Patents

Literature

40results about How to "Efficient demoulding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

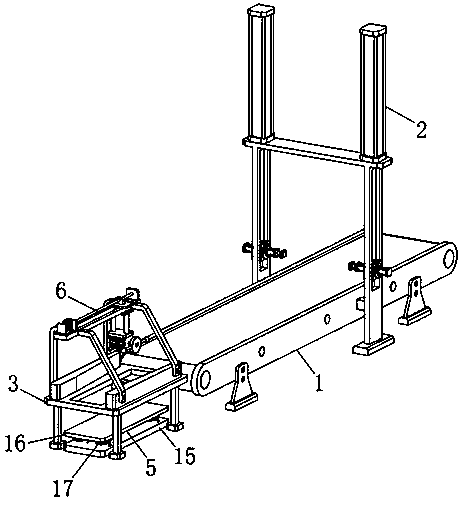

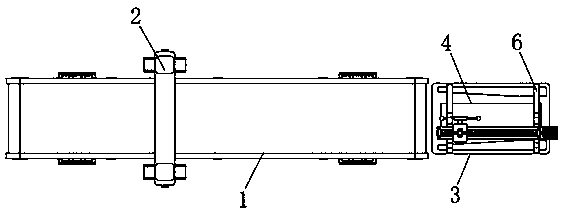

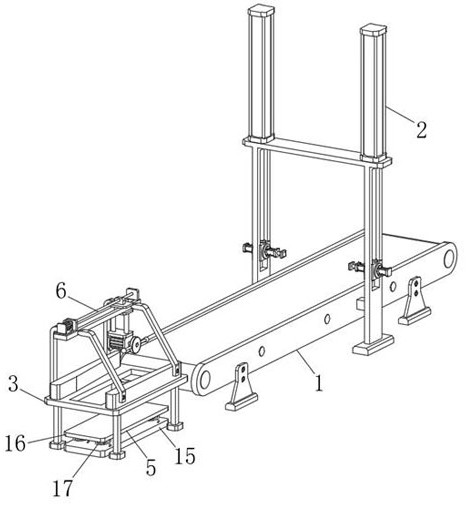

Automatic demolding device of frozen noodles production line

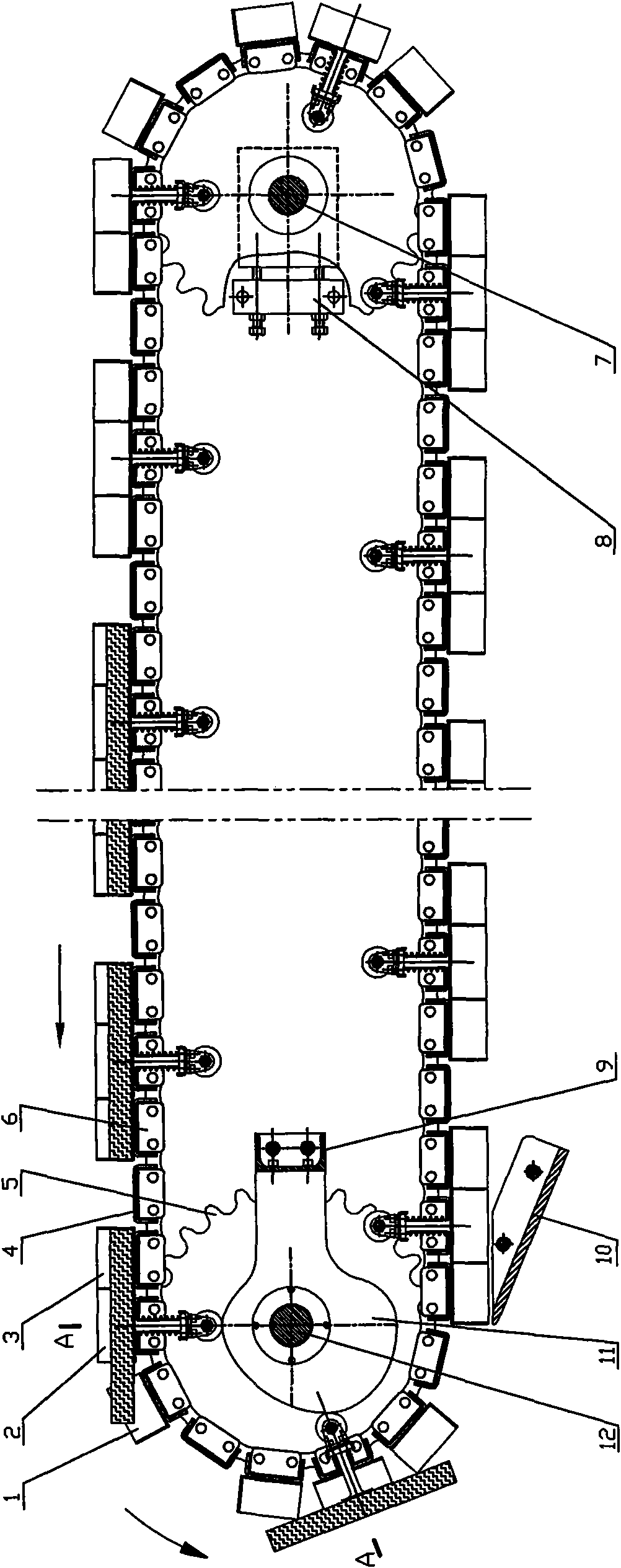

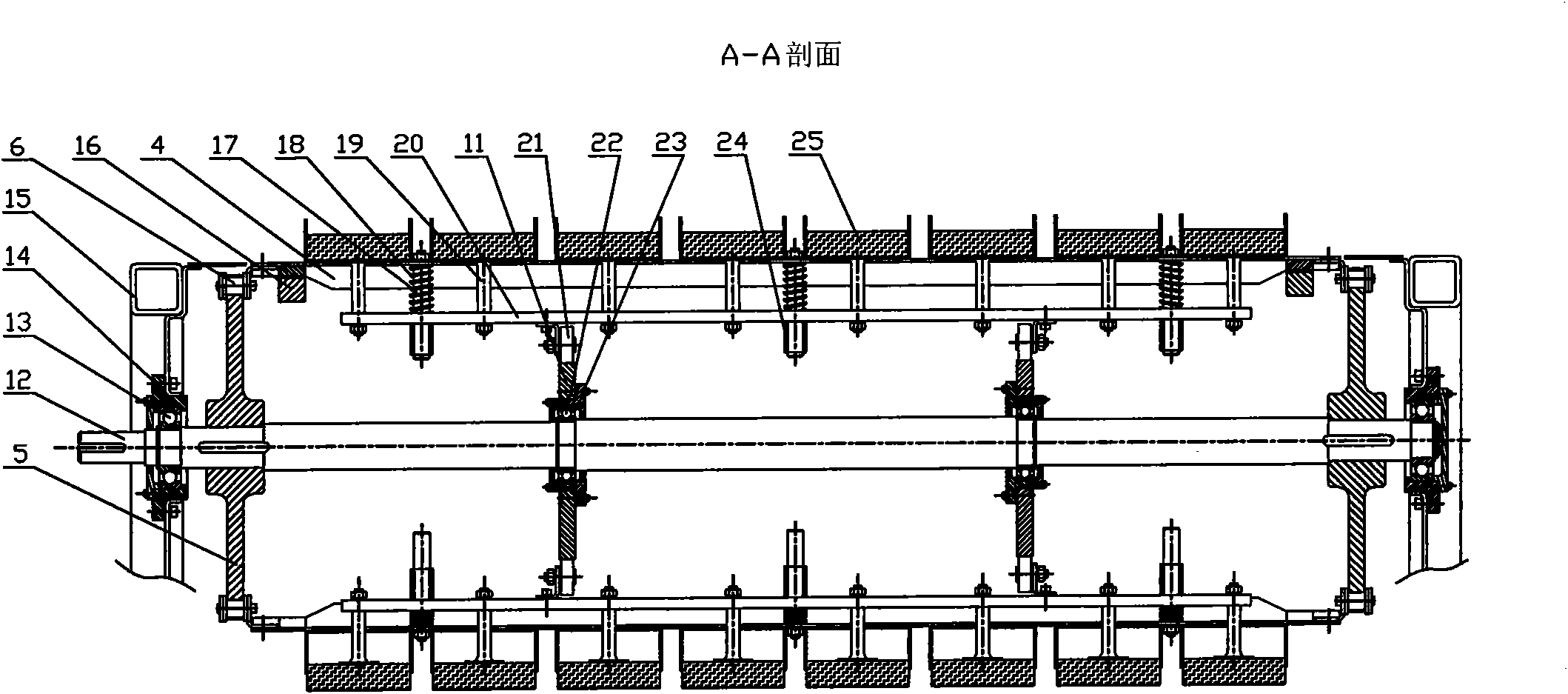

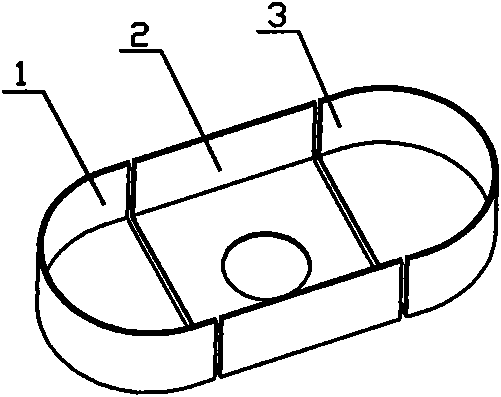

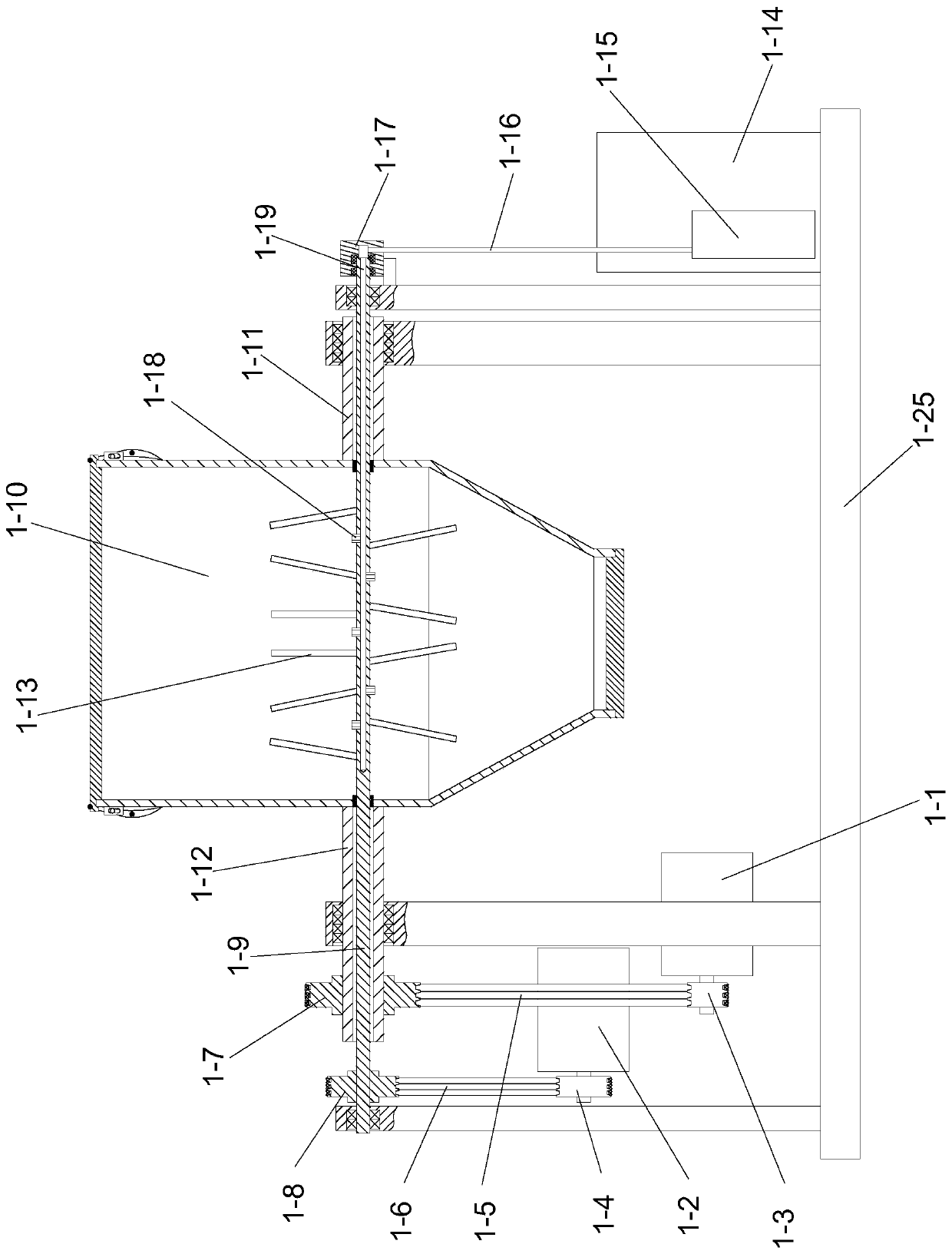

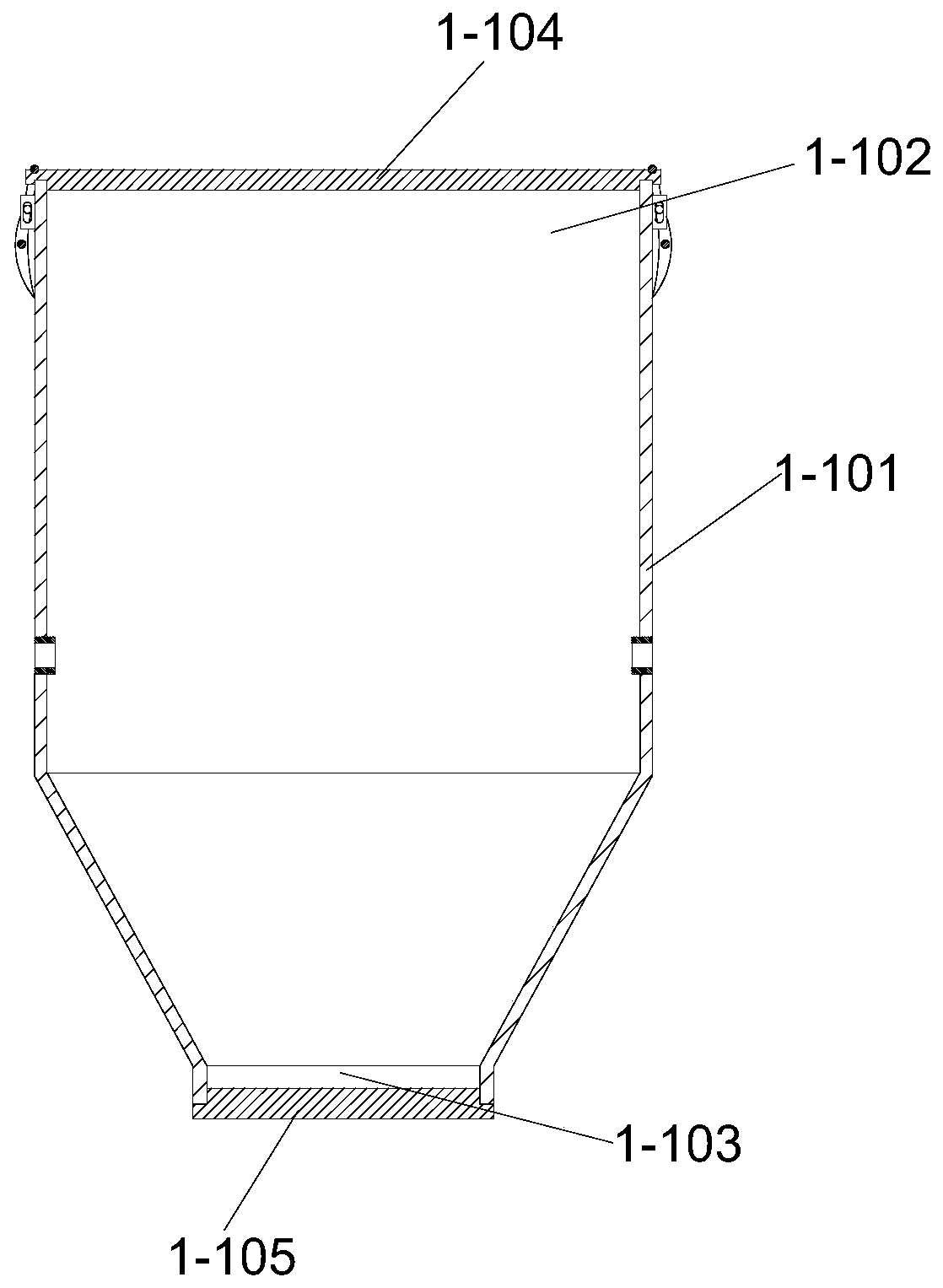

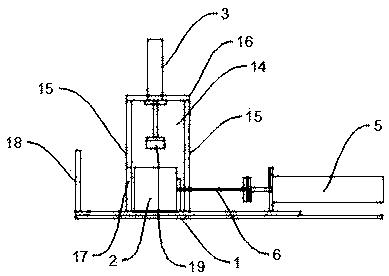

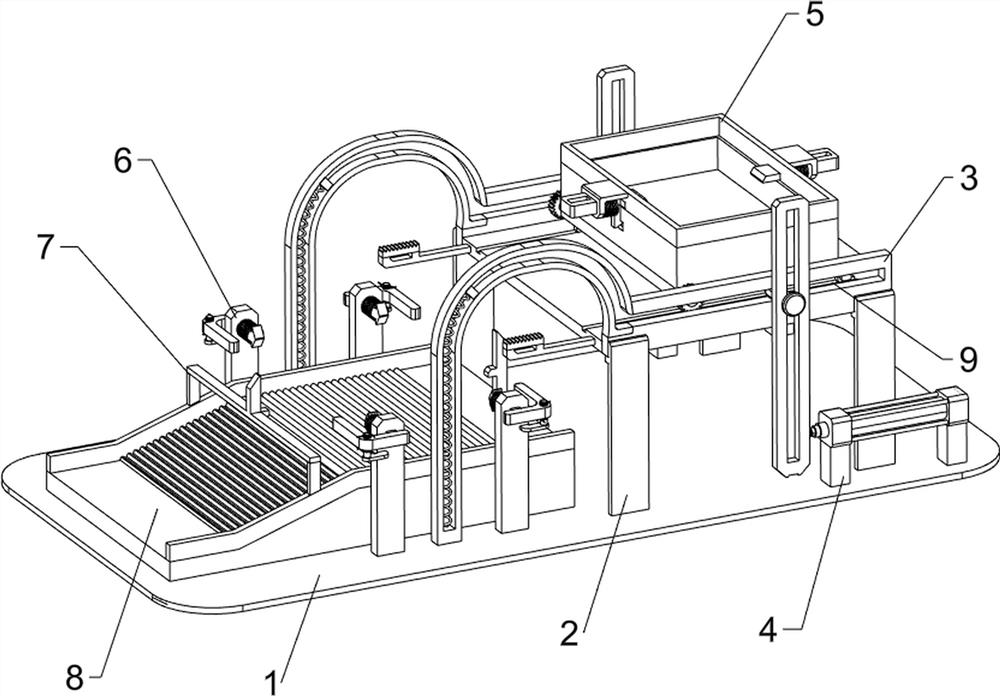

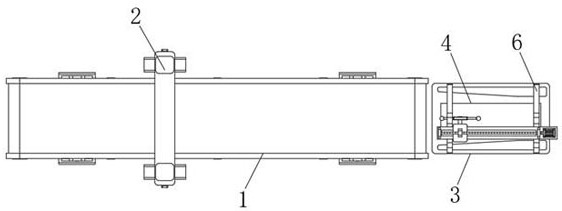

The invention provides an automatic demolding device of frozen noodles production line, belonging to the field of food processing machinery, wherein the demolding device consists of a split noodle die box, a chain-plate conveying mechanism, a cam mechanism, a prying plate and a rack; the split noodle die box consists of a front die box, a middle die box and a rear die box; the chain-plate conveying mechanism comprises chain wheels, chains with accessories, a driving shaft, a driven shaft, a chain plate, a tensioning device and the like; the tensioning device is connected with the driven shaft; two chains with accessories are connected with each other via the chain plate; the cam mechanism comprises a cam, a cam roller, a slot beam, a guide column, a top rod, a top rod seat, a guide sleeveand the like; the big end section of the cam is mounted on the driving shaft via a bearing; the other end is fixed on the slot beam; one end of the guide column is fixed with the chain plate; the other end of the guide column is in sliding match with the guide sleeve; and the prying plate is of a wedge-shaped structure, and is fixed with the rack. The demolding device can fast and reliable demoldthe whole row of frozen noodles; and the demolding device has the characteristics of compact structure, low cost and the like.

