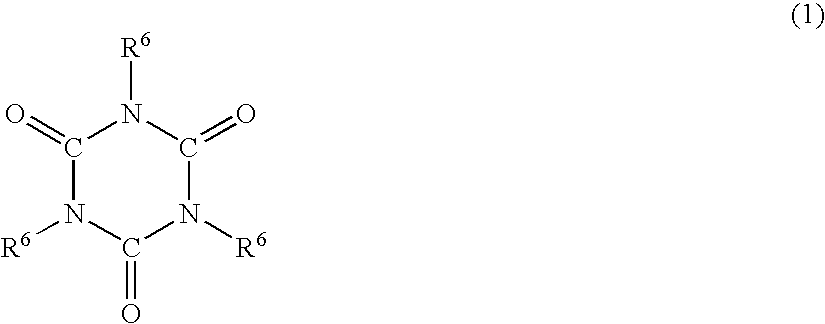

Semiconductor encapsulating epoxy resin composition and semiconductor device

InactiveUS7095125B2Effectively moldableImproved solder crack resistance and flame retardance and reliabilitySemiconductor/solid-state device detailsSynthetic resin layered productsPolymer scienceCrack resistance

A semiconductor encapsulating epoxy resin composition is provided comprising (A) an epoxy resin, (B) a phenolic resin curing agent, (C) a molybdenum compound, (D-i) an organopolysiloxane, (D-ii) an organopolysiloxane cured product, or (D-iii) a block copolymer obtained by reacting an epoxy resin or alkenyl group-bearing epoxy resin with an organohydrogenpolysiloxane, and (E) an inorganic filler. The composition has improved moldability and solder crack resistance while exhibiting high flame retardance despite the absence of halogenated epoxy resins and antimony oxide.

Owner:SHIN ETSU CHEM IND CO LTD

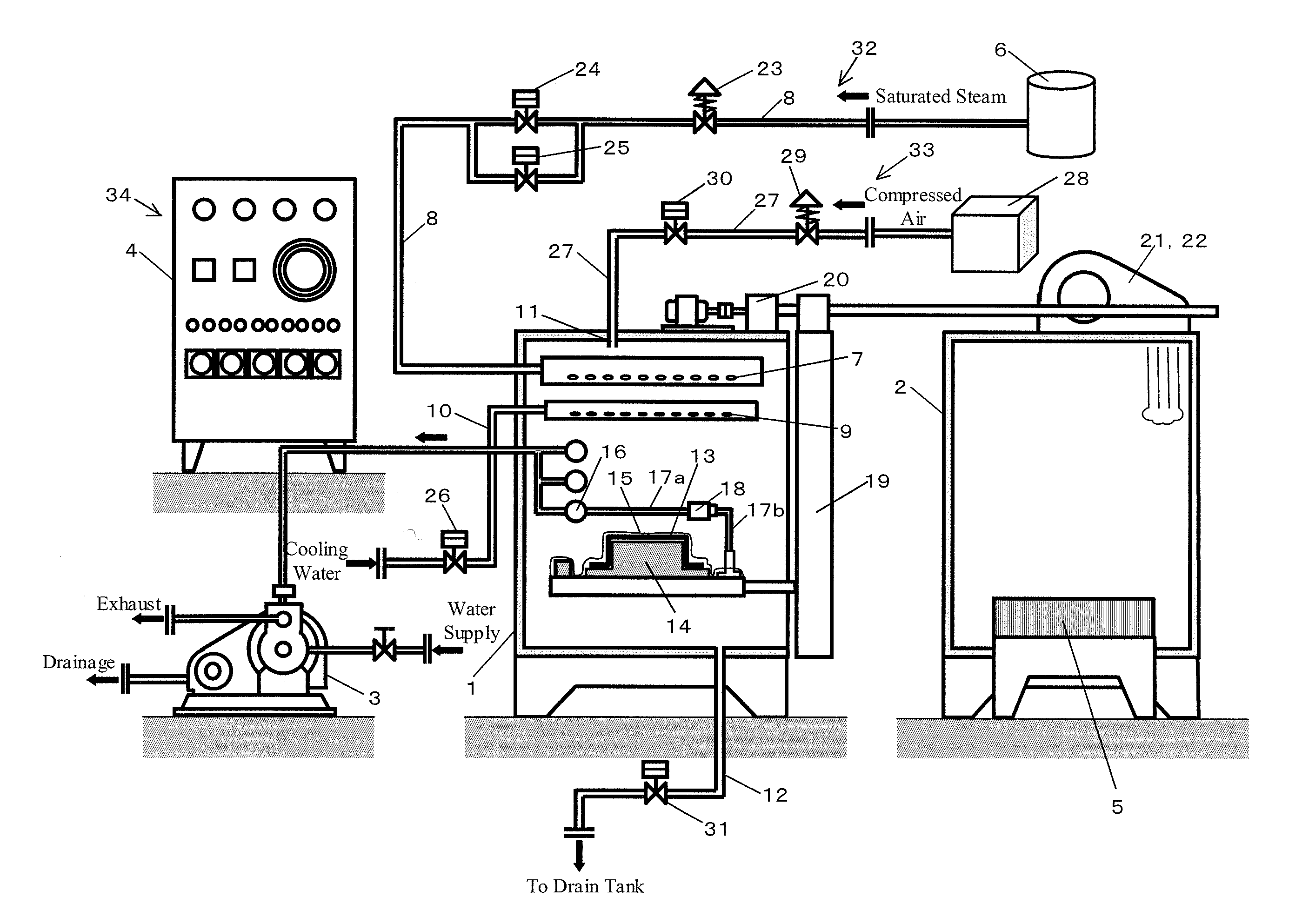

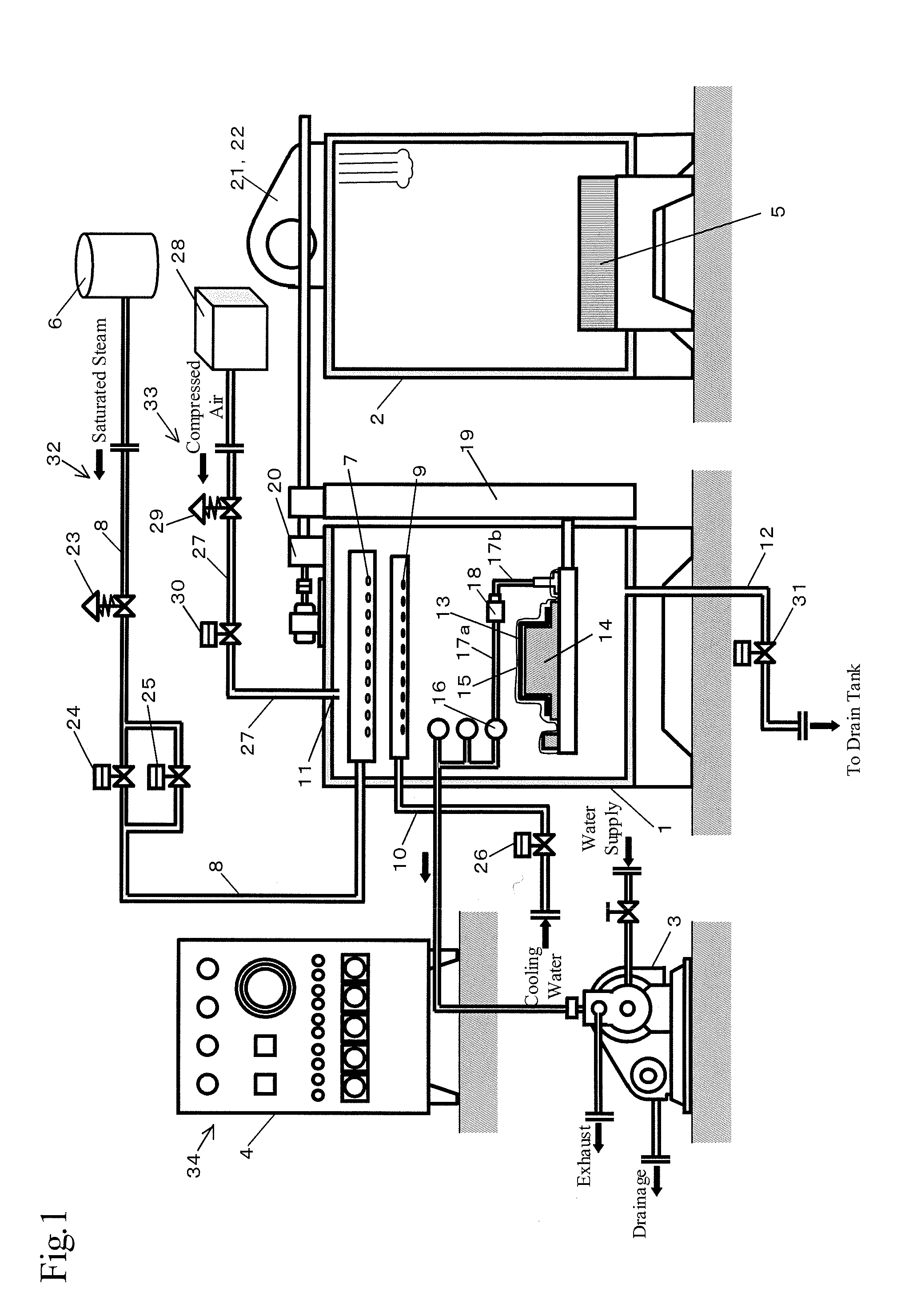

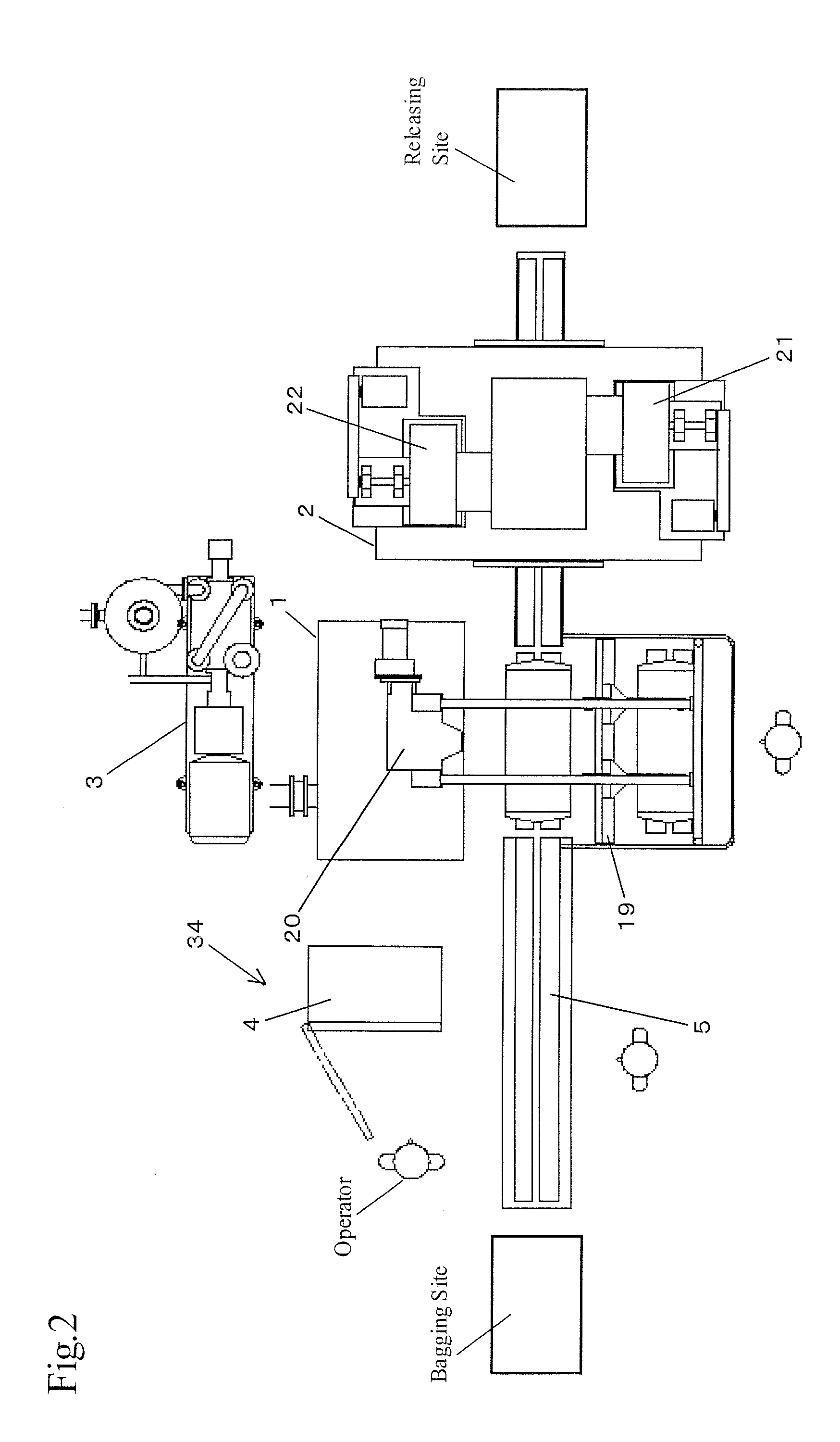

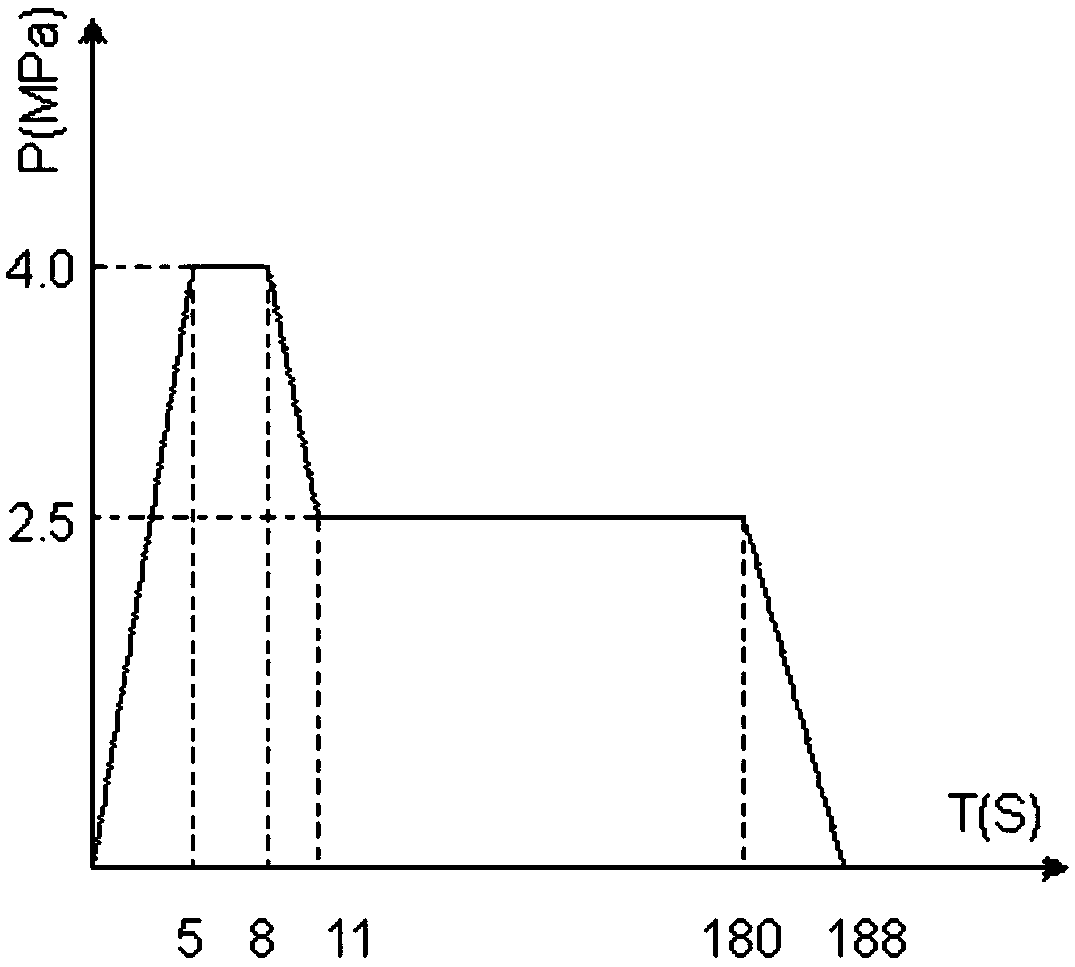

Autoclave molding method and autoclave molding apparatus

ActiveUS20120133067A1Effectively useReduce curing timeAuxillary shaping apparatusFiberElectrical and Electronics engineering

The composite material formed of a fiber substrate and a matrix is placed in a vacuum bag and then in the molding chamber. Saturated steam of a predetermined temperature needed for the composite material is supplied to the molding chamber, and the temperature and the pressure inside the molding chamber are controlled so that the inside of the molding chamber may be maintained at a predetermined temperature and a predetermined pressure needed for the composite material in order to carry out a curing step.

Owner:ASHIDA MFG

Broad band radome for microwave antenna

ActiveUS20170301983A1High strengthHigh precisionRadiating element housingsVibration dampingMicrowaveEngineering

A radome for an antenna is provided as a composite of an isotropic outer layer and a structural layer of foamed polymer material. The composite is dimensioned to enclose an open end of the antenna. The radome may be retained upon the antenna by a retaining element and fasteners. The outer layer may be a polymer material with a water resistant characteristic. The structural layer may project inward and / or outward with respect to a plane of the seating surface of the radome.

