Patents

Literature

36results about How to "Reliable demoulding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

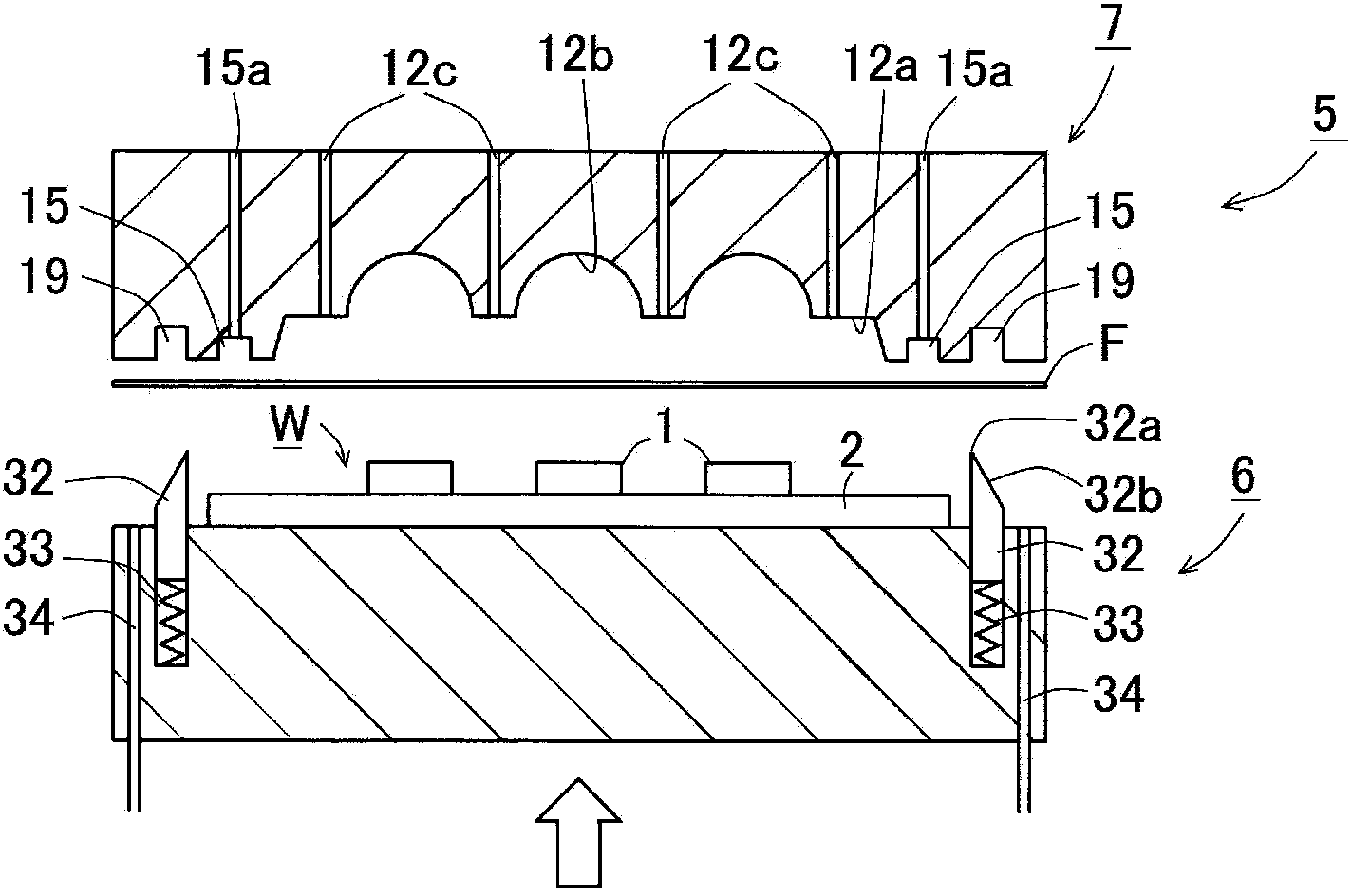

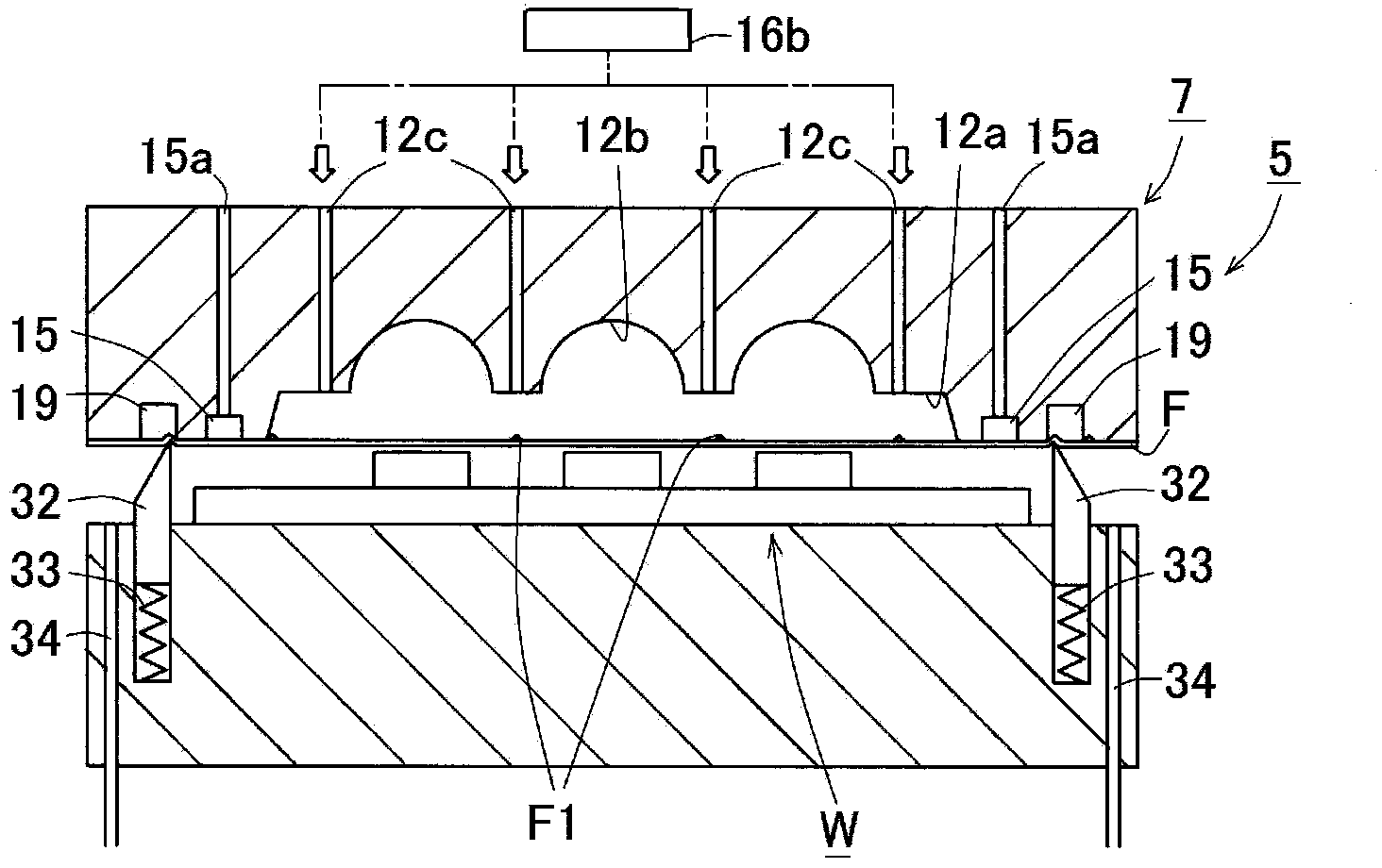

Resin molding machine and method of resin molding

ActiveCN103545224AImprove forming qualityReliable demouldingSolid-state devicesSemiconductor/solid-state device manufacturingWrinkleEngineering

The resin-molding apparatus improving further more, the filling ability and molding quality of the epoxy molded compound the work is resin-molded using the release film and resin-molding method of the long person shape are provided. The possible to squirt air and alienate the release film (F) from the molding clamp plane multiple vent holes (12c, 12e, 18a, 18b) inhaling air and absorbs the release film (F) in the avoirdupois clamp side or are installed in the avoirdupois (7). And in the type (6), as long as the width direction both sides of the release film (F) of the long person shape which is faced with the work mounting side and is returned suffers in the width direction both sides of the release film (F) of the long person shape and it is pressed down with the release film (F) and the tension is applied to not only the longitudinal direction but also the width direction and the film wrinkle is removed the film wrinkle correcting member (32) of pair is installed.

