Resin molding machine and method of resin molding

A resin mold and resin technology, applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of difficult demoulding, unstable position accuracy of movable pins, and easy wrinkles, etc., to improve filling and The effect of forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment

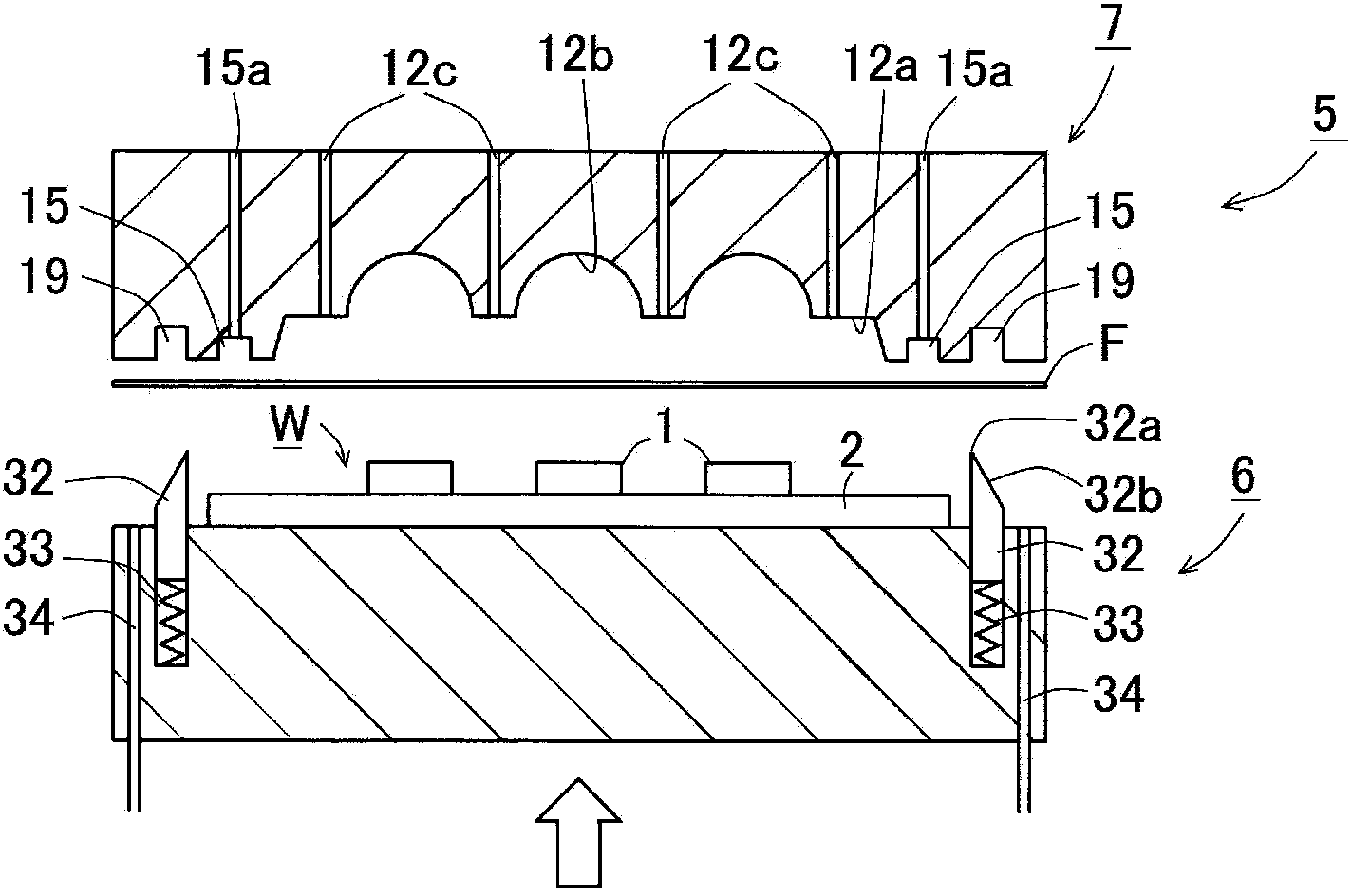

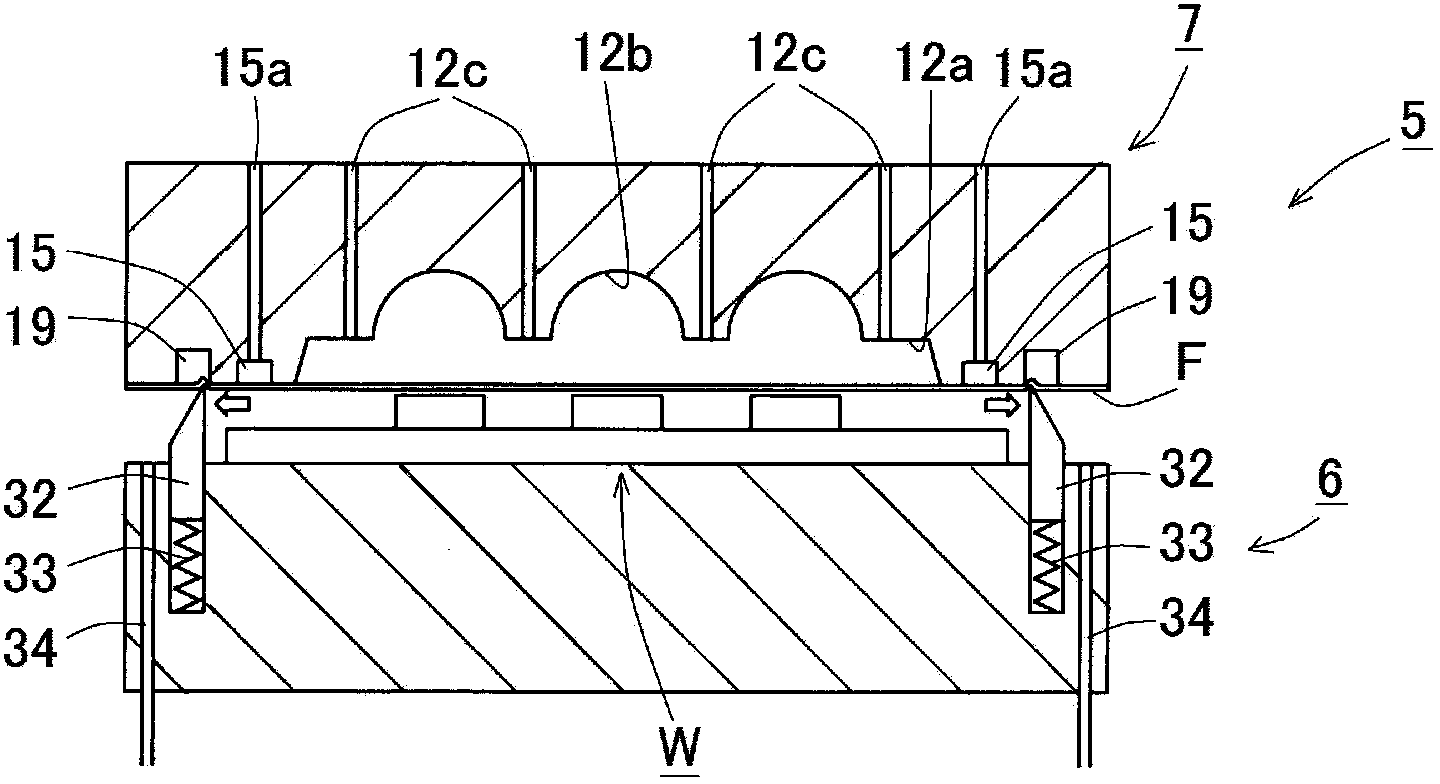

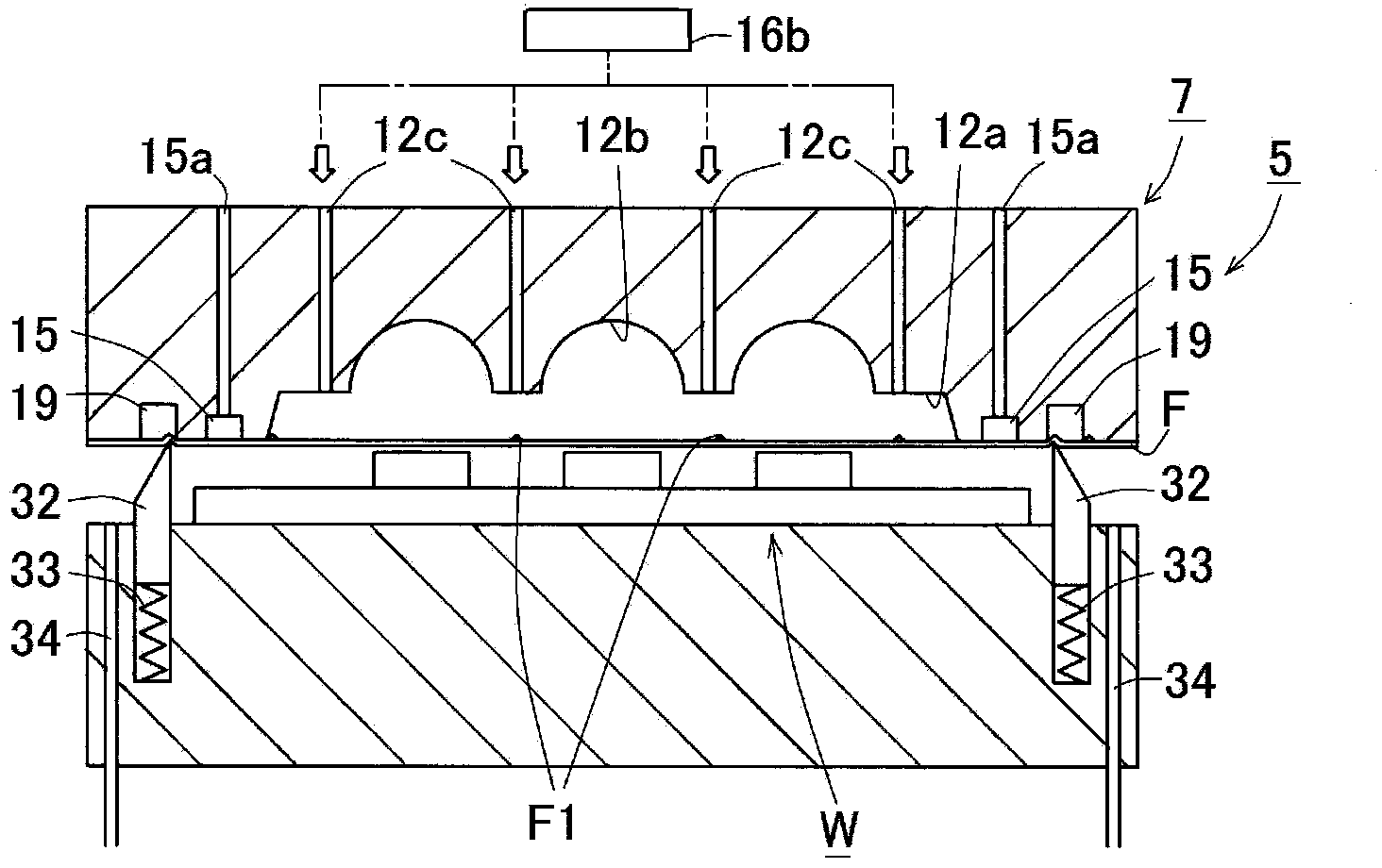

[0116] The case where the release film is sucked in the cavity, the resin molding apparatus, and the resin molding method will be described in detail. The same reference numerals are assigned to the same components as those in the first embodiment, and the above descriptions are referred to. exist Figure 12 Among them, the molding die 5 and the pressure driving mechanism are the same as those of the first embodiment. Also in this embodiment, the upper die 7 will be described as a fixed die and the lower die 6 will be described as a movable die. A first cavity concave portion 12 a is formed on an upper die clamping surface of a cavity core (cavity insert) 11 provided on the upper die 7 .

