Patents

Literature

103results about How to "Realize automatic shedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

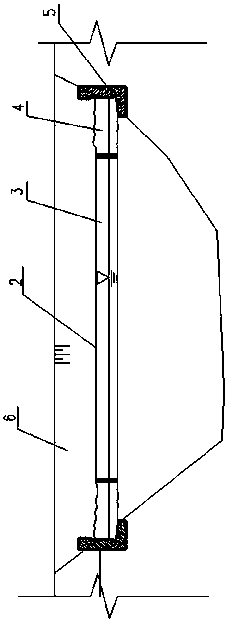

Composite fireproof cable

ActiveCN110047620ARealize SupplementRealize automatic sheddingInsulated cablesInsulated conductorsElectrical and Electronics engineeringCoating

The invention discloses a composite fireproof cable which comprises a cable main body formed by splicing one or more assembly cables and one or more connecting pieces. The cable main body is installedby suspending at the top. Each assembly cable comprises a first outer coating layer and a second outer coating layer, the first outer coating layer and the second outer coating layer are spliced intoa circular cable outer coating layer, the end faces of the two sides of the first outer coating layer and the second outer coating layer are rotationally connected with the connecting pieces throughrotating structures, and through holes are formed in the middles of the connecting pieces. As long as the cable is applied to a high position, the cable has very good protection performance and can automatically fall off after resisting burning of a flame cup, a new outer coating layer can be immediately replaced to continue to protect a cable core at the top, and flame is prevented from being transmitted to the cable core end.

Owner:亚星线缆集团有限公司

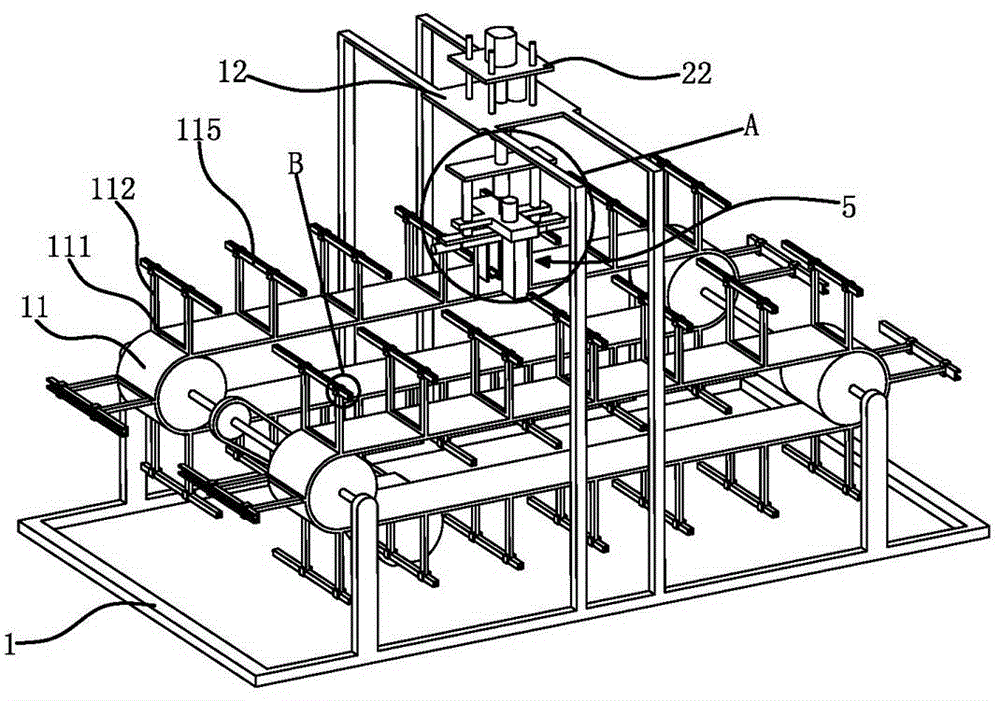

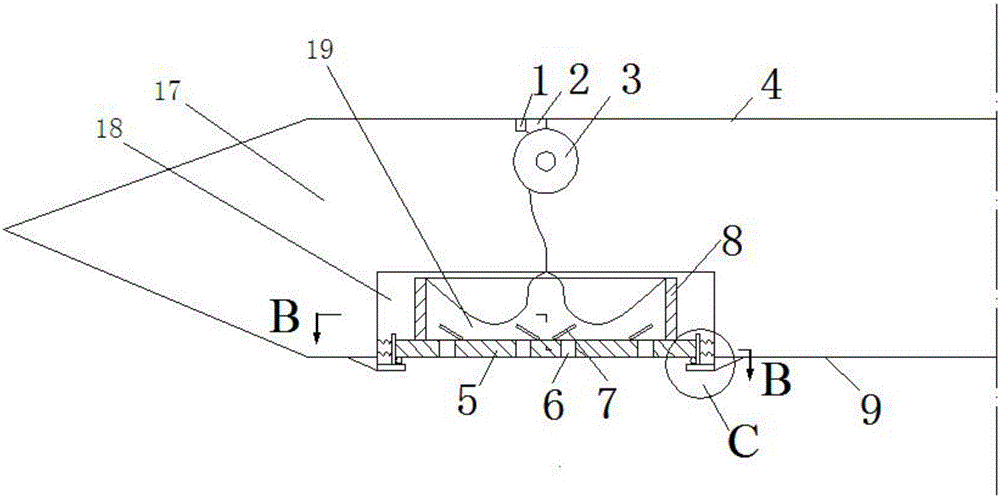

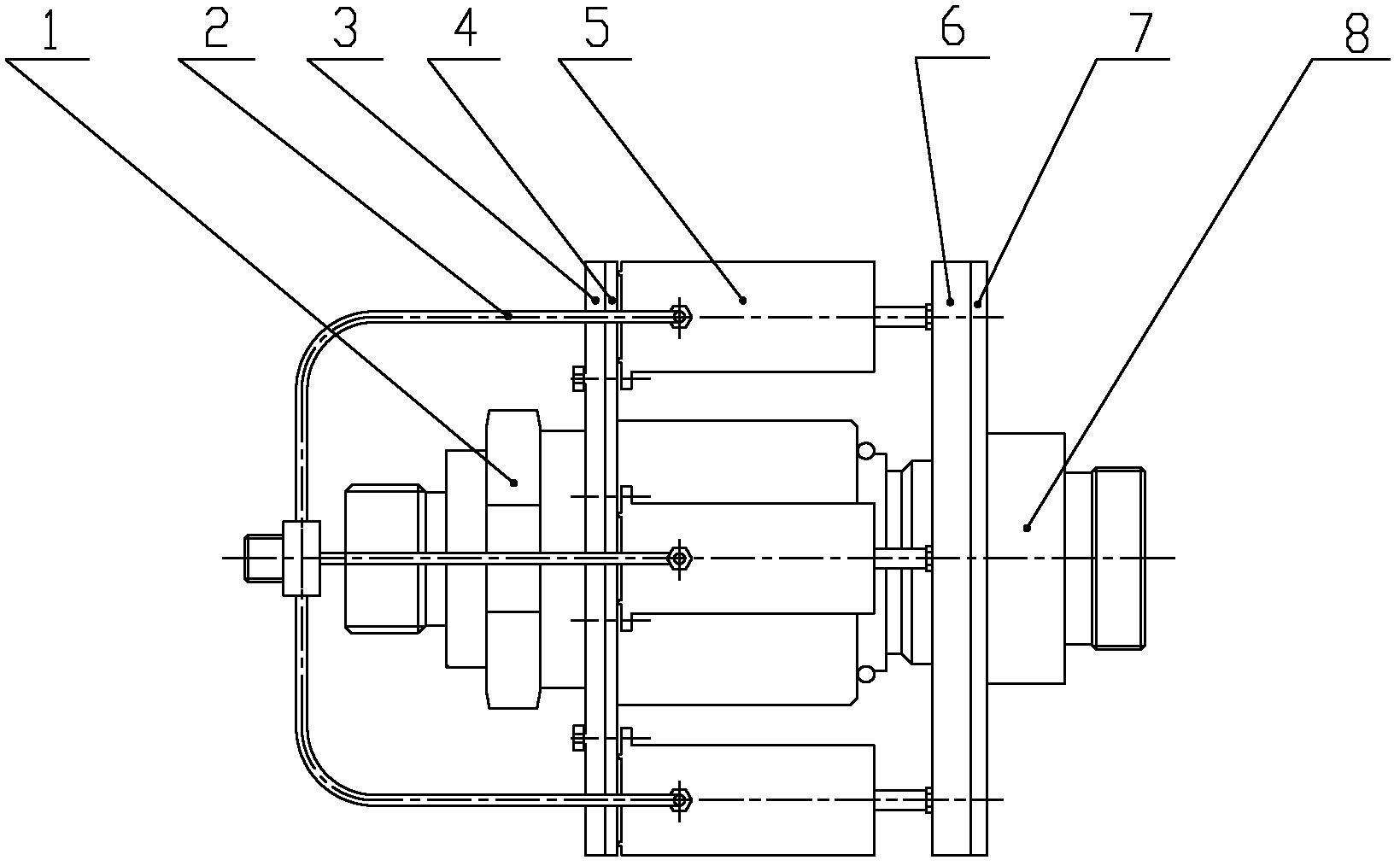

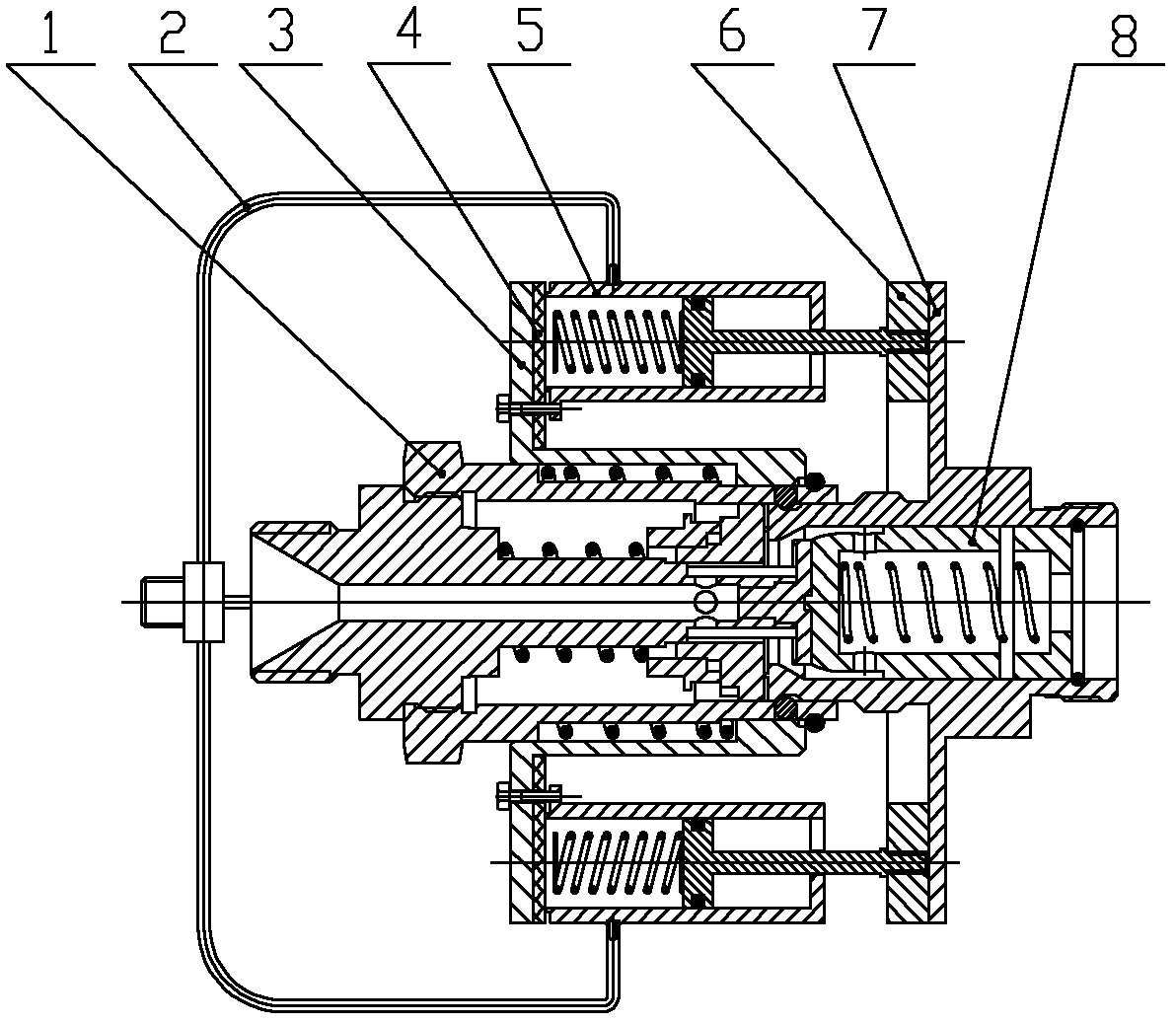

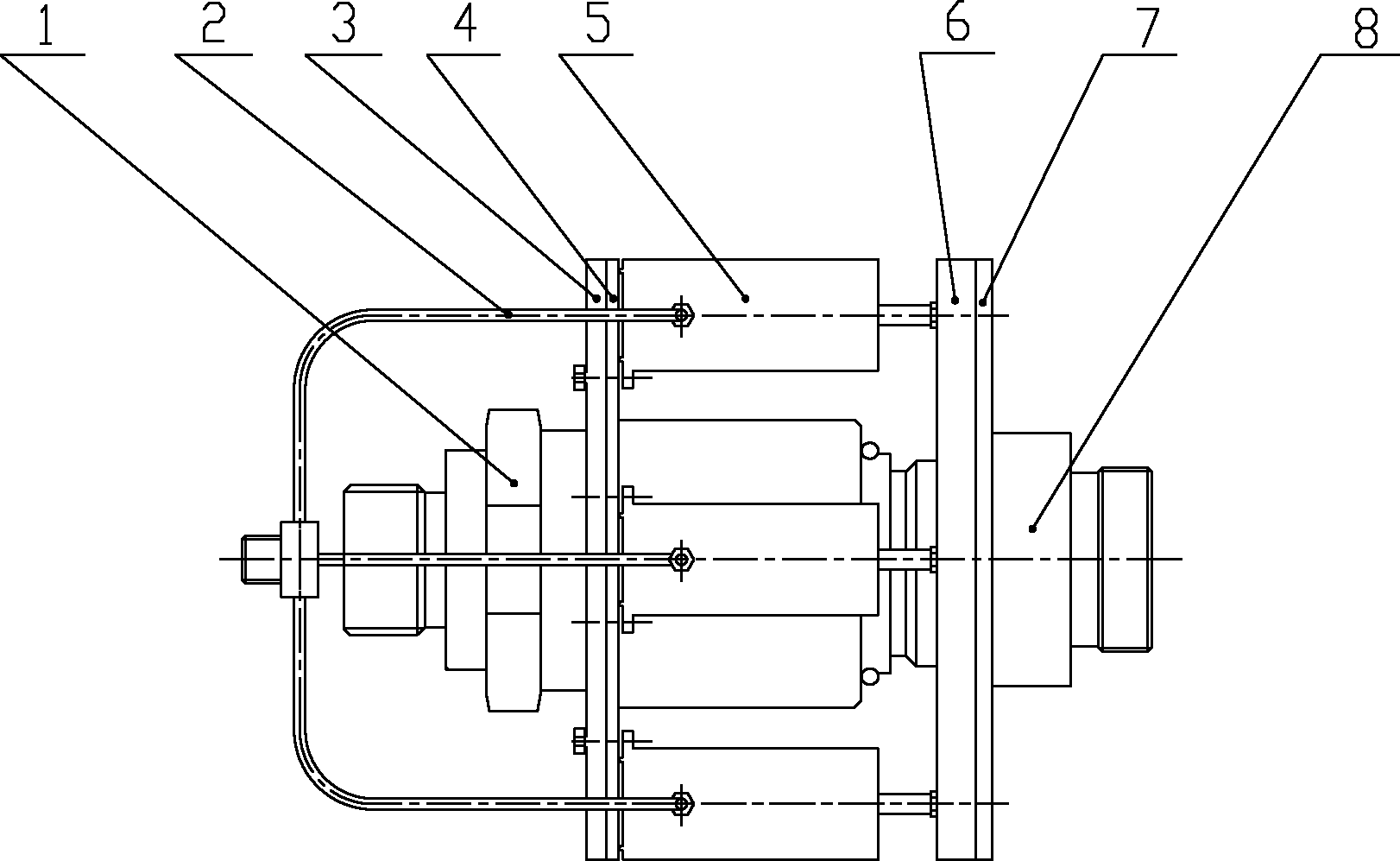

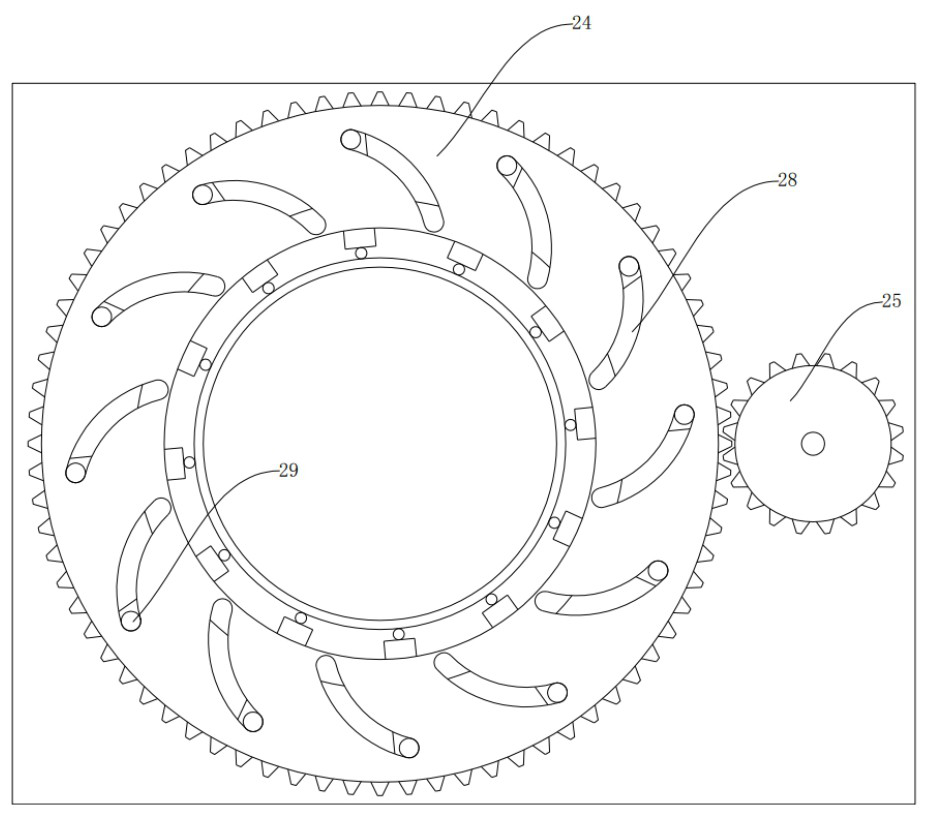

Winding binding machine for medical infusion tube

InactiveCN104015952AHigh degree of automationRealize automatic strappingBinding material applicationPaper/cardboard containersEngineeringConductor Coil

The invention provides a winding binding machine for a medical infusion tube and belongs to the technical field of medical device processing equipment. The winding binding machine for the medical infusion tube solves the problems that the existing infusion tube winding binding quality is low and efficiency is low. The winding binding machine for the medical infusion tube comprises a rack, wherein two conveyor belts are rotatably connected with the rack, a plurality of material carrying rods are respectively fixedly connected on the two conveyor belts, the rack is fixedly connected with one working platform, the working platform is connected with a main shaft in a sliding way along the vertical direction, a driving mechanism I and a driving mechanism II are arranged on the working platform, the main shaft is fixedly connected with a mainboard, the mainboard is connected with two winding rods, each material carrying rod is provided with a clamping mechanism, the mainboard is connected with a binding main body, and a binding device is arranged on the binding main body. The winding binding machine for the medical infusion tube can automatically wind the medical infusion tube and then automatically bind the medical infusion tube after winding, automation degree is high, and production efficiency is improved.

Owner:杨丽华

Self-opening velocity type hydraulic energy absorption and consumption device

ActiveCN105951581AReduce frictionReduce the impact of navigationBridge structural detailsEnergy absorptionHanging basket

The invention discloses a self-opening velocity type hydraulic energy absorption and consumption device. The self-opening velocity type hydraulic energy absorption and consumption device mainly comprises a steel box girder and a hanging basket, wherein the hanging basket is arranged in a square concave hole at the bottom of the steel box girder; the hanging basket comprises a hanging basket bottom plate and peripheral side walls; the hanging basket bottom plate is provided with a plurality of water through holes; a cover plate is hinged above the water through holes; one rope is connected with each of four corners at the upper part of the hanging basket; after the four ropes are bound together, the four ropes are connected with a hanging rope; the other end of the hanging rope is wound on one side of a rotary barrel; the rotary barrel is fixedly arranged on a top plate of the steel box girder; a pressing device and a friction sheet are mounted above the rotary barrel; a horizontal supporting plate is arranged at each of four corners of the bottom of the square concave hole; a vertical baffle is arranged on each horizontal supporting plate; the vertical baffles are connected with a side plate at the bottom of the square concave hole through limiting springs; and the four corners of the hanging basket bottom plate are supported on the four horizontal supporting plates at the bottom of the square concave hole through round balls. An energy consumption device can be automatically opened when a bridge starts to vibrate, and the vibration of the bridge is inhibited through hydraulic energy consumption.

Owner:HUNAN UNIV OF SCI & TECH

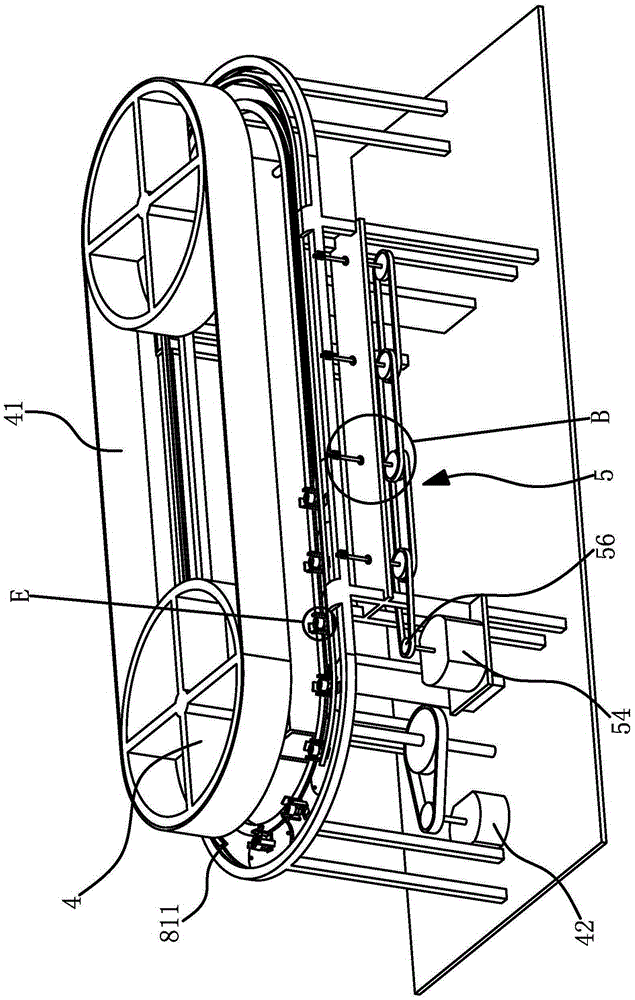

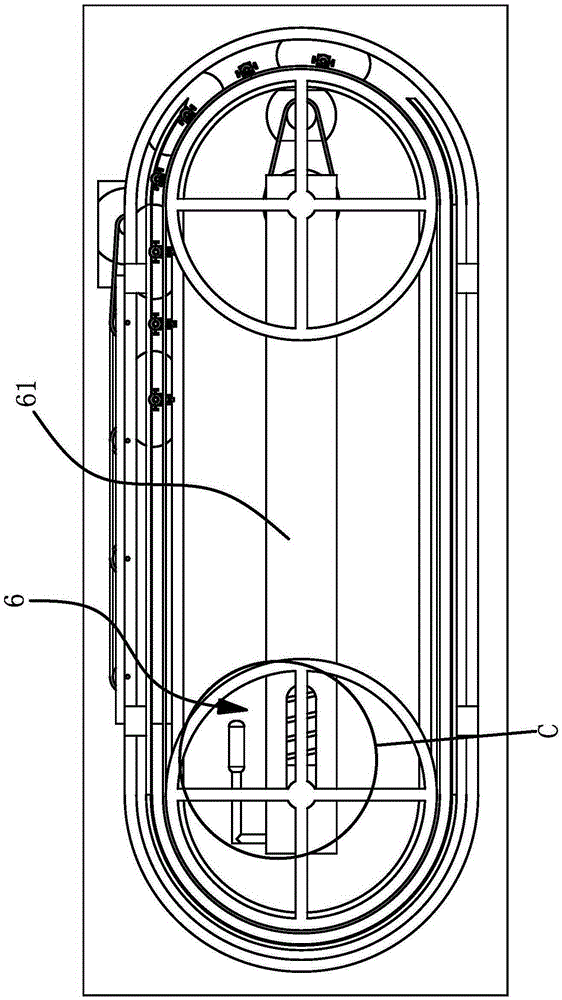

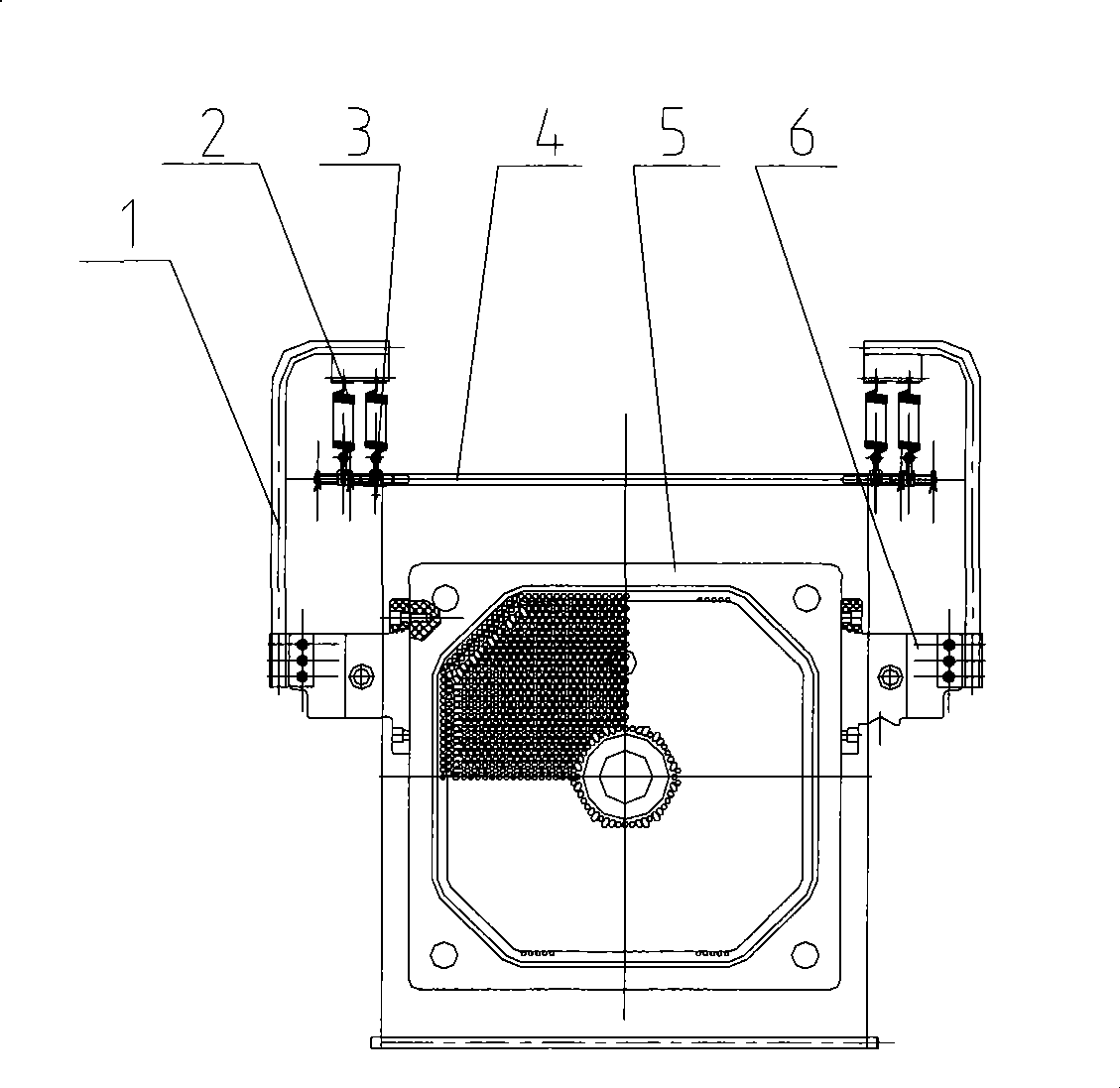

Winding and strapping machine for medical infusion tube

InactiveCN104085554AHigh degree of automationIncrease productivityBinding material applicationBundling machine detailsEngineeringMedical equipment

The invention provides a winding and strapping machine for a medical infusion tube, and belongs to the technical field of processing equipment of medical equipment. The winding and strapping machine solves the problems that an existing infusion tube is low in winding and strapping quality and efficiency. The winding and strapping machine for the medical infusion tube comprises a rack. The rack is connected with two conveying belts in a rotating mode, each conveying belt is fixedly connected with multiple material supporting rods, the rack is fixedly connected with a working table, the working table is connected with a main shaft in a sliding mode in the vertical direction and provided with a first driving mechanism and a second driving mechanism, the main shaft is fixedly connected with a main plate which is connected with two winding rods, a clamping mechanism is arranged on the material supporting rods, the main plate is connected with a strapping body, and the strapping body is provided with a strapping device. The winding and strapping machine for the medical infusion tube can wind the infusion tube automatically and strap the infusion tube automatically after the infusion tube is wound, is high in automation degree and improves production efficiency.