Owner:APIC YAMADA CORP

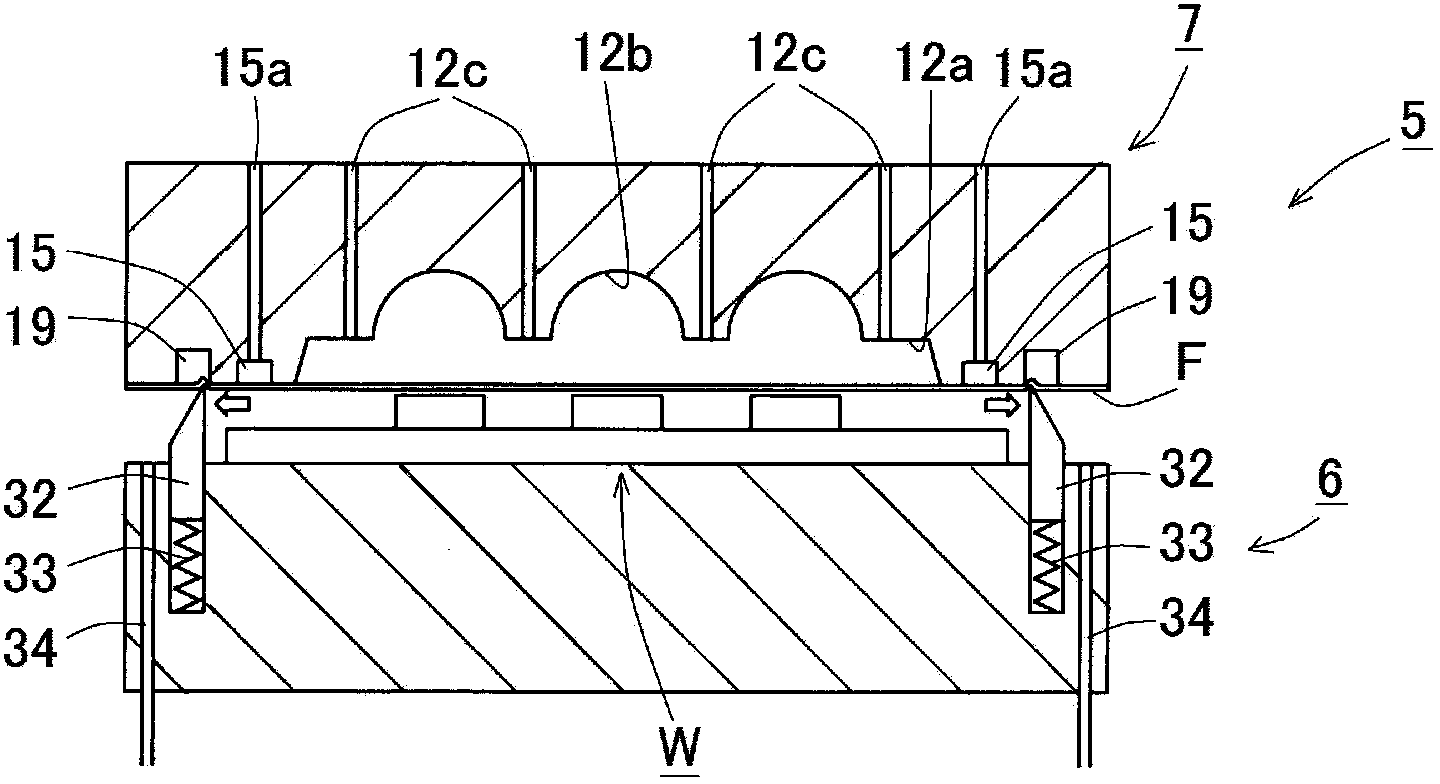

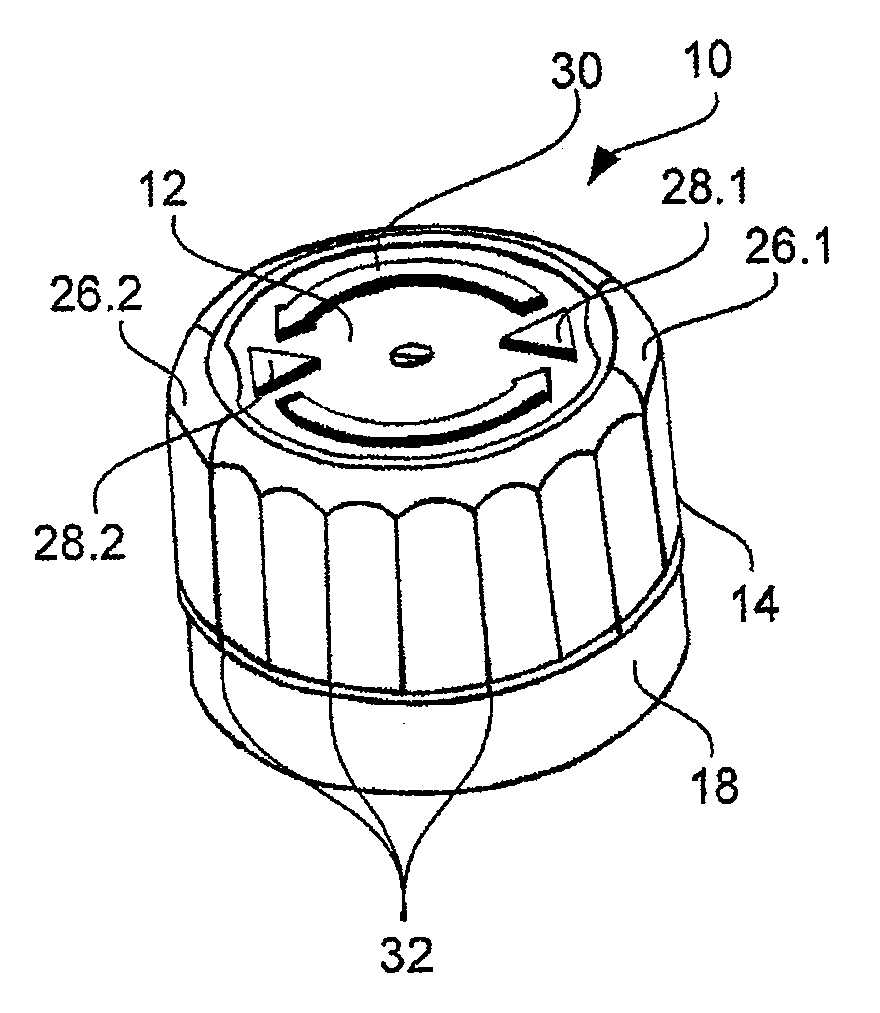

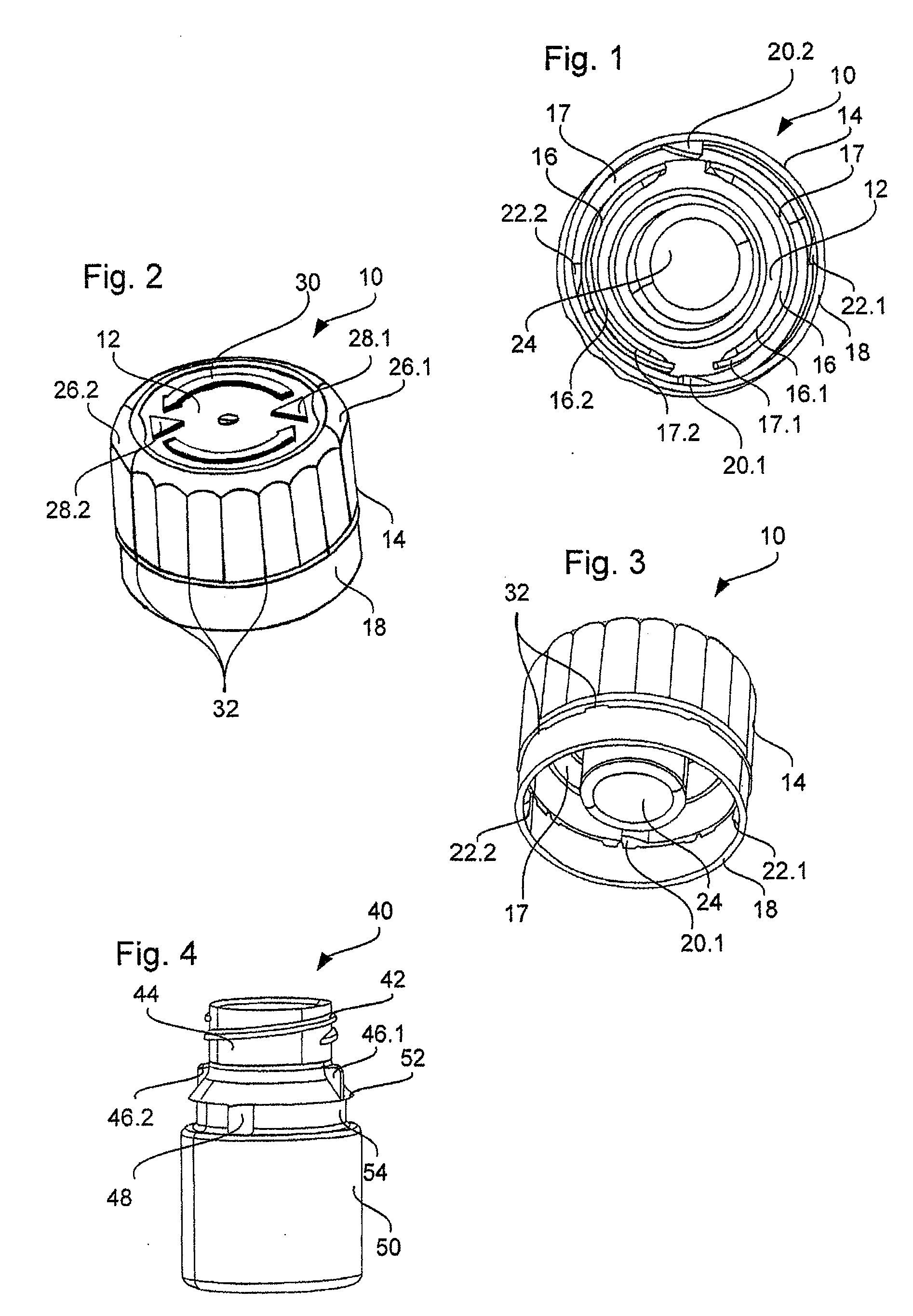

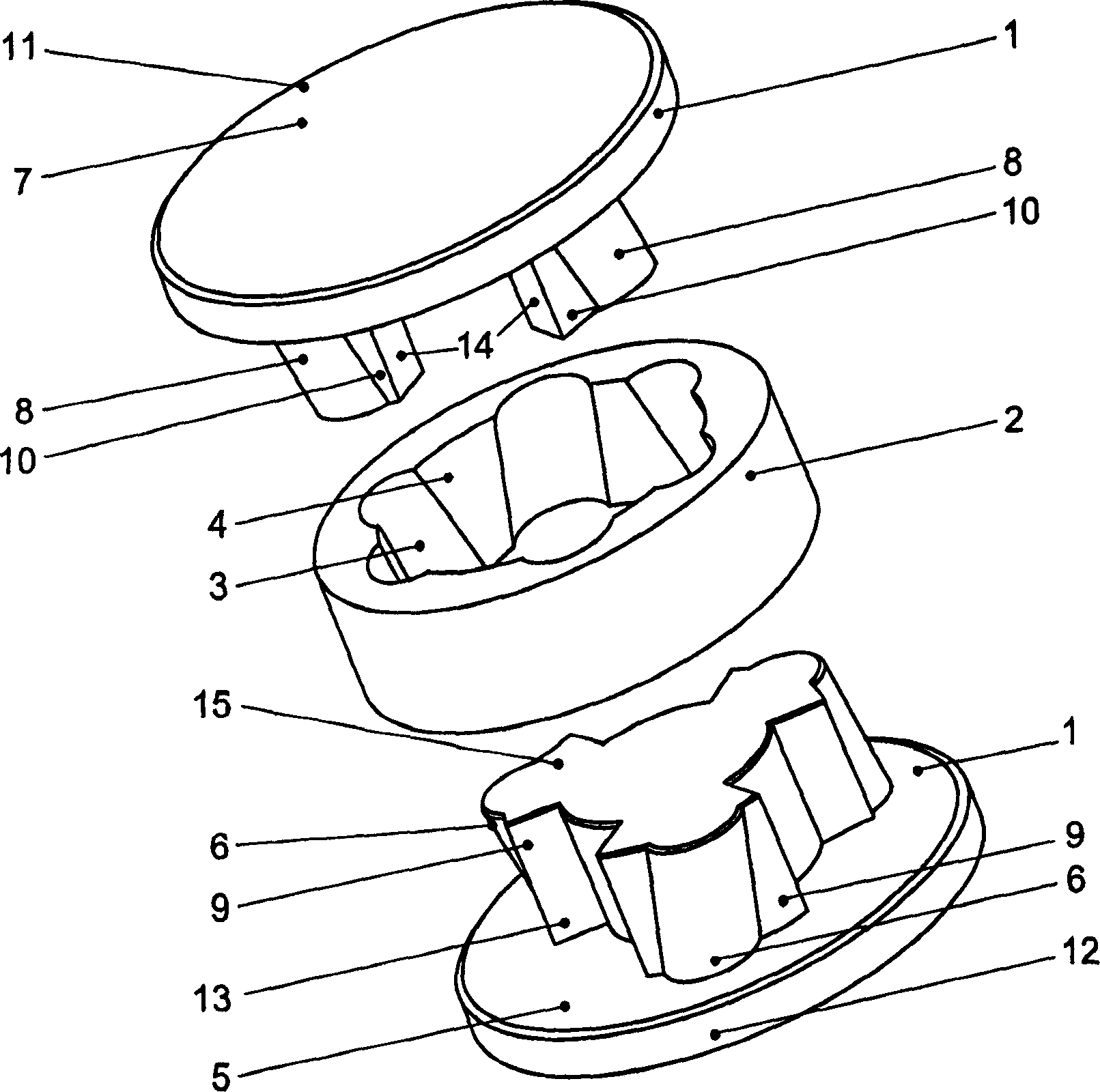

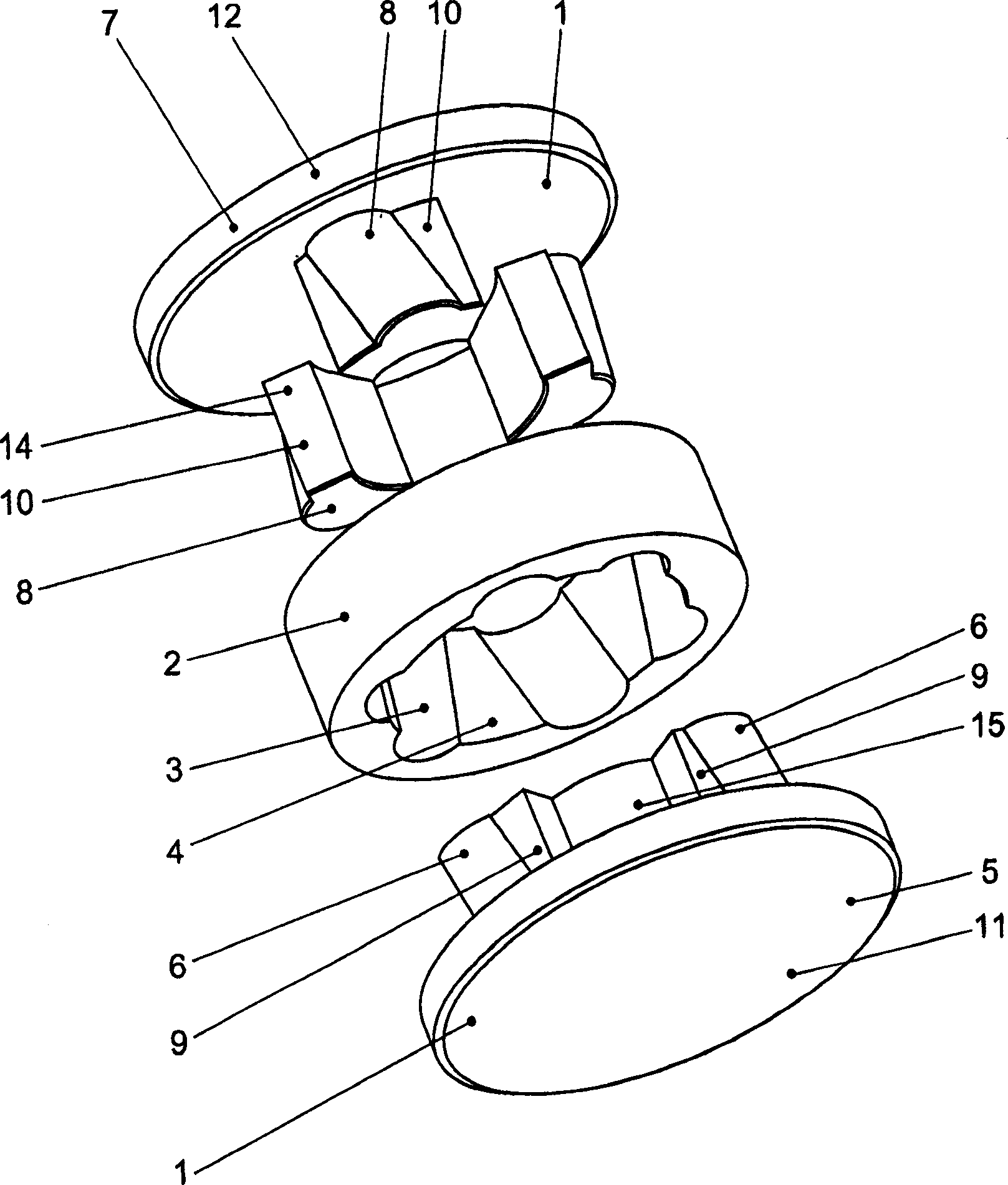

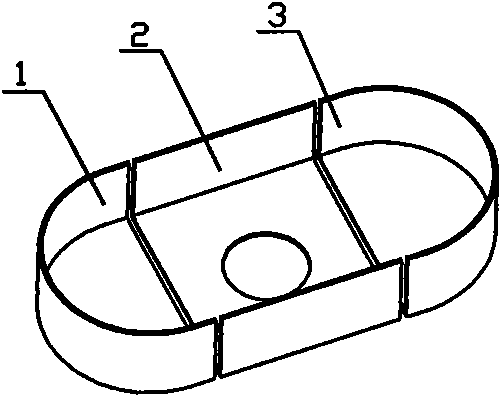

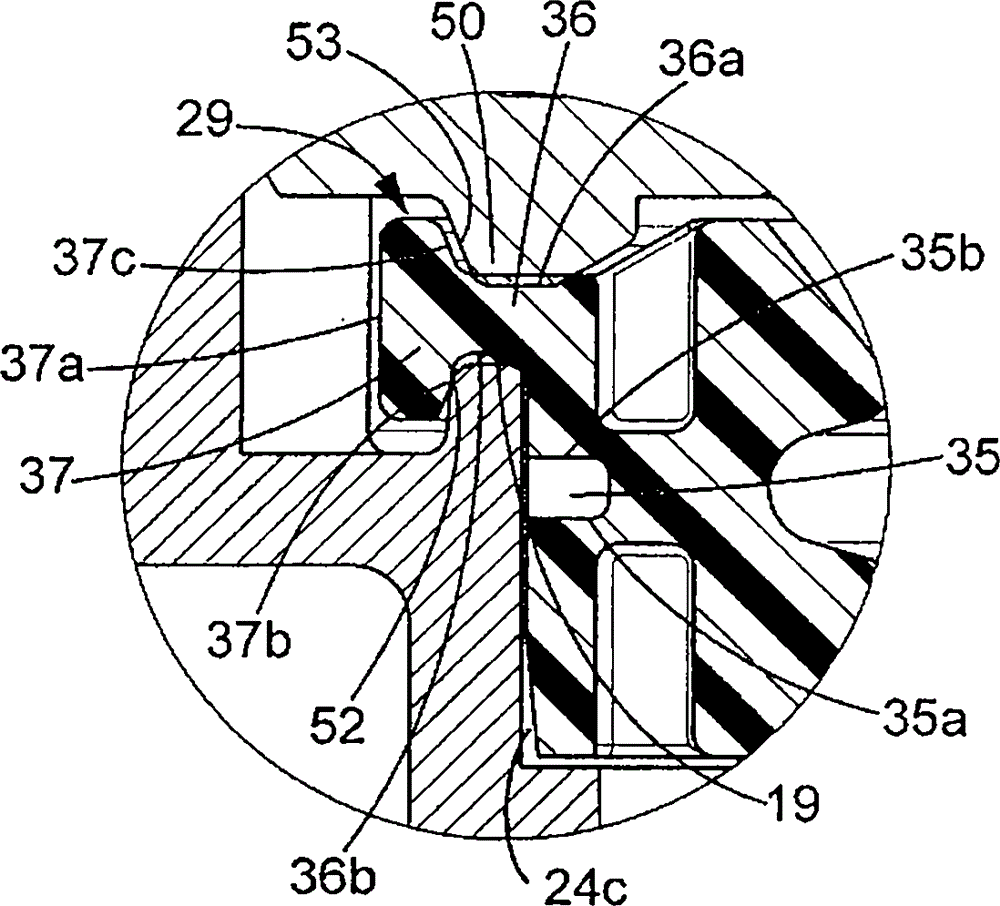

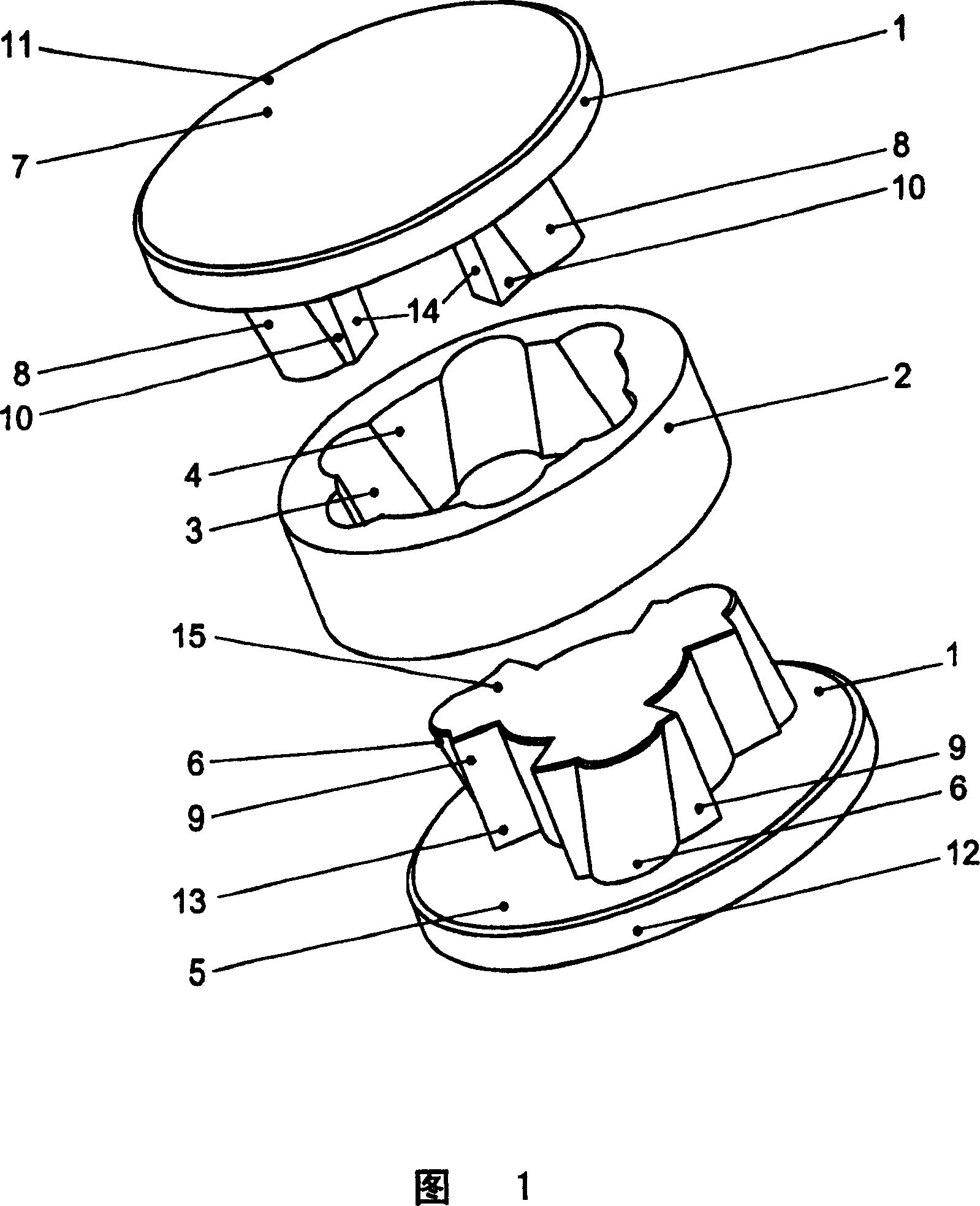

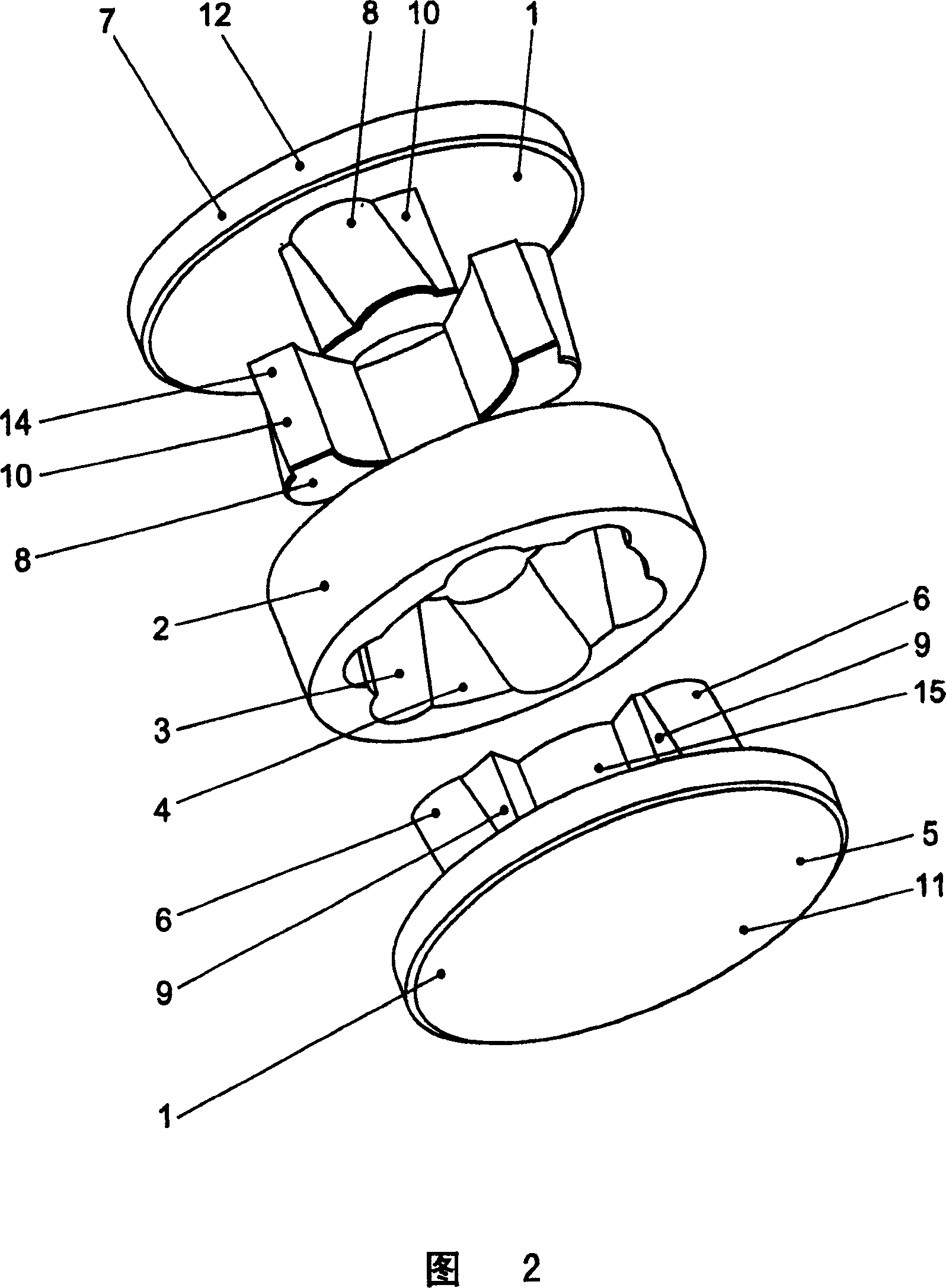

Screw cap, container body and container

ActiveUS20100102020A1Reliable and strong guidanceReliable demouldingCapsMouldsEngineeringScrew thread

The invention relates to a screw cap (10) capable of being screwed onto the neck (44) of a container body (40), the screw cap comprising a substantially cylindrical screw section (17) comprising a screw thread (16) on its inner face, at least one tamper evidence member (18) for indicating an initial opening of the screw cap (10), and a desiccant chamber (24) located radially inwardly to the screw section, wherein the screw section (17) is radially resilient.

Owner:AIRNOV INC

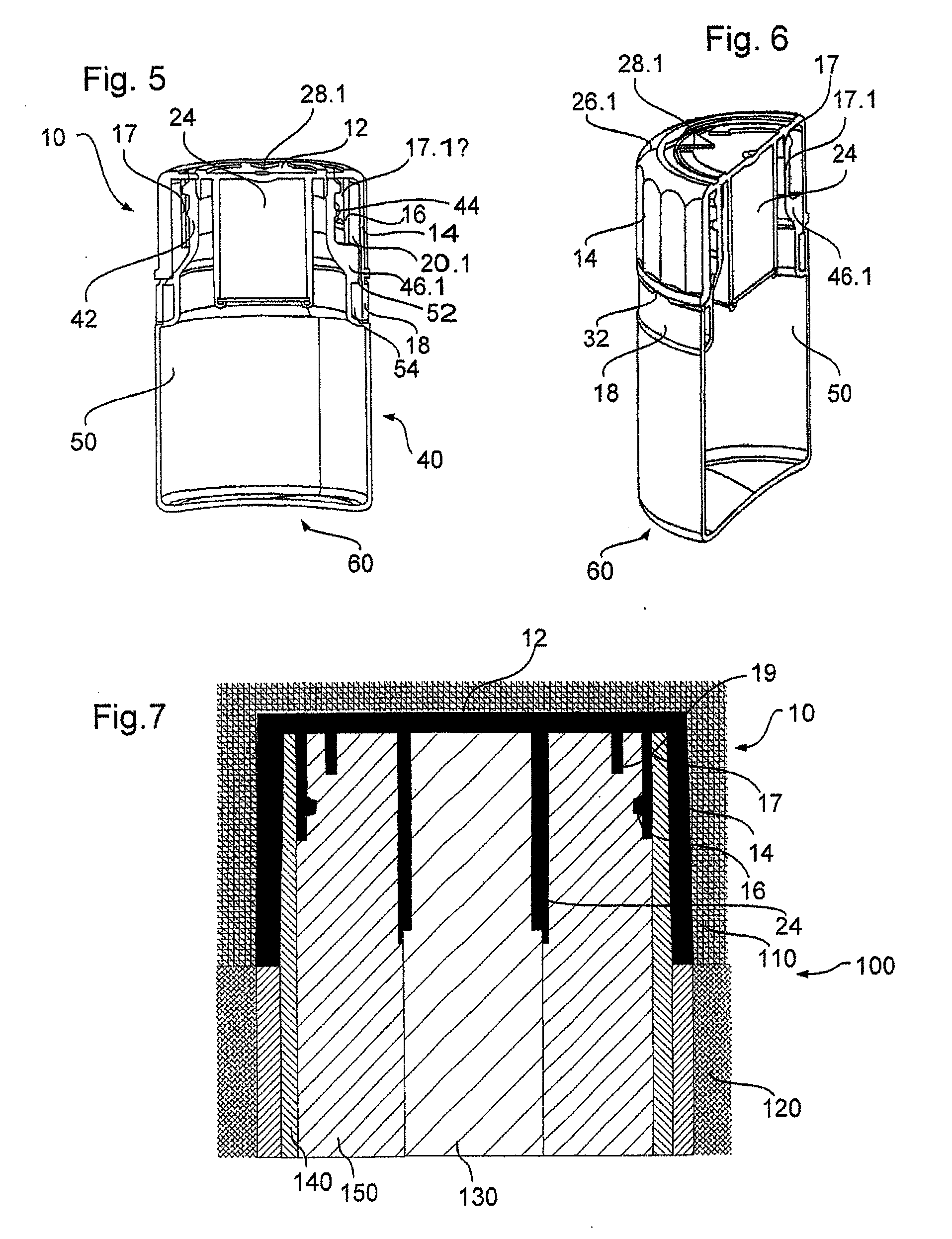

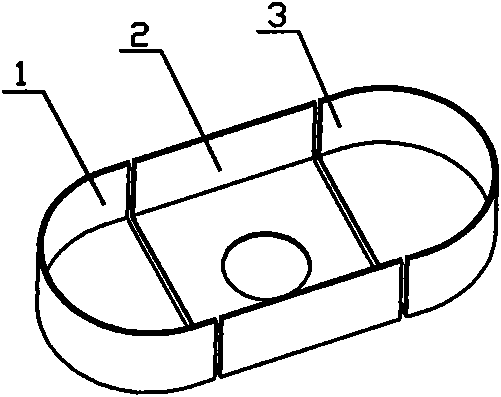

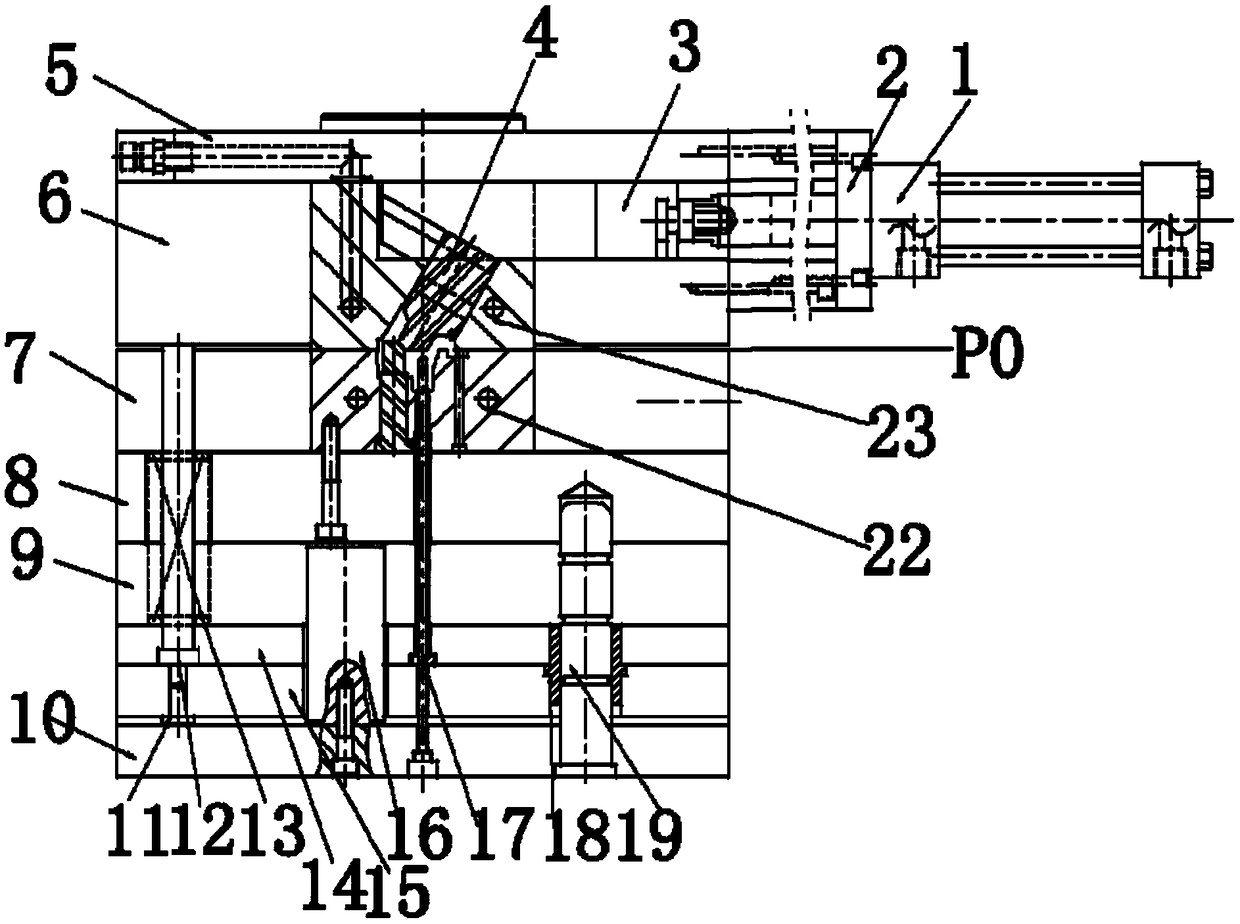

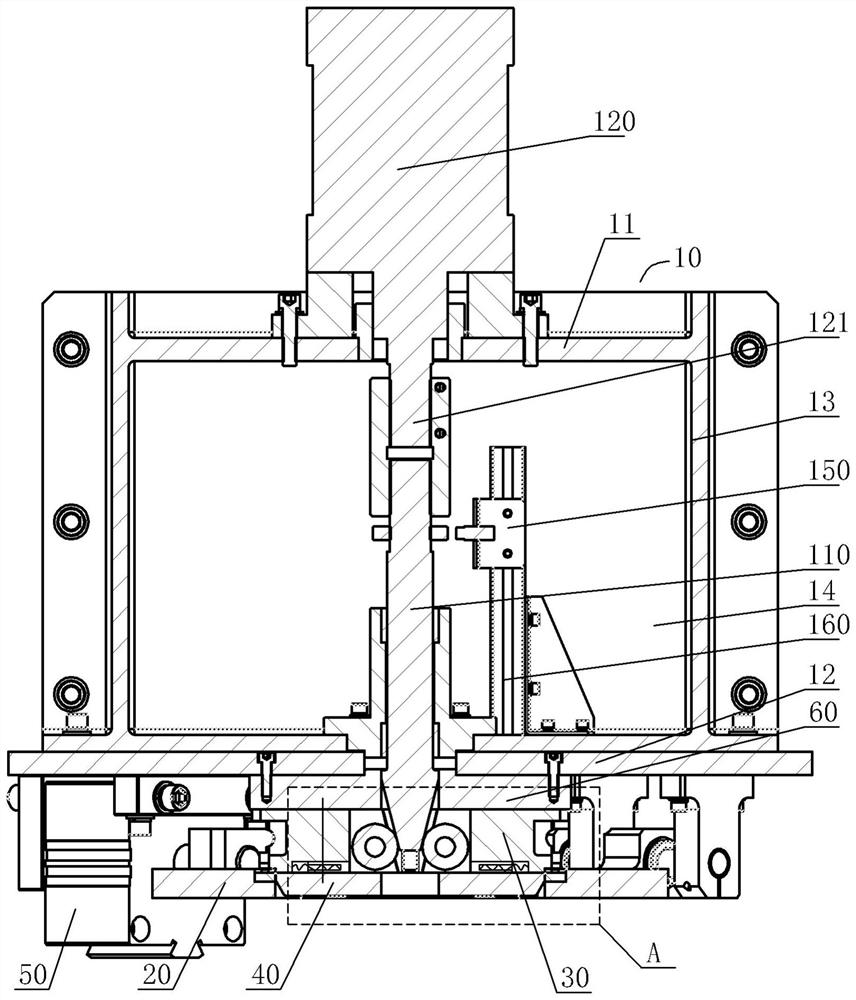

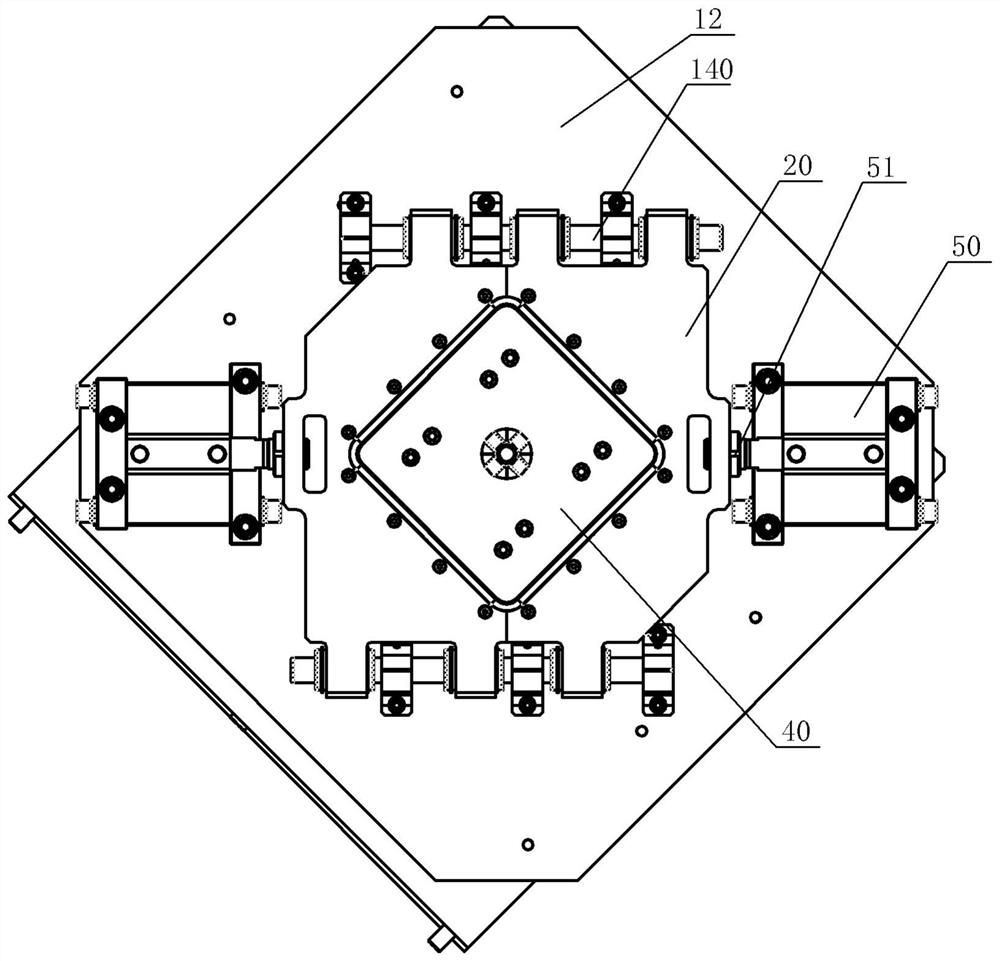

Large combined dual-jacking mould structure

InactiveCN103658491AAvoid damageReduce processing and repair costsForging/hammering/pressing machinesForgeMaterials science

The invention provides a large combined dual-jacking mould structure. The large combined dual-jacking mould structure can solve the problem that an upper mould cannot perform demoulding when an existing single-jacking mould is used for forging a large deep-cavity thin-walled forge piece. The large combined dual-jacking mould structure is simple and convenient to process and assemble; and the upper mould and a lower mould can both achieve demoulding of the forge piece in a jacking mode. The large combined dual-jacking mould structure comprises an upper mould structure and a lower mould structure; the upper mould structure comprises an upper mould base and the upper mould, wherein the upper mould is mounted beneath the upper mould base; a lower mould jacking mechanism is mounted in the lower mould structure. The large combined dual-jacking mould structure is characterized in that an upper mould jacking mechanism is mounted in the upper mould structure; the upper mould jacking mechanism comprises an upper jacking rod and a compression spring; the upper jacking rod sequentially penetrates through the upper mould and an upper jacking rod mounting hole of the upper mould base from bottom to top; the flange at the bottom of the upper jacking rod is in clearance fit with a groove of the upper mould; the diameter of the upper jacking rod mounting hole of the upper mould base is larger than that of an upper jacking rod mounting hole of the upper mould; the part, located in the upper jacking rod mounting hole of the upper mould base, of the upper jacking rod is sleeved with the compression spring which is locked on the top surface of the upper mould through a tight nut and a flat washer.

