Oil cylinder slider front-mold firstly-core-pulling injection molding mold

A technology of injection mold and oil cylinder, which is applied in the field of injection mold mechanism design, can solve the problems of high mold manufacturing cost and complex mold structure, and achieve the effect of reducing structural difficulty and manufacturing cost, reducing structural difficulty and manufacturing difficulty, and large core pulling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

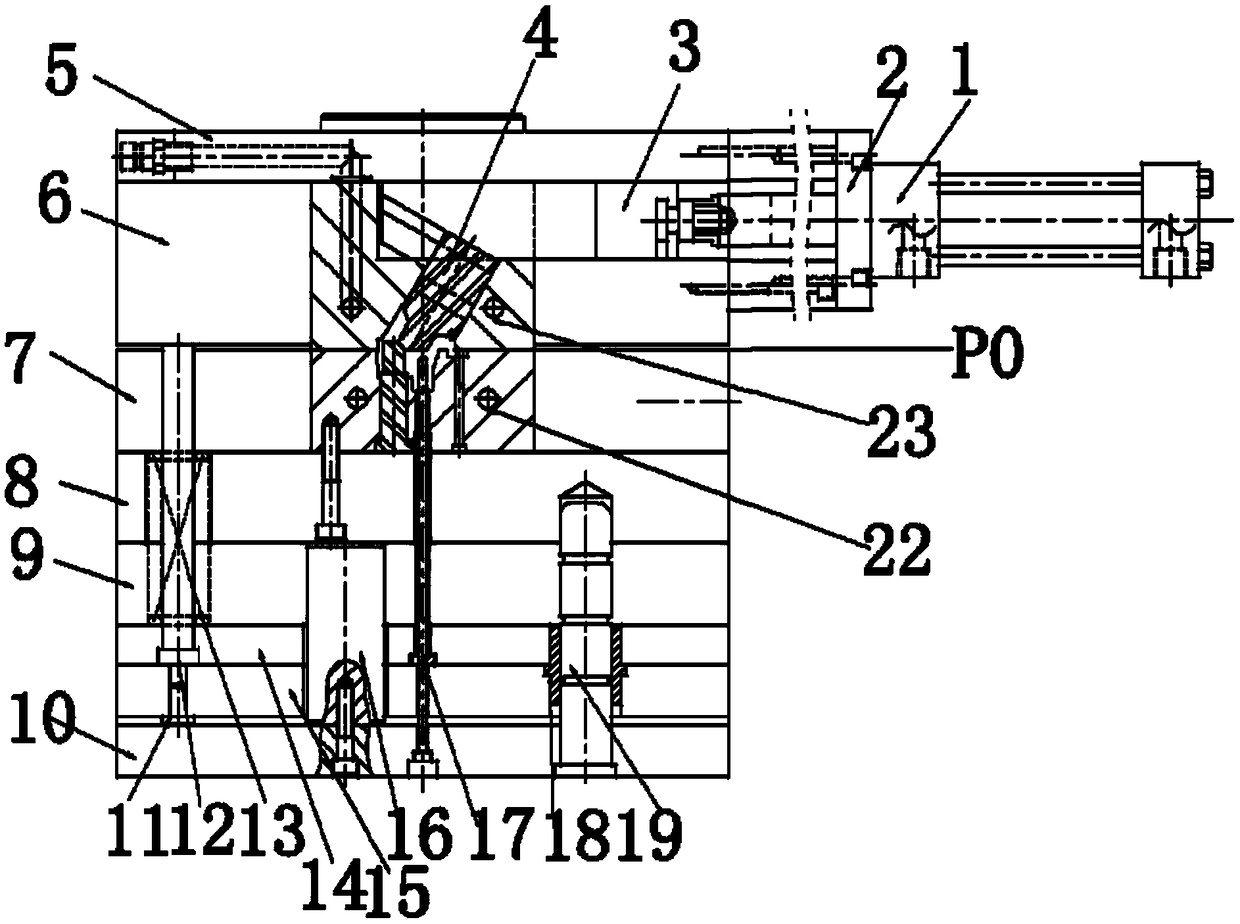