Owner:COMMSCOPE TECH LLC

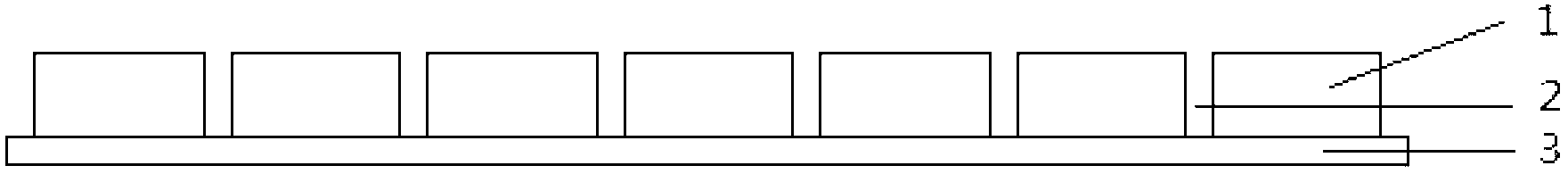

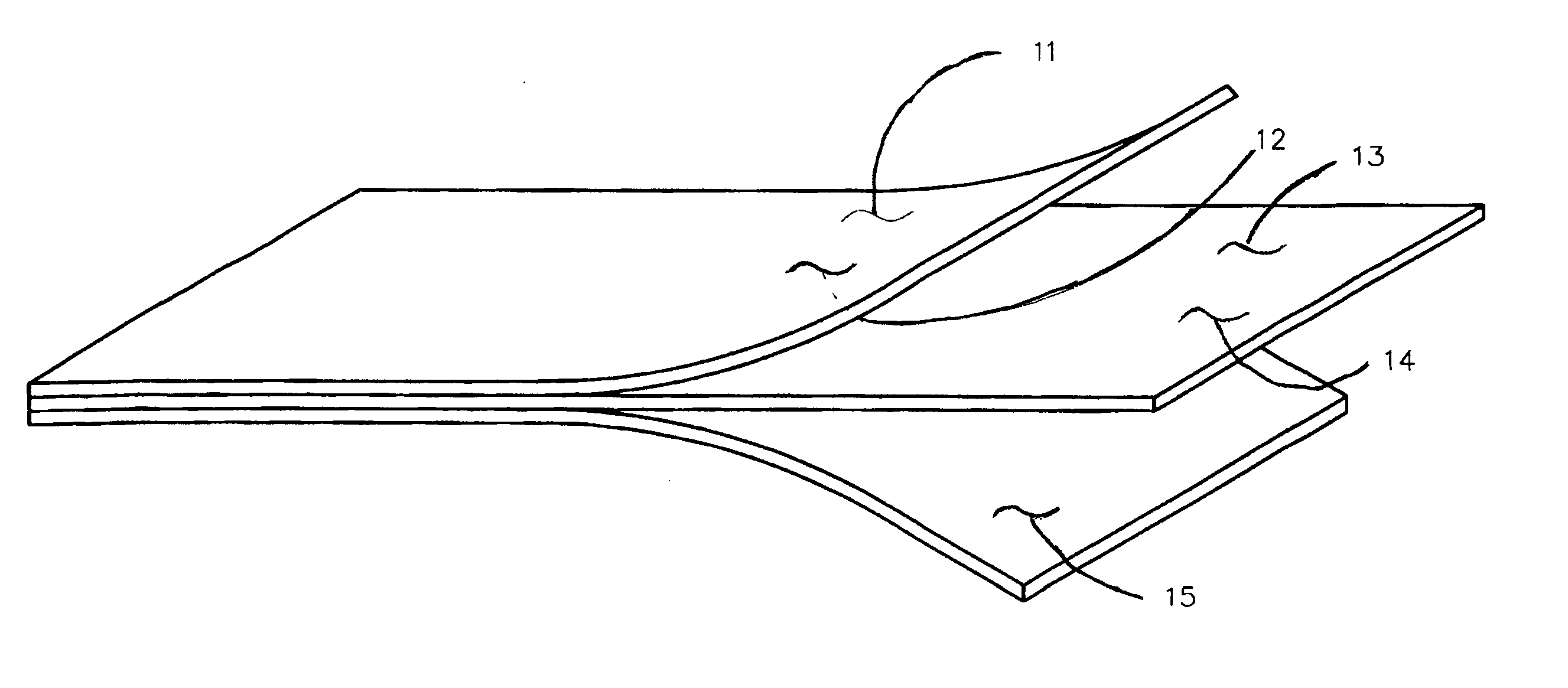

Novel flexible anti-cutting and stab-resistant discrete composite material and preparation method for same

ActiveCN106192431AImprove breathabilityIncrease flexibilityGlovesTextiles and paperPolymer sciencePolymer

The invention discloses a preparation method for a novel flexible anti-cutting and stab-resistant discrete composite material. The preparation method comprises the following steps: (1) preparation of a polymer glue solution: proportionally heating, mixing and de-foaming thermoplastic resin or thermosetting resin and an additive to prepare the polymer glue solution; (2) dispensing forming: dispensing the polymer glue solution prepared in step (1) on the base cloth of a fabric by adopting a multi-needle dispensing device; (3) solidification treatment: performing solidification treatment and rolling on the dispensed base cloth of the fabric to prepare the novel flexible anti-cutting and stab-resistant discrete composite material. According to the preparation method, a process flow is short, continuous production can be realized, and the preparation method is high in production efficiency and low in cost; the prepared discrete composite material is flexible, comfortable, high in air permeability, long in service life and wide in application range.

Owner:江苏保禾新材料科技有限公司

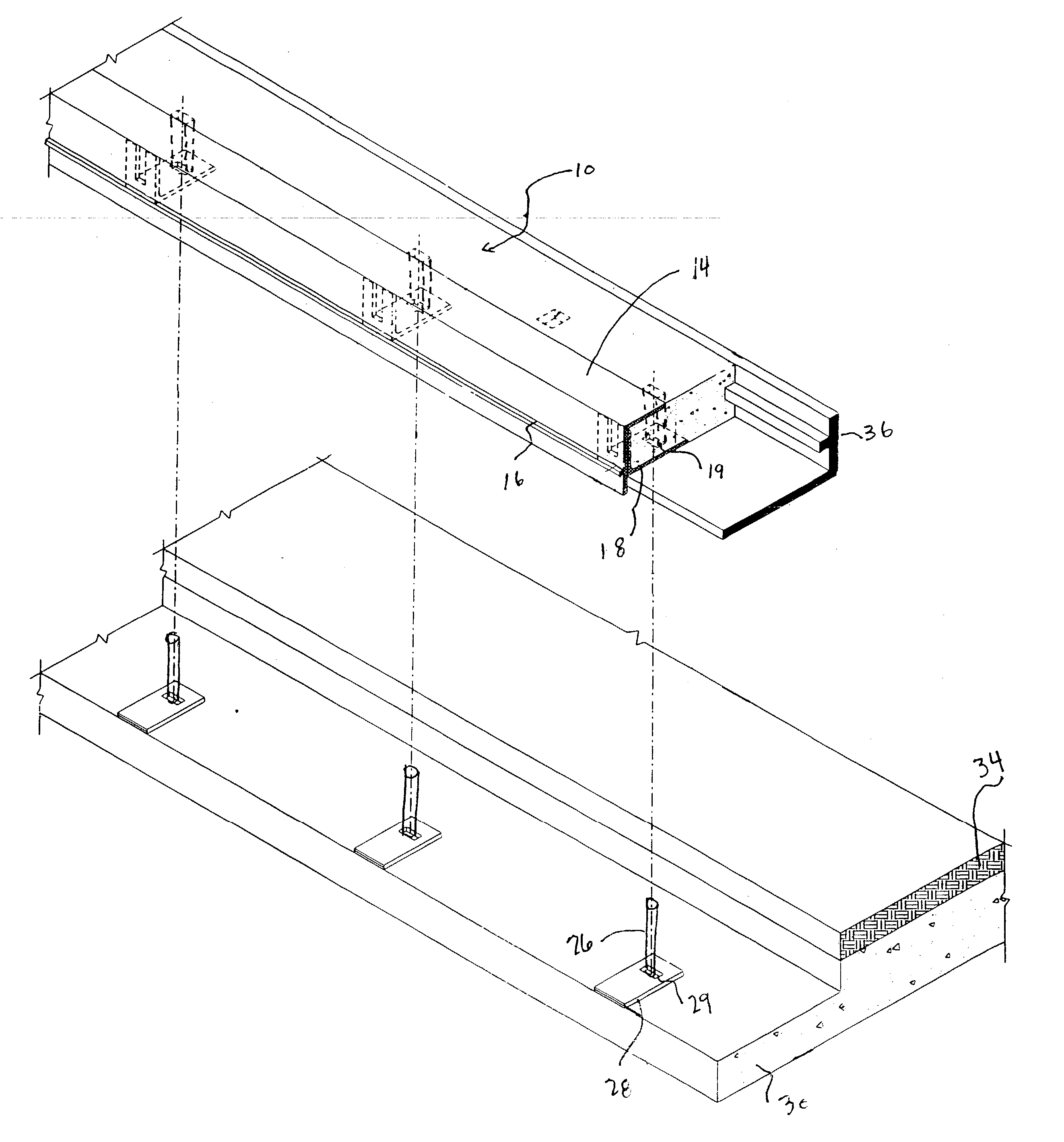

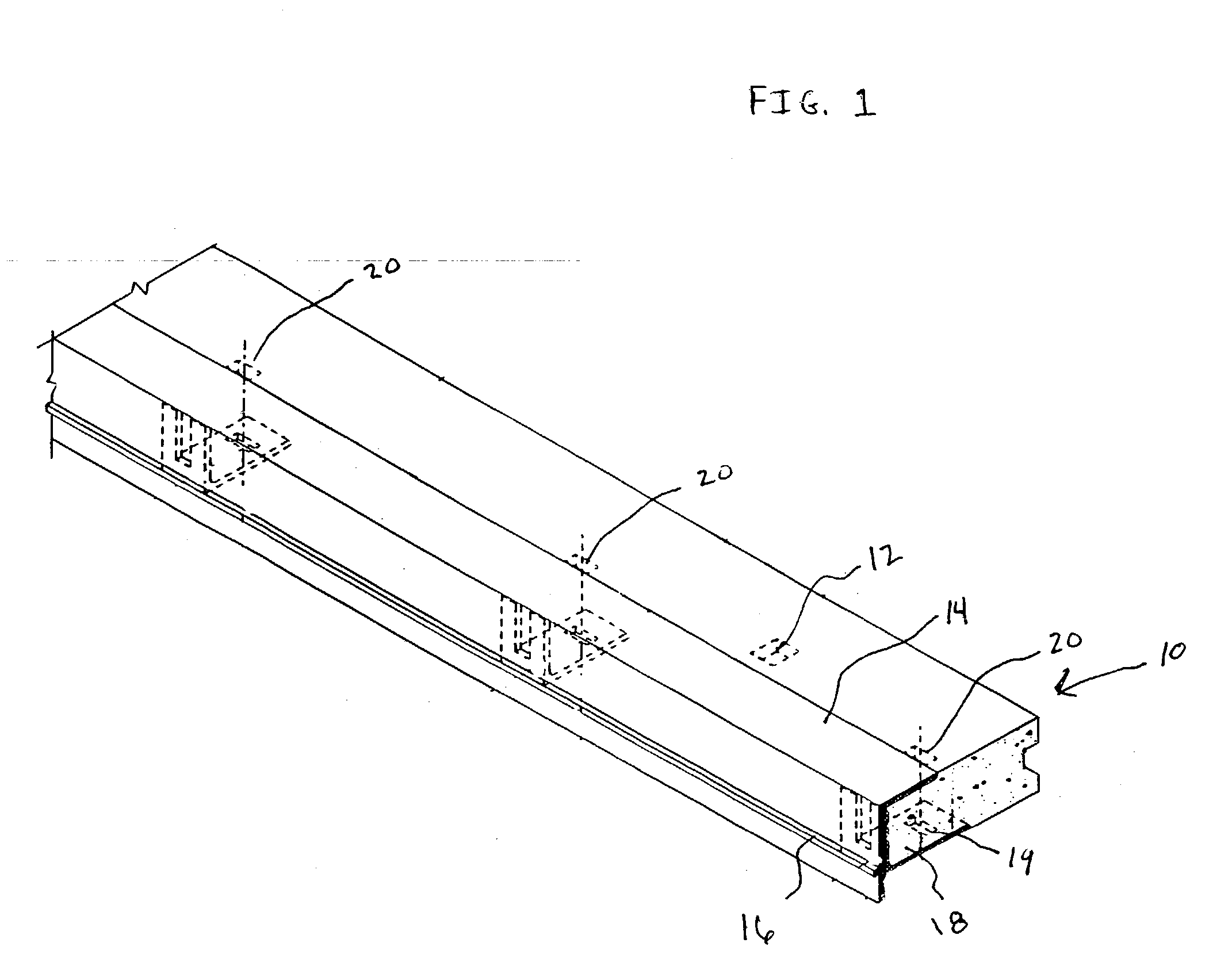

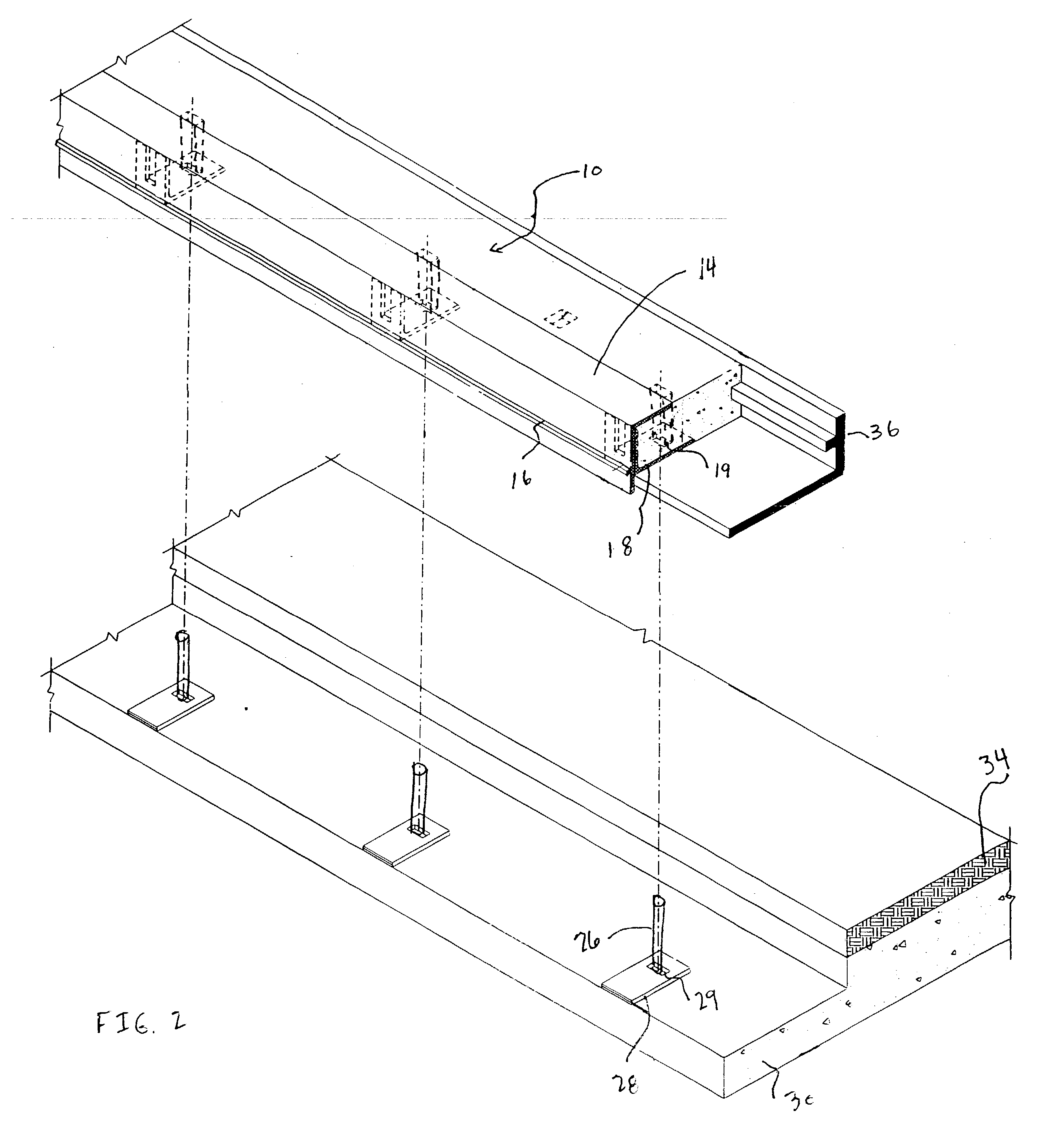

Precast composite header joint system and a method for forming and installing the same

InactiveUS20040154247A1Efficiently formingEffective installationBuilding repairsBridge structural detailsStructural engineeringSolid material

The invention disclosed relates to a precast composite header joint system and method for forming and installing the same in a concrete deck structure. According to the invention, the header is cast and cured before being positioned and secured in a recess formed in one of the concrete slabs. A viscous bonding agent is then poured into the void spaces between the header and the concrete slab recess. The bonding agent cures and forms a solid material which fills all of the space between the header and the concrete slab recess. Adjacent headers installed in opposing concrete slab recesses are coupled together by a joint to provide a continuous deck structure.

Owner:BELLINO JR FR

Powder compression molding machine and apparatus for continuous production of powder compression molded item using the machine

ActiveUS7883330B2High porositySatisfactory fabricationConfectioneryPharmaceutical product form changePorosityCompression molding

A powder compression molding machine is configured such that a plurality of lower and upper punches 61, 41 are allowed to enter a plurality of through-die holes 31 provided in first and second molding die sections 32, 33 of a slide plate 3 in a compression molding zone 21 to compressively mold powder and the slide plate 3 is slid to push out compacts downward and collect them in compact discharge zones 22a, 22b. Even when powder is compressively molded at a low compression force into solids having high porosity, compacts can satisfactorily be molded and collected without crumblingness, the compacts having sufficient high porosity and being dissolvable in water or the like.

