Apparatus and method for making spiral rollaway nest by pressure manufacturing or shaping

A processing and manufacturing, helical technology, applied in the field of devices and methods for press manufacturing or forming and manufacturing helical raceways, can solve the problems of narrow space conditions, complex operation of forming molds or forming tools, etc., and achieve high raceway precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

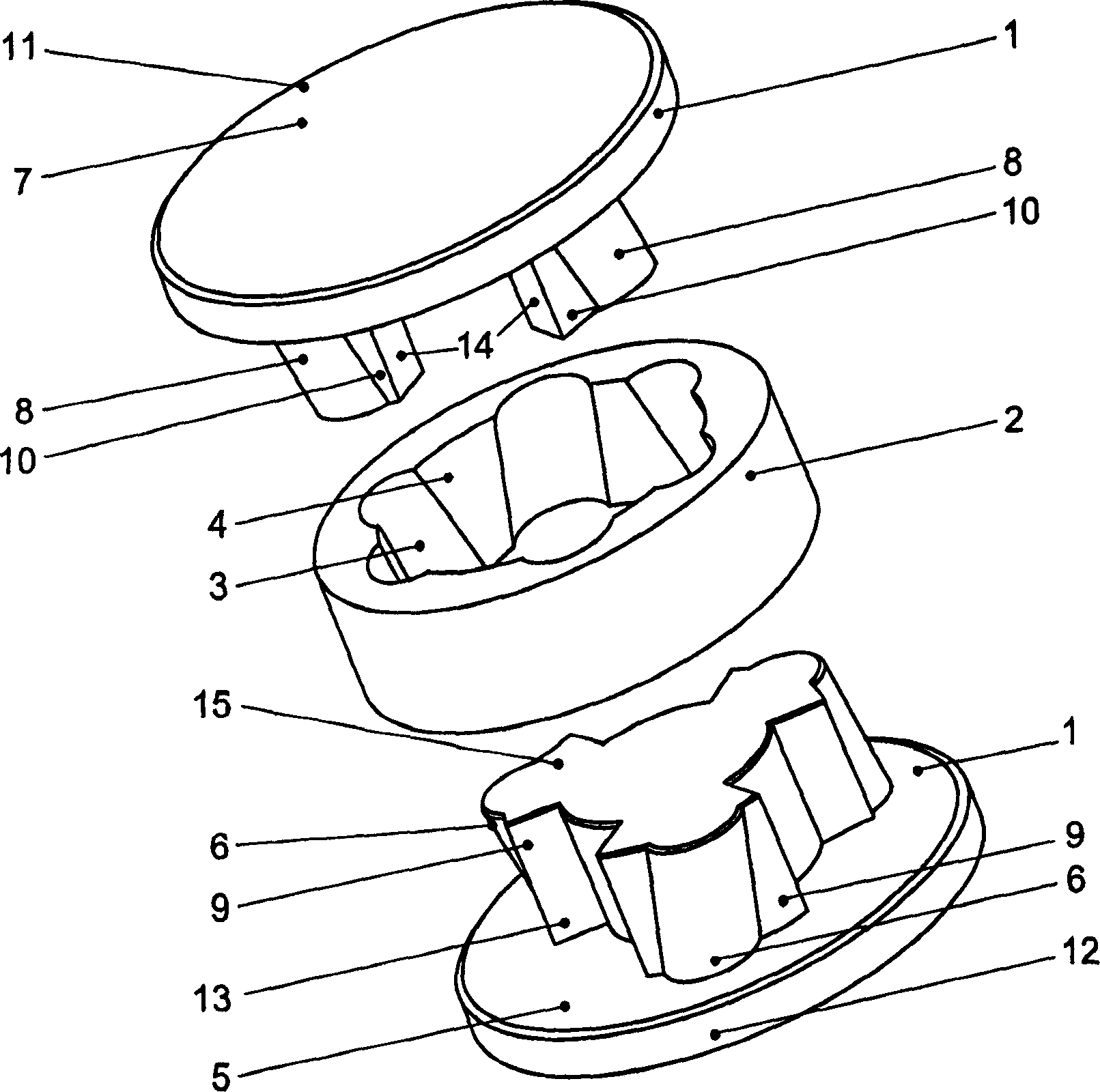

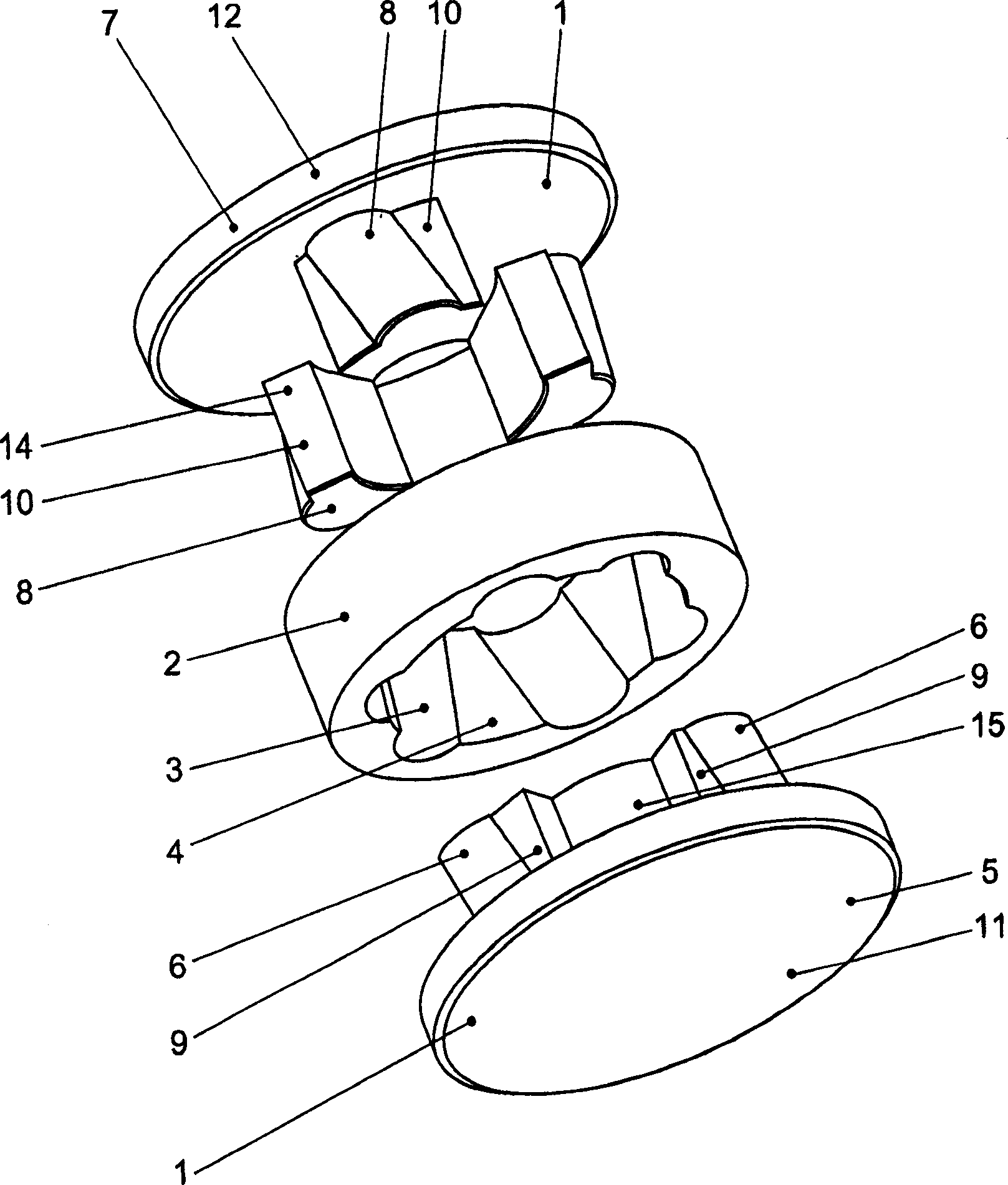