Owner:ZHENGZHOU UNIV

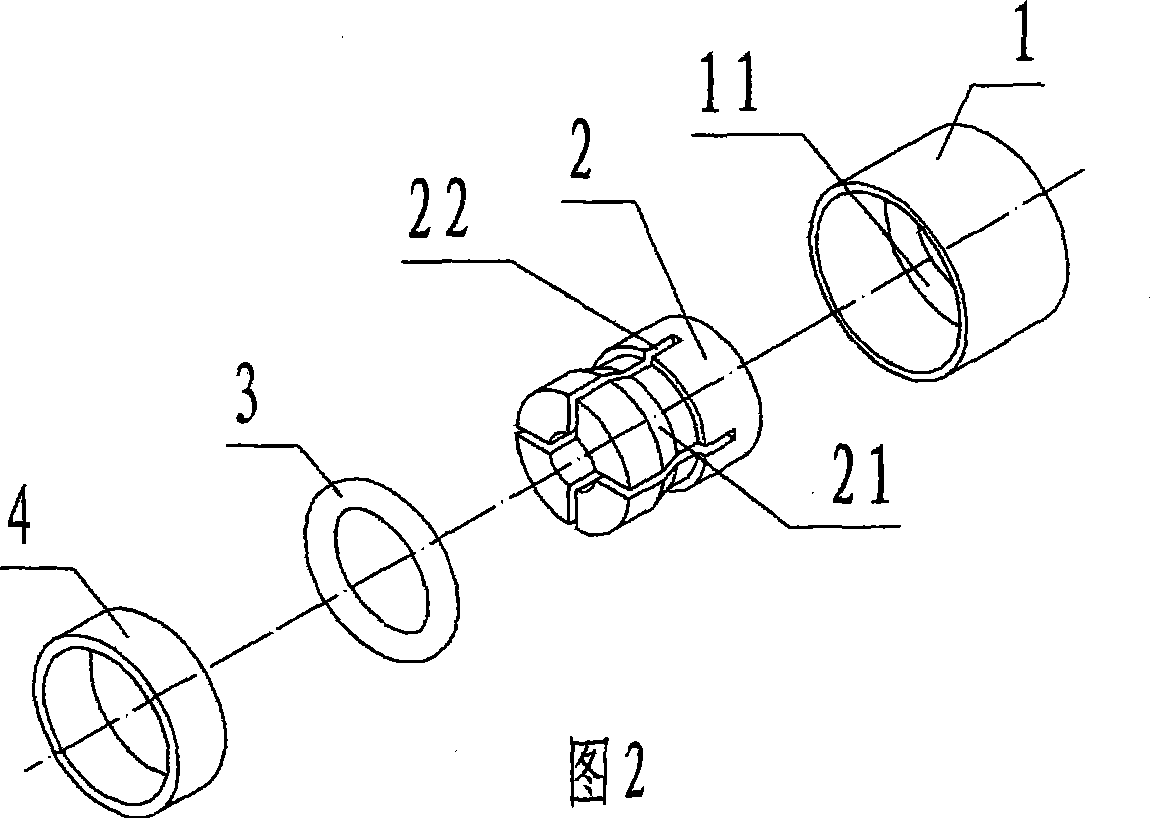

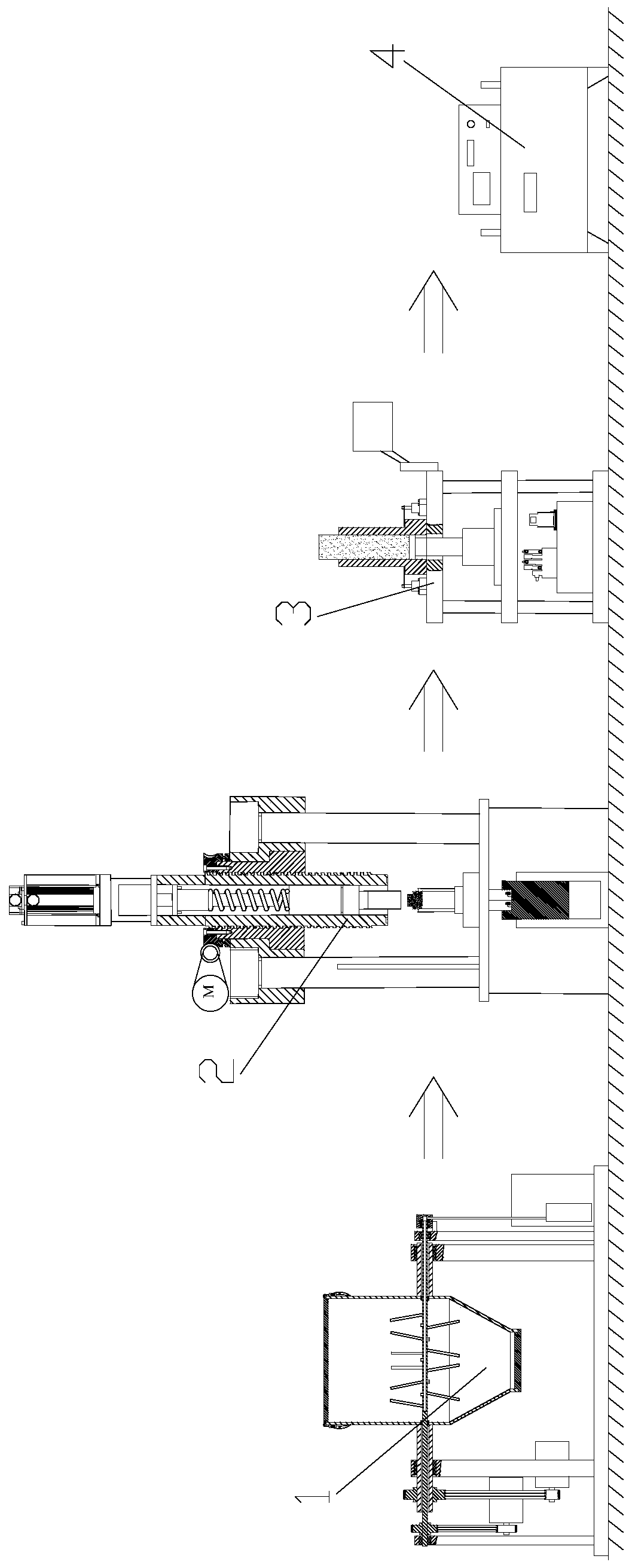

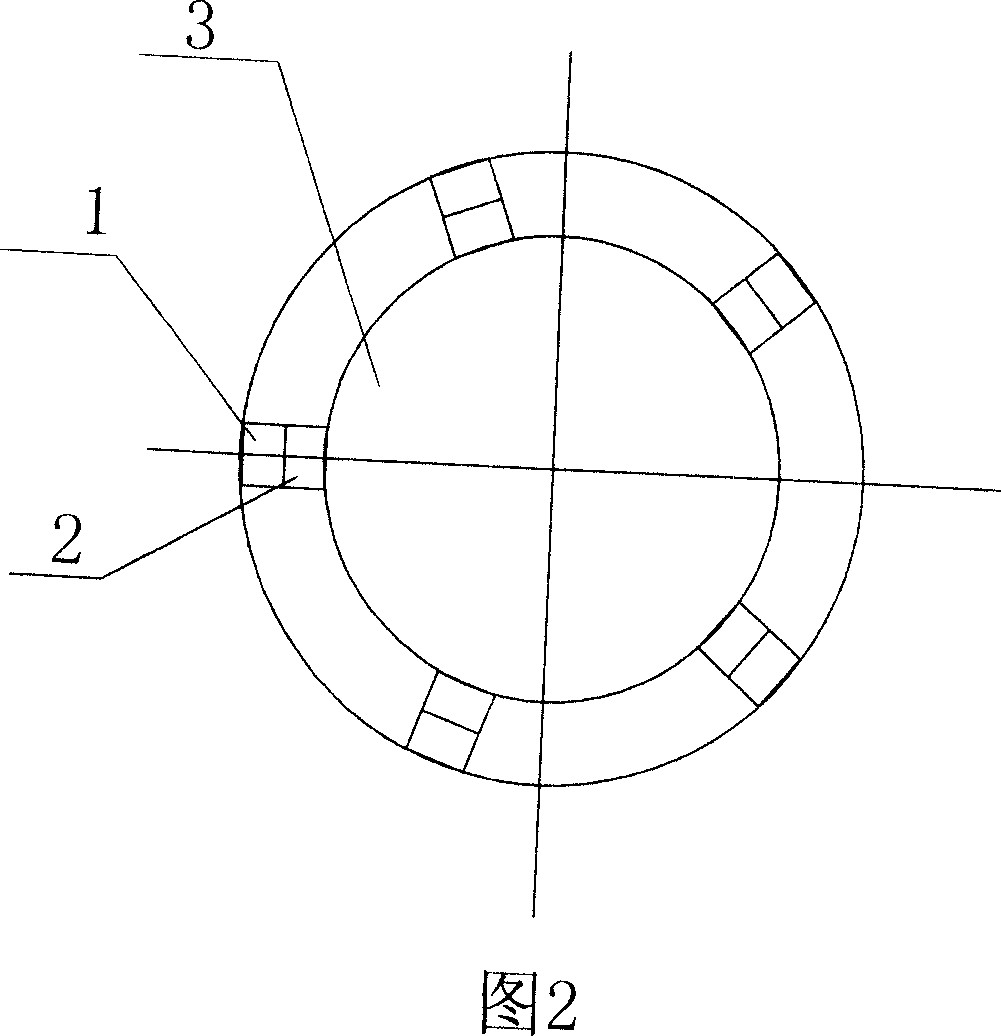

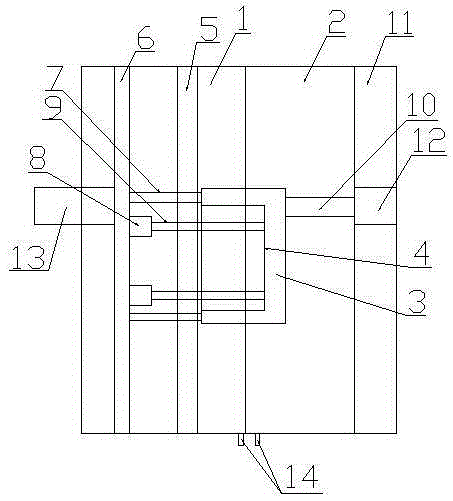

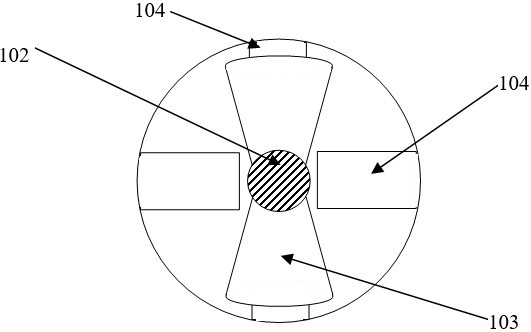

Multiple linkage reciprocating capsule stripping machine

InactiveCN101444942AEfficient demouldingSuitable for matchingHollow articlesProduction lineState of art

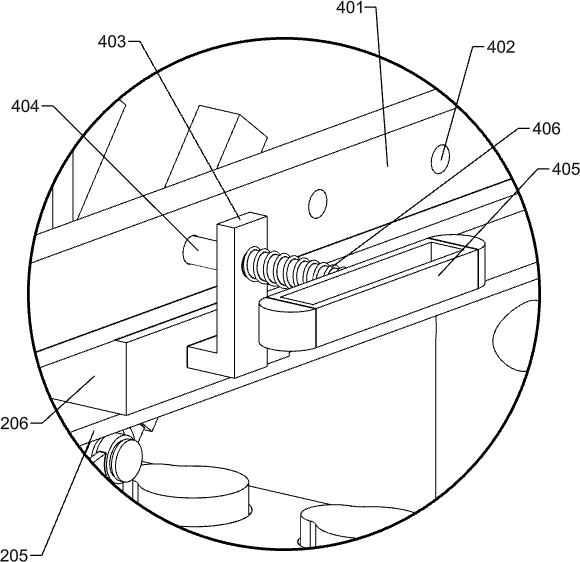

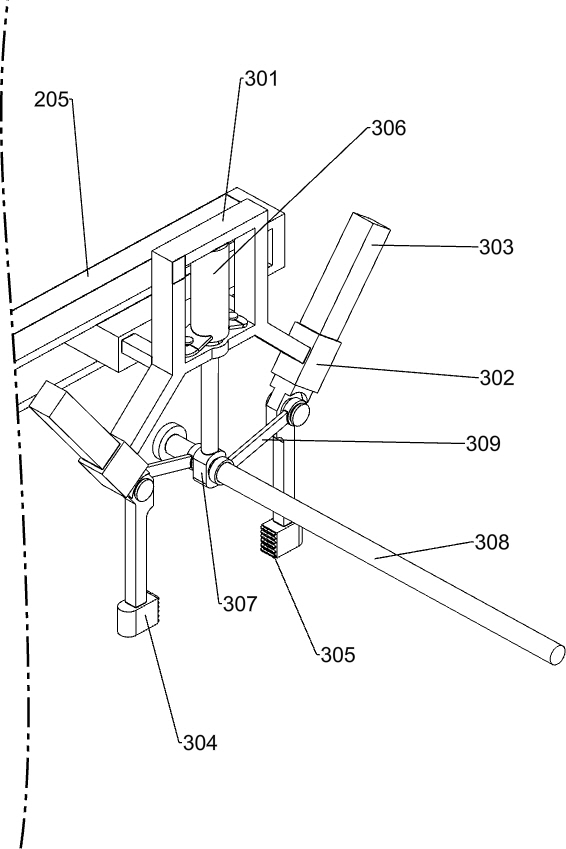

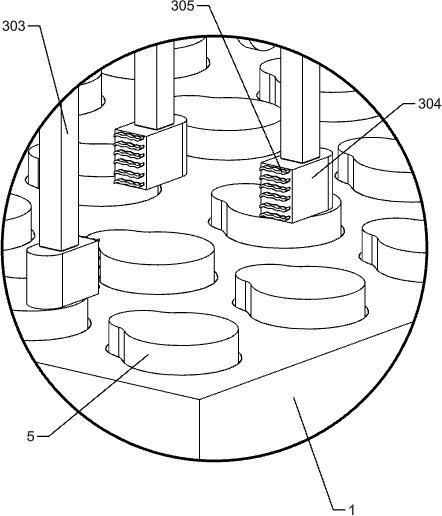

The invention discloses a multiple linkage reciprocating capsule stripping machine, which comprises a machine body (1), a clamping and pulling system (2), a power transmission system (3), an electric control system (4) and a gathering system (5). The invention adopts the technical scheme that a plurality of clamping and pulling boards (22) are linked and reciprocate to demold at a time, and overcomes the problems and the disadvantages that a clamping and pulling sleeve of the prior capsule stripping machine can reciprocate vertically for twice; the demolding process for transposition is needed; the machine body is large; the demolding efficiency is low; and the assorted scale production line is not suitable. The multiple linkage reciprocating capsule stripping machine needs no transposition; in situ reciprocation for once can complete the whole capsule stripping process of a plurality of capsule templates, so as to achieve the purposes of compact and delicate machine body, efficient demolding and suitability for assorted scale production line.

Owner:徐家业

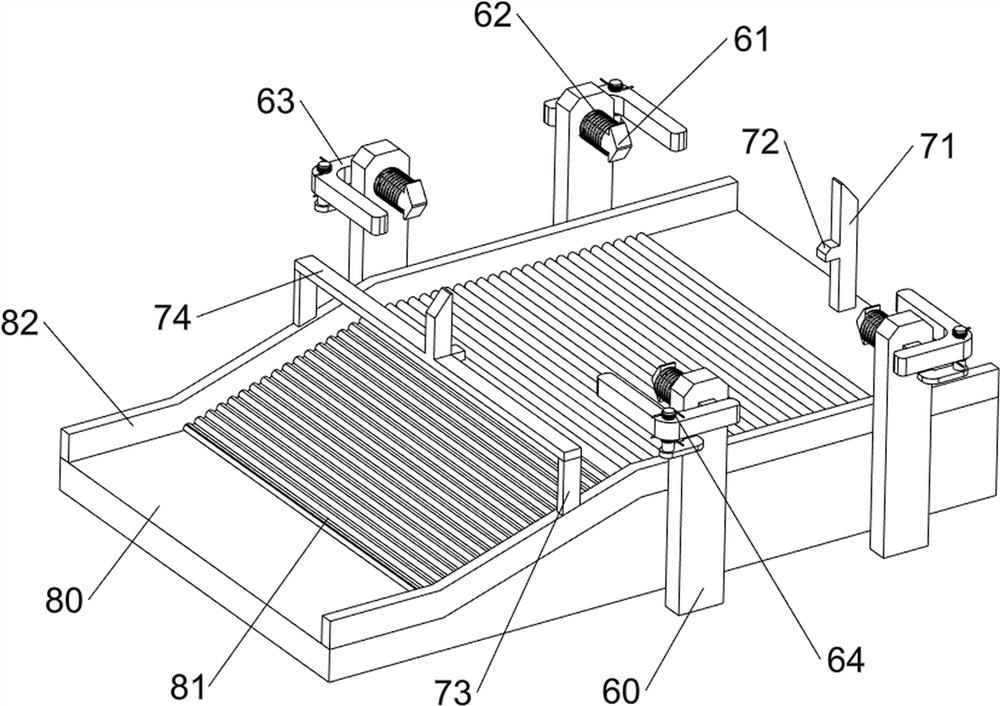

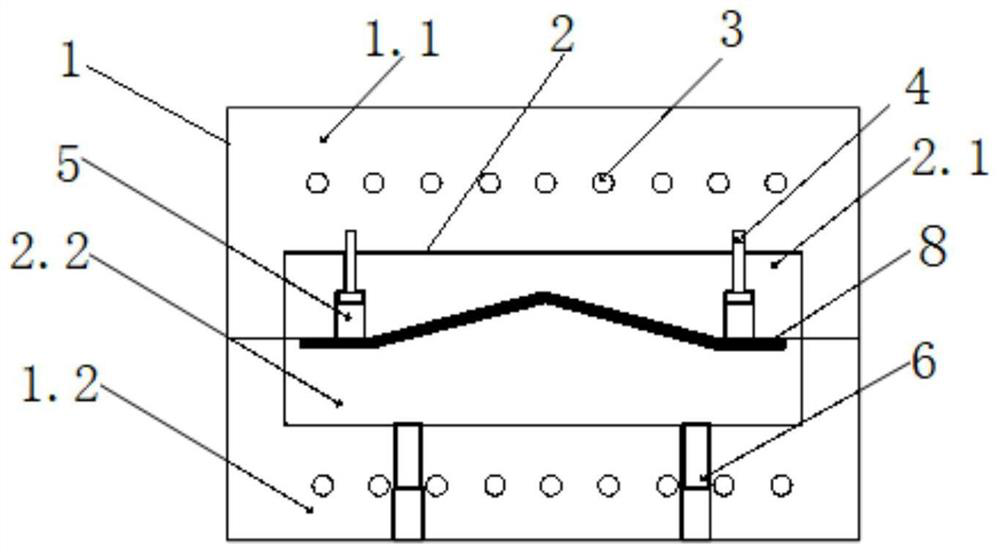

Prefabricated component assembling mold and use method

PendingCN109531784AImprove molding qualityEasy to demouldMouldsMould fastening meansRebarMaterials science

The invention discloses a prefabricated component assembling mold which comprises a lower side mold body and three side mold bodies for defining a prefabricated component pouring cavity. Each side mold body comprises an upper side mold main body, a middle side mold main body and a lower side mold main body, wherein the lower side mold main body is provided with first reinforcing steel bar holes and installed on the lower side of the middle side mold main body, the upper side mold main body is provided with second reinforcing steel bar holes and installed on the upper side of the middle side mold main body, the side, away from a prefabricated component, of the middle side mold main body is provided with a first demolding device, and the middle side mold main body, the lower side mold main body and the upper side mold main body are connected with one another. By means of the three-layer combined mold formed by the side mold main bodies on the upper side, the left side and the right side,the demolding process can be simple and efficient; the middle side mold main bodies are provided with no open grooves and are high in integrity and not prone to deformation; after the mold is installed, no clogging is needed, the operation steps are reduced, the mold assembling efficiency is improved, and the component forming quality is high.

