System and method of rapidly manufacturing coal-like rock similar material test piece

A technology of similar materials, coal and rock, applied in the field of making samples of coal and rock-like materials, can solve the problems of affecting the success rate of the test pieces, time-consuming and laborious, and inter-fracture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

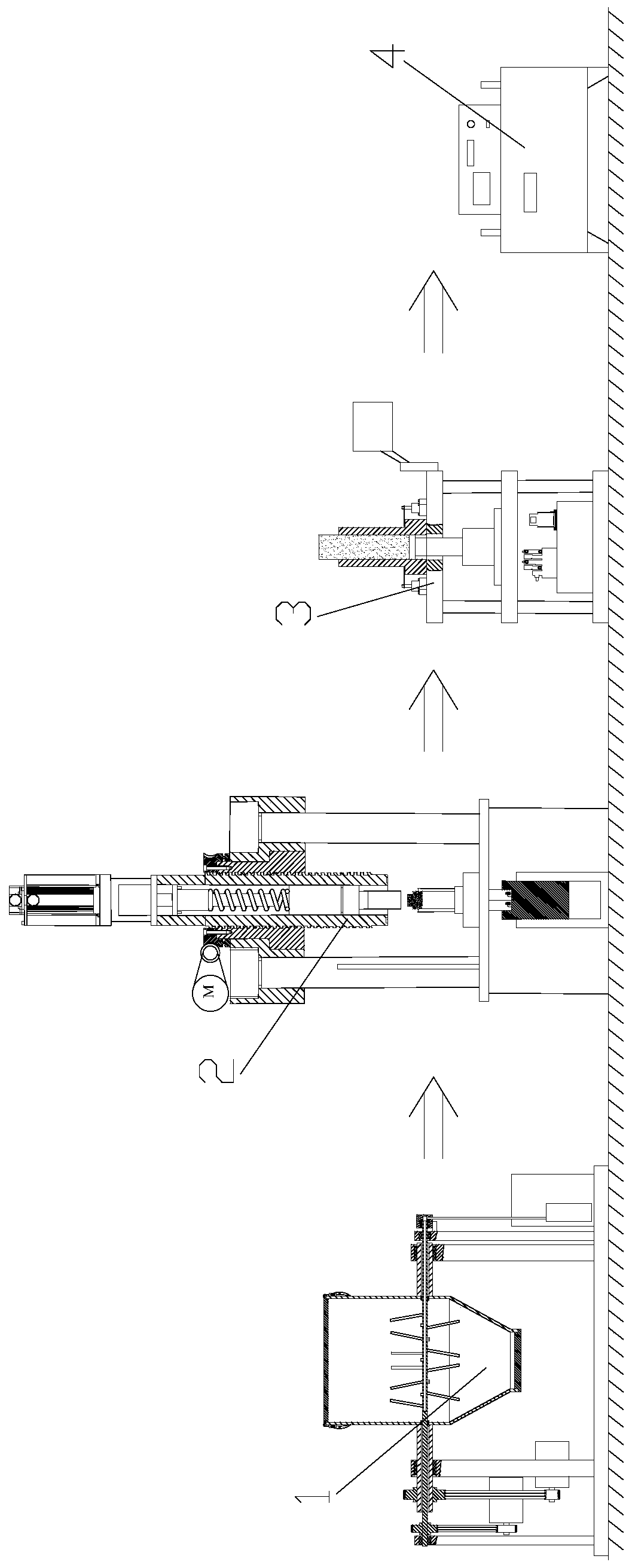

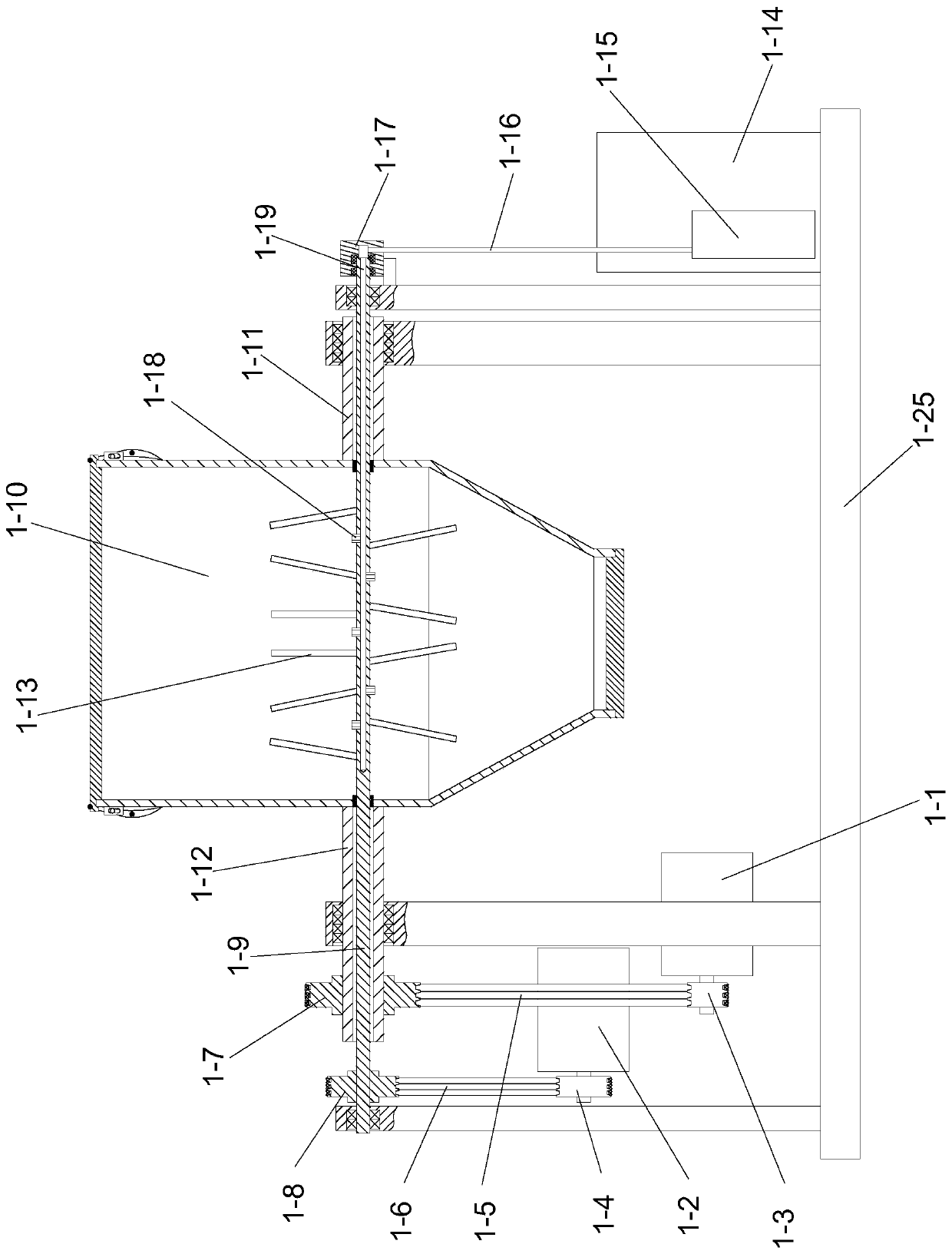

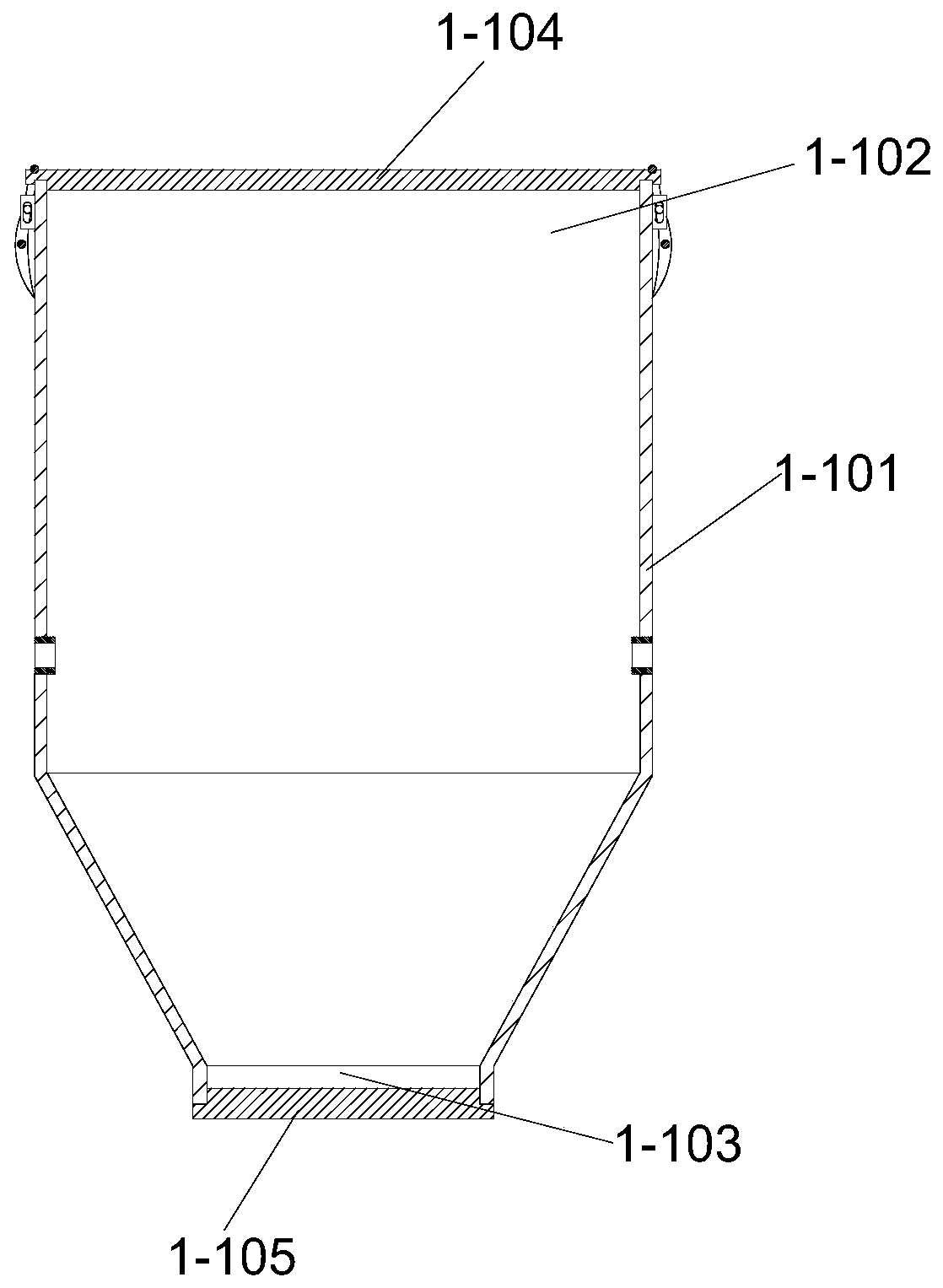

[0081] Such as figure 1 The system shown for quickly producing specimens of similar materials like coal and rock includes a quantitative water injection mixer 1, a high-frequency impact meter 2, an automatic demoulding machine 3, a constant temperature moisturizing box 4 and a foundation 5. The quantitative water injection mixer 1, The high-frequency impact meter 2, the automatic demoulding machine 3, and the constant temperature moisturizing box 4 are all arranged on the foundation 5. The quantitative water injection mixer 1 is arranged on the left side of the high-frequency impact meter 2 and the quantitative water injection mixer 1 is used to mix coal and rock The raw materials of similar materials are evenly stirred. The high-frequency impact meter 2 is set on the left side of the automatic demoulding machine 3 and the high-frequency impact meter 2 is used to uniformly stir the raw materials of coal-like similar materials through the mold by the quantitative water injection m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com