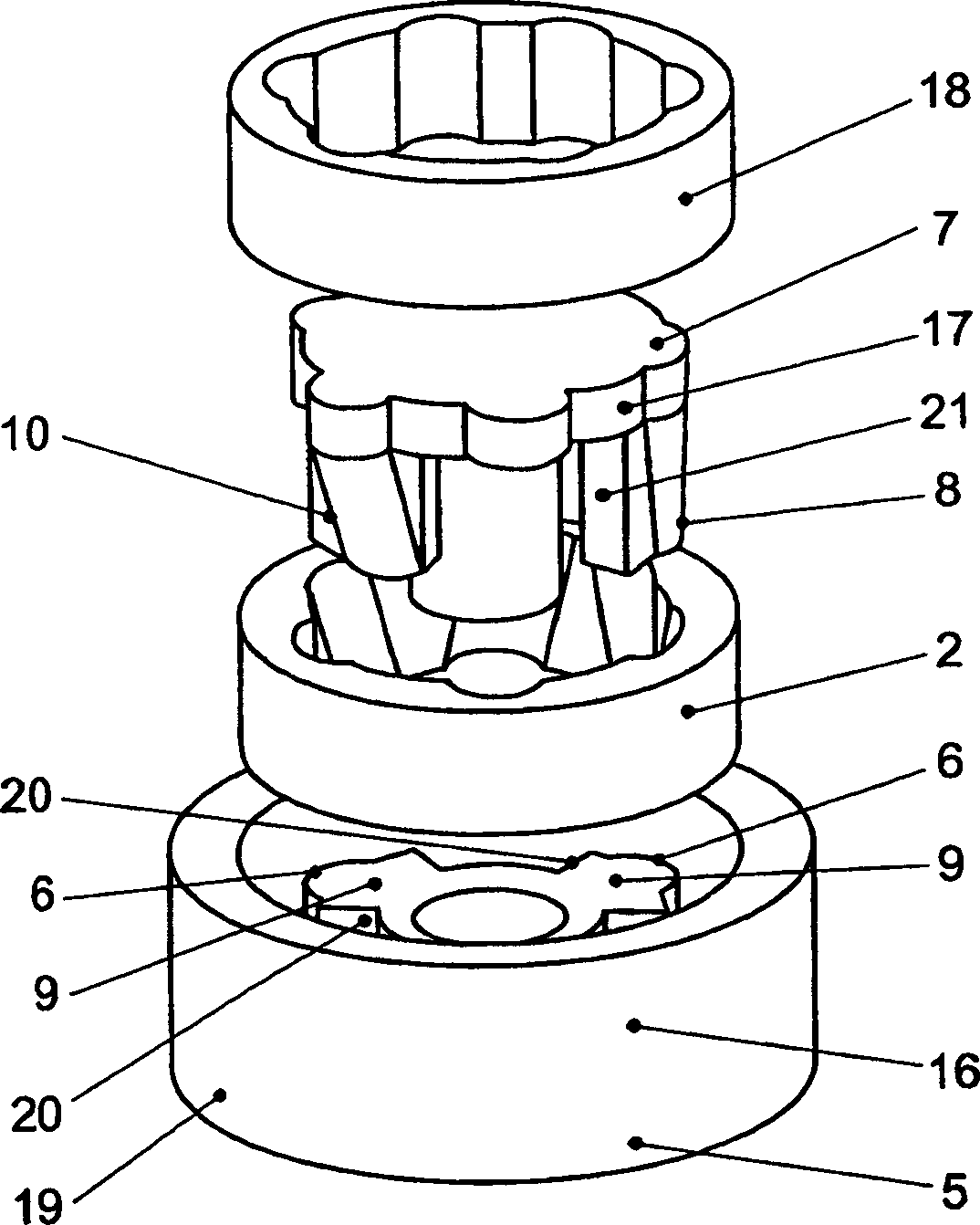

[0040] figure 1 , 2 Shown is a molding die 1 for a device for forming a spiral raceway on a joint member of a synchronous universal joint in a VL-shaped structure with crossed raceways. The following embodiments relate to a joint outer part 2 with a raceway 3 on the inner surface 4 . However, it is also possible to produce an articulated inner part with a raceway on the outer surface in a corresponding manner.

[0041] In the VL-type synchronous universal joint, a right pitch raceway and a left pitch raceway are provided on the outer member 2 and the inner member not shown. Typically, these raceways run linearly at an ascending angle of about 15 degrees relative to the longitudinal axis of the member. However, modified raceways 3 are used here, which run helically around the longitudinal axis of the component. Here, the pitch of the helices is chosen such that, after conventional machining, a similar inclination angle is obtained as in the case of a straight raceway.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com