Owner:QUALICAPS CO LTD +1

Lightweight high-strength inorganic shaving board and preparation method thereof

InactiveCN108608549AHigh mechanical strengthLow densityDomestic articlesFlat articlesWood shavingsAdhesive

The invention discloses a lightweight high-strength inorganic shaving board. The lightweight high-strength inorganic shaving board is prepared by mixing at least wood or non-wood shavings, an inorganic adhesive and sponge particles in the weight ratio of (40 to 60) to (100 to 120) to (1 to 3). A preparation method of the lightweight high-strength inorganic shaving board approximately comprises thefollowing steps: spraying the inorganic adhesive in the surfaces of the sponge particles and mixing uniformly; adding the wood or non-wood shavings and mixing uniformly; paving a mixture into a plateblank, and performing hot pressing to obtain a semi-finished product; and drying, edging and performing sanding treatment to obtain the lightweight high-strength inorganic shaving board after the semi-finished product is stacked. According to the lightweight high-strength inorganic shaving board disclosed by the invention, the application uniformity of the inorganic adhesive is effectively improved, and the density of the inorganic shaving board is effectively reduced to 0.8 to 1.0 g / m<3>, so that the weight of the inorganic shaving board is reduced; and moreover, the lightweight high-strength inorganic shaving board does not release free formaldehyde, and is waterproof, fireproof, high in mechanical strength and suitable to be popularized and applied in furniture production.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

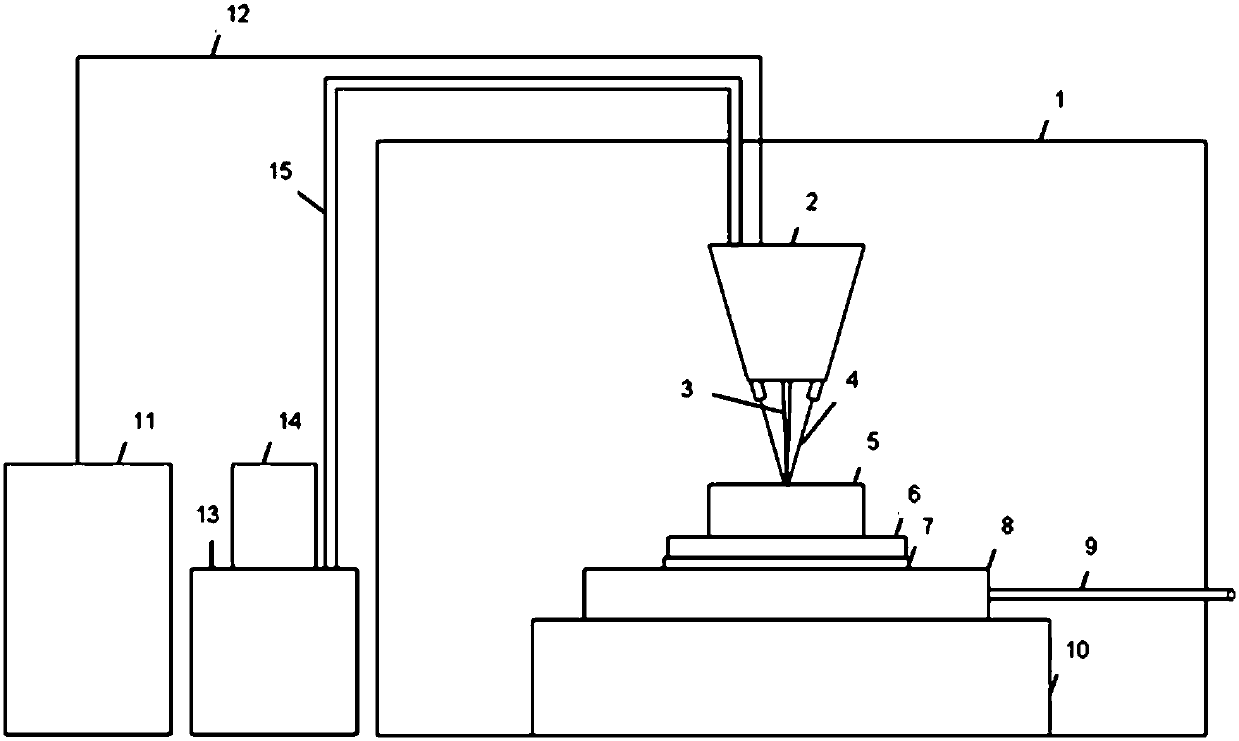

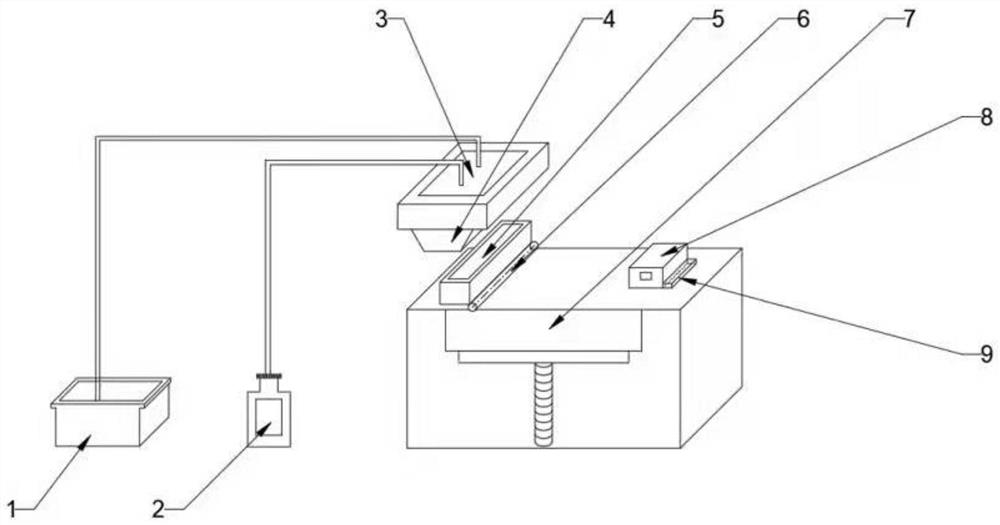

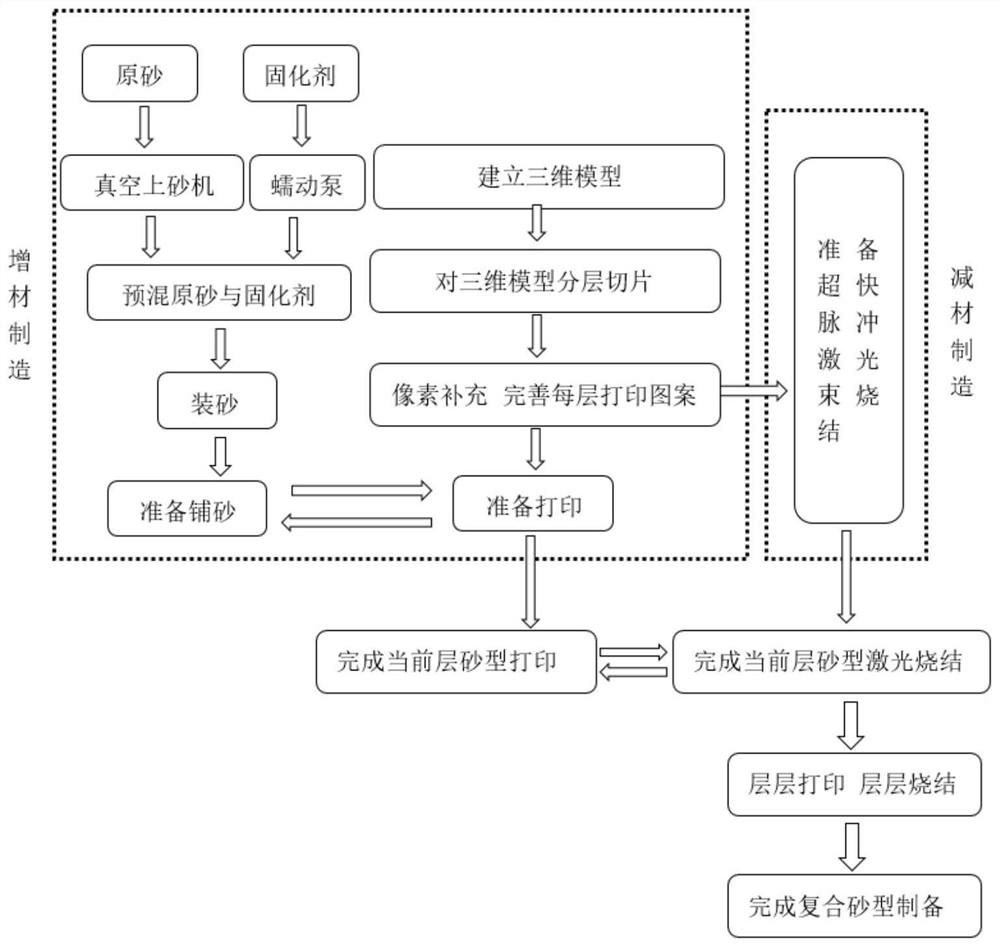

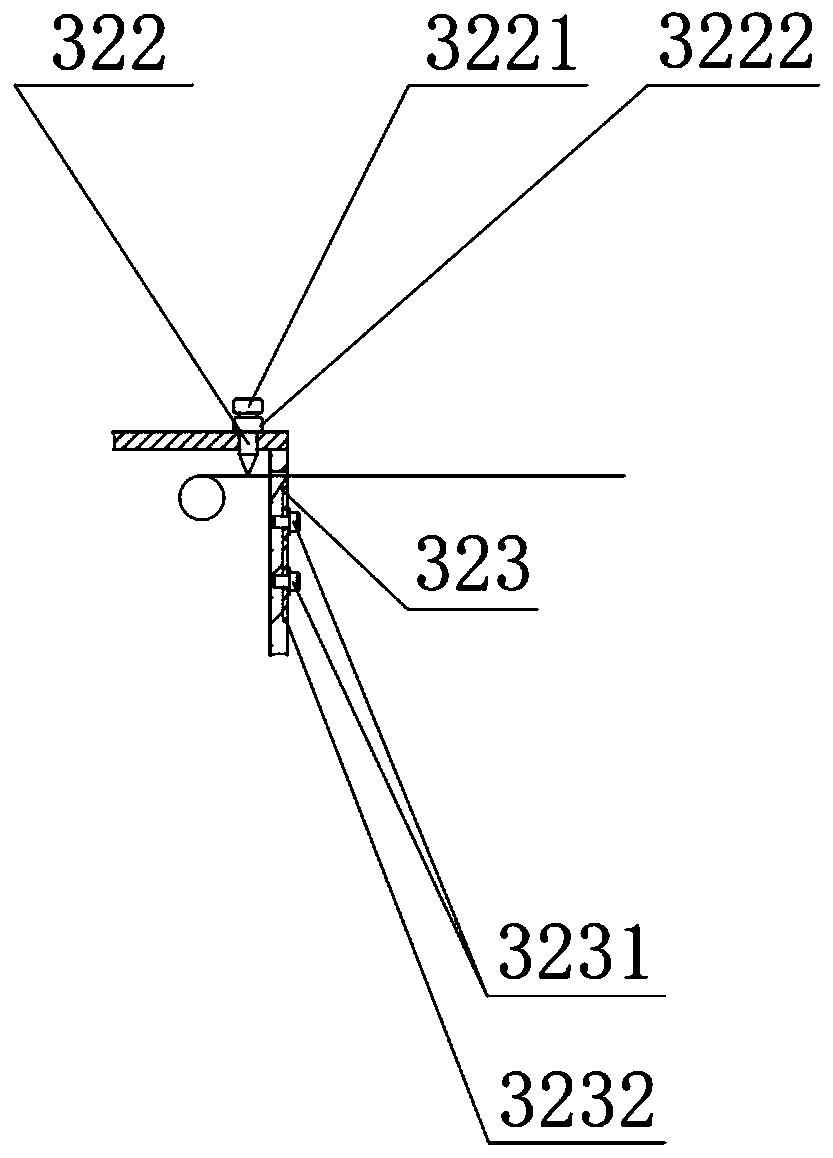

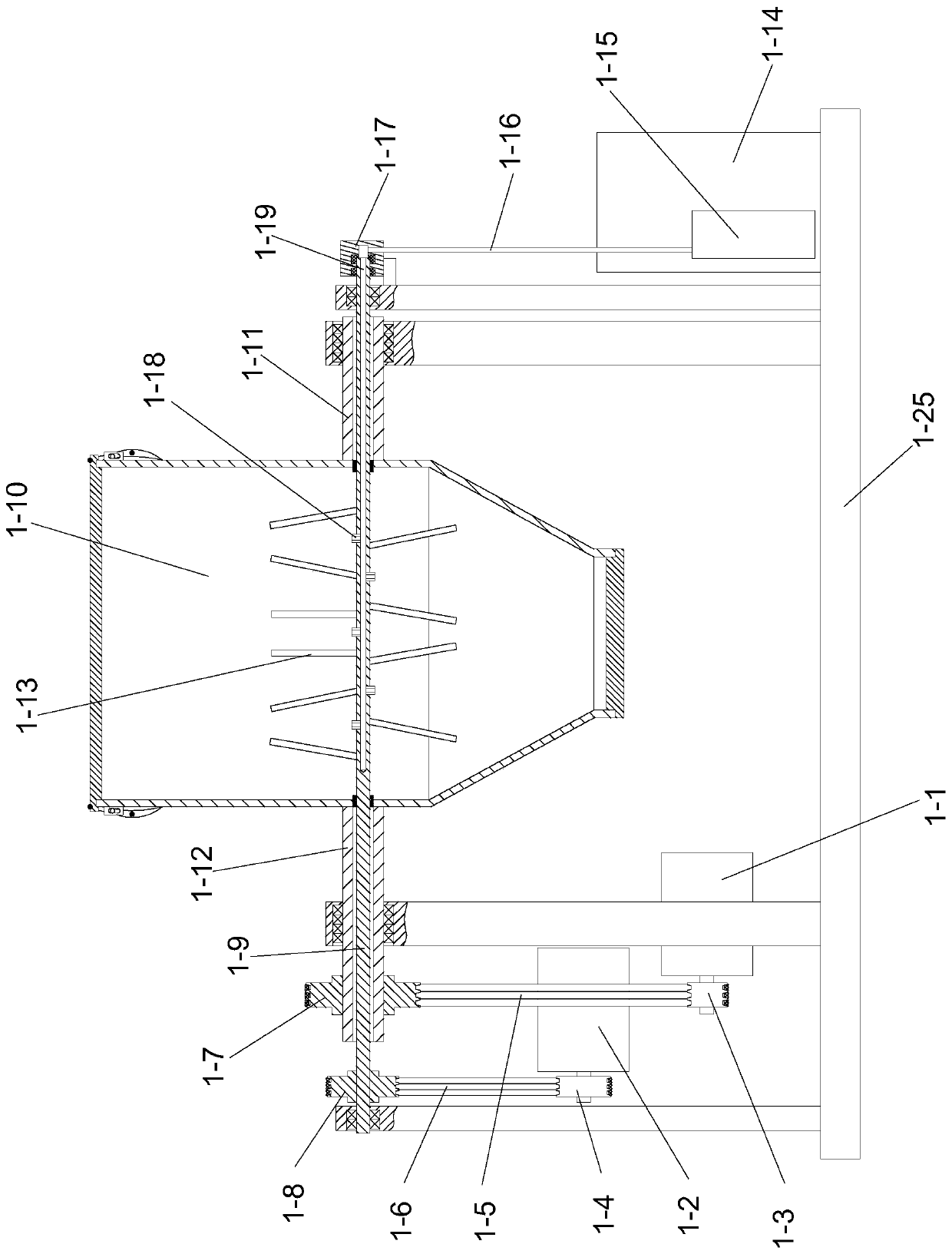

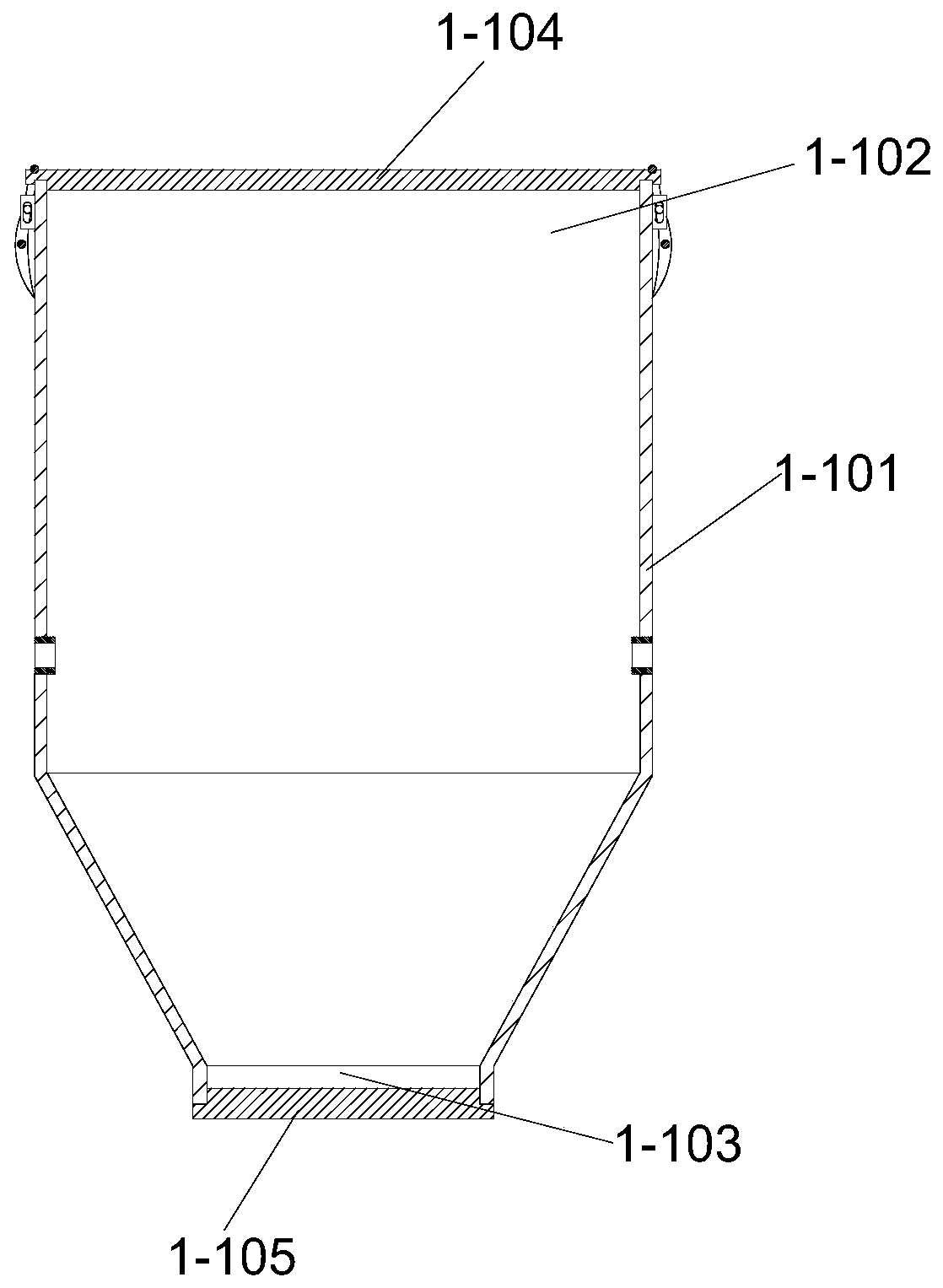

Multi-material composite sand mold forming method and device

PendingCN114289685AMold efficientEffective moldingAdditive manufacturing apparatusFoundry mouldsAdditive layer manufacturingHeating system

The invention belongs to the field of additive manufacturing, and discloses a multi-material composite sand mold forming method and device. The device comprises a molding sand pretreatment system, a vacuum sand feeding system, a multi-material sand paving system, a printing system, an infrared heating system and a lifting platform device. According to the method, additive manufacturing is carried out through the 3D printing (3DP) technology, preparation of the multi-material composite sand mold is achieved by combining the advantages of high flexible manufacturing capacity, high forming quality and high efficiency of the 3D printing (3DP) technology, and the method has great innovation, application, popularization and use values.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Optical component molding apparatus and method thereof

ActiveUS20060024403A1Save energySave spaceConfectioneryFilament manufactureMolding machineEngineering

A molding machine includes a fixed mold and a movable mold. The molding machine is a so-called micro-molding machine which provides less than 1.5 KN of the mold clamping force for clamping the fixed mold and the movable mold. A positional shift length between both molds is preset at ±20 μm or less. Further, cavities are inserted in base molds of both molds respectively. Furthermore, cores are inserted in the cavities. The position of each cavity is adjustable with respect to each associated base mold. The position of each core is also adjustable with respect to each associated cavity. Moreover, the molding machine can simultaneously mold a plurality of optical components.

