Construction method for ladle integral pouring and casing pouring liner

An integral pouring and construction method technology, applied in the direction of manufacturing tools, metal processing equipment, casting melt containers, etc., can solve the problems of difficult demoulding, inaccurate positioning of ladles, etc., and achieve simple construction, high demoulding success rate, and high precision high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

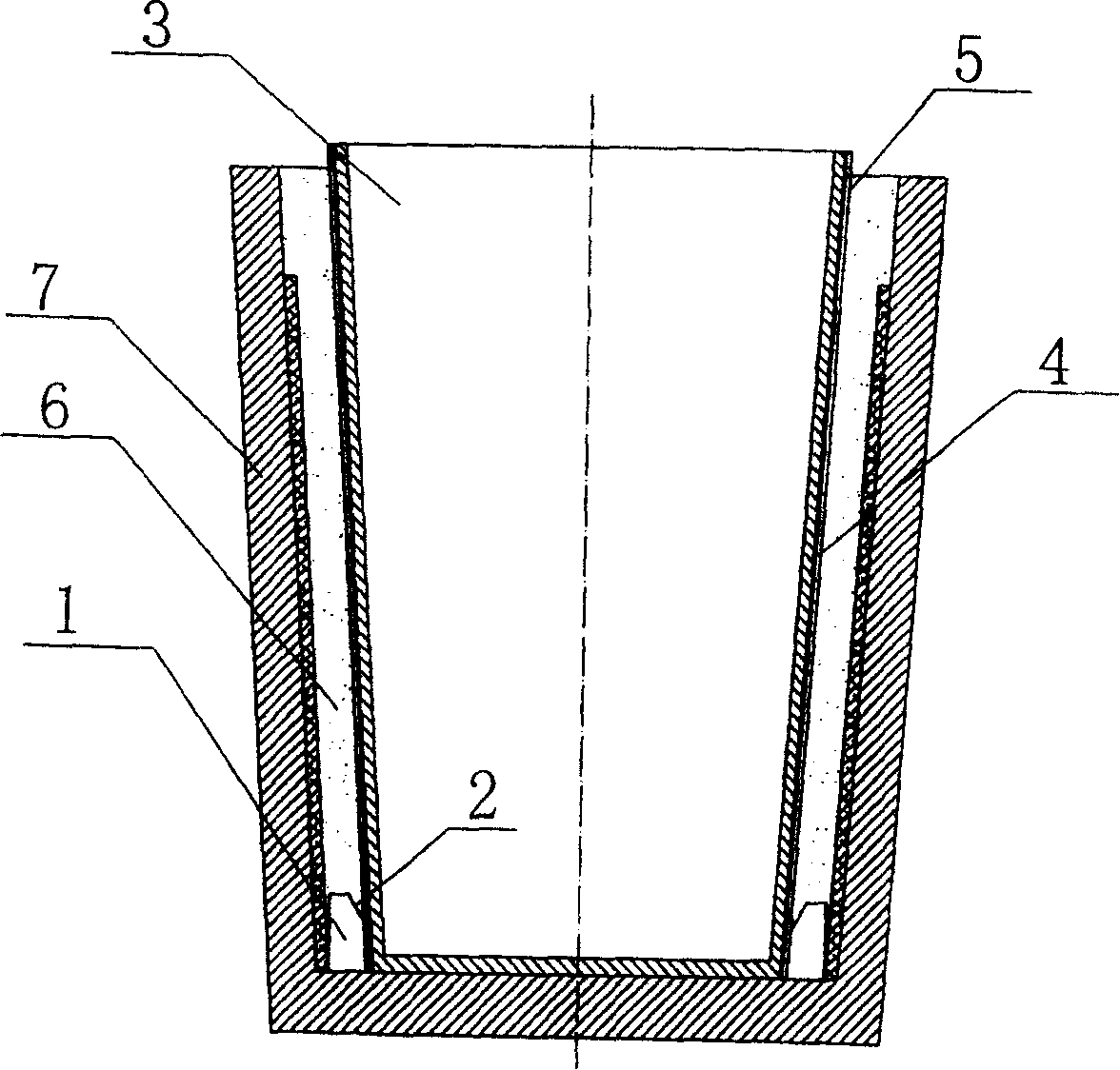

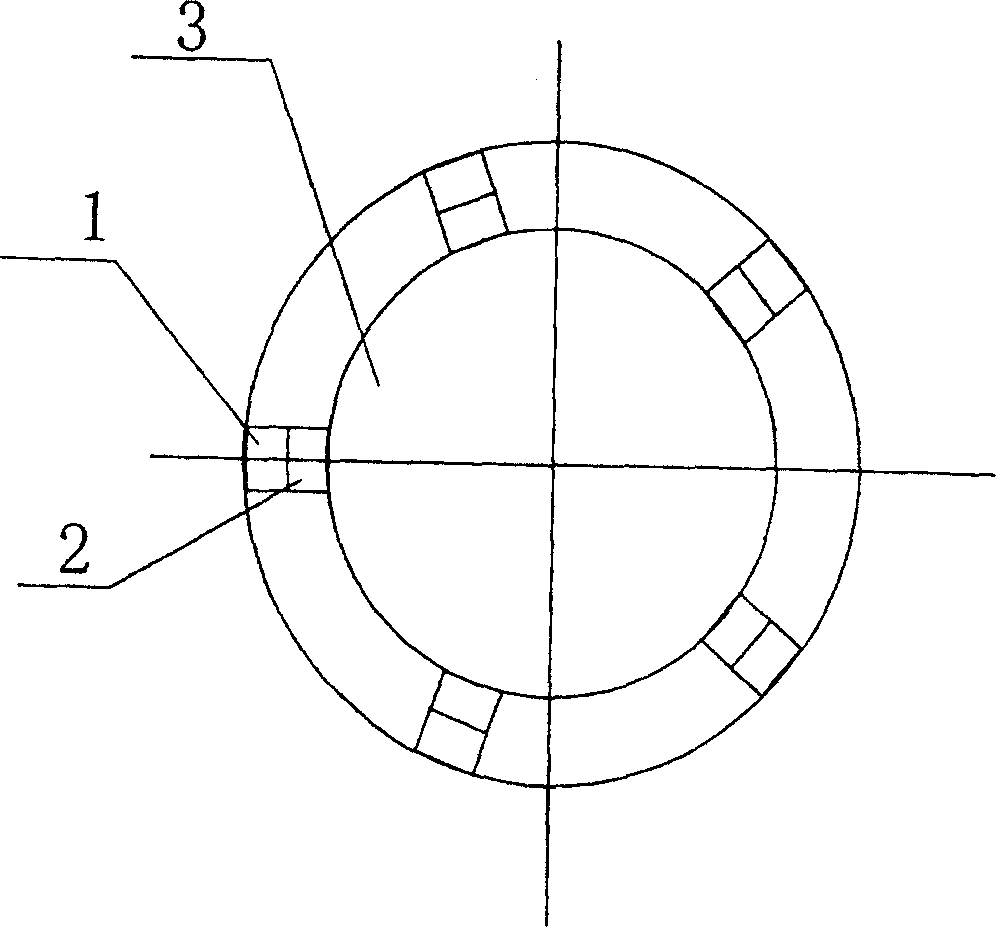

[0018] The construction method of integral pouring of the ladle and the inner lining of the ladle of the present invention includes the positioning and installation steps of the mould. In the positioning and installation steps of the mould, the number of positioning blocks is determined according to the size of the ladle to be poured and the thickness of the inner lining of the ladle and the size of the positioning block, refer to the following figure 1 , figure 2 Take the integral cast permanent layer as an example to illustrate the construction method of the present invention:

[0019] At first, five cube-shaped positioning blocks 1 are evenly placed on the periphery of the bottom of the ladle, such as figure 2 As shown, the radial width of the positioning block 1 is equal to the thickness of the permanent layer 6 to be poured, such as 110 millimeters, and the inner upper part of the positioning block 1 is provided with a chamfer 2, see figure 1 , so that each positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com