Owner:郭嘉川

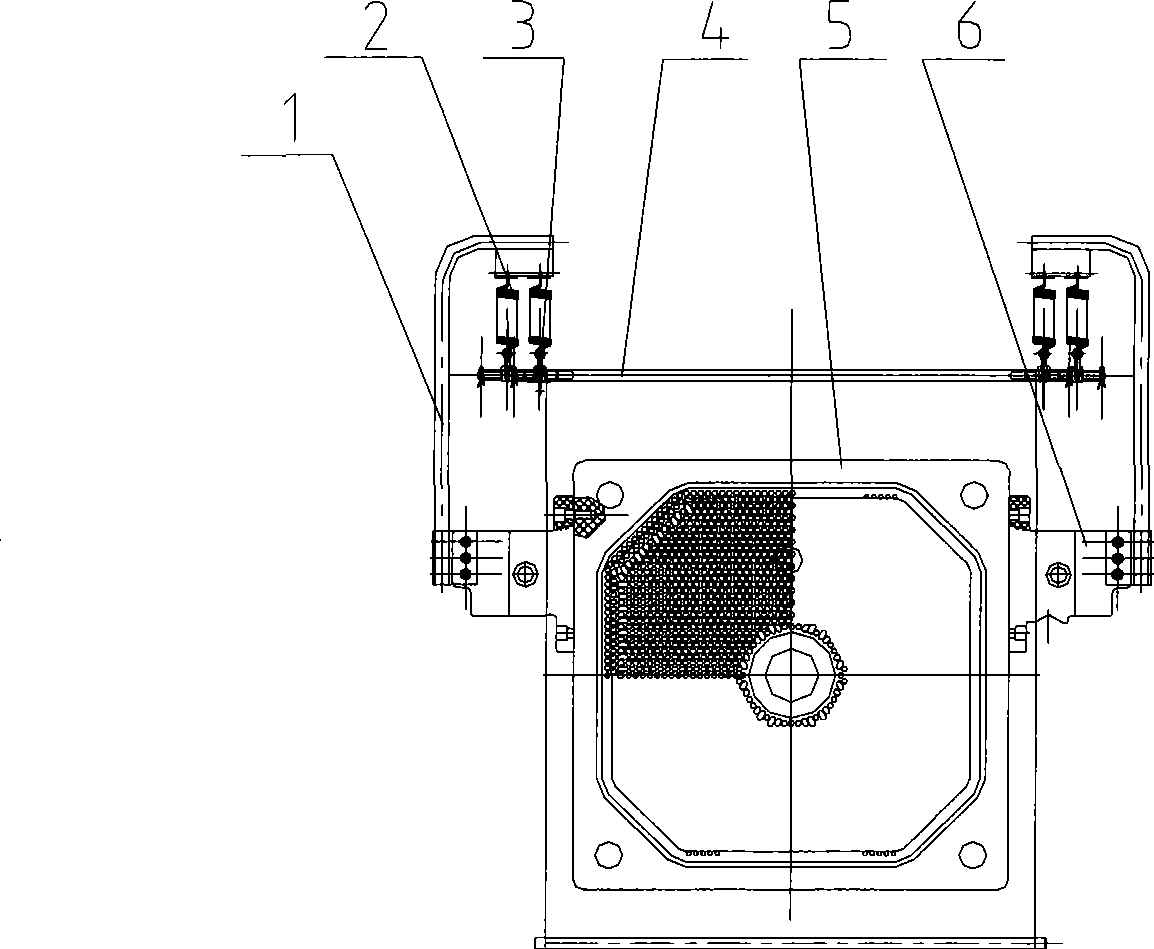

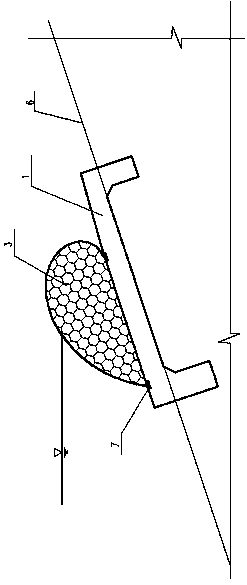

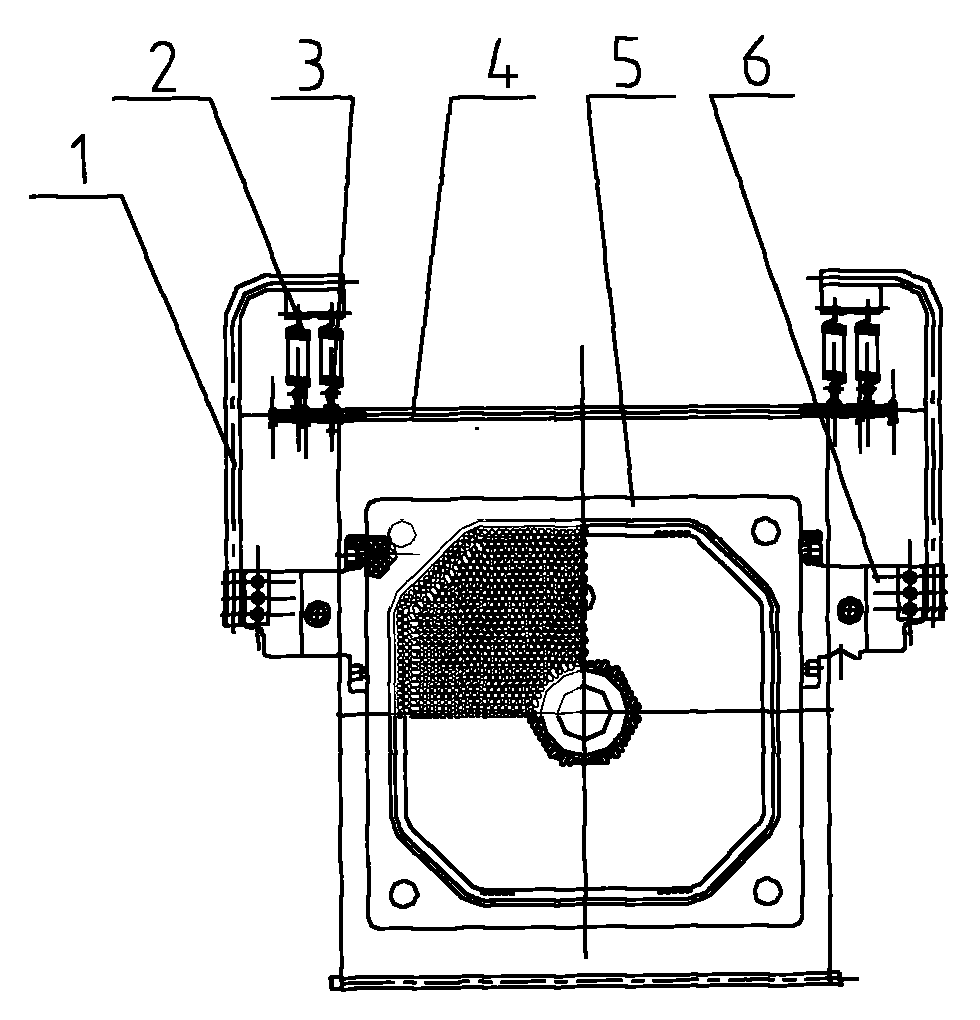

Mechanism for bending filter cloth and discharging material and automatic material-discharging method

ActiveCN101433780ARealize automatic sheddingGuaranteed stable workFiltration separationEngineeringFilter press

The invention relates to a curving discharge mechanism for a filter press, which can make a filter cloth automatically shake by means of stretching and vibrating, wherein filter cloth which is coated on outer surfaces of a plurality of filter plates respectively passes through respective filter cloth suspension rods respectively; both ends of every two suspension rods are connected with each other through a woven belt; both ends of each suspension rod are provided with eye bolts respectively; and the eye bolts are connected with respective curving supports through tension springs respectively. When the plurality of filter plates are pulled away, the filter cloth of the filter plates is pulled away at a certain angle through the respective tension springs and slightly vibrates to make filter cakes adhered to the surface of the filter cloth automatically fall off. The curving discharge mechanism for the filter press has the advantages that: firstly, the curving discharge mechanism for the filter press solves the problems of complex structures of various connecting pieces of the curving mechanism in the prior art, incapability of simultaneously washing a curving system and the filter cloth of the filter press, etc., and achieves the aims of stable and reliable operation, simple and reasonable structure, incapability of being influenced by the operating environment and economy and practicality; and secondly, tensioning peeling and slight vibration of the filter cakes on the surface of the filter cloth are realized through the pulling angle of the respective tension springs on the filter cloth of the filter plates, so that the aim of automatic falling of the filter cakes which are adhered to the surface of the filter cloth is realized.

Owner:杭州兴源环保设备有限公司

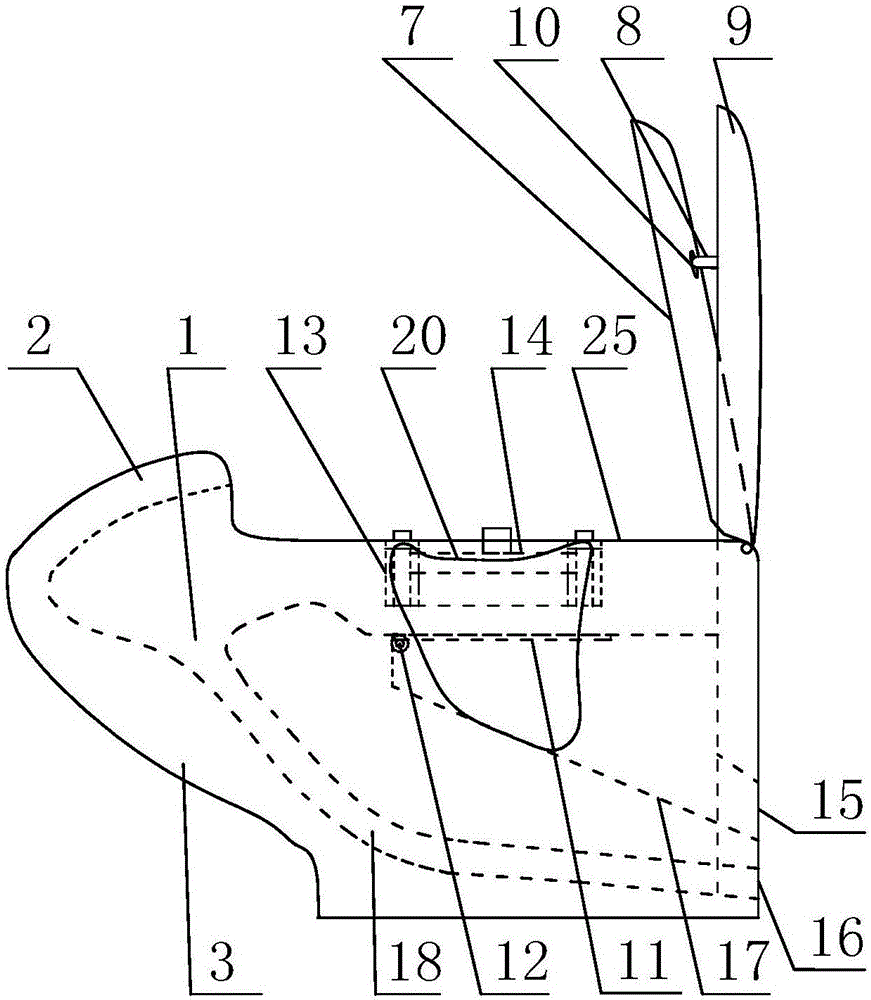

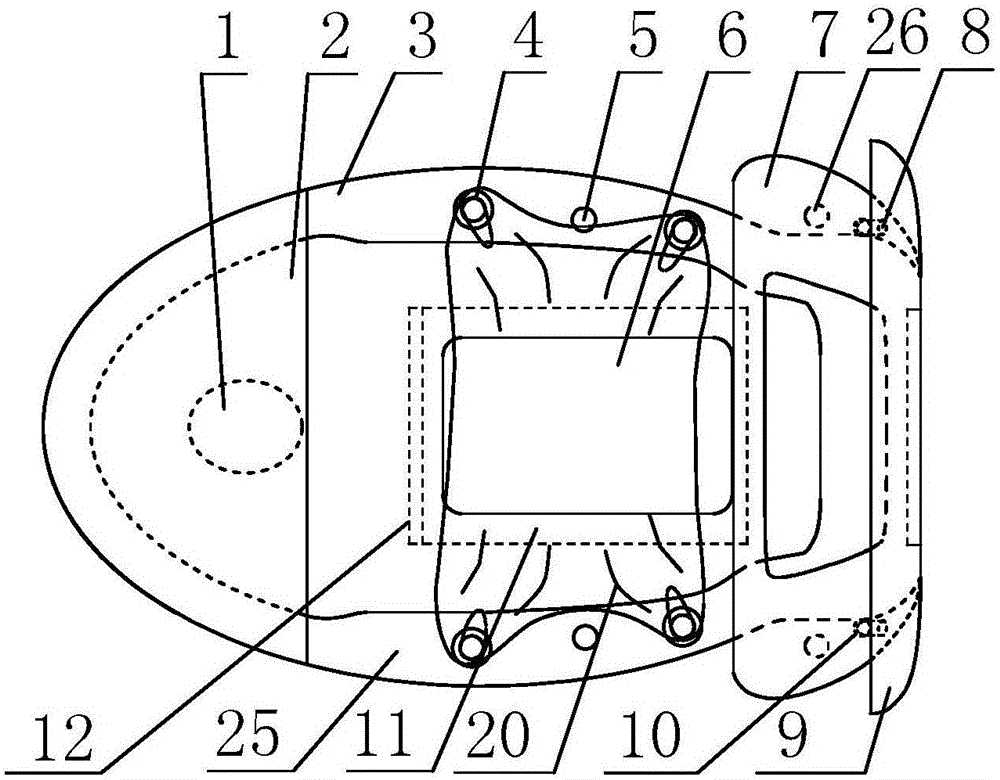

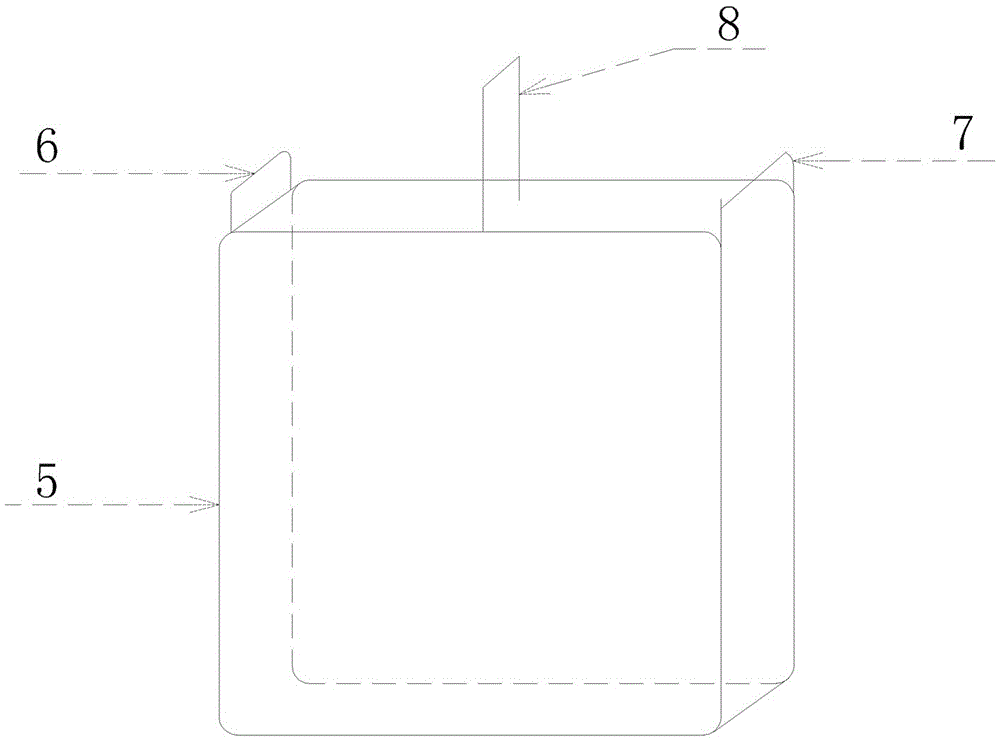

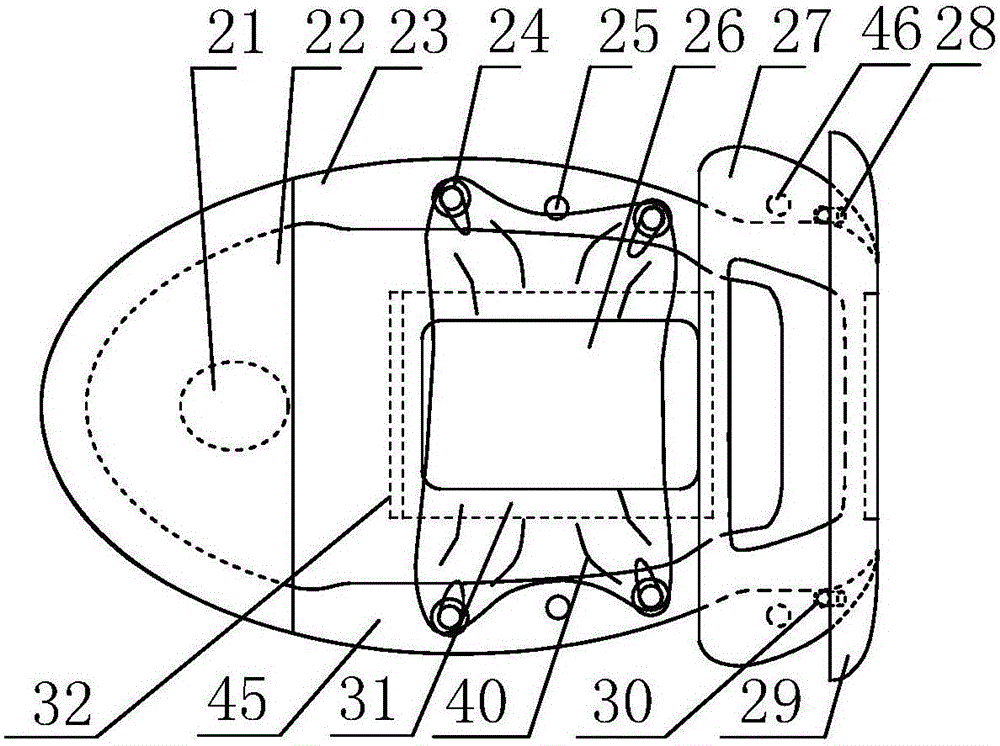

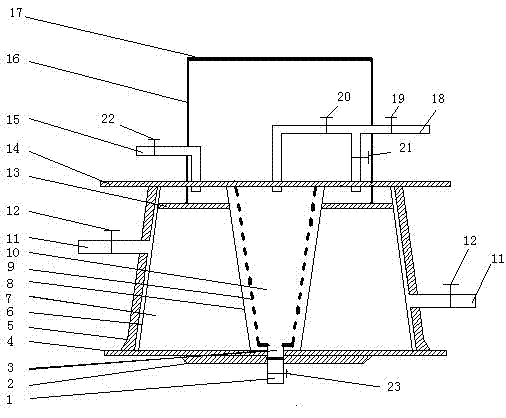

Flushing-free feces-urine-separation packaging toilet bowl

ActiveCN106175549AGreat ecological valueGreat economyBathroom accessoriesAgainst vector-borne diseasesAnimal fecesEngineering

The invention discloses a flushing-free feces-urine-separation packaging toilet bowl. The toilet bowl is provided with a urinating inlet and a feces inlet which are independently separated; bag hanging mechanisms are embedded into the toilet bowl faces of the upper ends of the two sides of a toilet bowl body respectively, and provided with four bag hanging columns jointly, and hanging-column connecting rods are transversely and fixedly connected to the middles of the bag hanging columns; the bag hanging columns are sleeved with hanging-column sleeves, sleeve side openings are formed in the hanging-column connecting rods of the hanging-column sleeves, openings are formed in the tops of the hanging-column sleeves, the lower portions of the hanging-column connecting rods of the bag hanging columns are sleeved with reset springs, and under the condition that external force is free, the tops of the bag hanging columns are ejected out of the top openings in the hanging-column sleeves and the toilet bowl faces through the reset springs, and feces packaging bags can be hung to the bag hanging columns; after toileting is completed, and a cover plate of the toilet bowl is put down, a triggering rod on the cover plate presses the hanging-column connecting rods to allow the packaging bags to fall off. According to the flushing-free feces-urine-separation packaging toilet bowl, a traditional flushing toilet bowl and the existing feces-packaging using mode in the world at present are overturned, the enormous social value, the enormous ecological value and the enormous economic value are contained, and the flushing-free feces-urine-separation packaging toilet bowl has broad application prospects.

Owner:云南八卫科技有限公司

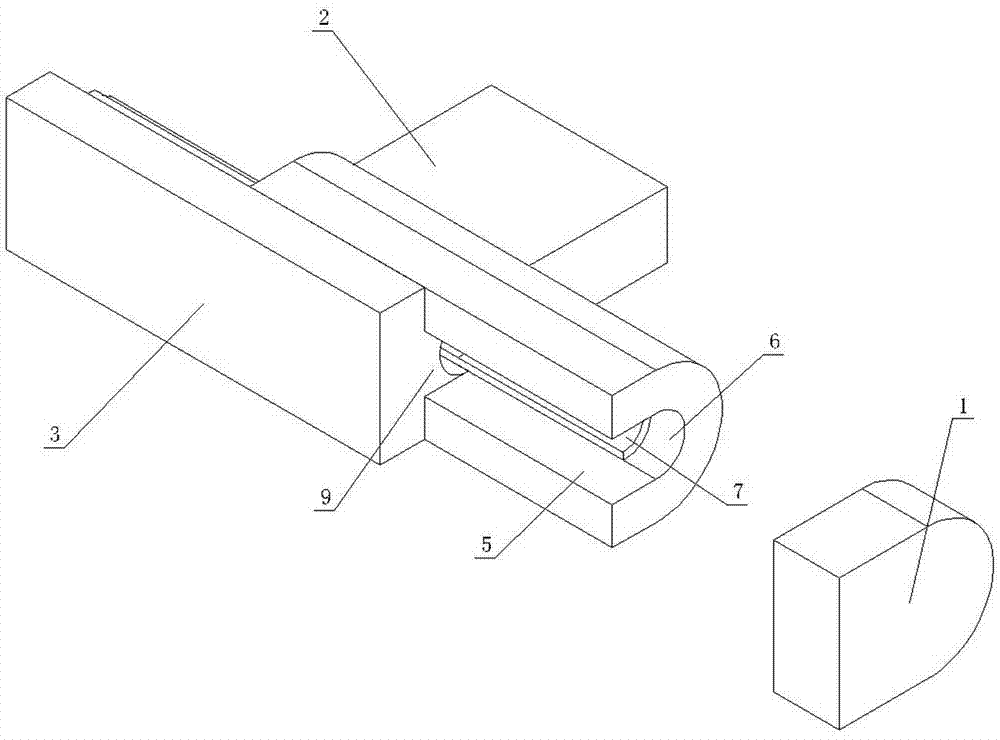

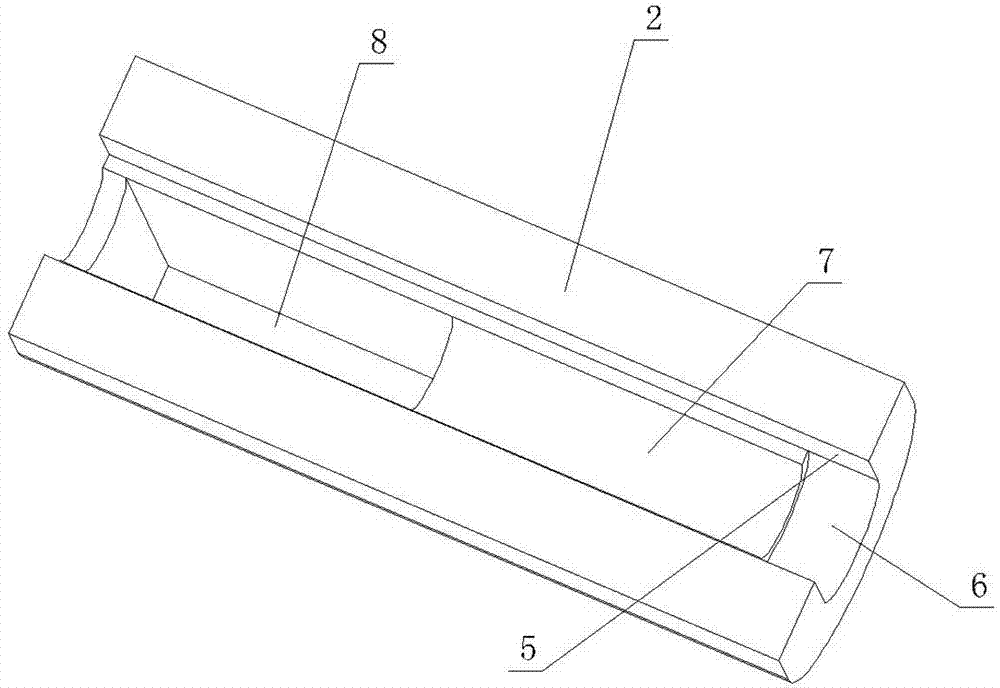

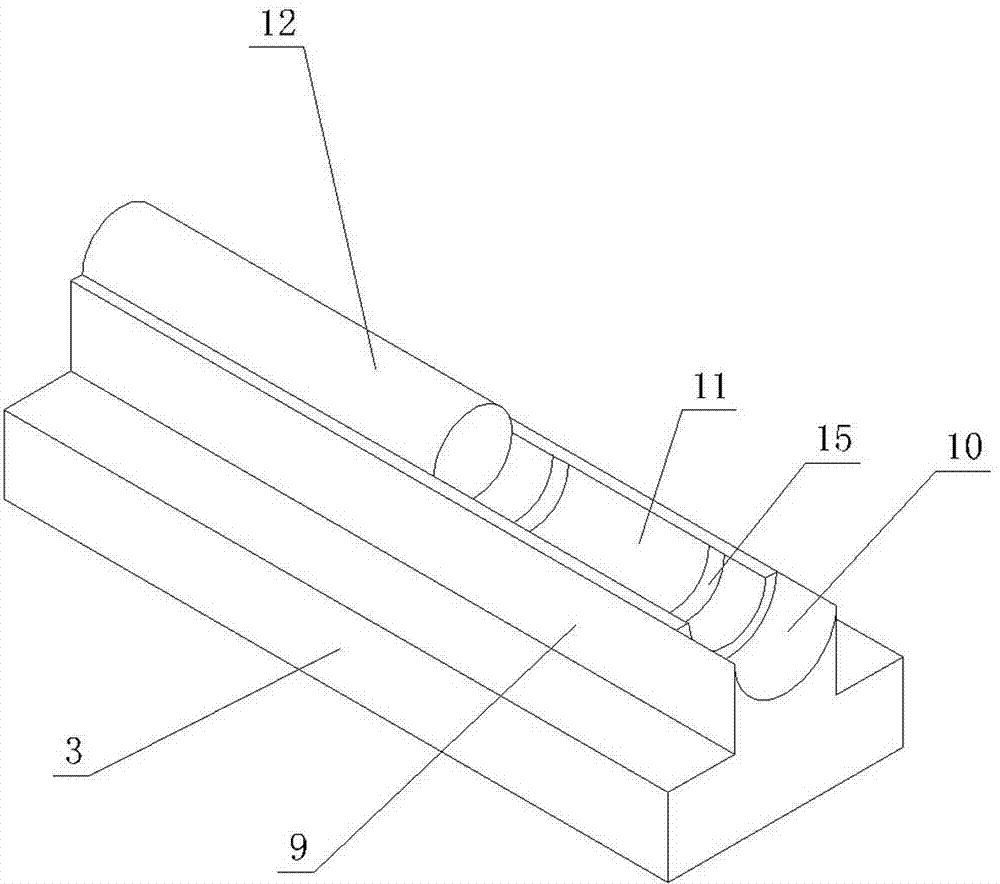

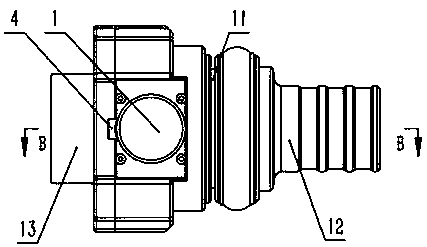

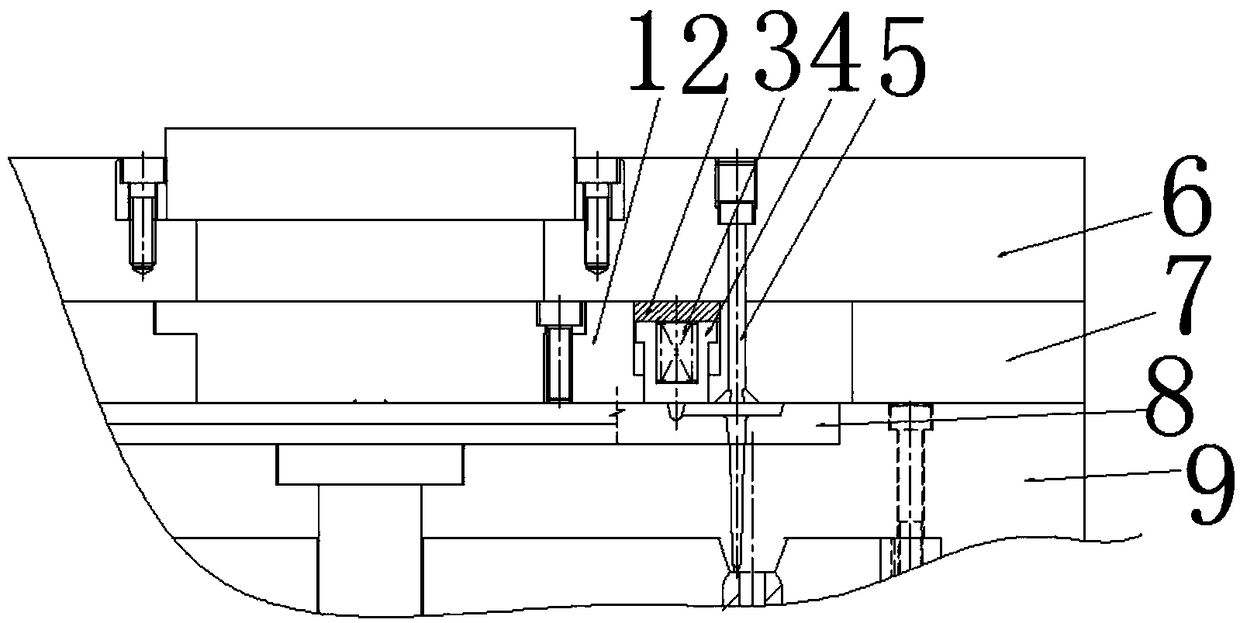

Die capable of continuously punching long screws

ActiveCN103495665AShort tripReduce energy consumptionShaping toolsStripping-off devicesPunchingEngineering