Owner:KONICA MINOLTA OPTO

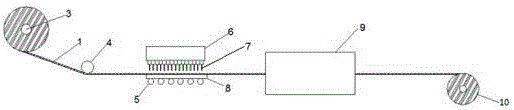

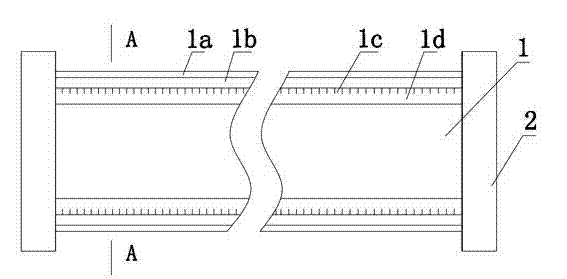

Large-caliber steel-plastic reinforced composite pipe section and reinforced composite pipe forming process

ActiveCN103615606AEffective moldingEnergy saving in molding processFlanged jointsRigid pipesEconomic benefitsHook wire

The invention provides a large-caliber steel-plastic reinforced composite pipe section and belongs to the technical field of reinforced composite pipelines. The large-caliber steel-plastic reinforced composite pipe section is composed of a reinforced composite pipe and flanges at two ends, a central layer of the reinforced composite pipe is a spiral welded steel pipe, the outer wall of the spiral welded steel pipe is provided with a glass reinforced plastic winding layer to form an outer layer of the reinforced composite pipe, and the inner wall of the spiral welded steel pipe is provided with a belt hook wire screen and a rotary-molding coating to form an inner layer of the reinforced composite pipe. A reinforced composite pipe forming process comprises the steps of adopting a spiral welding process to manufacture the spiral welded steel pipe, welding the belt hook wire screen on the inner wall of the steel pipe, adopting a rotary-molding forming device to manufacture the rotary-molding coating and arranging the formed glass reinforced plastic winding layer on the outer surface. The large-caliber steel-plastic reinforced composite pipe section has excellent corrosion resistance performance and light high-strength characteristic and is superior to various currently-used pipelines in the aspects of pressure resistance, corrosion resistance, service life, production cost and social and economic benefits, and high efficiency, energy saving and environmental protection are achieved in the forming process.

Owner:葛介昌

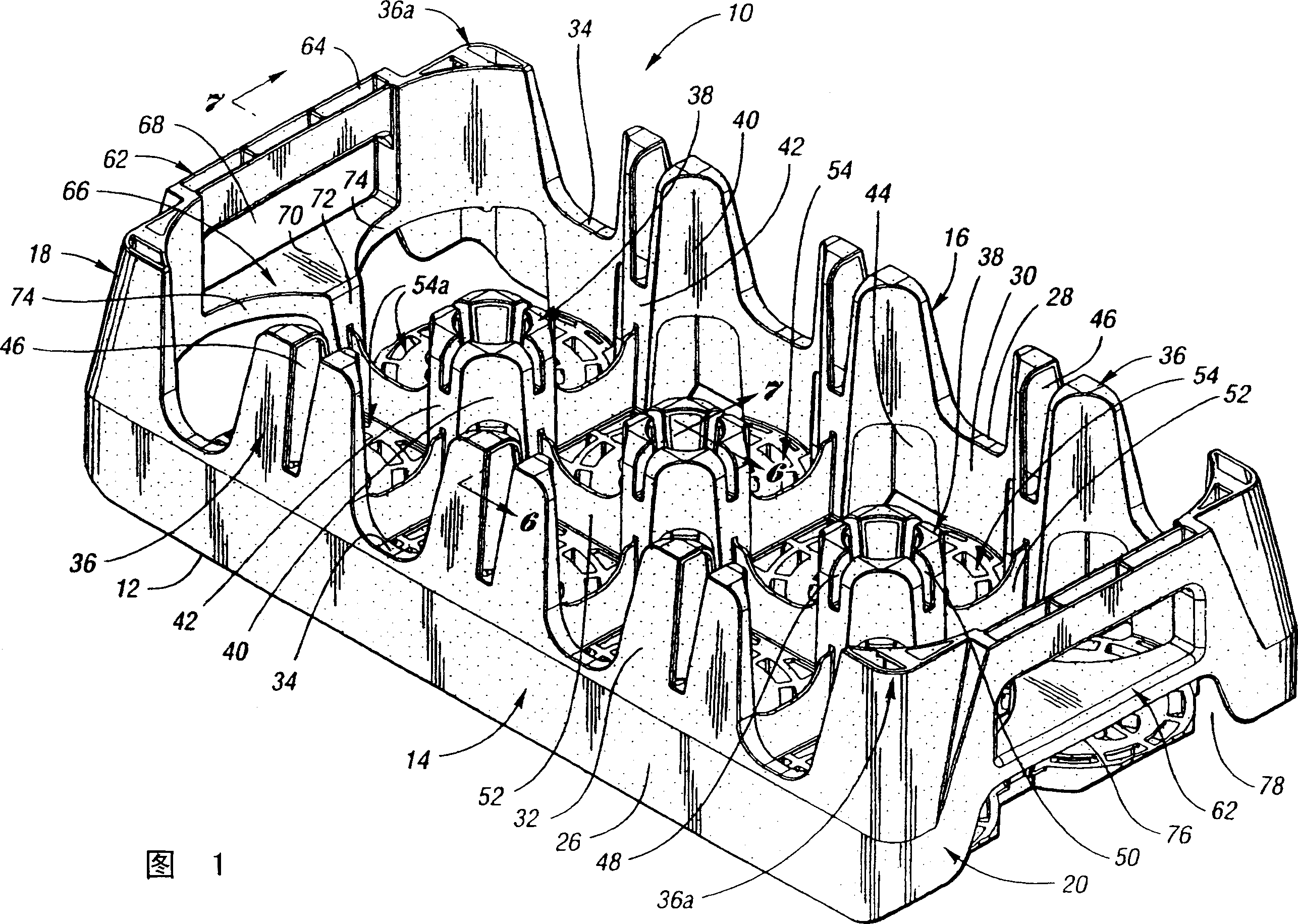

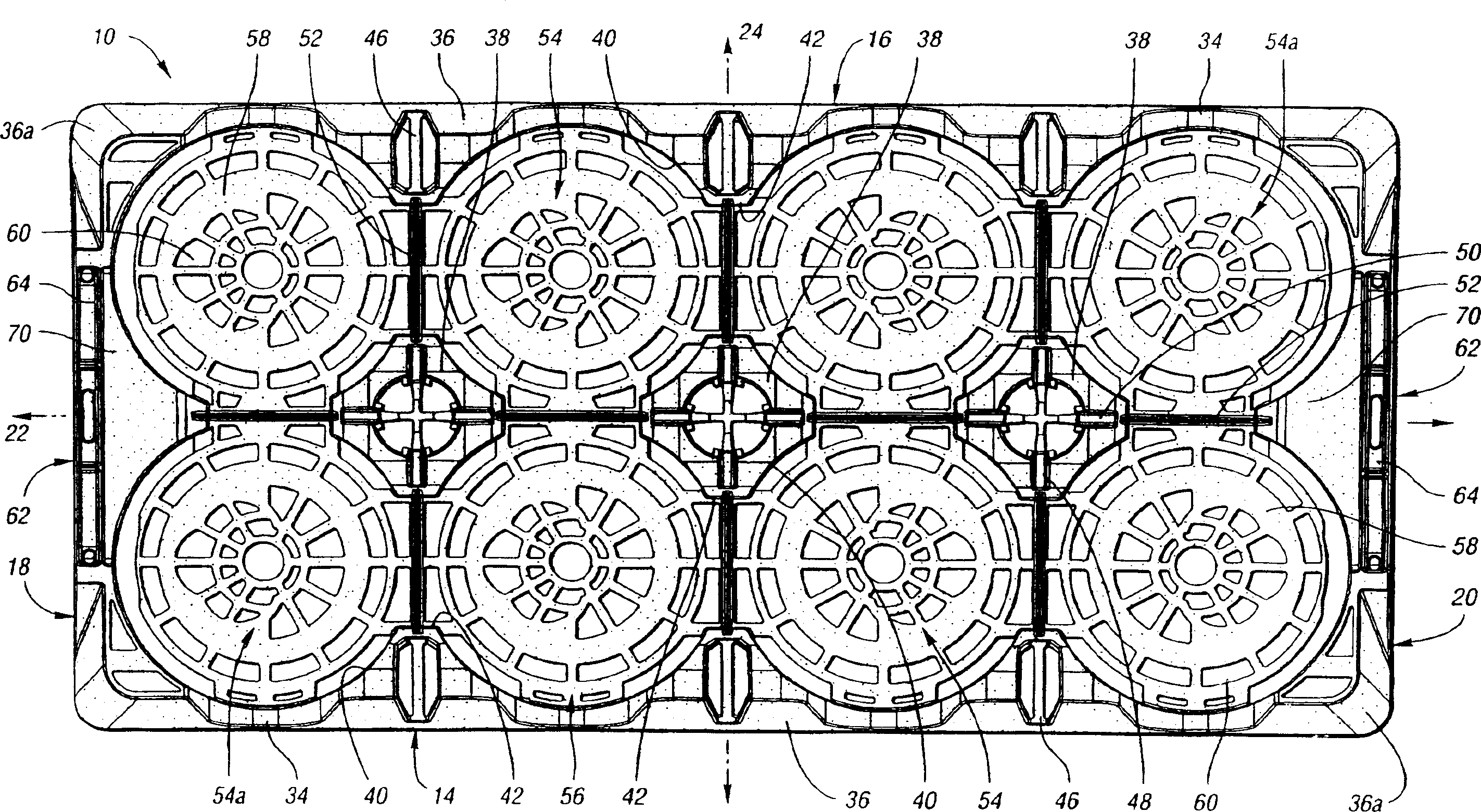

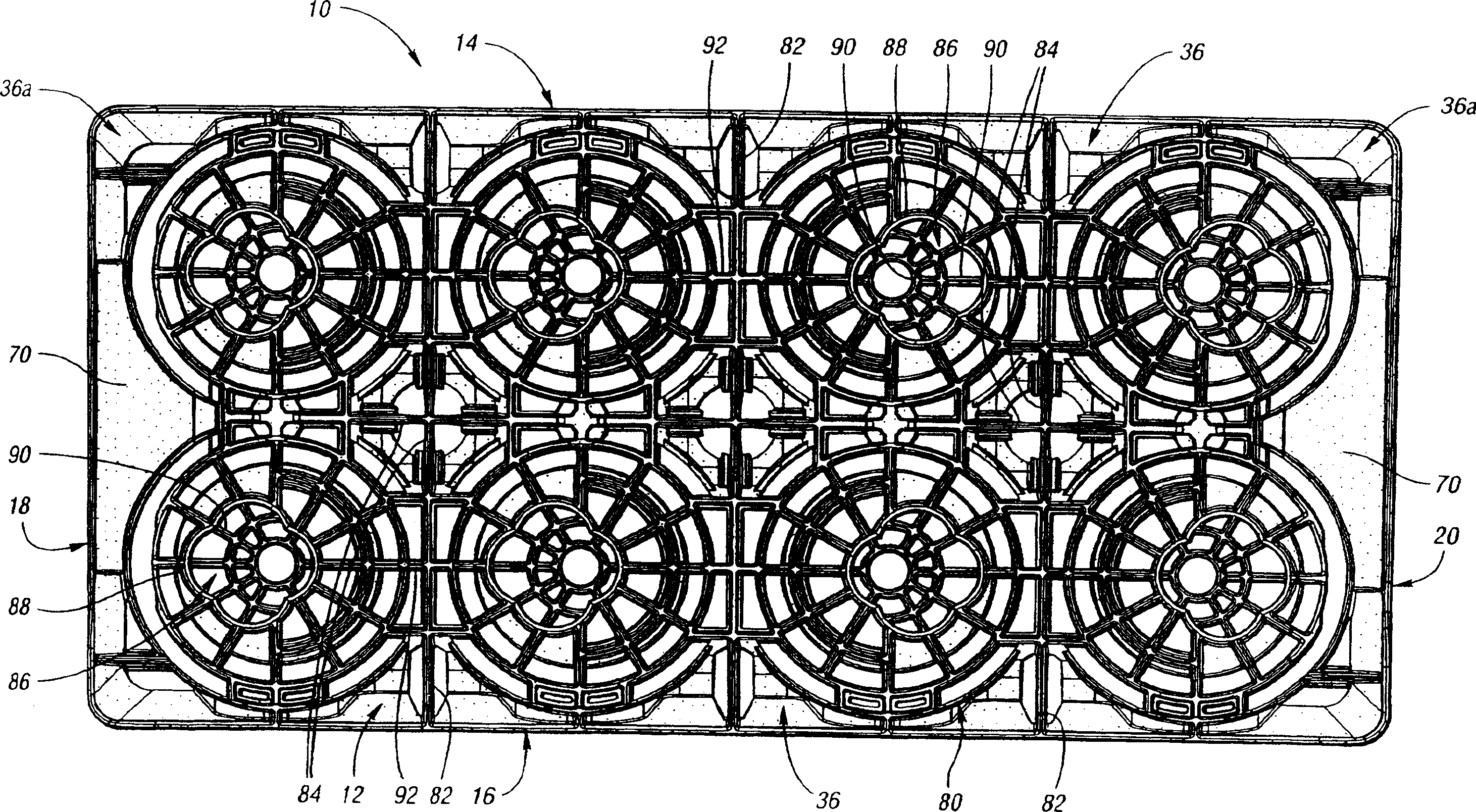

Stackable low depth tray

InactiveCN1547542AWithout compromising structural integrityWithout compromising stabilityPowder deliveryPeptide/protein ingredientsEngineeringBottle

A low depth tray (10) for bottles is provided which includes a first pair of opposed walls (14, 16), a second pair of opposed walls (18, 20) attached to the first pair of opposed walls (14, 16) to form a wall structure, a base (12) attached to the wall structure, and a plurality of interior divider walls (52) extending upwardly from the base (12). At least one member (38) projects upwardly from an interior of the wall structure and is conneected to the divider walls (52), where interior member (38) has a height less than the heigth of the wall structure and less than the height of bottles loaded in the tray. Together, the interior member (38), the base (12), the divider walls (52), and the wall structure define a plurality of bottle retaining pockets (54) which are sized to receive a single bottle therein.

Owner:REHRIG PACIFIC CO INC

Device for preparing carbon fiber thermoplastic dipping strips by water base powder dipping and method thereof

InactiveCN110712383AImprove uniformityPrevent subsidenceBeltsCoatingsMoulding devicePolymer chemistry

