A construction method of composite ladle permanent layer

A construction method and technology of permanent layer, applied in the direction of manufacturing tools, metal processing equipment, casting melt containers, etc., can solve the problems of increasing the cost of steelmaking and enterprise operation, increasing the labor intensity of workers, and poor resistance, and reducing the The labor intensity of workers, excellent thermal shock stability, and the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

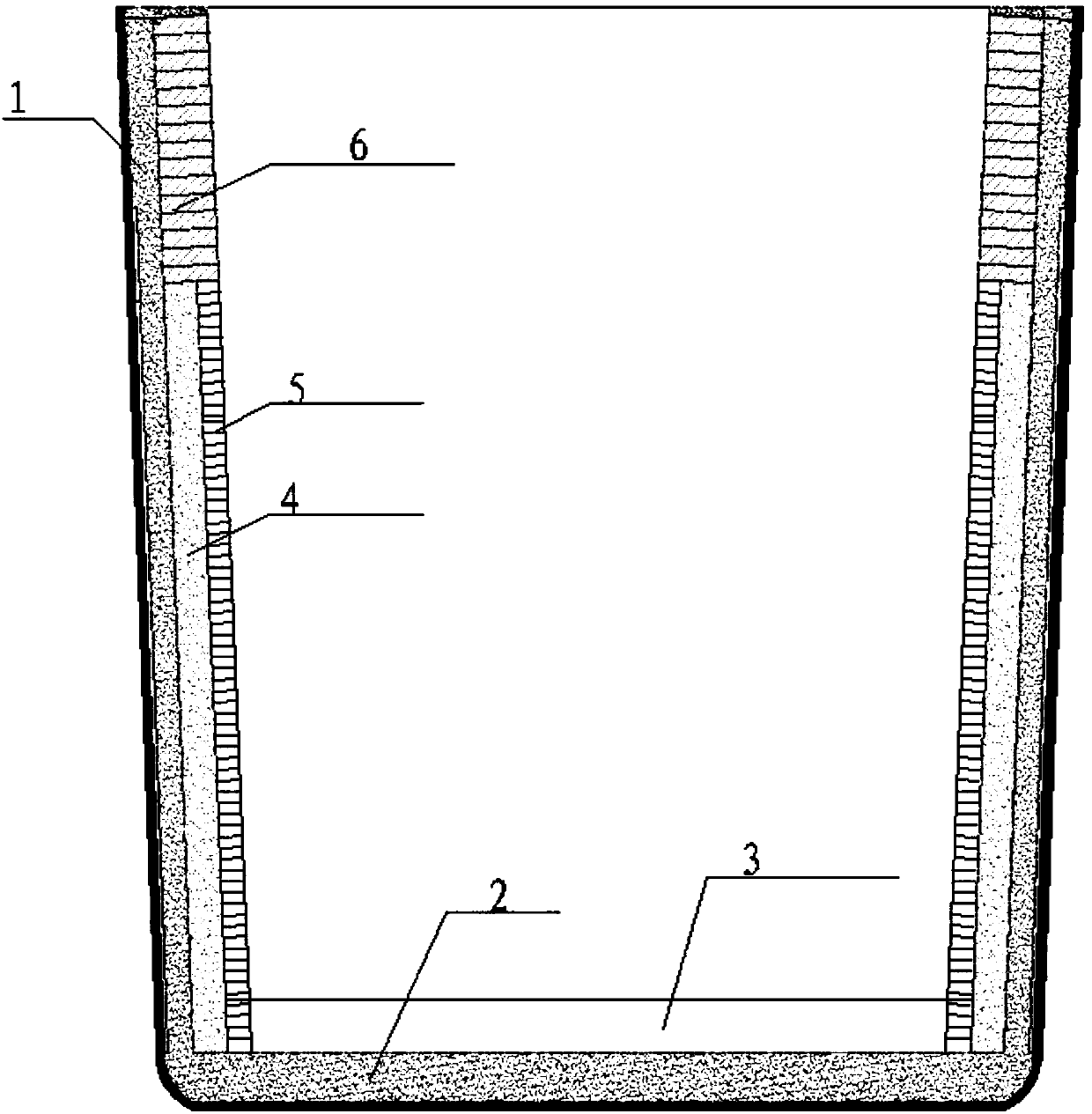

Image

Examples

Embodiment 1

[0028] A construction method for a composite ladle permanent layer, the specific construction steps are as follows:

[0029] Step (1), bottom permanent layer:

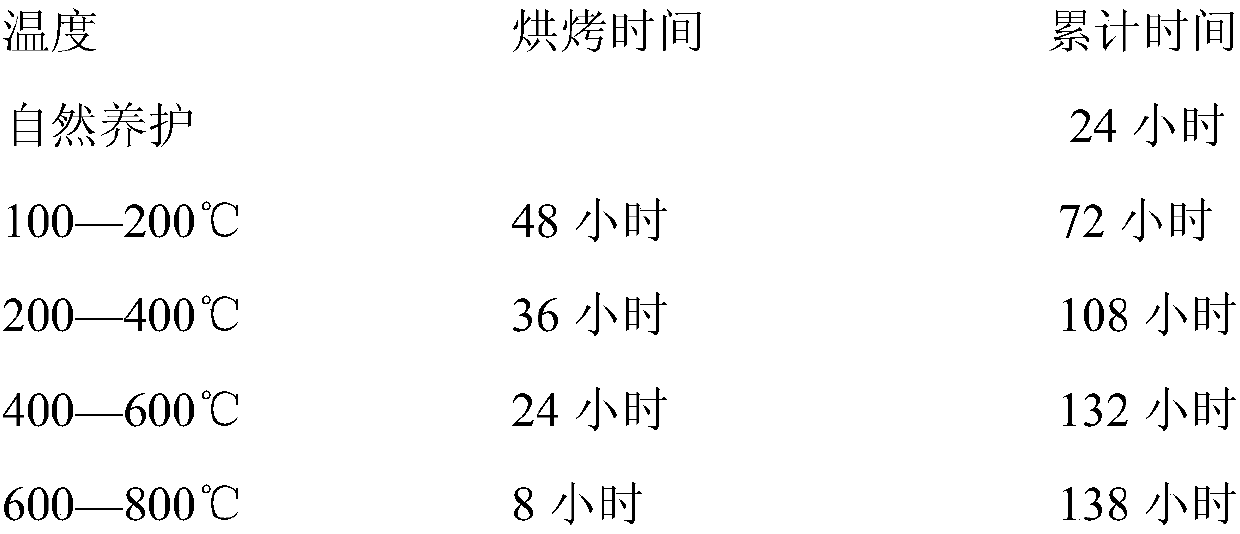

[0030] First hoist the ladle shell into the masonry work station, clean up the sundries on the bottom and wall of the ladle, and then put the air-permeable brick model and the nozzle block model into the corresponding positions in the ladle shell; Add in a blender, dry mix for 1 minute, add water, and fully stir for 7 minutes; pour it into the bottom of the bag after stirring evenly, and vibrate the slurry with a vibrating rod to make it flat and dense. After the permanent layer of the bottom of the bag is knotted, natural curing for 24 Hours, according to the site conditions, when the permanent layer at the bottom of the package condenses and reaches the demoulding strength, take out the breathable brick model and the nozzle seat brick model;

[0031] Step (2), permanent layer:

[0032] Put the ladle film coated wit...

Embodiment 2

[0046] A construction method for a composite ladle permanent layer, the specific construction steps are as follows:

[0047] Step (1), bottom permanent layer:

[0048] First hoist the ladle shell into the masonry work station, clean up the sundries on the bottom and wall of the ladle, and then put the air-permeable brick model and the nozzle block model into the corresponding positions in the ladle shell; Add in a blender, dry mix for 2 minutes, add water, and fully stir for 6 minutes; pour it into the bottom of the bag after stirring evenly, and vibrate the pulp with a vibrating rod to make it flat and dense. Hours, according to the site conditions, when the permanent layer at the bottom of the package condenses and reaches the demoulding strength, take out the breathable brick model and the nozzle seat brick model;

[0049] Step (2), permanent layer:

[0050] Put the ladle film coated with waste engine oil or wrapped with plastic film 1 # Hoist it into the steel ladle she...

Embodiment 3

[0063] A construction method for a composite ladle permanent layer, the specific construction steps are as follows:

[0064] Step (1), bottom permanent layer:

[0065] First hoist the ladle shell into the masonry work station, clean up the sundries on the bottom and wall of the ladle, and then put the air-permeable brick model and the nozzle block model into the corresponding positions in the ladle shell; Add in a blender, dry mix for 1.5 minutes, add water, and fully stir for 5 minutes; pour it into the bottom of the bag after stirring evenly, and vibrate the pulp with a vibrating rod to make it flat and dense. Hours, according to the site conditions, when the permanent layer at the bottom of the package condenses and reaches the demoulding strength, take out the breathable brick model and the nozzle seat brick model;

[0066] Step (2), permanent layer:

[0067] Put the ladle film coated with waste engine oil or wrapped with plastic film 1 # Hoist into the steel ladle shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com