The invention discloses a die capable of continuously punching long screws. The die comprises a front punch (1), an upper die casing (2) and a lower die casing (3). A guide groove penetrating through the upper die casing (2) is arranged on the upper die casing (2), the guide groove is provided with a first upper semicircle groove (6) and a second upper semicircle groove (7), a vertical blanking channel (8) is formed in the upper die casing (2), the lower die casing (3) is provided with a guide protruded stripe, the guide protruded stripe is provided with a first lower semicircle groove (10) and a second lower semicircle groove (11), a long screw head cavity (13) is formed by the first upper semicircle groove (6), the first lower semicircle groove (10), a rear end face of the front punch (1) and an inner hexagonal protrusion (4), and a long screw rod cavity (14) is formed by the second upper semicircle groove (7), a second lower semicircle groove (11) and a blocking column (12). The die is short in die opening and closing stroke, prevents a round bar used for punching the long screws from being bent in a punching process, is high in speed, is high in efficiency and is convenient to demould.

Owner:JIANGSU HAOJIA STAINLESS STEEL STANDARD PARTS

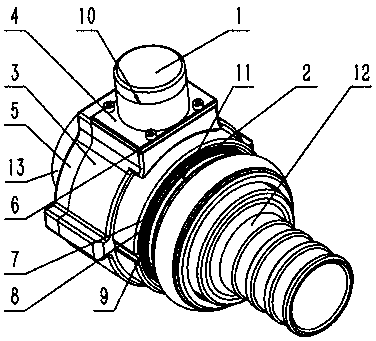

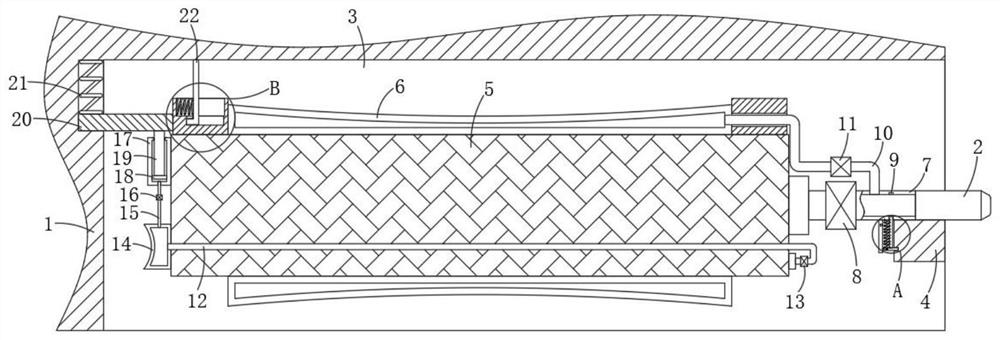

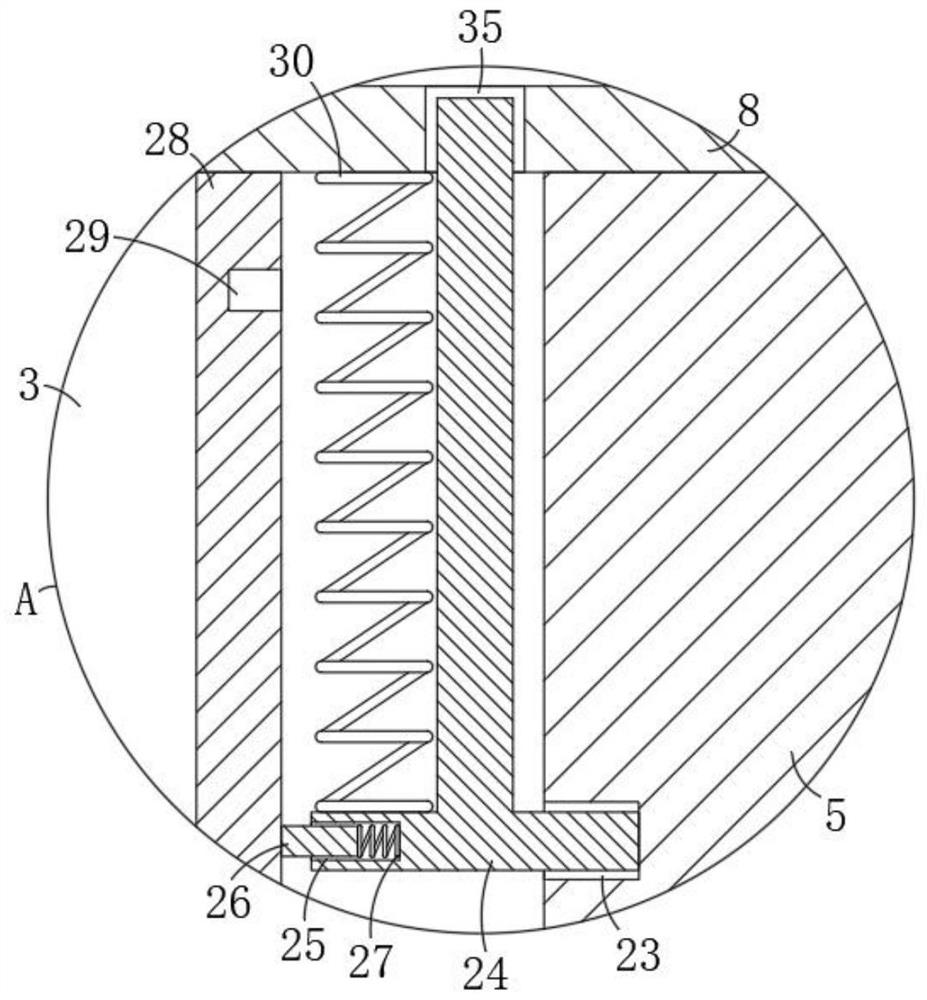

Self-sealing filling valve capable of automatically unlocking at low temperature

ActiveCN102518861ARealize automatic sheddingPromote sheddingOperating means/releasing devices for valvesPistonCircular disc

The invention discloses a self-sealing filling valve capable of automatically unlocking at a low temperature, which belongs to the field of low temperature technology. The filling valve comprises a socket assembly, an air inlet pipeline, an on-off cover, a sealing ring, cylinders, a supporting ring, a connecting cover and a plug assembly. The filling valve employs a plugging-pulling type structure. One end of the plug assembly extends into the socket so that the filling valve is on. A long cylinder of the on-off cover is sleeved on the socket assembly. Three cylinders are distributed around the outside of the socket assembly uniformly. A sealing ring is arranged between the left end cover of the cylinder and a circular flange disc of the on-off cover. The three are connected through bolts. The right ends of the piston rods of the three cylinders are connected with the supporting ring through screw threads. The supporting ring is located on the left side of a plug, and the connecting sleeve is sleeved on the plug assembly and the middle part of the connecting sleeve is a circular disc. The filling valve is a low temperature liquid filling valve which is light in weight, flexible toopen, convenient to operate and high in reliability. The valve is capable of solving a problem so that an aircraft is automatically separated from the filling pipeline after being filled with low temperature liquid on the ground.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

Bottom hanging preventive abandoning weight

The object of the present invention is to provide an anti-hanging bottom discarding pendant which prevents lead pendants from hanging to the bottom during fishing. The present invention is realized in this way, and it is characterized in that it is made up of pressure shedding pin, ring pendant and fishing line. Two pin hanging holes under pressure are set on the side, a tension safety ring is set in the center of the upper end of the three-ring pendant, and a hanging buckle and a buckle sleeve are set at one end of the fishing line. The two pin hanging holes of the ring pendant are under pressure and fall off. Cut one end of the fishing line into a double line, fasten the buckle according to the distance between the upper line hole and the line cylinder, and insert the front end of the buckle sleeve into the upper line hole in turn. After the thread hole and the lower hole, the buckle is placed on the hanging thread cylinder. The invention utilizes the principle of anti-hanging bottom abandonment pendant falling off under reverse force, and realizes the purpose of protecting the main line, the hook group and the hooked fish.

Owner:翟凤平

Flushing-free urine-feces separation, collection and resource utilization system for buildings

ActiveCN106214045AImprove processing efficiencyImprove utilization efficiencyBathroom accessoriesDomestic plumbingResource utilizationAnimal feces

The invention relates to a flushing-free urine-feces separation, collection and resource utilization system for buildings. A urine discharge main pipe, a feces discharge main pipe and an exhaust pipe which are separate and independent are arranged in a multistory building, the bottom ends of the urine discharge main pipe and the feces discharge main pipe are respectively communicated with the tops of a urine collection container and a feces collection container, and the tops of the urine collection container and the feces collection container are communicated with the exhaust pipe; each urine-feces separation toilet is provided with a urine pipeline and a feces pipeline which are separate and independent, bag hanging mechanisms for packing feces are respectively buried inside two sides of the seating surface at the upper end of each toilet body, a reset spring is arranged on the lower portion of each bag hanging mechanism, each bag hanging column is ejected out of the corresponding seating surface by the corresponding reset spring for hanging packing bags, and the urine and feces collection containers can perform fermentation and finished manure treatment. Water resources are saved, resource treatment and utilization efficiency of urine-feces manure is highly increased, and the system has great social value, ecological value and economic value and broad application prospect.

Owner:云南八卫科技有限公司

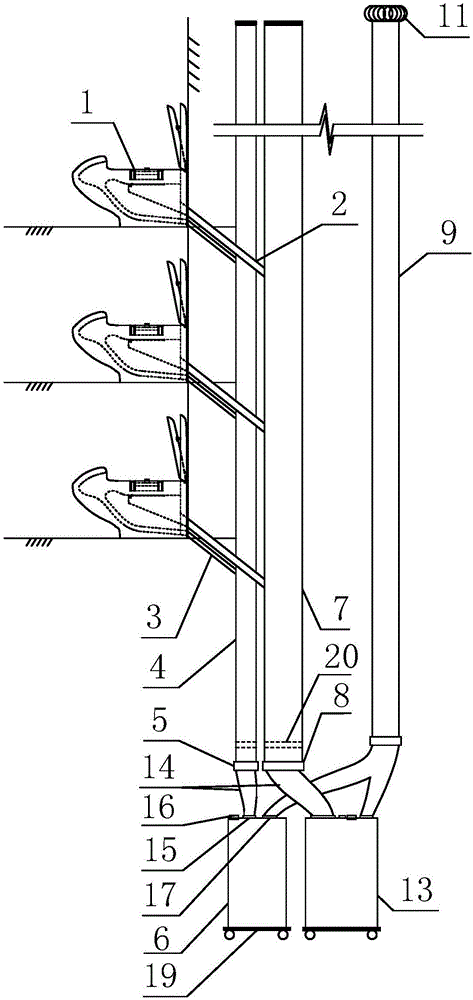

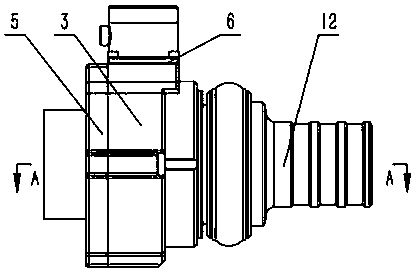

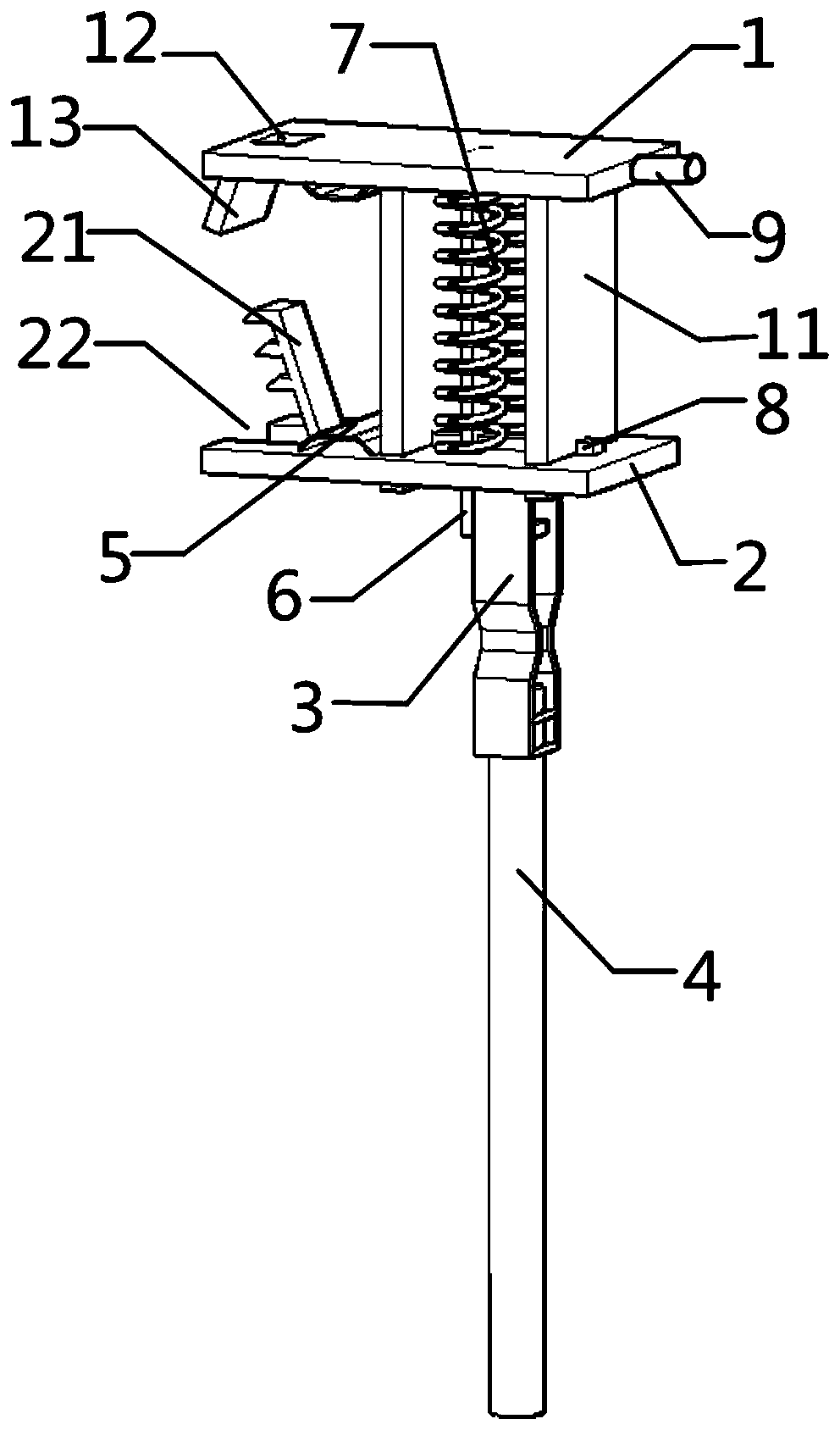

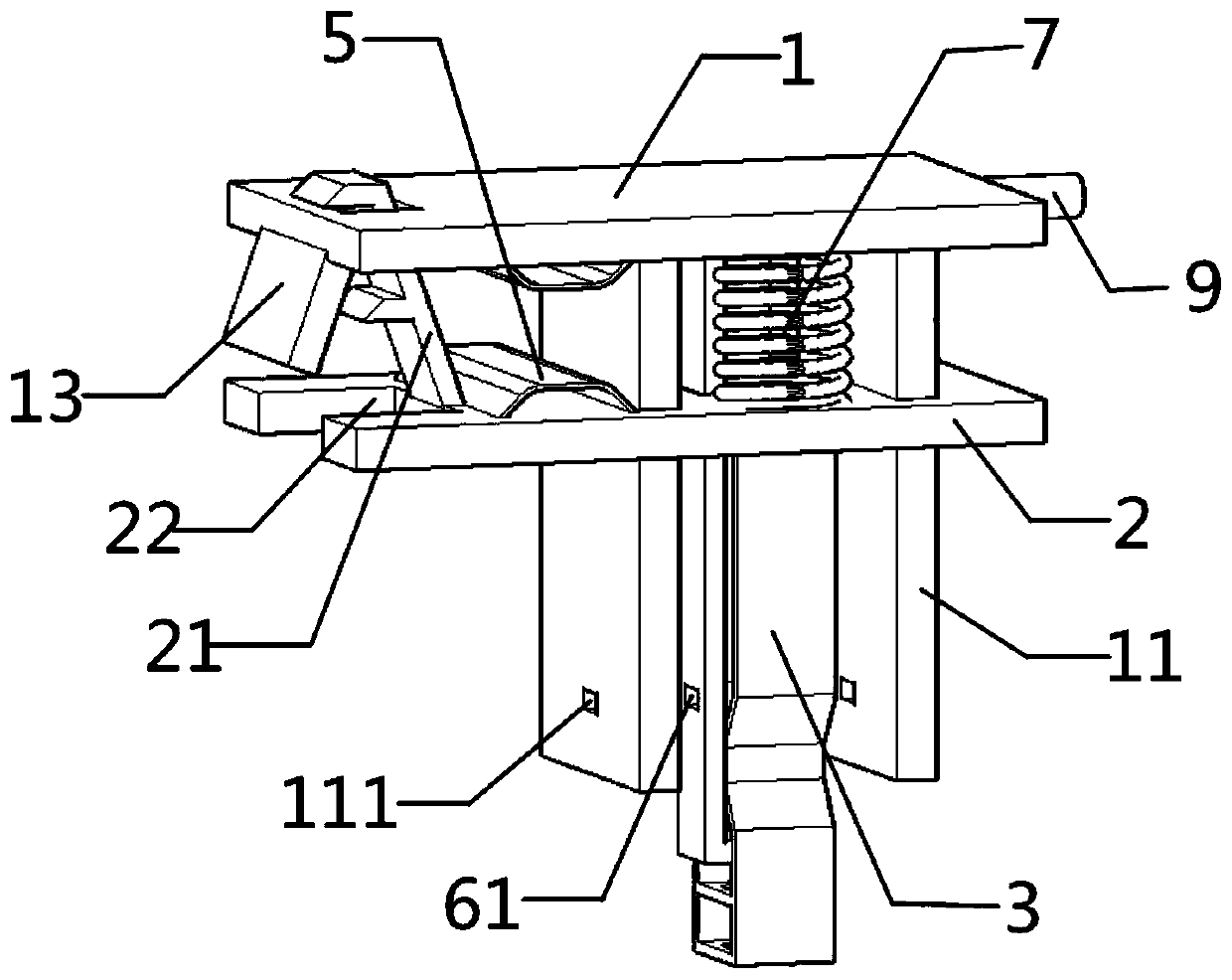

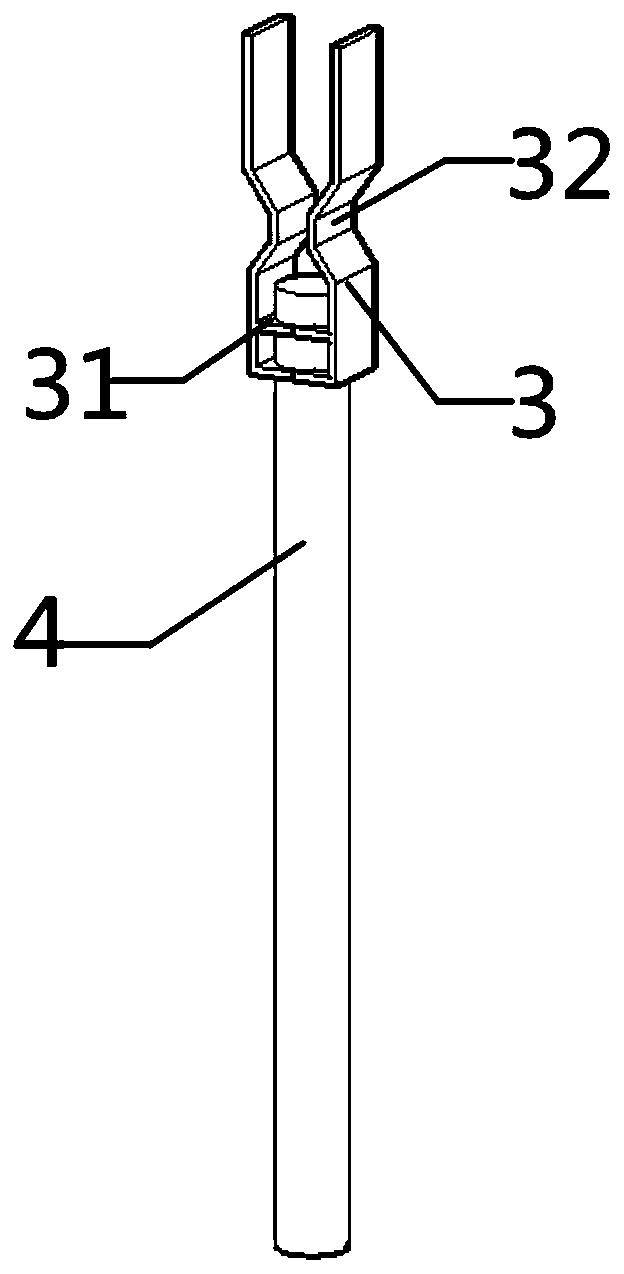

Automatic hose disengagement device of fire-fighting robot

The invention discloses an automatic hose disengagement device of a fire-fighting robot. The device is composed of a waterproof cover, an inner ring, an outer sleeve, an electromagnetic valve supporting frame, an outer sleeve blockage cover, a silica gel pad, a ball blockage cover, a compression spring, steel balls, an electromagnetic valve, a detacher, a water hose connector and a rapid port assembly. The structural way of reciprocating operation between the inner ring and the outer sleeve is adopted, sliding way balls are installed inside, stable work of the hose disengagement device is sufficiently ensured, the spring is arranged between the inner ring and the outer sleeve, the inner ring and the outer sleeve are moved repeatedly through opening and closing of the electromagnetic valveto spring out of the detacher, and therefore automatic disengagement of a fire fighting hose is achieved. The device has the advantages that the structure is simple and compact, occupied space is small, detaching is convenient, and the hose disengagement success ratio is high. Work is stable and reliable, and the fault ratio is low.