Owner:CHANGSHA BROAD HOMES IND GRP CO LED

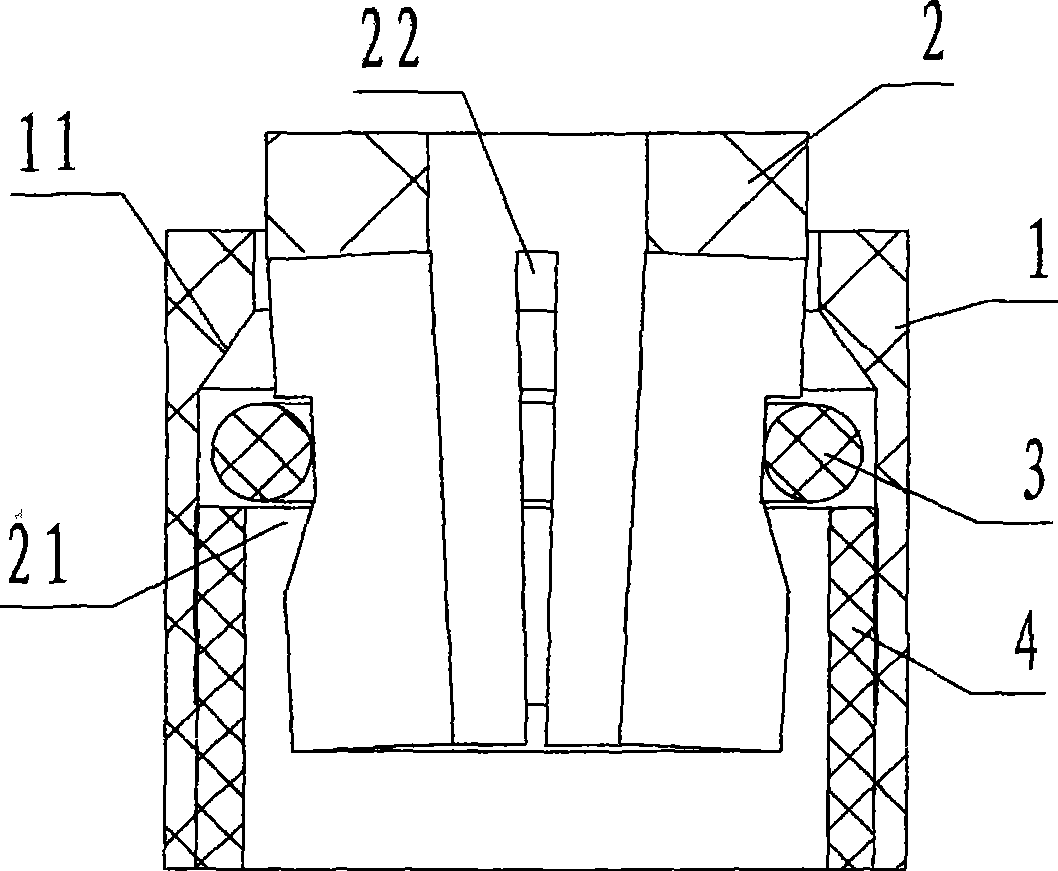

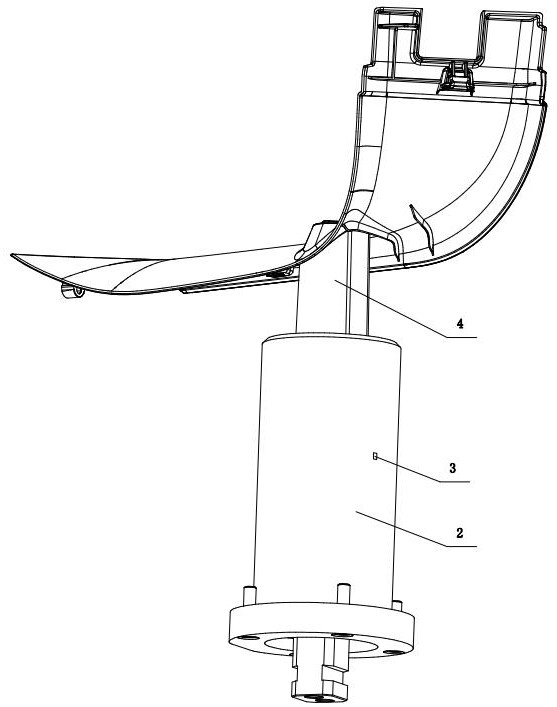

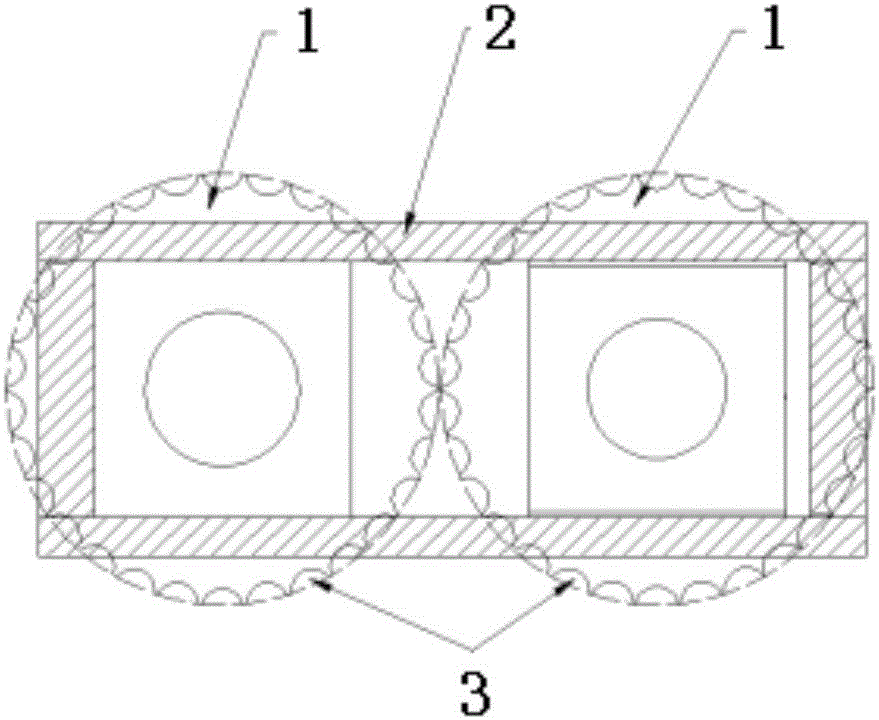

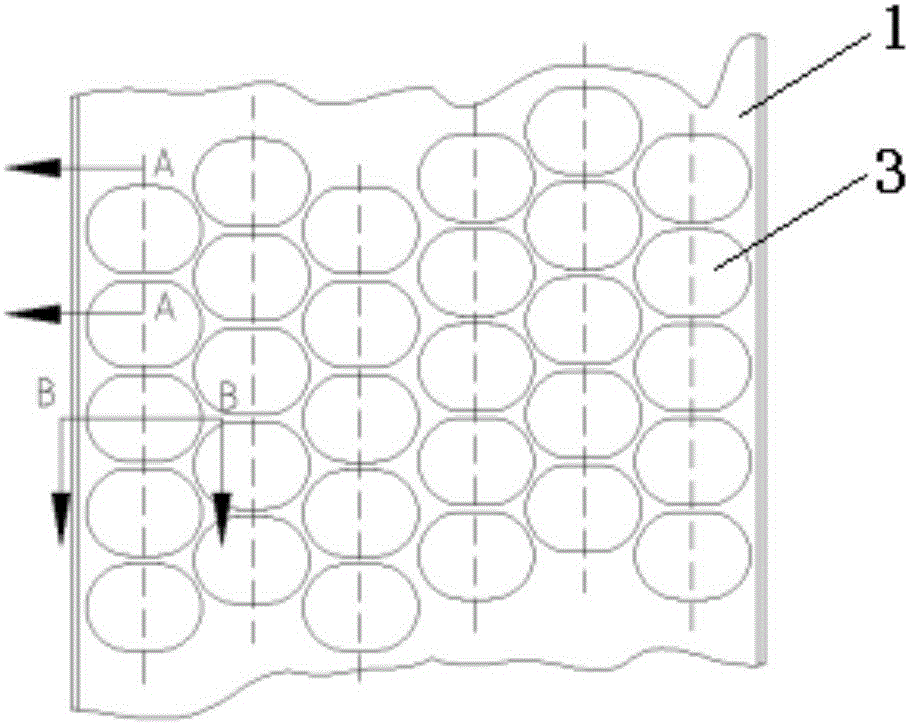

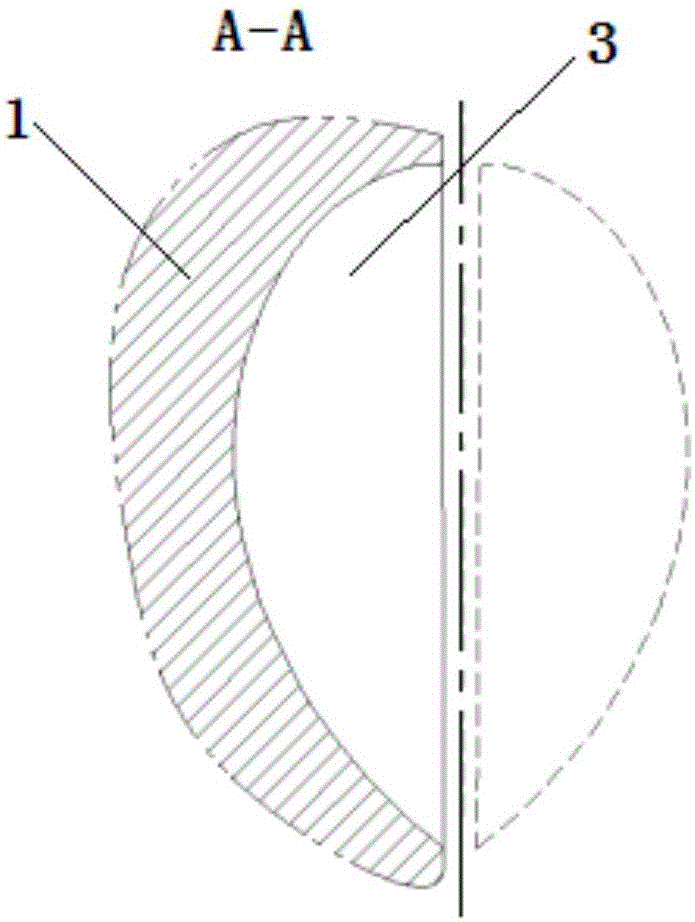

Capsule detachment conjoined device

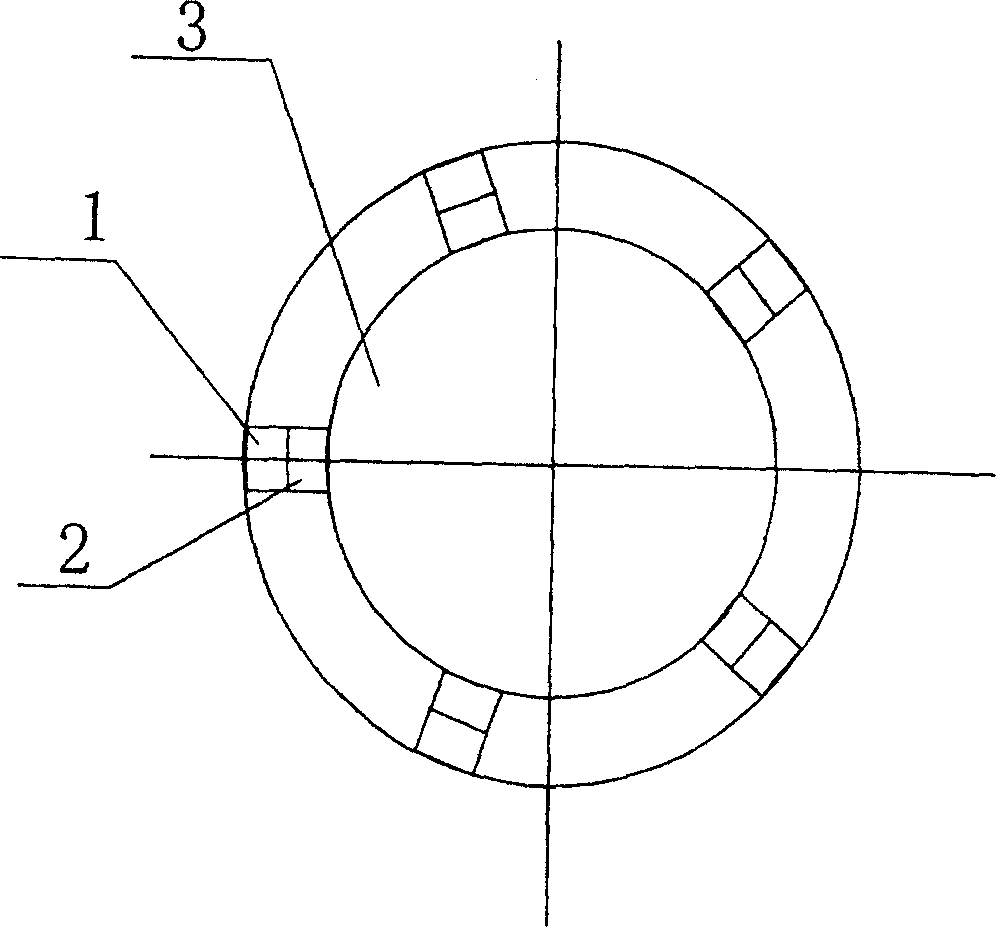

The present invention discloses a capsule pulling integral device which comprises a casing (1), a flexible clamping head (2), an O-shaped ring (3) and a linear bushing (4). The invention adopts a technical scheme of flexible clamp head which can be clamped and loosened controllably, overcomes the problems and insufficiencies of larger machine body of capsule mould stripper matched with the capsule pulling device, low mould stripping efficiency and unsuitability for matching with large-scale product line in the capsule pulling device of prior art. The capsule pulling integral device provided by the invention realizes repeated one-time completion of mould stripping action. Therefore the capsule mould stripper which is matched with the capsule pulling integral device and operates in a repeated one-time action program obtains the purposes of compact and elaborate of machine body, high-efficient mould stripping, and suitability for matching with large-scale product line.

Owner:徐家业

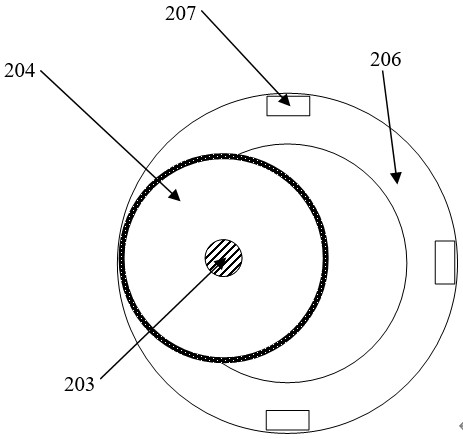

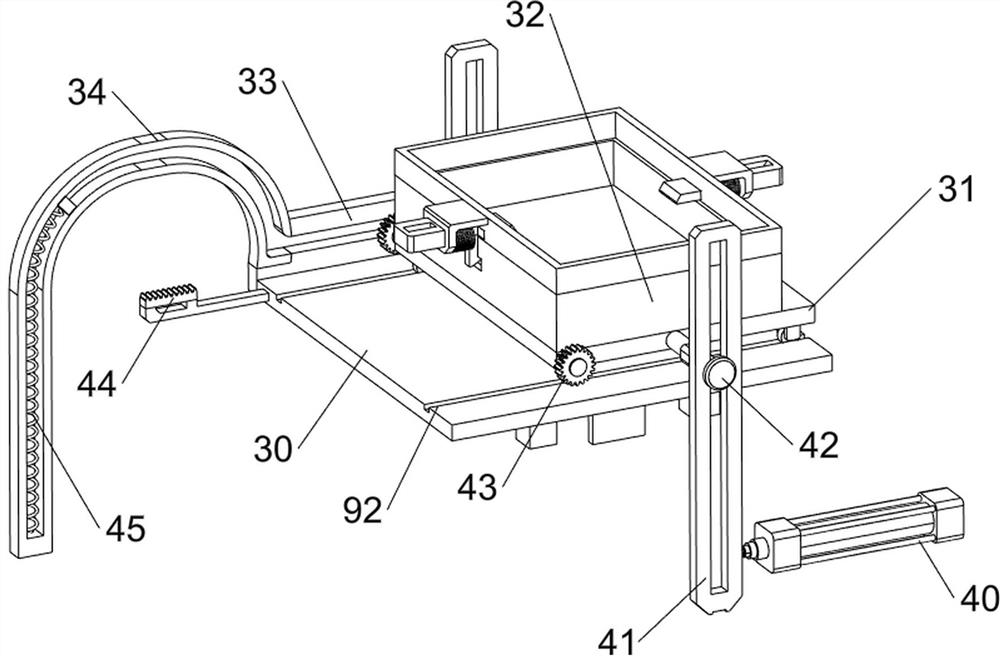

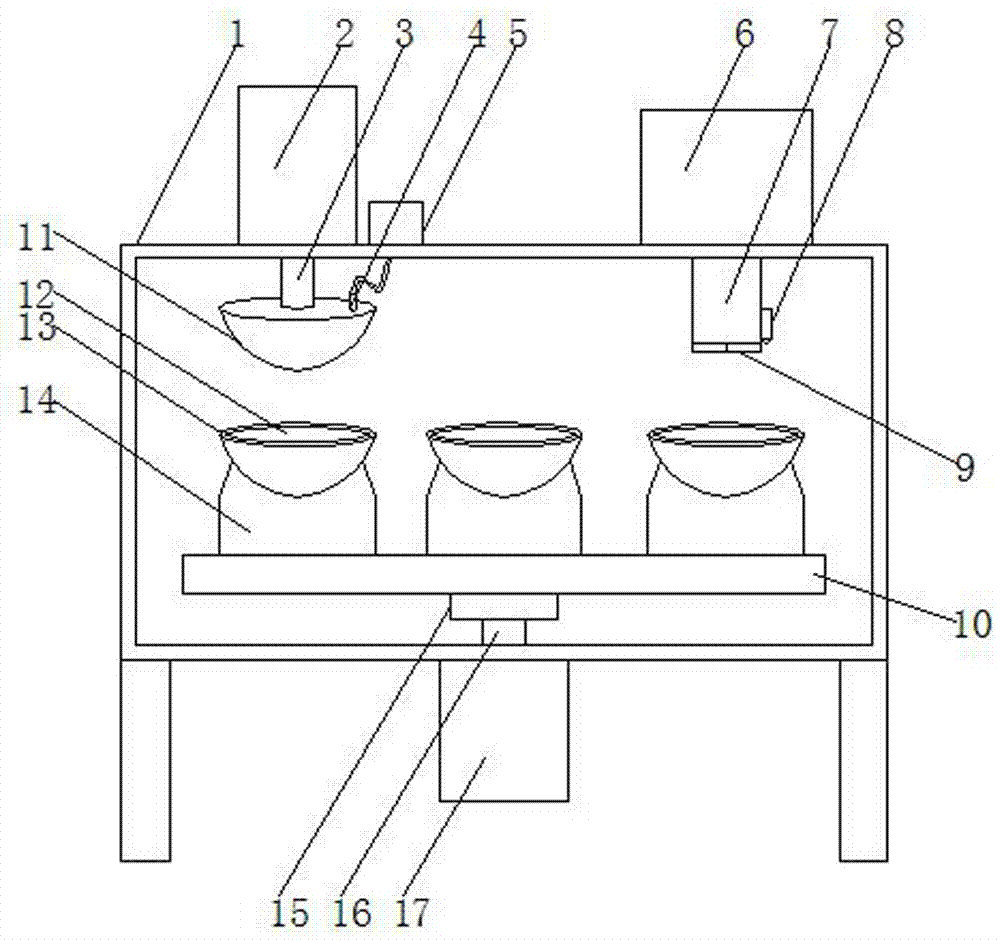

System and method of rapidly manufacturing coal-like rock similar material test piece

PendingCN109738267AEfficient demouldingEfficient mixingPreparing sample for investigationCoalEngineering

The invention discloses a system and a method of rapidly manufacturing a coal-like rock similar material test piece. The system comprises a quantitative water injection agitating machine, a high-frequency impact tester, an automatic strip machine, a constant temperature moisturizing cabinet, and a base, wherein the quantitative water injection agitating machine is arranged at the left of the high-frequency impact tester and is used for uniformly mixing raw materials of coal-like rock similar materials, the high-frequency impact tester is arranged at the left of the automatic strip machine andis used for pressing the raw materials of the coal-like rock similar materials mixed uniformly by the quantitative water injection agitating machine into a test piece through a mold, the automatic strip machine is arranged at the left of the constant temperature moisturizing cabinet and is used for ejecting the test piece pressed in the mold by the high-frequency impact tester out of the mold. Thesystem agitates, shapes, presses the test piece and demolds efficiently, in addition, the system can maintain the test piece in later period, thereby providing a good condition for tests of the testpiece.

Owner:XIAN UNIV OF SCI & TECH

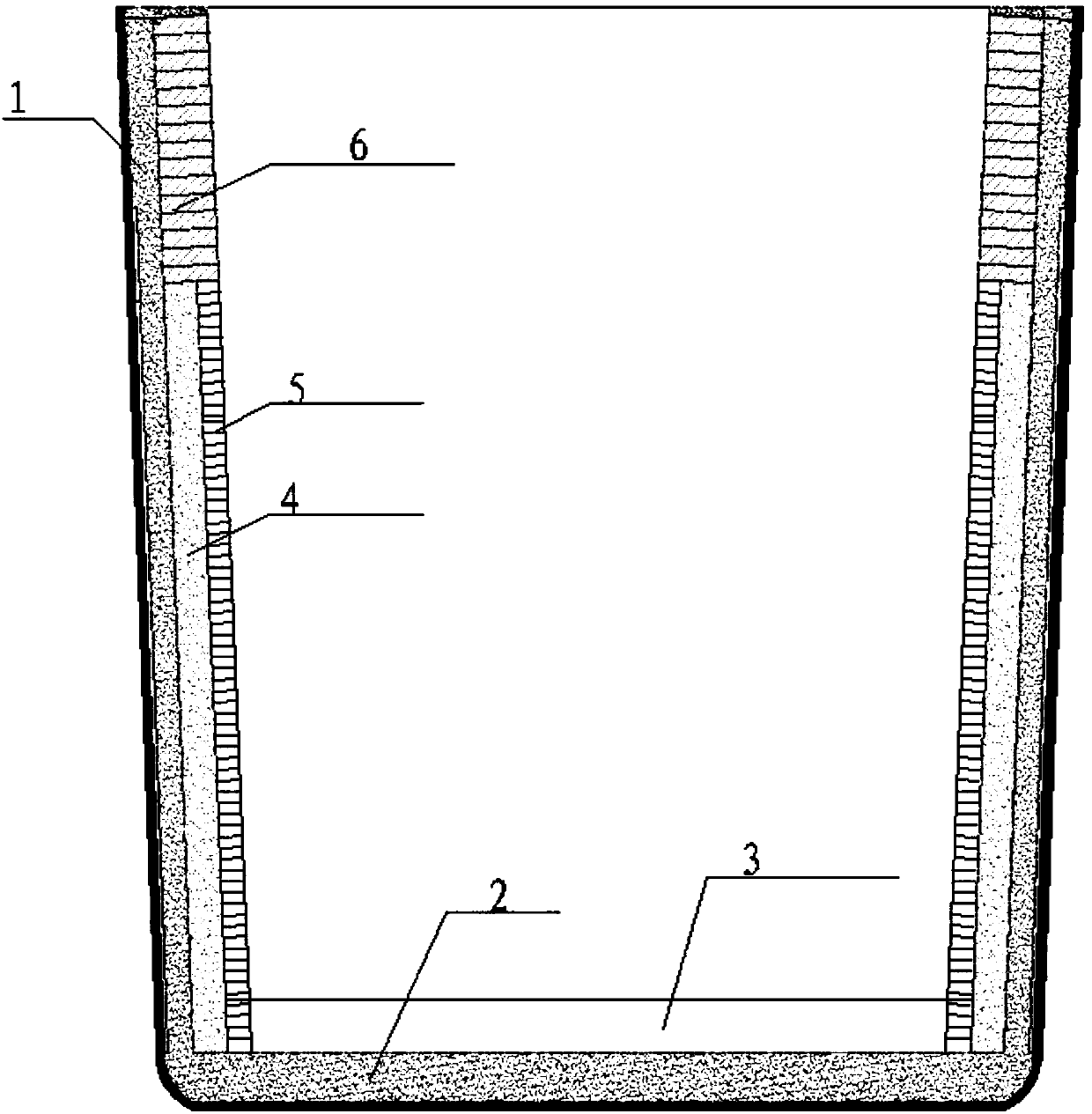

Construction method for ladle integral pouring and casing pouring liner

The invention discloses a constructing method of entire ladle casting and lining, which comprises the following steps: locating mould, assembling at least three locating blocks on the bottom of ladle, distributing the blocks on the periphery of ladle bottom, setting wedge angle in the locating block to make diameter of encircle of each locating block bottom more than the diameter of excircle on the mould bottom, adopting the same material for each locating block and ladle lining.

