Printed material bearing platform for curved surface printing

A support platform and curved surface printing technology, which is applied in printing, printing machines, rotary printing machines, etc., can solve the problems of lower printing efficiency, small application range, inconvenient picking and placing of printed materials, etc., and achieve convenient picking and placing, convenient multiple times Convenient and accurate printing and feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

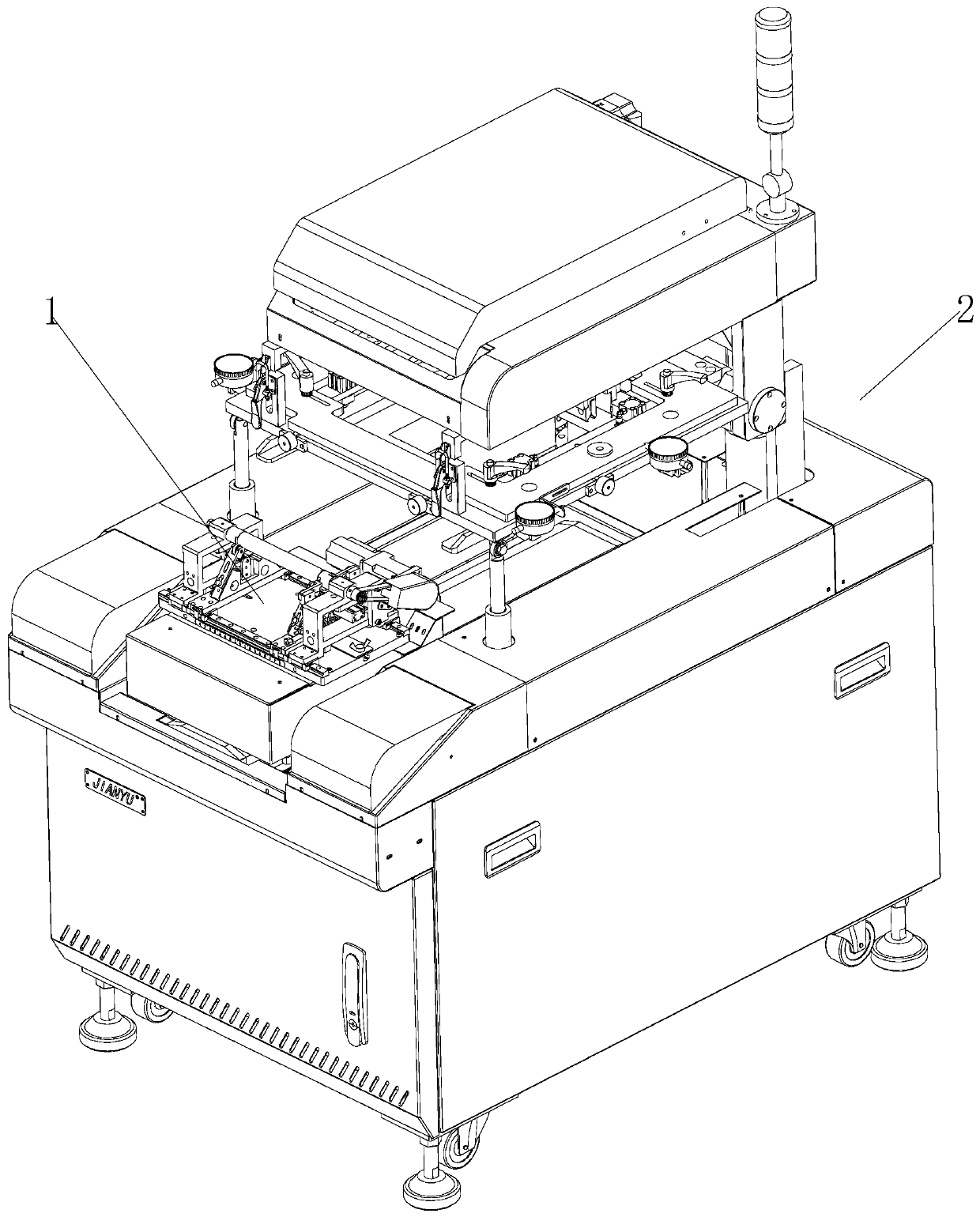

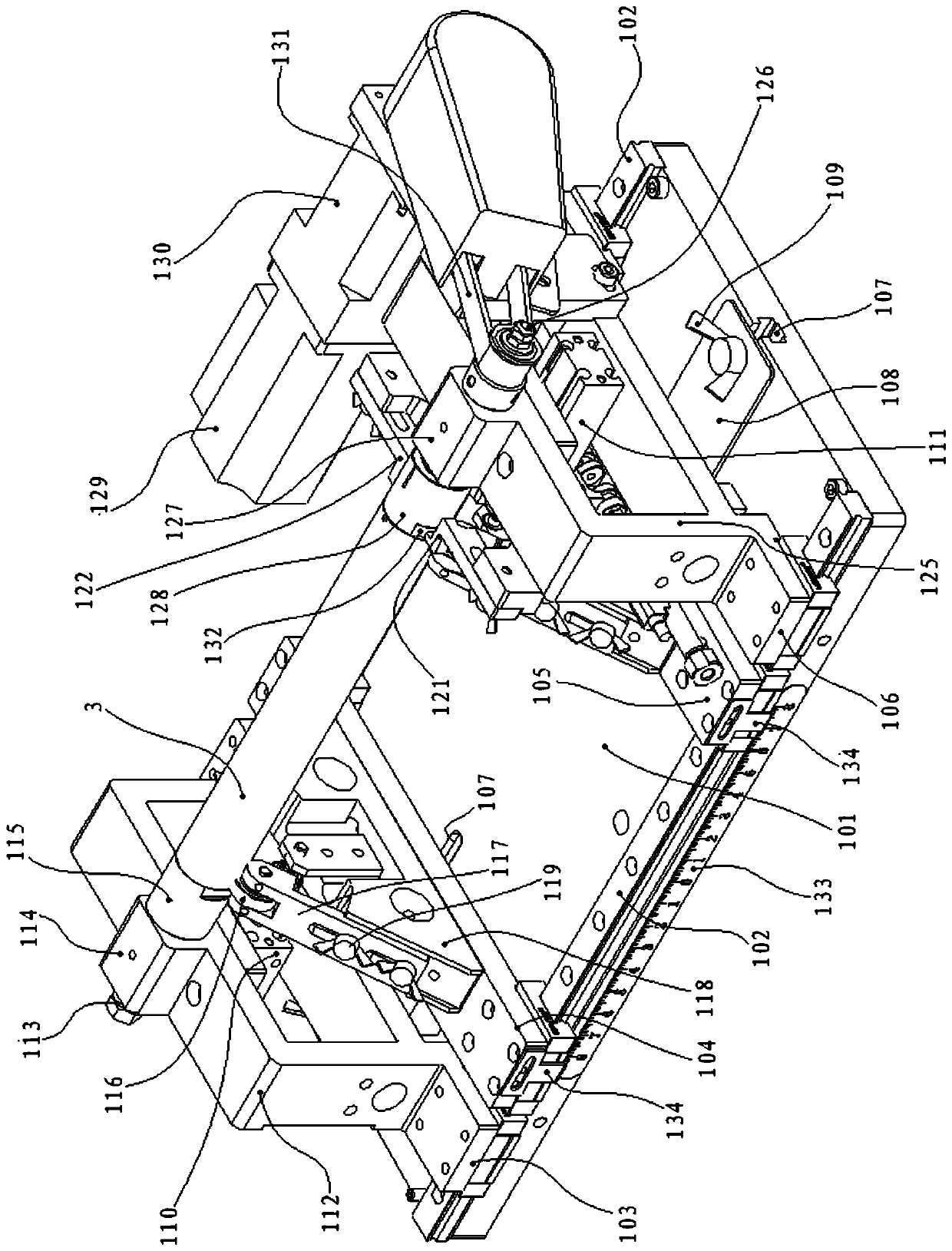

[0020] Referring to the accompanying drawings, which reflect a specific structure of the present invention, the substrate support platform 1 for curved surface printing is modularly assembled on the printing device 2, and the tubular substrate 3 is loaded on the substrate support platform 1 and then enters the printing device 2 to complete Exit and unload tubular substrate 3 after printing. And so the cycle works.

[0021] The substrate support platform 1 for curved surface printing includes two linear guide rails 102 installed on both sides of the base plate 101. The base plate 101 has a double guide rail arrangement, which is conducive to a higher coaxiality of the left and right rotation centers.