Owner:CITIC HIC KAICHENG INTELLIGENT EQUIP CO LTD

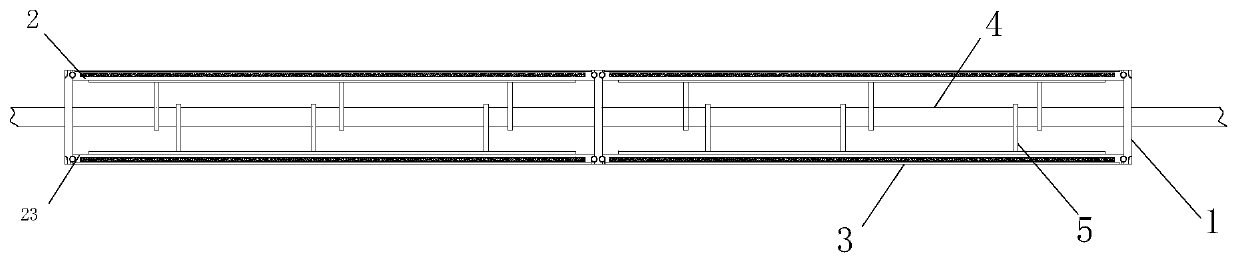

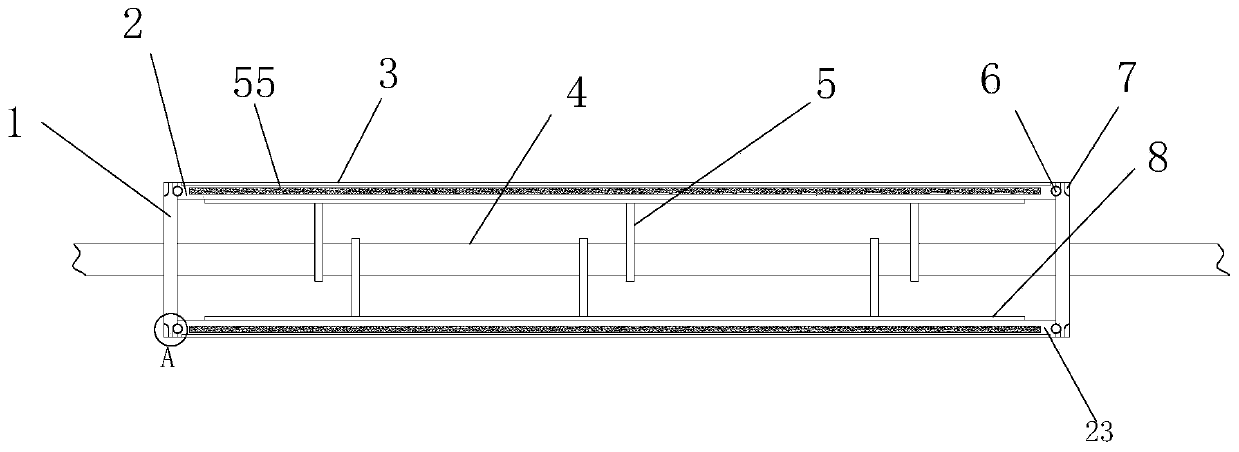

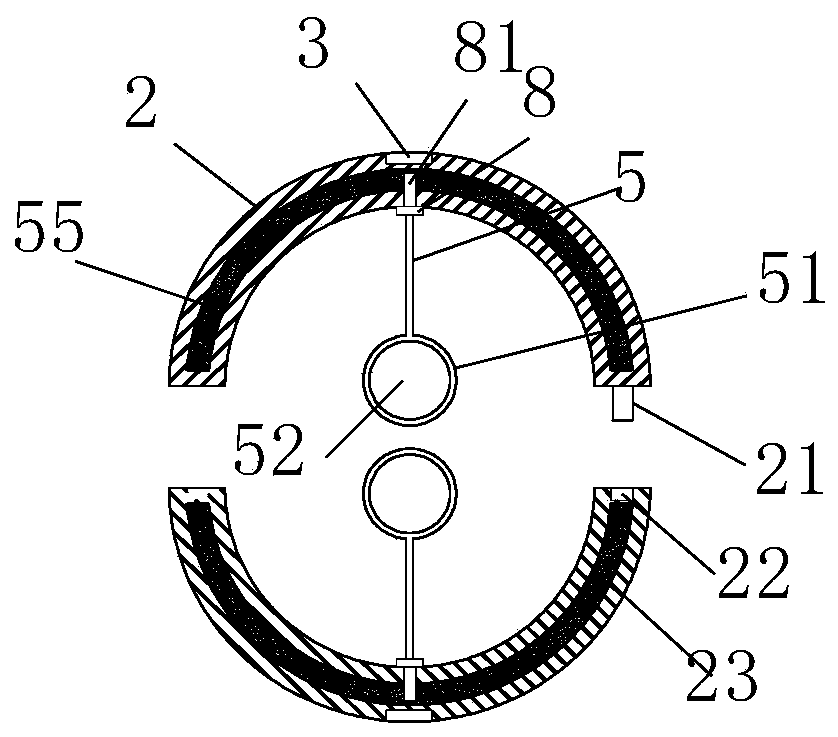

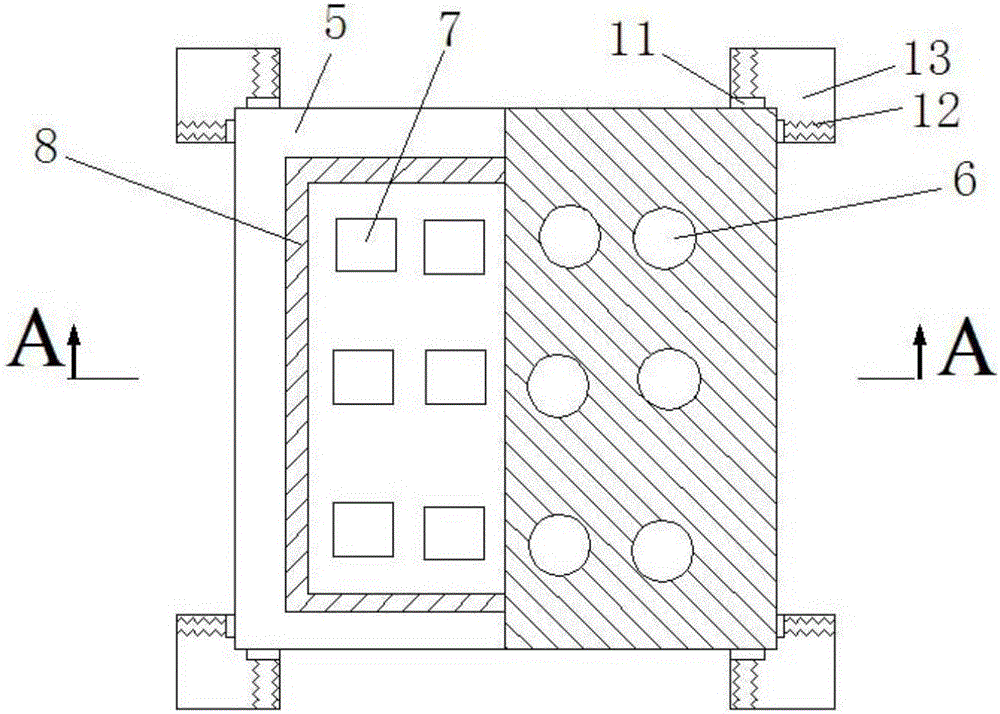

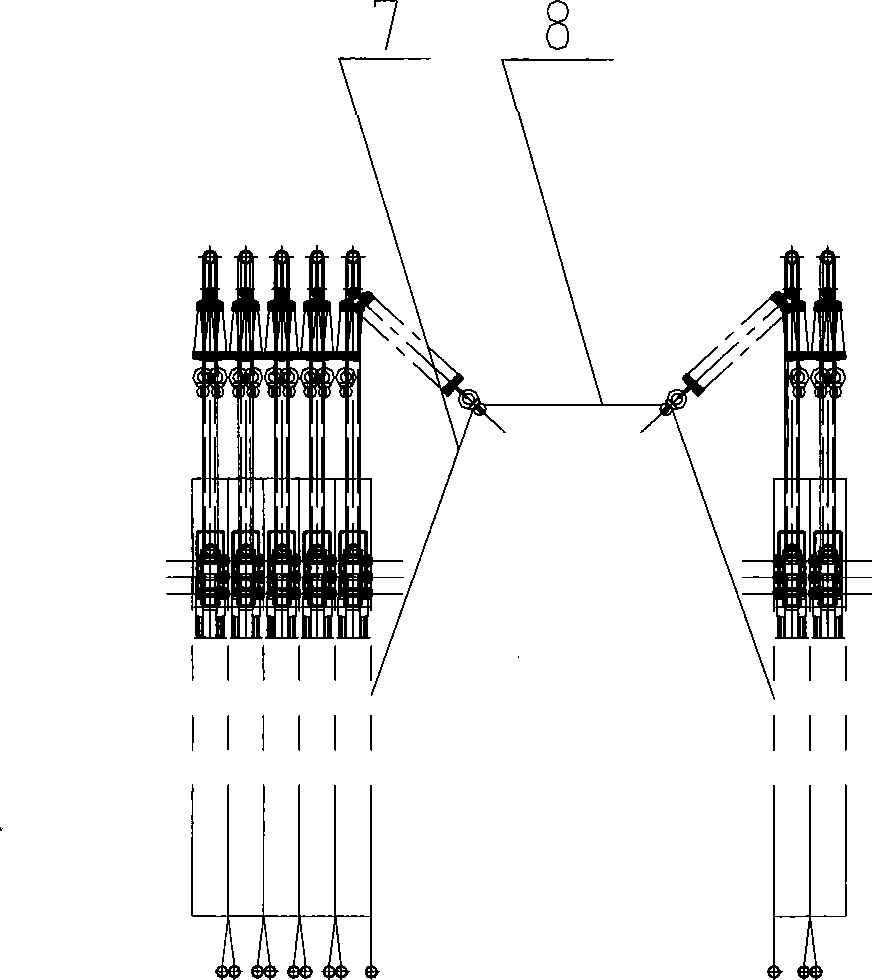

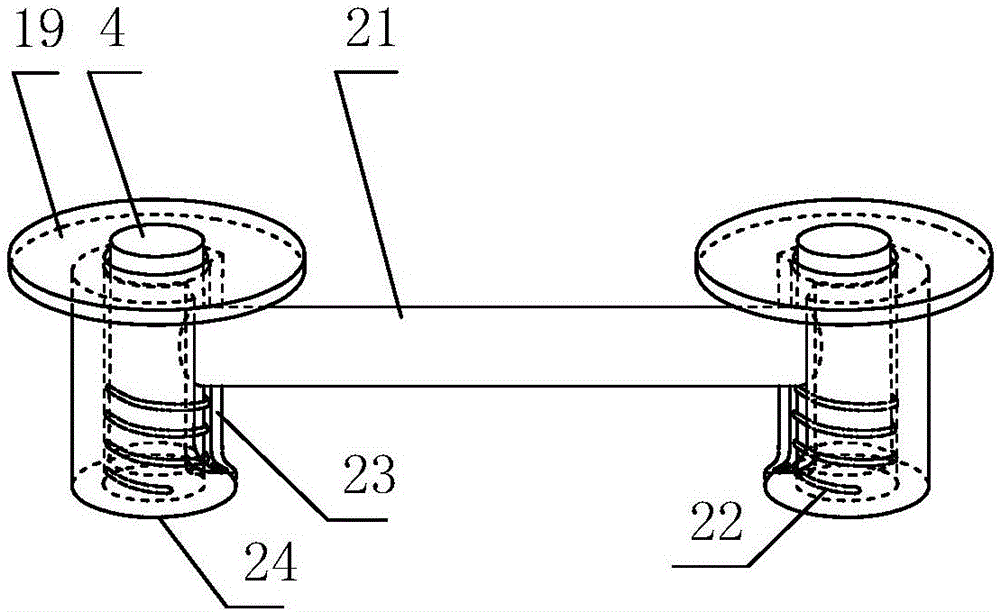

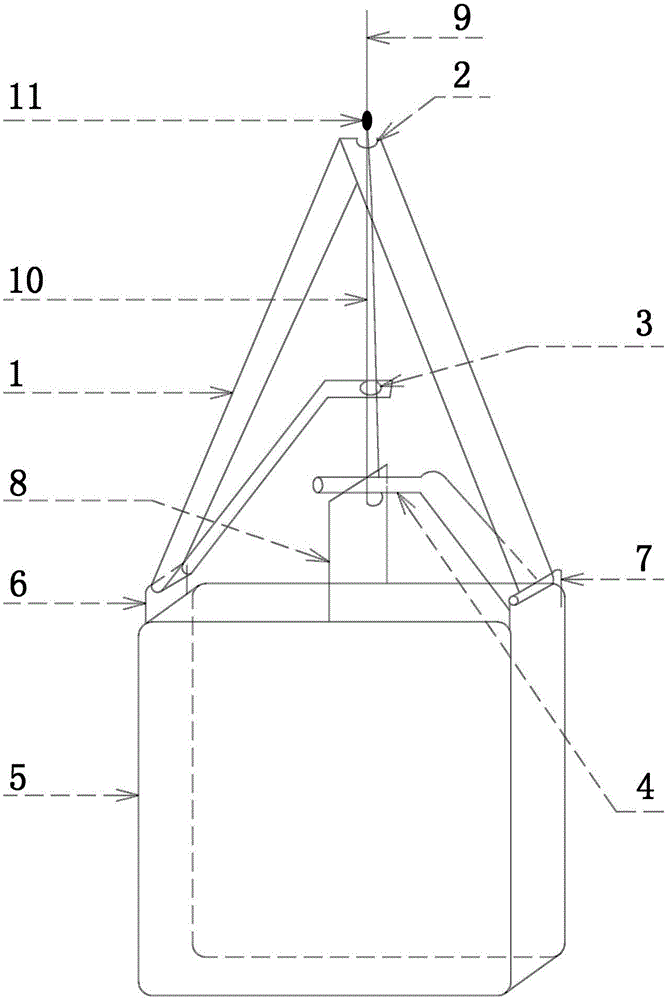

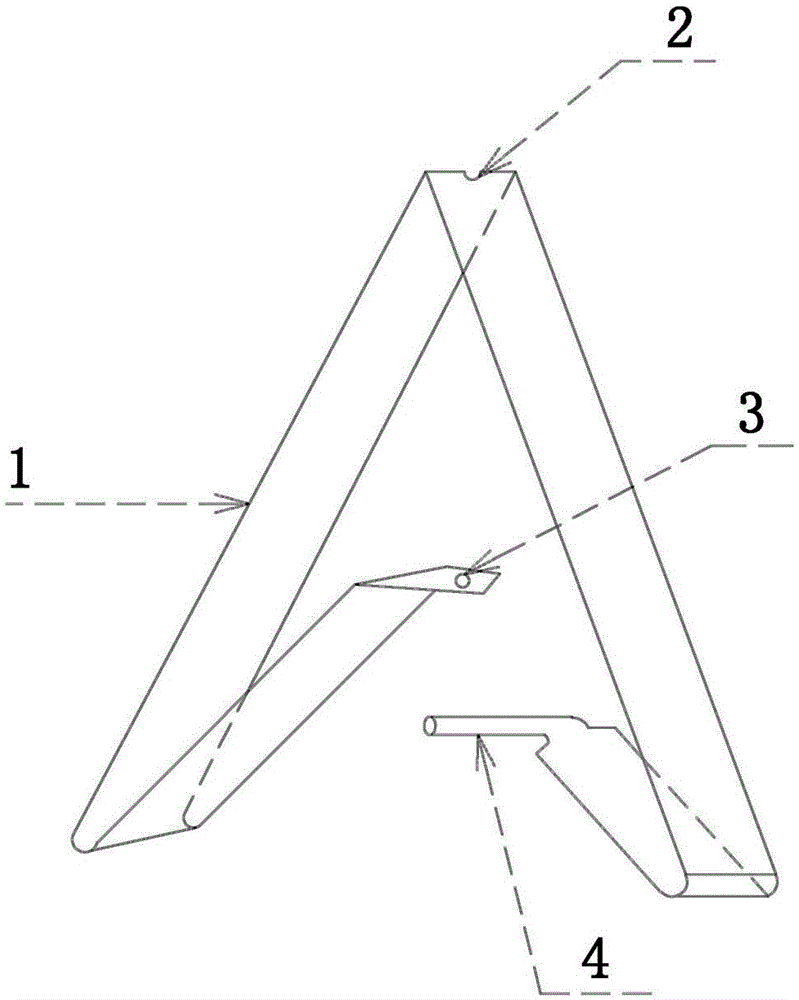

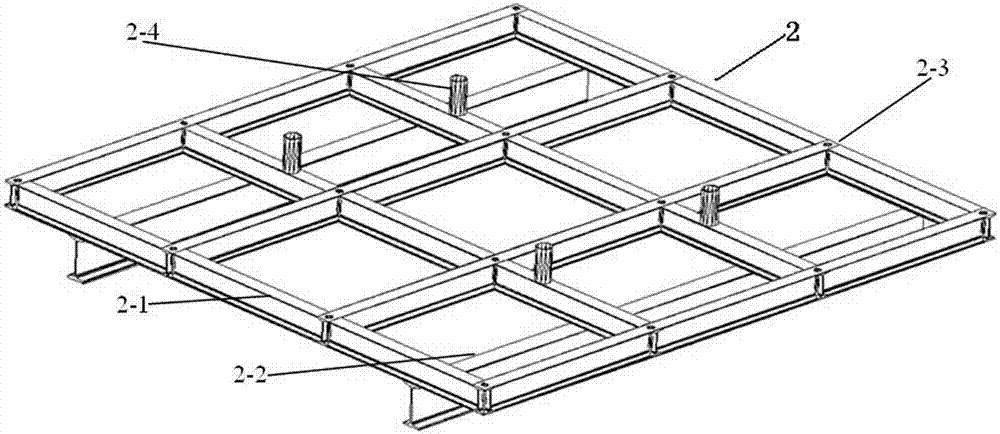

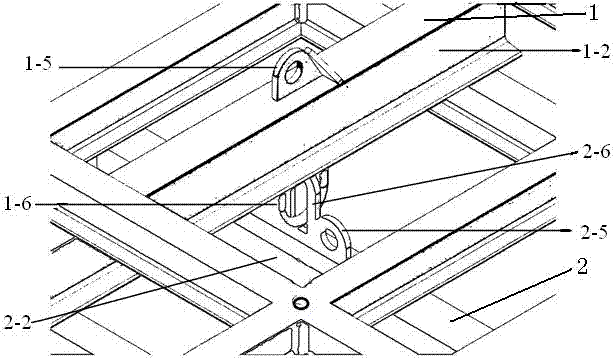

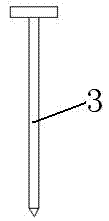

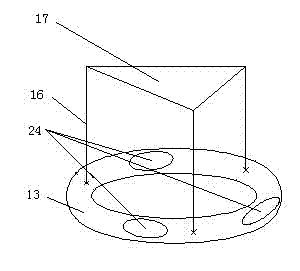

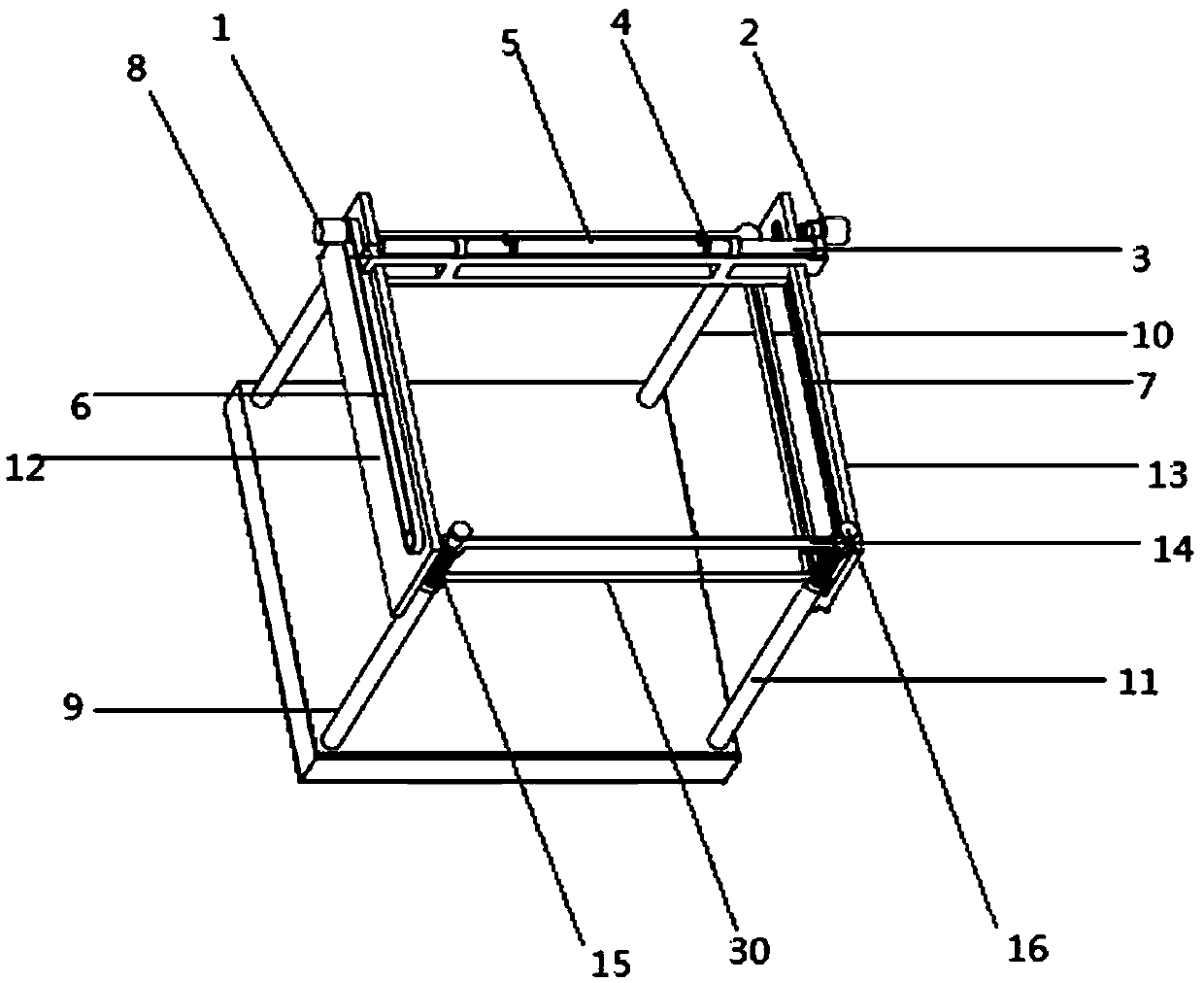

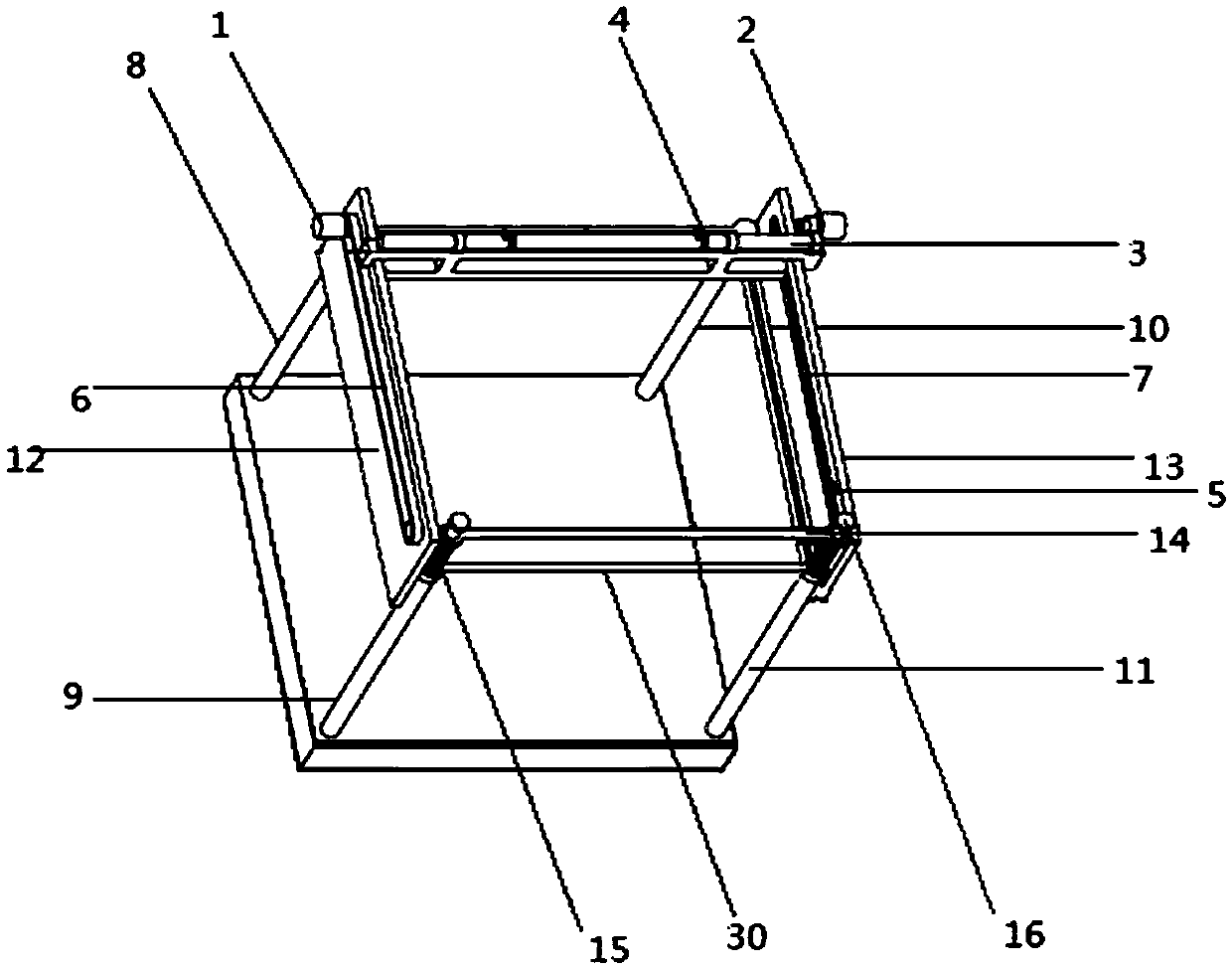

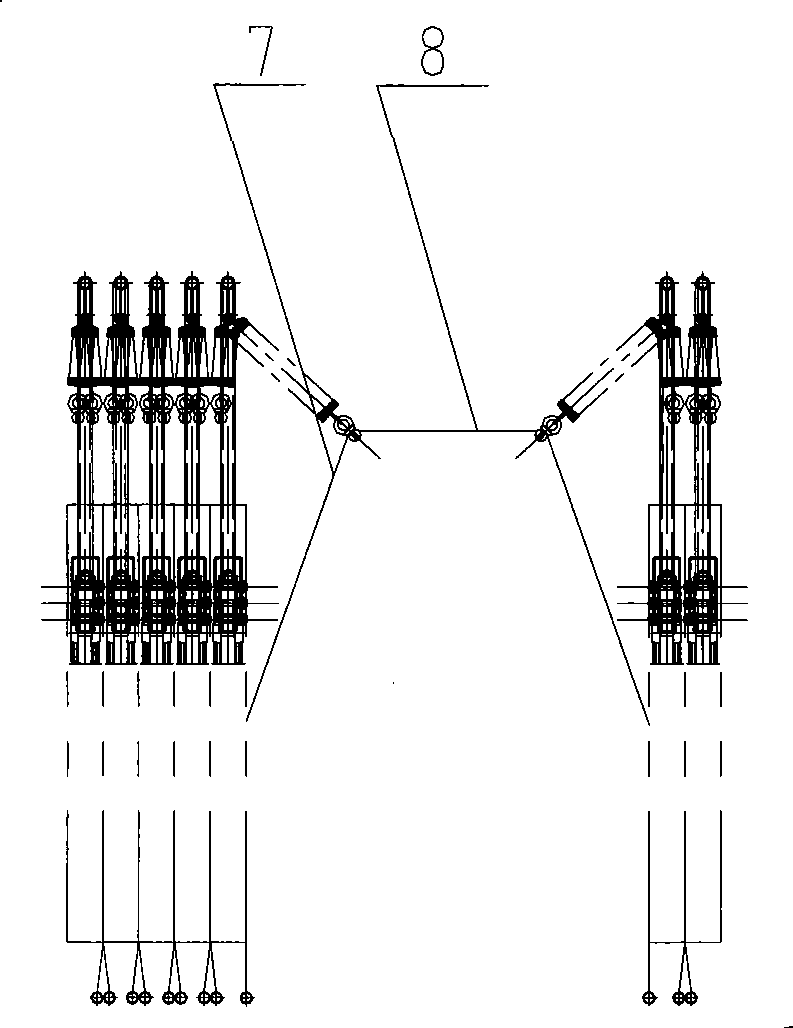

Special lifting appliance for dual-I-shaped water-permeable framework

ActiveCN103588085ARealize automatic sheddingAutomatic shedding reachesLoad-engaging elementsStructural engineeringEngineering

The invention discloses a special lifting appliance for a dual-I-shaped water-permeable framework, relates to a novel bunching fixed-point throwing lifting appliance for a dual-I-shaped water-permeable framework, and particularly relates to a lifting appliance for suspending the water-permeable framework for realizing the purpose that the framework can fall off automatically. The special lifting appliance for the dual-I-shaped water-permeable framework consists of an upper truss, a lower truss and bolts, wherein the upper truss and the lower truss are combined to form an integral structure; the upper truss comprises an upper truss framework, upper truss cross beams, upper truss bolt holes, upper truss spacing pipes, upper truss lifting buckles and upper truss spacing rings; the upper truss framework is a Sudoku-shaped framework formed through welding I-shaped steel; the upper truss cross beams are welded below the upper truss framework; the upper parts of the upper truss cross beams are positioned in the middles of the squares on two sides, and are welded with the two upper truss lifting buckles; the upper truss spacing rings are welded below the upper truss cross beams; the upper truss bolt holes are formed in the upper truss framework, and are welded with four upper truss spacing pipes; the lower truss comprises a lower truss framework, lower truss cross beams, lower truss bolt holes, lower truss spacing pipes, lower truss lifting buckles and lower truss spacing rings.

Owner:NANJING CHANGJIANG WATERWAY ENG BUREAU

Sheathed circular truncated cone type filter press

ActiveCN102728119AImprove pressure resistanceSolve the pressure resistanceMembrane filtersStationary filtering element filtersStructural engineeringFilter press

The invention discloses a sheathed circular truncated cone type filter press which comprises an outer circular truncated cone-shaped sleeve and an inner circular truncated cone-shaped sleeve, wherein the inner circular truncated cone sleeve is arranged at the middle part of the outer circular truncated cone sleeve; a filter press rubber sleeve is arranged on the inner wall of the outer circular truncated cone-shaped sleeve; a plurality of small holes are formed in the inner circular truncated cone-shaped sleeve; filtering cloth is arranged on the outer wall of the inner circular truncated cone-shaped sleeve; air inlet pipes are arranged at two sides of the outer circular truncated cone-shaped sleeve respectively; an inner sleeve water outlet pipe is arranged at the bottom of the inner circular truncated cone-shaped sleeve; a discharging plate is arranged at the upper part of a circular truncated cone-shaped filtering chamber; a plurality of discharging holes are formed in the discharging plate; a feeding pipe which is communicated with the inside part of the outer circular truncated cone-shaped sleeve is arranged at one side an upper cover; high pressure air inlet pipes which are respectively communicated with the inside parts of the inner circular truncated cone-shaped sleeve and the outer circular truncated cone-shaped sleeve are arranged at the other side of the upper cover; and a water outlet pipe of the filter press machine connected with an inner sleeve water outlet pipe is arranged on a bottom cover. The filter press dehydration is implemented through high pressure gas; fine coal grains are retained inside the circular truncated cone-shaped chamber to be formed as filter cakes; the filter cakes are discharged by opening the bottom cover automatically; the whole filter press process is simple and easy to implement with few maintenance and high efficiency; the solid and liquid separation effect is good; and the energy consumption is low.