Owner:谭洪生

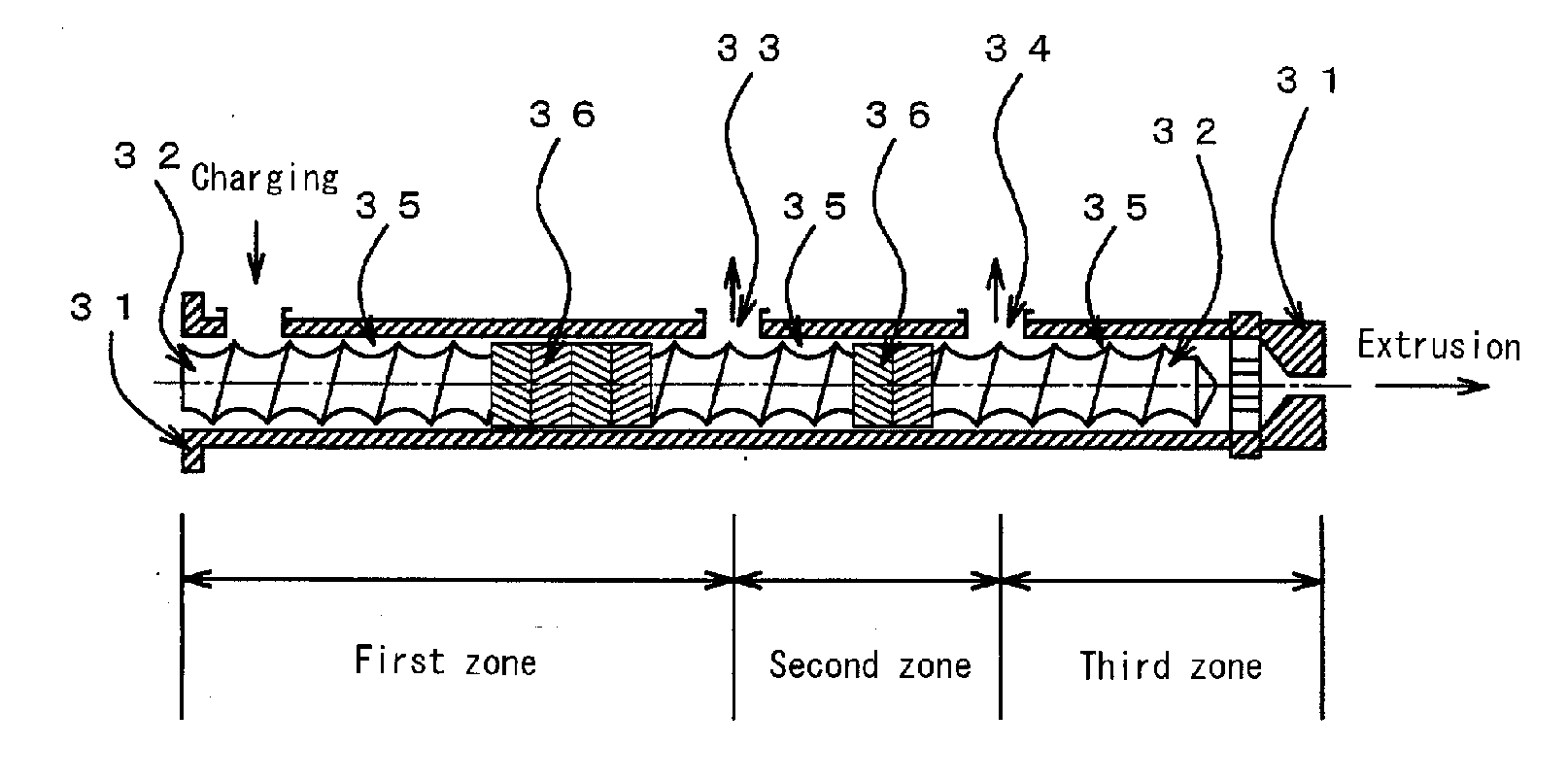

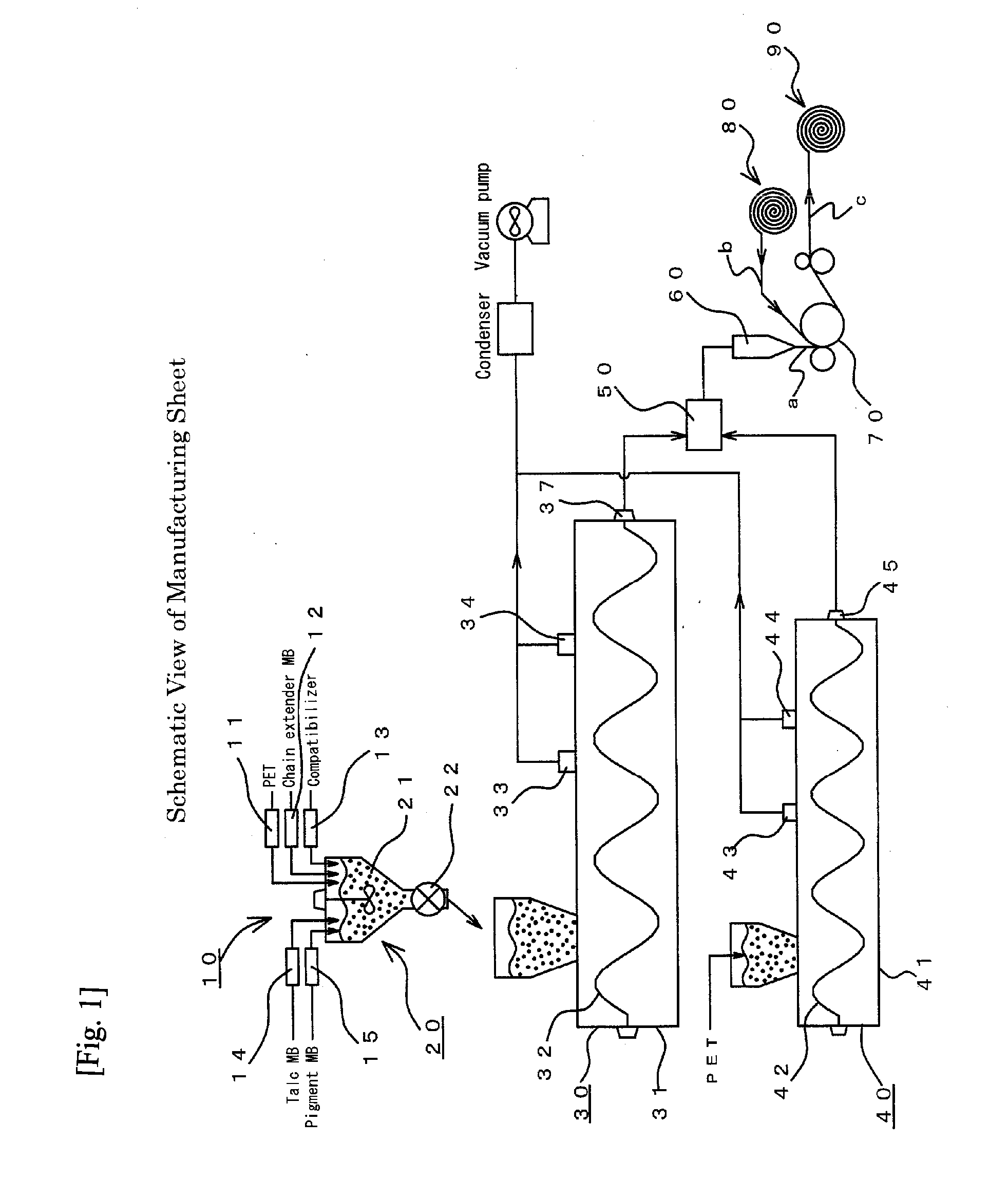

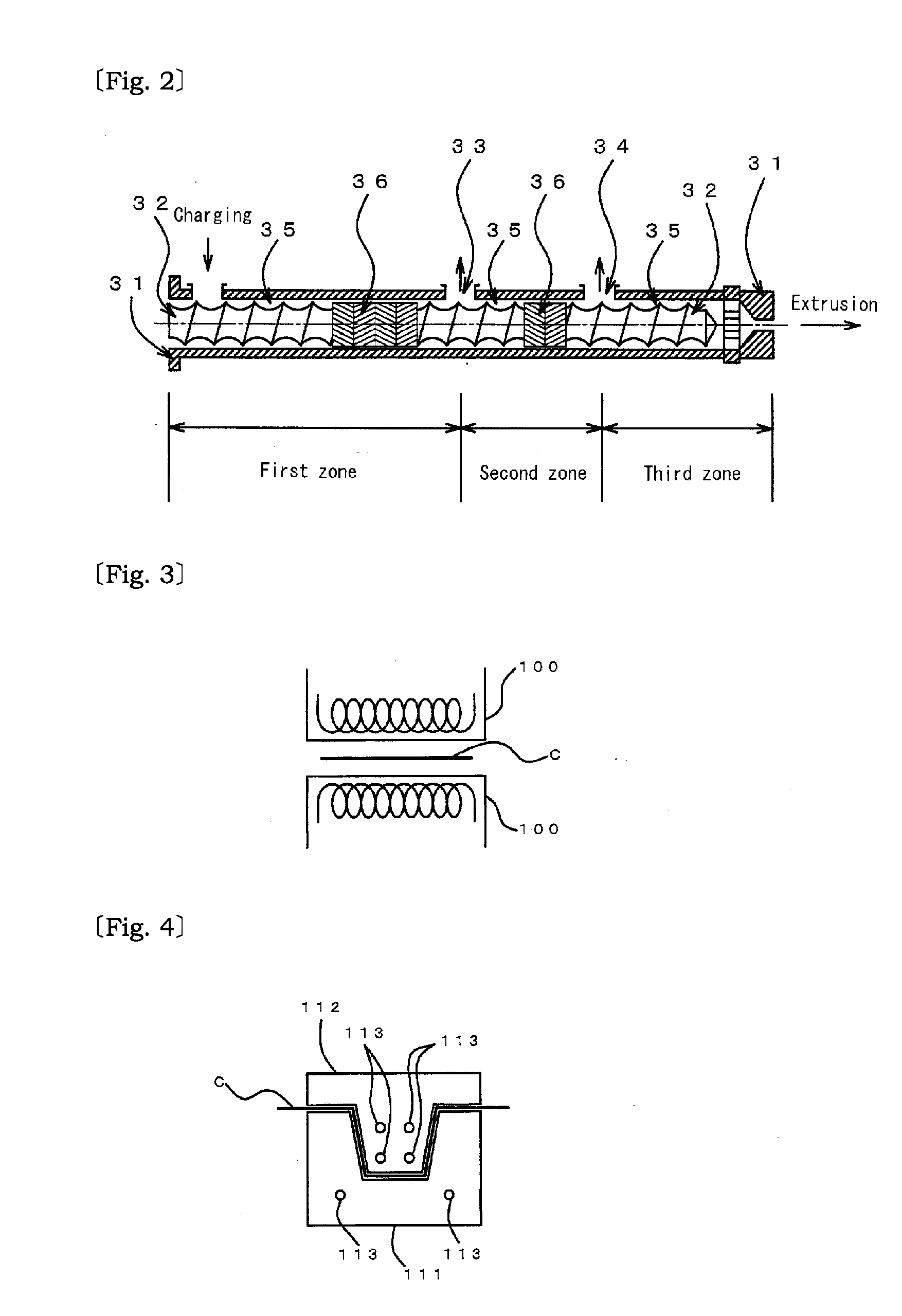

Heat-resistant food container and its manufacturing method

ActiveUS20140339124A1Low melt tensionImprove heat resistanceDomestic cooling apparatusLighting and heating apparatusFiberVacuum pressure

This invention provides a food container which can be manufactured cheaply by using inexpensive general PET resin or further inexpensive PET resin for fiber or recovered PET flakes, and nevertheless, which has a high heat resistance up to 250° C., and the container is obtained by adding a chain extender and a compatibilizer and talc to PET resin, charging the mixture into an extruder 30 having two or more vent holes, degassing under a condition where the PET resin is melted with heating by sucking at a high vacuum of −99.99 kPa or lower from the vent holes 33, 34, thereafter, forming a sheet by extrusion molding, pressure-forming with vacuum the sheet by a thermoforming machine, forming the container by keeping in a mold at 100-220° C. The container has a total of the content of crystal portion represented by the following formula and the content of talc being 25% by weight or more.

Owner:NAKAMOTO PAKKUSU

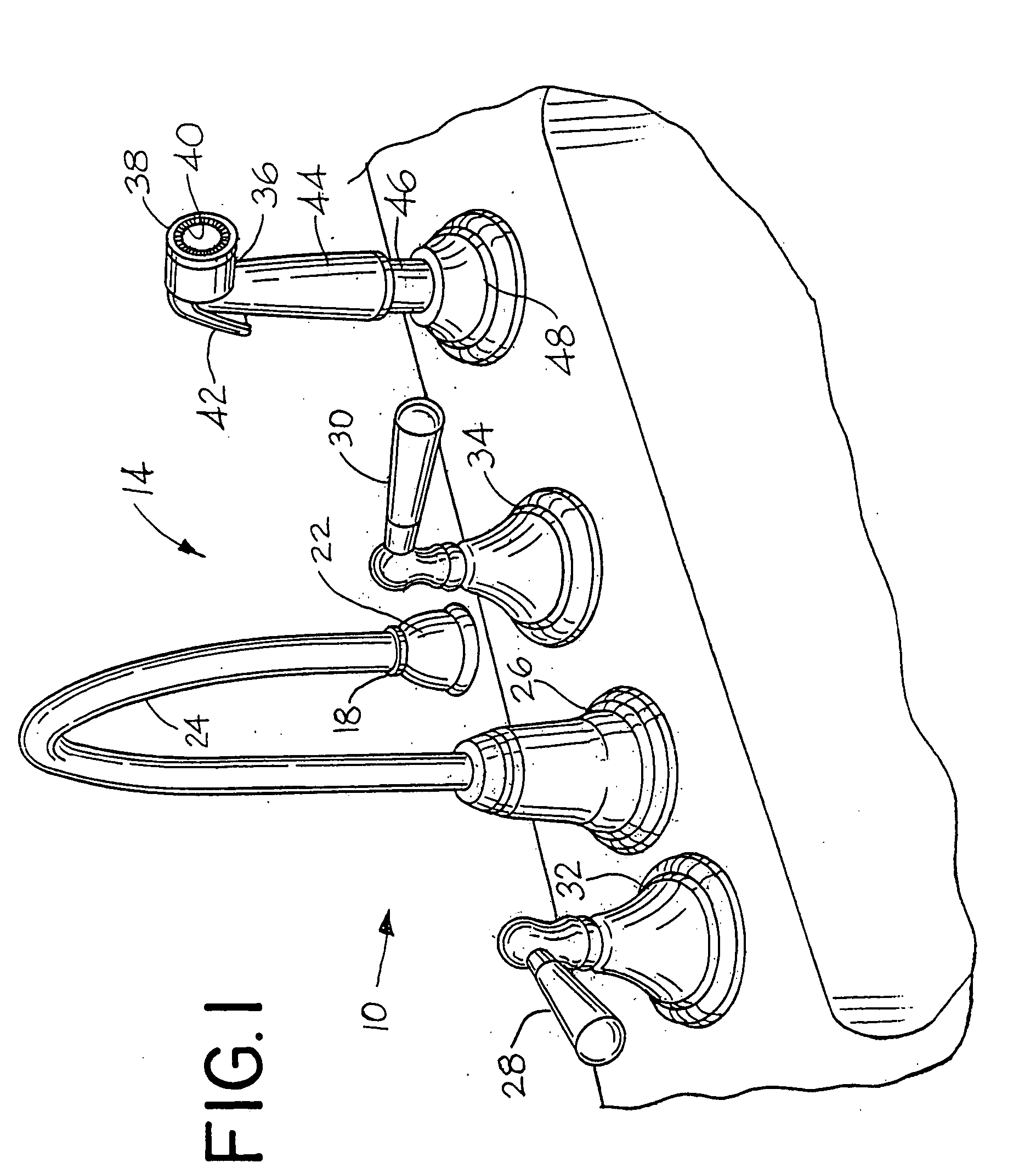

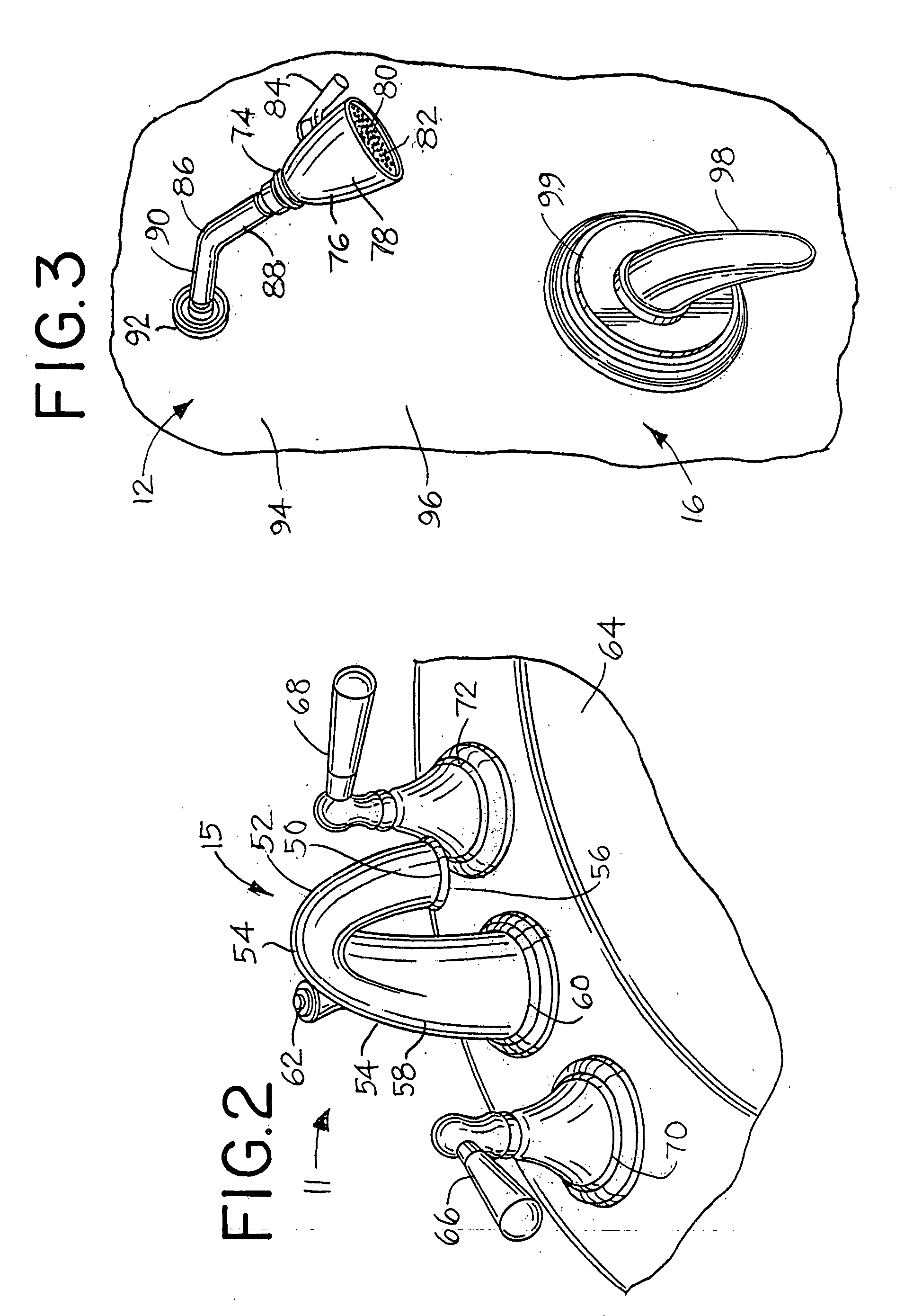

Plastic materials with metal weight simulation

Improved water taps, showerheads, faucets and other plumbing supplies and fixtures can be effectively molded with plastic materials with metal weight simulation. Preferably, the plastic materials comprise polybutylene terephalate (PBT) and acrylonitrile butadiene styrene (ABS).

Owner:JING MEI IND HLDG LTD

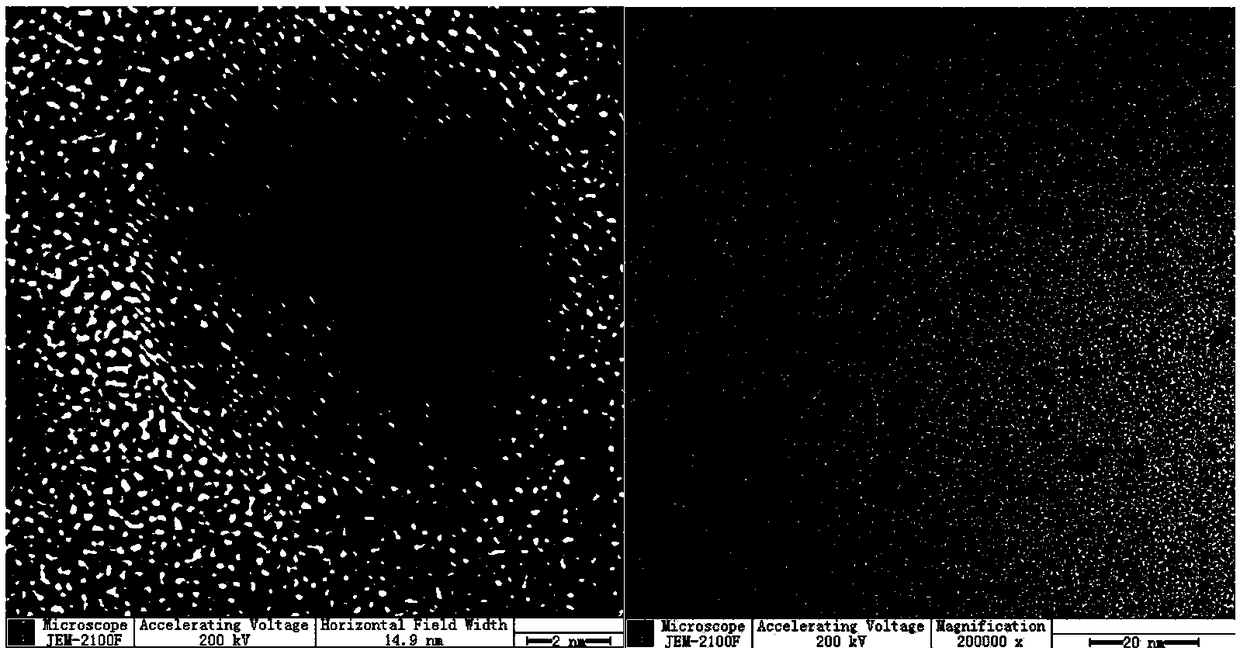

Loaded integral catalyst for catalytic oxidation of formaldehyde and preparation method thereof

InactiveCN108404949AEvenly distributedNo reunionGas treatmentDispersed particle separationNanoparticleSolid reaction

The invention discloses a loaded integral catalyst for catalytic oxidation of formaldehyde and a preparation method thereof. The catalyst is of a mesoporous-macroporous hierarchical-pore structure, and a block graphene integral carrier is good in mechanical performance and less prone to being broken; through an electrolytic deposition method, Pt nanoparticles are uniformly loaded on the surface ofthe carrier, then K2CO3 is used to modify Pt, so that proportion of Pt(O) / Pt(O)+PtOx is increased, low-temperature catalytic activity of the catalyst can be lowered effectively, and catalytic activity of the catalyst is far higher than that of similar powdery catalysts; through a hydrothermal method at temperature higher than 300 DEG C, the forming problem of graphene is solved effectively, and mass transfer rate of the catalyst in gaseous-solid phase reaction is increased.