Owner:崔东瑞

Insulating framework injection mold conducting demolding easily

Owner:深圳科仕瑅科技有限公司

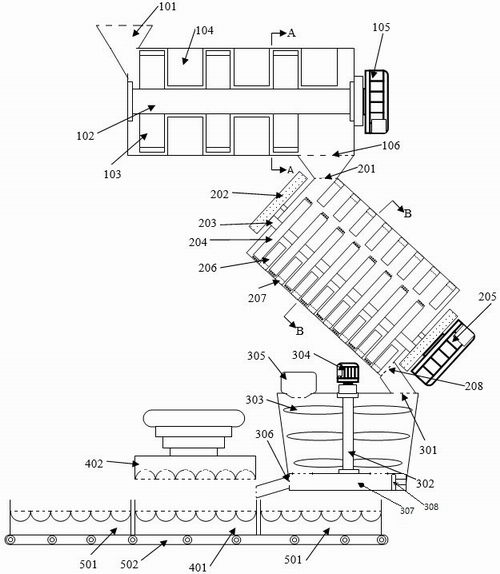

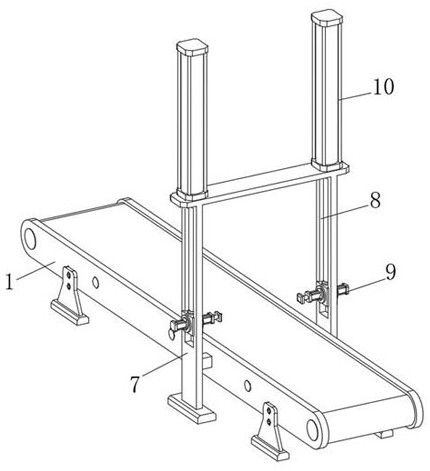

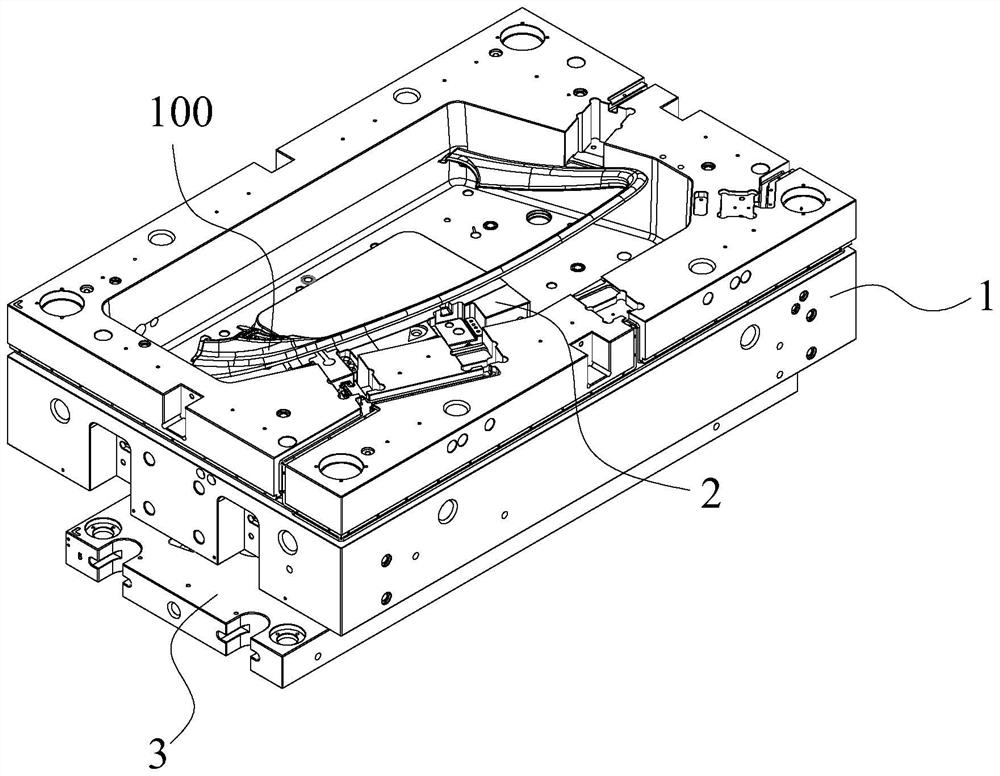

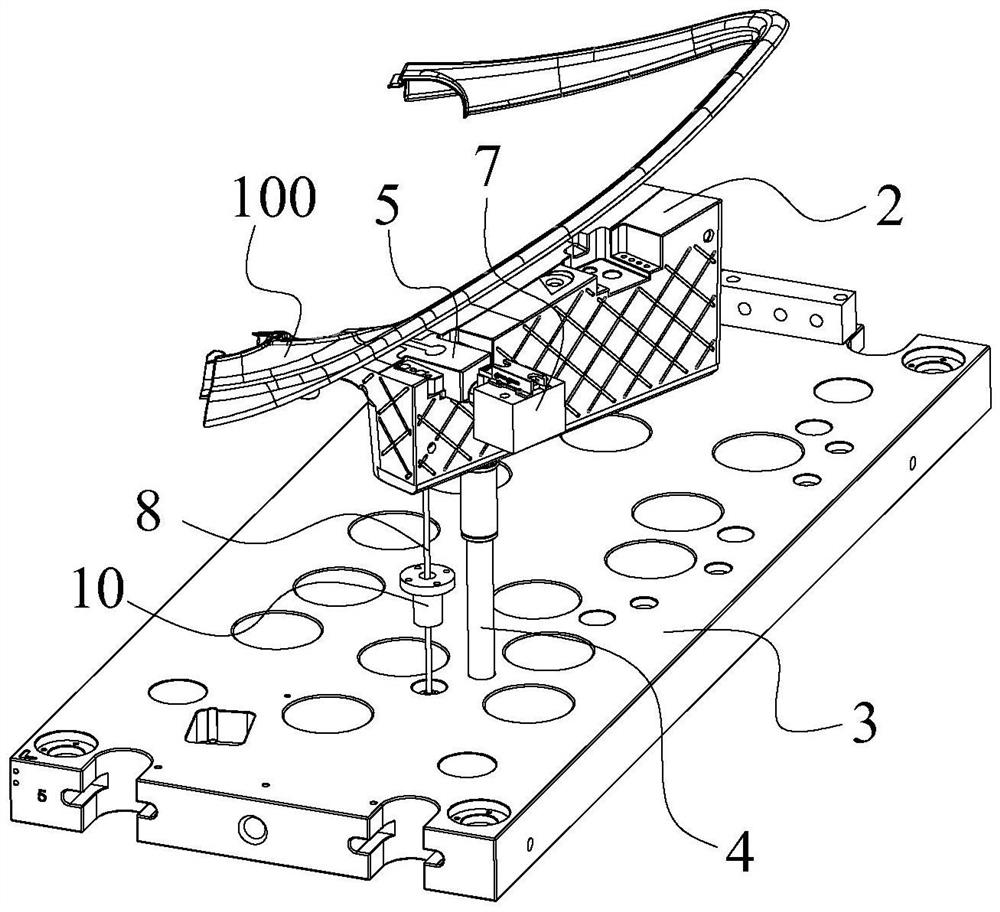

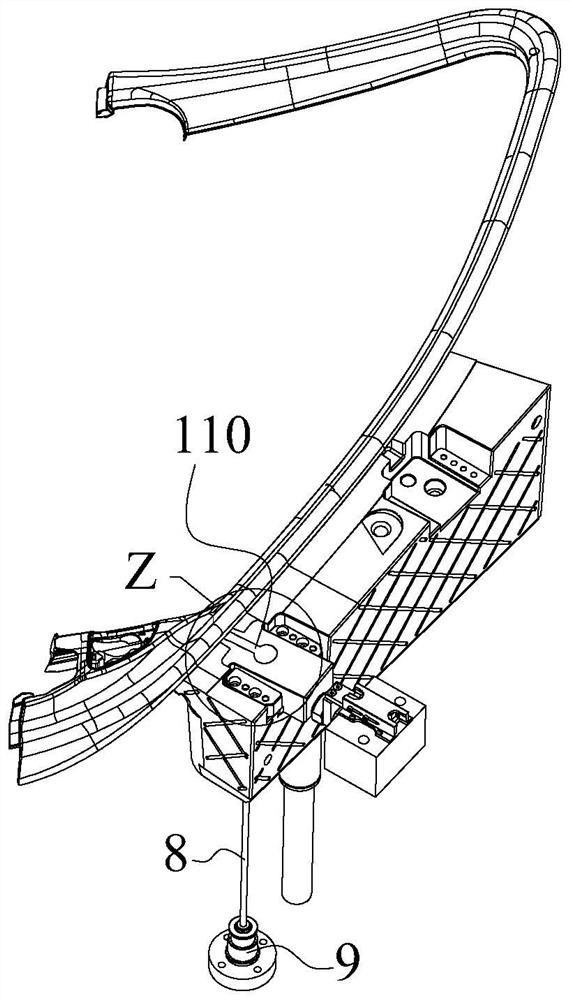

Production method and automatic production device of BCT sleeper

ActiveCN111283858AAvoid breakingImprove production and processing efficiencyDischarging arrangementRebarMechanical engineering

The invention discloses a production method of a BCT sleeper. The method comprises the following specific technological processes of 1, assembling a bottom mold, side molds and end molds together at amold assembling table position after demolding; 2, moving a mold to a sleeve table position to mount a nylon sleeve; 3, mounting a manufactured steel bar at a steel bar table position; and 4, transferring the assembled mold to the other side through a translation vehicle, and pouring concrete into the mold at a discharging table position. According to the production method and an automatic production device of the BCT sleeper, different from the prior art, when demolding is performed in the production and processing process of the BCT sleeper, the demolding process can be automatically carried out, so that the labor requirement is effectively reduced, the labor use cost is effectively reduced, and the normal production and processing efficiency of an enterprise is effectively improved; and meanwhile, through automatic demolding, the breakage and fragmentation generated when the sleeper is separated can be effectively avoided while high-efficiency demolding is ensured.

Owner:光明铁道控股有限公司

Inverted buckle forming mold

InactiveCN112848147AAvoid scrappingThe process of realizing the second ejectionStructural engineeringMechanical engineering

Owner:滁州市东升机械科技有限公司

Chinese herbal medicine crushing and grinding device

InactiveCN112519298AImprove effectivenessRealize the rolling operationTransportation and packagingRotary stirring mixersChinese herbsEngineering

The invention relates to a Chinese herbal medicine crushing and grinding device. The Chinese herbal medicine crushing and grinding device comprises a drying part, a crushing part, a grinding part, a mixing part and a pressing and pelleting part. According to the Chinese herbal medicine crushing and grinding device, all the parts are specifically arranged, especially the grinding part is specifically arranged, so that the traditional Chinese medicine pulverization treatment efficiency and effect are greatly improved, the mixing part is specifically arranged, so that mixed materials are discharged more easily, and the pressing and pelleting part is specifically arranged, so that efficient pressing and demolding effects are achieved.

Owner:王文娟

Concrete test block demolding device

InactiveCN110039644AQuick and efficient demoulding effectEfficient demouldingDischarging arrangementAutomationPush out

The invention belongs to the technical field of concrete manufacturing equipment, and particularly relates to a concrete test block demolding device. The device comprises a test mold position, a positioning push-out mechanism and a driving mechanism, wherein the positioning push-out mechanism comprises an upper driving cylinder positioned above concrete test molds and a side driving cylinder positioned on the sides of the concrete test molds; the driving mechanism comprises thrust cylinders with the same quantity with that of concrete test blocks and a thimble assembly which directly applies thrust to the concrete test blocks through the thrust cylinders; the thimble assembly comprises thimbles with the same quantity with that of the thrust cylinders and a connecting plate which is used for connecting the thimbles side by side; needle tips of the thimbles are opposite to round holes at the bottom of the concrete test molds; and the distances from any two needle tips to the concrete test blocks are different. According to the technical scheme of the device, rapid demolding is achieved, the concrete test blocks can be automatically transferred after demolding, the whole demolding process is high in automation degree, and the working efficiency is obviously improved.

Owner:CHONGQING CONSTR ENG NEW BUILDING MATERIALS +1

Preparation method of self-dropping nano-porous anodic alumina membrane

InactiveCN103374739AImprove oxidation efficiencyImprove product qualityAnodisationNano al2o3Electrochemistry

The invention discloses a preparation method of a self-dropping nano-porous anodic alumina membrane, wherein an electrochemically polished aluminum sheet is prepared to a dense porous nano alumina template by utilizing sulfuric acid as electrolyte, a nano-porous anodic alumina template is prepared by constant current electrolytic oxidation, the oxidation efficiency is high, alumina nanopores on the template are orderly and trimly arranged, the quality of the template is good and the product is trim. The technical problem to be solved in the invention is to improve the preparation maneuverability and demolding efficiency of the nano-porous alumina template, the constant current oxidization preparation manner is used for effectively reducing the preparation difficulty and improving the oxidization efficiency, the template growth speed is as high as 3-5 micron / h, the nanopore arrays are uniformly distributed, the template quality is high, and meanwhile, a reverse electrode gas hedge manner is used for quickly and efficiently demolding the template so as to ensure convenient and efficient production.

Owner:夏天

Cement board demolding device for production

ActiveCN112829052AEfficient demouldingAchieve clampingDischarging arrangementSolid waste managementCement boardEngineering

The invention relates to a cement board demolding device, and particularly relates to a cement board demolding device for production. The cement board demolding device for production is high in automation degree, high in demolding efficiency and good in demolding effect, and a cement board is not prone to being damaged. The cement board demolding device for production comprises a bottom plate, a containing mechanism and a demolding mechanism, wherein supports are evenly arranged on the bottom plate, the containing mechanism is arranged between the supports, and the demolding mechanism is arranged on the bottom plate. According to the cement board demolding device for production, a mold and the cement board are placed through the containing mechanism, and then efficient demolding of cement is achieved under cooperation of the demolding mechanism; and a clamping mechanism is arranged, and therefore clamping of the mold and the cement board is achieved.