Owner:CHINA UNIV OF MINING & TECH

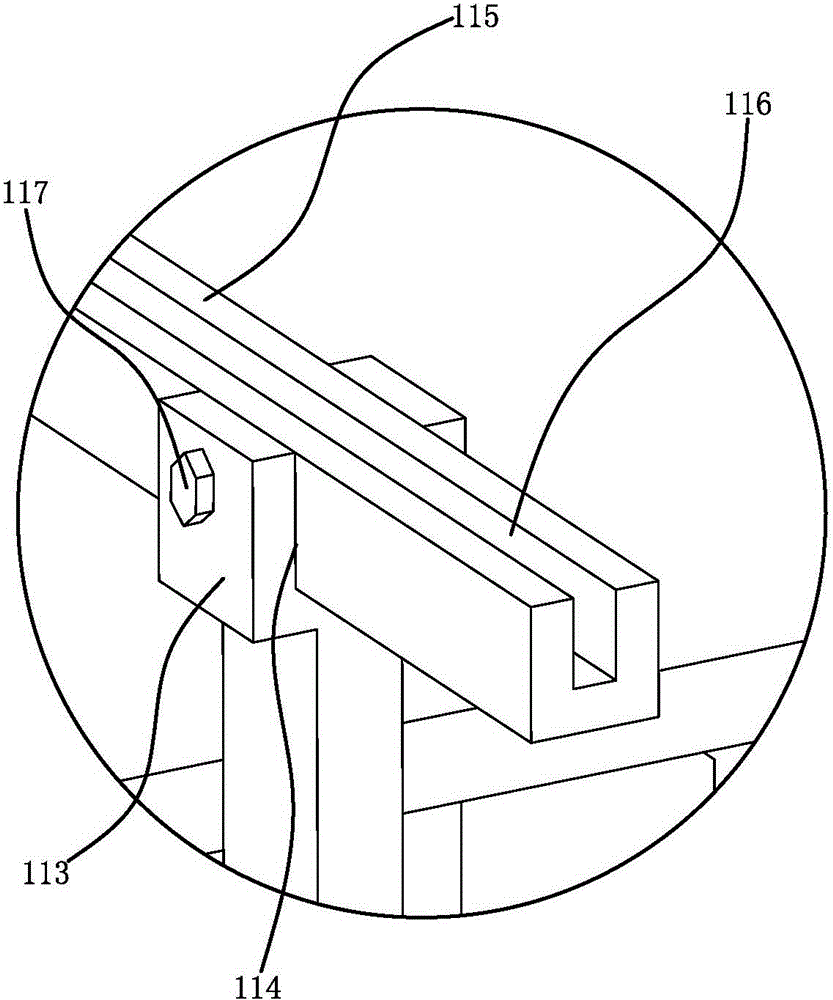

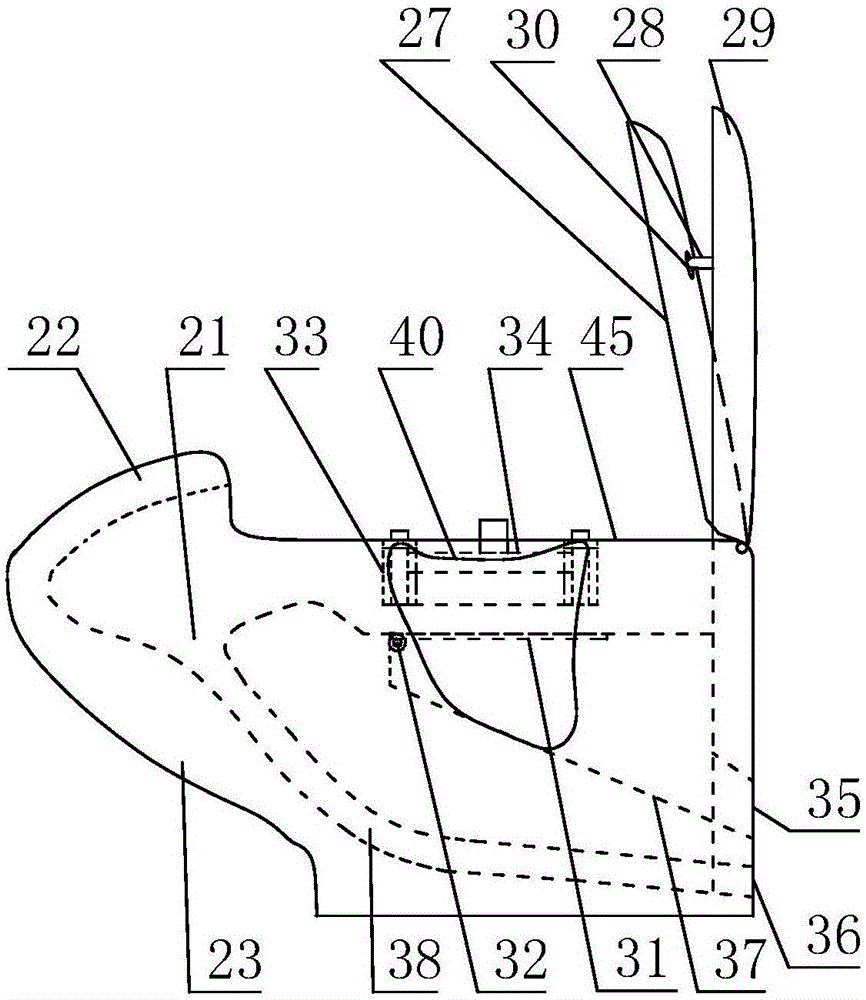

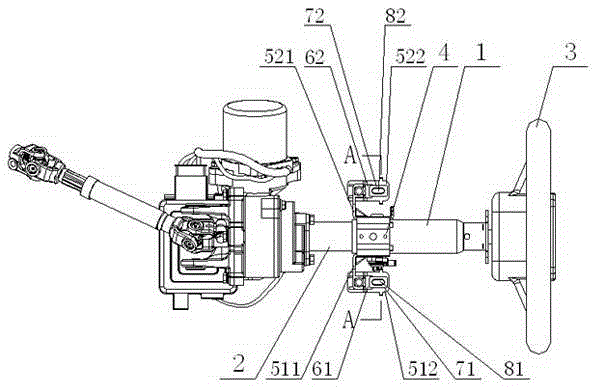

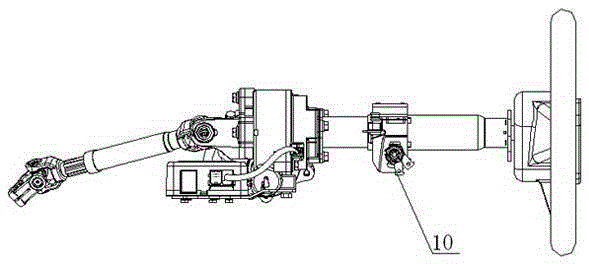

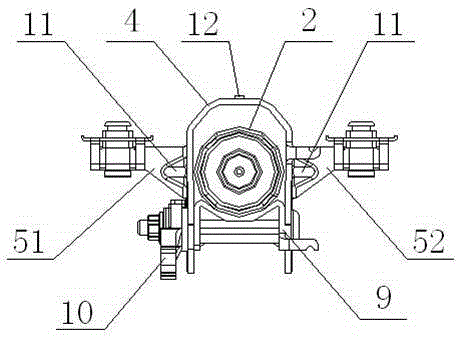

Collapse-type electric power steering column installing support

InactiveCN105313945AAvoid damageRealize automatic sheddingSteering columnsElectric power steeringInterference fit

The invention discloses a collapse-type electric power steering column installing support. The collapse-type electric power steering column installing support comprises a steering column upper transmission shaft connected to the rear end of a steering column. The connecting portion of the steering column upper transmission shaft and the steering column is sleeved with a support base which is fixed to the steering column upper transmission shaft. A left support lug and a right support lug are connected to the two sides of the support base respectively, the cross section of the left support lug and the cross section of the right support lug are of C-type structures, and pulling-falling block sliding grooves are formed in the left support lug and the right support lug respectively and arranged in the axis direction of the steering column upper transmission shaft. Support pulling-falling blocks are installed inside the left and right pulling-falling block sliding grooves respectively in an interference fit mode; installing bolt holes matched with an instrument panel support in a connected mode are formed in the left and right support pulling-falling blocks respectively. The safety of a steering wheel in the collision process is improved, and the collapse-type electric power steering column installing support is sensitive in reaction, good in reliability and convenient to install.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

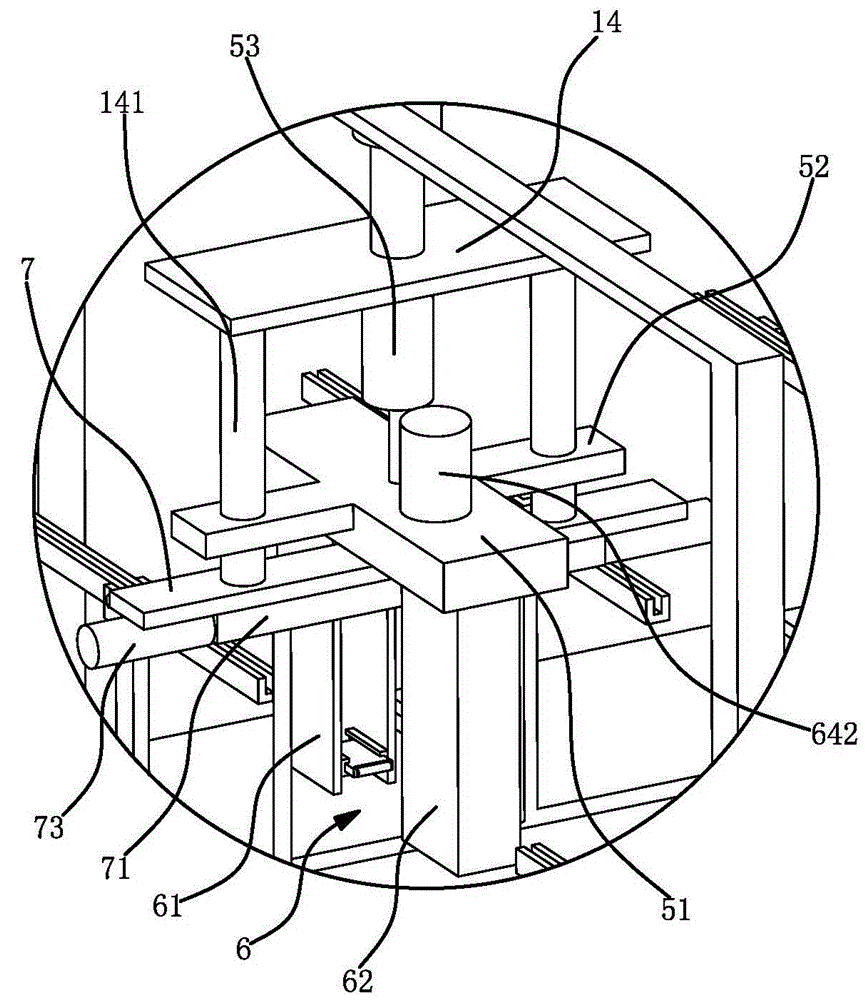

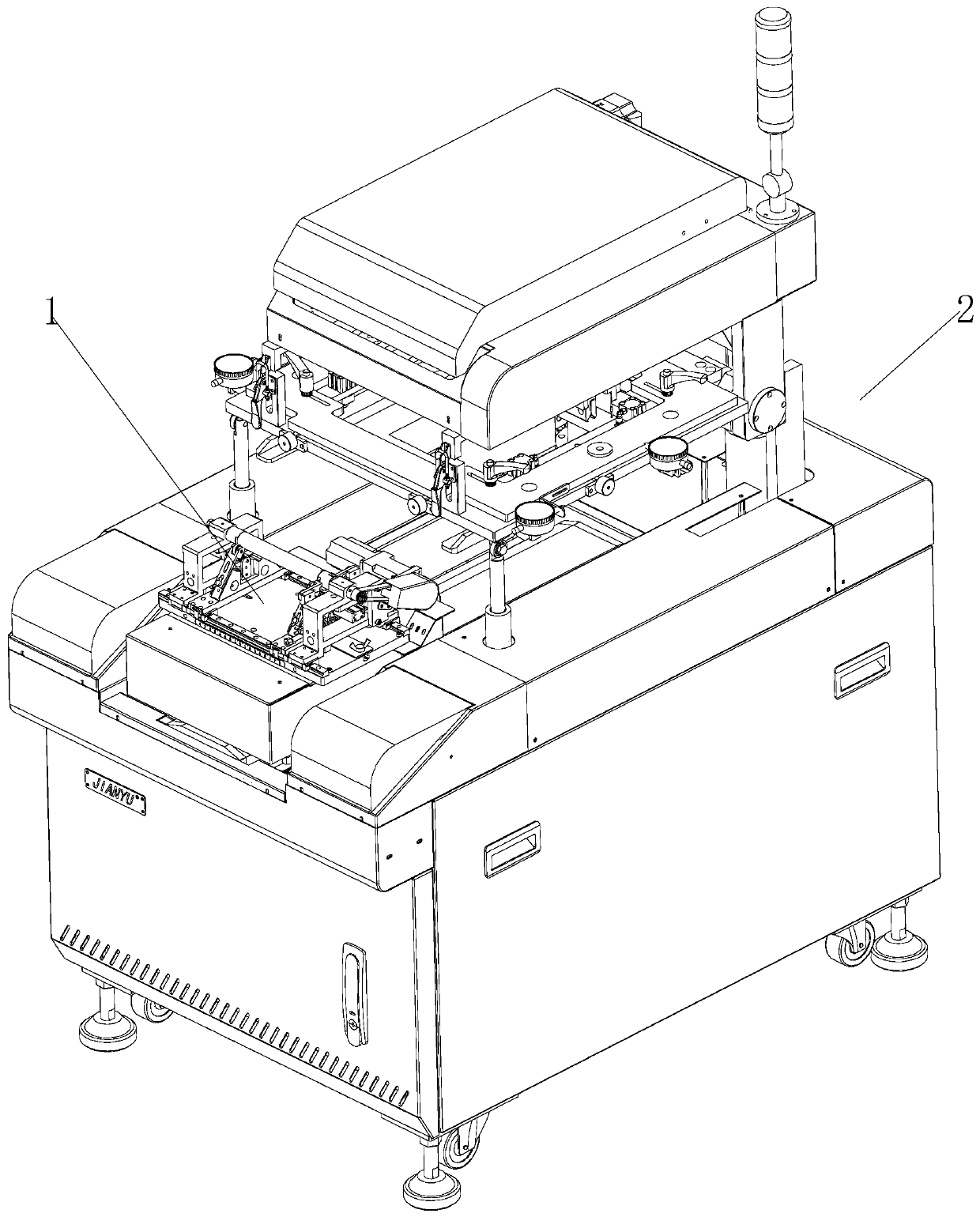

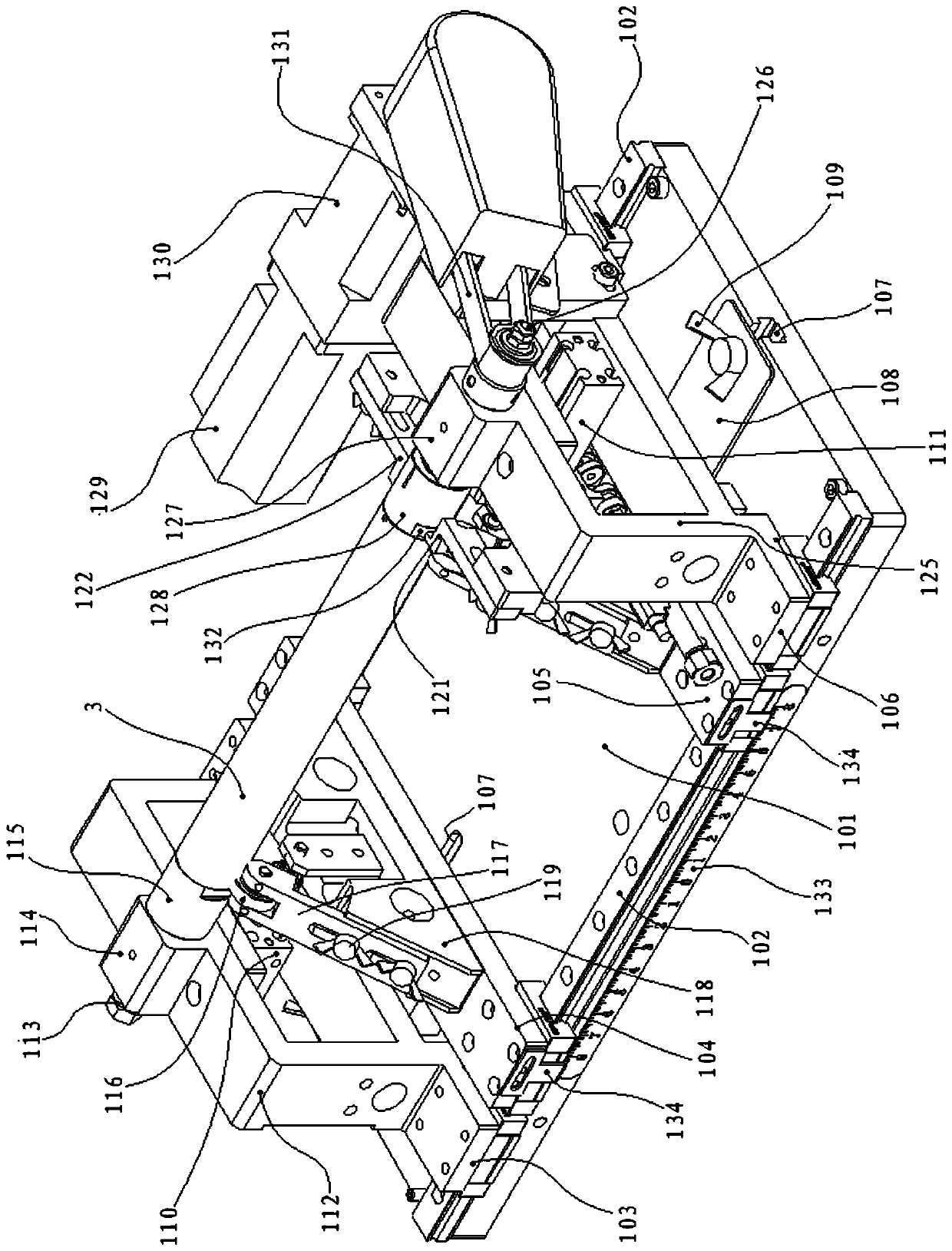

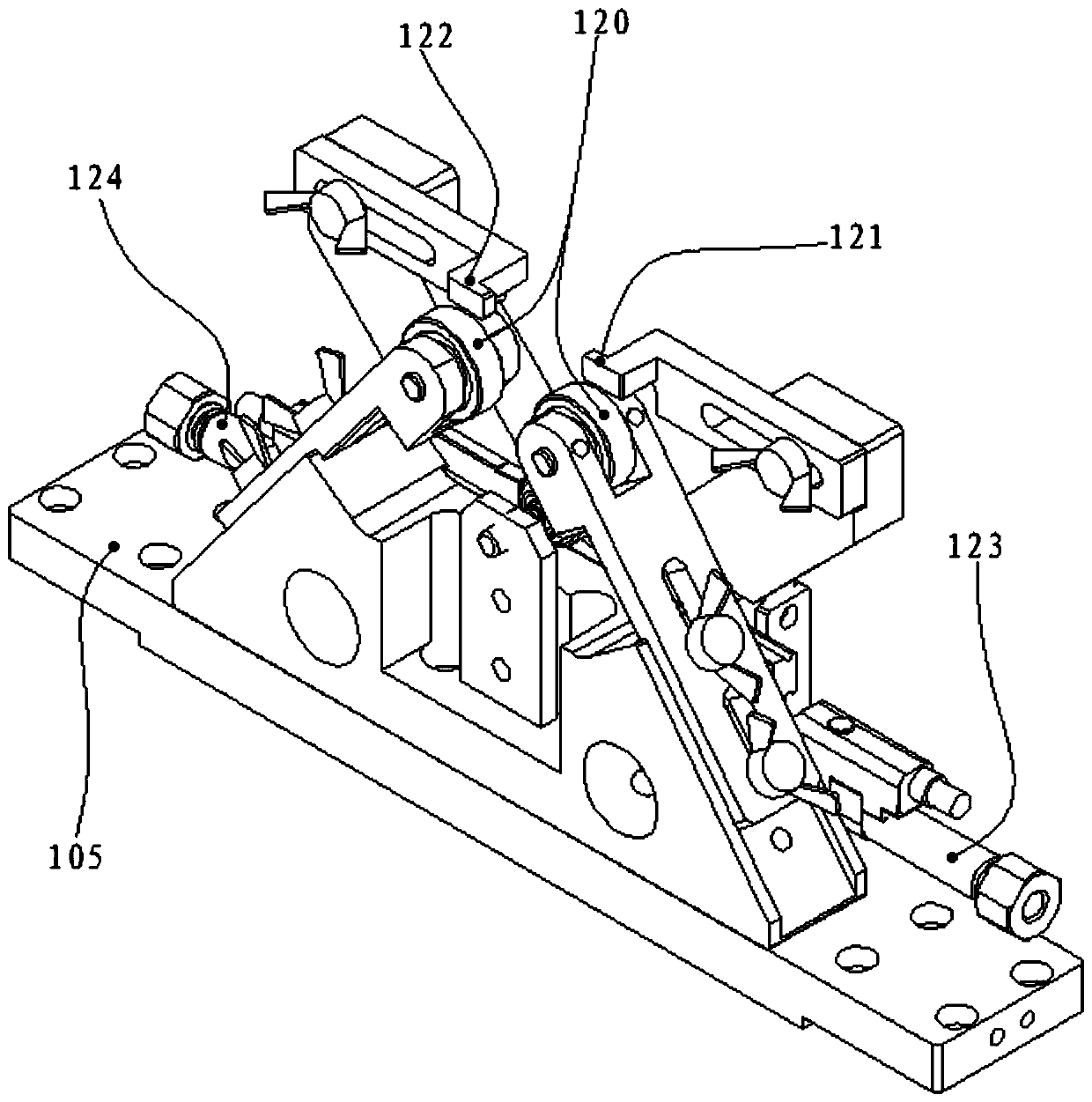

Printed material bearing platform for curved surface printing

ActiveCN110641138AEasy accessTake and unload position, convenient for multiple printingScreen printersStructural engineeringMechanical engineering

The invention discloses a printed material bearing platform for curved surface printing. The printed material bearing platform comprises a linear guide rail arranged on a substrate, and four sliding seats are sequentially arranged on the linear guide rail from left to right. The second sliding seat and the third sliding seat are movably connected with the substrate through locking assemblies. Thefirst sliding seat and the second sliding seat are connected through an air cylinder, and the third sliding seat and the fourth sliding seat are connected through an air cylinder. A left rotary moduleis arranged on the first sliding seat, and a left bearing wheel set is arranged on the second sliding seat. A right bearing wheel set is arranged on the third sliding seat, and a right rotary moduleis arranged on the fourth sliding seat. A right rotary shaft is connected with a rotary driving mechanism. A printed material actively rotates, the rotating initial position and end position and the taking and placing positions of the printed material can be precisely determined, repeated printing is convenient, and high precision is guaranteed. Feeding is convenient and accurate, the printed material can automatically fall off from a clamp, and taking and placing are convenient; and the printed material bearing platform can adapt to processing of printed materials of multiple specifications.