Owner:XI'AN PETROLEUM UNIVERSITY

Device for electrohydraulic forming of sheet metal

A device for electrohydraulic forming of sheet metal includes an upper die part having a die plate, and a lower die part on which an electrode frame is disposed. The frame accommodates at least two electrodes, and a metal sheet can be clamped in place between the die plate and the electrode frame in fluid-tight manner. At least one potential-free bridge element is disposed between at least two electrodes, within the electrode frame.

Owner:THEWES REINHOLD

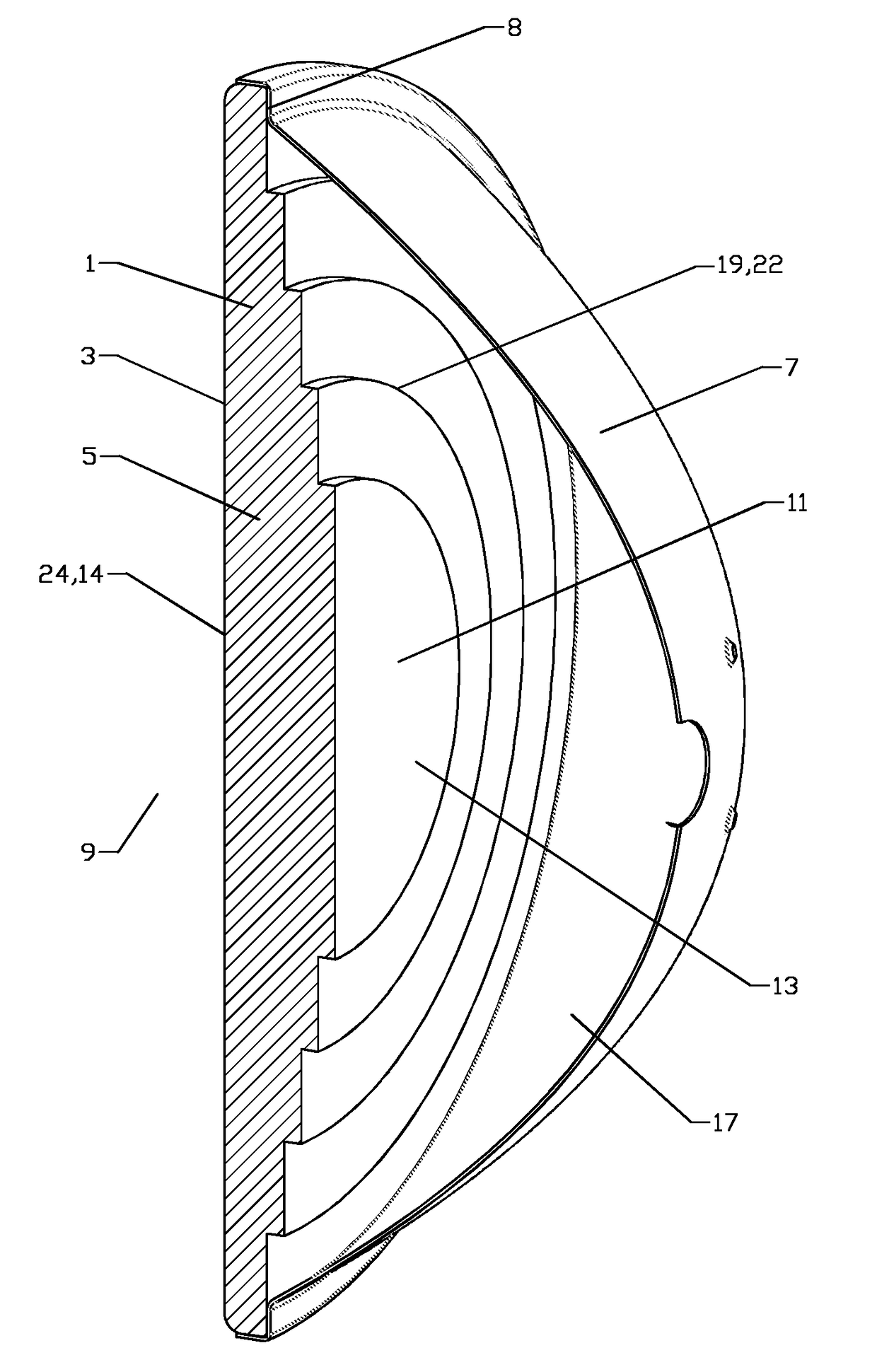

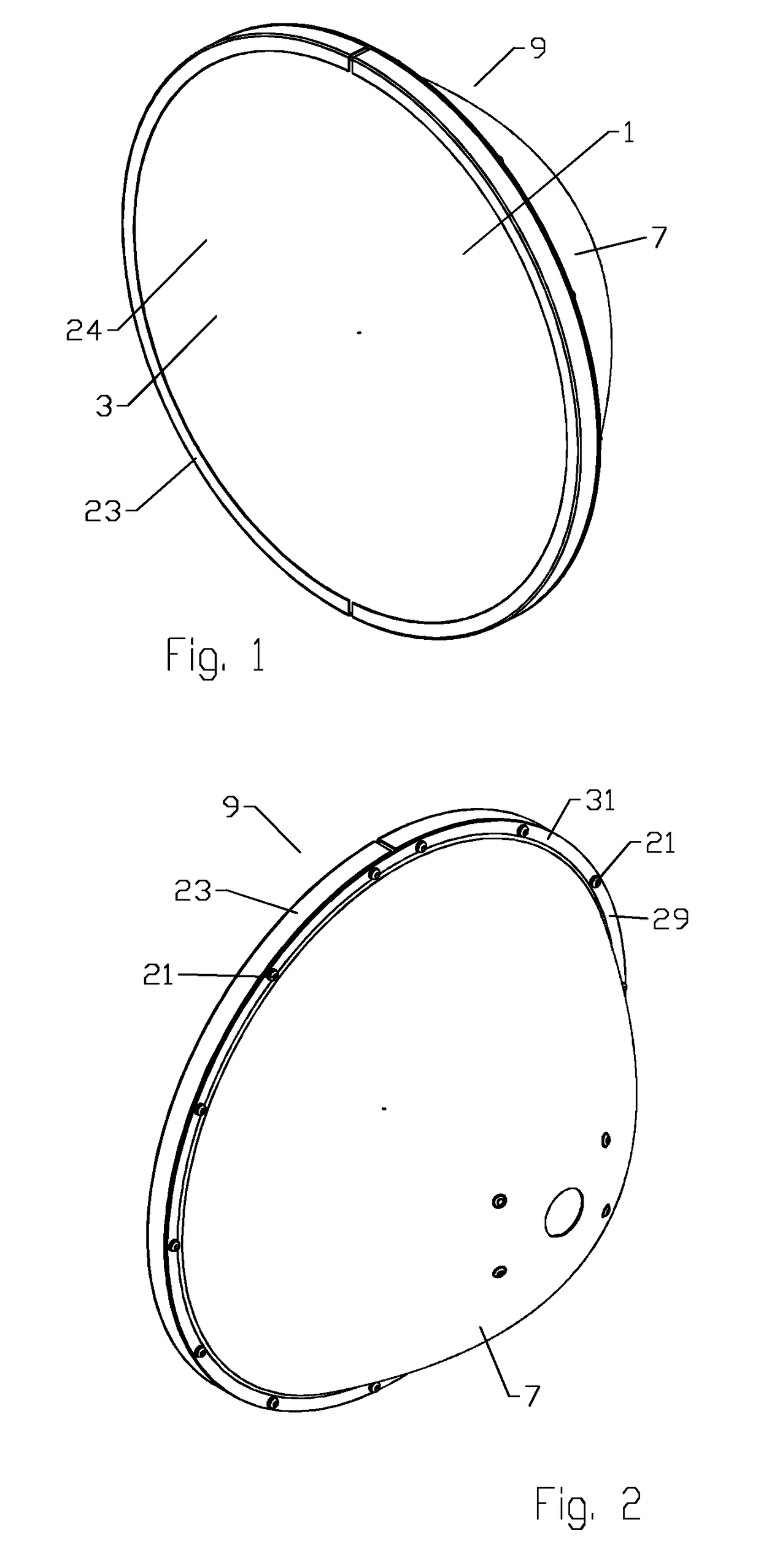

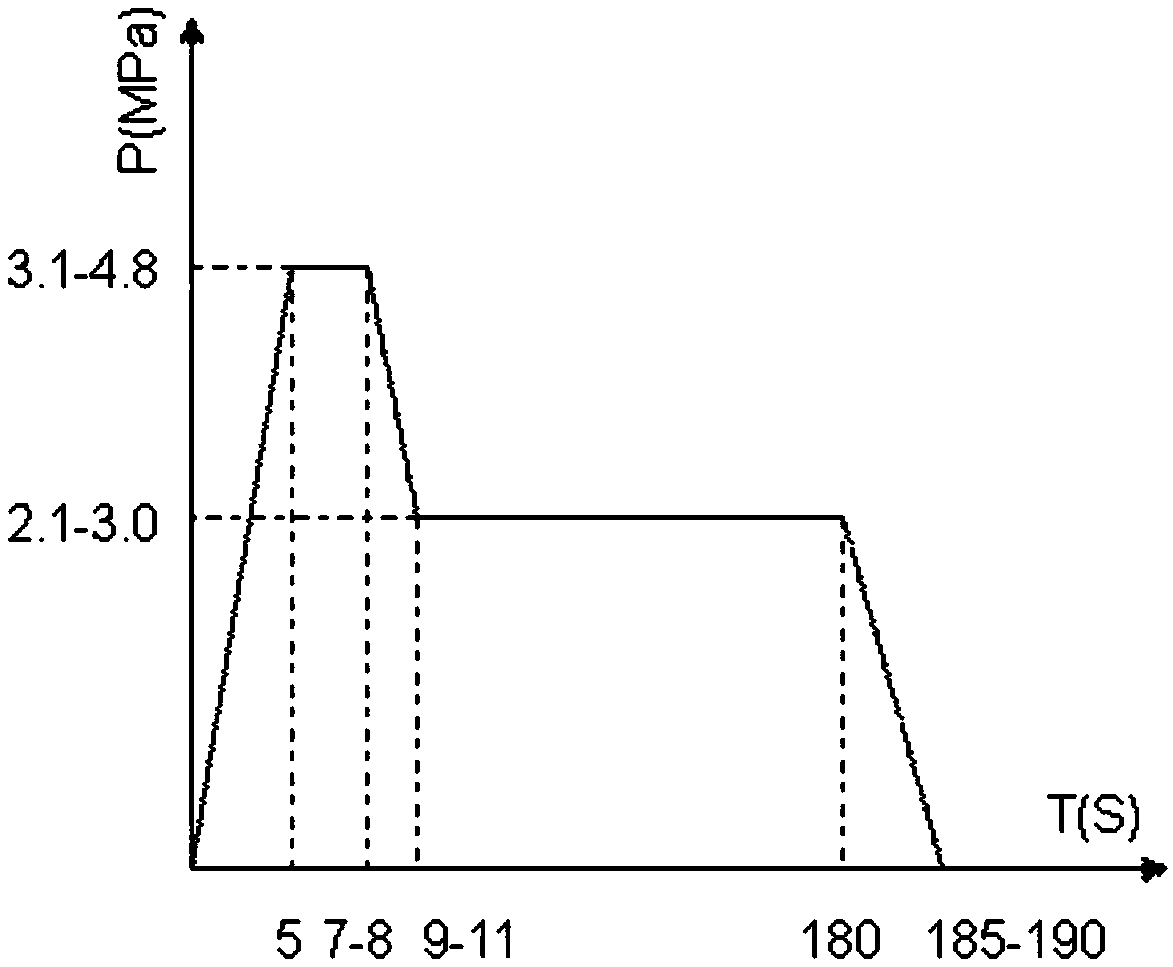

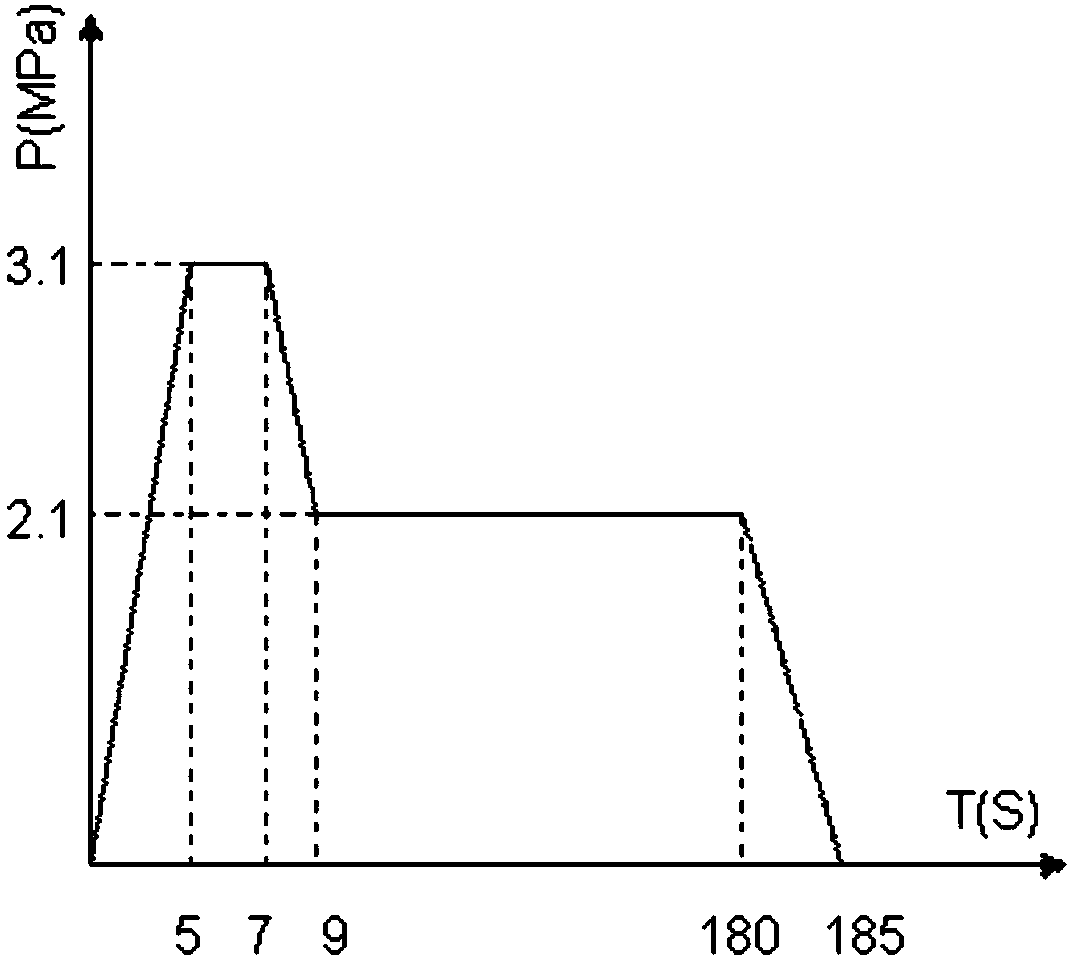

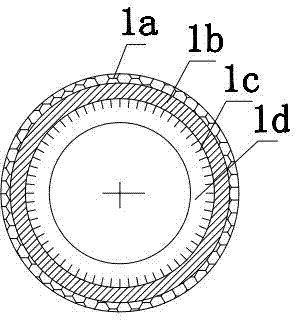

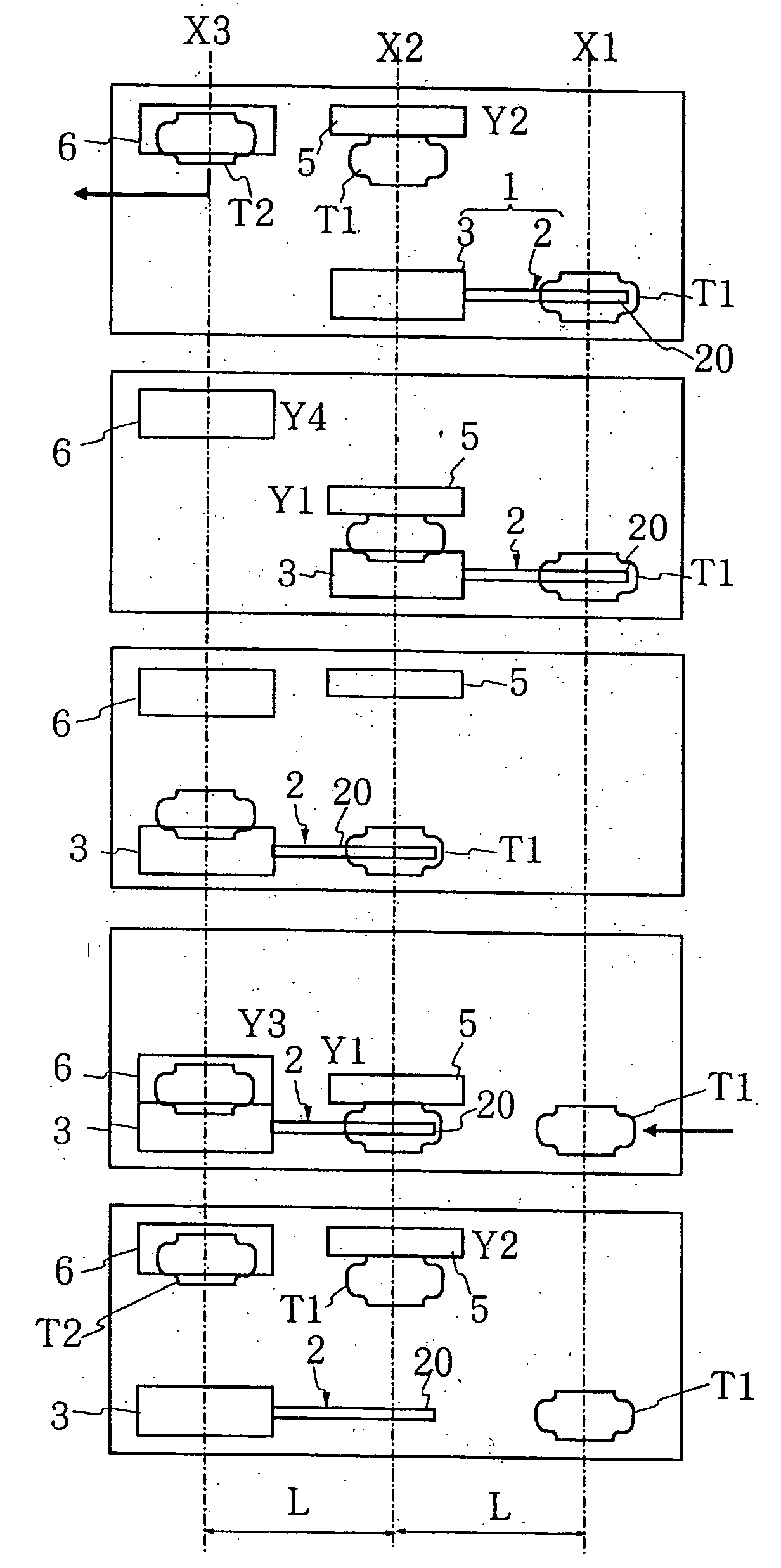

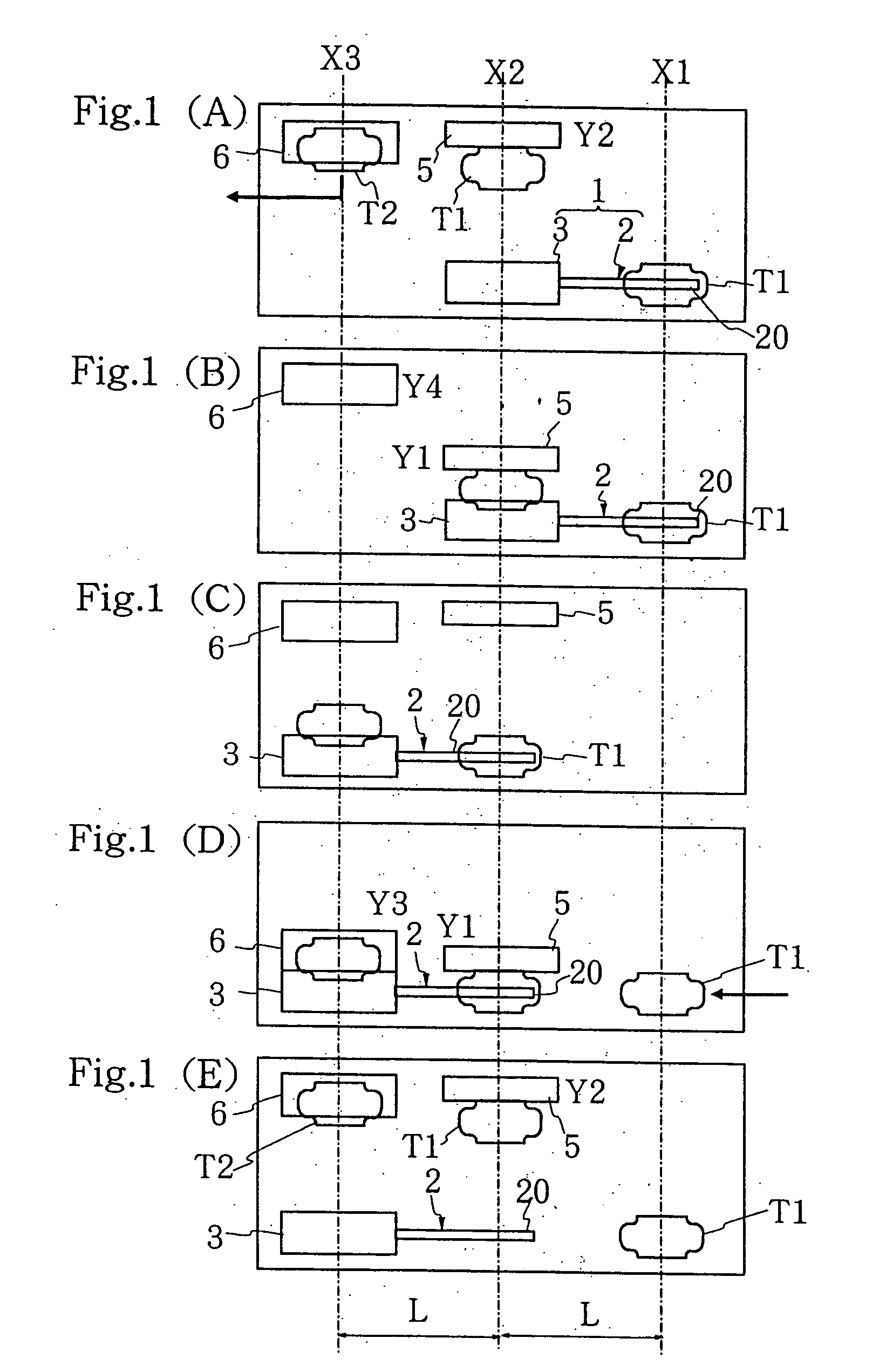

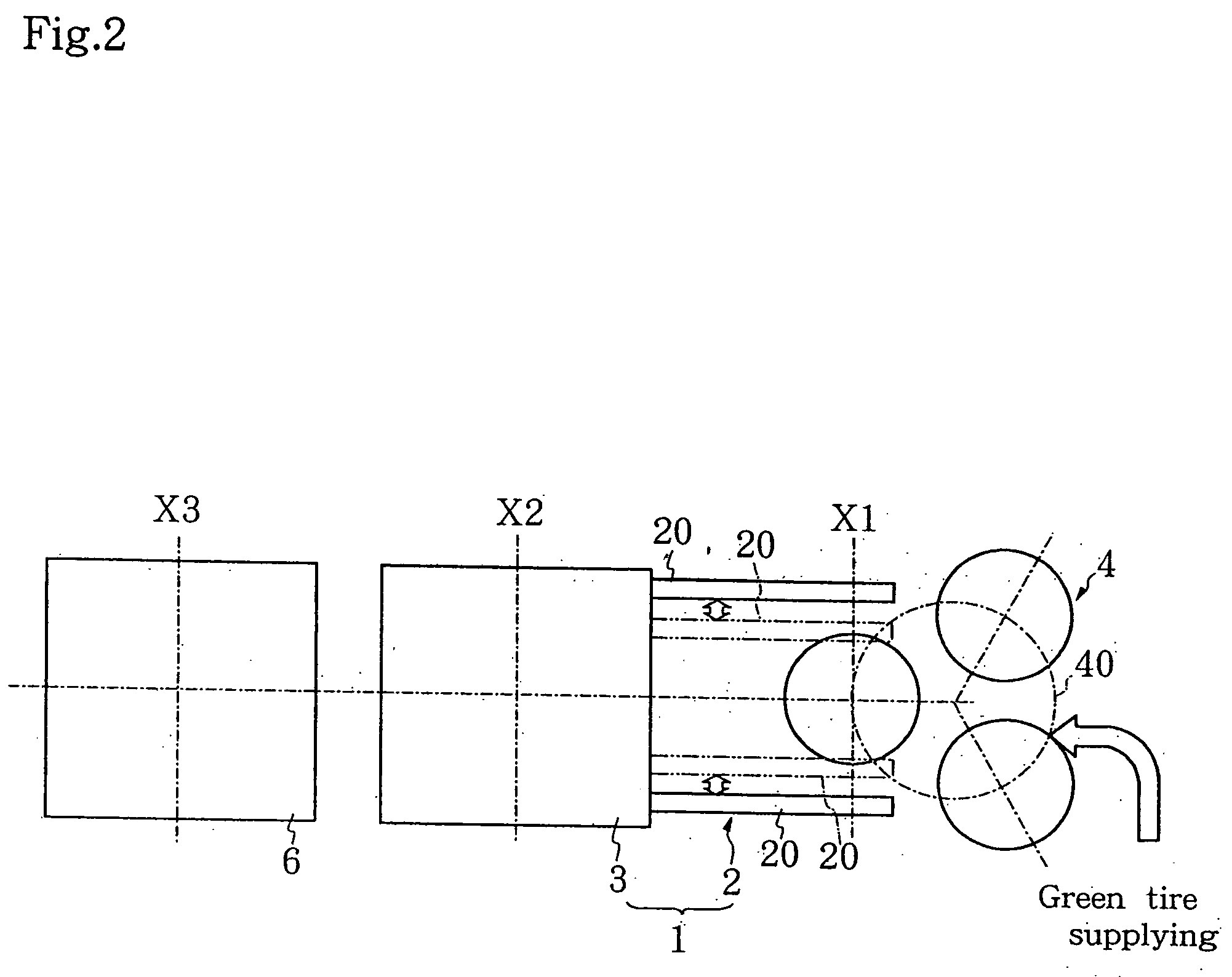

Tire vulcanizing apparatus

InactiveUS20050260294A1Reduce time lossEffective moldingTyresBeltsReciprocating motionAutomotive engineering

The invention provide a tire vulcanizing apparatus which can reduce a time loss and can efficiently vulcanize and mold employing a tire loading apparatus for positively loading the green tire, and forming a moving unit in which the tire loading apparatus and the lower mold are integrally connected. The tire vulcanizing apparatus is provided with a tire loading apparatus (2) which loads a green tire (T1) at a tire loading position (X1) and moves the green tire to a tire supplying position (X2), a tire elevating apparatus (5) which elevates at the tire supplying position so as to receive the green tire on the tire loading apparatus and sets the green tire to a lower mold (3), and an upper mold (6) which elevates at a tire vulcanizing position (X3) so as to vulcanize and mold the green tire with respect to the lower mold, the tire loading apparatus and the lower mold are simultaneously reciprocated between the respective positions by reciprocating a moving unit (1) in which the tire loading apparatus and the lower mold are integrally connected is formed.

Owner:ICHIMARU GIKEN

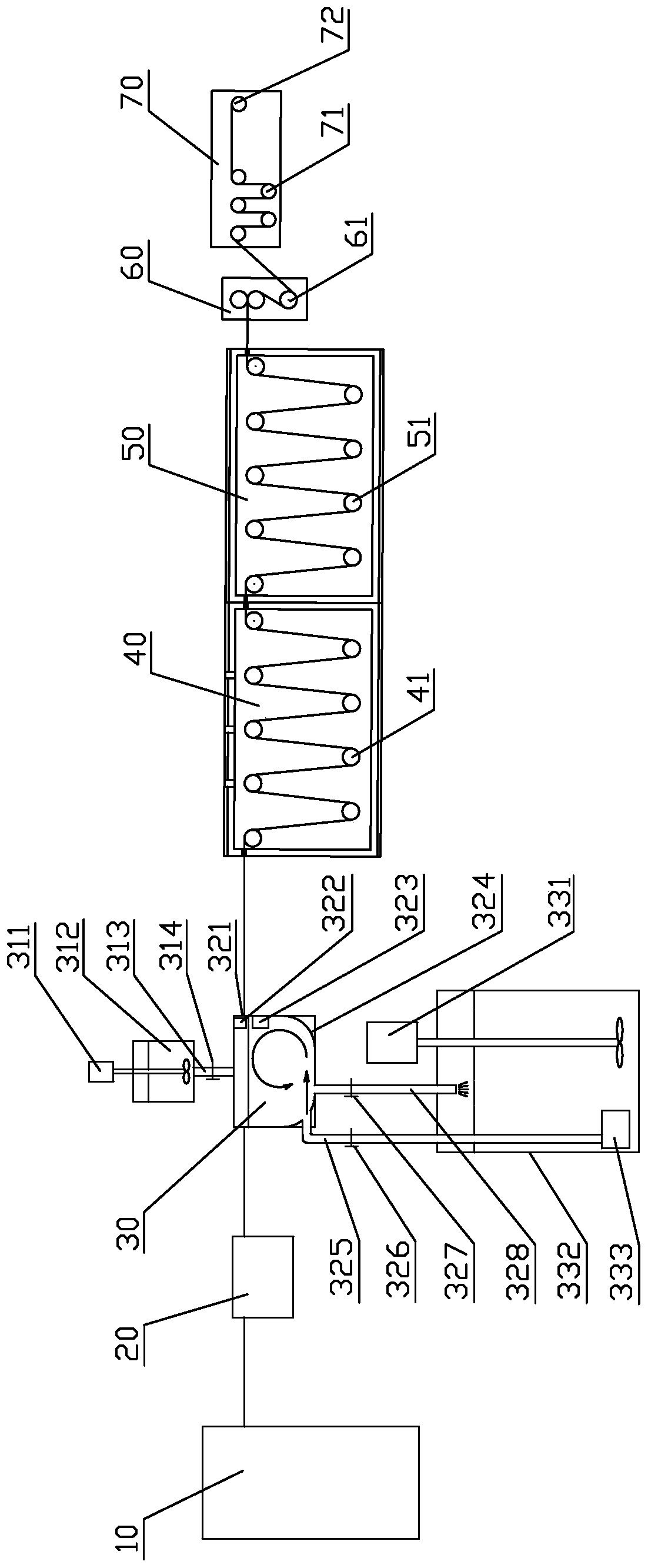

System and method of rapidly manufacturing coal-like rock similar material test piece

PendingCN109738267AEfficient demouldingEfficient mixingPreparing sample for investigationCoalEngineering

The invention discloses a system and a method of rapidly manufacturing a coal-like rock similar material test piece. The system comprises a quantitative water injection agitating machine, a high-frequency impact tester, an automatic strip machine, a constant temperature moisturizing cabinet, and a base, wherein the quantitative water injection agitating machine is arranged at the left of the high-frequency impact tester and is used for uniformly mixing raw materials of coal-like rock similar materials, the high-frequency impact tester is arranged at the left of the automatic strip machine andis used for pressing the raw materials of the coal-like rock similar materials mixed uniformly by the quantitative water injection agitating machine into a test piece through a mold, the automatic strip machine is arranged at the left of the constant temperature moisturizing cabinet and is used for ejecting the test piece pressed in the mold by the high-frequency impact tester out of the mold. Thesystem agitates, shapes, presses the test piece and demolds efficiently, in addition, the system can maintain the test piece in later period, thereby providing a good condition for tests of the testpiece.

