Full-automatic garlic clove separating process

A fully automatic, garlic technology, applied in the direction of seed and rhizome treatment, conveyor objects, conveyors, etc., can solve the problems of poor splitting effect and long working time of splitting, achieve high work efficiency, high product quality, improve The effect of institutional efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

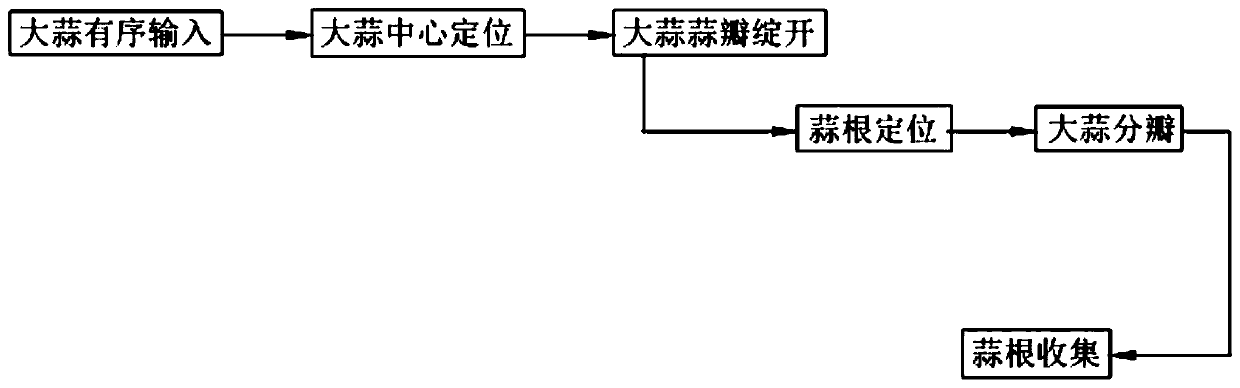

[0082] Such as figure 1 Shown, a kind of automatic garlic splitting technique, comprises:

[0083] Step 1, the garlic is input in an orderly manner, and the garlic is poured into the vibrator 112, and the garlic is vibrated by the vibrator 112, and the garlic heads are sequentially entered on the output table 113 upwards, and then pushed to the support table 12 in an orderly manner;

[0084] Step 2, the center of the garlic is positioned, the belt 135 on the conveying assembly a13 and the conveying assembly b14 pushes the garlic 10 backwards, the two sets of belts 135 gradually move closer together, and the garlic enters the center of the groove 151 of the clamping part 15;

[0085] Step 3, the garlic cloves are opened, the ejector assembly 21 is driven to the first guide assembly 22 along with the belt 135, the ejector rod 2122 is guided by the guide track 222, and the tapered column 2124 is squeezed toward the center of the garlic along the tapered groove 2129 Press, and th...