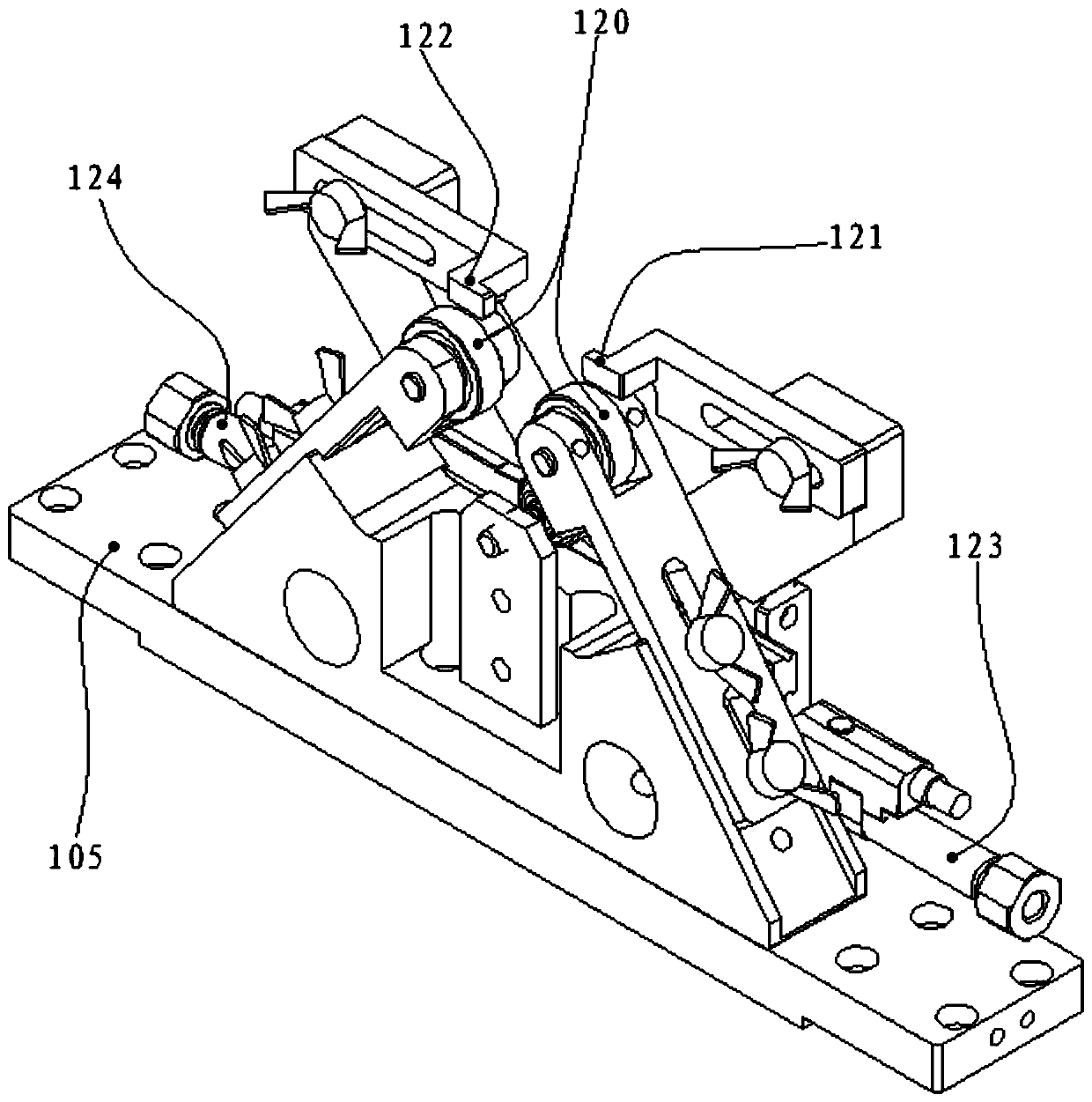

[0022] The first sliding seat 103, the second sliding seat 104, the third sliding seat 105, and the fourth sliding seat 106 are sequentially installed on the linear guide rail 102 from left to right; the linear guide rail 102 is provided with a position marking scale 133, so The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com