Owner:WUXI TURBINE BLADE

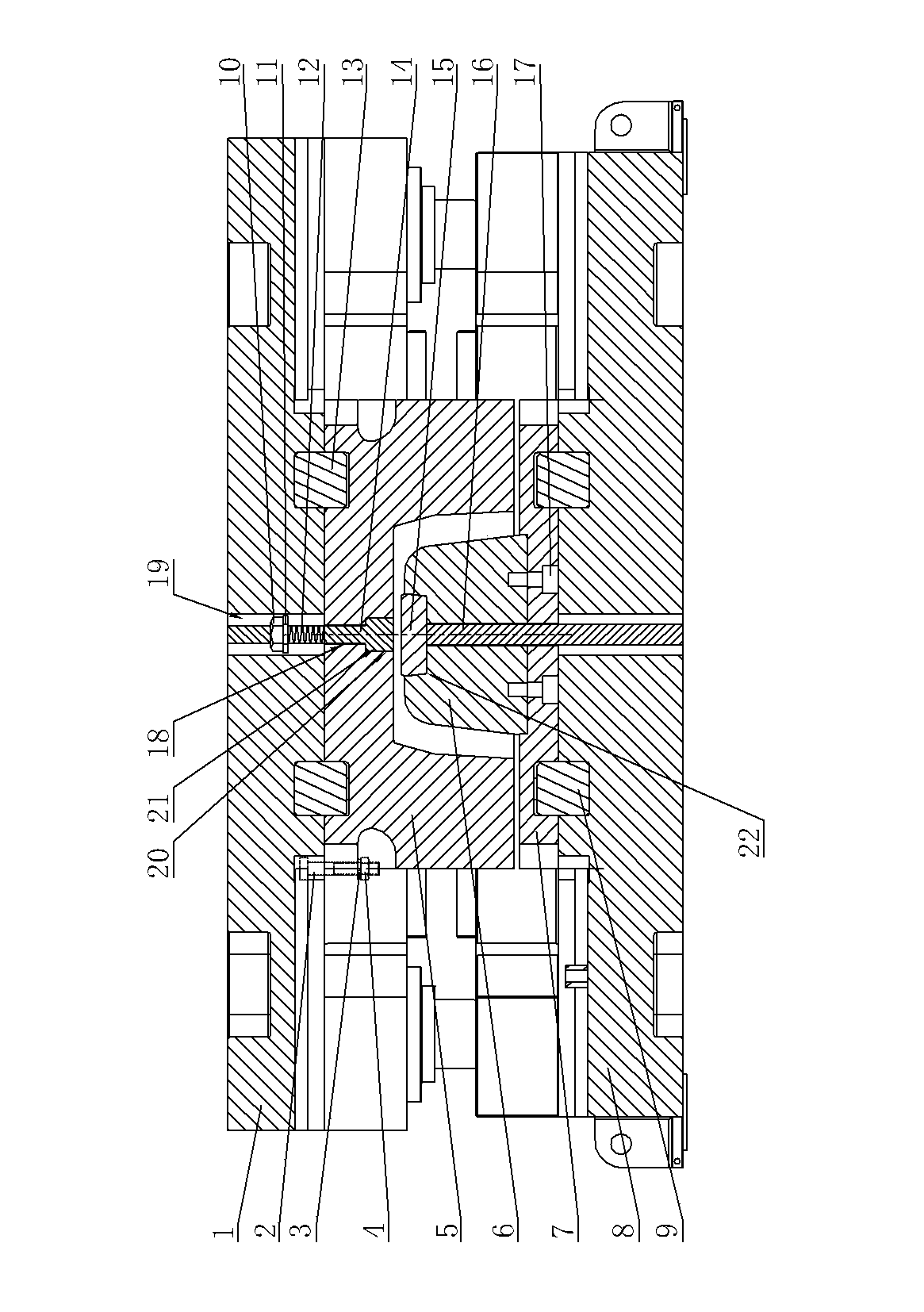

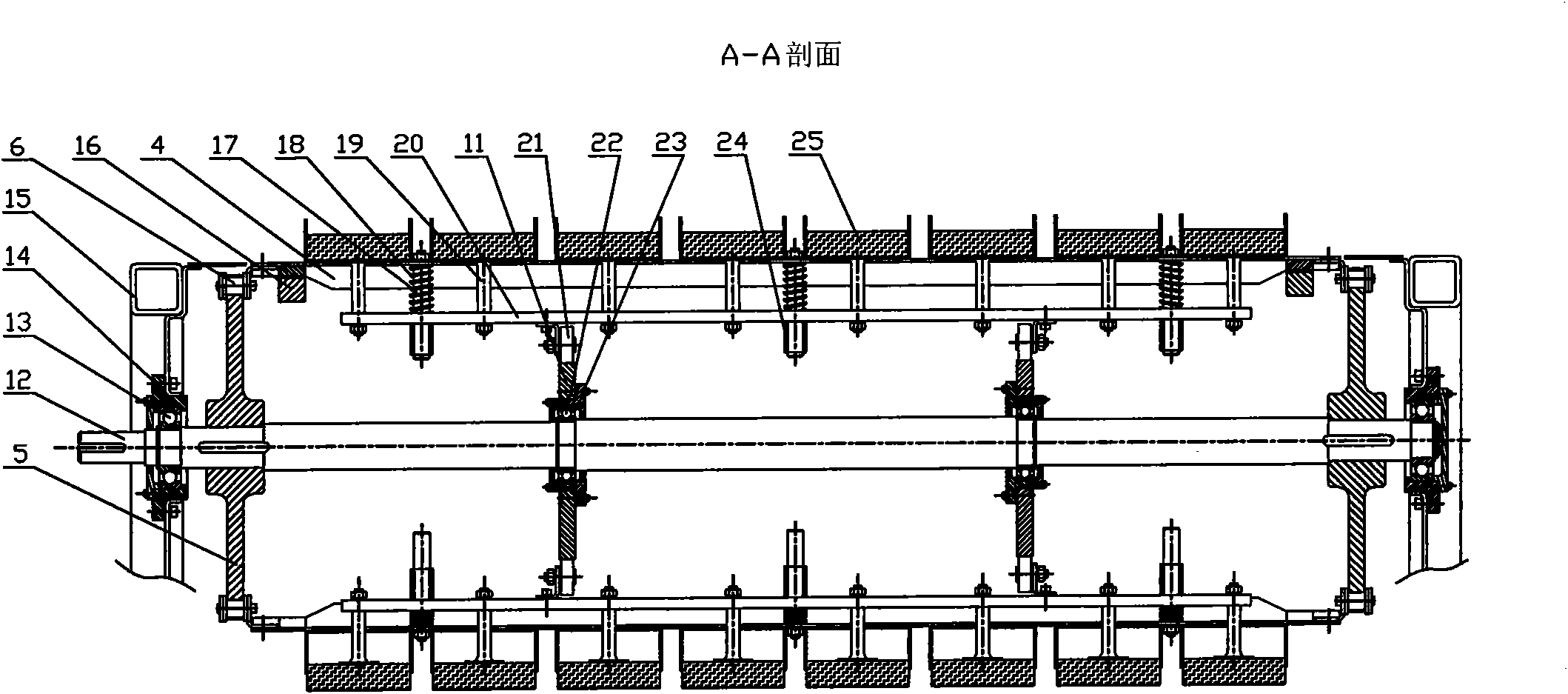

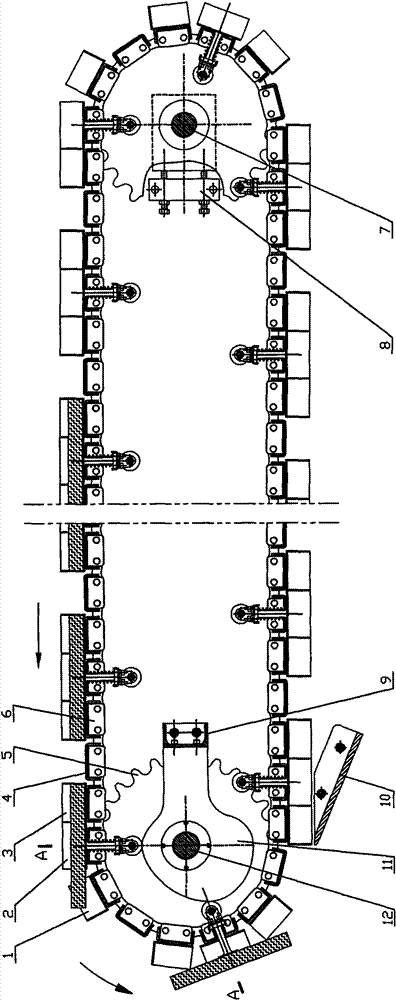

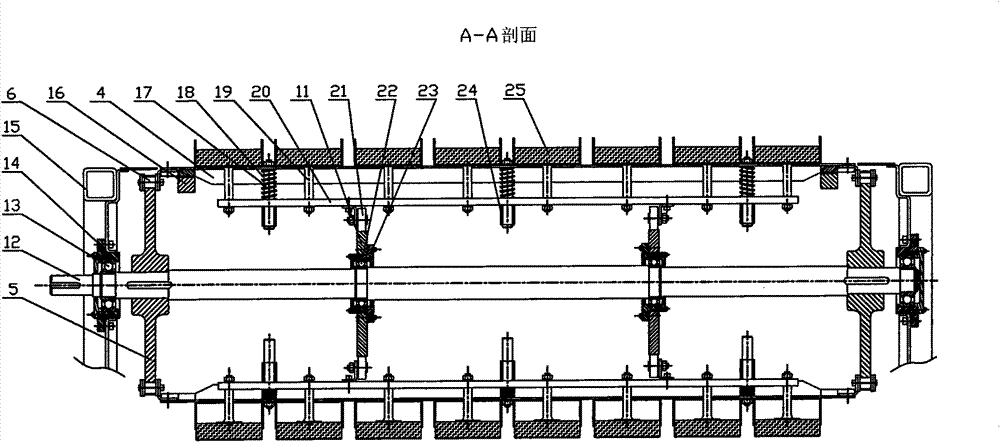

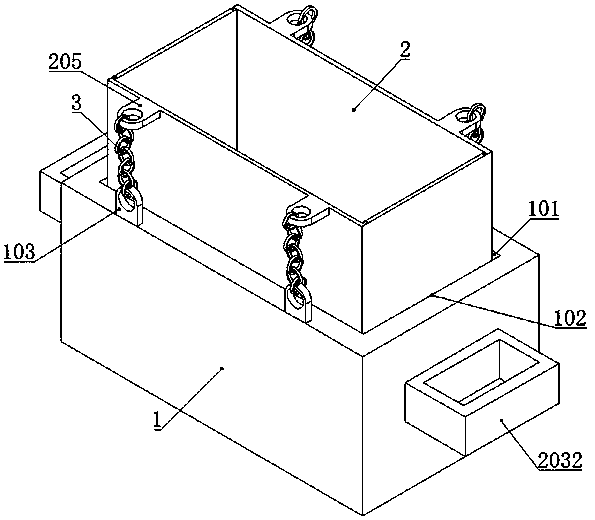

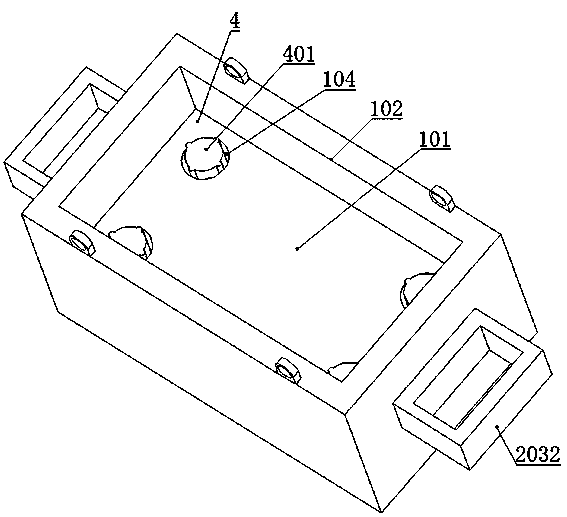

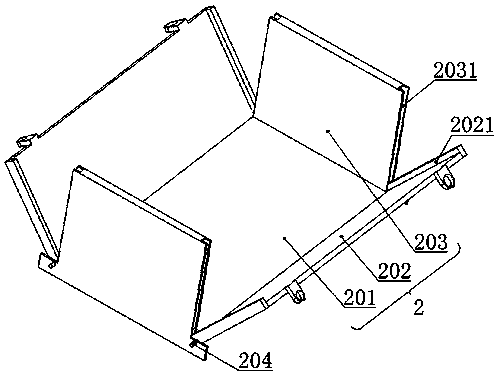

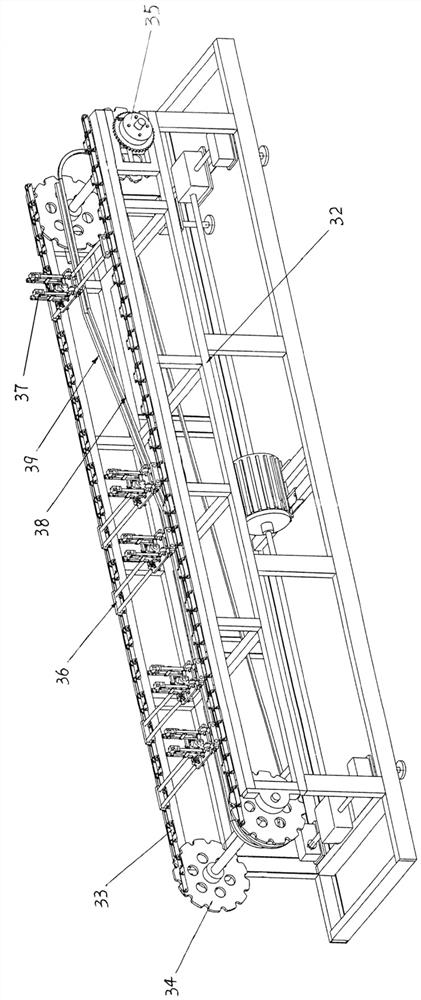

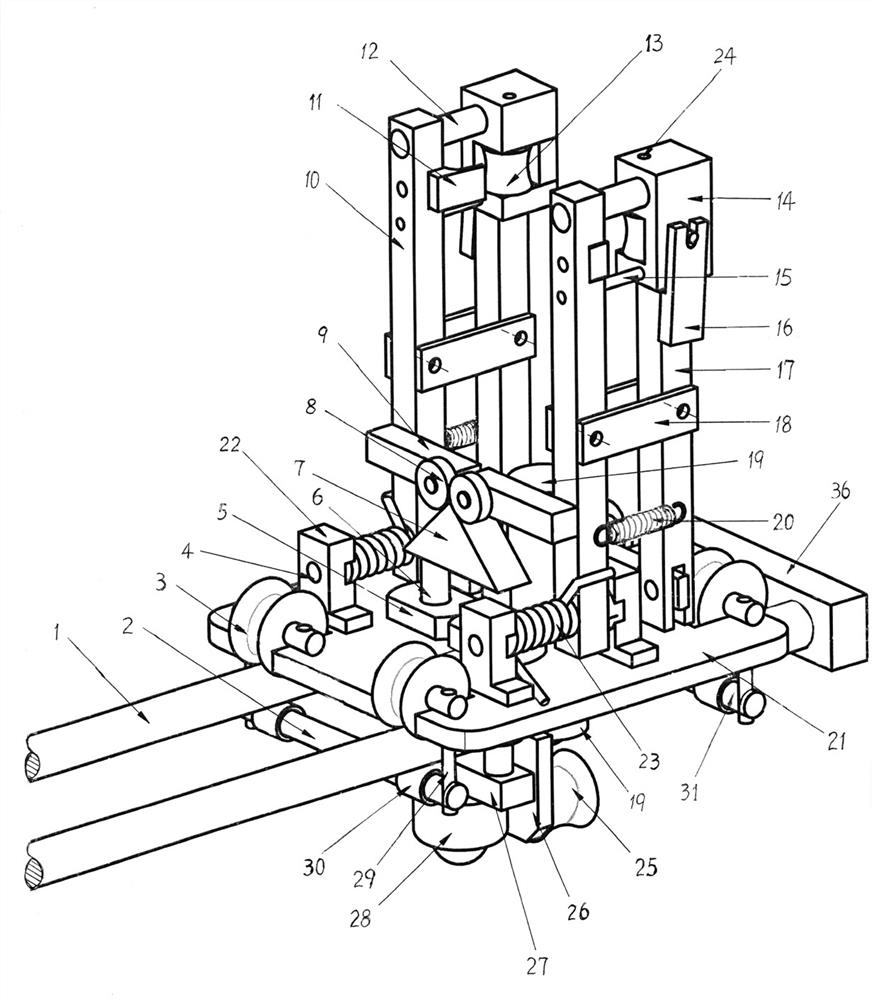

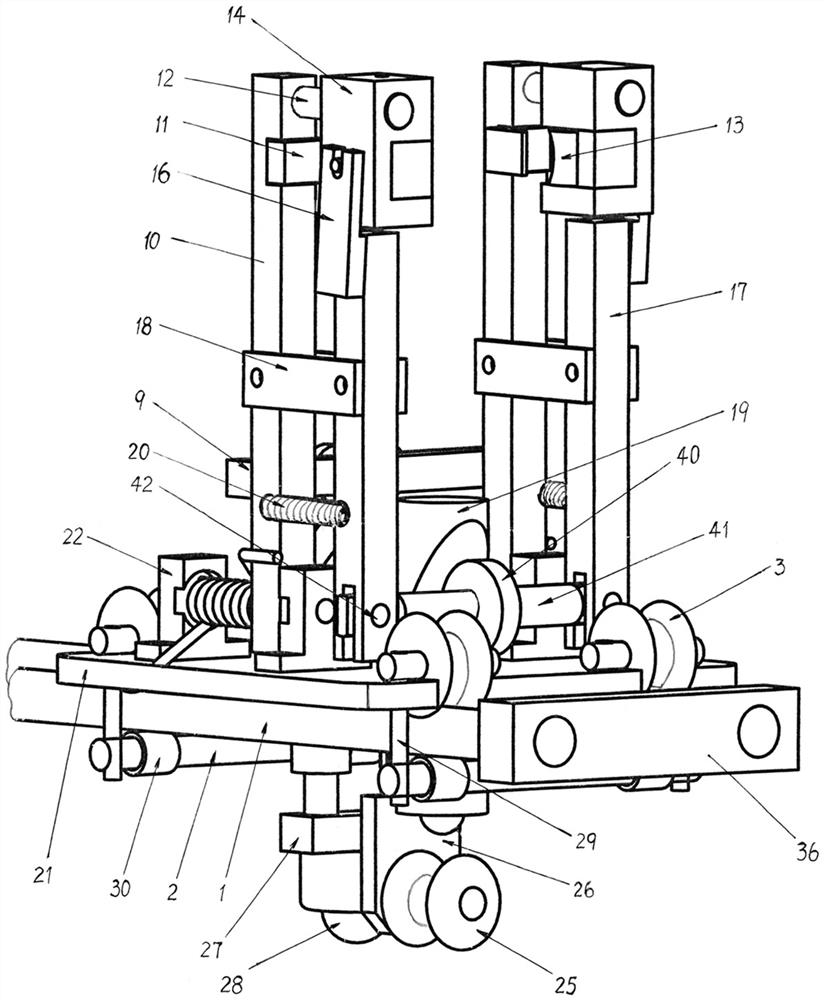

Automatic demolding device of frozen noodles production line

The invention provides an automatic demolding device of frozen noodles production line, belonging to the field of food processing machinery, wherein the demolding device consists of a split noodle die box, a chain-plate conveying mechanism, a cam mechanism, a prying plate and a rack; the split noodle die box consists of a front die box, a middle die box and a rear die box; the chain-plate conveying mechanism comprises chain wheels, chains with accessories, a driving shaft, a driven shaft, a chain plate, a tensioning device and the like; the tensioning device is connected with the driven shaft; two chains with accessories are connected with each other via the chain plate; the cam mechanism comprises a cam, a cam roller, a slot beam, a guide column, a top rod, a top rod seat, a guide sleeveand the like; the big end section of the cam is mounted on the driving shaft via a bearing; the other end is fixed on the slot beam; one end of the guide column is fixed with the chain plate; the other end of the guide column is in sliding match with the guide sleeve; and the prying plate is of a wedge-shaped structure, and is fixed with the rack. The demolding device can fast and reliable demoldthe whole row of frozen noodles; and the demolding device has the characteristics of compact structure, low cost and the like.

Owner:ZHENGZHOU UNIV

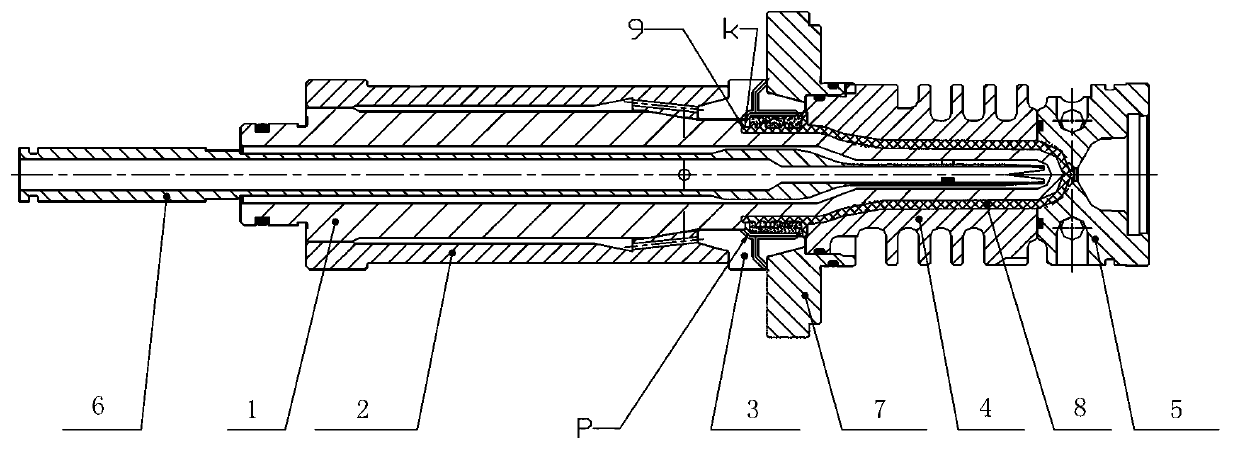

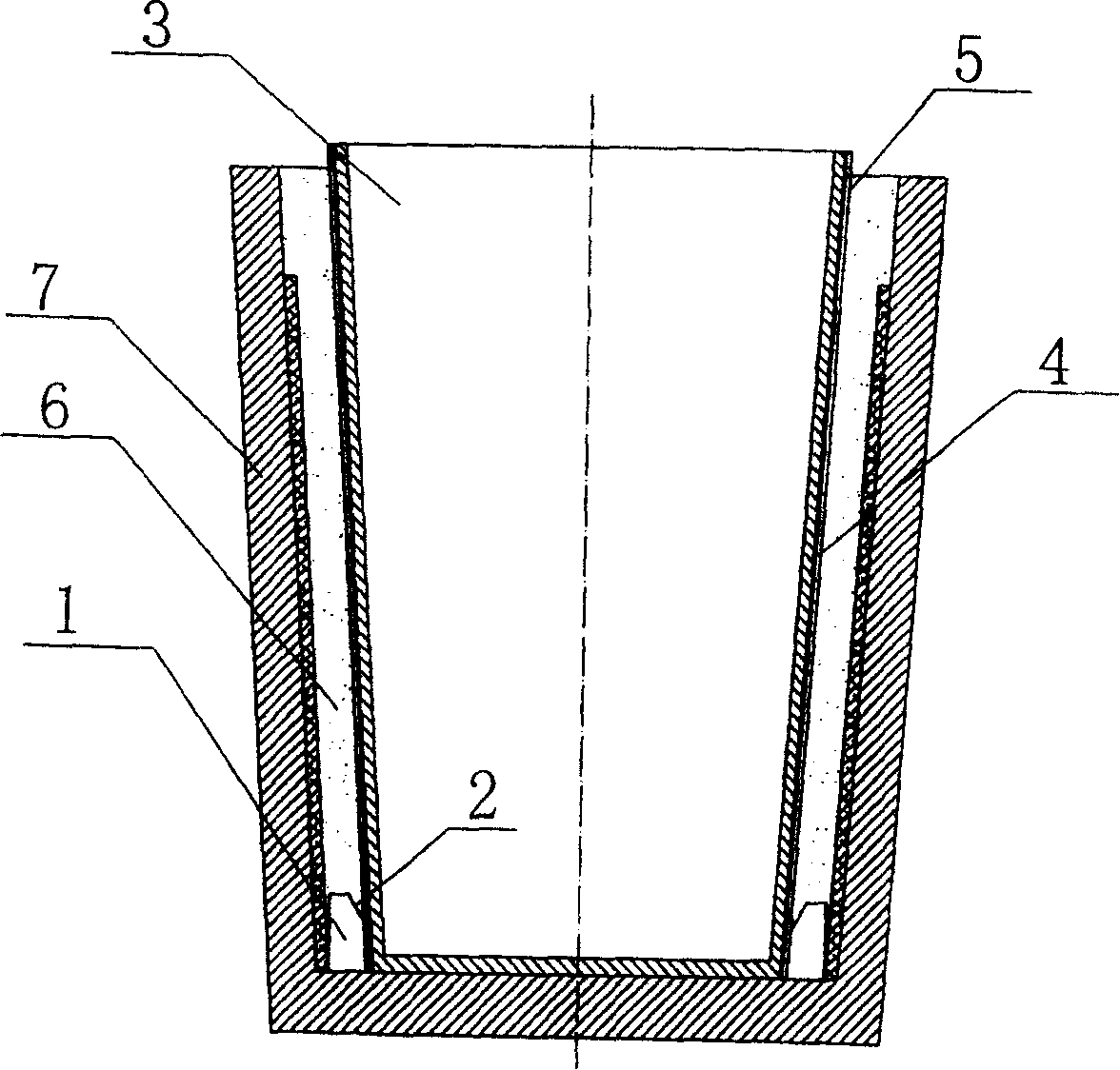

Bottle perform mold structure provided with bottle opening groove

The invention discloses a bottle perform mold structure provided with a bottle opening groove. A mold core mode-locking ring of the bottle perform mold structure is a hollow cone-column structure, the inside of the hollow cone-column structure is cylindrical, one peripheral end is a cone structure, one end is a cylindrical structure, a through hole is arranged on a wall at the combing position of the cone structure and the cylindrical structure, an annular groove is processed on the inner side cylindrical face at the end portion of the cylindrical structure of the mold core mode-locking ring, and an air vent groove is formed at the step transition position of the annular groove and the mold core outer cylindrical face. A mold lip consists of two split oppositely-opening pieces, and one piece is provided with the air vent groove on the contact face of the two pieces. The air vent groove is divided into two branches, one branch is parallel to the axial direction of the mold lip, one end of the one branch is led to the contact end face of the mold core mode-locking ring and the mold lip, and a distance from the contact end face to the mold lip is 0.025-1mm. The bottle perform mold structure achieves multiple-channel air venting and is high in air venting speed. A bonding line is close to a bottle opening. The required opening distance of the mold lip is short in demolding, and demolding and perform fetching are reliable.