Owner:西安兴旺盛建材有限公司

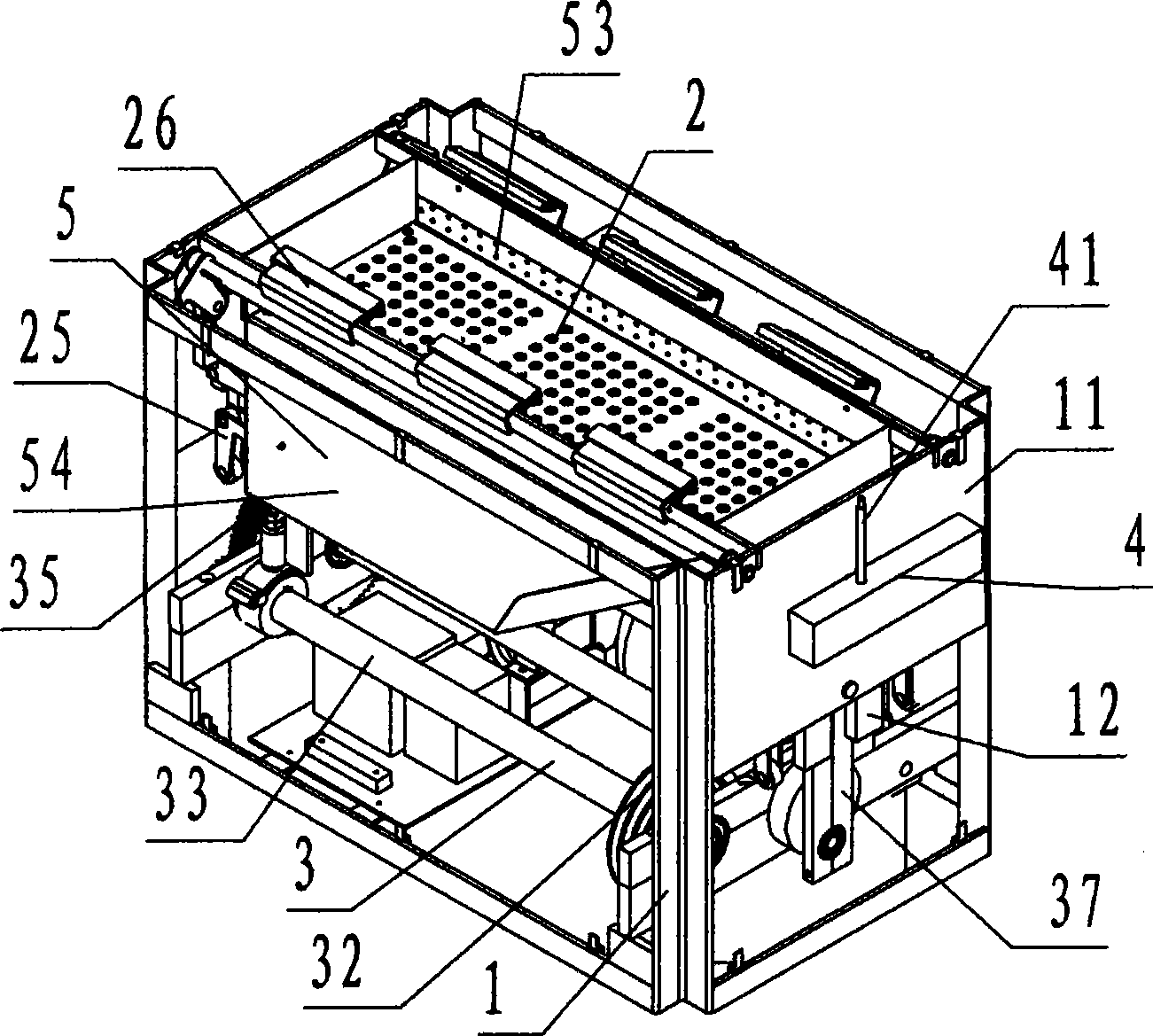

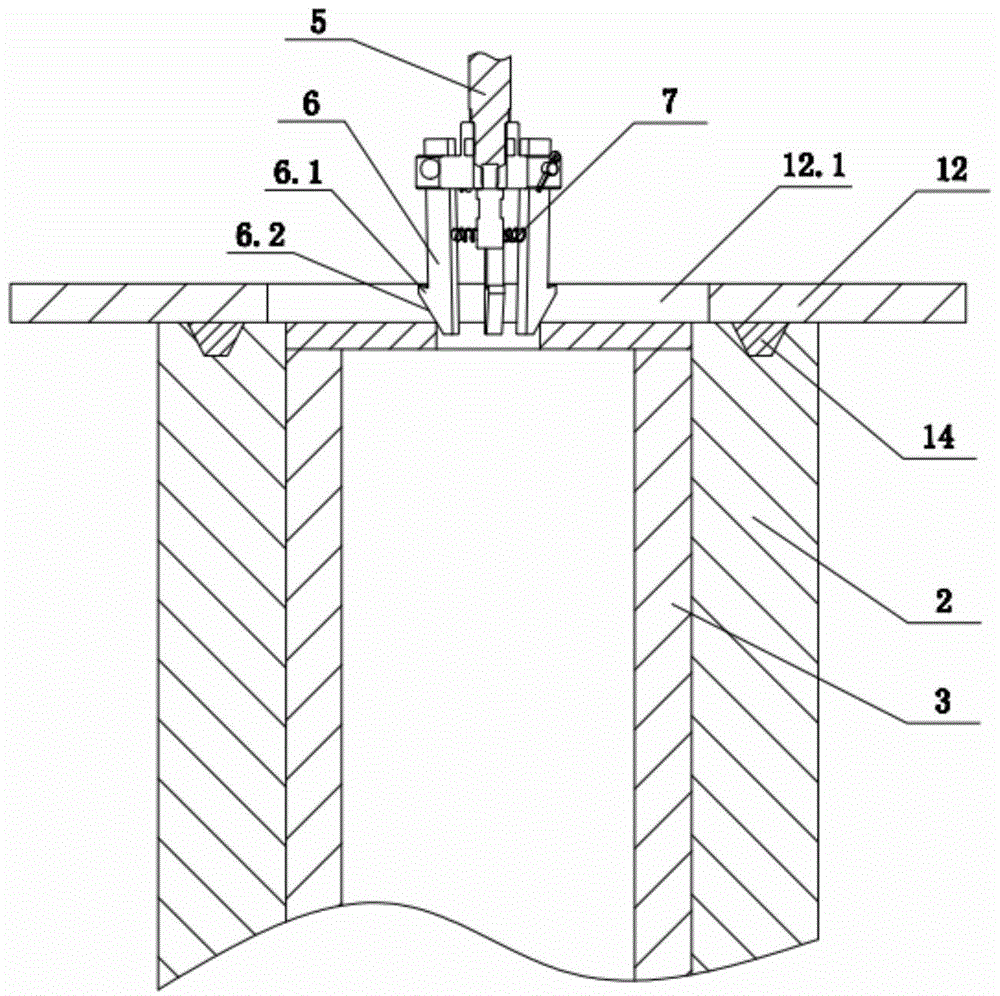

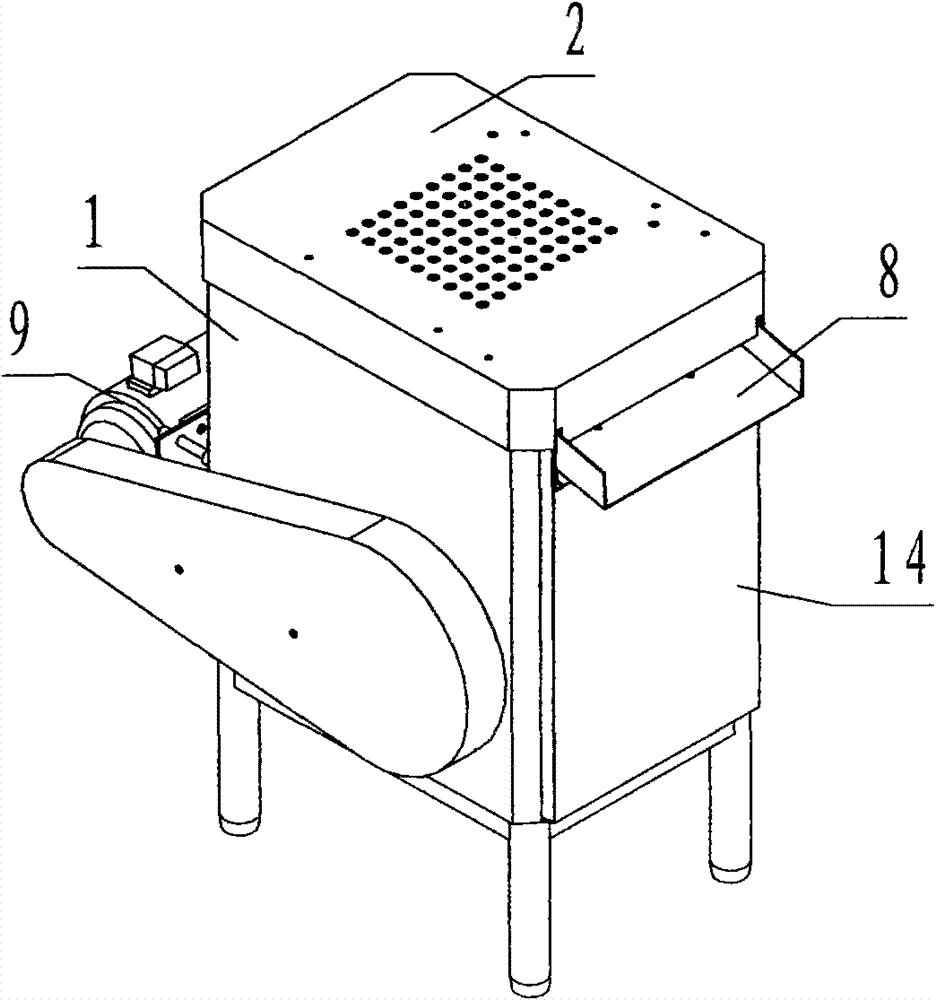

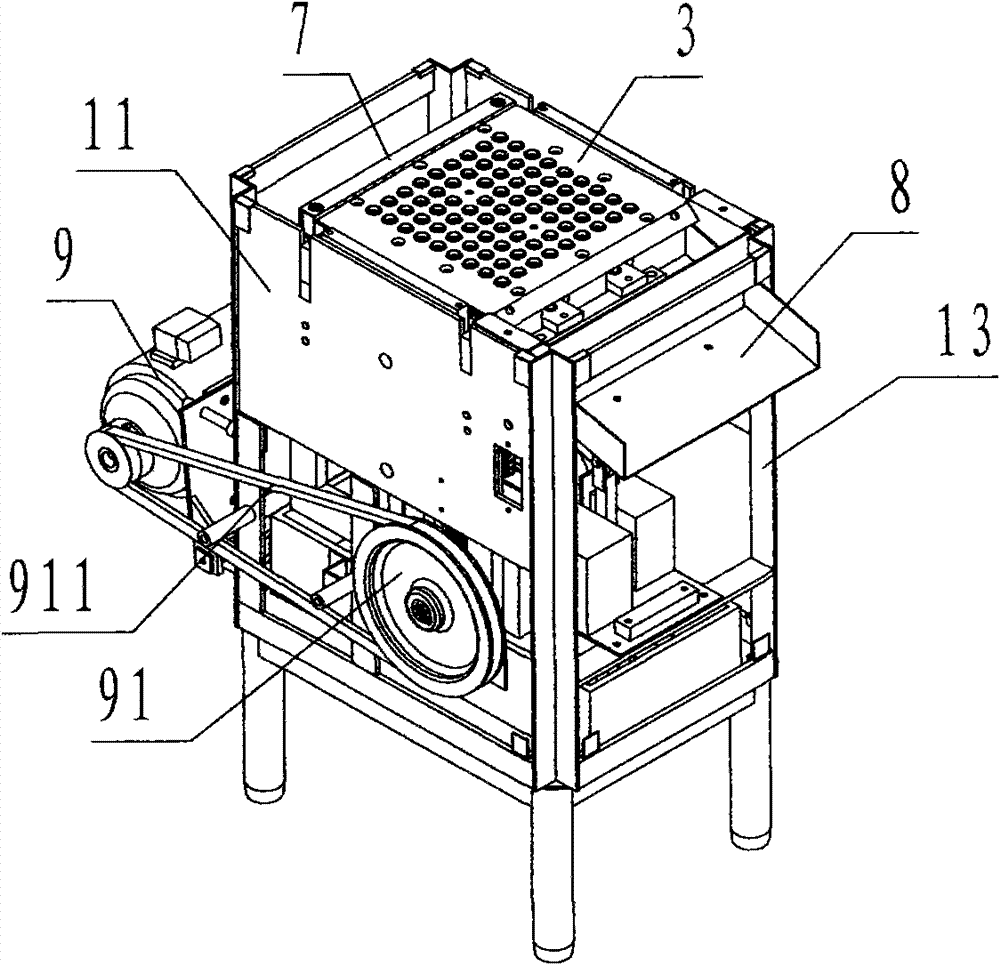

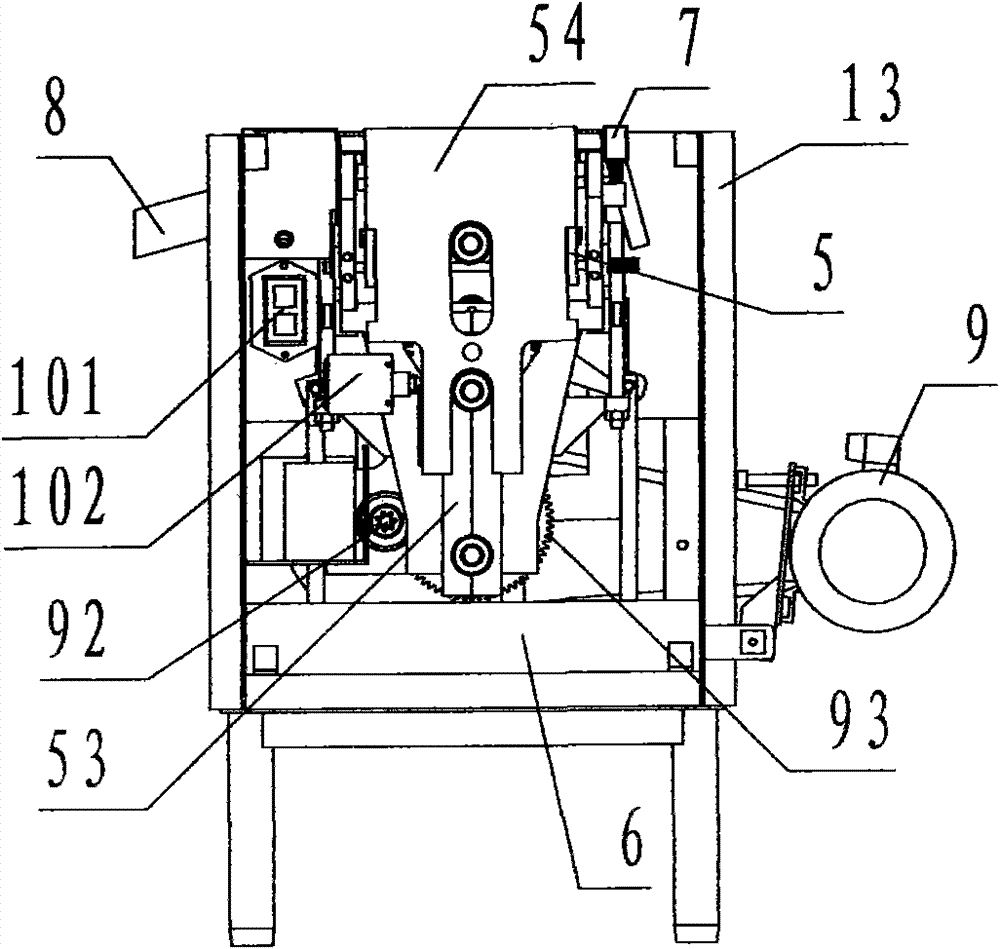

Automatic demolding device of frozen noodles production line

The invention provides an automatic demolding device of frozen noodles production line, belonging to the field of food processing machinery, wherein the demolding device consists of a split noodle die box, a chain-plate conveying mechanism, a cam mechanism, a prying plate and a rack; the split noodle die box consists of a front die box, a middle die box and a rear die box; the chain-plate conveying mechanism comprises chain wheels, chains with accessories, a driving shaft, a driven shaft, a chain plate, a tensioning device and the like; the tensioning device is connected with the driven shaft; two chains with accessories are connected with each other via the chain plate; the cam mechanism comprises a cam, a cam roller, a slot beam, a guide column, a top rod, a top rod seat, a guide sleeve and the like; the big end section of the cam is mounted on the driving shaft via a bearing; the other end is fixed on the slot beam; one end of the guide column is fixed with the chain plate; the other end of the guide column is in sliding match with the guide sleeve; and the prying plate is of a wedge-shaped structure, and is fixed with the rack. The demolding device can fast and reliable demold the whole row of frozen noodles; and the demolding device has the characteristics of compact structure, low cost and the like.

Owner:ZHENGZHOU UNIV

A sponge mop demoulding device

The invention relates to a demoulding device for a mop, in particular to a demoulding device for a sponge mop. The technical problem is: to provide a sponge mop demoulding device which saves time and effort, improves demoulding efficiency, and can adapt to sponge mop molds of different heights. The invention provides such a sponge mop demoulding device, which includes a sponge mop mould, an adjustment mechanism and a demoulding mechanism; the sponge mop mold is evenly equipped with a sponge mop body, and the left and right sides of the sponge mop mold are placed on the ground with adjustment mechanisms , The upper part of the adjustment mechanism is equipped with a demoulding mechanism. The adjustment mechanism can be used to demould the sponge mop molds of different heights, expanding the scope of application of the equipment; the demoulding mechanism can be used to demould the sponge mop body, which can save manpower and improve the efficiency of demoulding; use the limit mechanism , can quickly find a suitable demoulding position, save time and improve the efficiency of demoulding.