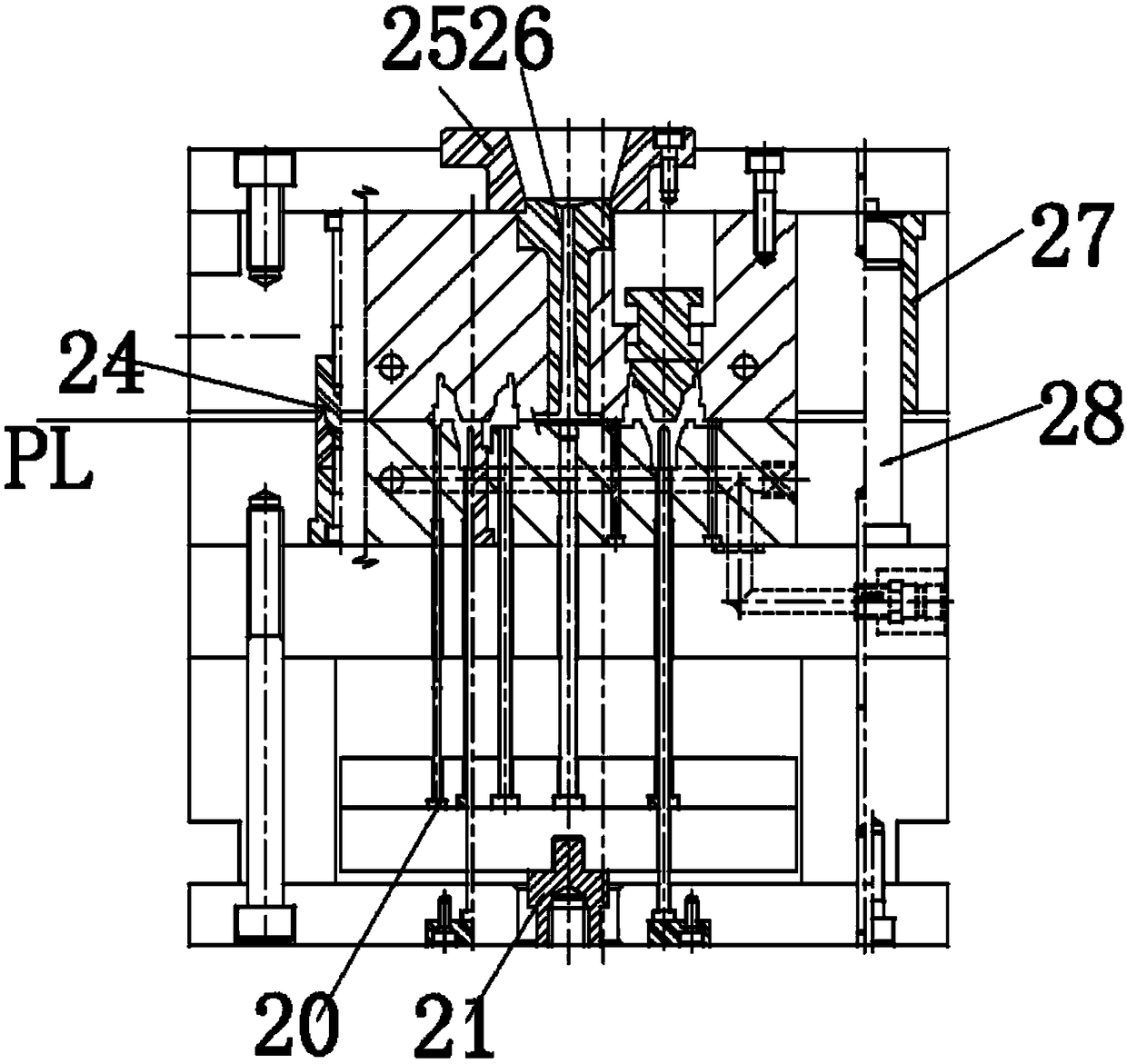

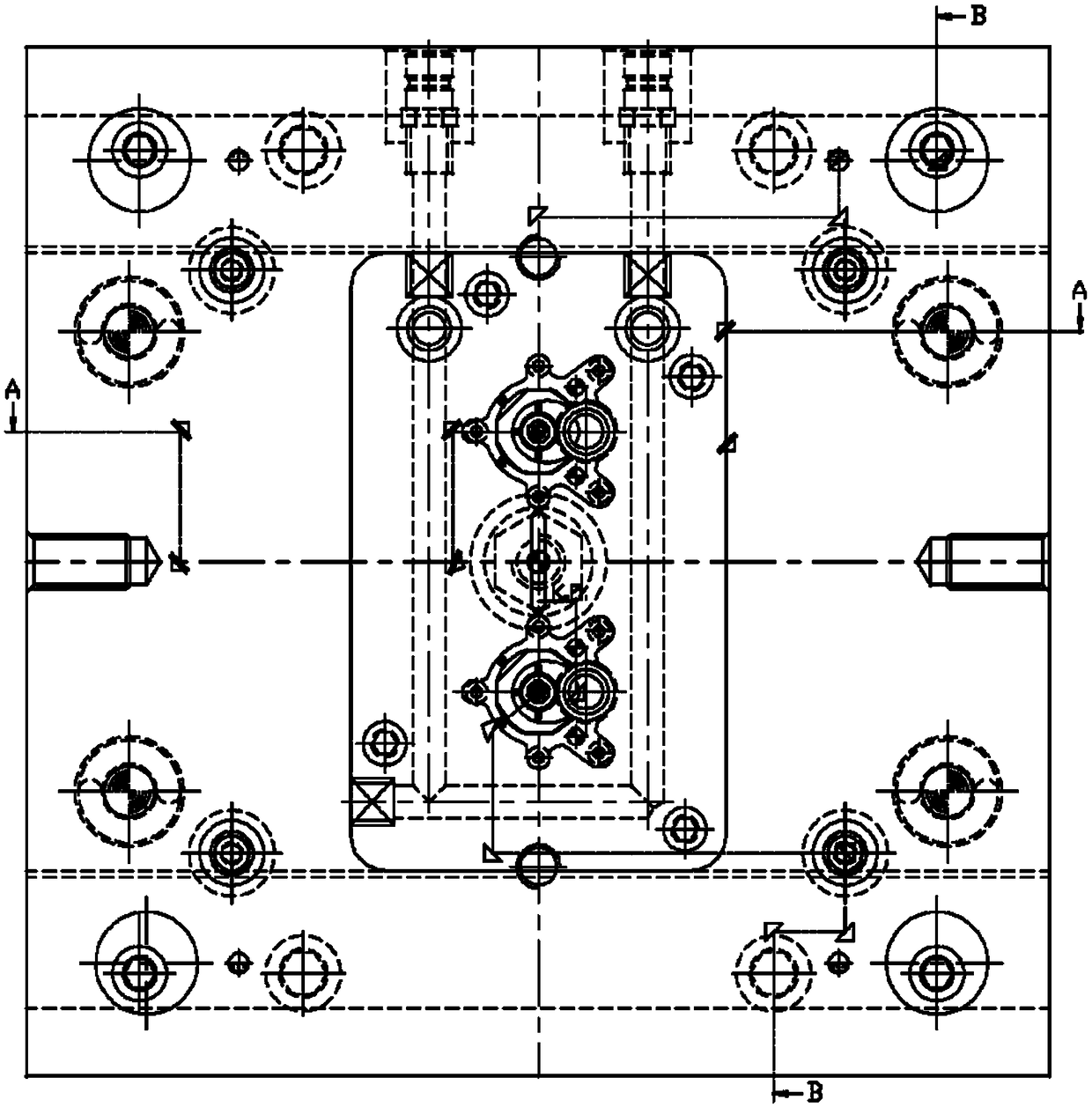

[0018] Figure 1-4 Shown is the relevant explanatory figure of the present invention; The specific embodiment is, as figure 1 , figure 2 , image 3 , Figure 4 As shown, a core-pulling injection mold for the front mold of the cylinder row position includes a core-pulling drive cylinder 1 for the front mold, a sliding support for the oil cylinder 2, a horizontal core-pulling slider body 3, an oblique core-pulling insert 4, a panel 5, a fixed Template 6, movable template 8, movable mold pad 9, movable mold bottom plate 10, garbage nail 11, reset lever 12, reset lever spring 13, thimble panel 14, thimble push plate 15, support column 16, push tube 17, thimble plate Guide sleeve 18, thimble plate guide post 19, thimble pin 20, ejector rod sleeve 21, male mold insert 22, female mold insert 23, positioning taper sleeve 24, positioning ring 25, sprue bushing 26, fixed mold guide sleeve 27 , fixed mold guide post 28.

[0019] The oblique core-pulling assembly driven by the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com