Owner:GUANG DONG XING LIAN PRECISE MACHINERY

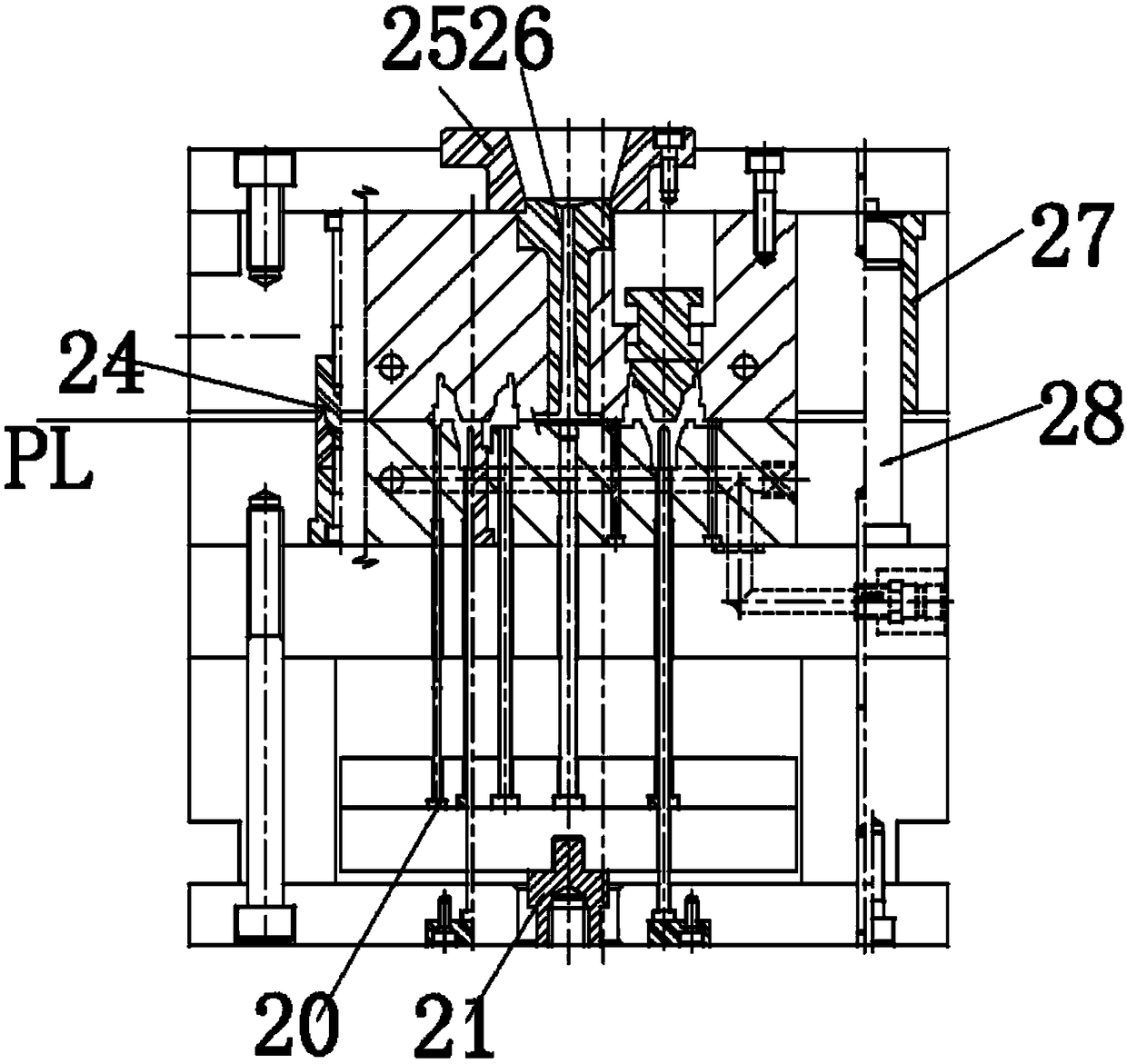

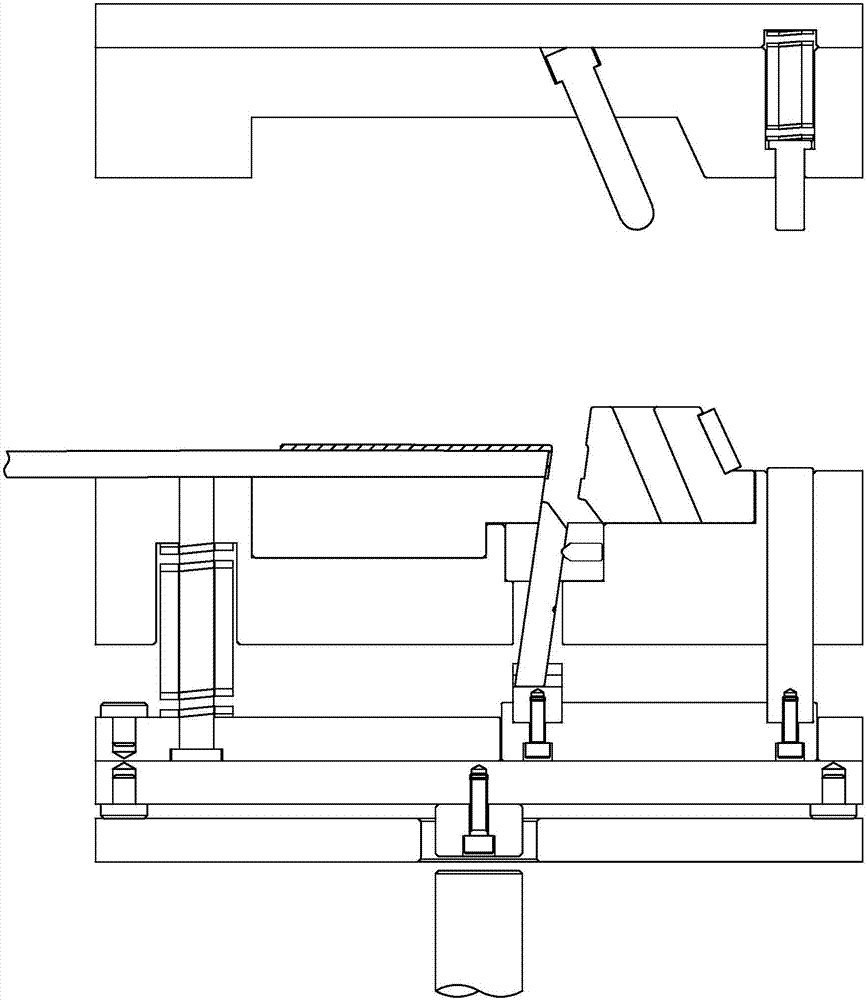

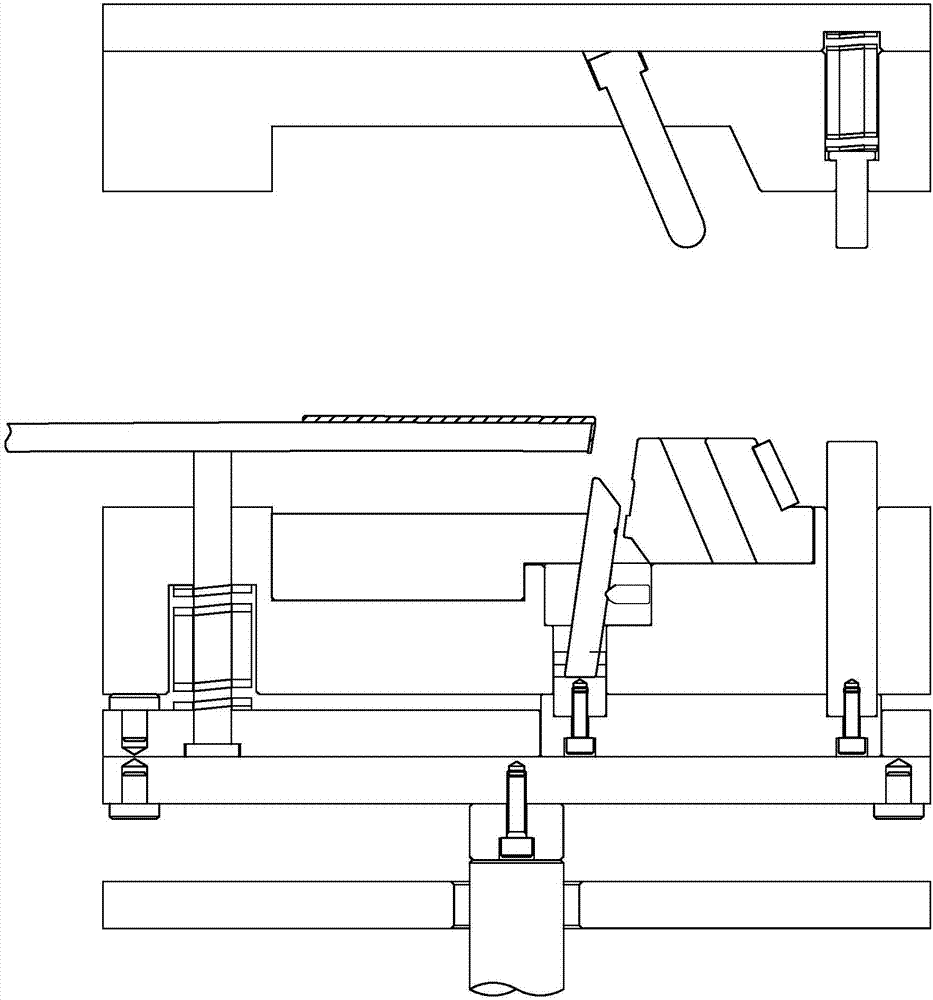

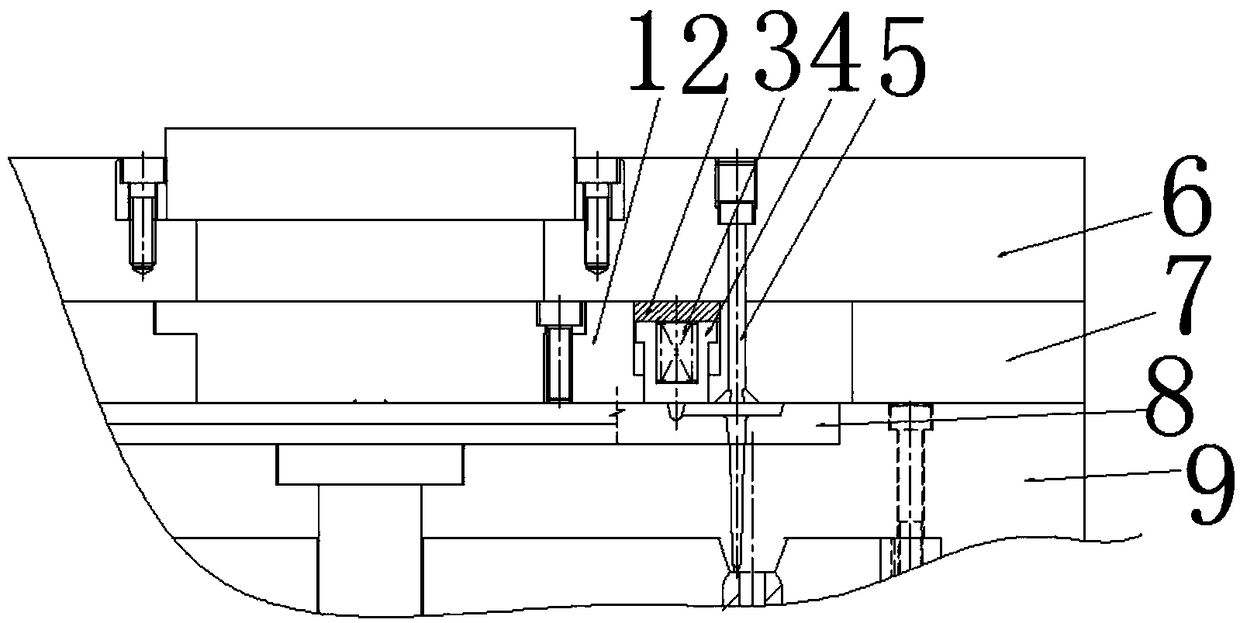

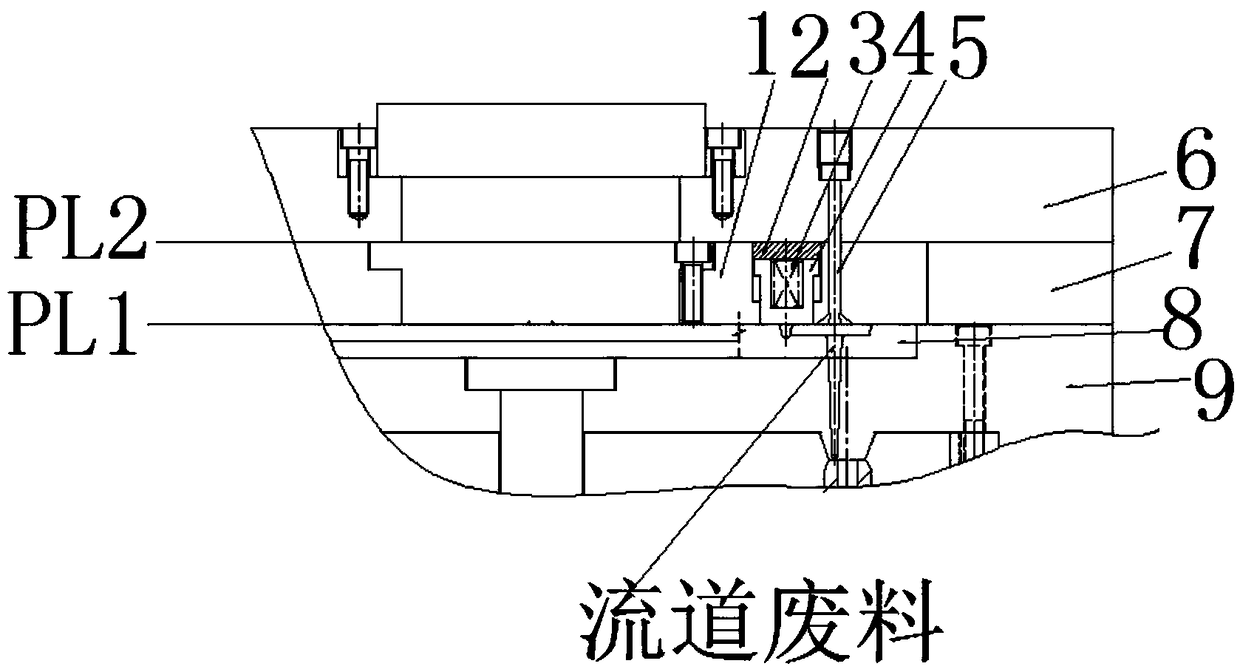

Oil cylinder slider front-mold firstly-core-pulling injection molding mold

The invention provides an oil cylinder slider front-mold firstly-core-pulling injection molding mold. The mold structurally comprises a front-mold oil cylinder driven inclined-core-pulling assembly, amold base structure assembly, a jacking-out mechanism assembly, a mold cavity forming assembly, a pouring system assisting assembly and a mold positioning mechanism assembly. A two-plate-mold cold runner side gate pouring mode is adopted for the structural layout of the mold, and the mold layout is of a one-mold two-cavity mode. A pipe water cooling mode is adopted for cooling, an exhaust edge exhaust manner is adopted for exhaust, and the exhaust gap is 0.02 mm. The technical problem that a product front mold requires core pulling and demoulding and is large in packaging force, a core pulling mechanism cannot perform core pulling and demoulding easily and reliably when a general inclined guide pillar or a bent pin is used for core pulling, the manufacturing cost of the mold is high, theoccupied mold structure space is large, and arrangement of other auxiliary mechanisms of the mold is not facilitated are solved. The oil cylinder slider front-mold firstly-core-pulling injection molding mold has the beneficial effects that straightly driven type core pulling and demoulding are performed through an oil cylinder plus an inclined slider, the reliability of the action of a core pulling and demoulding mechanism is improved, the structure difficulty of the mold is lowered, the manufacturing cost of the mold is lowered, and the mold structure space is effectively utilized.

Owner:乌鲁木齐九品芝麻信息科技有限公司

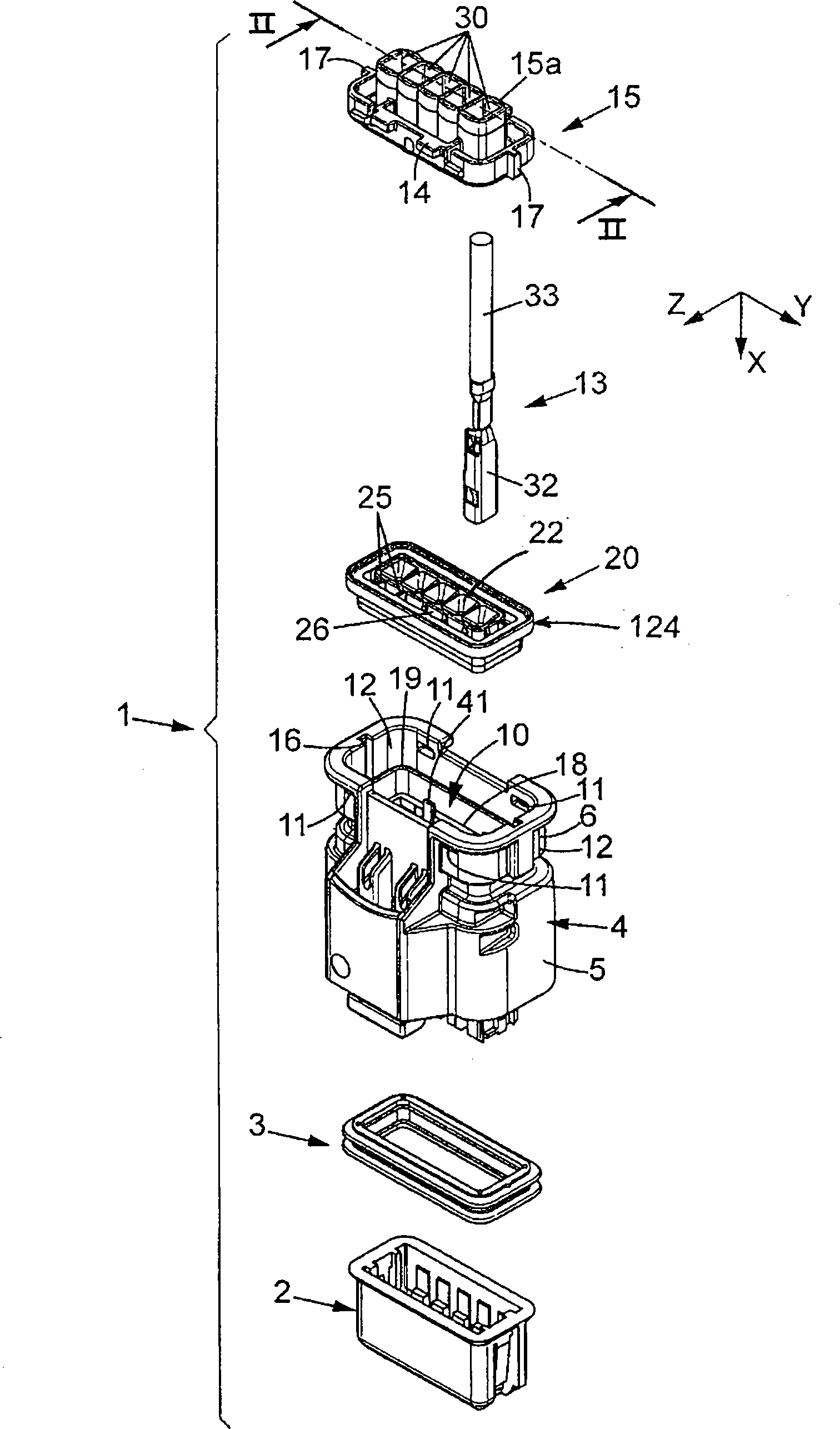

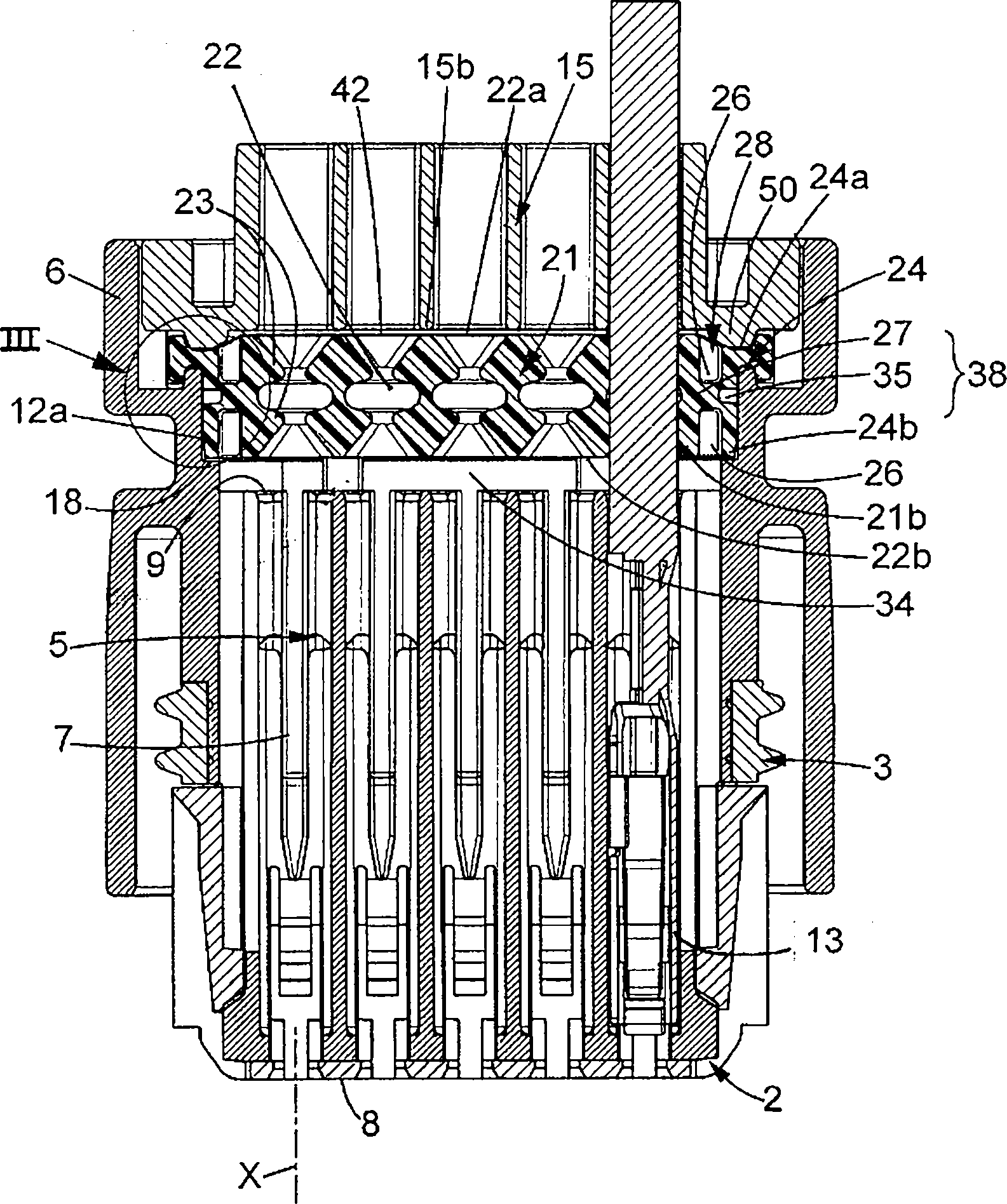

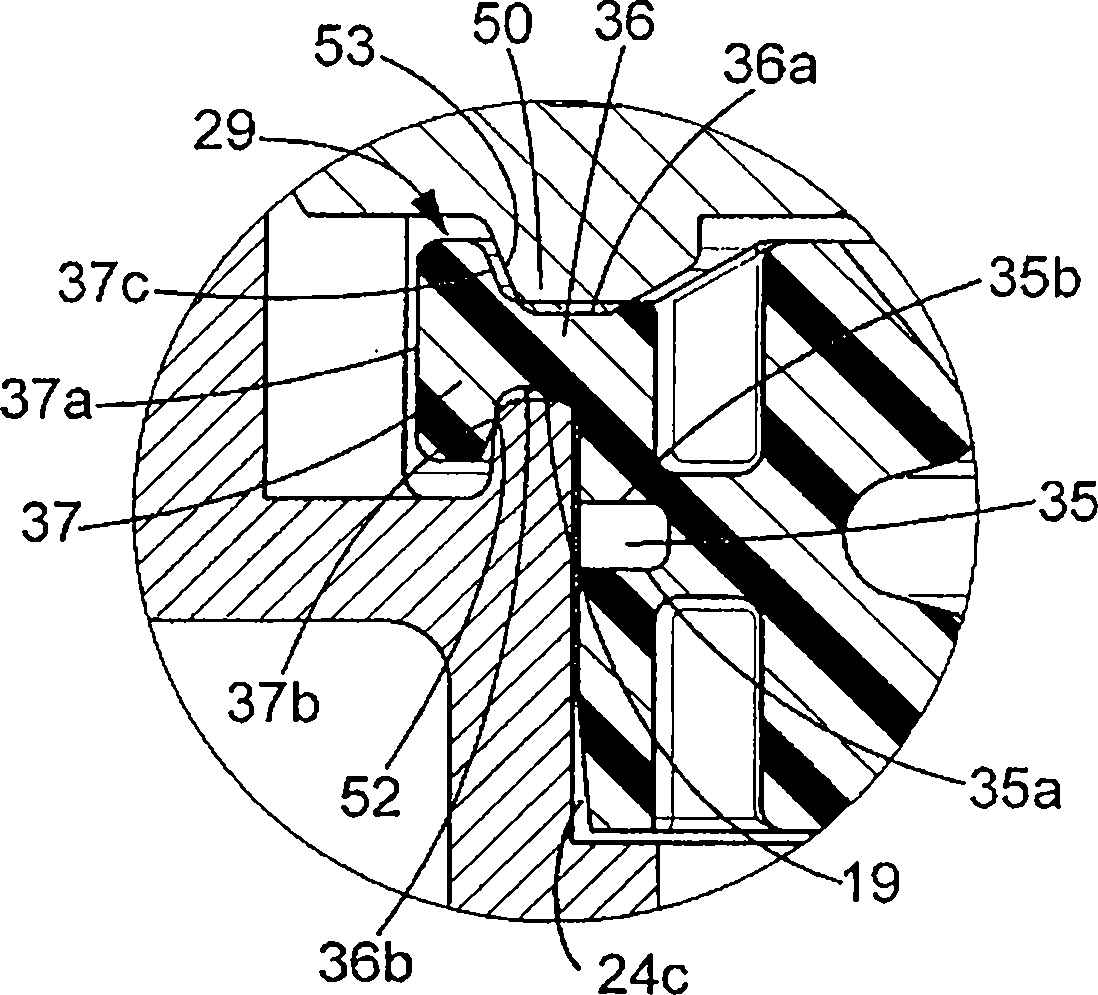

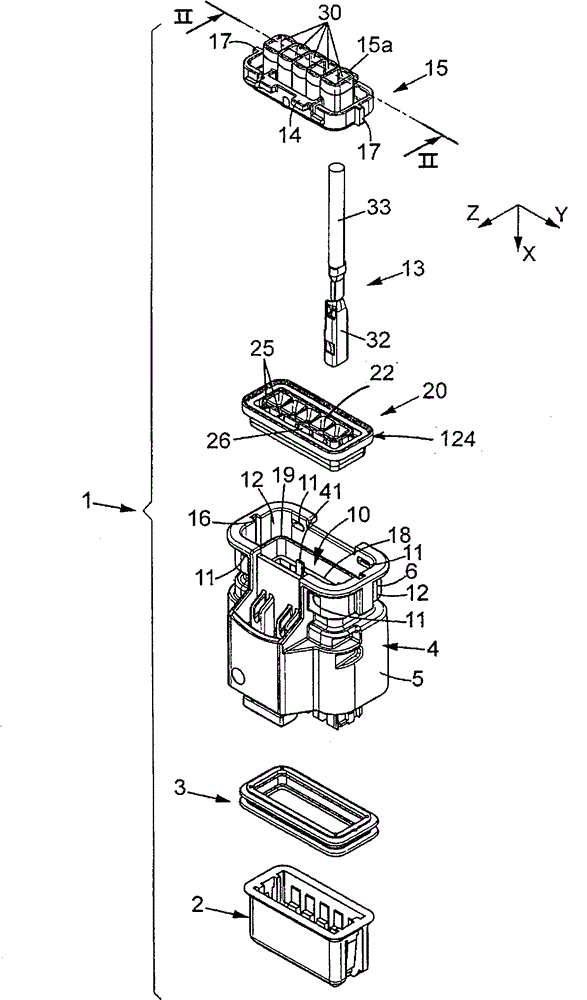

Mat sealing joint, electrical connector, and method of manufacture

ActiveCN102640364ALow costSuitable for demouldingCouplings bases/casesElectrical connectorBiomedical engineering

Owner:APTIV TECH LTD

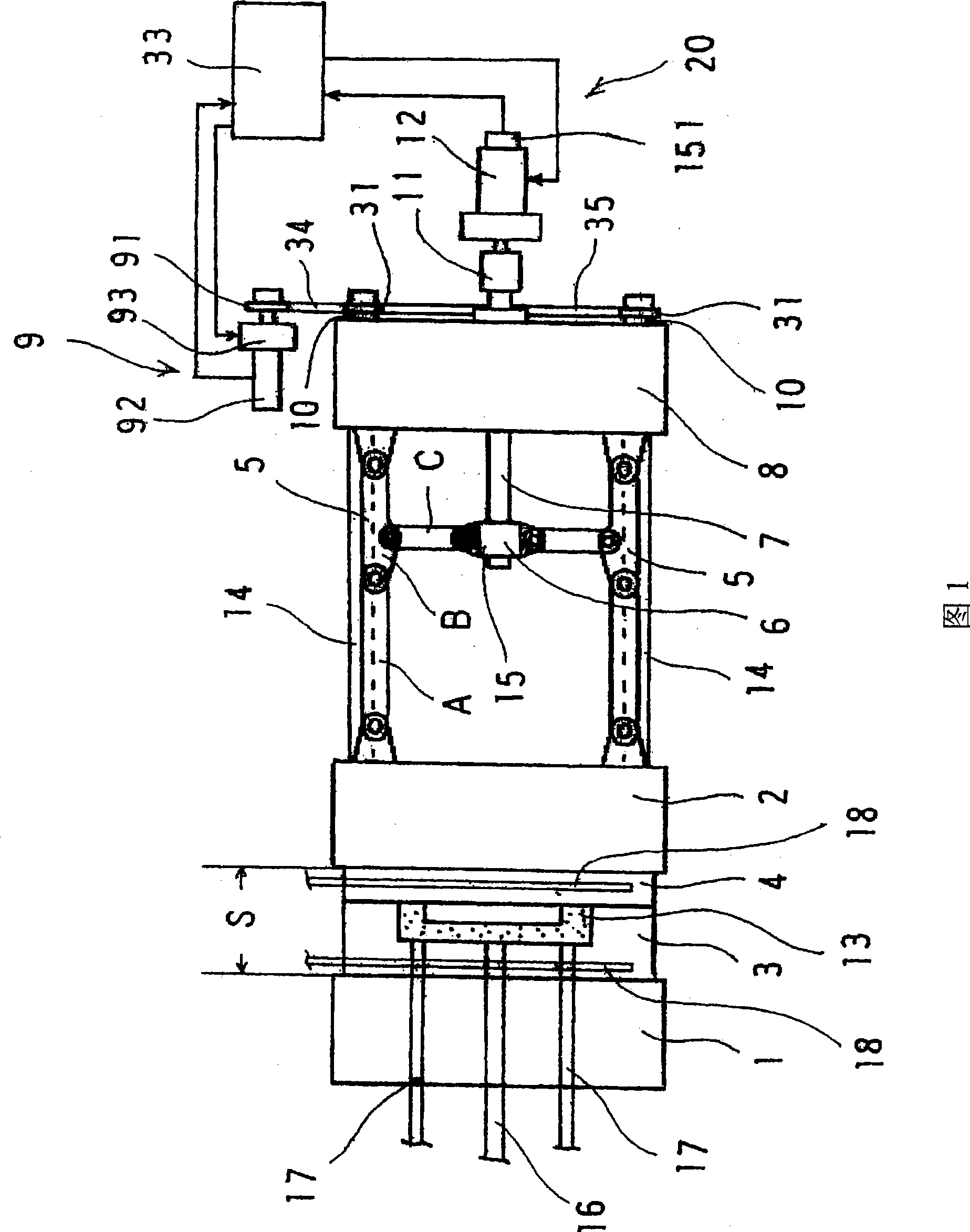

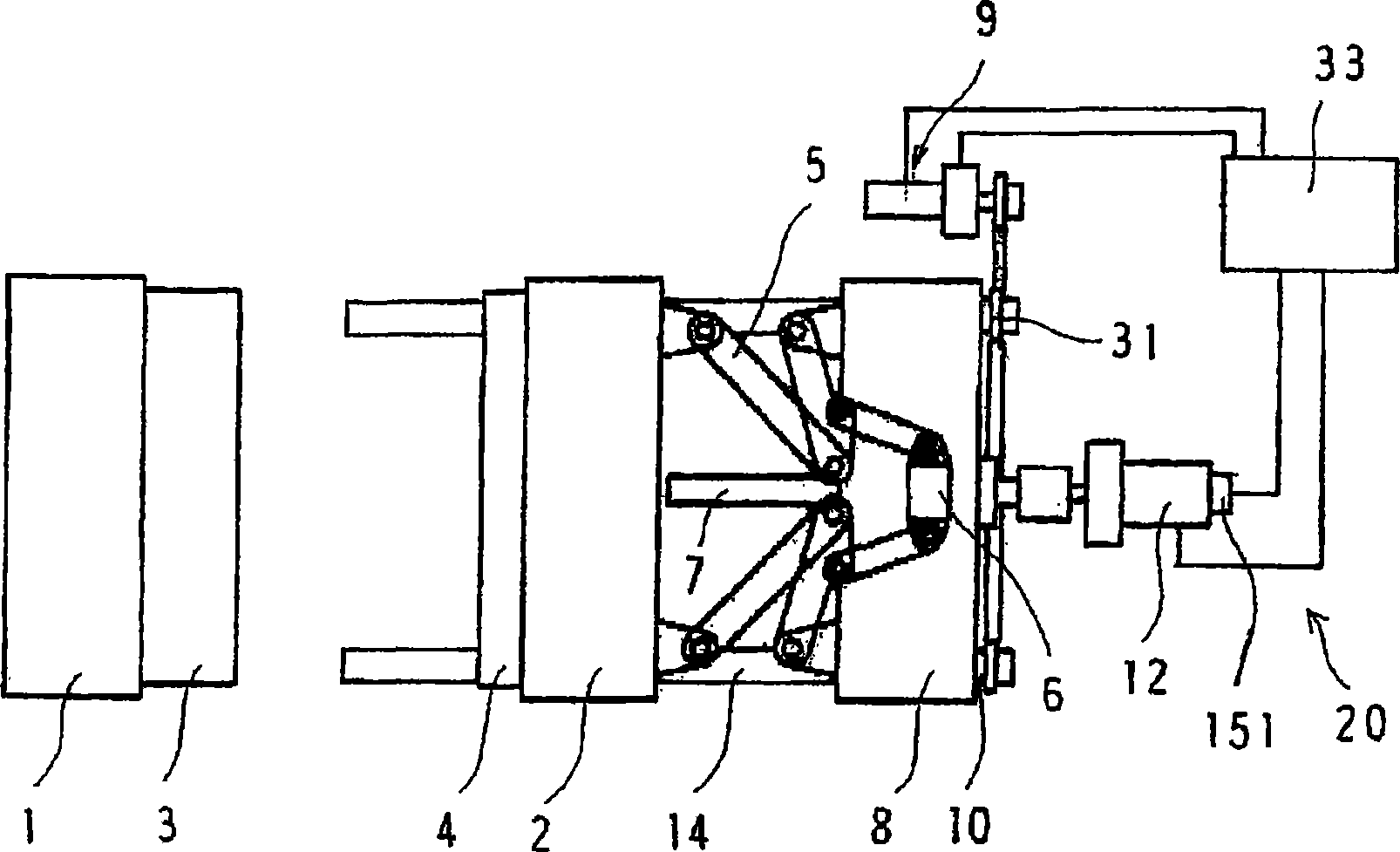

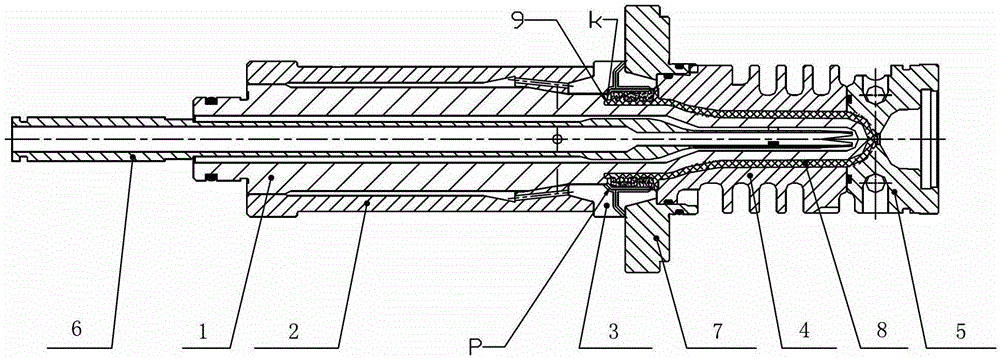

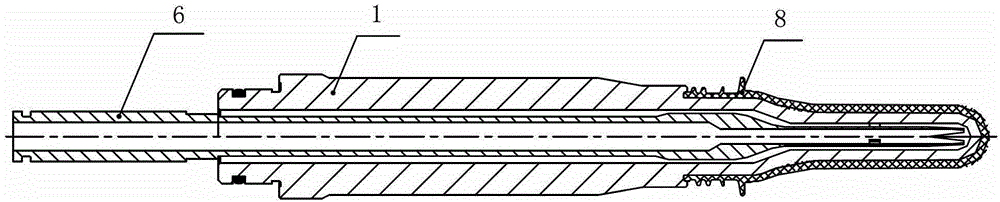

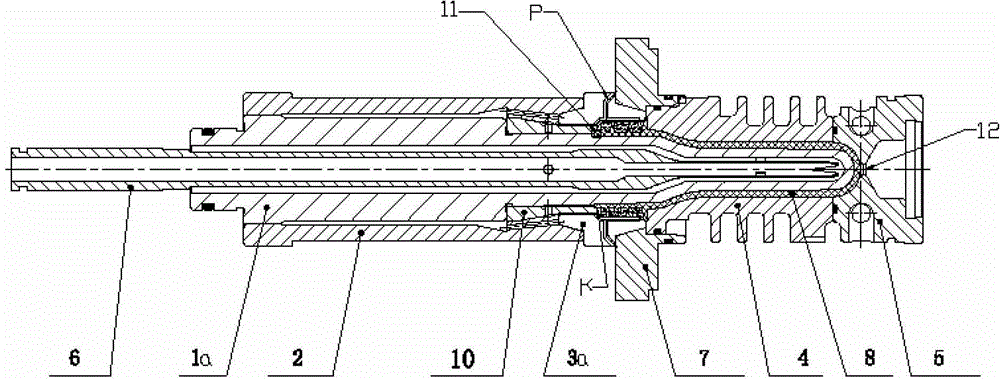

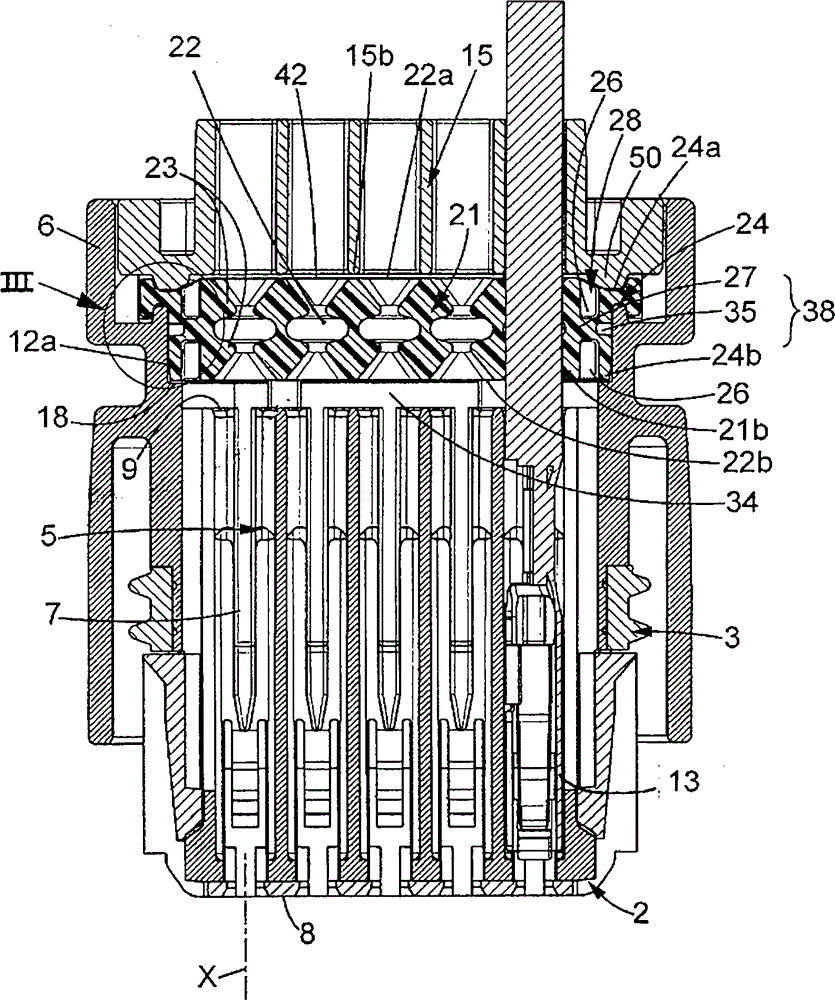

Foamed resin molding machine and method of operating the same

A die opening and closing device for a movable die plate 2 and a fixed die plate 1 includes a toggle link 5 disposed between the movable die plate 2 and a die tightening housing 8, a cross head 6 for flexing the toggle link 5, and a motor-driven ball screw 7 penetrating through the die tightening housing 8 and inserted into the cross head 6, and this die opening and closing device is provided with die thickness adjusting means 9 for adjusting the die thickness S when the die is tightened by extension of the toggle link 5, and ball screw rotation control means 20 for controlling constant the cracking gap, and a foamed resin molding machine is presented, together with its operating method.