[0117] The first cavity recessed portion 12 a is used to house and mold the workpiece W on which the light emitting elements 1 are mounted in a matrix on the substrate 2 as a whole. In addition, a plurality of second cavity recesses 12b having a depth deeper than the depth of the cavity b...

no. 3 Embodiment

[0143] The resin molding apparatus and method for blowing and releasing the mold after forming will be described in detail. The same reference numerals are assigned to the same components as those in the first embodiment, and the above descriptions are referred to.

[0144] exist Figure 11 In the work W, light-emitting elements 1 are flip-chip-connected (or wire-bonded) on a substrate 2 in a row-column manner. exist Figure 9 In the case of a rectangular (short length) substrate 2 , an example in which a plurality of (for example, 18) molded products are mounted is shown in . In addition, various plate-shaped members such as a resin substrate, a metal (for example, aluminum, copper, etc.) substrate, a ceramic substrate, a lead frame, and a carrier can be used as the substrate 2 used as a base material. In addition, as the workpiece W, a wafer on which bumps are formed, a carrier on which electronic components are mounted and fixed by bonding, or the like can be used.

[0...

no. 4 Embodiment

[0168] The resin molding apparatus and method of the molded film supporting pin and air blowing combined type will be described in detail. The same reference numerals are assigned to the same components as those in the first embodiment, and the above descriptions are referred to. exist Figure 32 Herein, the schematic structure and the pressure driving mechanism of the molding die 5 are the same as those of the first to third embodiments, and the description will focus on different structures. It should be noted that because the release using the membrane support pin is to be explained in detail, the Figure 32 to Figure 36 Illustration of the peripheral groove 15 , the film wrinkle correcting member 32 for flattening the wrinkle of the release film, the housing recess 19 , and the air blowing units 27 , 28 , which are necessary structures before forming, is omitted.

[0169] First, refer to Figure 8 The structure of the upper die 7 will be described. A peripheral groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com