Owner:CHANGSHA JIANYU SCREEN PRINTING MACHINERY

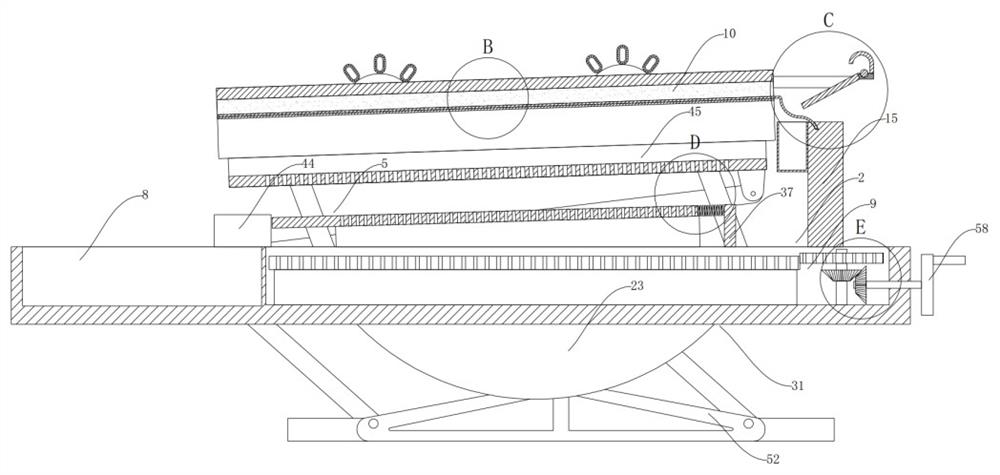

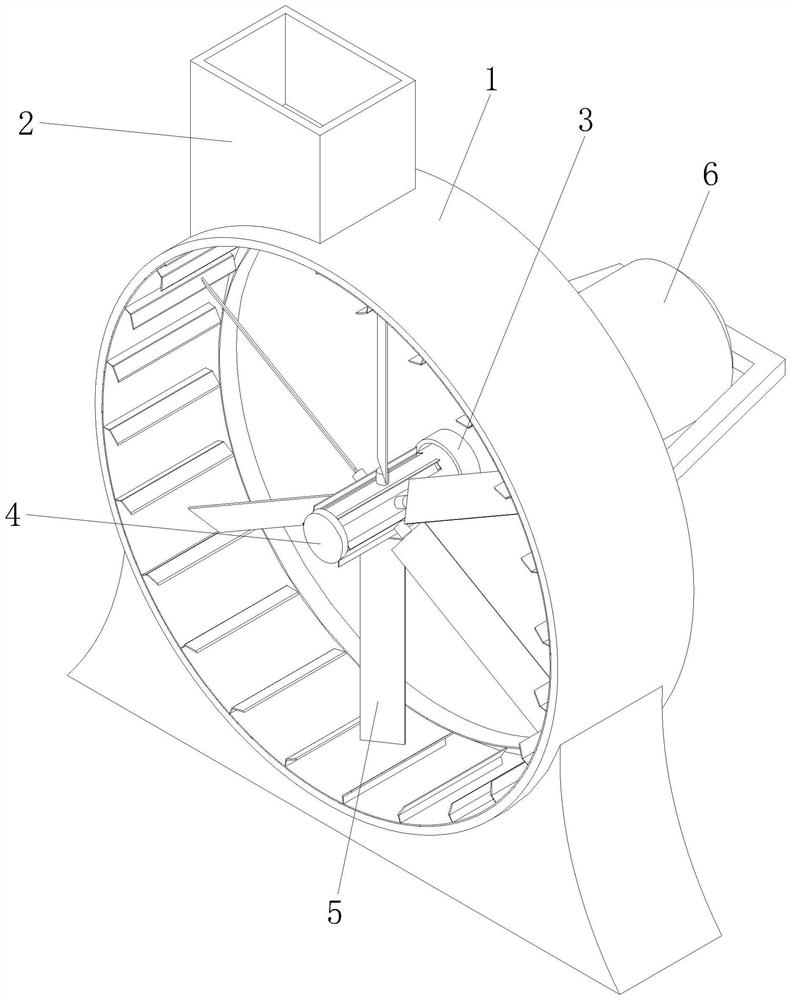

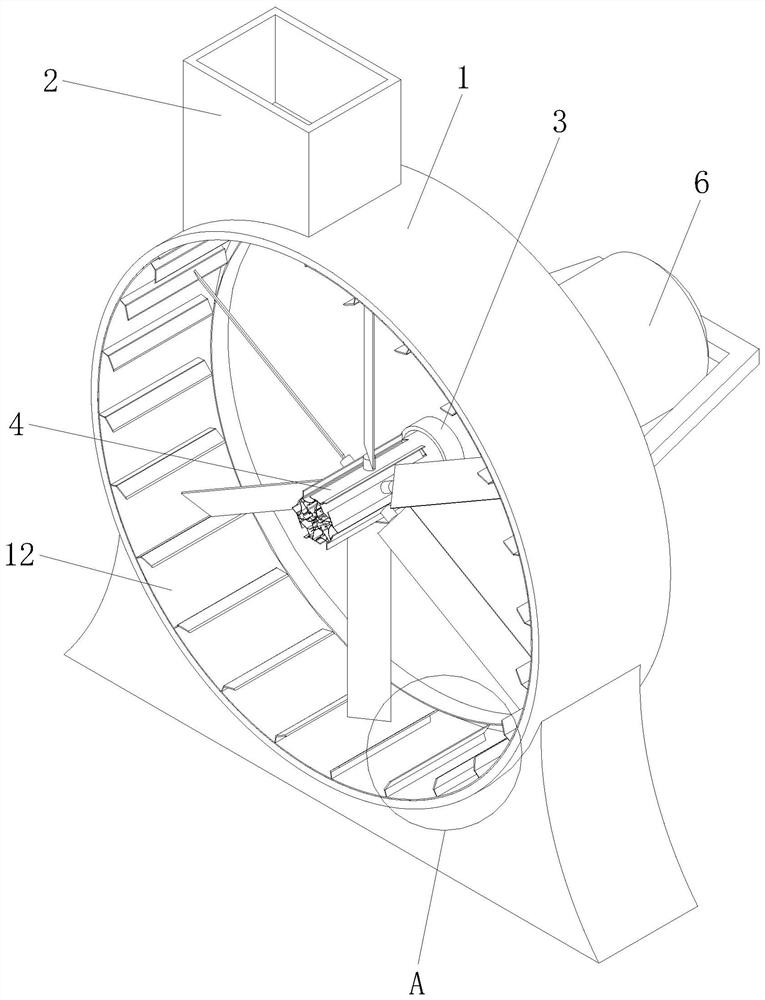

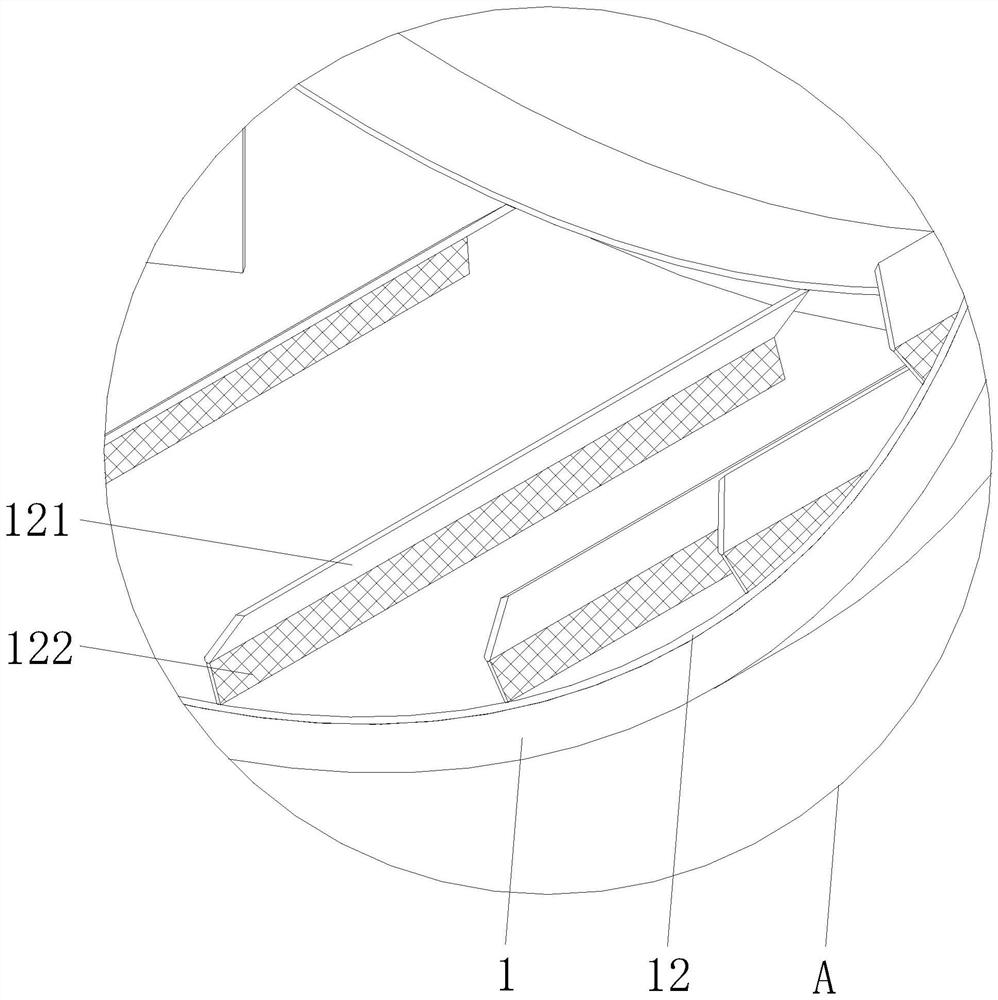

Hidden lossless transition type self-resetting dust suppression ore screening machine

ActiveCN113600478ASolve contradictory technical problems that will not bounce aroundRealize automatic sheddingSievingScreeningMining engineeringRockdust

The invention discloses a hidden lossless transition type self-resetting dust suppression ore screening machine. The hidden lossless transition type self-resetting dust suppression ore screening machine comprises a hidden ore lossless transition unit, a self-resetting dust preliminary suppression passive collection unit, a passive action type vibration conversion dust fall unit, a primary vibration screening unit, a gravity conversion type passive vibration secondary screening unit, a circulating movement advancing unit, a supporting operation platform, an ore harvesting groove and a collection unit operation groove. The invention belongs to the field of ore screening equipment, and particularly relates to the hidden lossless transition type self-resetting dust suppression ore screening machine. According to the hidden lossless transition type self-resetting dust suppression ore screening machine, under the condition that no sensor is used, part of splashing ore can still fall off automatically after being collected, under the condition that no mechanical transmission mechanism is used, splashing ore can still be grabbed, and the contradictory technical problem that in the prior art, the aims of screening core and also guaranteeing that ore does not fly everywhere in the screening process are hard to achieve is solved.

Owner:徐州安瑞机械制造有限公司

Honeycomb dam slope protection structure

ActiveCN108221841ARealize automatic sheddingEliminate damageCoastlines protectionHydraulic engineering apparatusHoneycombEngineering

The invention provides a honeycomb dam slope protection structure which comprises a bottom plate. The honeycomb dam slope protection structure has the advantages that the destructive effect of ice thrust, ice pullout, floating ice impact and the like generated by icing of a reservoir in winter on the upstream dam slope of a dam can be effectively reduced, a dam slope panel is effectively protected, an ice cover can automatically fall off, and the danger of manual ice drilling is avoided. The structure is long in service life and low in manufacturing cost and can be used for protecting cold region reservoir dam slopes and river channel bank slopes, and safety of the dam and the river channel bank slopes is improved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

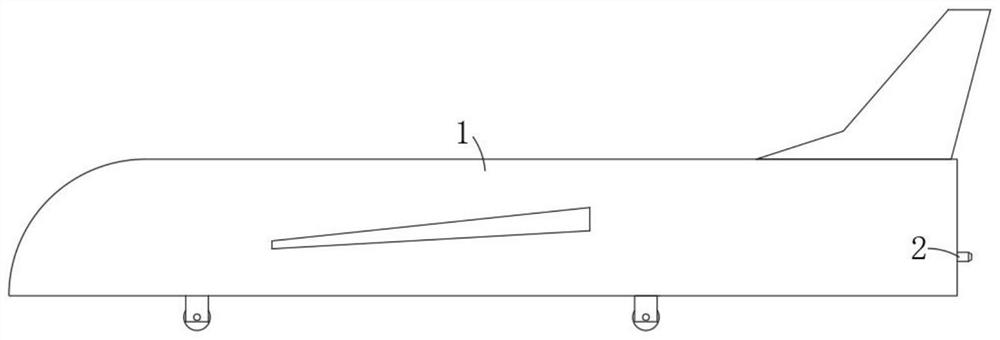

High-pressure pneumatic boosting take-off device for light unmanned aerial vehicle

ActiveCN111717409ARealize automatic sheddingReduce weightLaunching/towing gearMarine engineeringGas cylinder

The invention discloses a high-pressure pneumatic boosting take-off device for a light unmanned aerial vehicle. The device comprises a machine body; a first mounting groove is formed in the bottom ofthe machine body; a stop block is fixedly mounted on the inner side wall of the first mounting groove; a high-pressure gas cylinder is connected into the first mounting groove in a sliding manner; a first sliding groove is formed in the side wall of the high-pressure gas cylinder; a first communicating pipe communicating with the interior of the high-pressure gas cylinder is fixedly installed on the side wall of the high-pressure gas cylinder; a first valve is arranged on the first communicating pipe; the bottom of the first communicating pipe abuts against the top of the stop block; and an injection pipe is fixedly installed on the top of the stop block. According to the invention, the device is reasonable in structural design; the high-pressure gas cylinder and other devices can be automatically separated from the machine body after the machine body takes off; the weight of the machine body is reduced to a large extent; the voyage of the machine body is increased; the separated high-pressure gas cylinder can be effectively protected; and it is guaranteed that the high-pressure gas cylinder can continue to be normally used.

Owner:西安宇立航空科技有限公司

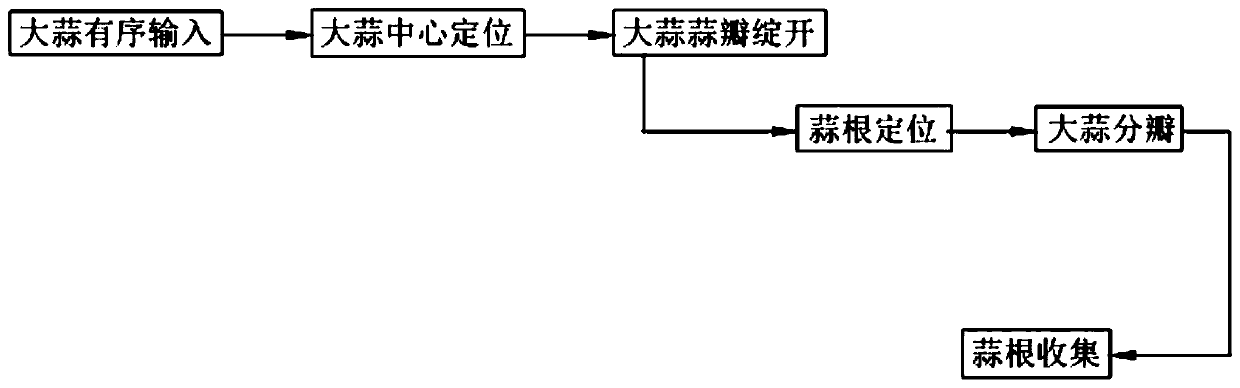

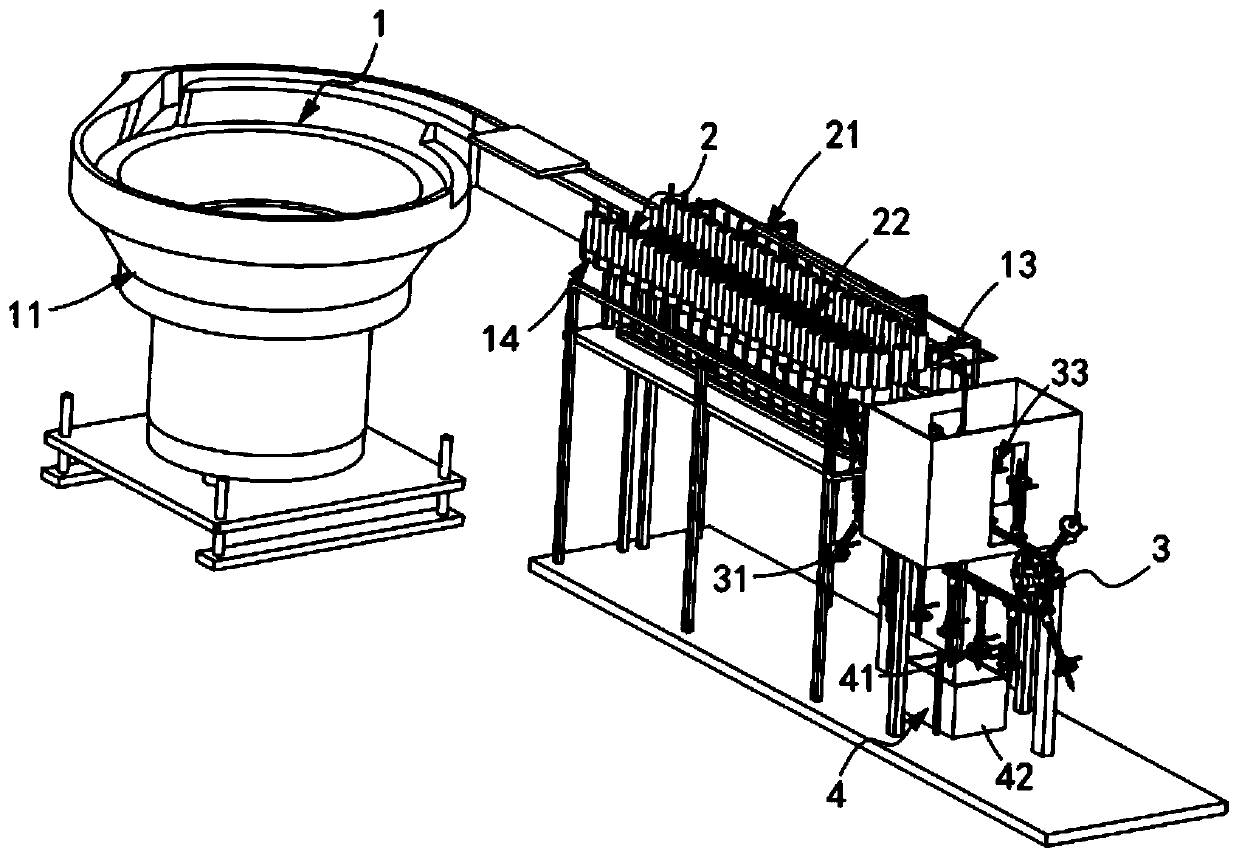

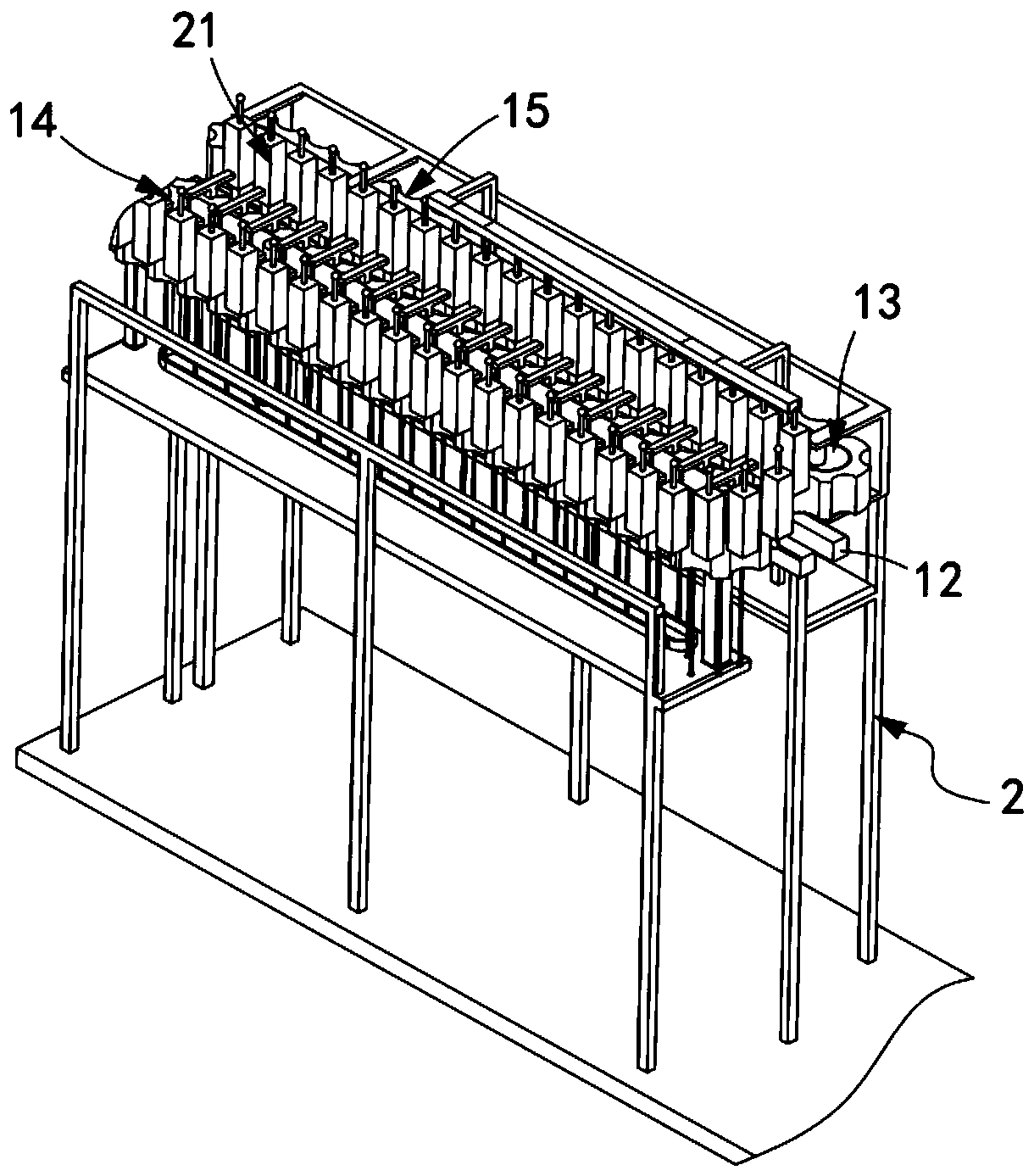

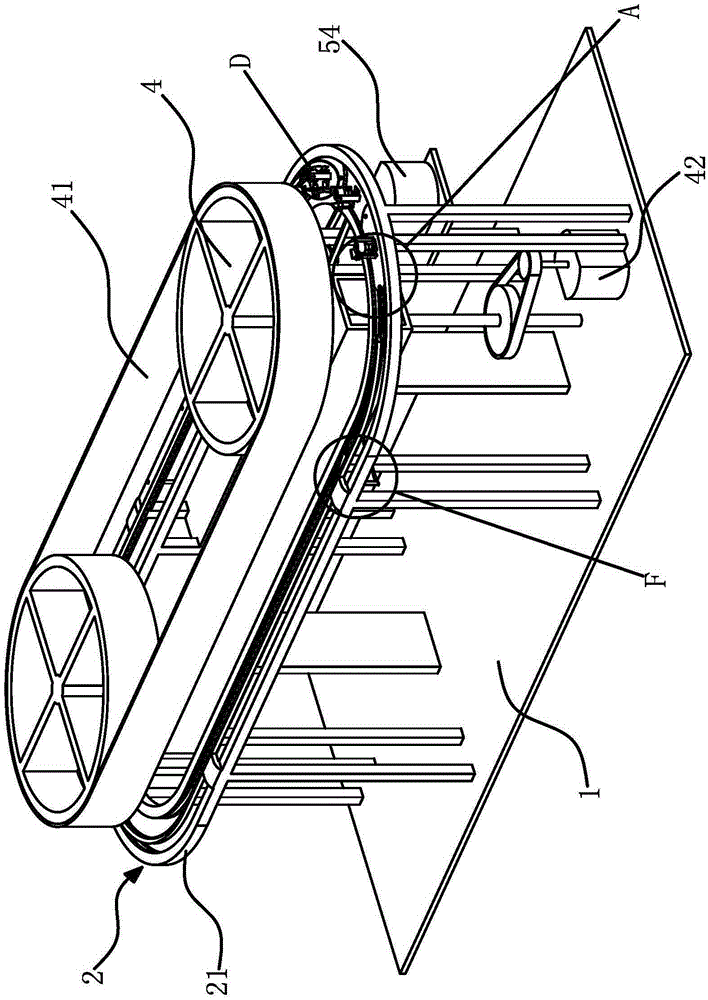

Full-automatic garlic clove separating process

ActiveCN111358024AHigh degree of automationRealize automatic sheddingConveyorsSeed and root treatmentEngineeringAllium sativum

The invention relates to a full-automatic garlic clove separating process. The process comprises the following steps: step one, orderly inputting garlic; step two, performing garlic center positioning, wherein belts on a conveying assembly a and a conveying assembly b extrude garlic and drive the garlic backwards to be pushed, the two sets of belts get close gradually, and the garlic enters the center of a groove; step three, blooming garlic cloves; step four, positioning garlic roots; step five, separating the garlic cloves, wherein a gear drives a pricking needle to synchronously rotate under the driving of a rack, so that the bloomed garlic is centrifugally rotated and bloomed, and the garlic automatically falls into a storage box body to be collected; step six, collecting the garlic roots, wherein the garlic roots are transmitted into a stripping space along with the pricking needle, the garlic roots automatically fall into a garlic root collecting box under the guide of a pushingrail, and the pricking needle automatically resets along with a telescopic unit b after leaving the pushing rail. The full-automatic garlic clove separating process the technical problems that garlicis rubbed, stirred and separated through rotation of a clove separating wedge plate, the clove separating working time is long, and the clove separating effect is poor.

