Concrete test block demolding device

A technology of concrete test blocks and demoulding devices, which is applied in the direction of unloading devices, manufacturing tools, etc., and can solve the problems of low demoulding efficiency, time-consuming and laborious, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

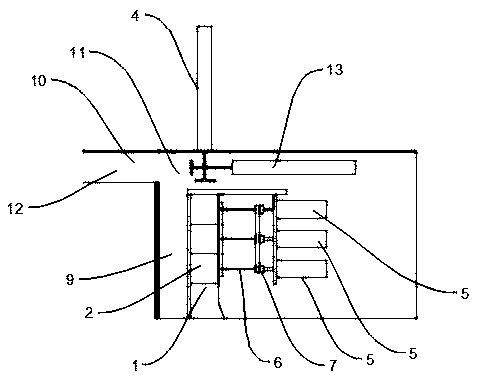

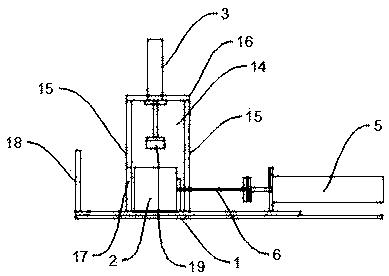

[0028] Such as figure 1 - Figure 5As shown, the present embodiment provides a demoulding device for a concrete test block, including a test form position 1 for defining the position of the concrete test form 2, a positioning push-out mechanism for positioning and pushing out the concrete test form 2, and a The driving mechanism that pushes the concrete test block out of the concrete test mold 2, the positioning push-out mechanism includes the upper driving cylinder 3 located above the concrete test mold 2 for compacting the concrete test mold 2 from the vertical direction and the side of the concrete test mold 2 The side drive cylinder 4 is used to push the concrete test mold 2 out from the entrance of the test mold position 1; the driving mechanism includes a thrust cylinder 5 that is consistent with the number of concrete test blocks and a thrust cylinder that directly applies thrust to the concrete test block through the thrust cylinder 5 The thimble assembly, the thimbl...

Embodiment 2

[0032] This embodiment is optimized and defined on the basis of the above-mentioned embodiment 1.

[0033] In order to realize the parallel connection of the thimbles 6, the thimbles 6 are arranged side by side on the connecting plate 7, the connecting plate 7 is fixedly connected with the piston rod of the thrust cylinder 5, and the piston rod of the thrust cylinder 5 is coaxial with the corresponding thimble 6.

Embodiment 3

[0035] This embodiment is optimized and defined on the basis of the above-mentioned embodiment 1.

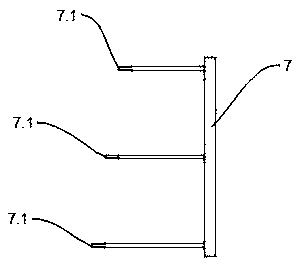

[0036] Such as Image 6 As shown, in order to realize the side-by-side connection of the thimbles 6, the connecting end of the thimble 6 is fixedly connected with the piston rod of the thrust cylinder 5, and the thimble 6 is fixedly connected with the connecting plate 7 in turn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com