Front mould automatic shooting material mechanism of injection mold of three plates mold and using method thereof

A technology of injection mold and three-plate mold, which is applied in the field of automatic elastic mechanism of the front mold of three-plate injection mold, which can solve the problems such as difficulty in continuing the mold work, failure of ejection of runner waste, etc., and achieve the effect of guaranteeing the function of automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

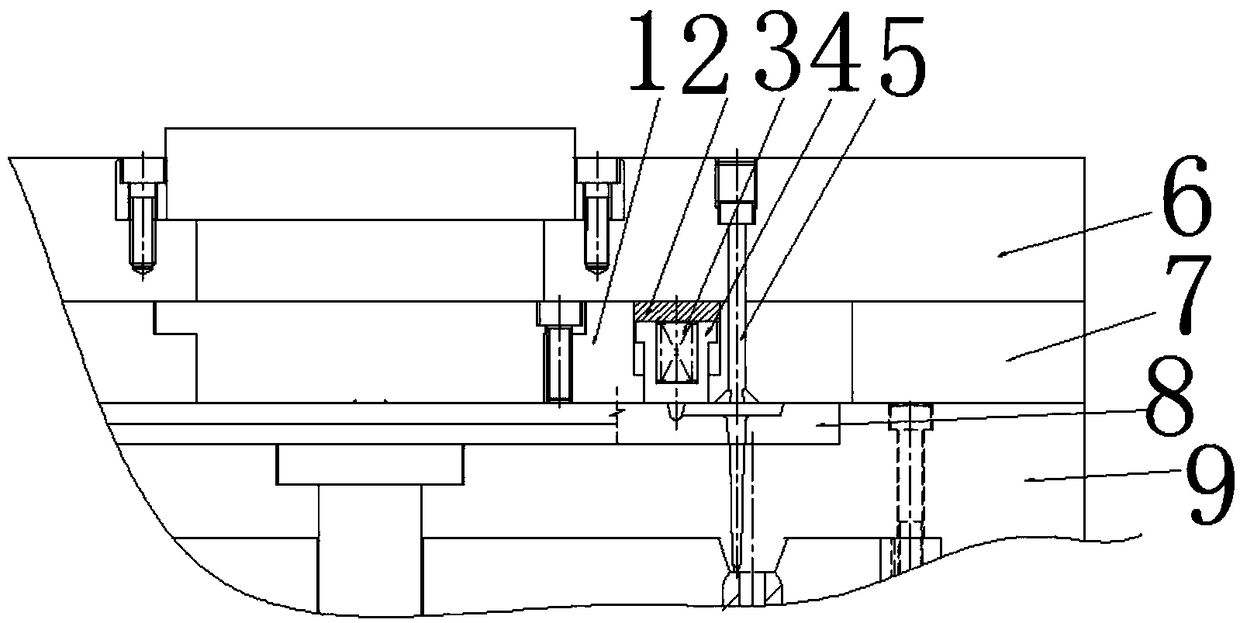

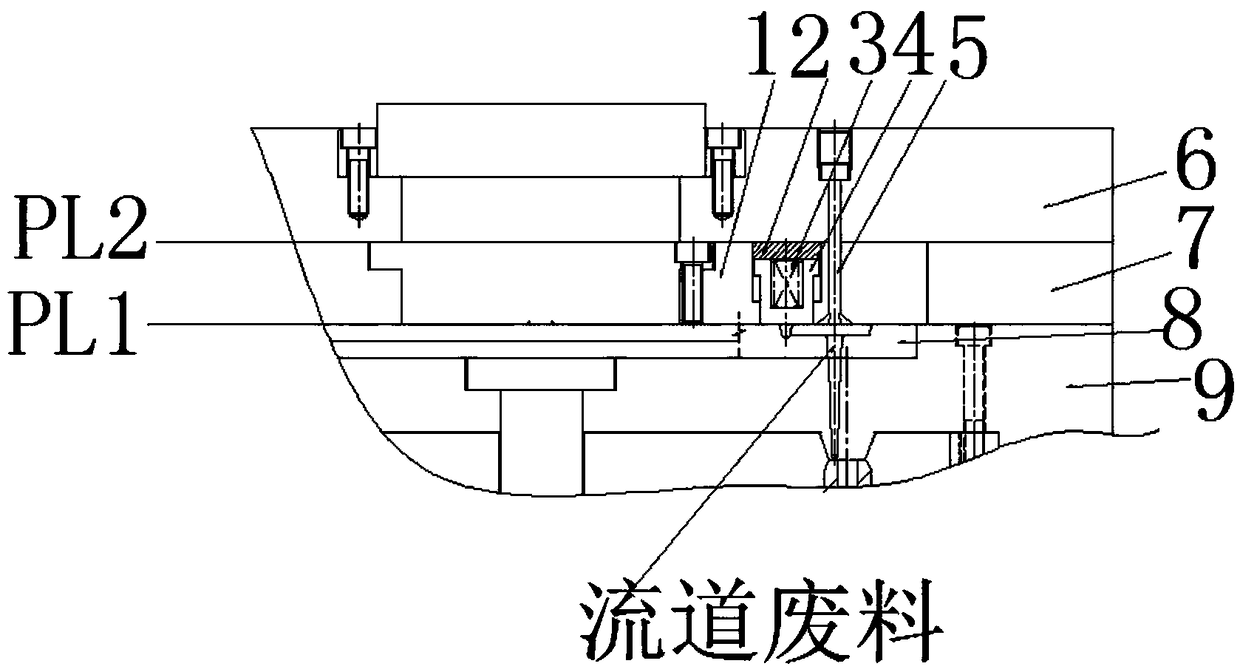

[0012] Figure 1-2 Shown is the relevant explanatory figure of the present invention; The specific embodiment is, as figure 1 , figure 2 As shown, an automatic spring material mechanism for the front mold of a three-plate mold injection mold includes a spring material insert block 1, a spring pressure plate 2, a spring 3, a spring pressure sleeve 4, a pull rod 5, a front mold panel 6, a runner plate 7, Front mold runner insert plate 8, front template 9.

[0013] In the mechanism, the bullet insert block 1 is fastened on the flow channel plate 7 by screws, and the bullet insert block 1 is provided with a hole for installing the elastic sleeve 4, and the elastic sleeve 4 is loaded into the bullet insert block 1 After entering the hole, its cooperation with the hole on the bullet insert block 1 is a sliding fit; the spring 3 is set in the hole of the spring sleeve 4, and it is pressed by the spring pressure plate 2, and the spring sleeve 4 is installed on the bullet. In the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com