Owner:阜阳佰恩得新材料技术有限公司

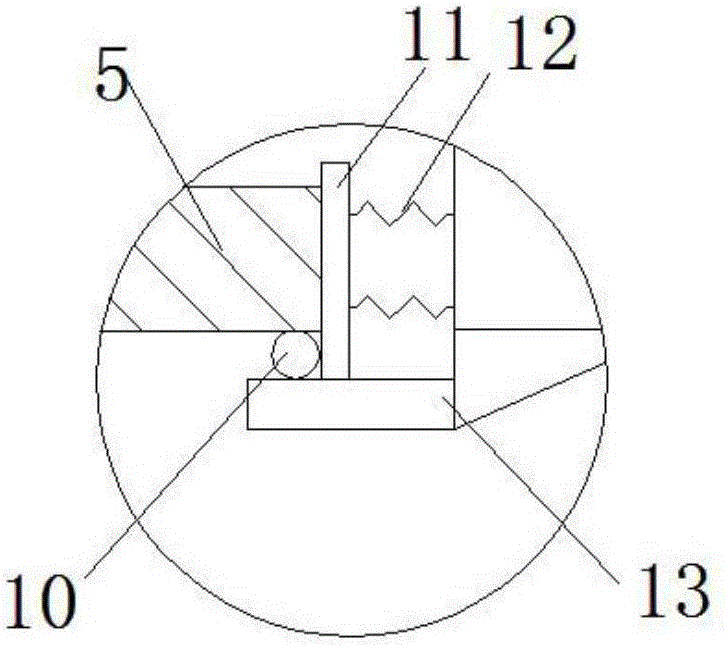

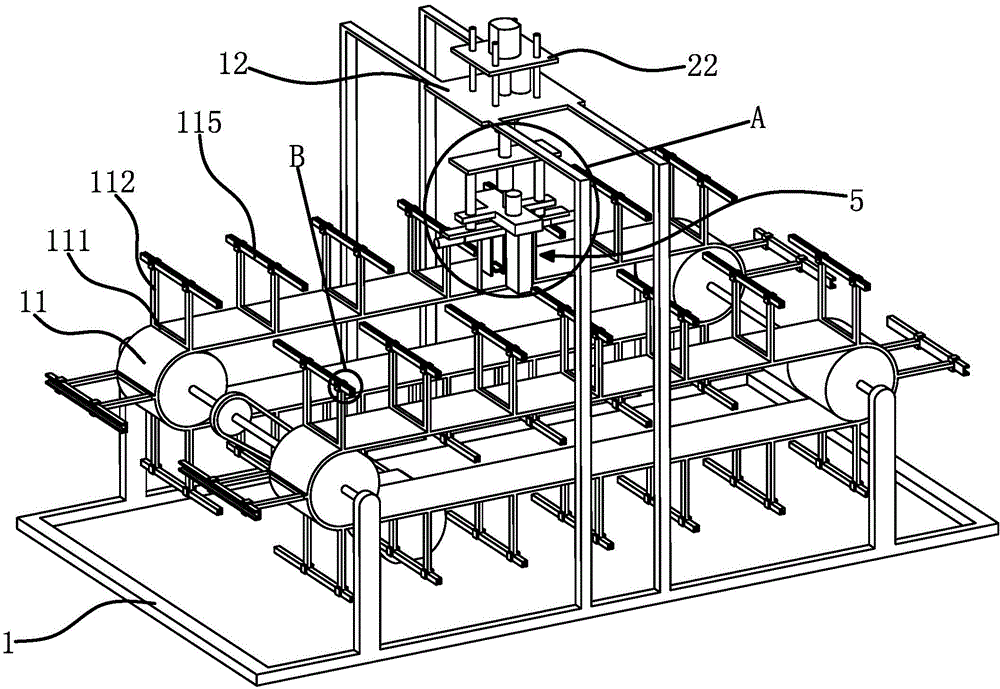

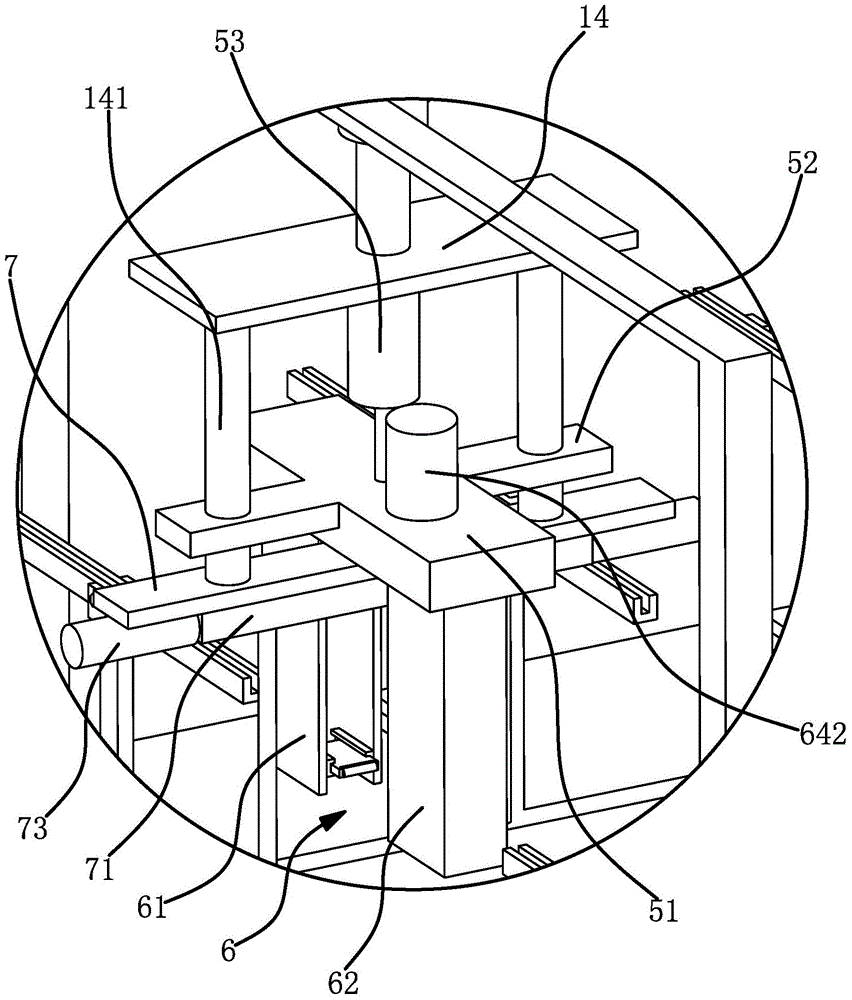

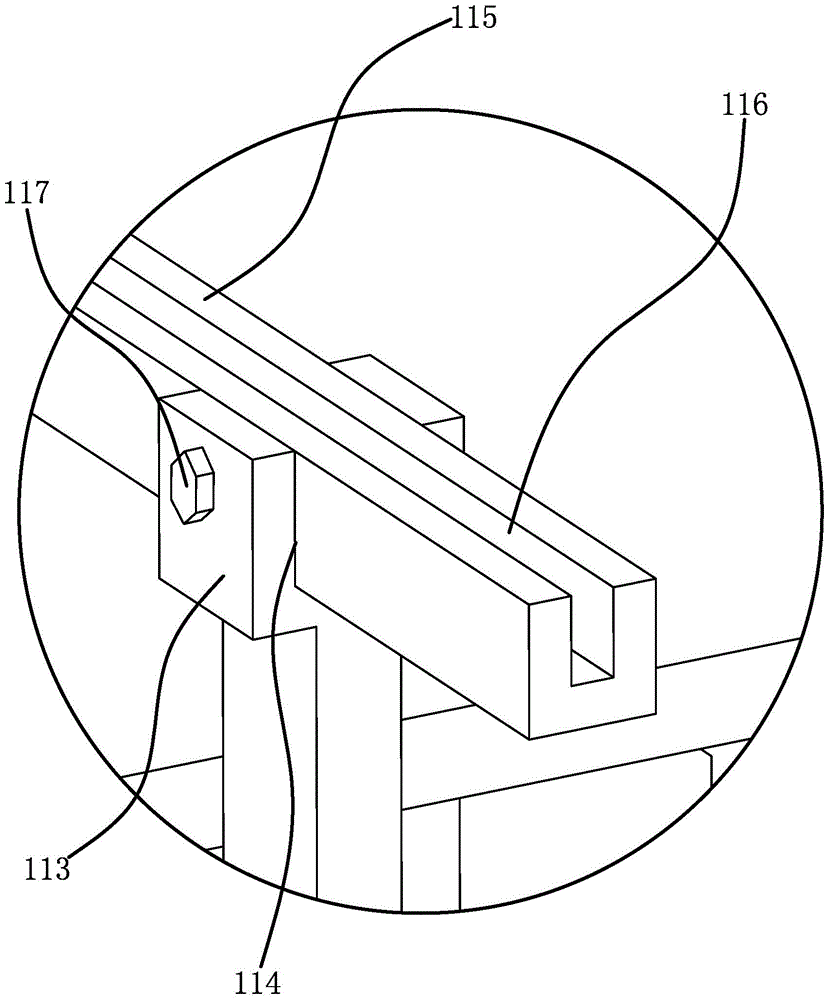

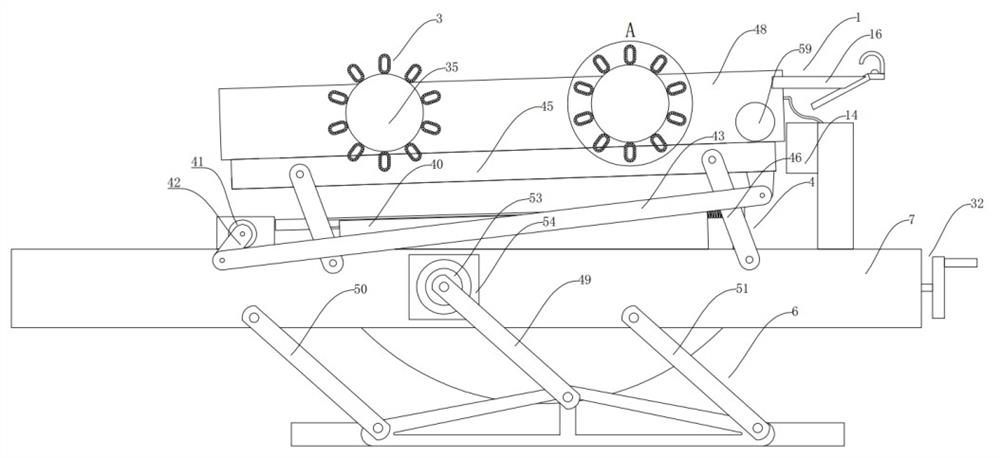

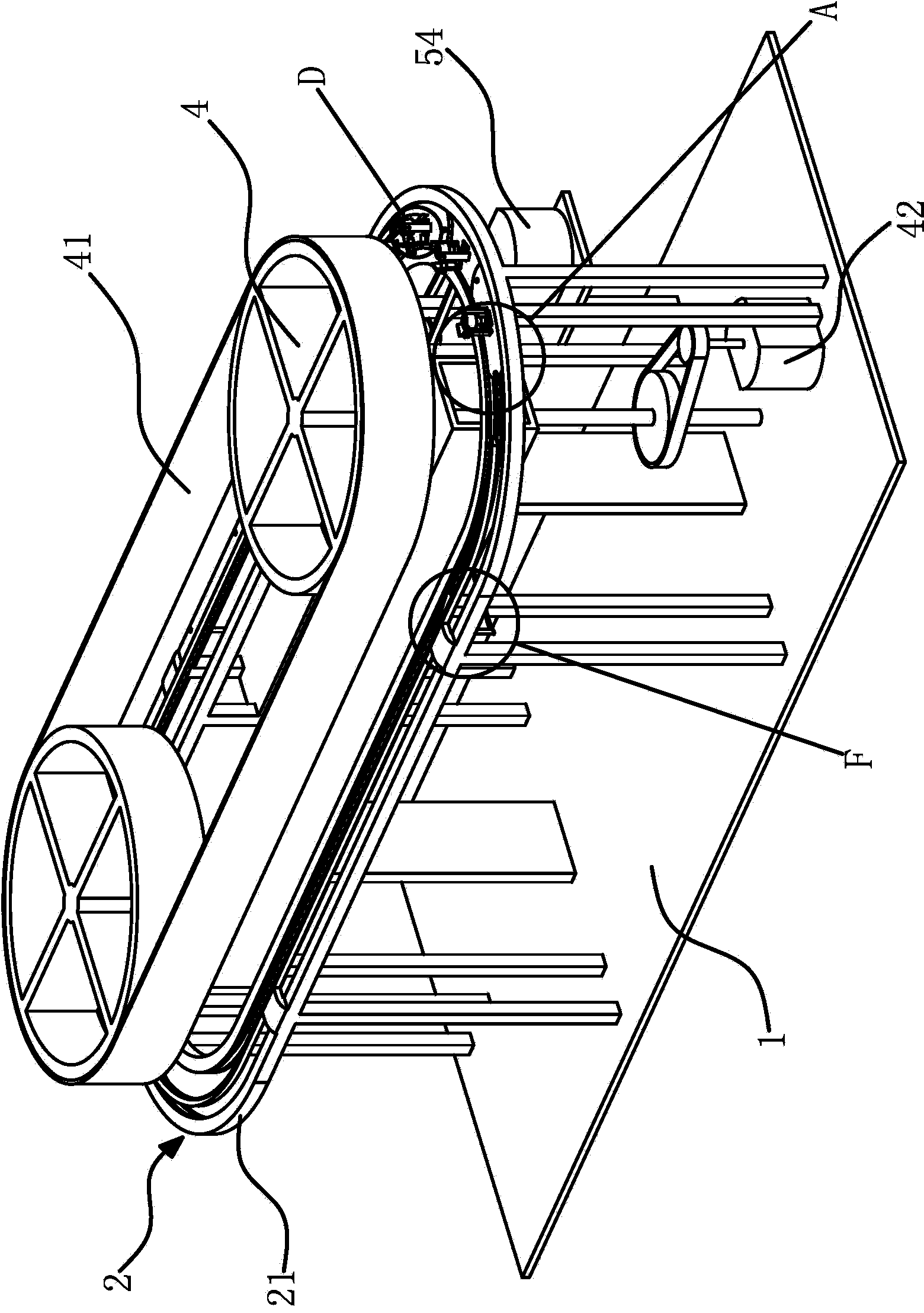

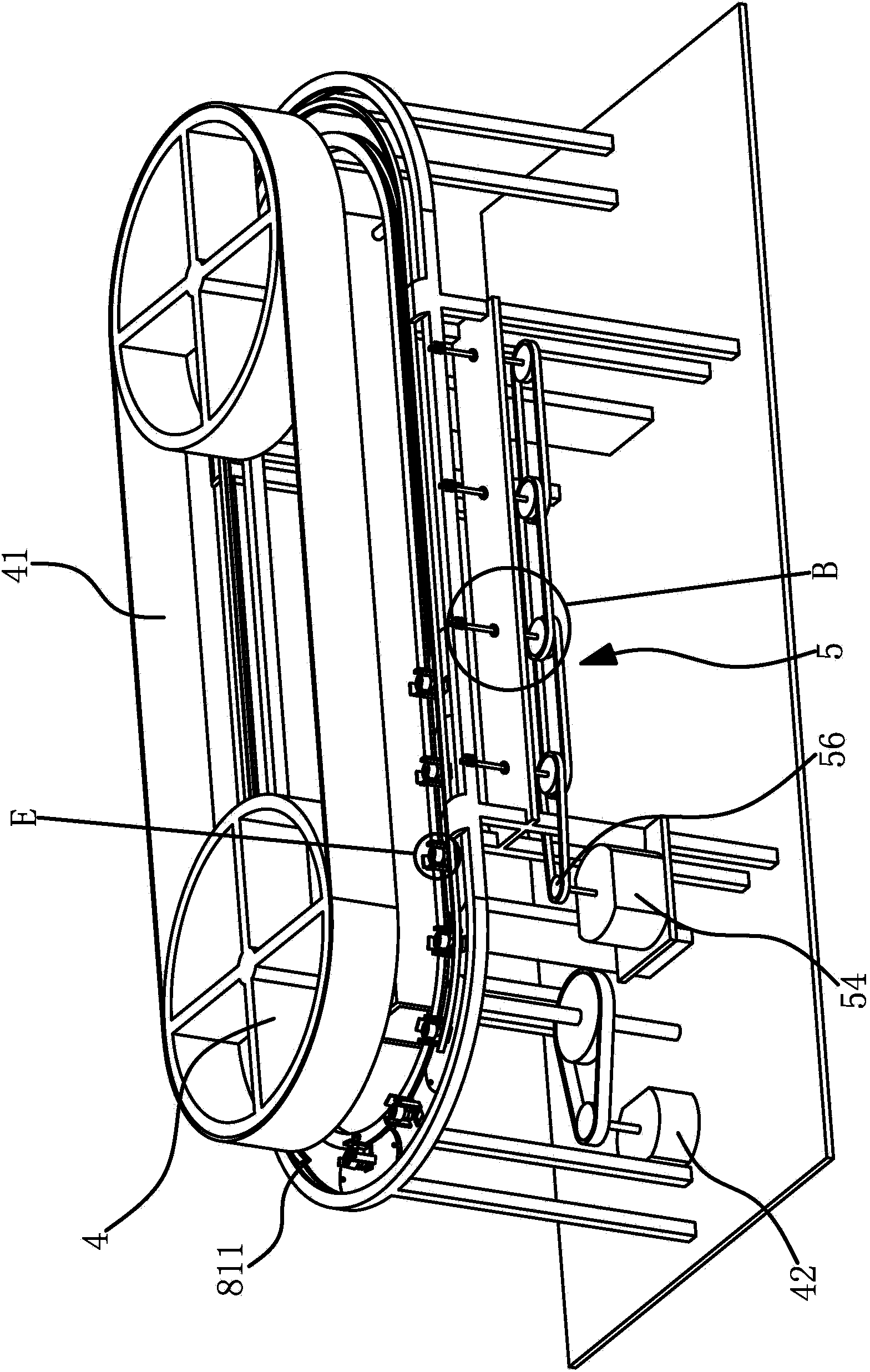

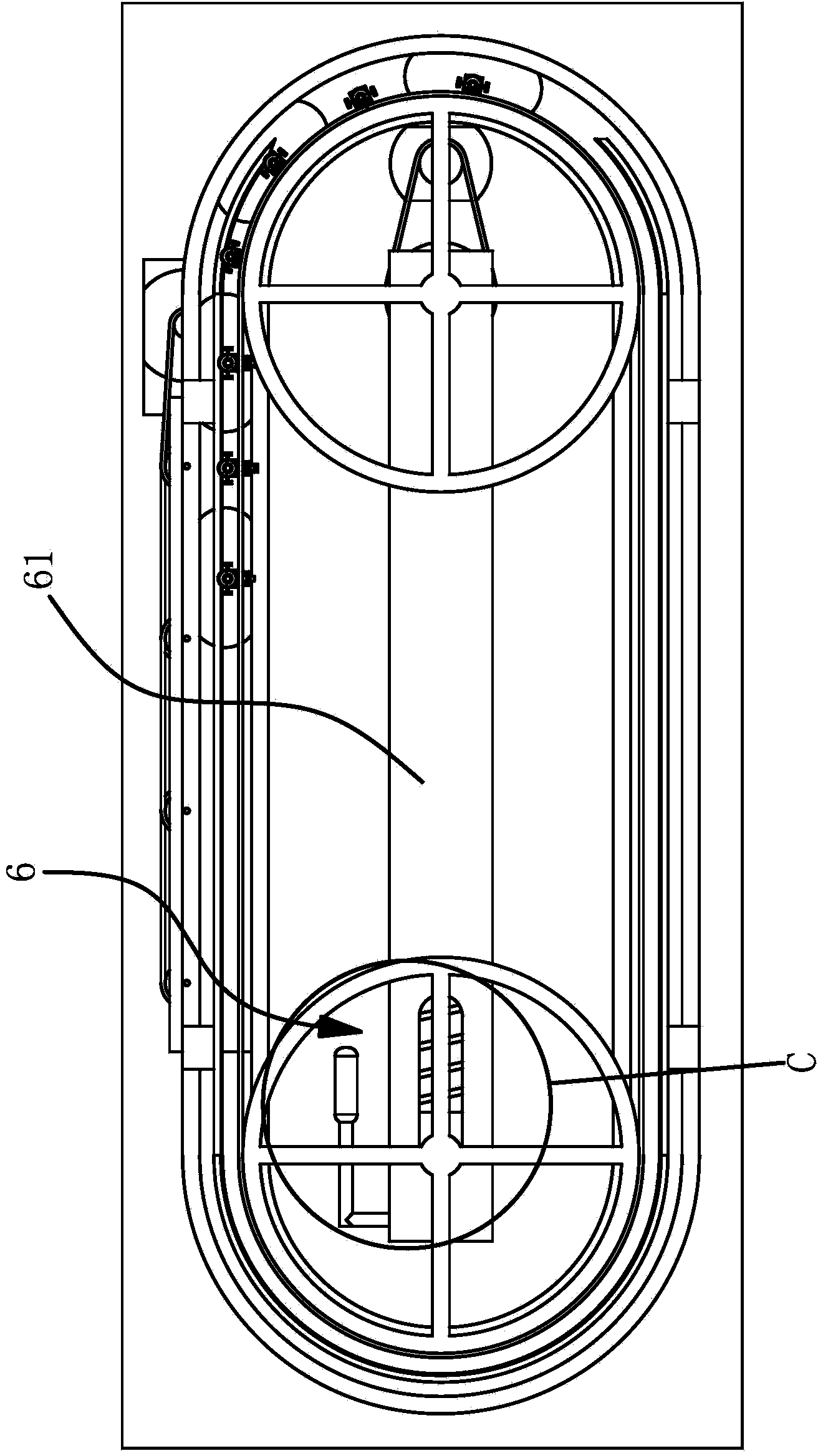

Automatic chopstick forming machine with rotating device

InactiveCN105290924AIncrease productivityEfficient grindingGrinding drivesBelt grinding machinesEngineeringMechanical engineering

The invention provides an automatic chopstick forming machine with a rotating device, and belongs to the technical field of processing equipment. The problems that in existing chopstick processing, time and energy are wasted and production efficiency is low are solved through the automatic chopstick forming machine with the rotating device. The automatic chopstick forming machine with the rotating device comprises a base plate, a guide rail is horizontally erected on the base plate and is in sliding connection with a supporting plate, and the guide rail is provided with a driving device. The middle of the guide rail is in rotary connection with two grinding belt wheels which are sleeved with a grinding abrasive belt, the grinding belt wheels are connected with a power mechanism, and a tensioning device is arranged between the two grinding belt wheels. The supporting plate is fixedly connected with two side plates, a connecting sleeve is connected between the two side plates, a locating sleeve is rotationally connected in the connecting sleeve, and a compressing device is arranged on the supporting plate. The rotating device is arranged on the guide rail. A stripping device is arranged between the guide rail and the supporting plate. The automatic chopstick forming machine can automatically grind the heads of chopstick blanks to enable the heads of the chopstick blanks to be cylindrical, in this way, labor is saved, and the production efficiency is high.

Owner:魏元利 +2

Method for automatically removing powders in process of electrolytic preparing metal powder body

InactiveCN101407926ARealize automatic sheddingReduce labor intensityElectrolysisUltimate tensile strength

The invention relates to an automatic powder removing method in the process of preparing metal powder by electrolysis, which is characterized in that: in the process of preparing the metal powder by electrolysis, intermittent ultrasonic-reverse pulse current is exerted, a metal powder product on an anode is removed from a cathode surface under the synergic action of the ultrasonic waves and reverse pulse current, wherein, the synergic action time of the ultrasonic waves and the reverse pulse current is 1 to 30s, and the action time interval is 20 to 2000s. The method can effectively alleviate the labor intensity, reduce the energy consumption and improve the working conditions of metal power electrolysis; in addition, the method can ensure the continues operation of the electrolysis process, and has the advantages of good power removing effect, stable product stability and being capable of obviously improving production efficiency.

Owner:NORTHEASTERN UNIV

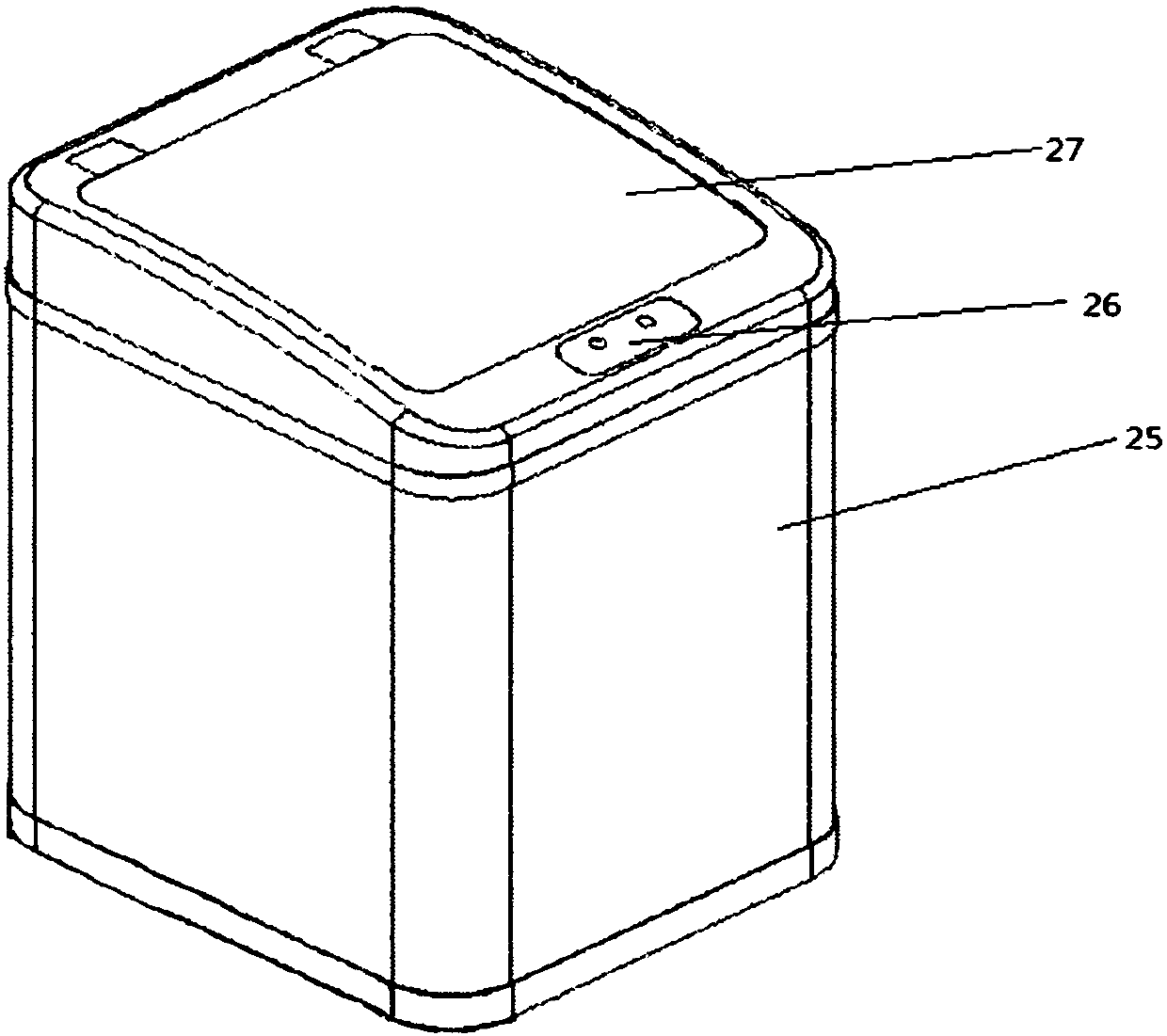

Intelligent trash can

ActiveCN107857018ARealize automatic packagingThe suit is firmRefuse receptaclesMotor driveReciprocating motion

The invention provides an intelligent trash can. The intelligent trash can comprises a shell and a bag opening structure inside the shell. The bag opening structure comprises a drive device, a connection piece, a connection piece drive assembly and slide rails. The slide rails are arranged between a front supporting column and a rear supporting column on one side of the shell. The connection pieceis fixedly connected with the connection piece drive assembly. The drive device drives the connection piece drive assembly to do reciprocating motion along the two slide rails and moreover drives theconnection piece to rotate when the connection piece is located on the side of the front supporting column. The intelligent trash can can automatically and accurately open bags. Moreover, a complex mechanical structure and redundant motor drive are avoided in the shell of the intelligent trash can, the using cost is greatly reduced, the structural performance of the intelligent trash can is improved, and a user can conveniently use the intelligent trash can.

Owner:爱国者(北京)电子有限公司

Chopstick automatic forming machine

ActiveCN103817578AIncrease productivityEfficient grindingGrinding drivesBelt grinding machinesEngineeringMachining

The invention provides a chopstick automatic forming machine, and belongs to the technical field of machining equipment. The chopstick automatic forming machine solves the problems that an existing chopstick machining method consumes time and labor and is low in production efficiency. The chopstick automatic forming machine comprises a base plate, wherein a guide rail is horizontally erected on the base plate, the guide rail is connected with supporting plates in a sliding mode, a driving device is arranged on the guide rail, two grinding belt wheels are connected in the middle of the guide rail in a rotary mode, a grinding sanding belt is arranged on the two grinding belt wheels in a sleeved mode, the grinding belt wheels are connected with a power mechanism, a tensioning device is arranged between the two grinding belt wheels, the supporting plates are fixedly connected with two side plates, a connecting sleeve is connected between the two side plates, a positioning sleeve is connected inside the connecting sleeve in a rotary mode, a compressing device is arranged on the supporting plates, a rotating device is arranged on the guide rail, and a discharging device is arranged between the guide rail and the supporting plates. The chopstick automatic forming machine can automatically grind the heads of chopstick blanks to be cylindrical, not only saves labor, but also is high in production efficiency.

Owner:启东翔龙旅游开发有限公司

Self-locking type electrified lapping wire clamp

ActiveCN110336143AFast implementation providesFast implementation of powerElectric connection structural associationsSelf locking

Owner:GUIZHOU POWER GRID CO LTD

Mechanism for bending filter cloth and discharging material and automatic material-discharging method

ActiveCN101433780BRealize automatic sheddingGuaranteed stable workFiltration separationEngineeringFilter press

The invention relates to a curving discharge mechanism for a filter press, which can make a filter cloth automatically shake by means of stretching and vibrating, wherein filter cloth which is coated on outer surfaces of a plurality of filter plates respectively passes through respective filter cloth suspension rods respectively; both ends of every two suspension rods are connected with each other through a woven belt; both ends of each suspension rod are provided with eye bolts respectively; and the eye bolts are connected with respective curving supports through tension springs respectively. When the plurality of filter plates are pulled away, the filter cloth of the filter plates is pulled away at a certain angle through the respective tension springs and slightly vibrates to make filter cakes adhered to the surface of the filter cloth automatically fall off. The curving discharge mechanism for the filter press has the advantages that: firstly, the curving discharge mechanism for the filter press solves the problems of complex structures of various connecting pieces of the curving mechanism in the prior art, incapability of simultaneously washing a curving system and the filtercloth of the filter press, etc., and achieves the aims of stable and reliable operation, simple and reasonable structure, incapability of being influenced by the operating environment and economy andpracticality; and secondly, tensioning peeling and slight vibration of the filter cakes on the surface of the filter cloth are realized through the pulling angle of the respective tension springs on the filter cloth of the filter plates, so that the aim of automatic falling of the filter cakes which are adhered to the surface of the filter cloth is realized.

Owner:杭州兴源环保设备有限公司

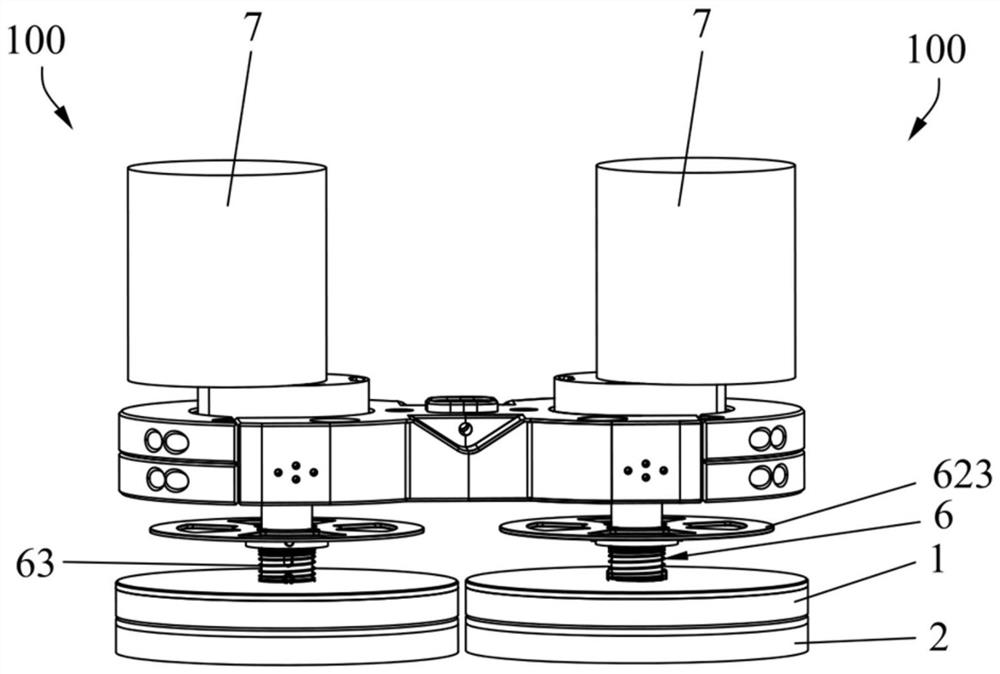

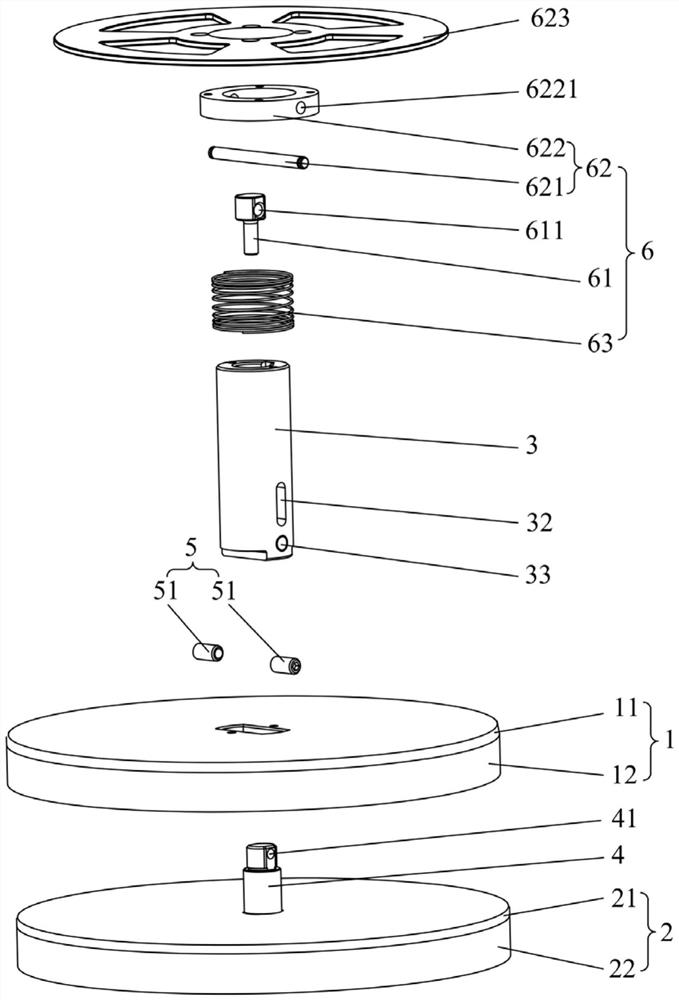

Nursing module and stone nursing robot

ActiveCN111657789ARealize automatic sheddingAchieve separationCarpet cleanersFloor cleanersEngineeringFamily medicine

The invention discloses a nursing module and a stone nursing robot, and belongs to the field of stone intelligent nursing. The nursing module comprises a first nursing assembly, a second nursing assembly, an elastic clamping assembly and a dismounting assembly, the first nursing assembly is connected with a first rotating shaft, a containing cavity is formed in the first rotating shaft, the secondnursing assembly is connected with a second rotating shaft extending into the containing cavity, the first rotating shaft is further provided with a guide hole communicating with the containing cavity, the elastic clamping assembly is arranged on the first rotating shaft and extends into the containing cavity to clamp the second rotating shaft, the dismounting assembly comprises a pressing piecearranged in the containing cavity and a sliding assembly connected with the pressing piece, and the sliding assembly can slide along the guide hole relative to the first rotating shaft so as to drivethe pressing piece to abut against the second rotating shaft, so that the second rotating shaft overcomes clamping of the elastic clamping assembly and is disengaged from the first rotating shaft. Thestone nursing robot comprises the nursing module. Automatic falling of the second nursing assembly can be achieved, the working efficiency is high, and the device is particularly suitable for nursingof large-area stone grounds.