Owner:DAISEN IND CO LTD

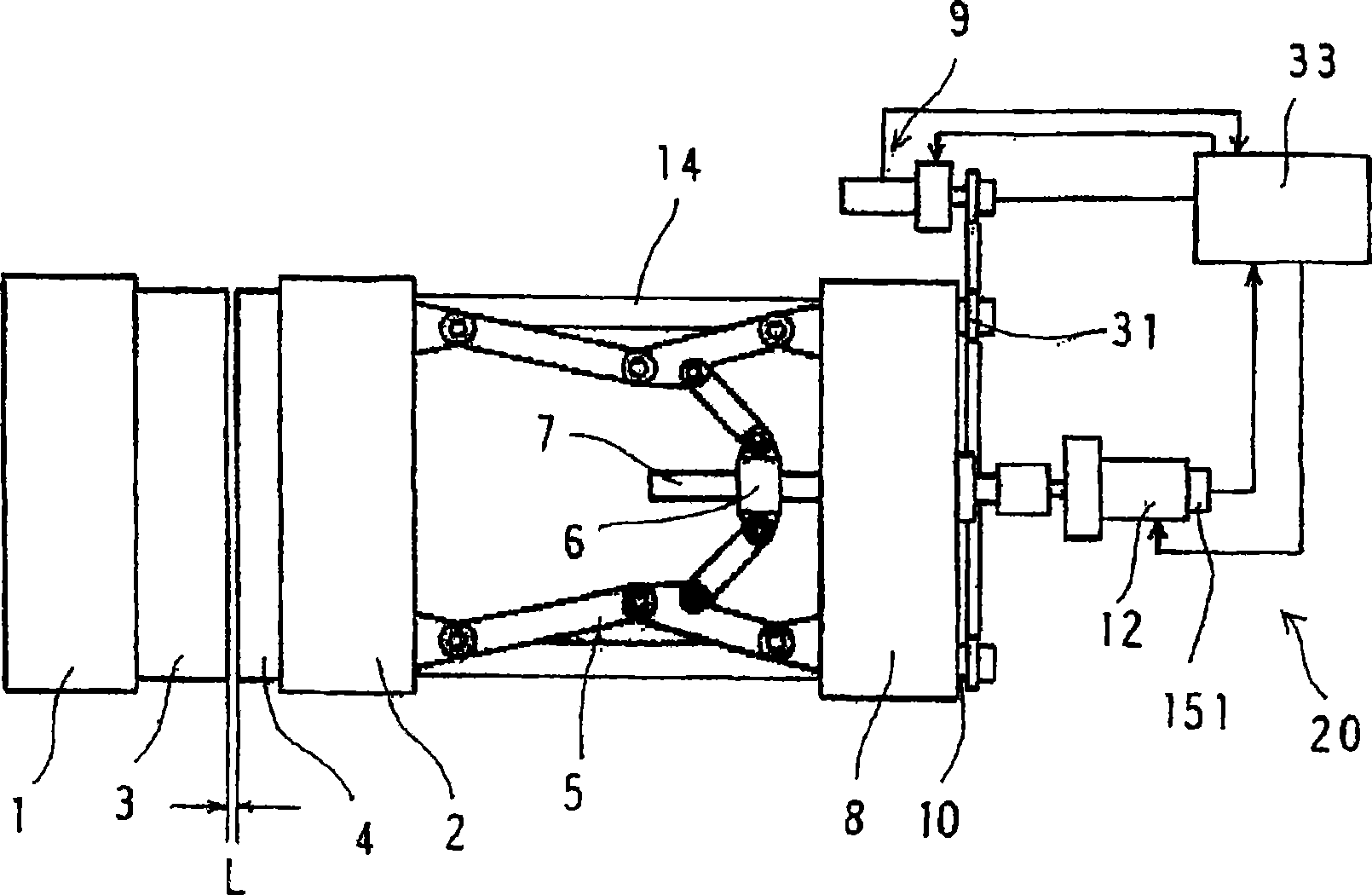

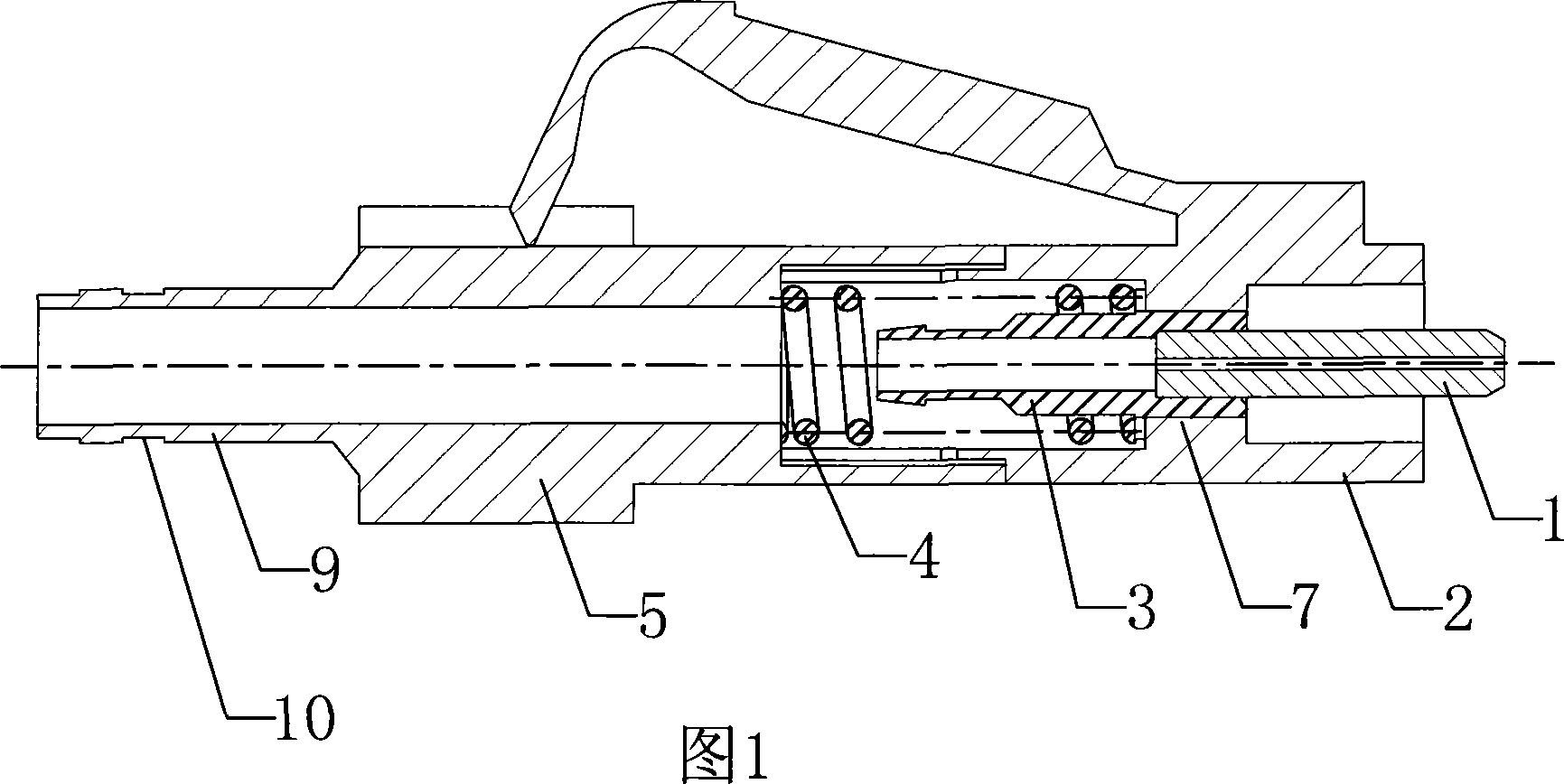

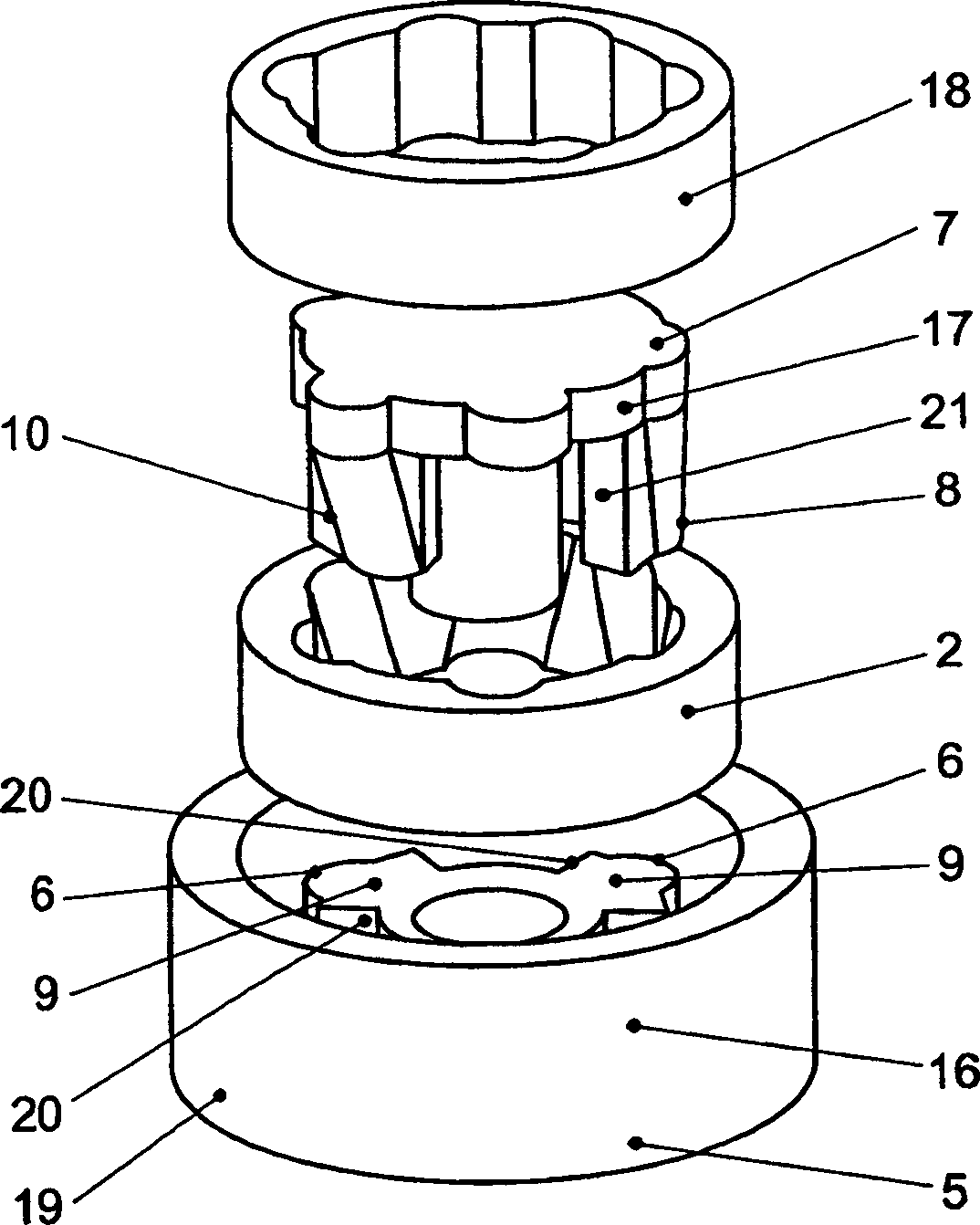

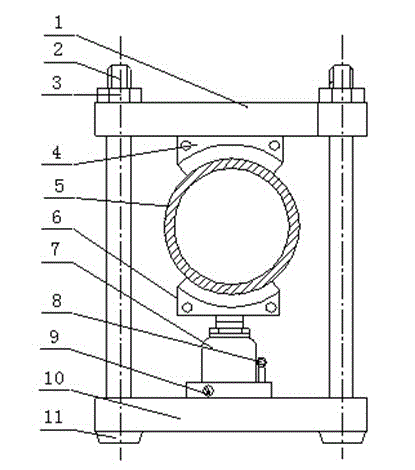

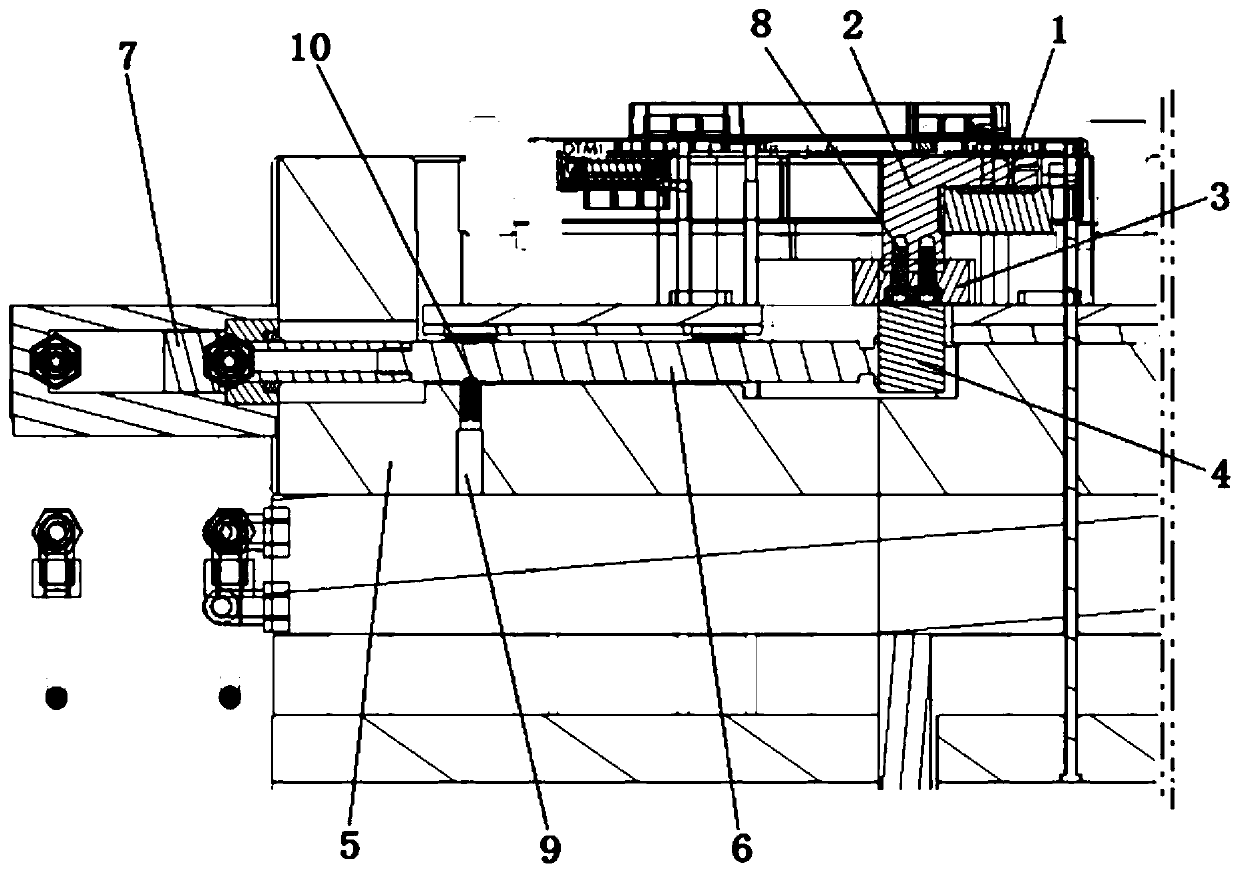

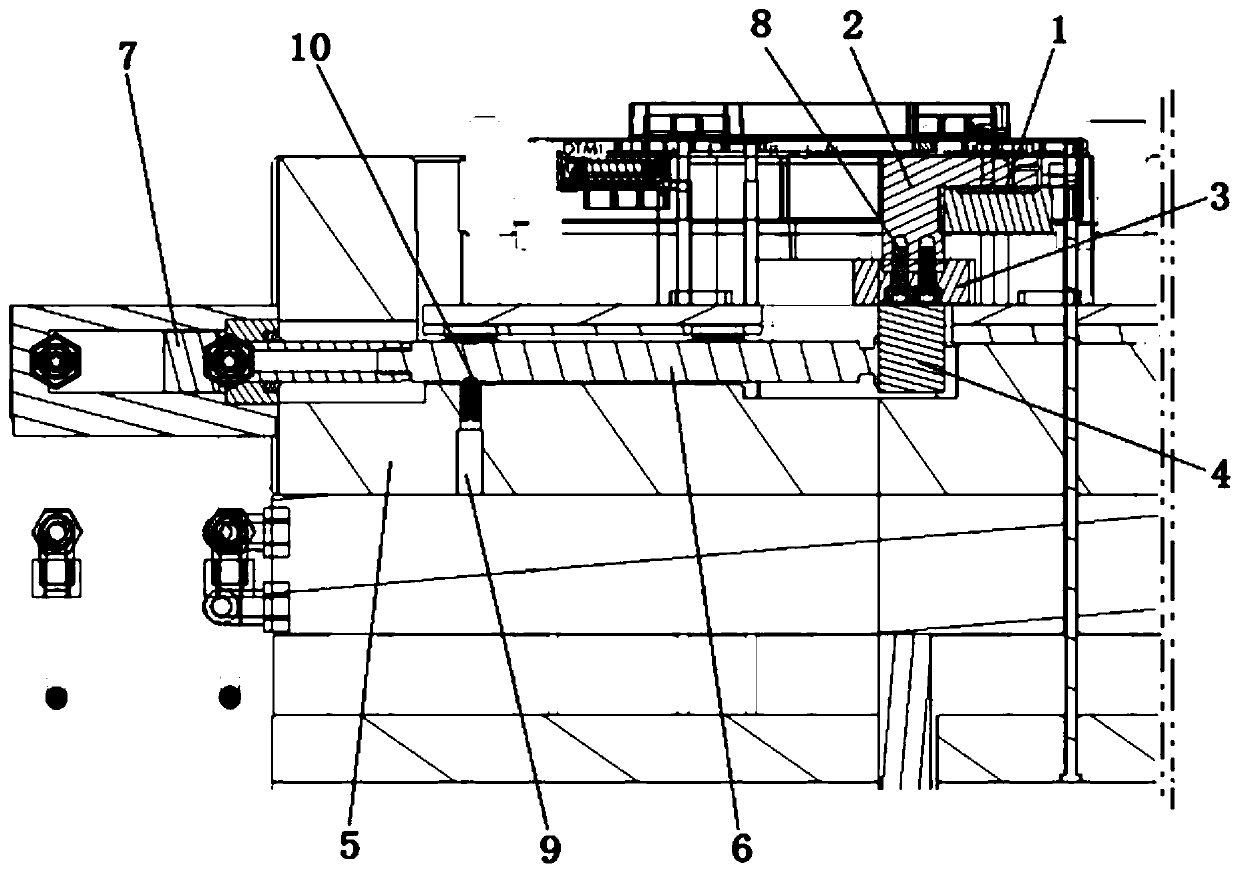

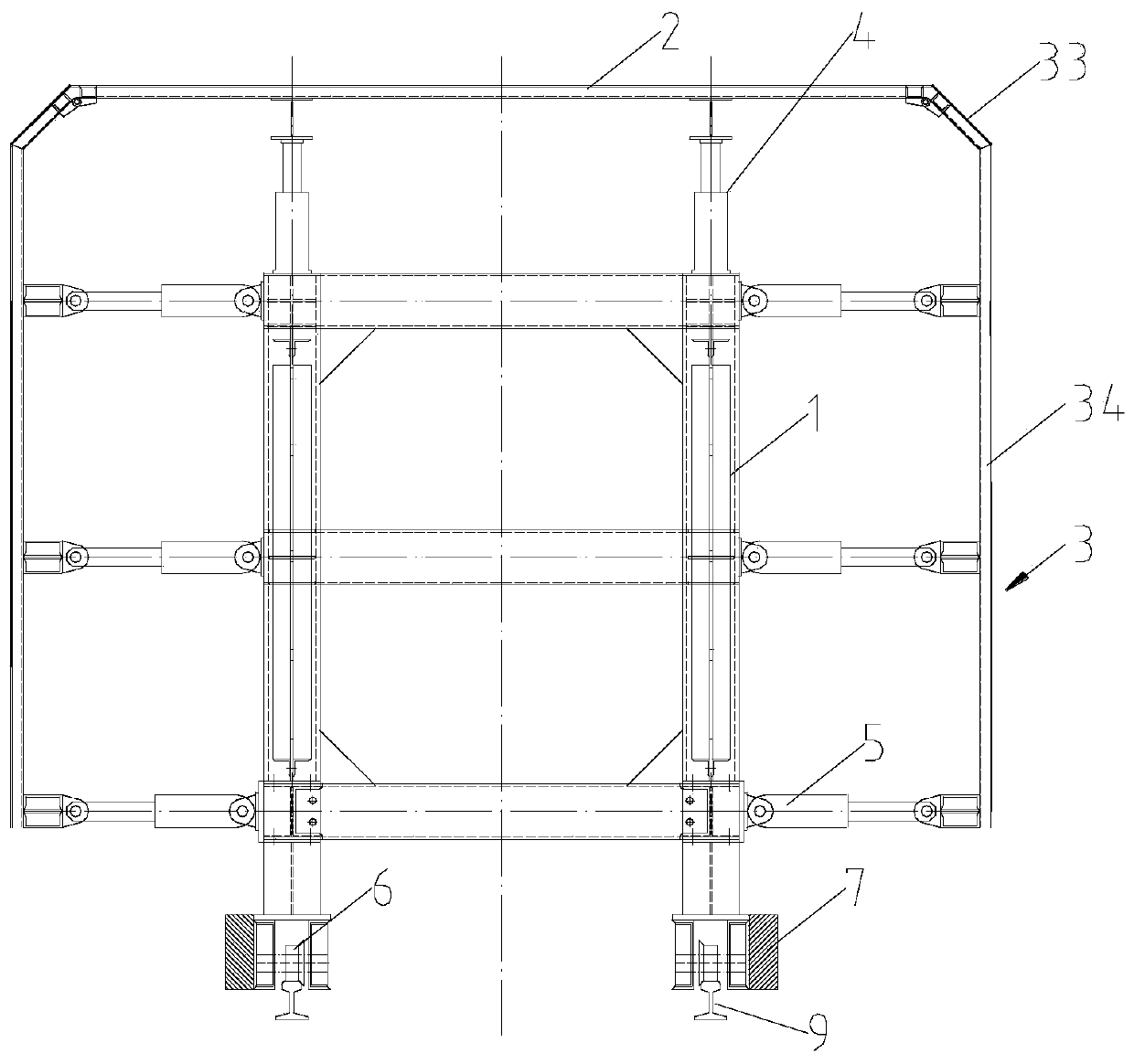

Inner gear ring correction constant-pressure machine

The invention discloses an inner gear ring correction constant-pressure machine, and relates to a supporting device for heat treatment of an inner gear ring. An upper crossbeam (1) and a lower crossbeam (10) are fixedly connected with each other through four upright bodies (2) to form a framework structure, the upper crossbeam (1) and the upright bodies (2) are fixed through upright body fixed nuts (3), the bottom of the framework structure is provided with a base (11), a hydraulic cylinder (7) is arranged inside the framework structure, a lower correction mold (6) and an upper correction mold (4) are connected above the hydraulic cylinder (7), the lower part of the hydraulic cylinder (7) is provided with a pressure releasing screw (9), and the side edge of the hydraulic cylinder (7) is provided with a pulling handle hole (8). The inner gear ring correction constant-pressure machine is simple in structure, the correction mold is reliable to demold, and easiness for loading and unloading a workpiece can be realized, and convenience in operation can be realized; and convenience, safety and sensitivity in local operation can be realized.

Owner:JIANGXI HONGDU AVIATION IND GRP

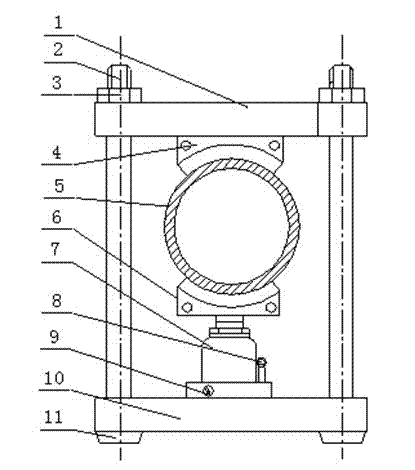

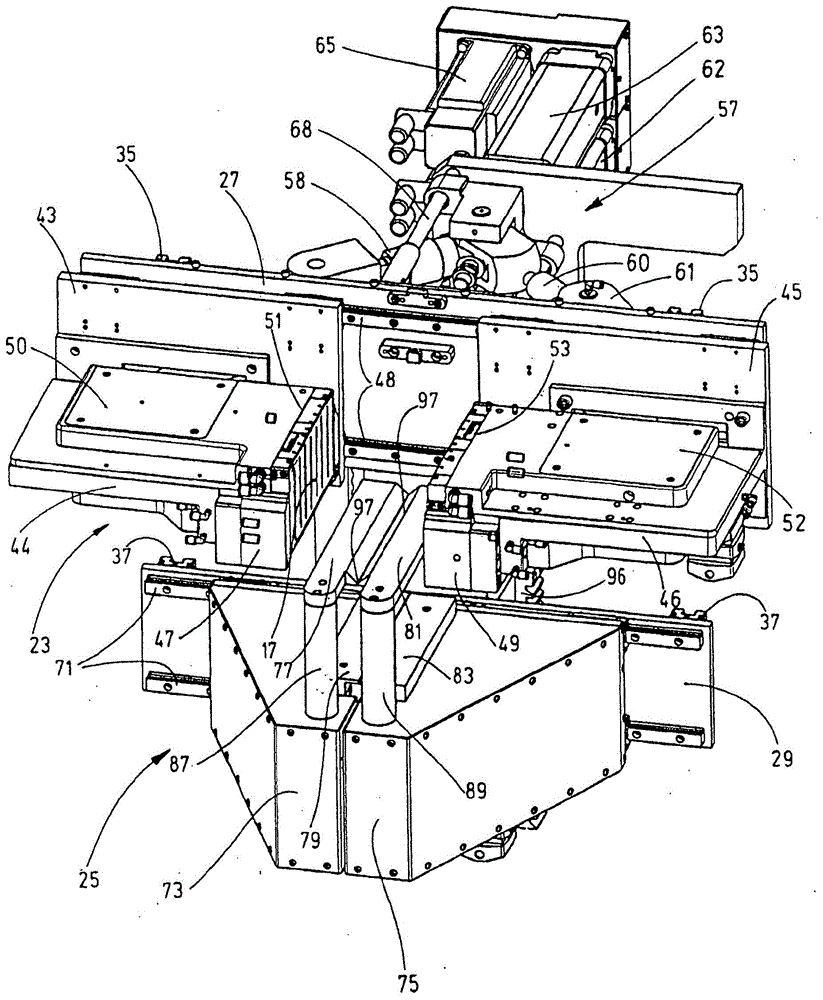

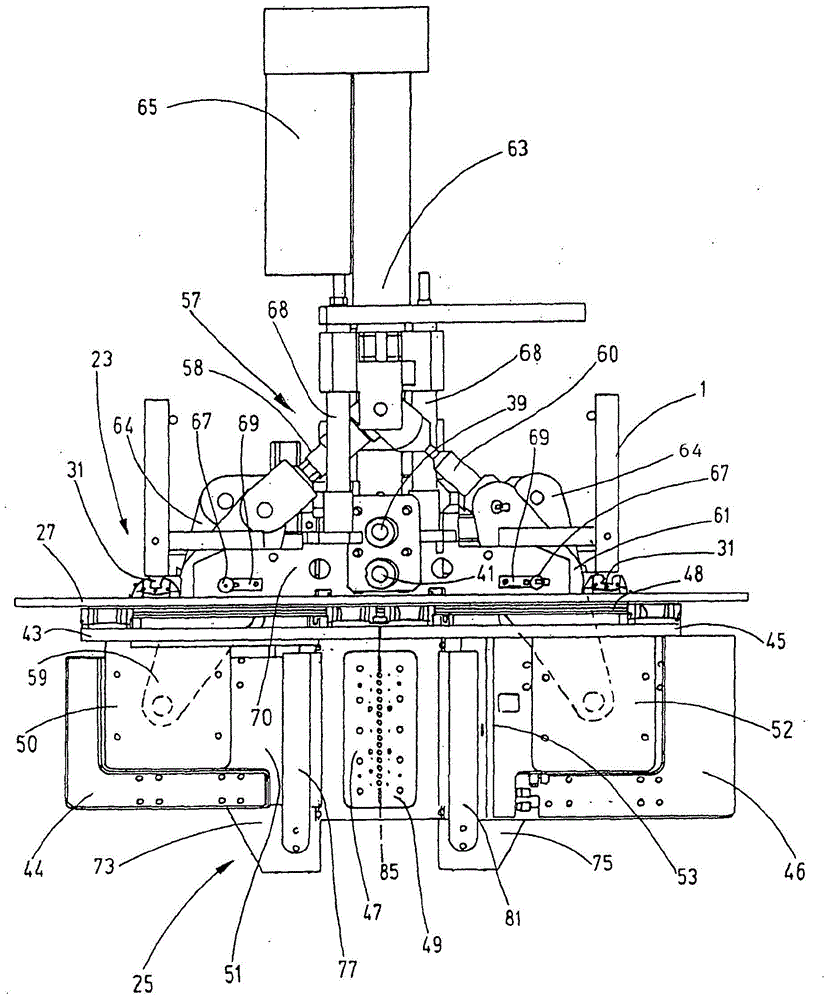

Device for producing container products consisting of plastic materials

The invention is a device for producing container products which consist of plastic materials, particularly by carrying out a moulding, filling and sealing method, and comprising a moulding device (13) that can be supplied with a moulding tube (15) of plasticized plastic materials and that has a movable moulding surface (17), adapted to the predefinable geometry of the container, on which said moulding tube (15) can be laid for a shaping, filling and / or sealing process. The invention is characterised so that a guide and retainer device (25) is provided which comprises movable guide and retainer parts (77, 81, 79, 83) able to be controlled such that these engage, in at least one of the possible functional positions outside the moulding region of the moulding device (13), on said moulding tube (15) itself and / or on the plastic material that surrounds each at least one manufactured container product and / or its content.