Embodiment 2

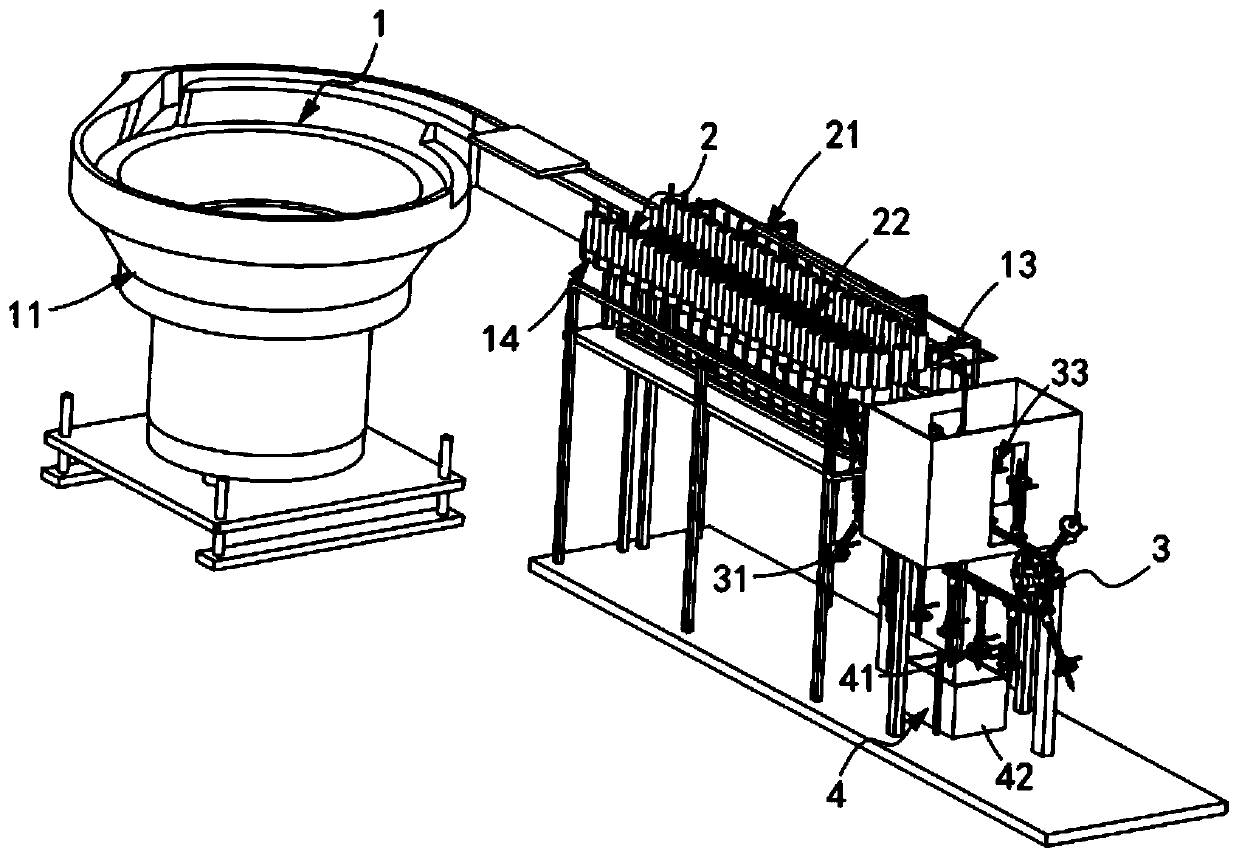

[0099] Such as figure 2 , Figure 4 Shown, a kind of automatic garlic splitting device comprises:

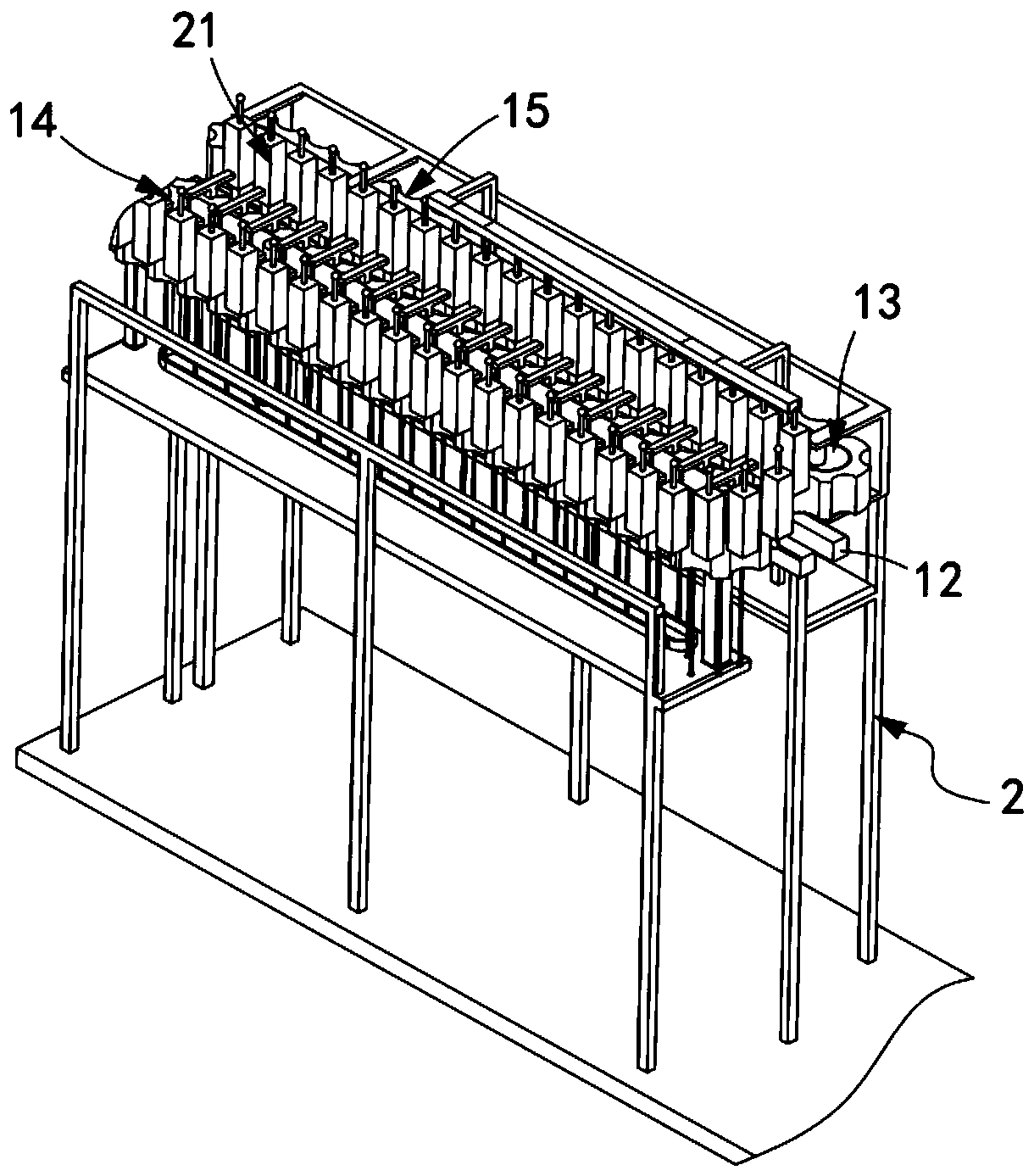

[0100] The transmission forward mechanism 1, the transmission forward mechanism 1 includes a sorting feeding assembly 11, a supporting platform 12 arranged at the output end of the sorting feeding assembly 11, and two sets of conveying assemblies arranged on both sides of the supporting platform 12 a13 and conveying assembly b14, the conveying assembly b14 is provided with a tightening part 15 along its transmission direction, and two sets of tightening parts 15 are correspondingly arranged to match the structure of the garlic 10, and the center of the output end of the support table 12 There are through slots 121 along its length;

[0101]The garlic opening mechanism 2, the garlic opening mechanism 2 includes an ejection assembly 21 arranged above any of the clamping parts 15 and a first guide assembly 22 arranged above the support table 12, and the ejection assembly 21 slid...

Embodiment 3

[0139] Such as Figure 29 , Figure 27 and Figure 28 As shown, the parts that are the same as or corresponding to those in the second embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of simplicity, only the differences from the second embodiment will be described below. The difference between this embodiment three and embodiment two is:

[0140] further, such as Figure 29 , Figure 27 and Figure 28 As shown, the revolving assembly 33 includes a gear 331 that is coaxial and fixedly connected with the needle 319 and a rack 332 arranged horizontally and meshed with the gear 331. The rack 332 is installed on the conveying assembly a13 superior.

[0141] In this embodiment, by setting the turnover assembly 33 to cooperate with the transmission of the sprocket chain unit 311, the gear 331 drives the pricking needle 319 to rotate synchronously, and then the opened garlic 10 is centrifugally rotated to open, and the garlic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com