Owner:盐城永盛海绵制品有限公司

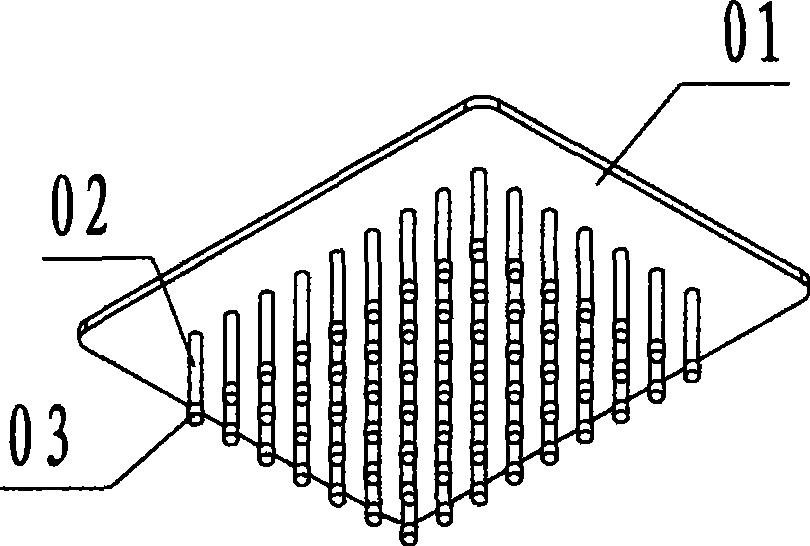

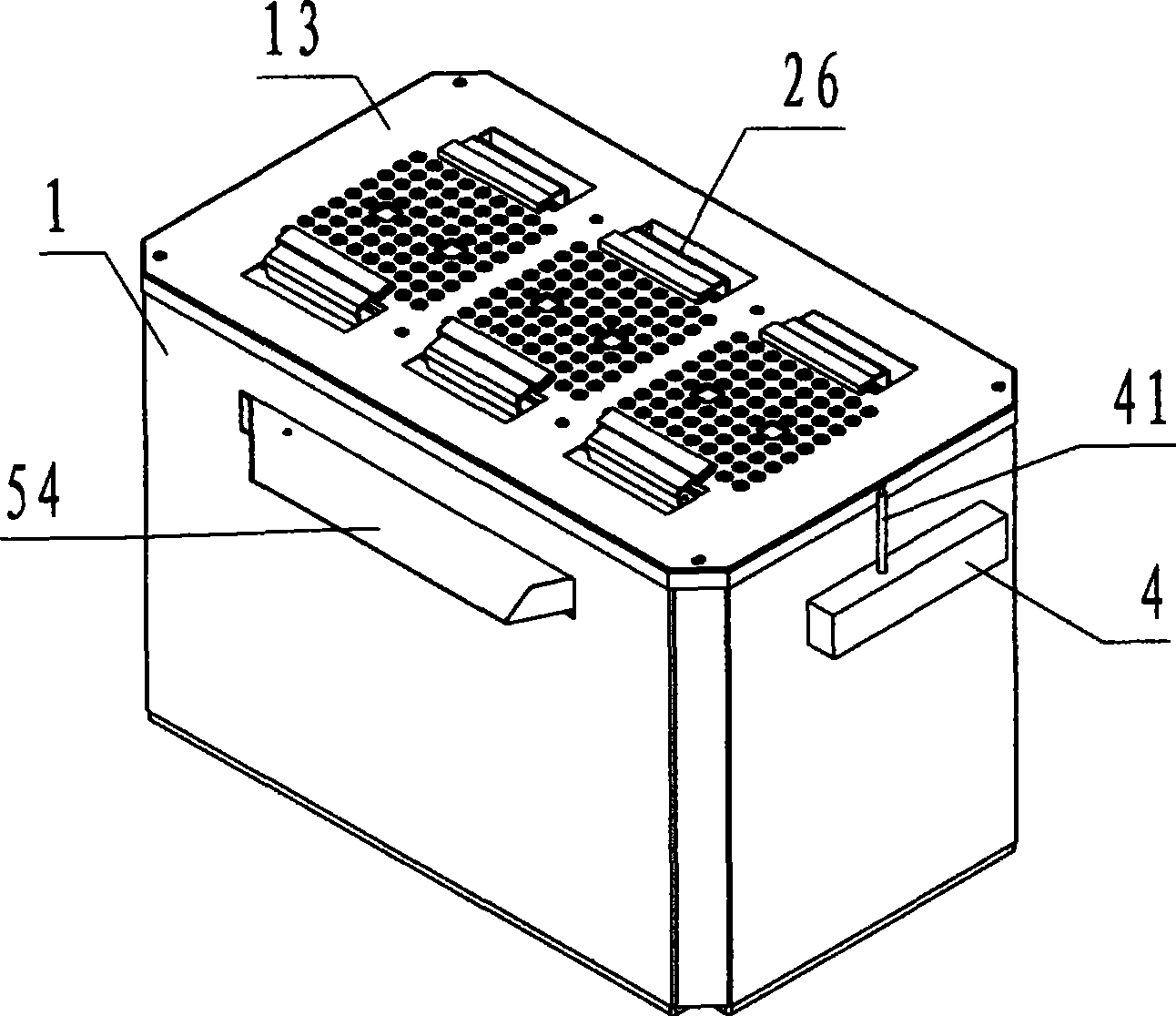

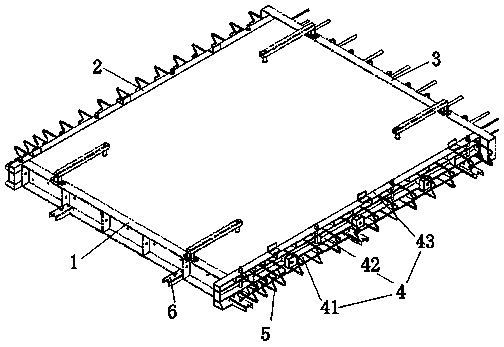

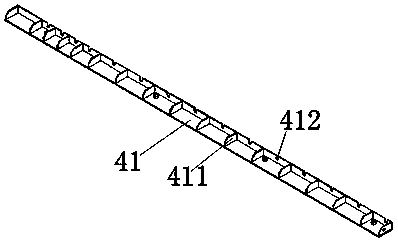

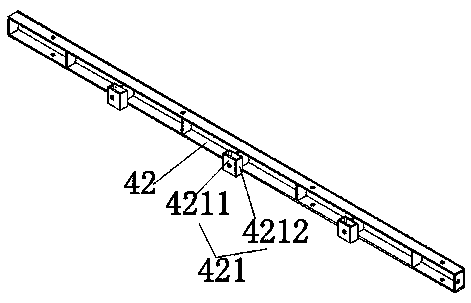

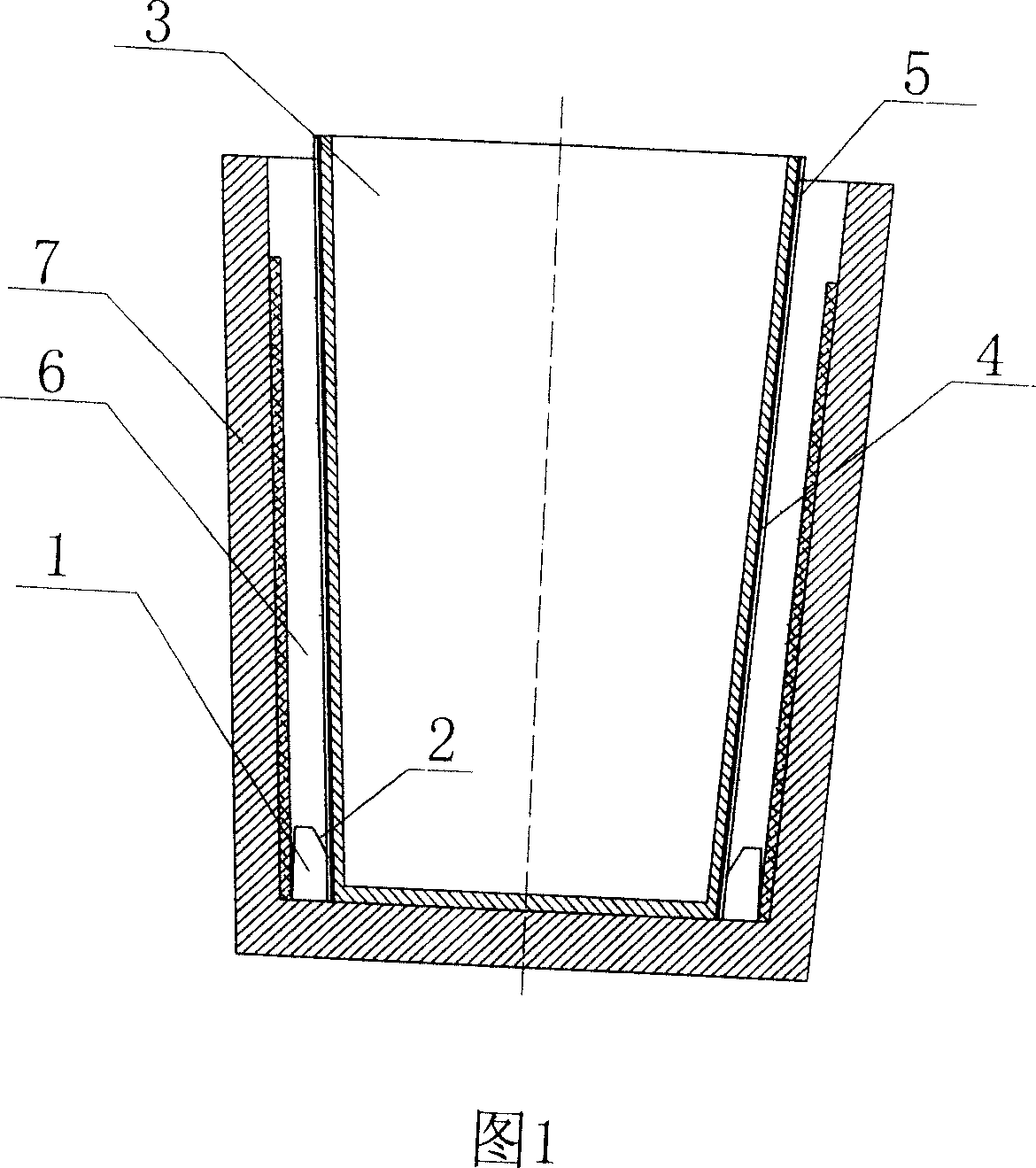

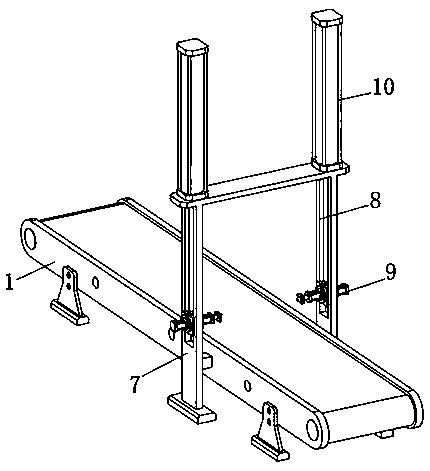

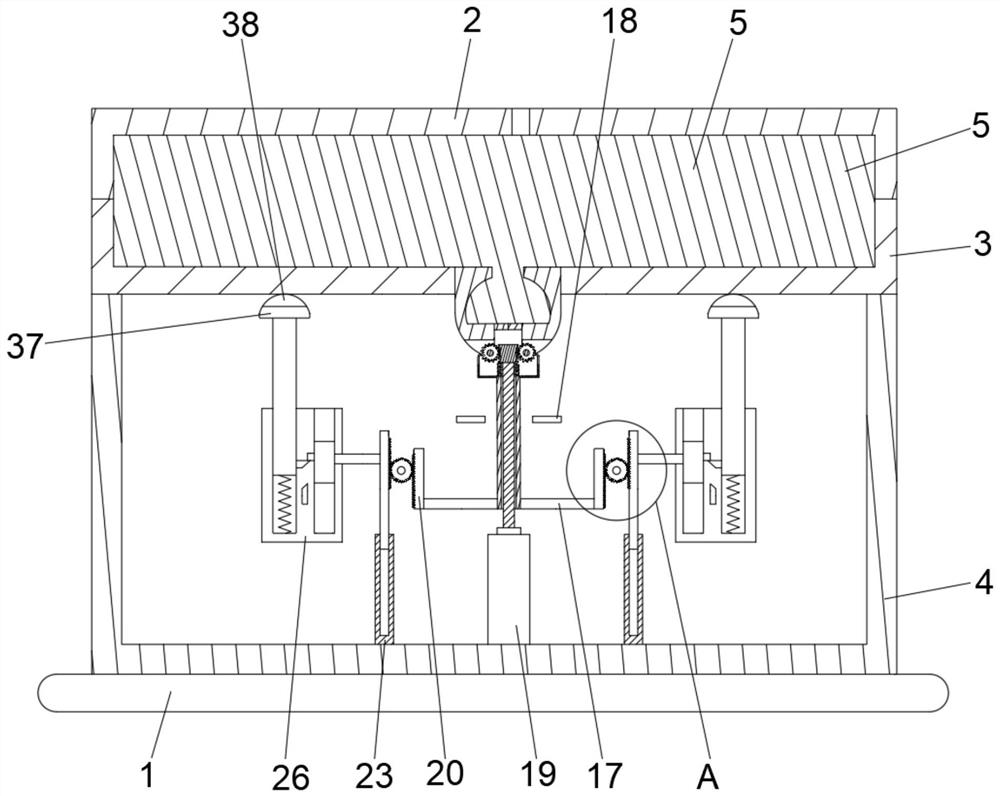

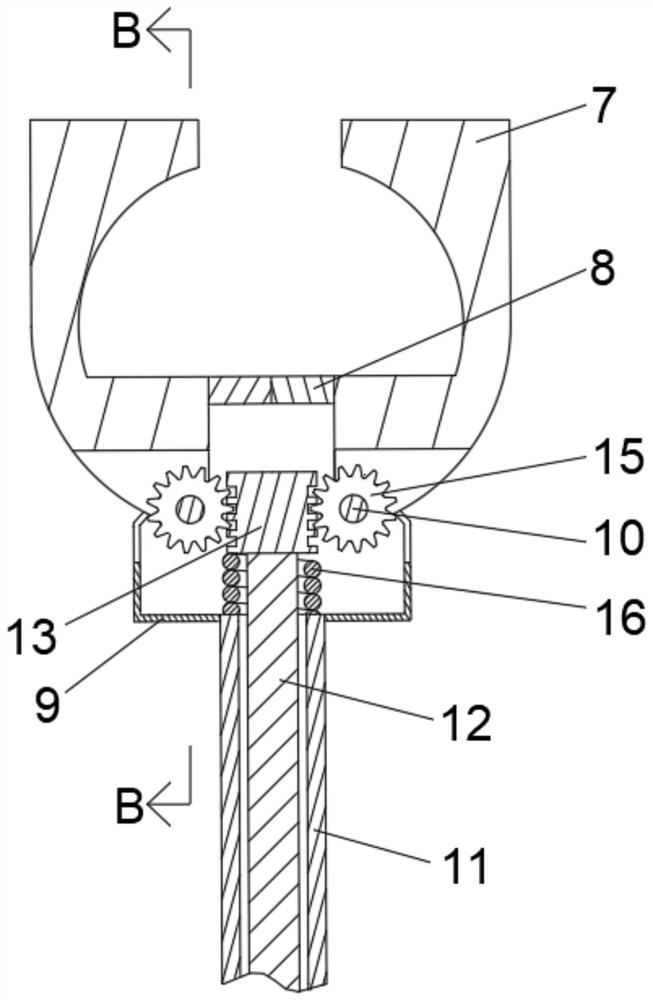

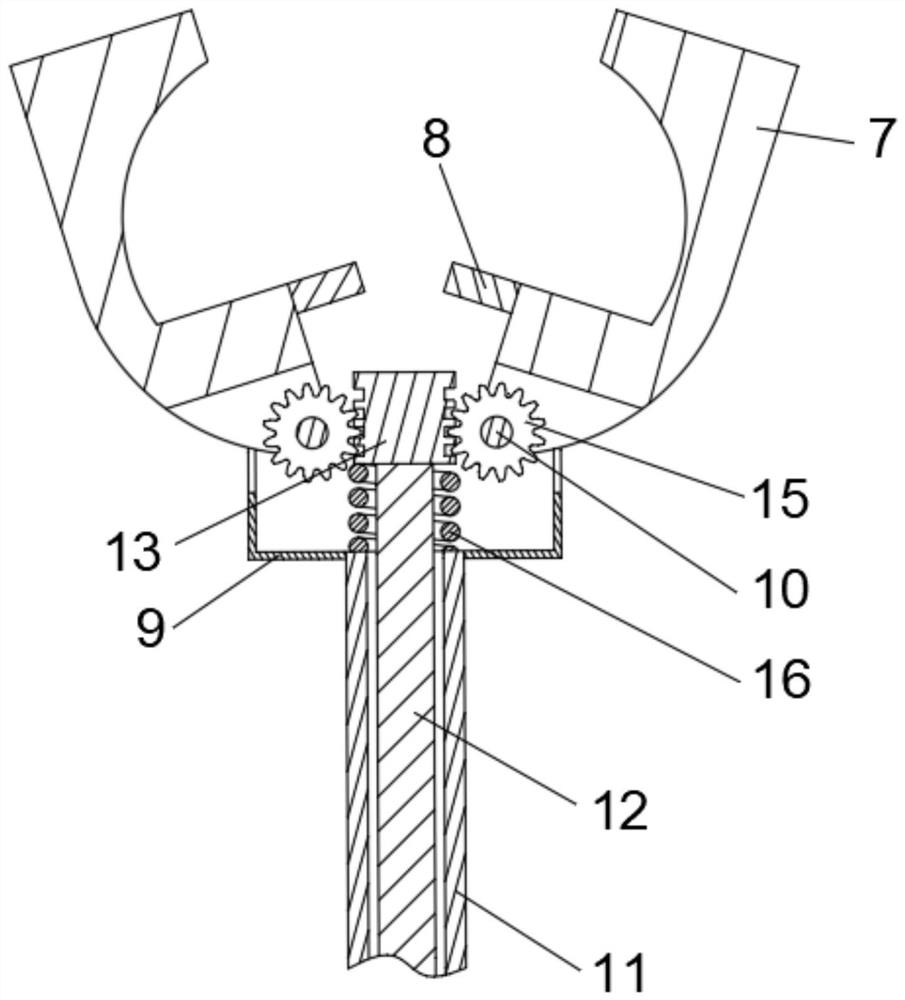

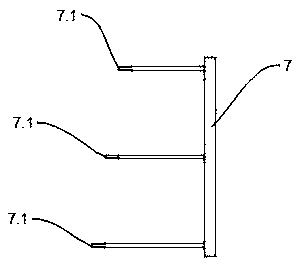

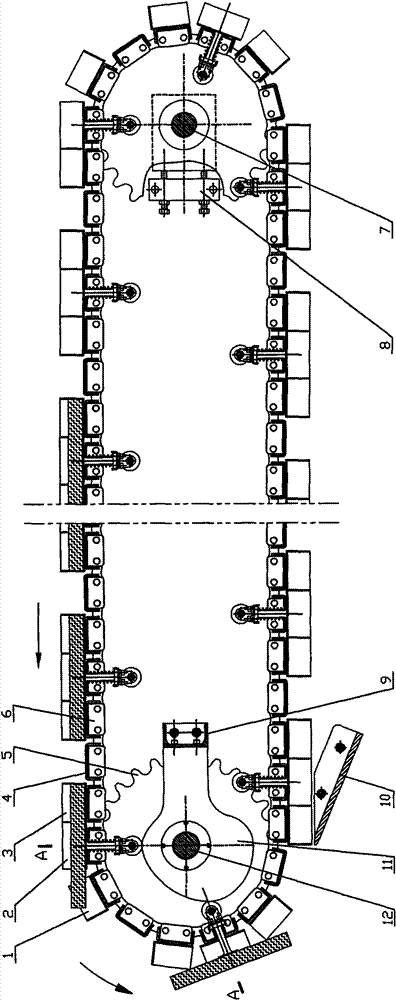

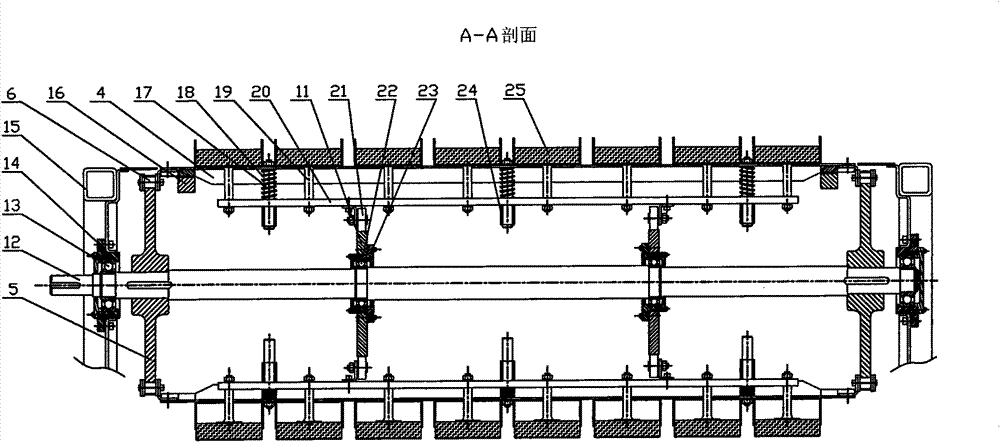

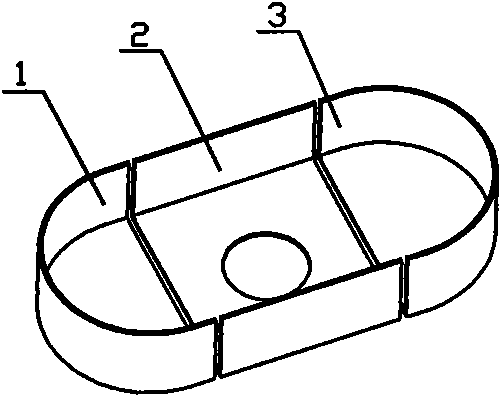

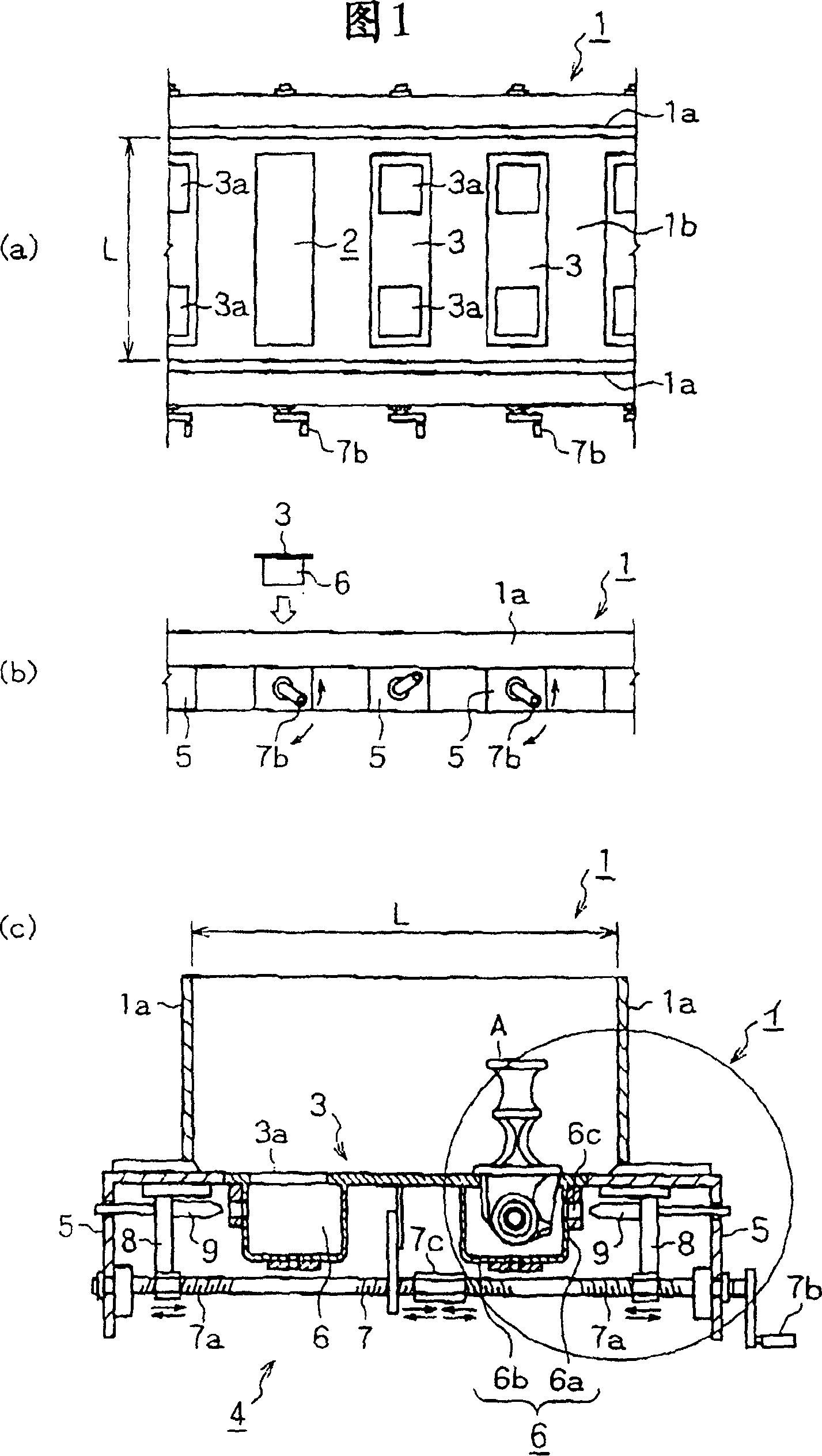

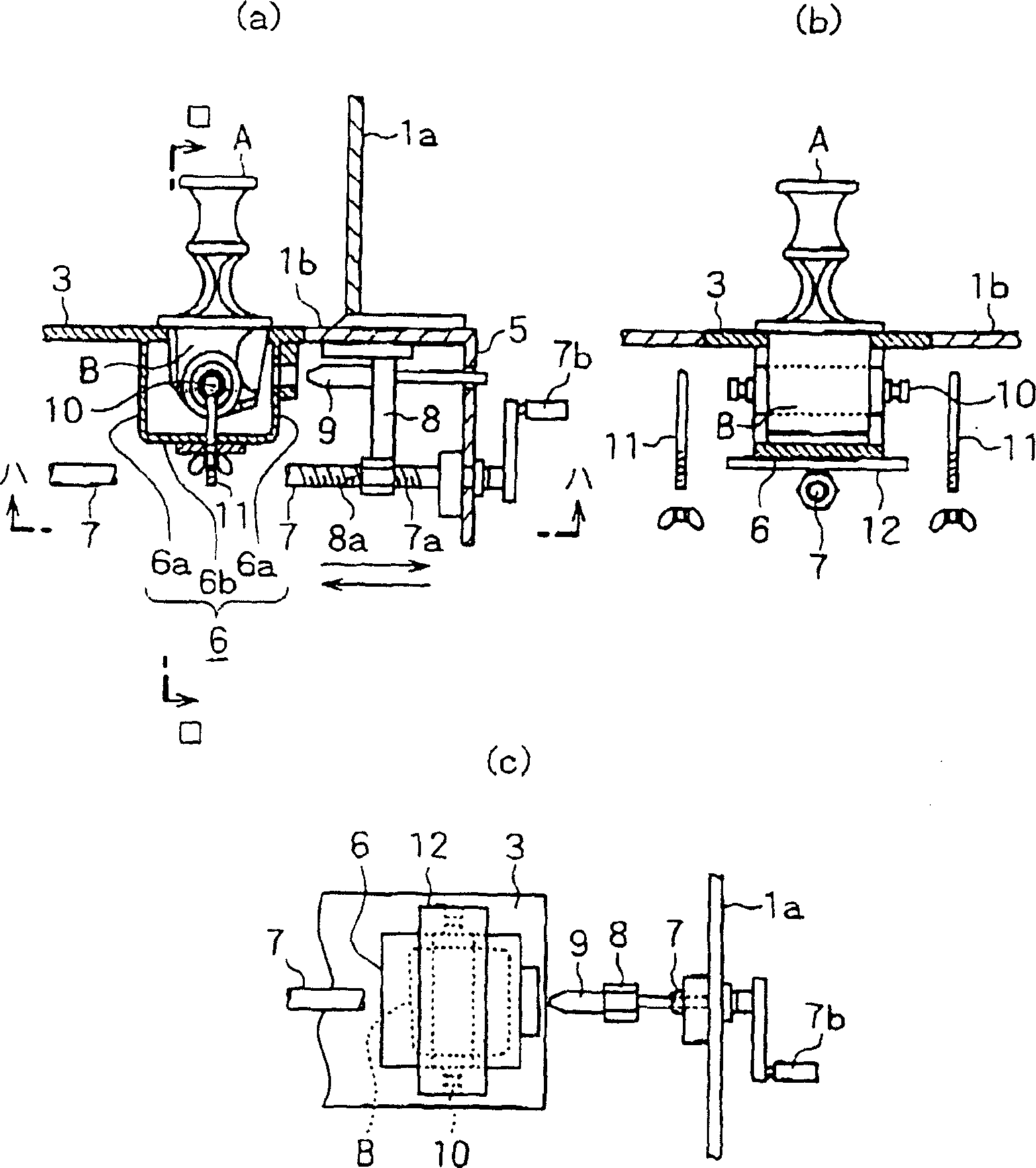

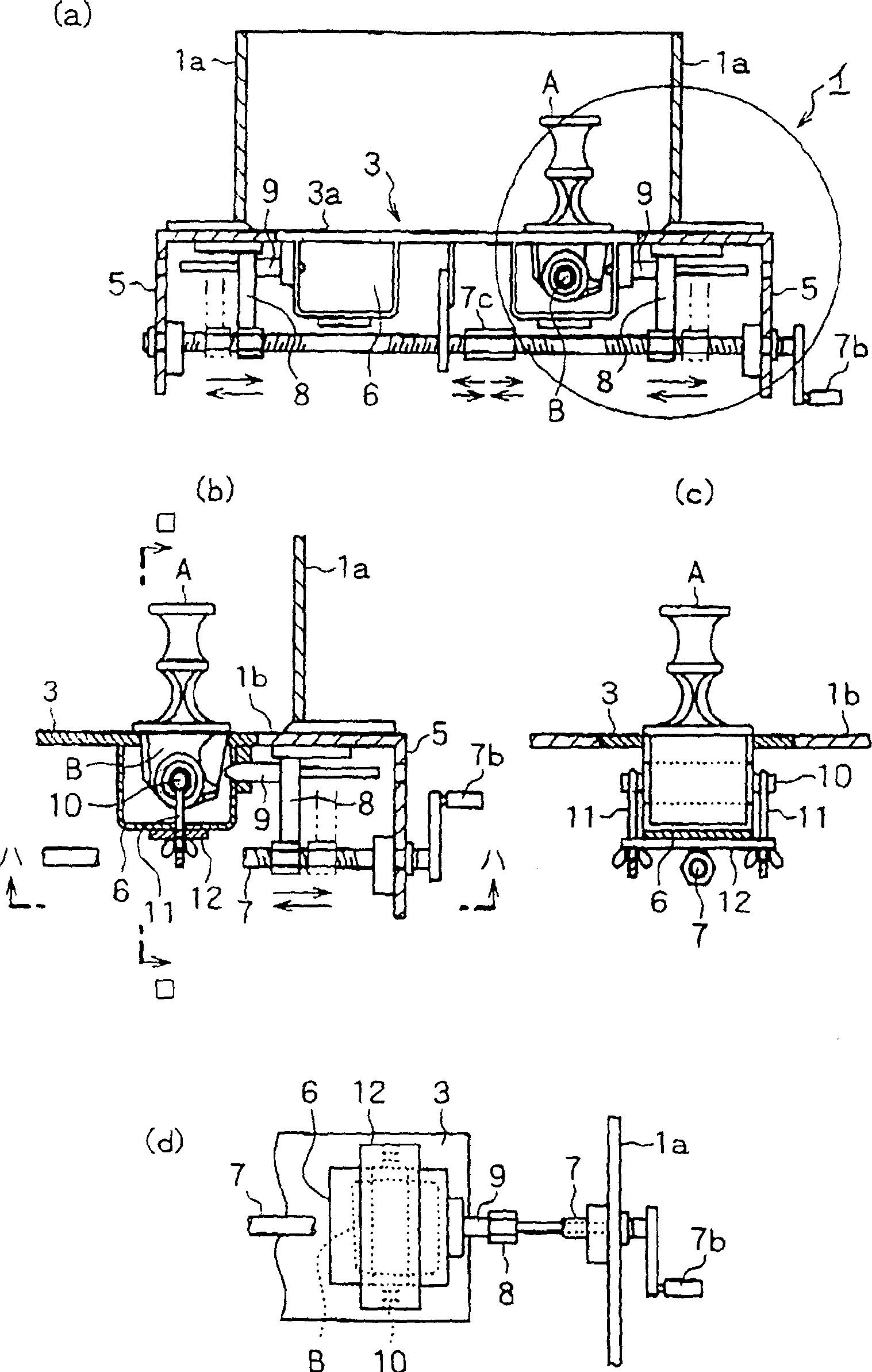

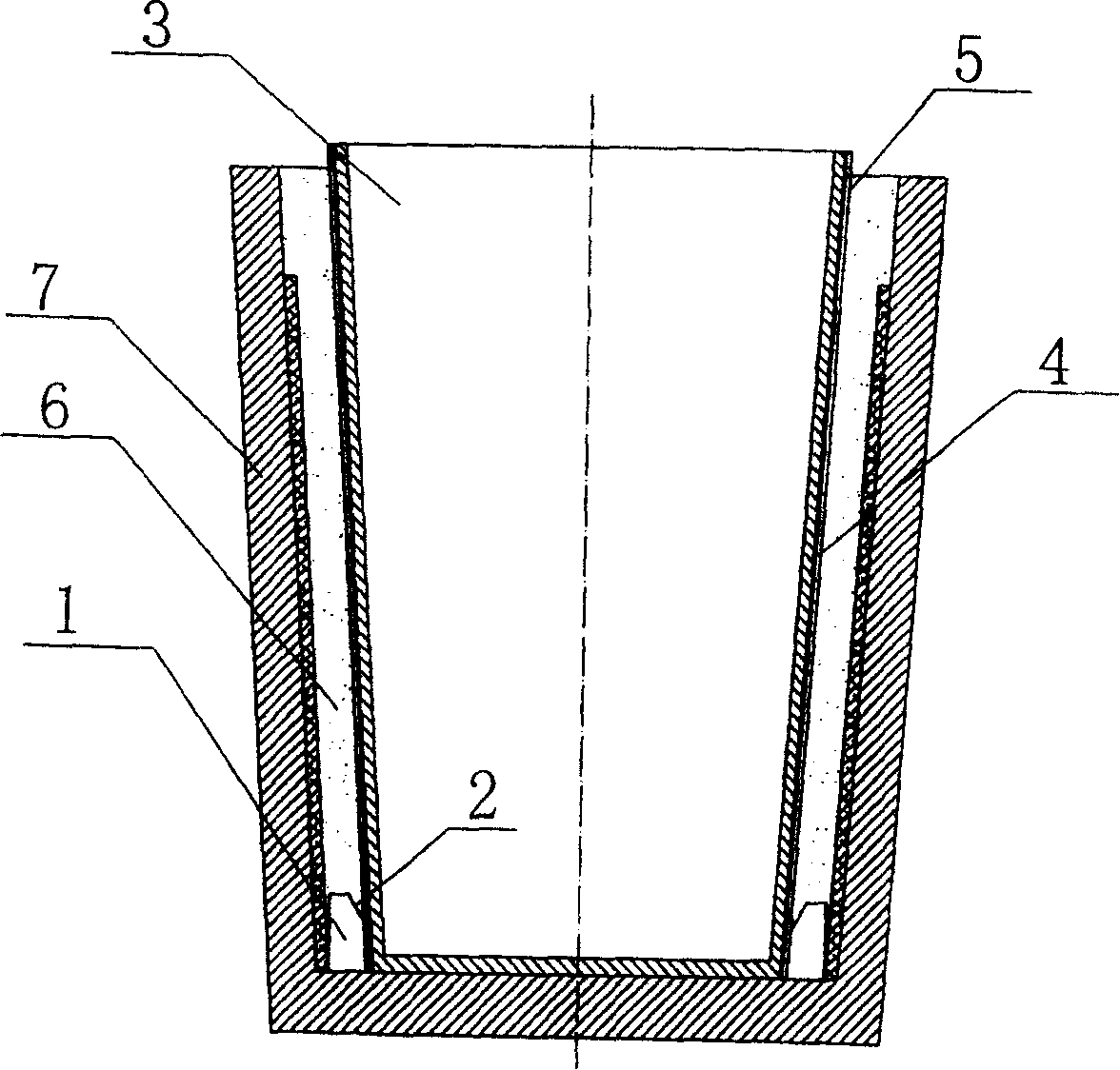

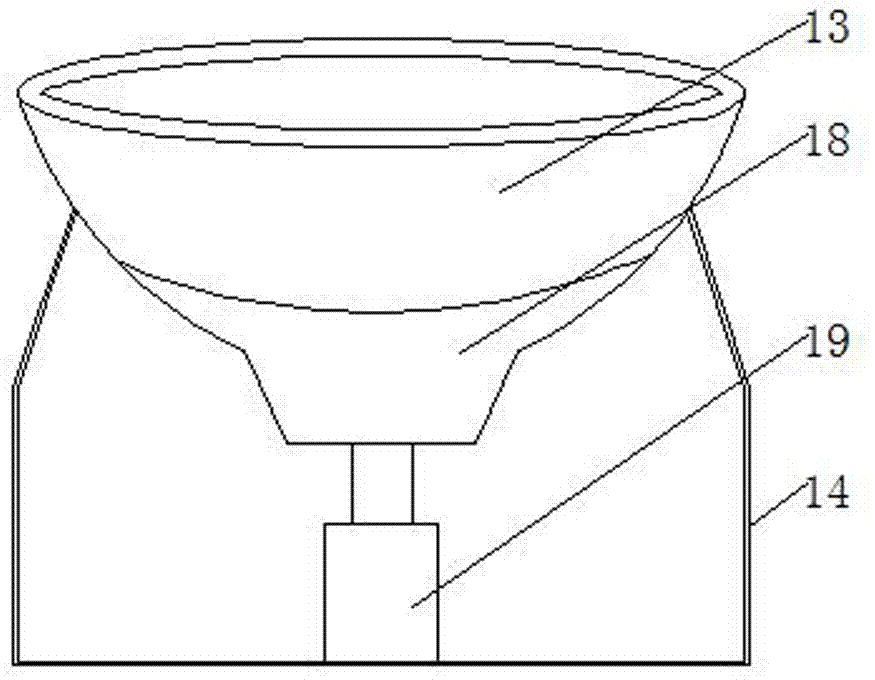

Concrete member manufacturing molding box

InactiveCN1669757AEfficient demouldingEasy to operateMould separation apparatusMouldsEngineeringSmall hole

Provided is a form for production of a concrete member which can easily be separated from the form without damaging it even when producing a concrete sleeper having numerous shoulders. This form is composed of a form body 1 having the openings 2 on its bottom, the bottom forms 3 detachably installed in the openings 2, and a holding mechanism 4 for releasably fixing the bottom forms 3 to the lower side of the form body 1. The bottom form 3 has a small hole necessary for setting up an anchor member A to the inside of the form body 1 in reversion. The holding mechanism 4 is composed of the rotary rods 7 bridging horizontally between the legs 5 and 5, the movable rods 8 installed vertically between respective receivers 6 and the legs 5, and the holding pins 9 set up horizontally on the upper ends of the movable rods 8.

Owner:NIPPON KOGEN KONKURIITO

Low-cost mass production technological process for preparing large-thickness composite material and forming mold of large-thickness composite material

PendingCN112537046AEfficient matching of takt timesIncrease productivityManufactured materialMechanical engineering

The invention discloses a low-cost mass production technological process for preparing a large-thickness composite material and a forming mold of the large-thickness composite material. The forming mold comprises an outer mold, an inner mold, a heating pipeline, a bolt, an inner mold blocking block and an ejection device; The low-cost mass production technological process comprises the steps of A,composite material blank paving, B, composite material blank preheating, C, mold pressing curing, D, demolding and E, inner mold lower mold recycling. In conclusion, a detachable inner mold form is adopted, a plurality of inner mold lower molds can be configured at the same time, different inner molds can be designed and manufactured for use, the takt time of mold pressing process mass productioncan be effectively matched, the production efficiency is improved, and the production cost is reduced; preparation of composite materials of different structures is achieved, and the design and manufacturing cost of an extra mold is reduced; a rapid blank preheating mode is adopted, so that uniform heating of the large-thickness composite material is ensured, and the forming quality and the mechanical property of the composite material are ensured; and application of an internal releasing agent is omitted, and the raw material cost is reduced.