Owner:KOCHER PLASTIK MASCHBAUU

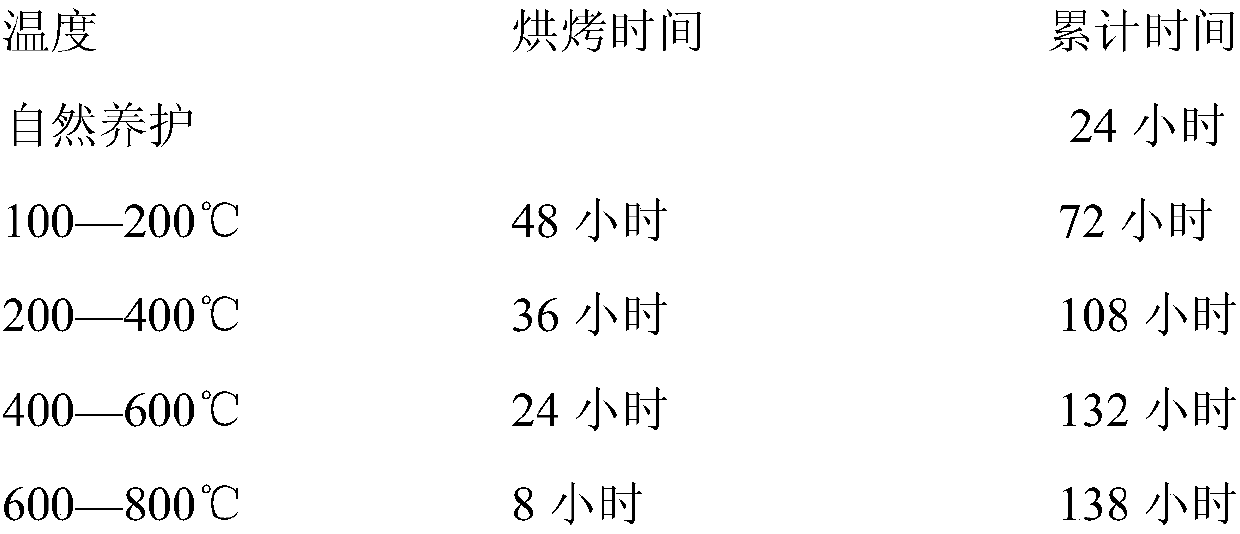

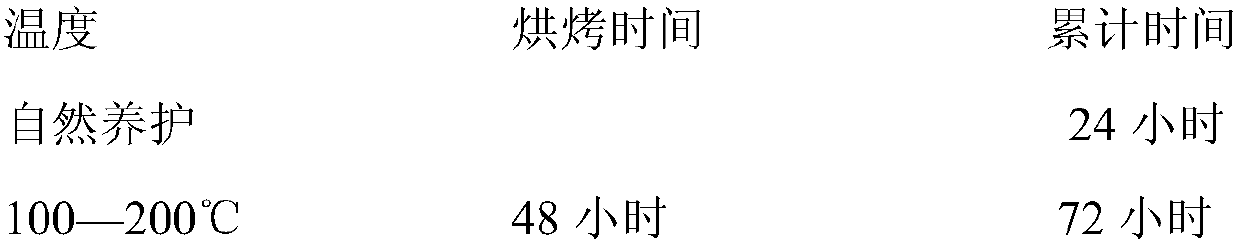

Construction method for ladle integral pouring and casing pouring liner

The invention discloses a constructing method of entire ladle casting and lining, which comprises the following steps: locating mould, assembling at least three locating blocks on the bottom of ladle, distributing the blocks on the periphery of ladle bottom, setting wedge angle in the locating block to make diameter of encircle of each locating block bottom more than the diameter of excircle on the mould bottom, adopting the same material for each locating block and ladle lining.

Owner:崔东瑞

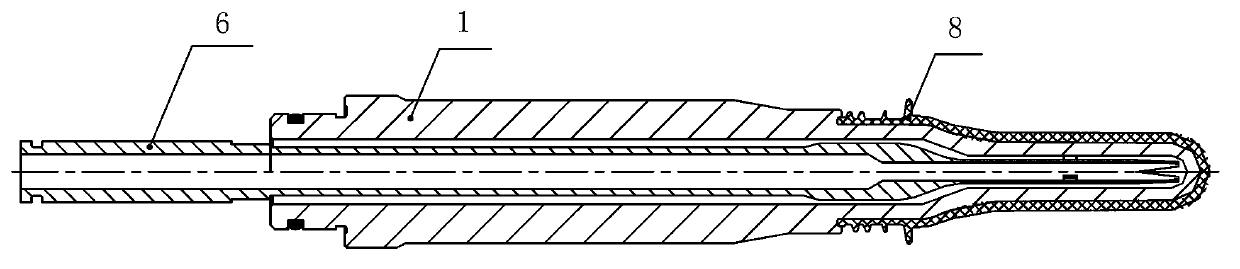

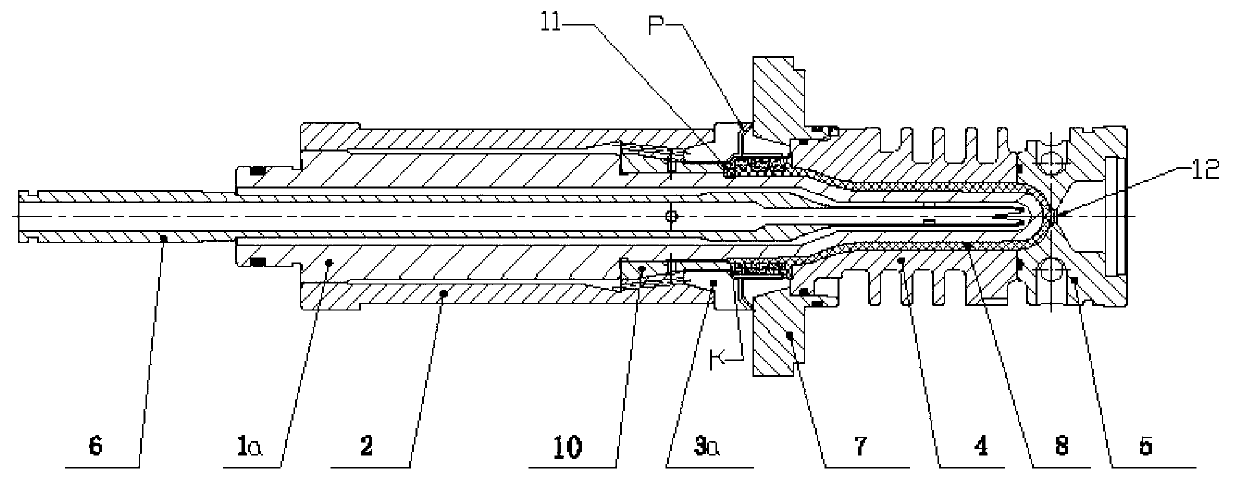

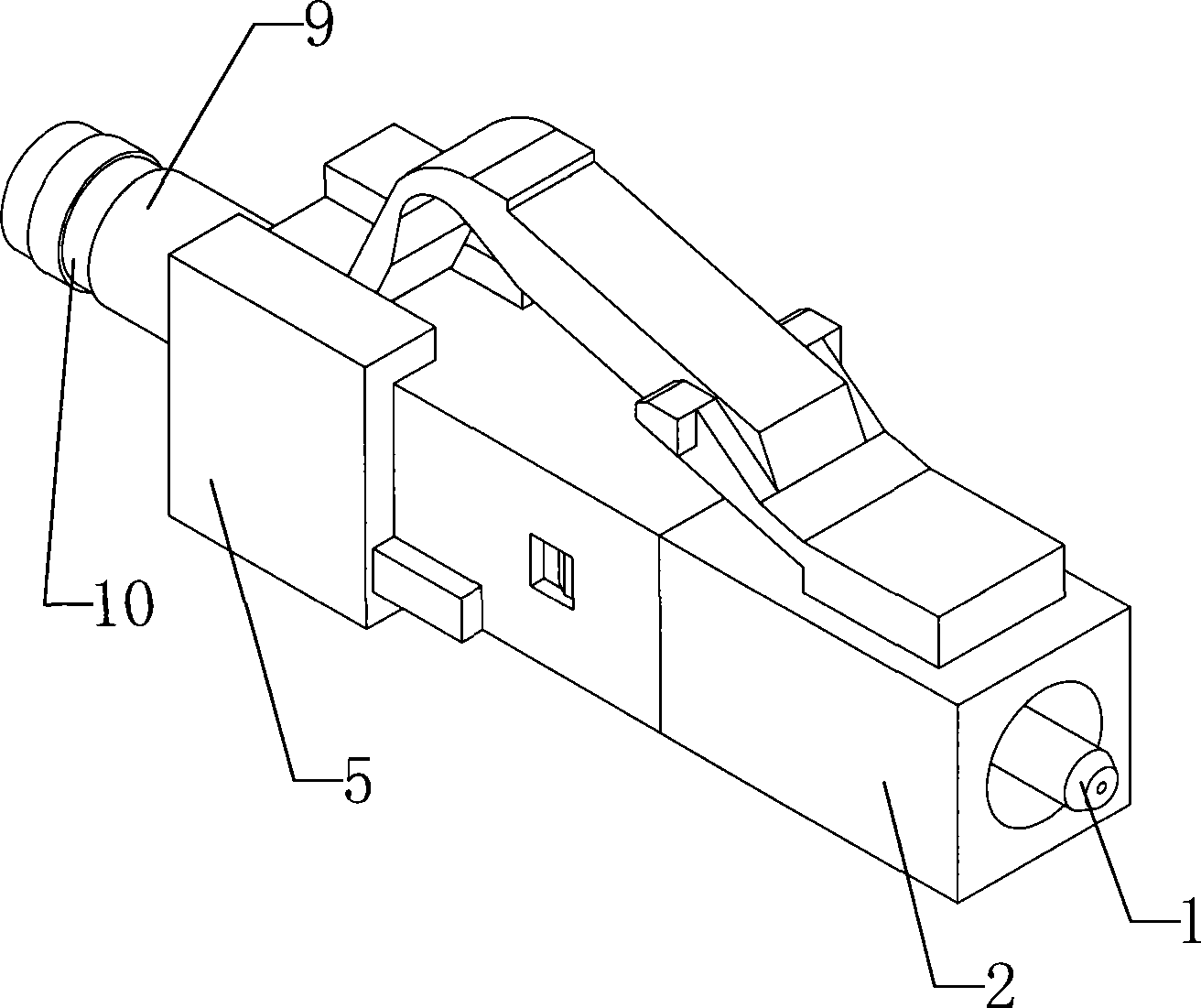

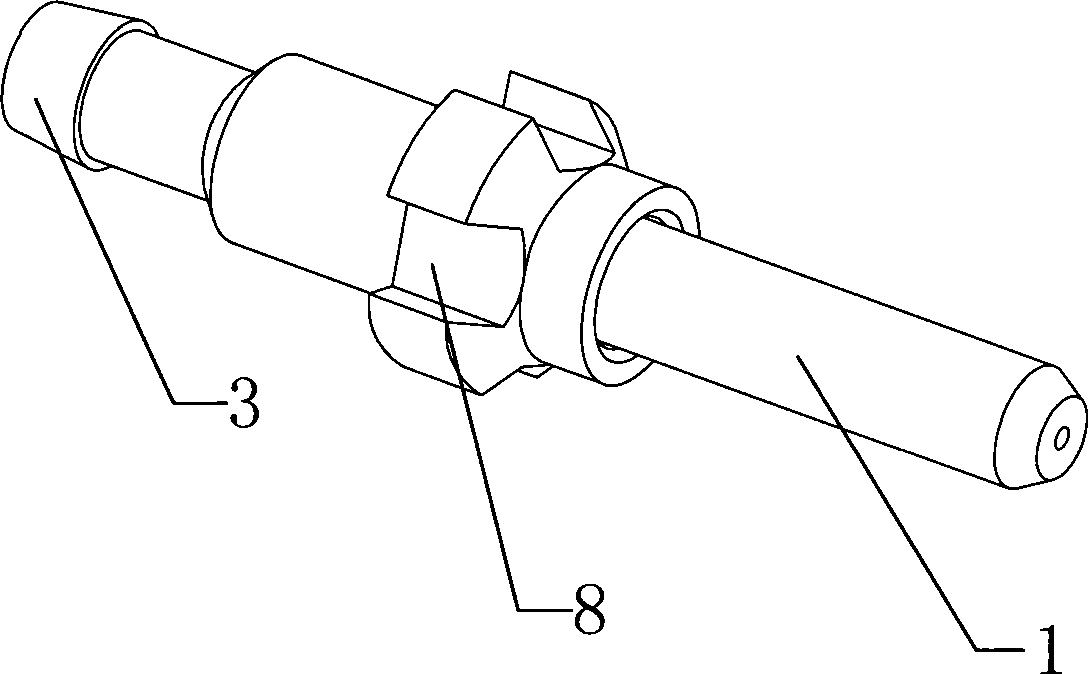

Optical fiber connector

InactiveCN101446672AGood mechanical propertiesHigh strengthCoupling light guidesOptical fiber connectorEngineering

The invention relates to an optical fiber connector comprising a casing and a contact pin component spliced in the casing; the contact pin component includes a flange which is matched with a positioning interface arranged inside the casing; the positioning interface in the casing is a ring surface; swirl reducing grooves are uniformly formed on the periphery of the flange; swirl reducing bonds extending from the ring surface to the rear end of the casing in the axial direction of the flange are arranged in the casing; the number of the swirl reducing bonds is less than that of the swirl reducing grooves; the peripheral angle formed by each two adjacent swirl reducing bonds is an integral multiple of the peripheral angle formed by each two adjacent swirl reducing grooves; and the swirl reducing bonds are matched with the swirl reducing grooves. The optical fiber connector which adopts the technical scheme is characterized in that the swirl reducing bonds are arranged corresponding to the positions of the swirl reducing grooves formed on the flange in the casing, and serve as a strengthening rib in the casing, thereby intensifying the strength of the casing.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

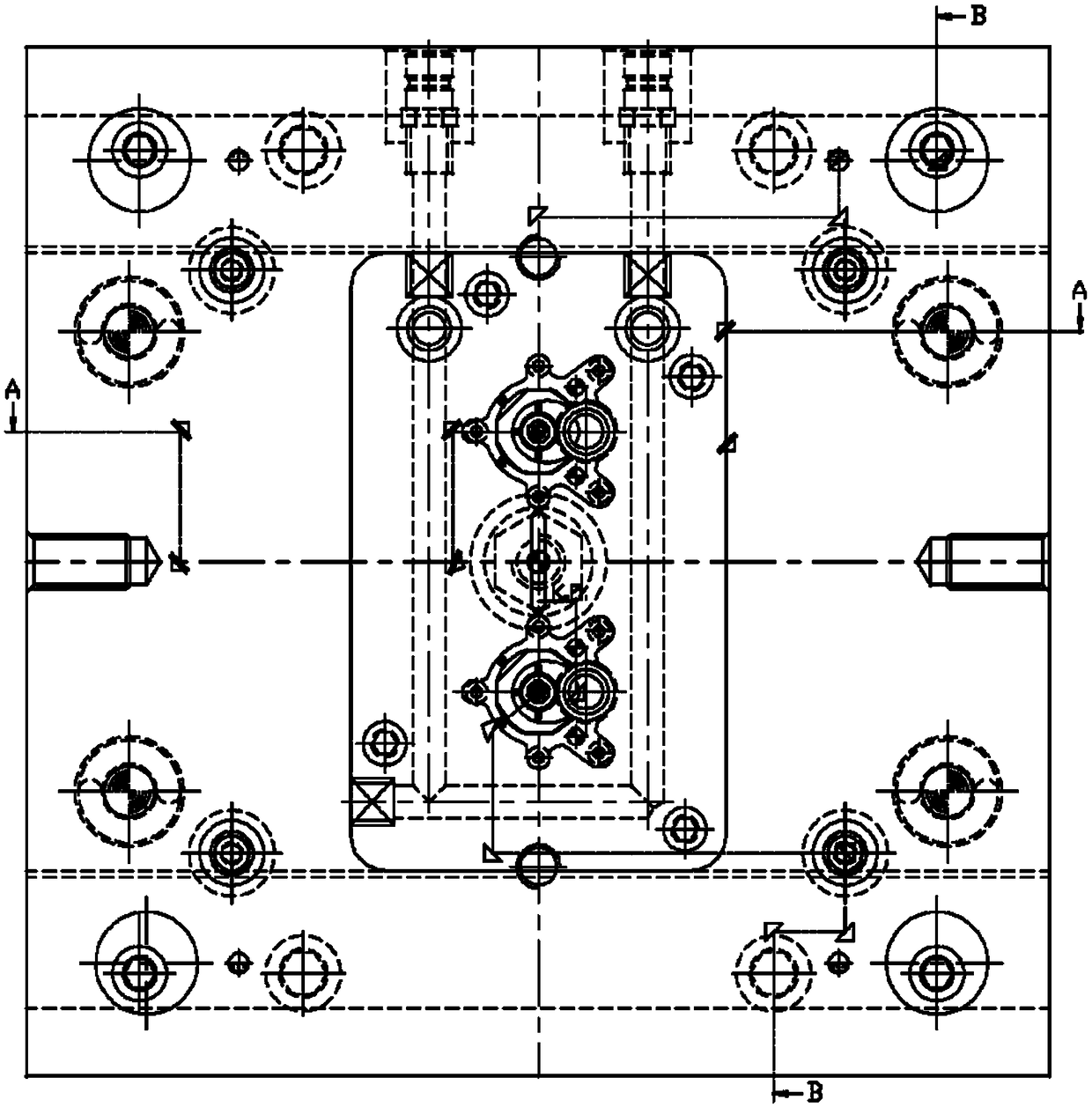

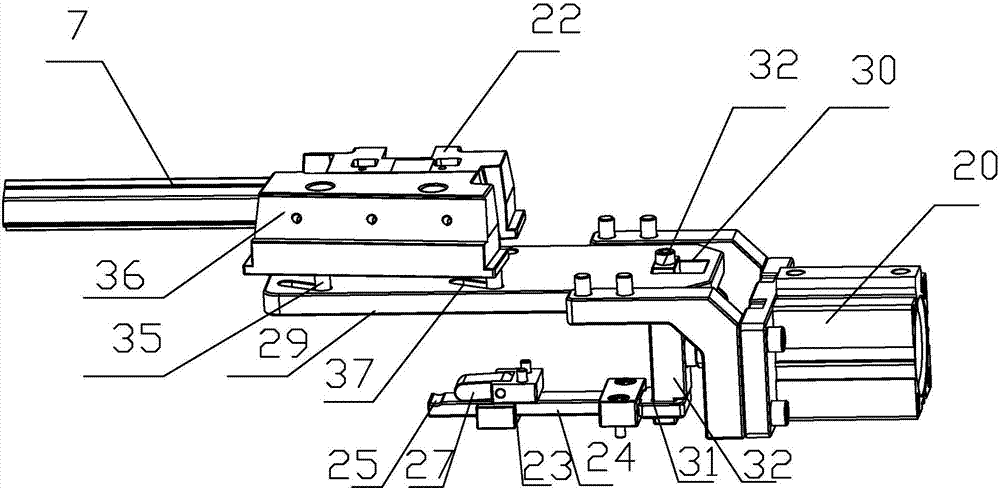

Injection mold for embedding of automobile sealing strip insert

PendingCN107160630AImprove securityNo personal injuryDomestic articlesComposite materialSafety coefficient

The invention discloses an injection mold for embedding of an automobile sealing strip insert. The injection mold comprises an upper mold plate (1), a lower mold plate (2), an ejection plate (3), a base plate (4) and a sealing strip (7). The ejection plate (3) is located on the base plate (4). The lower mold plate (2) is located between the upper mold plate (1) and the ejection plate (3). An upper mold plate (5) is arranged below the upper mold plate (1). A lower mold plate (6) is arranged above the lower mold plate (2). The lower mold plate (2) is provided with an oblique slide block (8) used for forming the rubber coating part of the front end face of the sealing strip (7), a slide block (22) used for forming the rubber coating part of the inner side face of the sealing strip (7) and a mobile slide block (36) positioning the outer side face of the front end of the sealing strip (7). The upper mold plate (1) is provided with an oblique guide column (33) slidably matched with the oblique slide block (8). By adoption of the injection mold for embedding of the automobile sealing strip insert, personal injury cannot be caused, so that the safety coefficient is high.