Owner:XIAN UNIV OF SCI & TECH

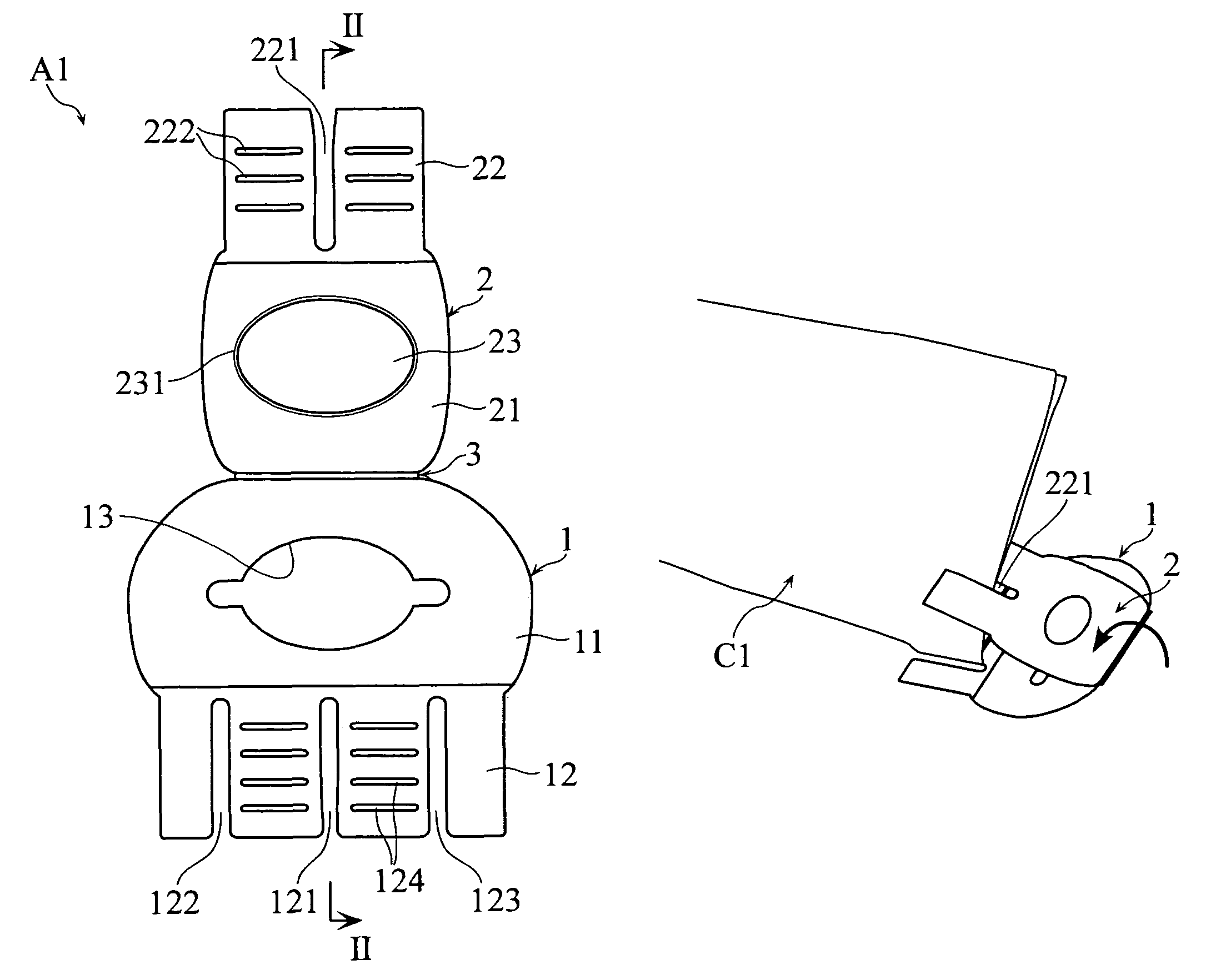

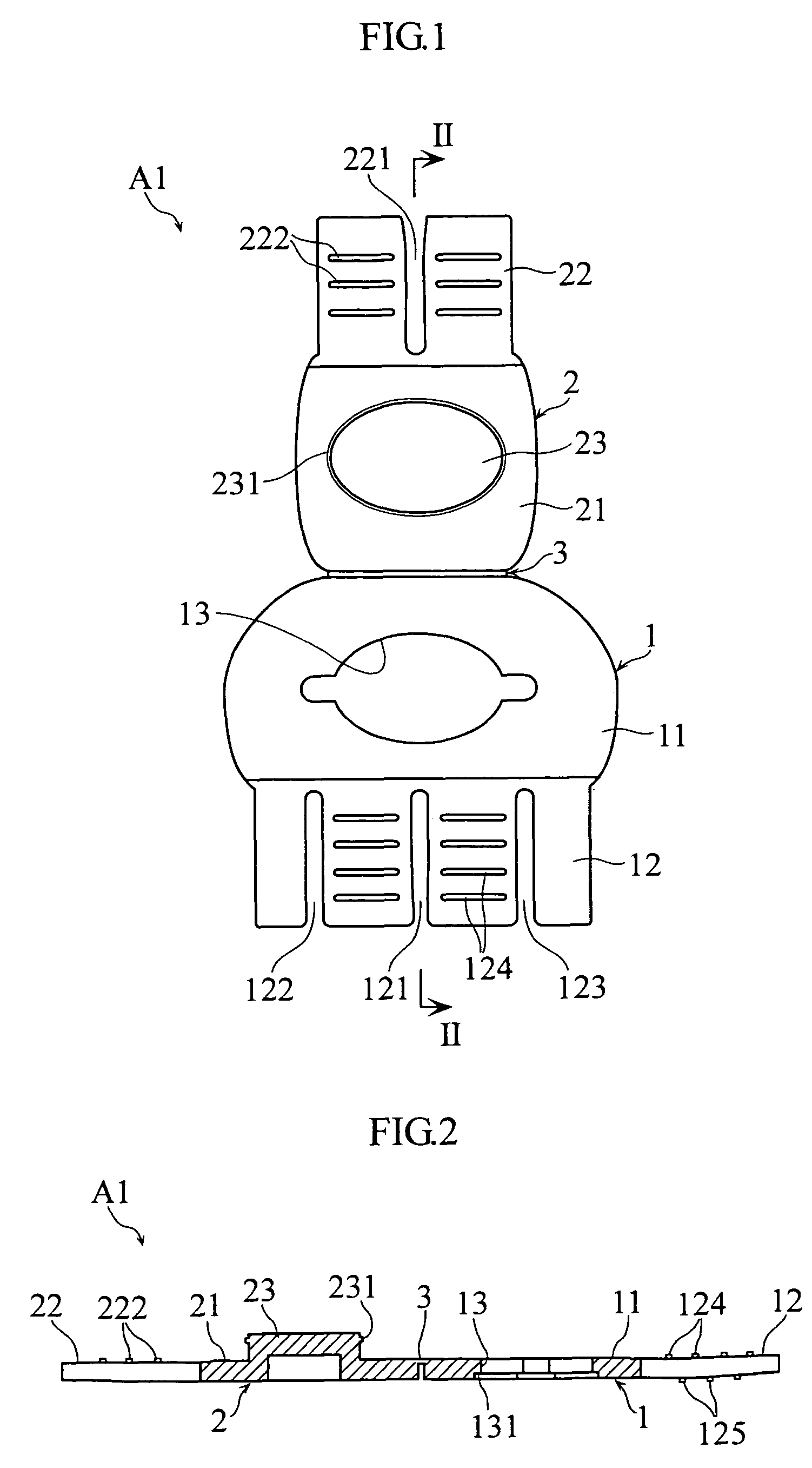

Handicraft clip

A handicraft clip is provided for forming a pleat in a cloth. The clip includes a relatively wide base plate and a narrower fastening plate connected to the base plate via a connecting hinge portion having a reduced thickness for allowing pivotal movement of the fastening plate relative to the base plate. The base plate is formed with a generally elliptical through-hole, while the fastening plate is provided with a locking protrusion to be fitted into the through-hole of the base plate when the base plate and the fastening plate are superposed on each other. The fastening plate includes a cloth holding portion of a generally constant width. The cloth holding portion is formed with a slit for insertion of a cloth. The slit extends from the distal end of the cloth holding portion toward the locking protrusion.

Owner:CLOVER MFG CO LTD

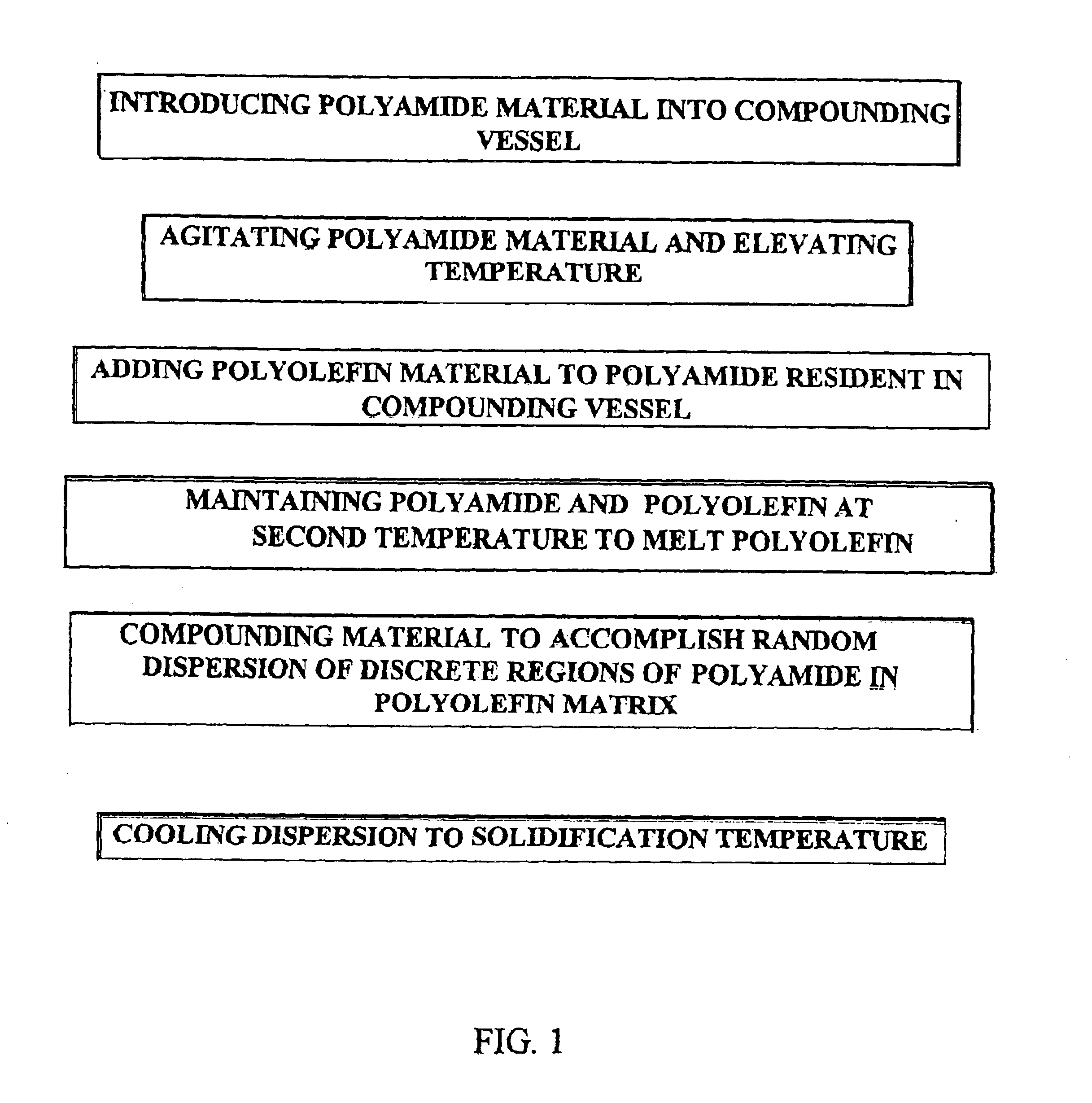

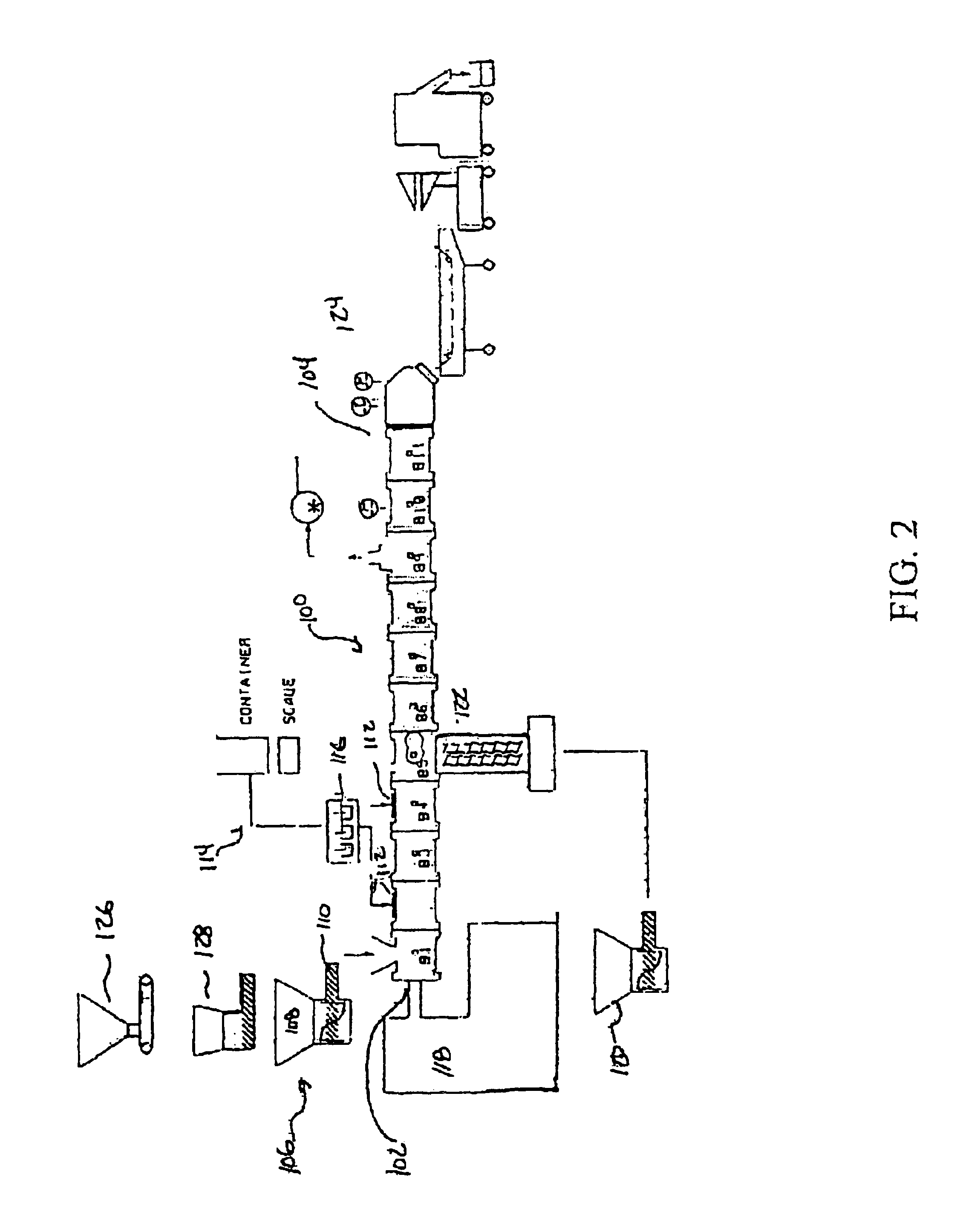

Olefin-based thermoplastic alloy, process for making the same and molded parts containing the same

InactiveUS6870005B1Unique characteristic of resistance to abrasion and scratchSuitable impact modificationSynthetic resin layered productsThin material handlingThermoplasticPolyolefin

A polymeric composition and process for making the same suitable for injection molding processes and procedures containing an olefinic polymer component selected from at least one a group which includes polyalkylenes, copolymers of polyalkylenes and a non-olefinic thermoplastic. The non-olefinic and olefinic polymeric components are present in random orientable locations in the initial polymeric composition. When injection molded against a temperature gradient, the resulting workpiece composed of the composition has distinctive regions of elevated non-olefinic concentration proximate the outwardly oriented surface and distinctive regions of elevated olefinic polymeric concentration proximate to interior regions of the workpiece. The non-olefinic thermoplastic may be at least one of thermoplastic polyamides, thermoplastic polyolefins and thermoplastic polycarbonates.

Owner:ACI TECH

Silicone composition and cured product

A silicone composition is provided comprising (A) an organopolysiloxane of resin structure consisting of R1SiO1.5, R22SiO, and R3aR4bSiO(4−a−b) / 2 units, wherein R1, R2, and R3 are methyl, ethyl, propyl, cyclohexyl or phenyl, R4 is vinyl or allyl, a is 0, 1 or 2, b is 1 or 2, a+b is 2 or 3, the number of recurring R22SiO units being 10 to 300, (B) an organohydrogenpolysiloxane of resin structure consisting of R1SiO1.5, R22SiO, and R3cHdSiO(4−c−d) / 2 units, wherein R1, R2, and R3 are as defined above, c is 0, 1 or 2, d is 1 or 2, c+d is 2 or 3, the number of recurring R22SiO units being 10 to 300, and (C) a platinum catalyst. The silicone composition cures into a product exhibiting flexibility and minimized surface tack, and can be effectively molded on the existing molding machines.

Owner:SHIN ETSU CHEM IND CO LTD

Method for packaging light emitting diode

The present invention discloses a method for packaging light emitting diode. Firstly, a light emitting diode chip is combined with a carrier so that the light emitting diode chip is electrically connected with the carrier. Secondly, the carrier is heated for increasing the temperature of carrier. Afterwards, a packaging colloid is formed through a dispensing mode for coating the light emitting diode chip, wherein the viscosity of packaging colloid when the packing colloid does not contact the carrier is lower than the viscosity when the packaging colloid contacts the carrier. Finally the packaging colloid is solidified.

Owner:LEXTAR ELECTRONICS CORP

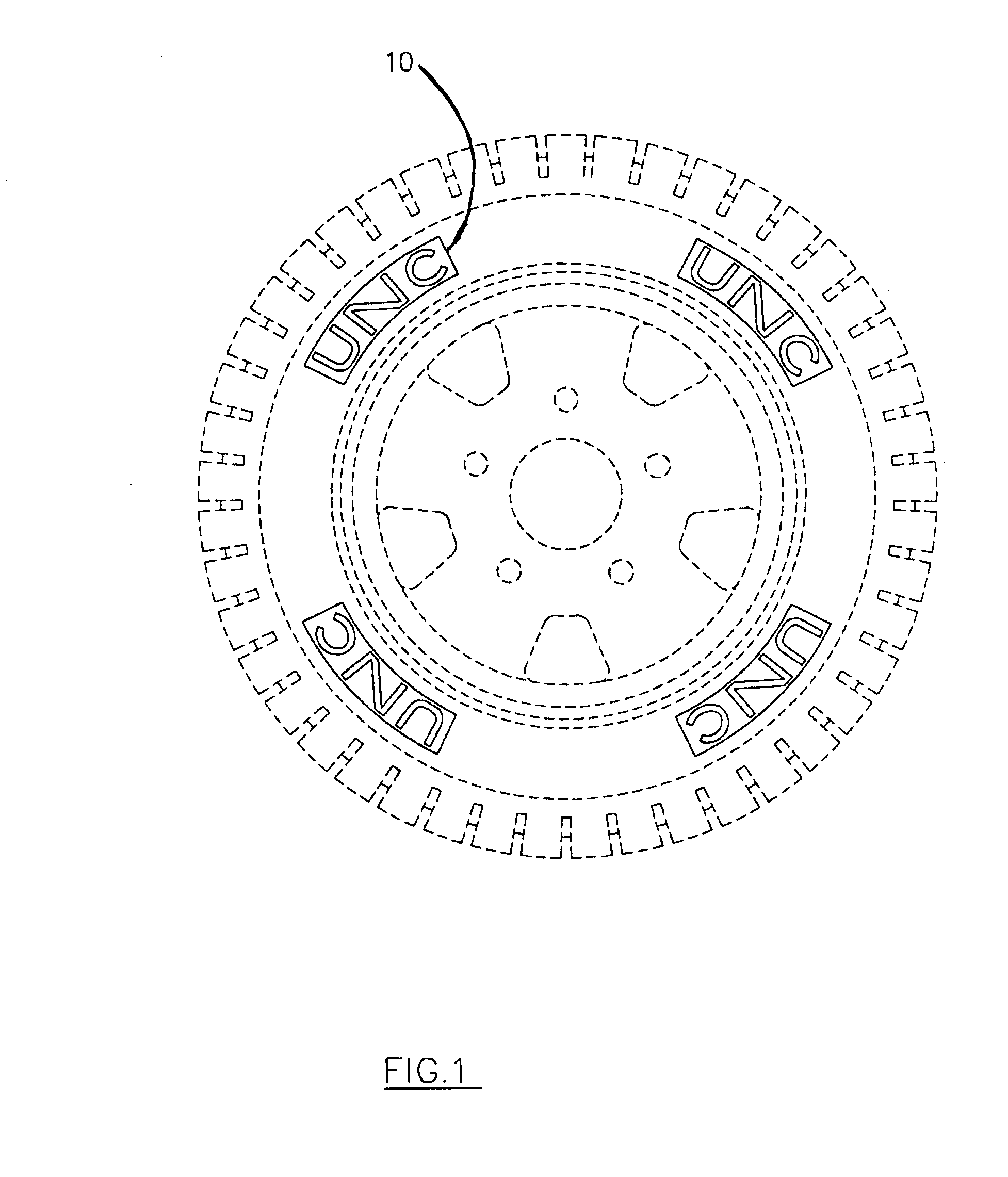

Temporary Tatoo for Rubber Tires

InactiveUS20080216947A1Prolong visible integrityEasy to disassembleLayered productsDecorative surface effectsComputer graphics (images)Moisture

The present invention is an article and method for applying a moisture transferable image to the surface of a tire, whereby the image retains visual integrity for up to six months.

Owner:GILCHRIST RAEL M

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com