Owner:廊坊市飞泽复合材料科技有限公司

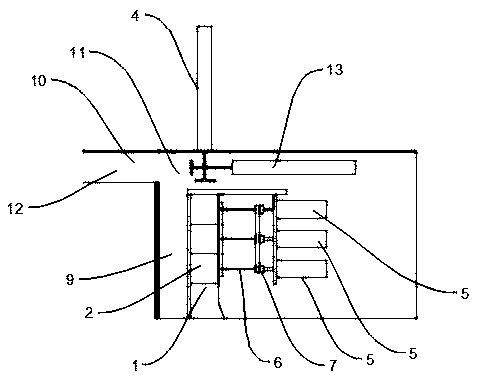

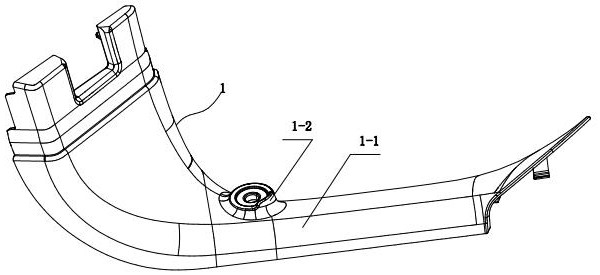

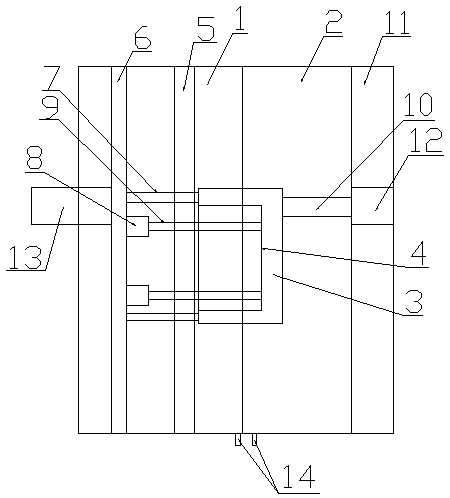

Demolding device of injection mold used for inner and outer inverted buckle structure

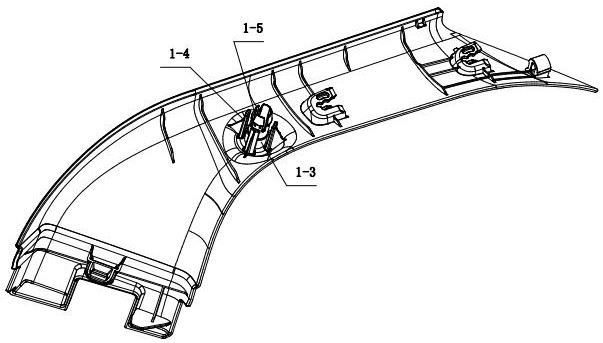

The invention discloses a demolding device of an injection mold used for an inner and outer inverted buckle structure. The demolding device comprises a forming core rod and a driving assembly, wherein the forming core rod is used for forming inverted buckles composed of inner inverted buckles (1-5) and outer inverted buckles (1-4), and the driving assembly is used for driving the forming core rod to move so as to complete demolding of the inverted buckles. The forming core rod sequentially comprises an outer core rod body (4), a middle core rod body (5) and an inner core rod body (6) from outside to inside, and the driving assembly is installed in the mold and connected with the lower end of the forming core rod and comprises a primary core pulling driving assembly for sequentially driving the inner core rod body (6) to achieve core pulling and a secondary core pulling driving assembly for driving the middle core rod body (5) and the outer core rod body (4) to achieve core pulling at the same time. The primary core pulling driving assembly and the secondary core pulling driving assembly are connected through a linkage mechanism. Therefore, the inner inverted buckles and the outer inverted buckles can achieve sequential graded one-time demolding, the structure is simple, and demolding is more effective.

Owner:宁海县第一注塑模具有限公司

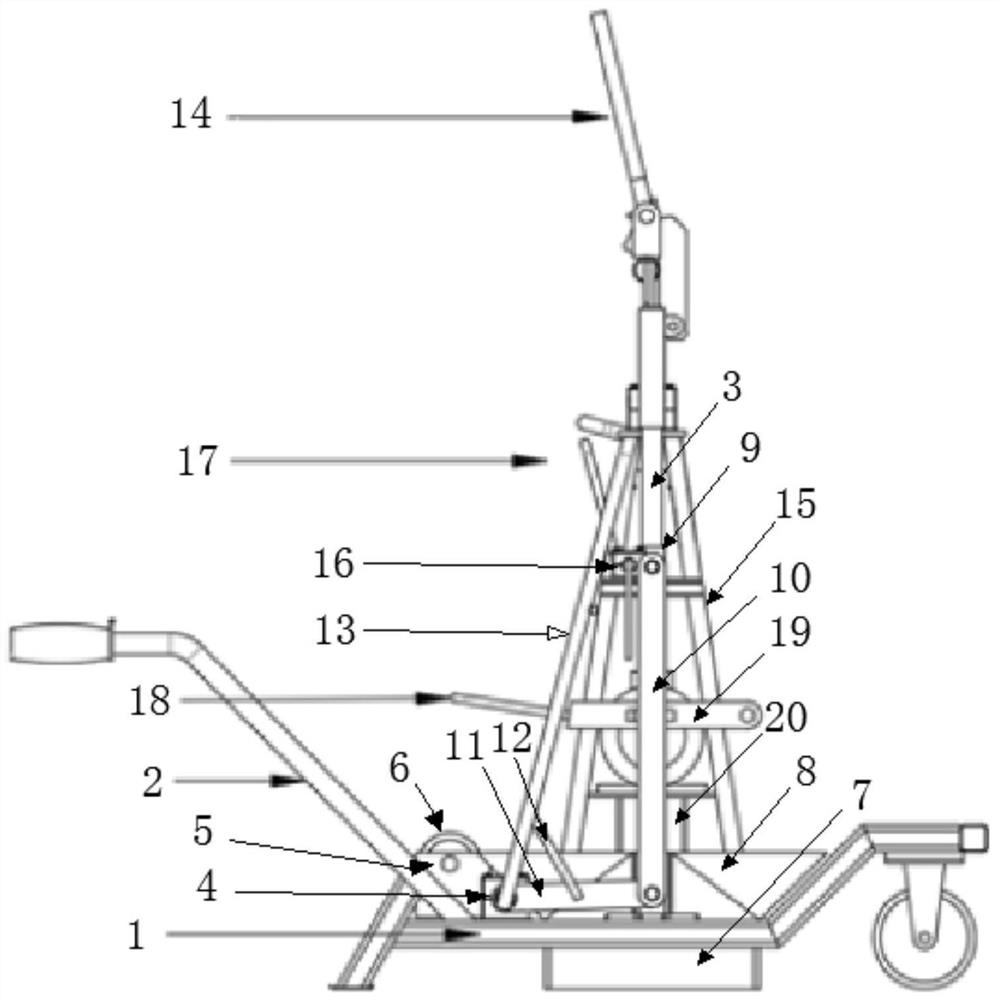

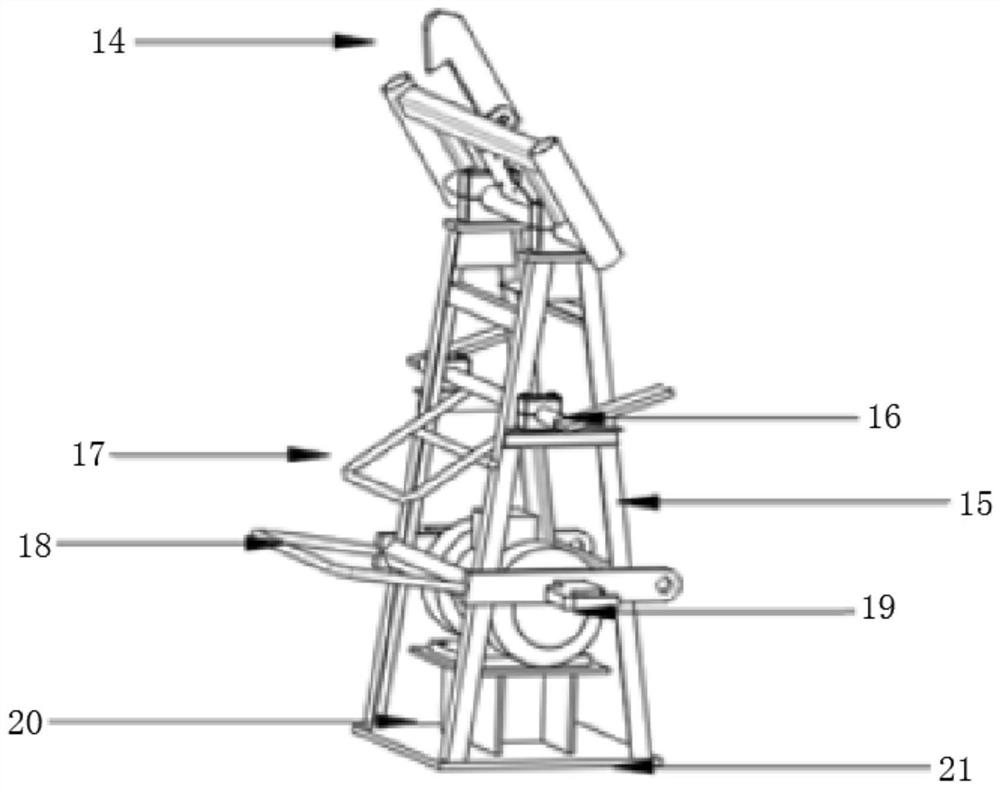

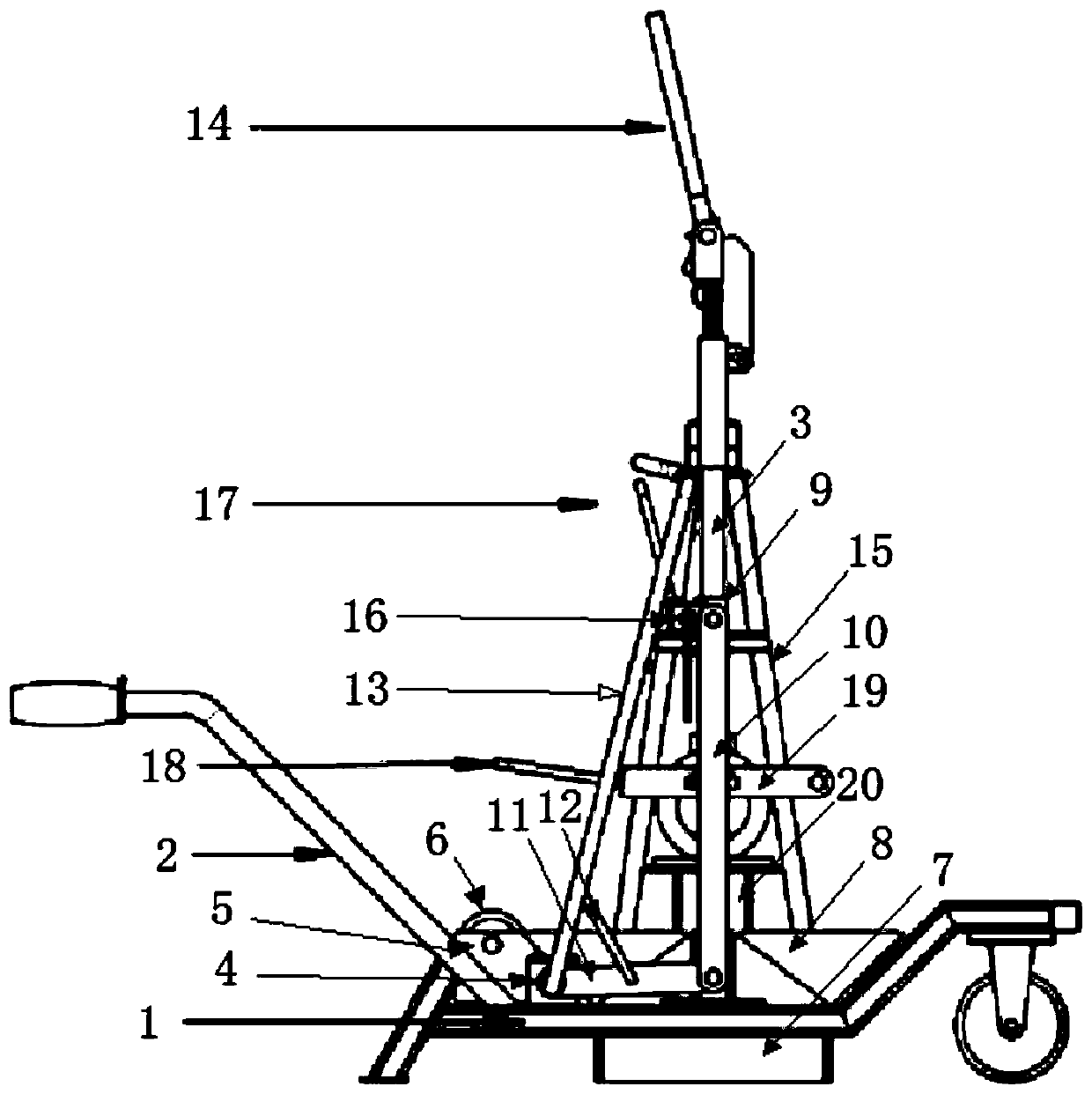

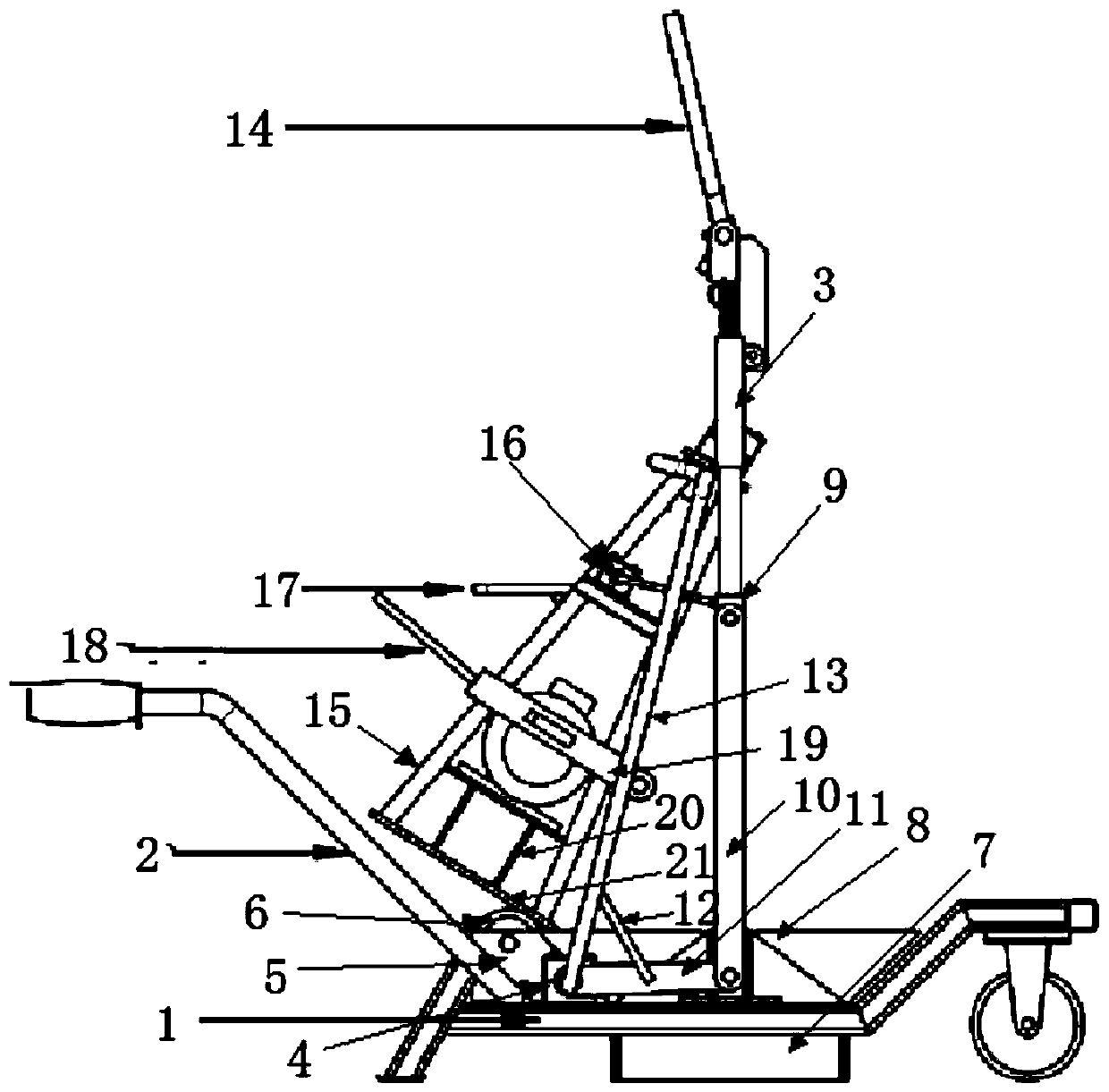

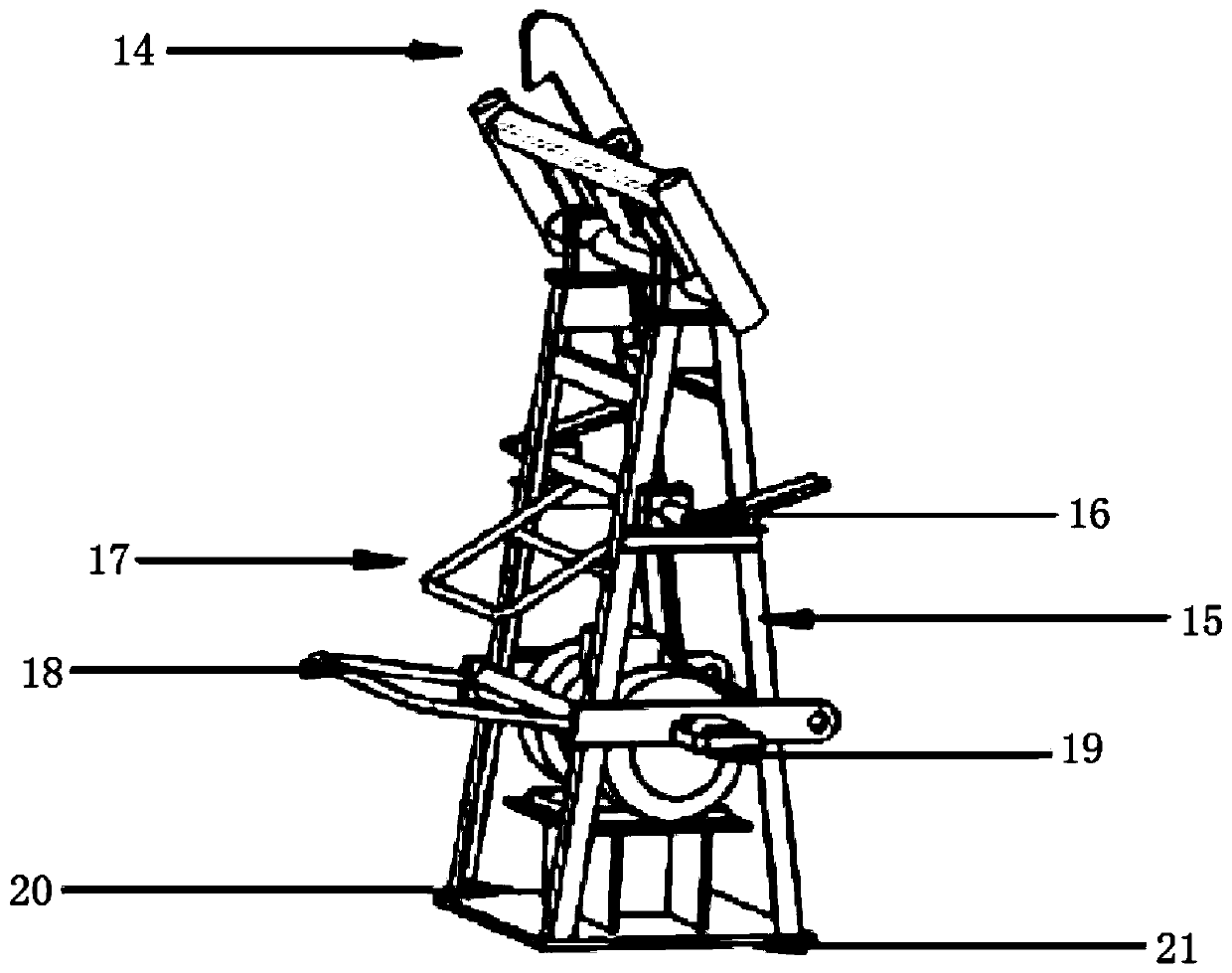

A mobile asphalt mixture stripping machine

ActiveCN111519504BEasy to compact and formEfficient demouldingRoads maintainenceVehicle frameAsphalt

The invention discloses a mobile asphalt mixture stripping machine, which comprises a vehicle frame, the top left side of the vehicle frame is fixedly installed with a frame handrail, and the top right side of the vehicle frame is fixedly installed with oppositely arranged guides at the front and rear. Rod, the top right side of the frame is fixedly installed with a fixed block and a release agent brushing box, and the release agent brushing box is located inside the fixed block, and the inside of the release agent brushing box is equipped with a release agent roller brush , There is a through groove inside the frame, which is convenient to limit the forming mold inside the through groove, and a receiving hopper and a sliding sleeve are fixedly installed on the top of the forming mold, so that the asphalt mixing bucket can be poured through the receiving hopper. into the fixed block, and at the same time, the receiving hopper is movably socketed on the guide rod, so that the forming mold and the receiving hopper can be limited. The second pull plate and the first pull plate move.