Owner:NINGHAI HESHI PLASTIC CO LTD

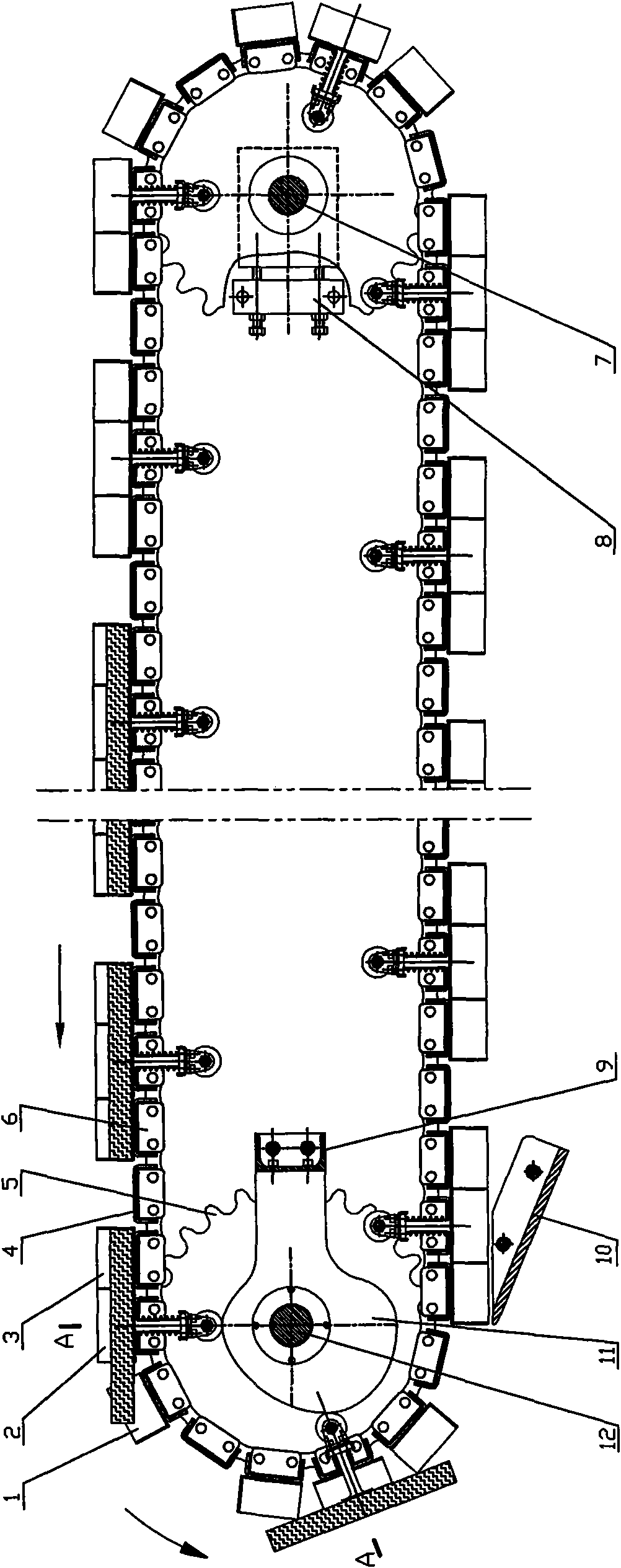

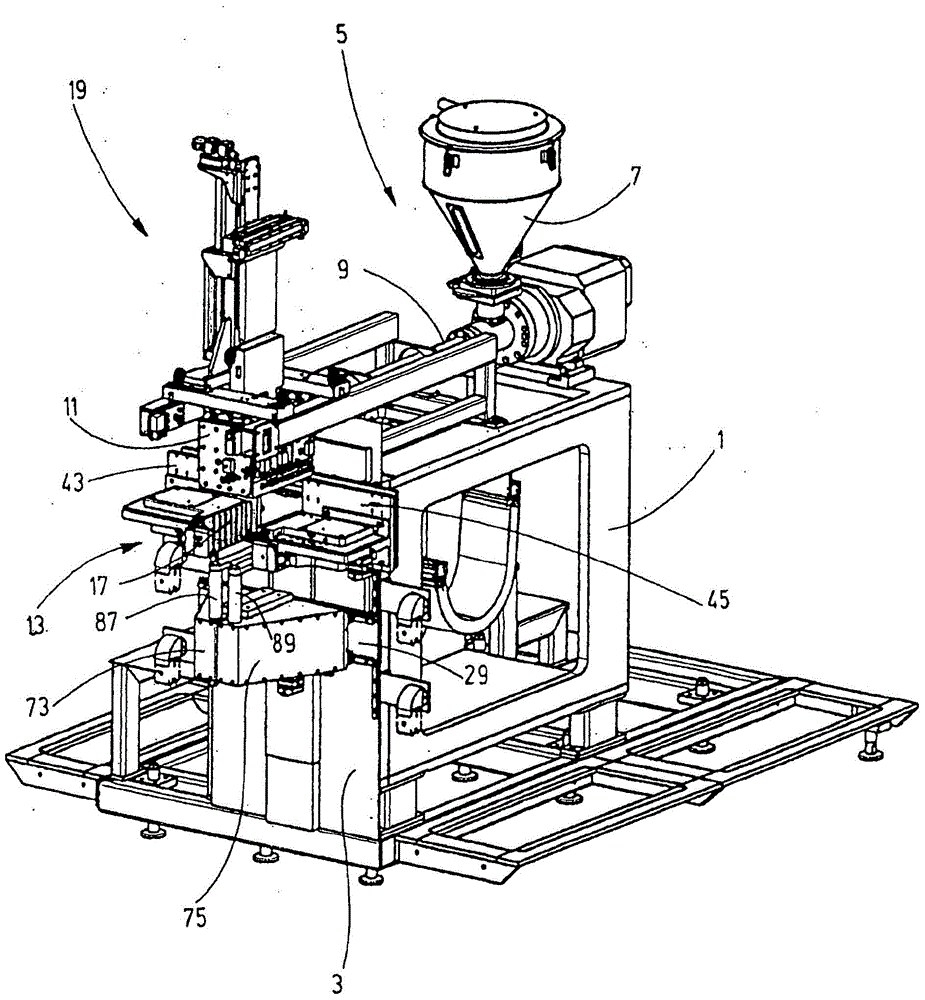

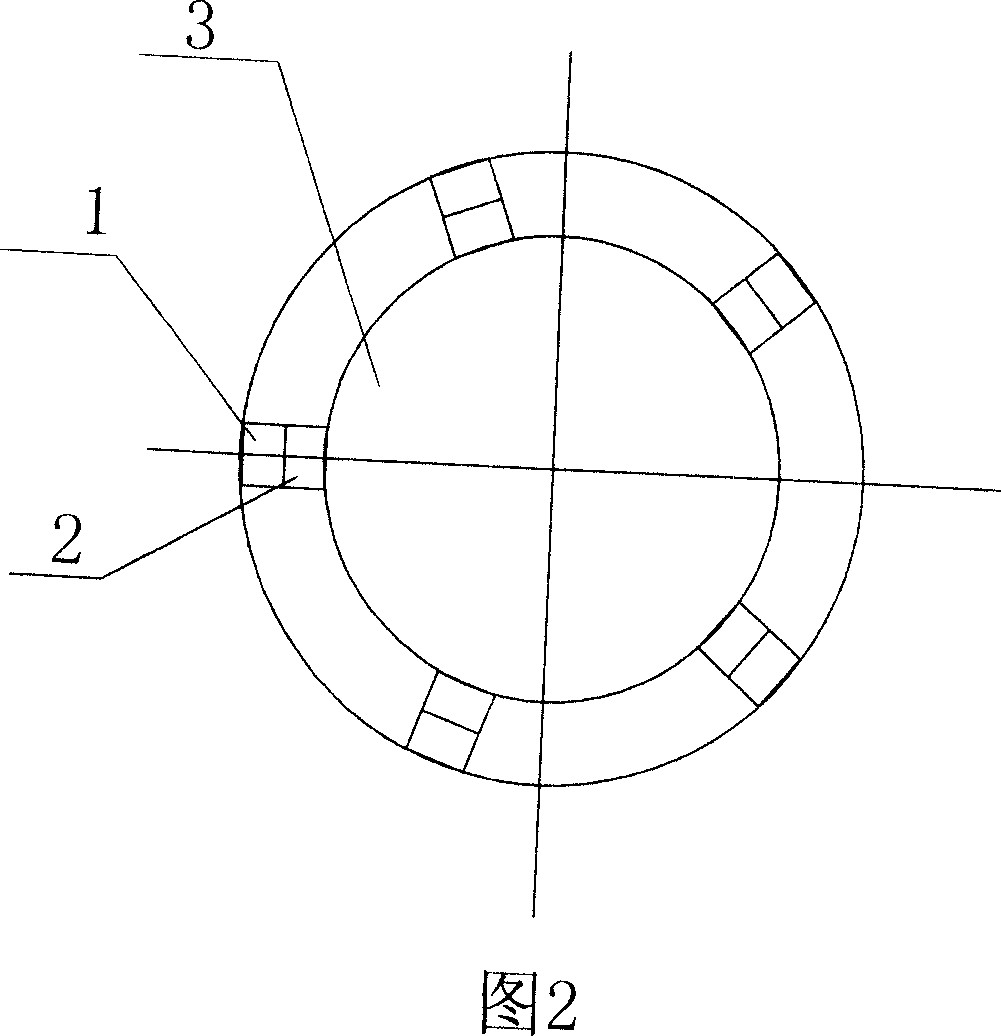

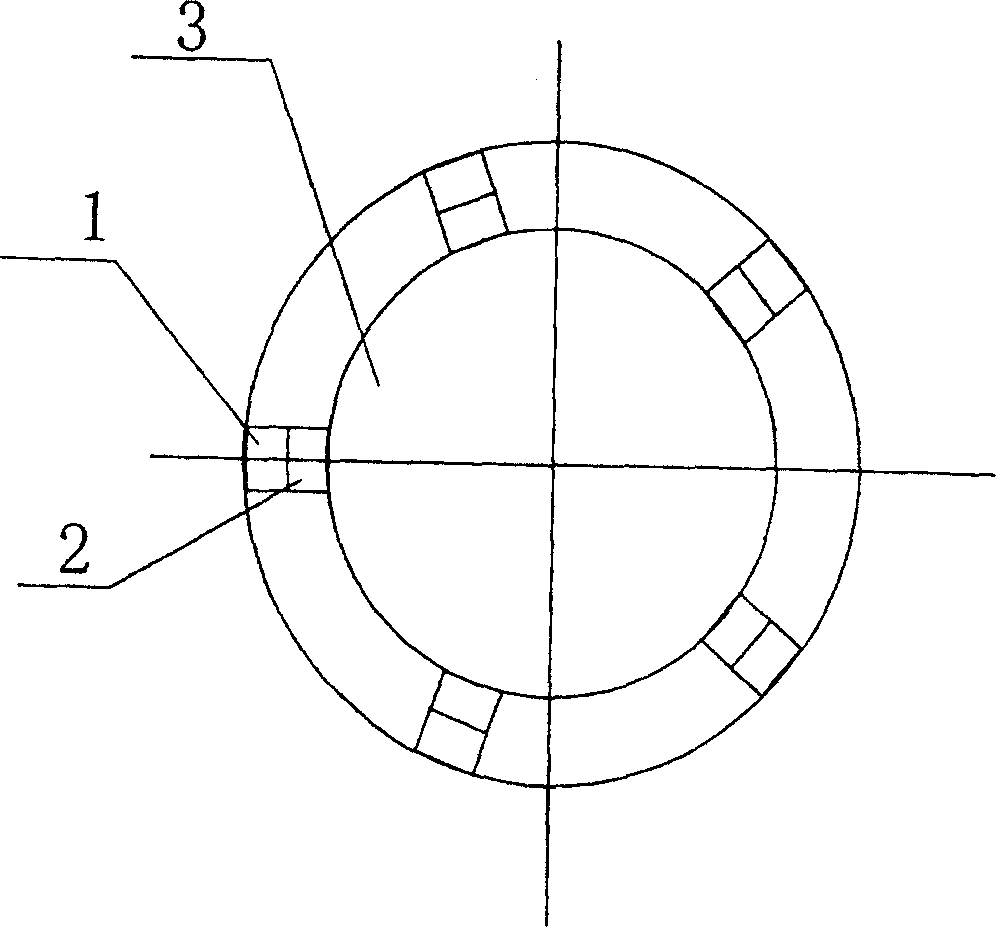

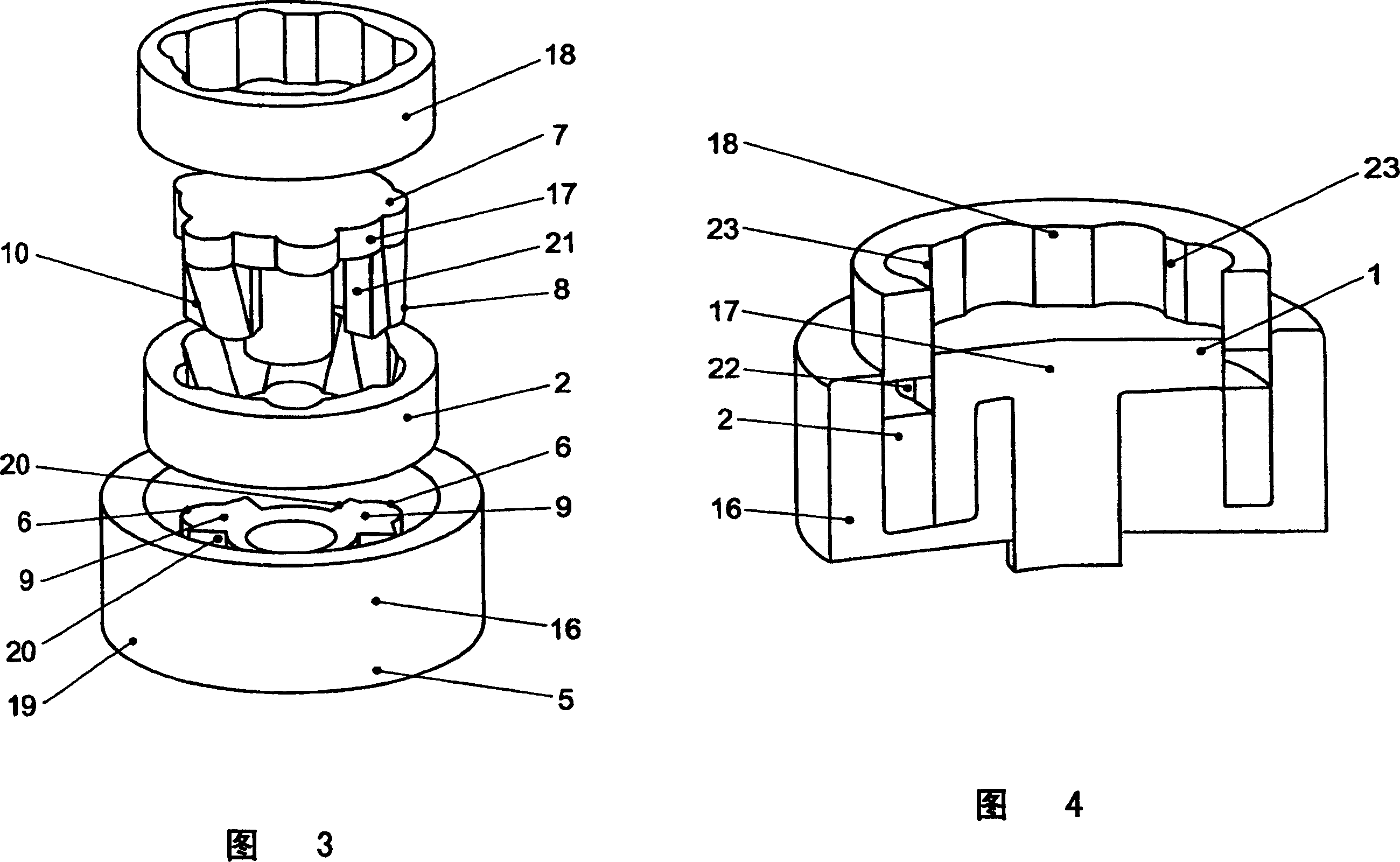

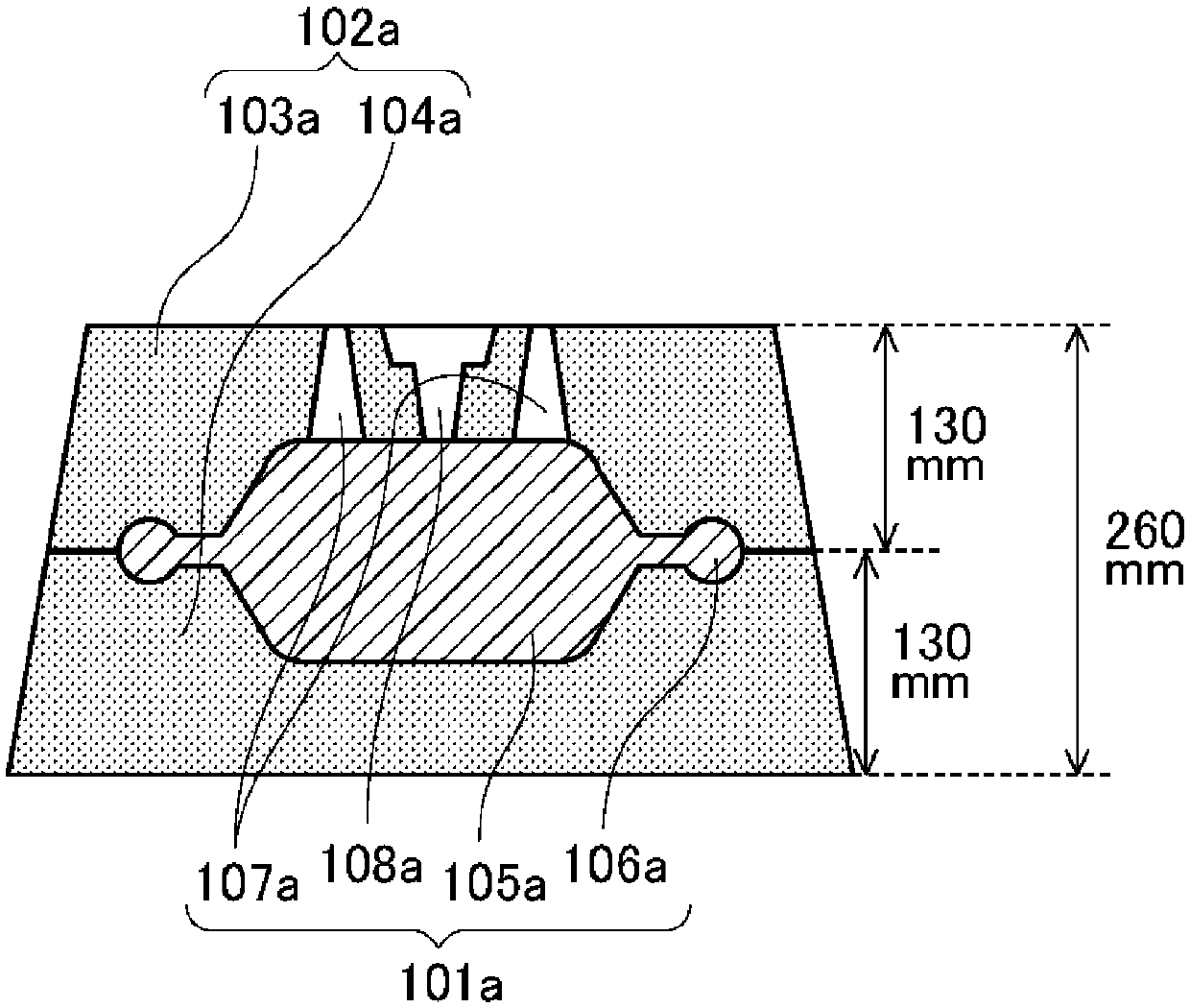

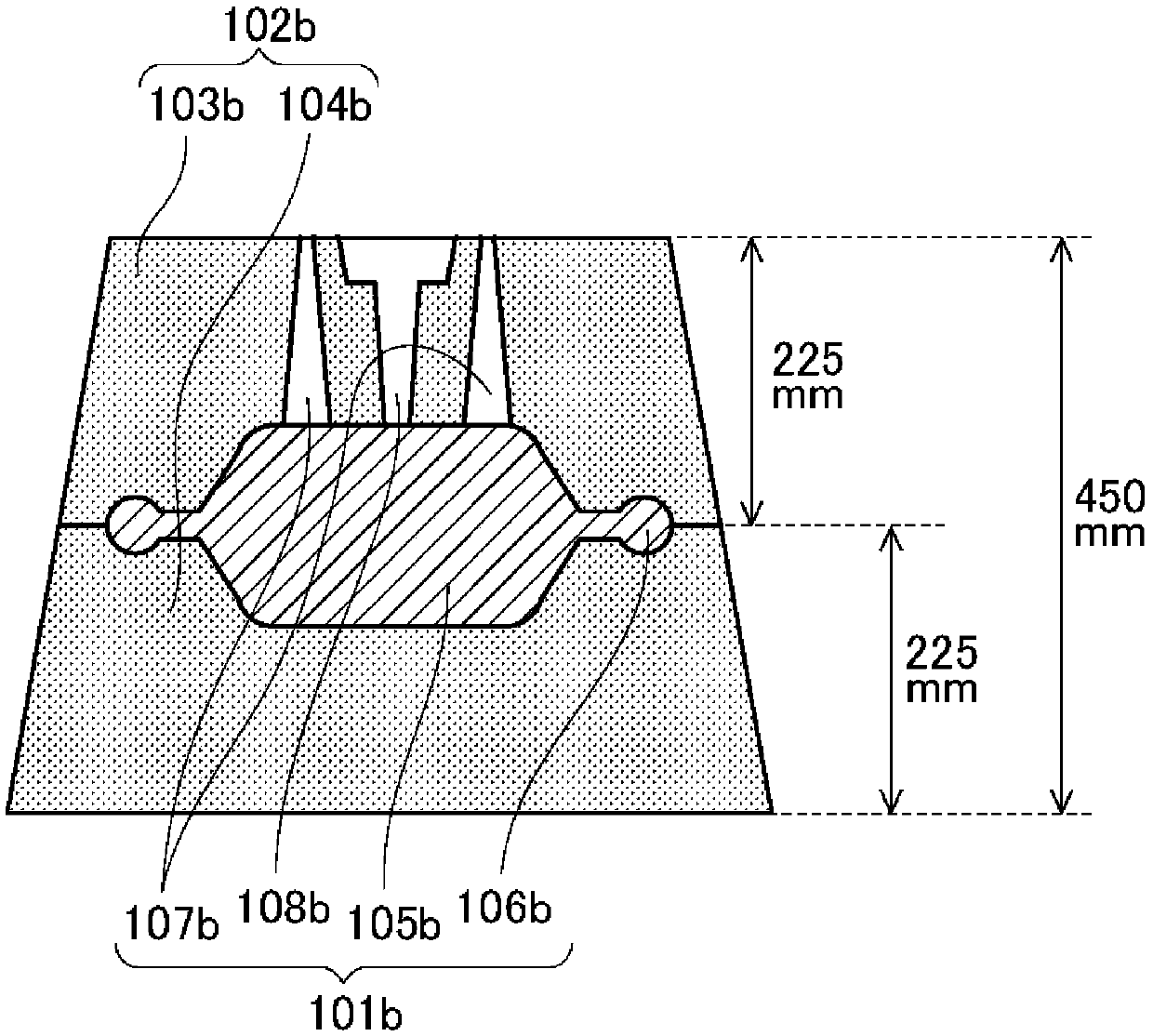

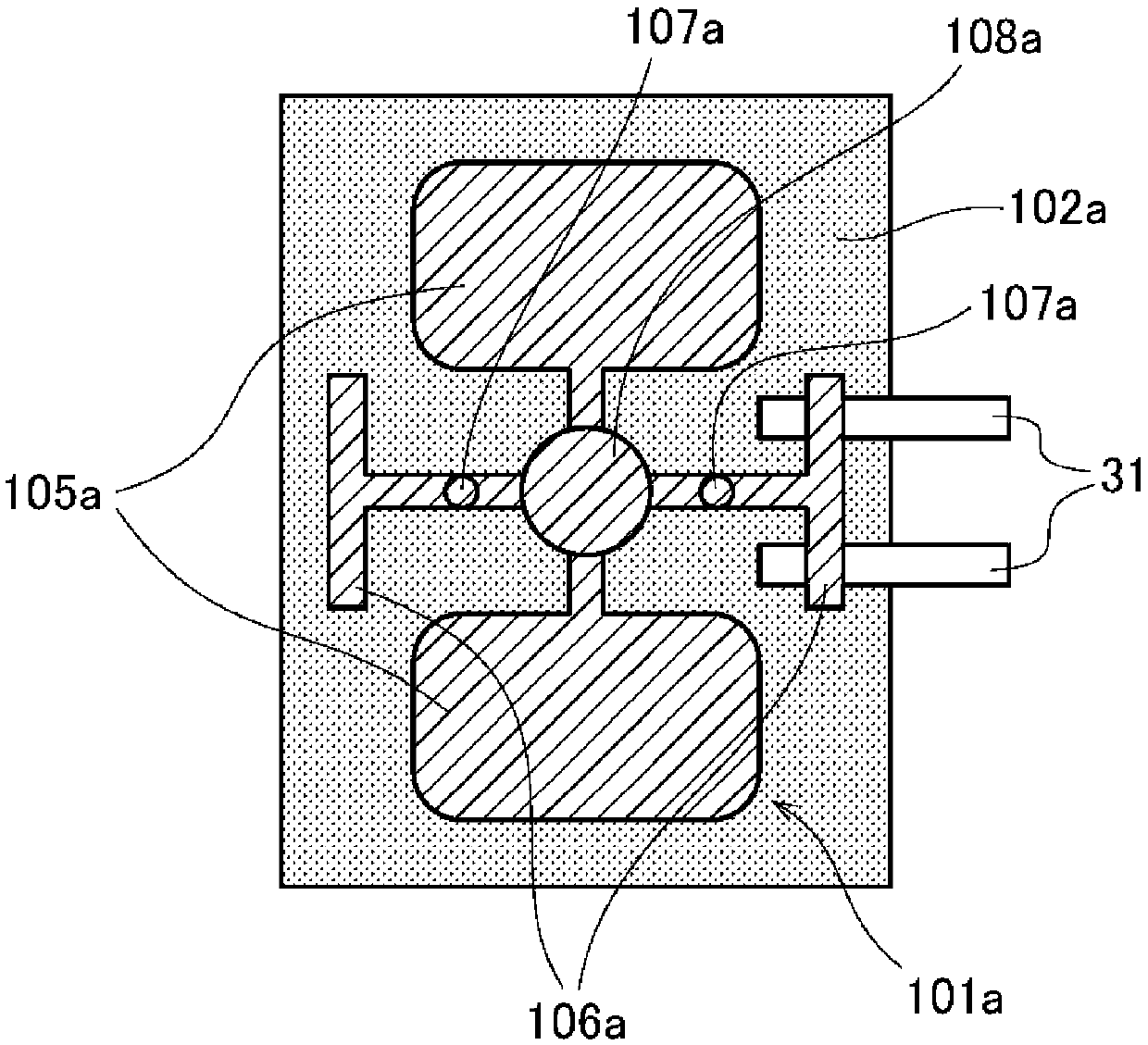

Apparatus and method for making spiral rollaway nest by pressure manufacturing or shaping

InactiveCN1550271AHigh raceway accuracySimple structureYielding couplingForging/hammering/pressing machinesMetal formingEngineering

Device for producing by metal forming or primary shaping spiral running tracks on inner and outer parts of homocinetic joints in VL style with crossed running tracks comprises a contour tool (1) with a negative contour of the running tracks and consisting of a first tool part (5) with negative contours (6) for right-hand running tracks and a second tool part (7) with negative contours (8) for left-hand running tracks, which slide together to form the contour tool. To eject a manufactured homocinetic joint inner part or outer part, the two tool parts are axially pulled apart without rotation, at the same time releasing the homocinetic joint inner part or outer part into a rotating motion. - An INDEPENDENT CLAIM is also included for the production by metal forming or primary shaping of spiral running tracks on inner and outer parts of homocinetic joints in VL style with crossed running tracks.

Owner:VOLKSWAGEN AG

Bottle perform mold structure provided with bottle opening groove

The invention discloses a bottle perform mold structure provided with a bottle opening groove. A mold core mode-locking ring of the bottle perform mold structure is a hollow cone-column structure, the inside of the hollow cone-column structure is cylindrical, one peripheral end is a cone structure, one end is a cylindrical structure, a through hole is arranged on a wall at the combing position of the cone structure and the cylindrical structure, an annular groove is processed on the inner side cylindrical face at the end portion of the cylindrical structure of the mold core mode-locking ring, and an air vent groove is formed at the step transition position of the annular groove and the mold core outer cylindrical face. A mold lip consists of two split oppositely-opening pieces, and one piece is provided with the air vent groove on the contact face of the two pieces. The air vent groove is divided into two branches, one branch is parallel to the axial direction of the mold lip, one end of the one branch is led to the contact end face of the mold core mode-locking ring and the mold lip, and a distance from the contact end face to the mold lip is 0.025-1mm. The bottle perform mold structure achieves multiple-channel air venting and is high in air venting speed. A bonding line is close to a bottle opening. The required opening distance of the mold lip is short in demolding, and demolding and perform fetching are reliable.

Owner:GUANG DONG XING LIAN PRECISE MACHINERY

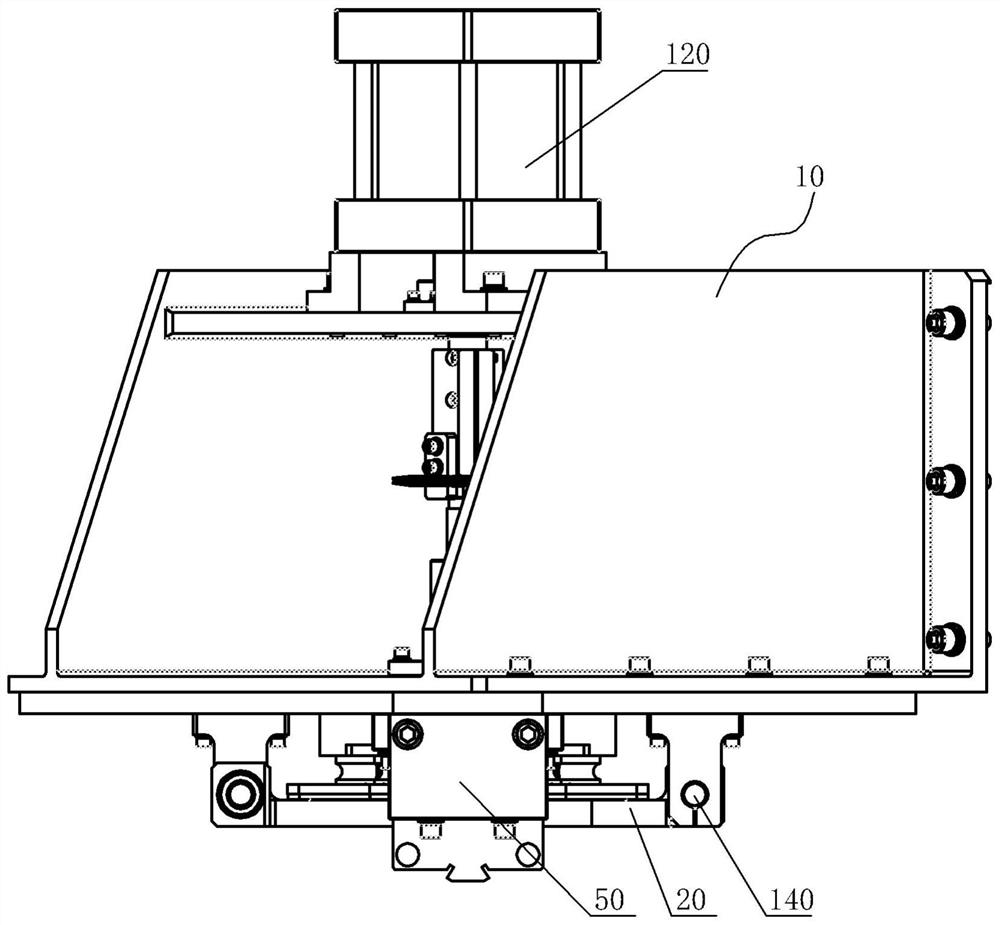

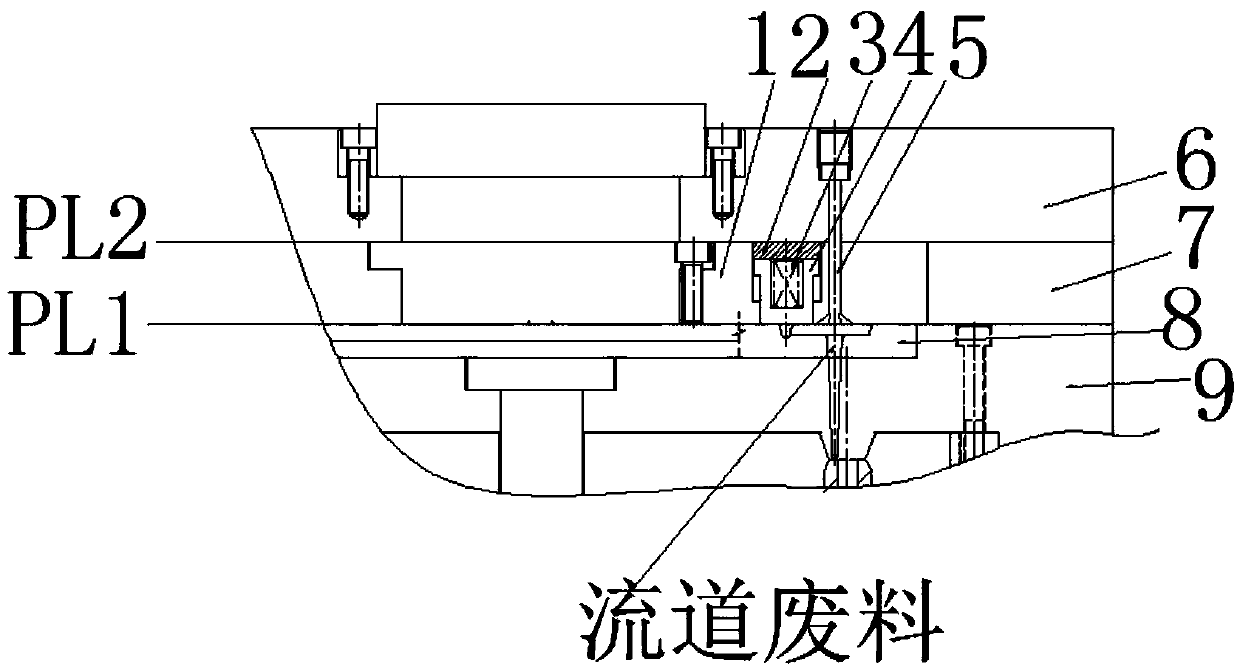

Front mould automatic shooting material mechanism of injection mold of three plates mold and using method thereof

InactiveCN108099101AGuaranteed automated production functionsRealize automatic sheddingPlastic wasteWaste material

The invention discloses a front mould automatic shooting material mechanism of an injection mold of a three plates mold. The front mould automatic shooting material mechanism of the injection mold ofthe three plates mold is used to solve the problem of incompletely shedding of a runner waste material in demolding on the three plates. The problem that various plastic waste materials adhere on a runner plate is aimed to be carried out to reliably demould by the front mould automatic shooting material mechanism. The situations that various plastic automatically dropped off the runner plate and is not adhered to the runner plate are realized, and the function of mould automatic production is ensured. The front mould automatic shooting material mechanism is reasonable in design, compact in structure, stable in work, safe, reliable, and convenient to use.

Owner:李睿

Automatic demolding device of frozen noodles production line

The invention provides an automatic demolding device of frozen noodles production line, belonging to the field of food processing machinery, wherein the demolding device consists of a split noodle die box, a chain-plate conveying mechanism, a cam mechanism, a prying plate and a rack; the split noodle die box consists of a front die box, a middle die box and a rear die box; the chain-plate conveying mechanism comprises chain wheels, chains with accessories, a driving shaft, a driven shaft, a chain plate, a tensioning device and the like; the tensioning device is connected with the driven shaft; two chains with accessories are connected with each other via the chain plate; the cam mechanism comprises a cam, a cam roller, a slot beam, a guide column, a top rod, a top rod seat, a guide sleeve and the like; the big end section of the cam is mounted on the driving shaft via a bearing; the other end is fixed on the slot beam; one end of the guide column is fixed with the chain plate; the other end of the guide column is in sliding match with the guide sleeve; and the prying plate is of a wedge-shaped structure, and is fixed with the rack. The demolding device can fast and reliable demold the whole row of frozen noodles; and the demolding device has the characteristics of compact structure, low cost and the like.