Owner:苏州高之仙自动化科技有限公司

Cutting device for silicon single crystal rod

InactiveCN113001795ACutting stabilityPrevent sparks from splashingWorking accessoriesFine working devicesPistonPiston cylinder

The invention relates to a cutting device for a silicon single crystal rod. The cutting device comprises a fixed box, a base, a cutting mechanism, a moving mechanism and a clamping mechanism, wherein the cutting mechanism comprises a driving box, a rotating rod and a blade, the clamping mechanism comprises a piston cylinder, an abutting plate, a moving rod, a spring, a piston and a clamping assembly, and the moving mechanism comprises a lead screw, a bearing seat, a walking ring, a connecting rod, a moving block and a positioning box. By using the cutting device for the silicon single crystal rod, movement of a main body and control on the cutting amount of the main body are both achieved through the moving mechanism, so that the cutting size of the main body is conveniently adjusted; the main body is automatically clamped through the clamping mechanism and can automatically fall off through restoring force of the spring without disassembling the main body by opening the fixed box for multiple times, so that the use practicability is improved; and in addition, the clamping mechanism herein is of a pure mechanical structure and clamps the main body through thrust of the main body, so that the service life is prolonged.

Owner:王慧芝

Energy-saving fan

InactiveCN113700661AReduce cleaning frequencySave waterPump componentsPump installationsElectric machineryDrive motor

The invention discloses an energy-saving fan, and relates to the technical field of ventilation equipment. The energy-saving fan comprises a machine body, wherein the interior and the front side of the machine body are hollowed out, an exhaust pipe is arranged at the top of the machine body, a fixing sleeve penetrates through the center of the rear side of the machine body and is fixed to the machine body, and a rotating shaft is sleeved with the fixing sleeve. According to the energy-saving fan, a pneumatic driving plate is arranged, so that the position of an impact cleaning block can be changed by utilizing gas entering the rotating shaft in the rotating process of the rotating shaft; when the fan is closed, the flow of the gas entering the rotating shaft is reduced, the pneumatic driving plate can reset under the action of an elastic piece, and the impact cleaning block can impact the inner wall of the rotating shaft; and vibration generated by impact is transmitted to fan blades so that dust on the fan blades can be separated, and therefore the dust on the surfaces of the fan blades can automatically fall off, the cleaning frequency of the fan blades is effectively reduced, water resources are saved, the weight of the fan blades is reduced after the dust is separated from the fan blades, and the energy consumption of a driving motor is also reduced.

Owner:罗玉洁

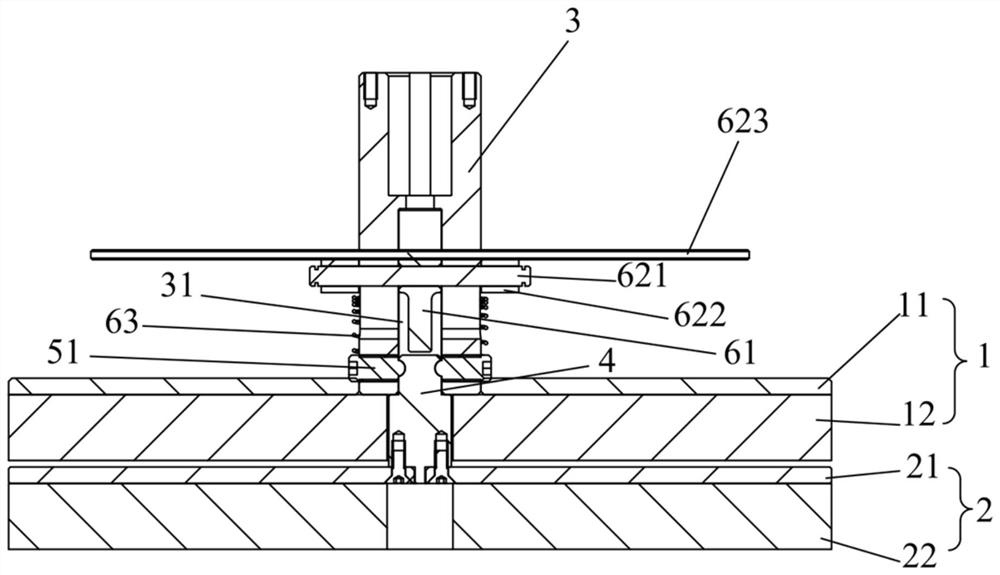

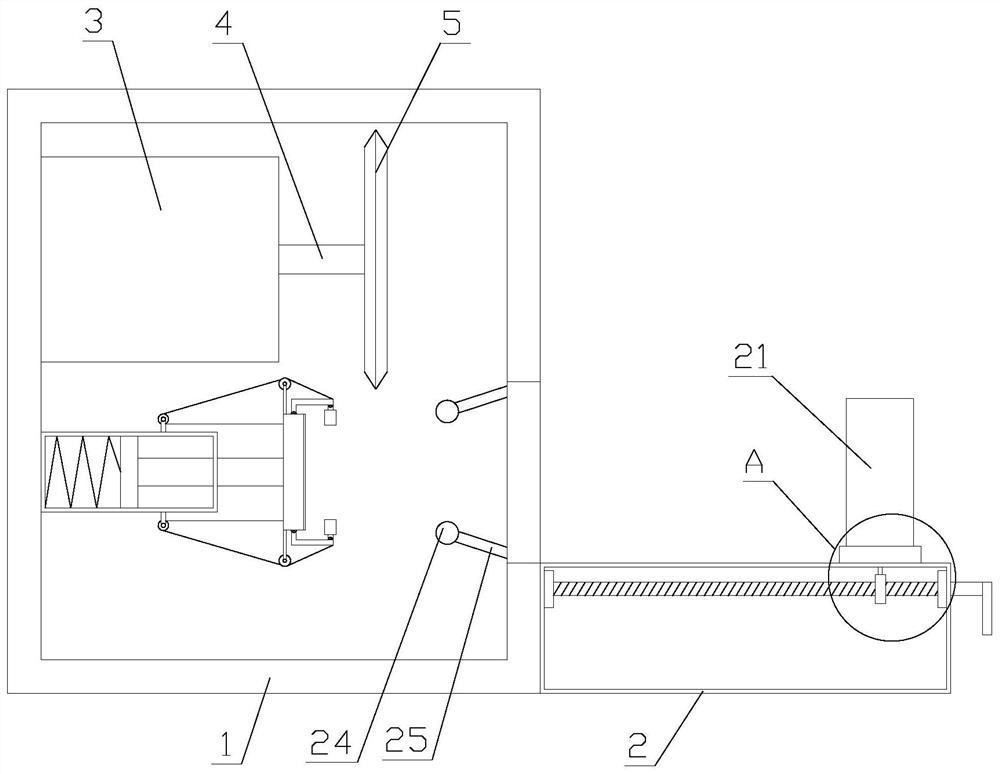

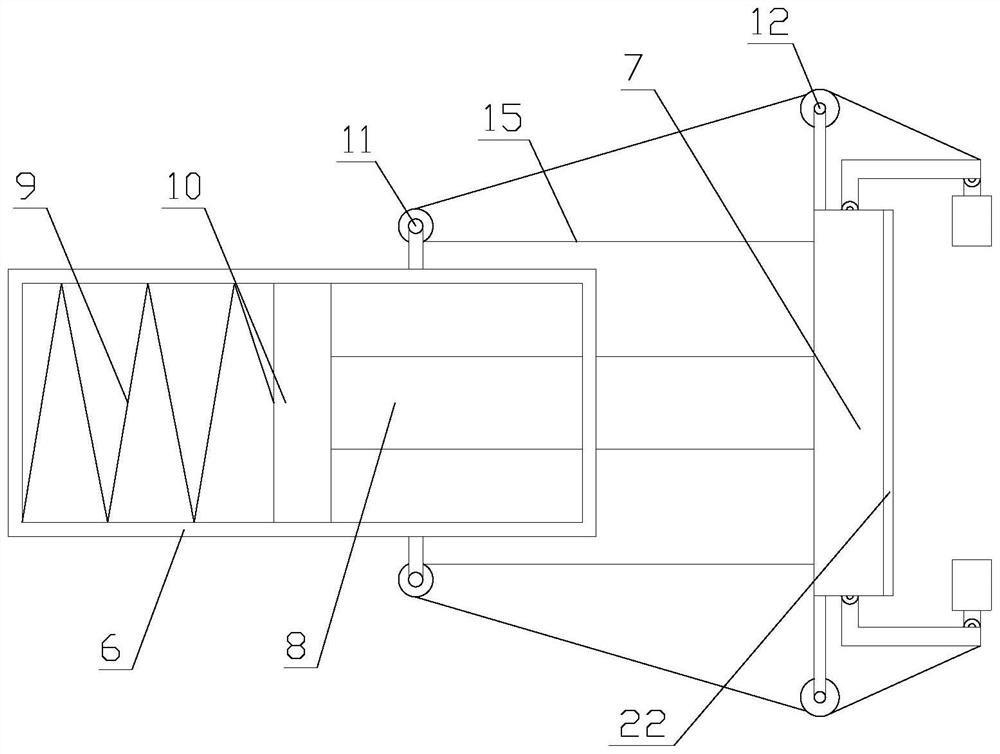

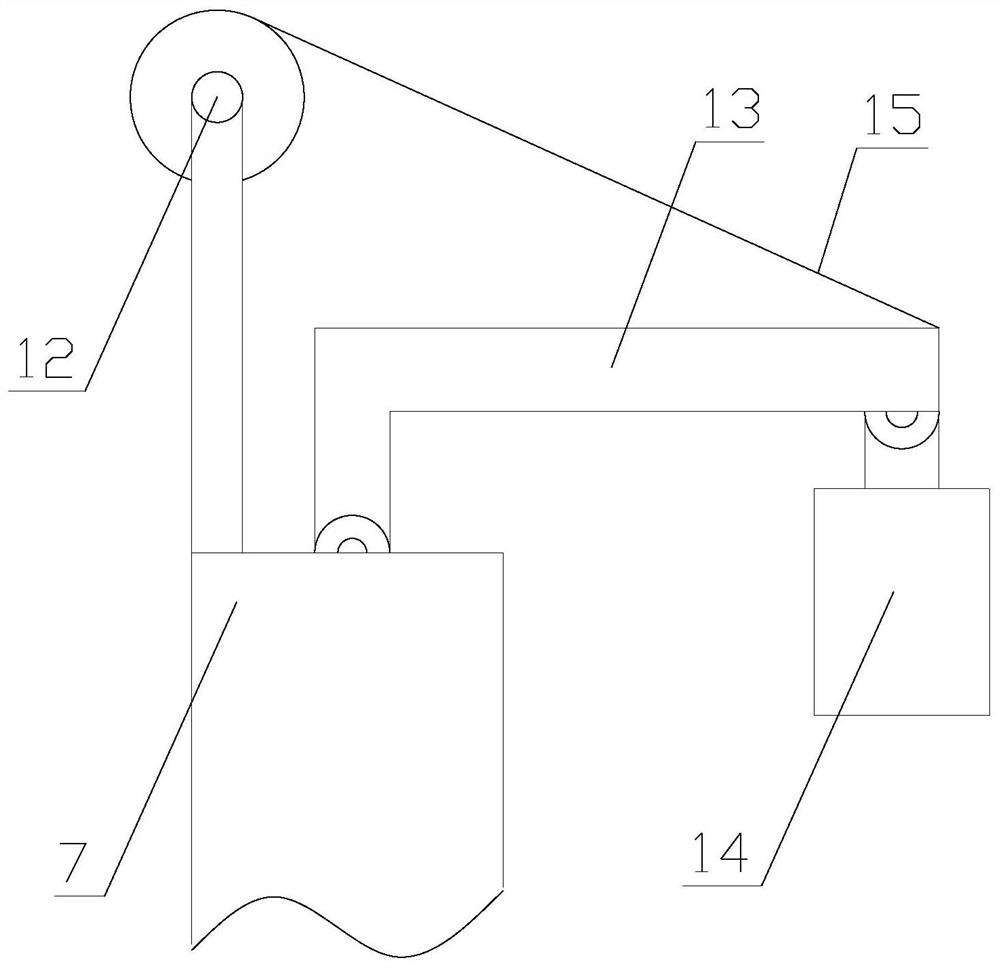

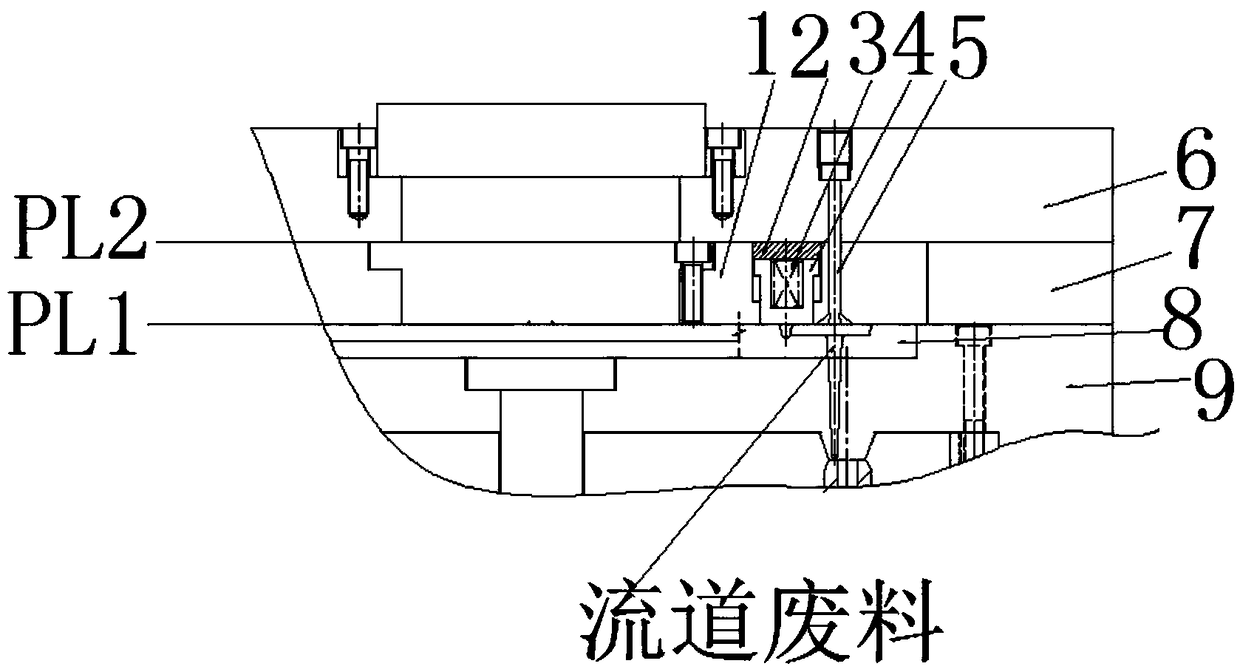

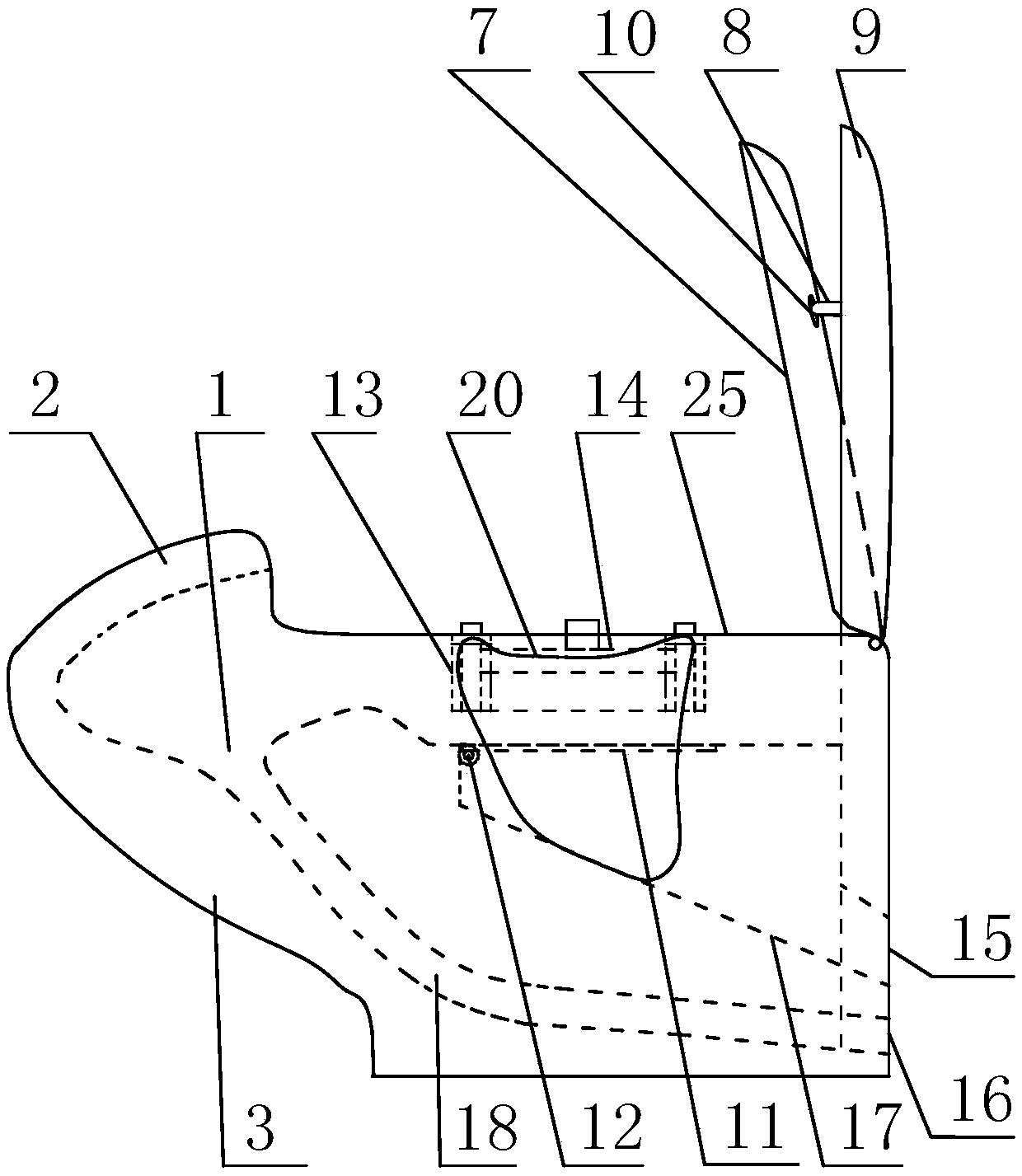

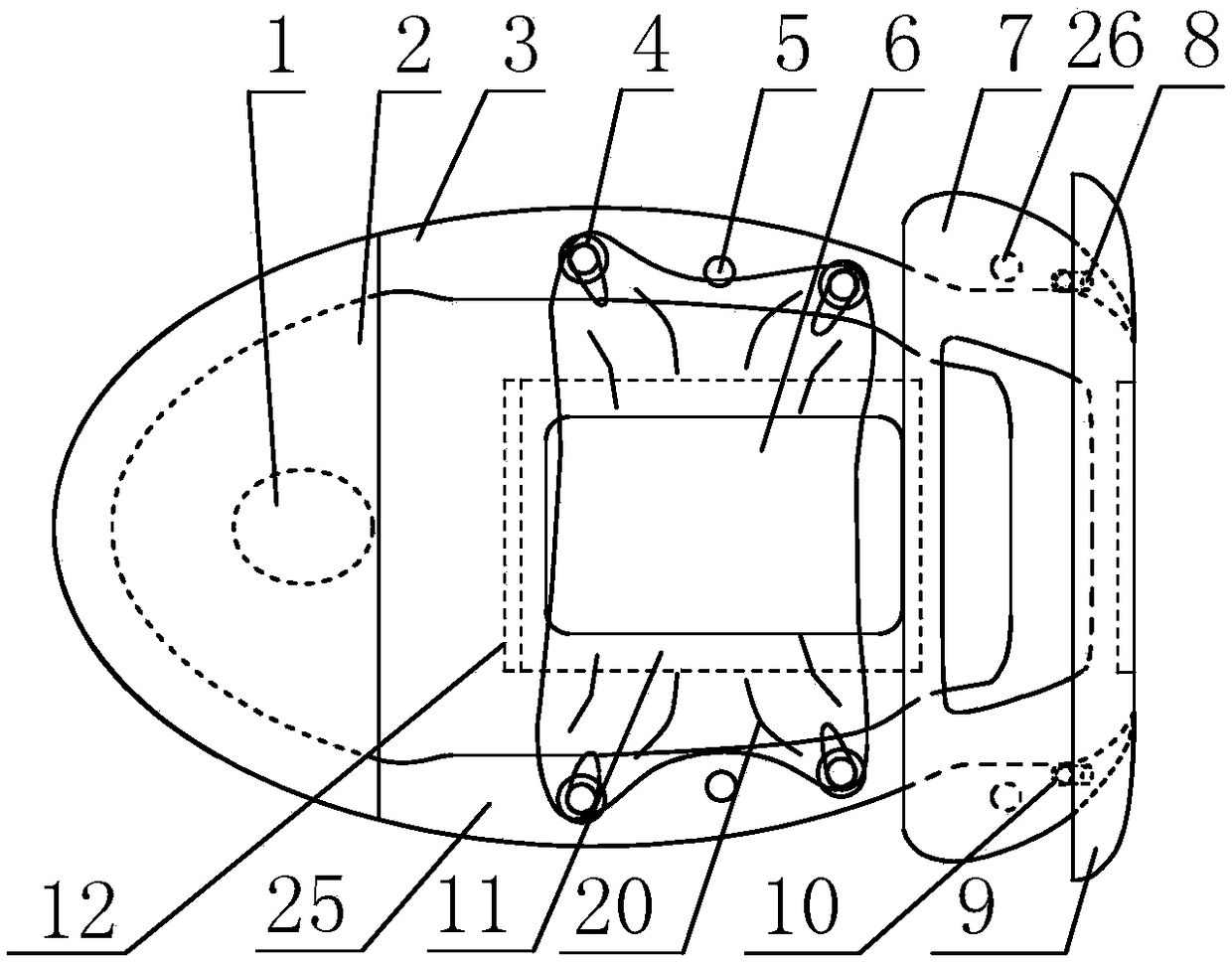

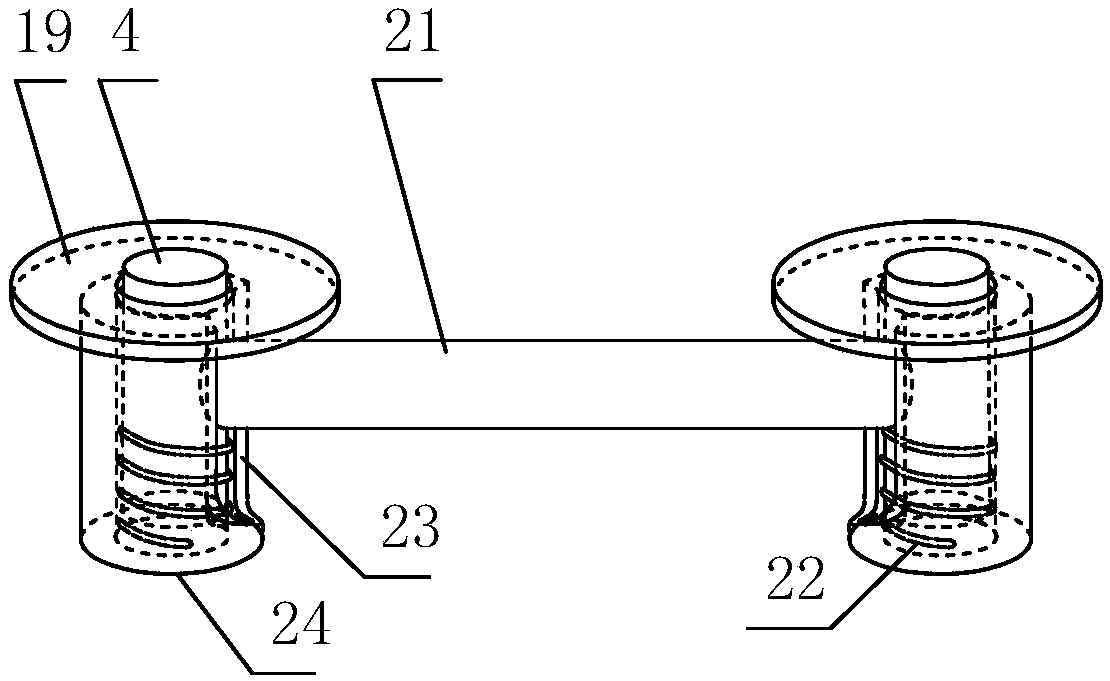

Front mould automatic shooting material mechanism of injection mold of three plates mold and using method thereof

InactiveCN108099101AGuaranteed automated production functionsRealize automatic sheddingPlastic wasteWaste material

The invention discloses a front mould automatic shooting material mechanism of an injection mold of a three plates mold. The front mould automatic shooting material mechanism of the injection mold ofthe three plates mold is used to solve the problem of incompletely shedding of a runner waste material in demolding on the three plates. The problem that various plastic waste materials adhere on a runner plate is aimed to be carried out to reliably demould by the front mould automatic shooting material mechanism. The situations that various plastic automatically dropped off the runner plate and is not adhered to the runner plate are realized, and the function of mould automatic production is ensured. The front mould automatic shooting material mechanism is reasonable in design, compact in structure, stable in work, safe, reliable, and convenient to use.

Owner:李睿

Water-free flushing feces and urine separation packing toilet

ActiveCN106175549BRealize water-free flushingSave waterBathroom accessoriesAgainst vector-borne diseasesEngineeringFlush toilet

The invention discloses a flushing-free feces-urine-separation packaging toilet bowl. The toilet bowl is provided with a urinating inlet and a feces inlet which are independently separated; bag hanging mechanisms are embedded into the toilet bowl faces of the upper ends of the two sides of a toilet bowl body respectively, and provided with four bag hanging columns jointly, and hanging-column connecting rods are transversely and fixedly connected to the middles of the bag hanging columns; the bag hanging columns are sleeved with hanging-column sleeves, sleeve side openings are formed in the hanging-column connecting rods of the hanging-column sleeves, openings are formed in the tops of the hanging-column sleeves, the lower portions of the hanging-column connecting rods of the bag hanging columns are sleeved with reset springs, and under the condition that external force is free, the tops of the bag hanging columns are ejected out of the top openings in the hanging-column sleeves and the toilet bowl faces through the reset springs, and feces packaging bags can be hung to the bag hanging columns; after toileting is completed, and a cover plate of the toilet bowl is put down, a triggering rod on the cover plate presses the hanging-column connecting rods to allow the packaging bags to fall off. According to the flushing-free feces-urine-separation packaging toilet bowl, a traditional flushing toilet bowl and the existing feces-packaging using mode in the world at present are overturned, the enormous social value, the enormous ecological value and the enormous economic value are contained, and the flushing-free feces-urine-separation packaging toilet bowl has broad application prospects.

Owner:云南八卫科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com