Owner:吉林嘉鹏公路养护有限公司

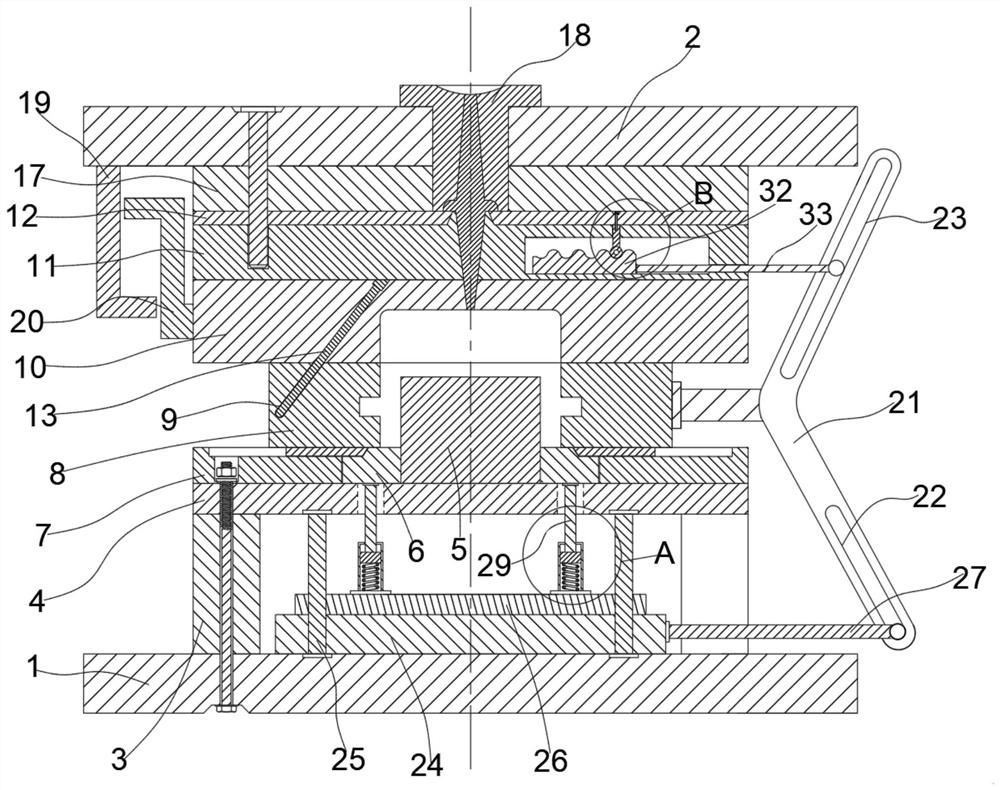

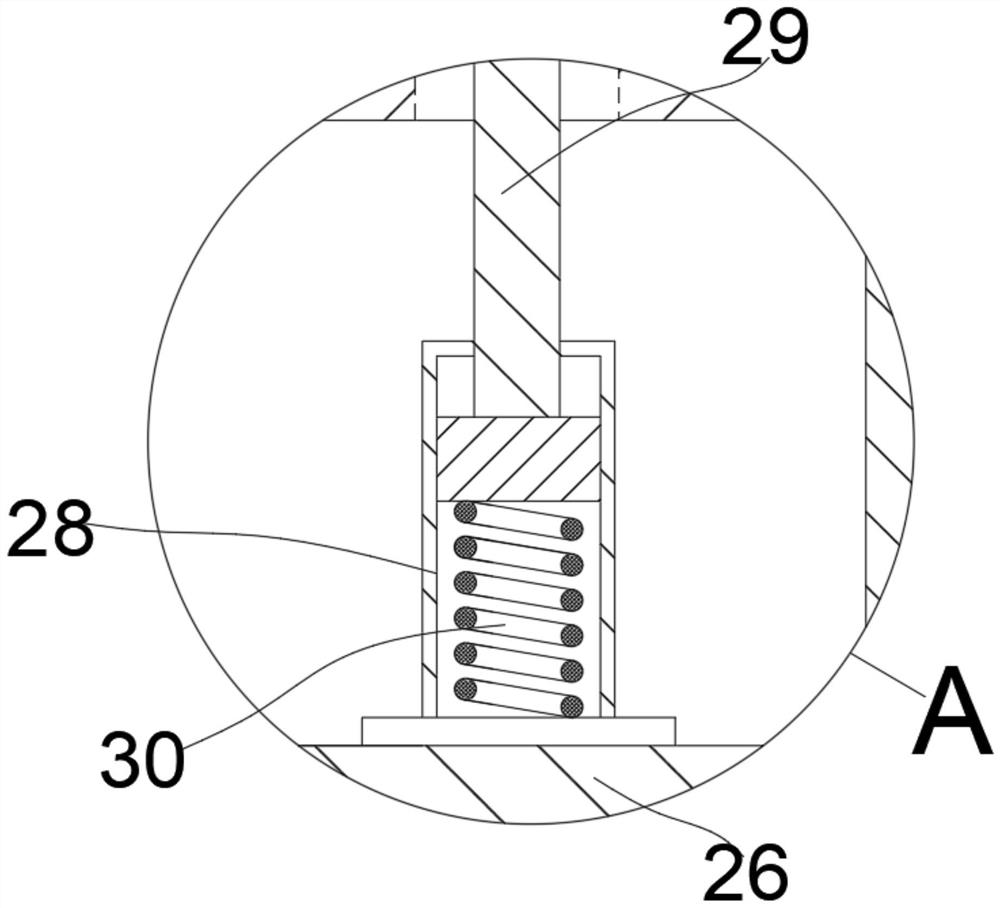

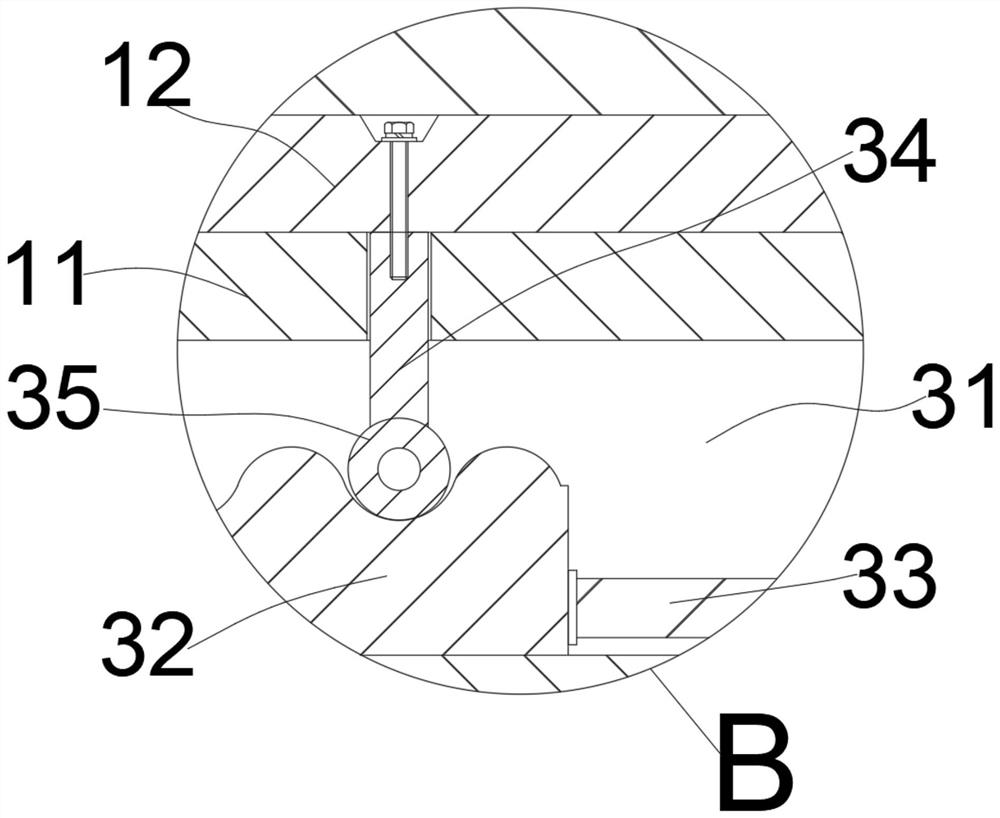

Injection mold capable of efficiently demolding

The invention discloses an injection mold capable of efficiently demolding. The injection mold comprises a movable mold base plate and a fixed mold base plate, wherein a fixed mold mechanism and a movable mold mechanism are installed between the movable mold base plate and the fixed mold base plate; a lateral movement mechanism is installed at the side of the movable mold mechanism; a condensate ejection mechanism is arranged on the movable mold mechanism; an ejection mechanism is arranged on the fixed mold mechanism; and the two ends of the lateral movement mechanism are movably connected with the condensate ejection mechanism and the ejection mechanism separately. Through the arrangement of the lateral movement mechanism, the condensate ejection mechanism and the ejection mechanism, condensate is firstly ejected out in the side core-pulling process, and then a formed plastic part is pushed out of a mold core, so that the effect of efficient demolding is achieved.

Owner:吴丽珠

Novel ball socket structure capable of facilitating demolding of ball press machine

The invention discloses a novel ball socket structure capable of facilitating demolding of a ball press machine. The novel ball socket structure comprises a compression roller. A ball socket is formed in the roller surface of the compression roller, and the depth curve of the ball socket is in the shape of an inverted water drop formed by opposite involutes. According to the dimensions of the ball socket, the length of the ball socket is 32-42mm, the width of the ball socket is 25-30mm, and the depth of the ball socket is 6-15mm. The shape of an opening of the ball socket is a long circle. The novel ball socket structure has the advantages that demolding can be achieved depending on the pressure of the ball press machine to pellets, the demolding pressure can be utilized to the greatest degree, the pellets can be efficiently demolded, and thus the adaptability to raw materials is widened. The influence coefficients of the ball socket size and depth on demolding are lowered, the phenomenon that one material can frequently only select the ball socket shape, size and depth of the specific design is avoided, and universality of the ball press machine is greatly improved.

Owner:SHENWU TECH GRP CO LTD

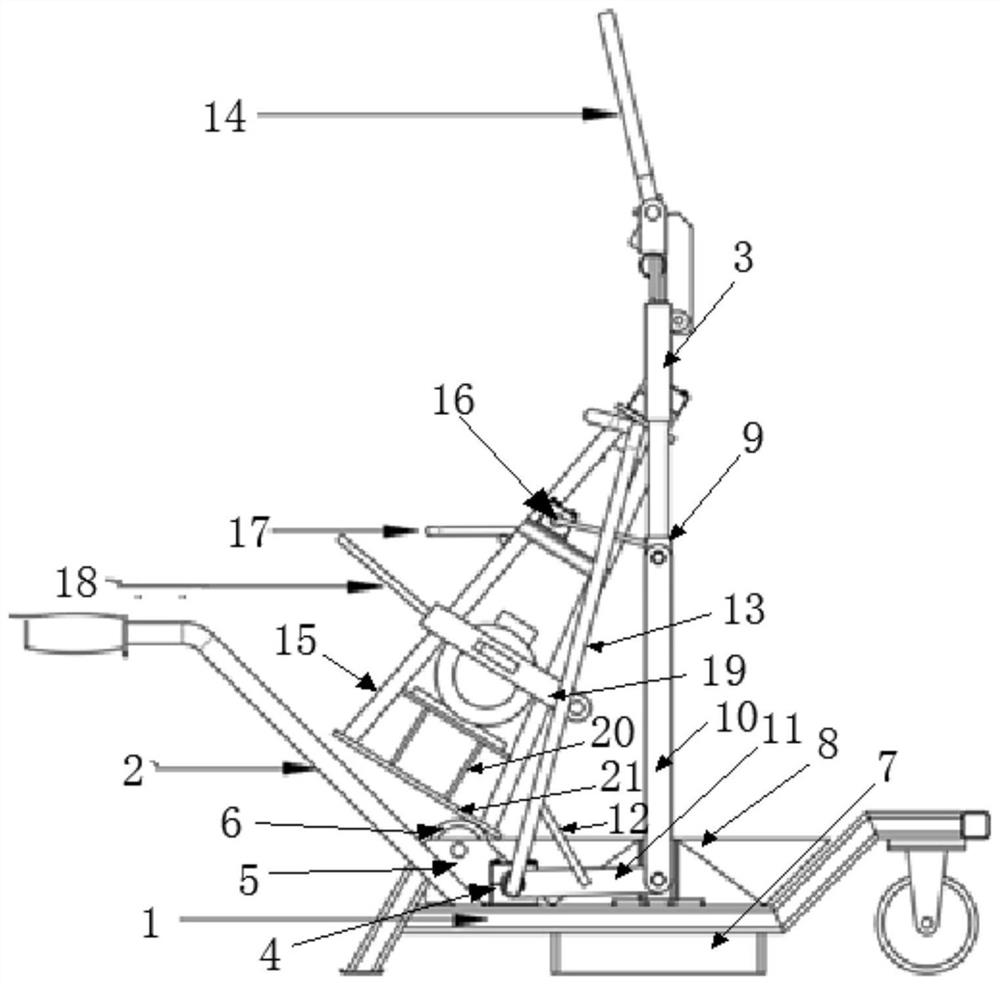

A kind of production method of bct sleeper and its automatic production device

ActiveCN111283858BEffective percussion separationAvoid breakingDischarging arrangementProcess engineeringRebar

The invention discloses a production method of a BCT sleeper. The specific technological process is as follows: 1. The bottom mold after demoulding is assembled with the side mold and the end mold at the mold loading platform; 2. The mold is moved to the casing platform Install the nylon casing; 3. Install the prepared steel bars on the steel bar platform; 4. Transfer to the other side by a translational vehicle, and then pour concrete into the blanking platform. The production method and automatic production of this BCT sleeper The device, which is different from the existing technology, can automatically carry out the demoulding process during the production and processing of BCT sleepers, effectively reducing the demand for labor, thereby effectively reducing the cost of labor use, and effectively improving the normal production and processing efficiency of the enterprise. At the same time, through automatic demoulding, while ensuring efficient demoulding, it can effectively avoid damage and fragmentation when the sleeper is detached.

Owner:光明铁道控股有限公司

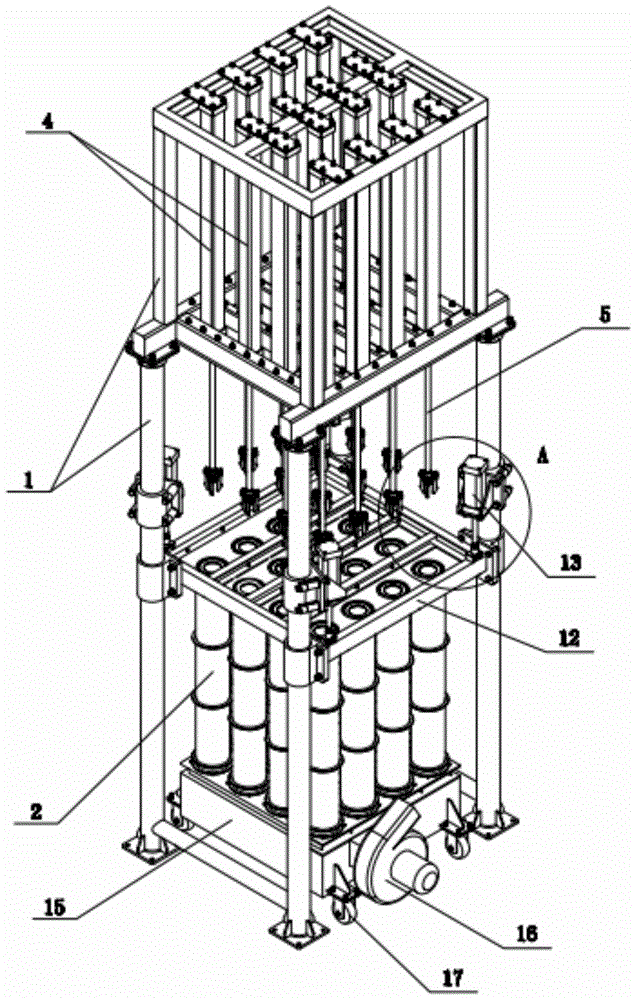

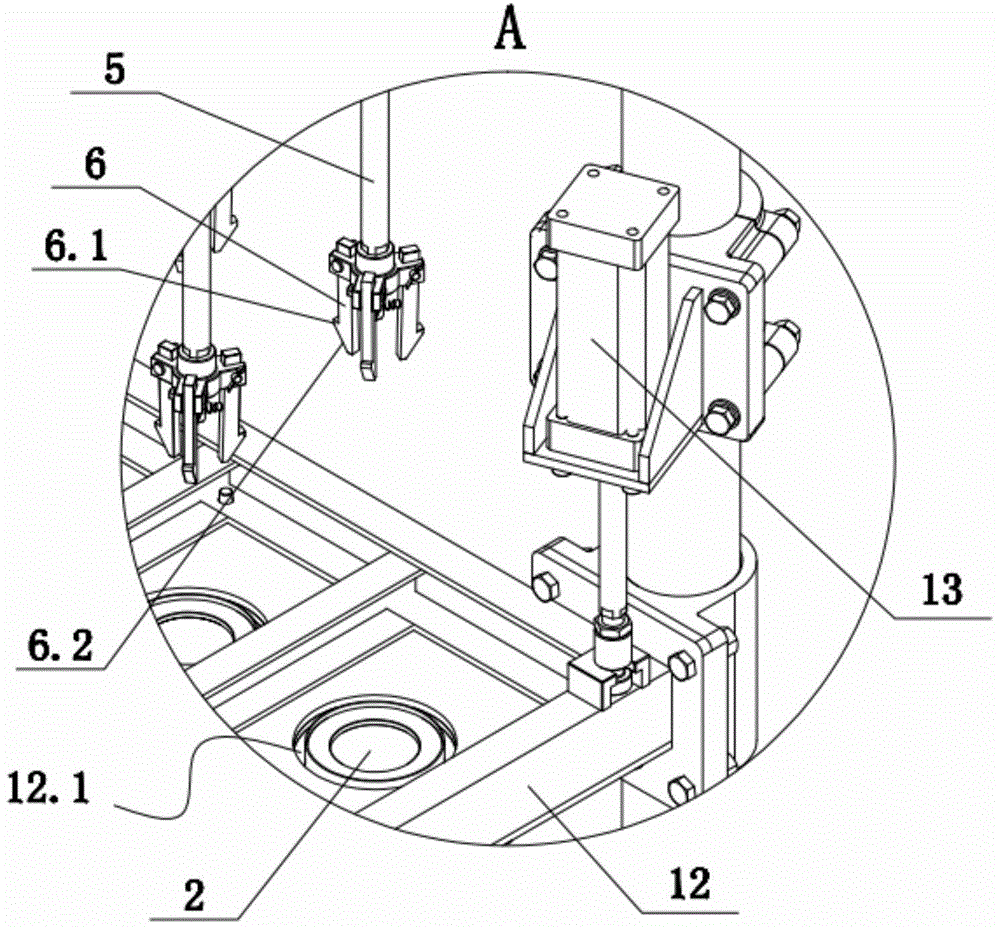

Filter tube ejection device

ActiveCN104476668BEfficient demouldingThe demoulding mechanism realizes the synchronous and efficient core-pulling and demoulding of the filter tubeCeramic shaping apparatusEngineeringPower output

The invention discloses a mold stripping device for a filter pipe. The mold stripping device comprises a bracket (1) and a clamping mechanism arranged on the bracket (1) for fixing a mold (2), wherein the a driver (4), a connecting rod (5) and a gripper mechanism which is used for clamping a filter pipe (3) are arranged on the bracket (1) and located above the mold (2); the driver (4) is fixed with the bracket (1); the power output end of the driver is connected with the upper end of the connecting rod (5); the lower end of the connecting rod (5) extends to be above the filter pipe (3); the gripper mechanism is fixed with the lower end of the connecting rod (5). The invention provides the mold stripping device of the filter pipe, which has the advantages that the synchronous mold stripping of a plurality of filter pipes of the same molded cavity can be realized so as to guarantee high processing efficiency, and the phenomenon that mold stripping cannot be carried out due to the cooling of the filter pipes can be avoided.

Owner:萍乡市普天高科实业有限公司

Once reciprocating reverse jacking type capsule de-molding machine

InactiveCN102078260BEfficient demouldingSuitable for matchingCapsule deliveryProduction lineMolding machine

Owner:徐家业

Material cutting mechanism of injection mold

The invention provides an injection mold material cutting mechanism which comprises a fixed mold block, a large sliding block is arranged on the fixed mold block in a sliding mode, an ejector plate is arranged below the fixed mold block, an ejector rod used for driving the large sliding block to slide is arranged on the ejector plate, a small sliding block is arranged on the large sliding block in a sliding mode, and a feeding runner communicated to a mold cavity is arranged on the small sliding block. A driving cylinder used for driving the small sliding block to be separated from the large sliding block is arranged on the fixed mold block, so that material cutting of a material head in the feeding runner and a product in the mold cavity is achieved; the ejector plate is further provided with an ejector rod and a driving assembly in a sliding mode, wherein the driving assembly is used for driving the ejector rod to eject and drive the stub bar to be separated from the feeding runner. According to the material cutting mechanism of the injection mold, rapid separation of an injection product and a material head can be achieved, the separated material head can be effectively separated from the runner, and the demolding efficiency is improved.

Owner:NINGBO FANGZHENG TOOL

Construction method for ladle integral pouring and casing pouring liner

InactiveCN100389912CPrecise positioningHigh precisionMelt-holding vesselsWedge angleMaterials science

The invention discloses a constructing method of entire ladle casting and lining, which comprises the following steps: locating mould, assembling at least three locating blocks on the bottom of ladle, distributing the blocks on the periphery of ladle bottom, setting wedge angle in the locating block to make diameter of encircle of each locating block bottom more than the diameter of excircle on the mould bottom, adopting the same material for each locating block and ladle lining.

Owner:崔东瑞

Movable asphalt mixture blank removing machine

ActiveCN111519504AEasy to compact and formEfficient demouldingRoads maintainenceHandrailVehicle frame

The invention discloses a movable asphalt mixture blank removing machine. The machine comprises a frame; a frame handrail is fixedly mounted on the left side of the top of the frame; opposite guide rods are fixedly installed on the right side of the top of the frame in a front-back direction; a fixed block and a separant brushing box are fixedly mounted on the right side of the top of the frame; the separant brushing box is positioned on the inner side of the fixed block; a separant rolling brush is movably mounted in the separant brushing box; a through groove is formed in the frame; a forming mold can be conveniently limited in the through groove; a receiving hopper and a sliding sleeve are fixedly mounted at the top of the forming mold; An asphalt mixture can be poured into the fixed block through the receiving hopper; and the receiving hopper is movably connected to the guide rod at the same time, so that the forming mold and the receiving hopper can be limited; a lever lifting frame is installed on the fixed block through a bearing; and the lever lifting frame can conveniently drive a second pull plate and a first pull plate to move through a reinforcing rod.

Owner:吉林嘉鹏公路养护有限公司

Demolding mechanism for production of rice crusts

The invention discloses a demolding mechanism for production of rice crusts. The demolding mechanism comprises a machine body, an upper mold body and a lower mold body, wherein a heating device is mounted on the right side of a mold pressing cylinder fixed at the top of the machine body, the upper mold body is fixedly connected with the mold pressing cylinder through a piston rod, the upper mold body is located in the machine body, a discharge box mounted at the top end of the machine body is located on the right side of the heating device, and the bottom of the discharge box is fixedly connected with one end of a feed pipe; an infrared ray inducing device is arranged on the right side of the feed pipe, and the lower mold body is connected with a rotary table through the lower mold body fixing seat; and a demolding pan bottom arranged at the bottom of the lower mold body is fixedly connected with a demolding cylinder through the piston rod, the demolding cylinder is located in the lower mold body fixing seat, and a semicircular shaping groove is formed in the middle of the lower mold body. The demolding mechanism is simple and reasonable in structural design, quick and convenient to demold, high in automation degree, high in production efficiency and high in economical and practical properties.

Owner:合肥杰代机电科技有限公司

Insulation skeleton injection mold for easy demoulding

Owner:深圳科仕瑅科技有限公司

A construction method of composite ladle permanent layer

The invention relates to a construction method of a composite steel ladle permanent layer. The construction method comprises the steps of constructing a ladle bottom permanent layer, a ladle wall permanent layer and a safety layer, and laying ladle bottom bricks, a ladle wall work layer and slag line bricks. The composite steel ladle permanent layer can be on line for use normally after laying construction is completed. According to the construction method, the safety layer is laid between the ladle wall permanent layer and the ladle wall work layer, and a safety layer material for building the safety layer is one of a magnesium-aluminum refractory material, an aluminum- spinelle refractory material, an aluminum-magnesium-chrome refractory material, a corundum refractory material and a magnesium-chrome refractory material. The material has high strength, corrosion resistance, thermal shock resistance and excellent linear change, the effective service life of a steel ladle permanent lining is greatly prolonged, potential safety hazards existing in an existing steel ladle work layer material are avoided, and the service life of a steel ladle work layer can be effectively prolonged.

Owner:FANYI HONGQI BURDEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com