Owner:ZHENGZHOU UNIV

A kind of inner gear calibrating balance press

Owner:JIANGXI HONGDU AVIATION IND GRP

Cast iron mold with rapid demoulding function

PendingCN109277531AReduce labor intensityNot easy to damageFoundry mouldsFoundry coresCasting moldCast iron

The invention discloses a cast iron mold with a rapid demoulding function. The cast iron mold solves the problems that manual knocking demoulding is prone to causing damage of the cast iron mold and the labor intensity of workers is high. The cast iron mold comprises a base mold and a casting mold, wherein the casting mold is movably arranged in a mold cavity of the base mold through a mold opening of the base mold. The casting mold comprises a bottom plate, two side mold plates and two end mold plates, the end mold plates are symmetrically and fixedly connected to both ends of the bottom plate, and the lower ends of the side mold plates are symmetrically connected to both sides of the bottom plate by rotating shafts in a pivoted mode. Sealing grooves are formed in the end faces of the twoends of the end mold plates, sealing barrier strips are arranged on the inner side surfaces of the two ends of the side mold plates, and the barrier strips are detachably connected into the sealing grooves. Pulling cables are arranged between the upper end surfaces of the two sides of the base mold and the outer side surfaces of the upper ends of the side mold plates; and an ejector device for ejecting the casting mold is arranged at the bottom of the base mold. The pulling cables pull the side mold plates of the casting mold to be separated from the end mold plates, and iron blocks and the casting mold are directly separated without manual knocking. The demoulding speed is high, the casting mold is not prone to being damaged, and the labor intensity of the workers is low.

Owner:荣成富邦金属科技有限公司

Laterally formed oil cylinder slider mechanism

The invention discloses a laterally formed oil cylinder slider mechanism. The laterally formed oil cylinder slider mechanism comprises a pull rod and a slider casting insert, a slider connection guideblock is arranged at one end of the slider casting insert, the sliderconnection guide block is connected with a slider base, and the slider casting insert, the slider connection guide block, and theslider base are integrally connected through a screw; the slider base is mounted on a sliding track of a public template, and a spring dial bead is arranged on the public template; and the pull rod isconnected with the slider base in the sliding direction of the slider casting insert, the other end of the pull rod is connected with an oil cylinder, and the pull rod is provided with a positioninggroove matched with the spring dial bead. The laterally formed oil cylinder slider mechanism drives the slider casting insert to move in a balanced mode to avoid the buckle groove structure of a product through extraction power of the oil cylinder, the structure is simple, demolding is stable and reliable, manufacturing is easy, and the mold manufacturing cost can be reduced greatly.

Owner:PERLMAN ELECTRICAL KUSN

Blowing-free demolding machine for colloidal gloves

The invention relates to a blowing-free demolding machine for rubber gloves, which is structurally characterized in that synchronous chains are arranged on a machine body, a plurality of walking racks are bridged on the two groups of synchronous chains, a set of demolding manipulator is arranged on each walking rack, and the demolding manipulators reciprocate on the walking racks. The demolding manipulator is composed of a bottom plate, a glove wrist clamping and expanding mechanism, a manipulator pushing mechanism, a wrist opening flanging clamping mechanism, a sliding block push-pull mechanism and the like, wherein the glove wrist clamping and expanding mechanism, the manipulator pushing mechanism, the wrist opening flanging clamping mechanism and the sliding block push-pull mechanism are arranged on the bottom plate. Two guide rails are arranged on the machine body, and one guide rail is used for controlling the demolding manipulator to move back and forth on the walking rack; and the other one is used for controlling the glove demoulding action of the demoulding manipulator. According to the demolding machine, gloves on a production line are demolded in a pure mechanical mode, an air blowing process is omitted, energy consumption and production cost are reduced, high-decibel noise pollution is avoided, and the demolding machine is beneficial to the environment and the body health of production workers.

Owner:石家庄启腾机械制造有限公司

Mat sealing joint, electrical connector, and method of manufacture

ActiveCN102640364BLow costSuitable for demouldingCouplings bases/casesElectrical connectorBiomedical engineering

Owner:APTIV TECH LTD

Intelligent pneumatic flanging mechanism

InactiveCN114160638AAchieve flanging effectReliable productionShaping toolsStructural engineeringExplorator

The invention provides an intelligent pneumatic flanging mechanism which enables flanging manufacturing to be rapid and reliable, is stable and reliable in demolding and ensures normal production and manufacturing. The flanging frame comprises an upper plate, a lower plate and two side vertical plates, the upper plate is connected with the lower plate through the two side vertical plates, and cavities are formed in the two side vertical plates; two flanging explorators are arranged; flanging the inner die; a guide block; the lower surfaces of the two sides of one diagonal line of the lower plate are fixedly provided with profile modeling air cylinders respectively, the piston ends of the two profile modeling air cylinders are oppositely arranged, each piston end is fixedly connected with a flanging profile modeling on the corresponding side, and the upper surfaces of the inner ends of the two flanging profile modeling are arranged in a manner of copying the flanging shape of a product; the center position of the lower plate is connected with a guide block through a connecting seat and a connecting column; the periphery of the guide block is arranged in a shape of an opening in the upper surface of a product; a plurality of flanging inner dies are arranged in the space between the connecting base and the guide block, and an avoiding notch is formed in the position, corresponding to the connecting column, of each flanging inner die.

Owner:SUZHOU HYCAN HLDG CO LTD

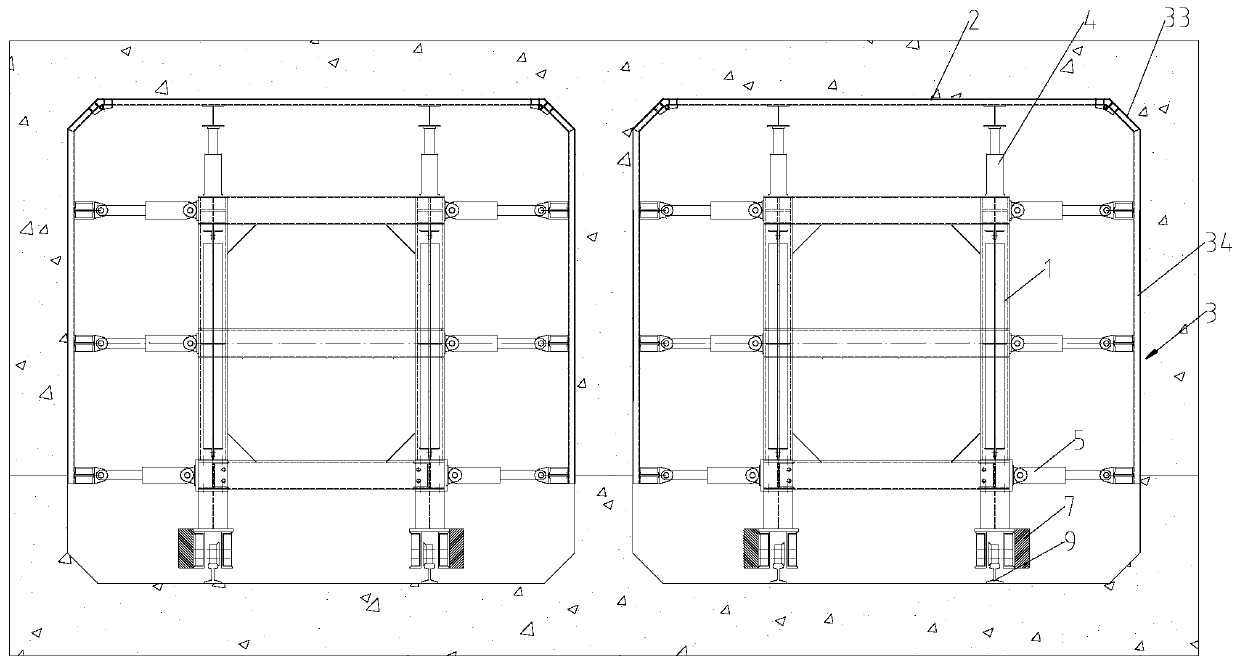

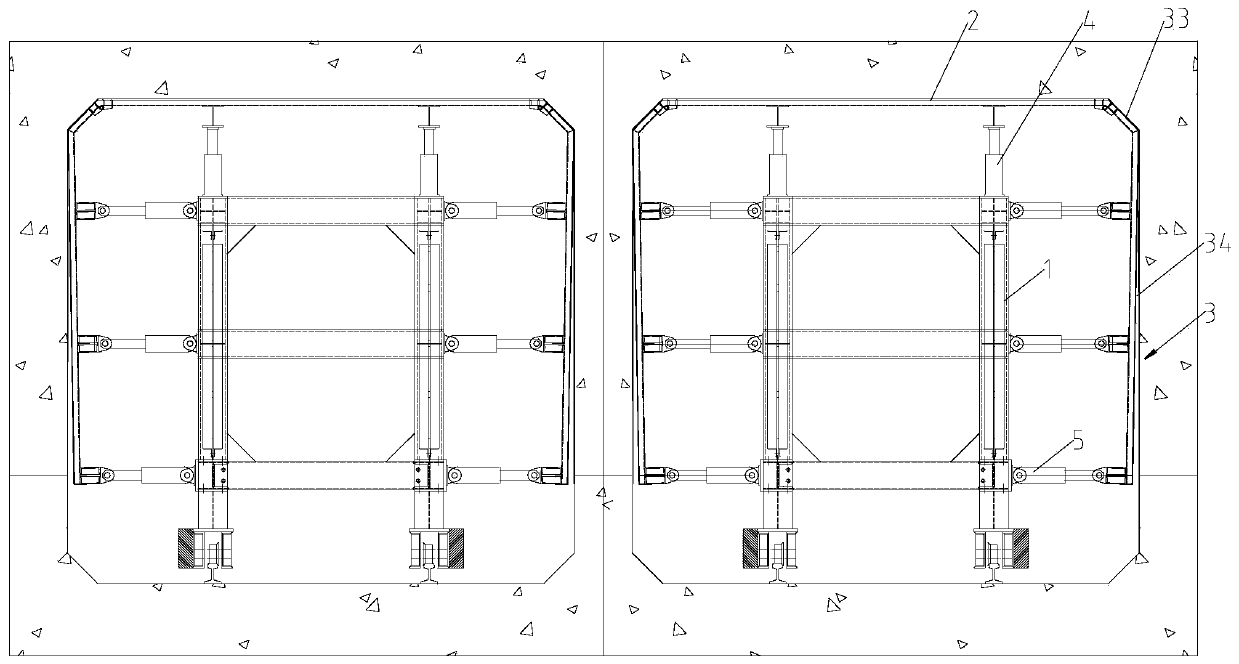

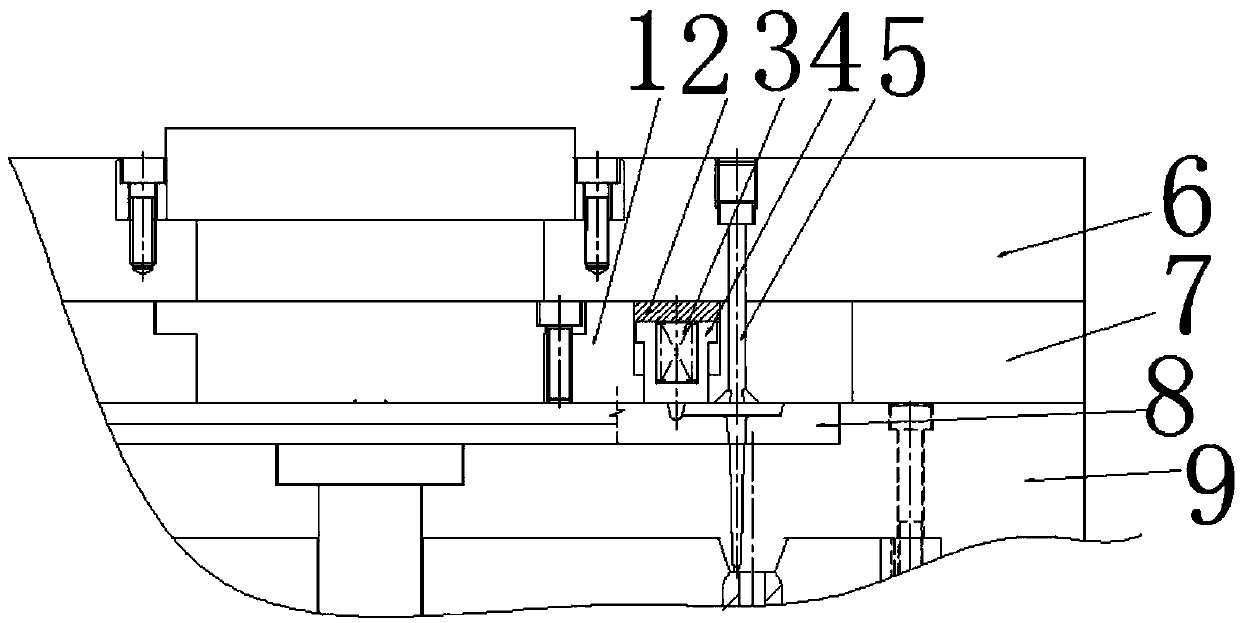

Construction method of pipe gallery construction using formwork trolley

ActiveCN108661670BLight weightImprove mobilityUnderground chambersTunnel liningArchitectural engineeringPipe

The invention discloses a construction method for pipe gallery construction through a formwork trolley, and belongs to the field of pipe gallery construction. The construction method aims to improve the forming quality of concrete and improve the construction efficiency. The construction method comprises the following sequentially-conducted steps that 1, a horizontal hydraulic jack is retracted, so that a lateral formwork rotates slightly with the hinged position of the lateral formwork and a top formwork as the axis so as to be disengaged from a concrete pouring layer; and 2, the top formworkis lowered, so that the top formwork is disengaged from the concrete pouring layer until the formwork trolley for pipe gallery construction can travel freely. According to the construction method, firstly, the top formwork and the lateral formwork are hinged into a whole, so that the integrality and the strength and rigidity properties of the formwork trolley are improved, formwork expansion is avoided, and splicing seams are less; secondly, the self weight of the trolley is low relatively, maneuverability and flexibility are good, so that the efficiency of jack supporting and formwork disengaging is improved, and the moving speed is increased; thirdly, the horizontal hydraulic jack is downsized and miniaturized, materials used by the formworks and a truss are subjected to optimization design, thus waste is avoided, and the manufacturing cost is lowered significantly; and fourthly, through a formwork disengaging mode, stress is safer and more reasonable, and formwork disengaging is quicker and more reliable.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

Injection mold and application method thereof

InactiveCN110103422AGuaranteed automated production functionsRealize automatic sheddingMechanical engineering

Owner:李睿

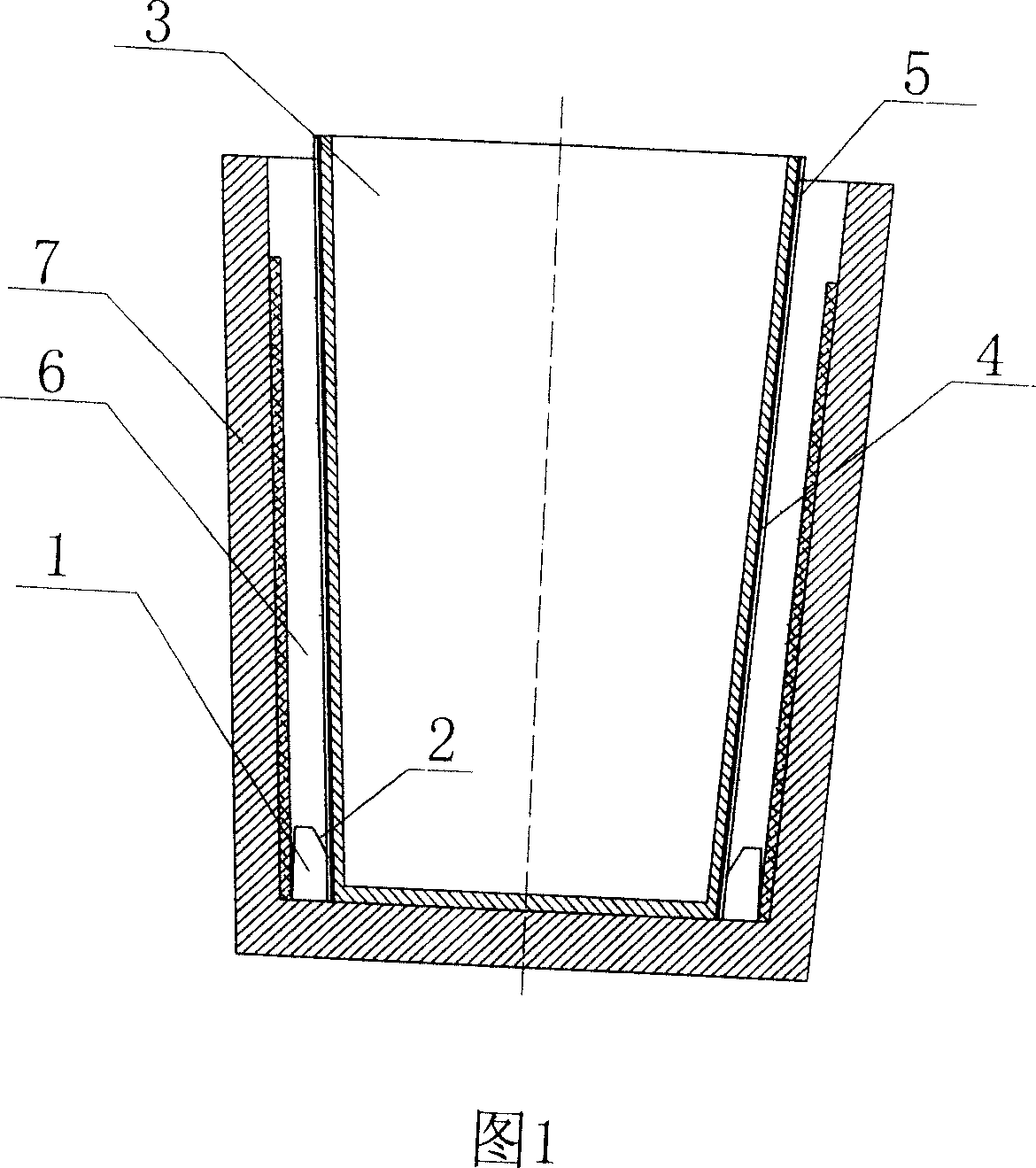

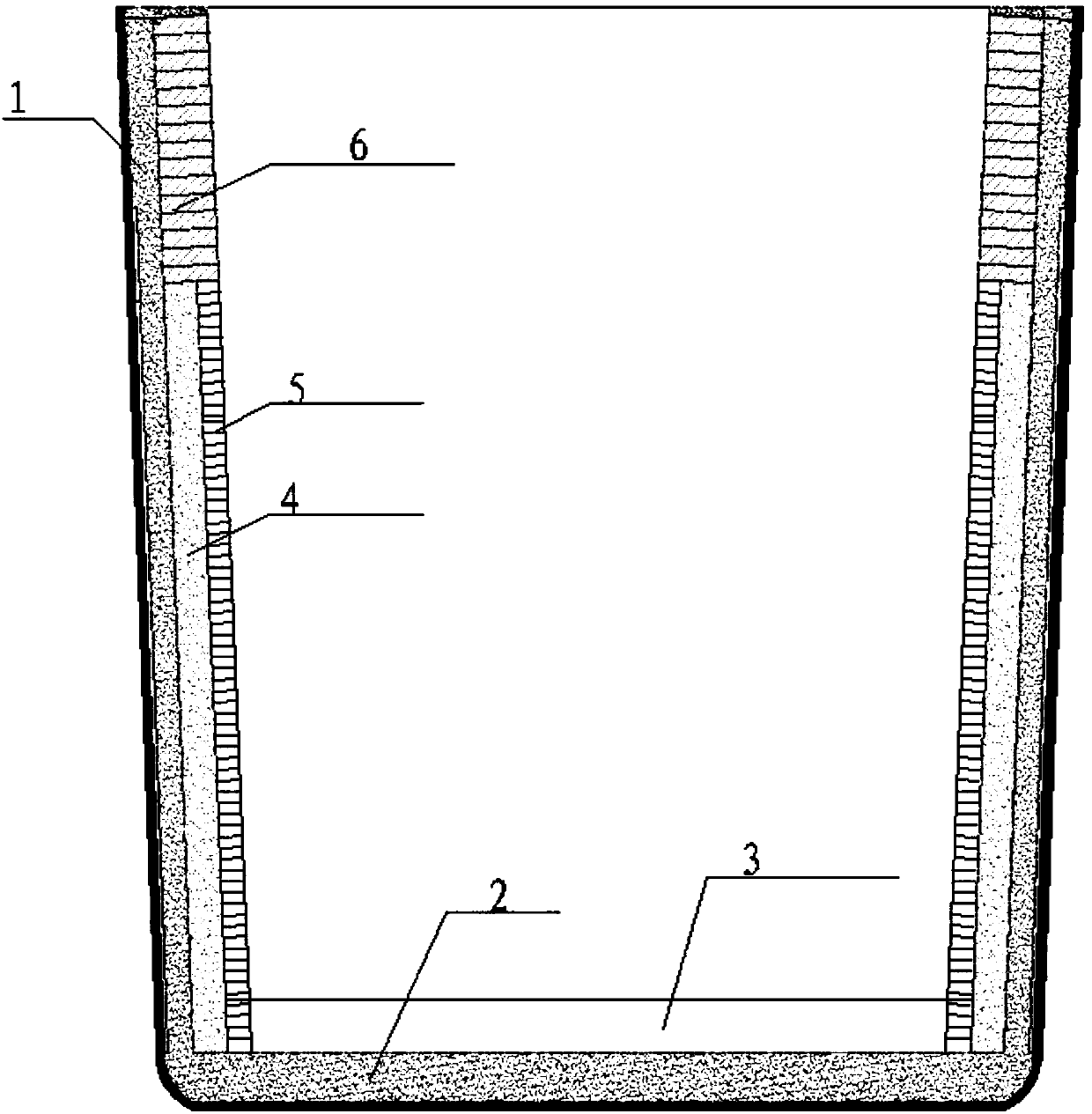

Construction method for ladle integral pouring and casing pouring liner

InactiveCN100389912CPrecise positioningHigh precisionMelt-holding vesselsWedge angleMaterials science

The invention discloses a constructing method of entire ladle casting and lining, which comprises the following steps: locating mould, assembling at least three locating blocks on the bottom of ladle, distributing the blocks on the periphery of ladle bottom, setting wedge angle in the locating block to make diameter of encircle of each locating block bottom more than the diameter of excircle on the mould bottom, adopting the same material for each locating block and ladle lining.

Owner:崔东瑞

Apparatus and method for making spiral rollaway nest by pressure manufacturing or shaping

InactiveCN100358649CSimple structureNot easy to failYielding couplingForging/hammering/pressing machinesMetal formingEngineering

Device for producing by metal forming or primary shaping spiral running tracks on inner and outer parts of homocinetic joints in VL style with crossed running tracks comprises a contour tool (1) with a negative contour of the running tracks and consisting of a first tool part (5) with negative contours (6) for right-hand running tracks and a second tool part (7) with negative contours (8) for left-hand running tracks, which slide together to form the contour tool. To eject a manufactured homocinetic joint inner part or outer part, the two tool parts are axially pulled apart without rotation, at the same time releasing the homocinetic joint inner part or outer part into a rotating motion. - An INDEPENDENT CLAIM is also included for the production by metal forming or primary shaping of spiral running tracks on inner and outer parts of homocinetic joints in VL style with crossed running tracks.

Owner:VOLKSWAGEN AG

A construction method of composite ladle permanent layer

The invention relates to a construction method of a composite steel ladle permanent layer. The construction method comprises the steps of constructing a ladle bottom permanent layer, a ladle wall permanent layer and a safety layer, and laying ladle bottom bricks, a ladle wall work layer and slag line bricks. The composite steel ladle permanent layer can be on line for use normally after laying construction is completed. According to the construction method, the safety layer is laid between the ladle wall permanent layer and the ladle wall work layer, and a safety layer material for building the safety layer is one of a magnesium-aluminum refractory material, an aluminum- spinelle refractory material, an aluminum-magnesium-chrome refractory material, a corundum refractory material and a magnesium-chrome refractory material. The material has high strength, corrosion resistance, thermal shock resistance and excellent linear change, the effective service life of a steel ladle permanent lining is greatly prolonged, potential safety hazards existing in an existing steel ladle work layer material are avoided, and the service life of a steel ladle work layer can be effectively prolonged.

Owner:FANYI HONGQI BURDEN

Method for separating mold and device for separating mold

A method for separating a mold and a device for separating a mold are capable of separating a mold reliably. A casting mold in which a casting having a casting part and a hanger part is formed is separated from the casting. First, based on the position of the hanger part of the casting with reference to the mounting surface of the casting mold, the relative position between the hanger part of thecasting and a hanger hook is adjusted so that the hanger hook can hook the hanger part, and the mounting surface is further rotated by decreasing an angle formed by the mounting surface of the castingmold and the gravity direction, such that while the hanger part of the casting hooks the hanger hook, the casting mode is dropped from the mounting surface.

Owner:SINTOKOGIO LTD

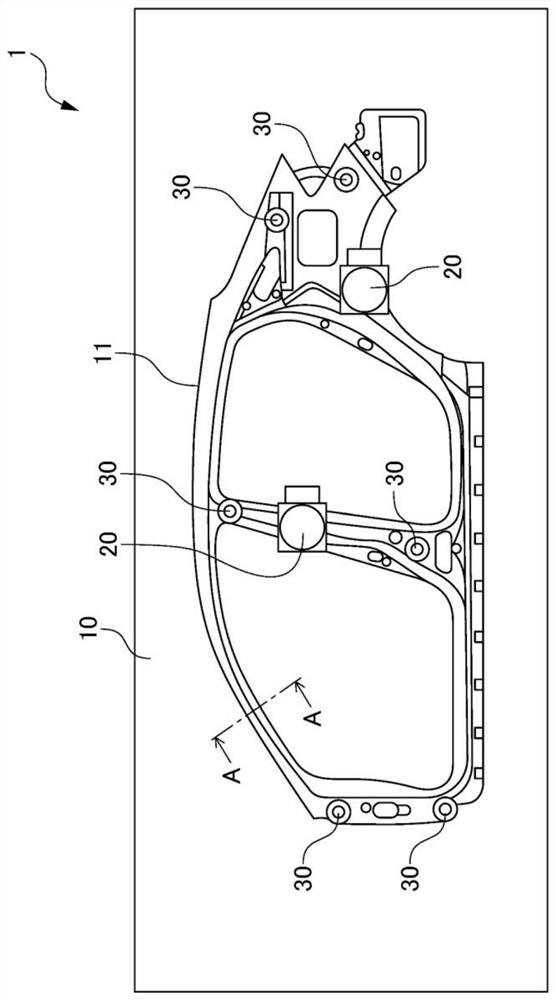

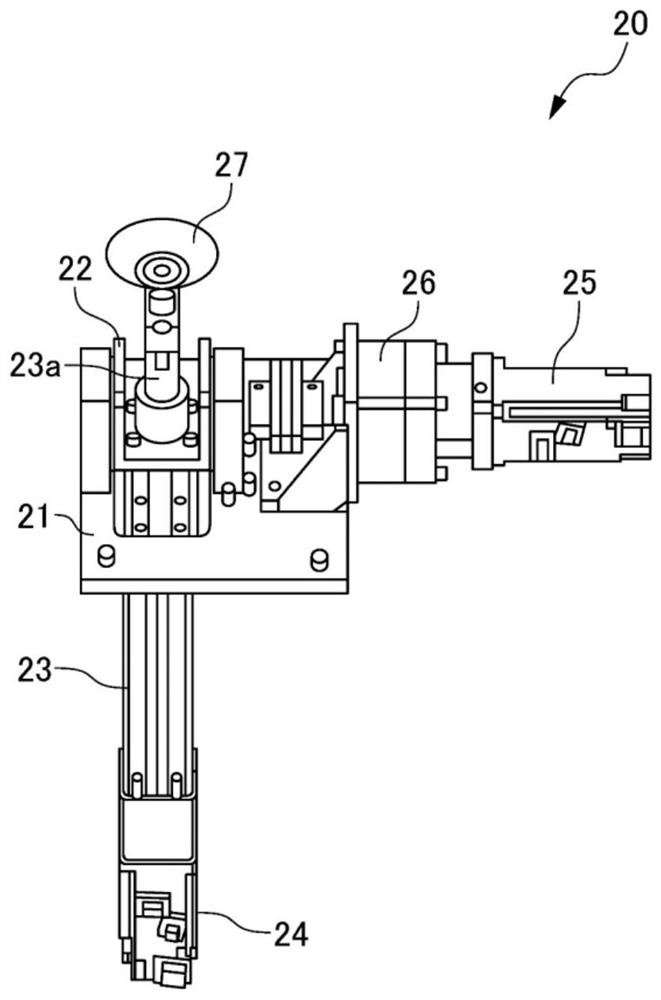

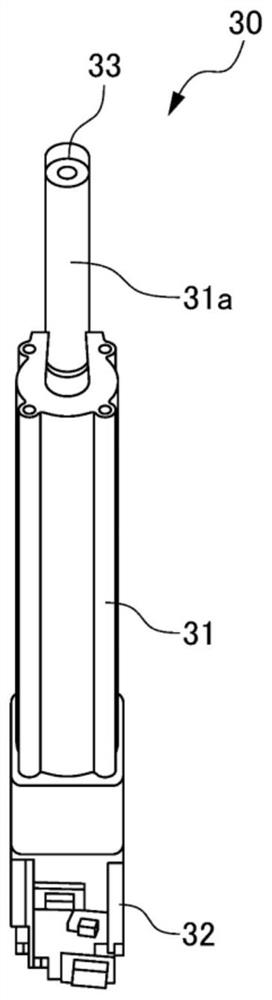

Die device

There is provided a die device capable of reliably releasing a workpiece from a die even when the workpiece has an undercut, and conveying the workpiece to a next process. The die device includes a lower die; and a lifter that lifts a pressed workpiece from the lower die. The lower die has an undercut region which is a portion that interferes with the workpiece when the workpiece is moved along a press direction, and the lifter includes a vacuum cup that comes into contact with the workpiece; a rod part having a distal end provided with the vacuum cup; and a linear drive servomotor for causing the rod part to advance / retreat in an axial direction, and further including a rotary drive servomotor that turns the lifter in a direction orthogonal to the axial direction, wherein the lifter moves the workpiece by combining both movement along the press direction and movement in a direction inclined to the press direction.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com