Composite fireproof cable

A fire-proof cable and cable technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of flame erosion of the inner core wire, easy to be burned, and the cable is not fireproof.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

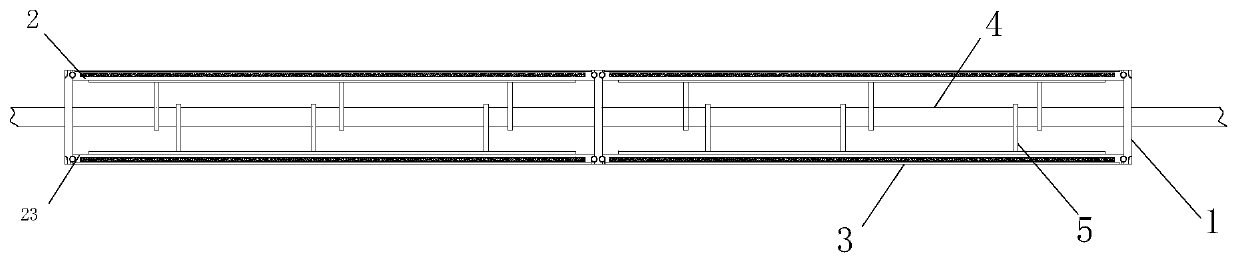

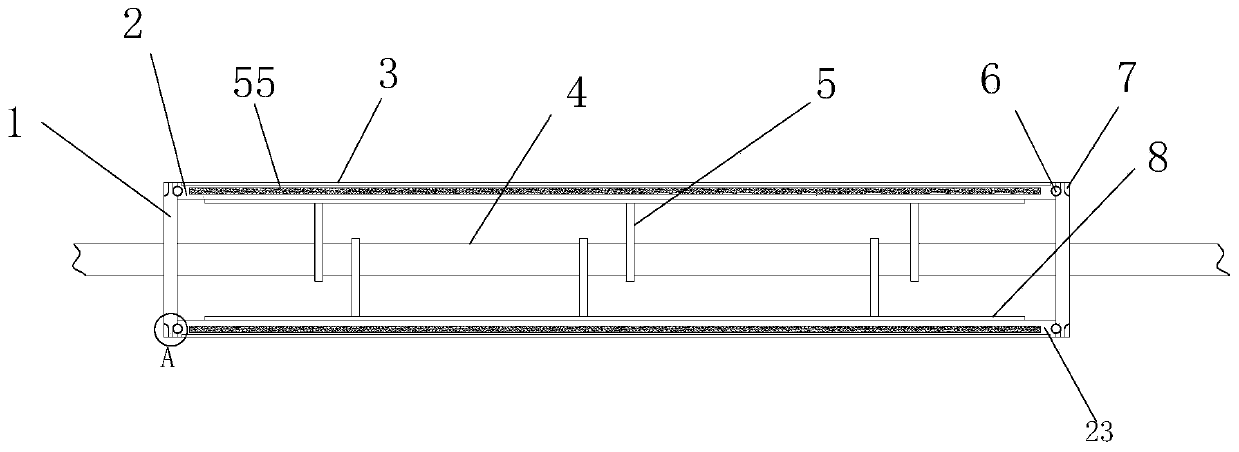

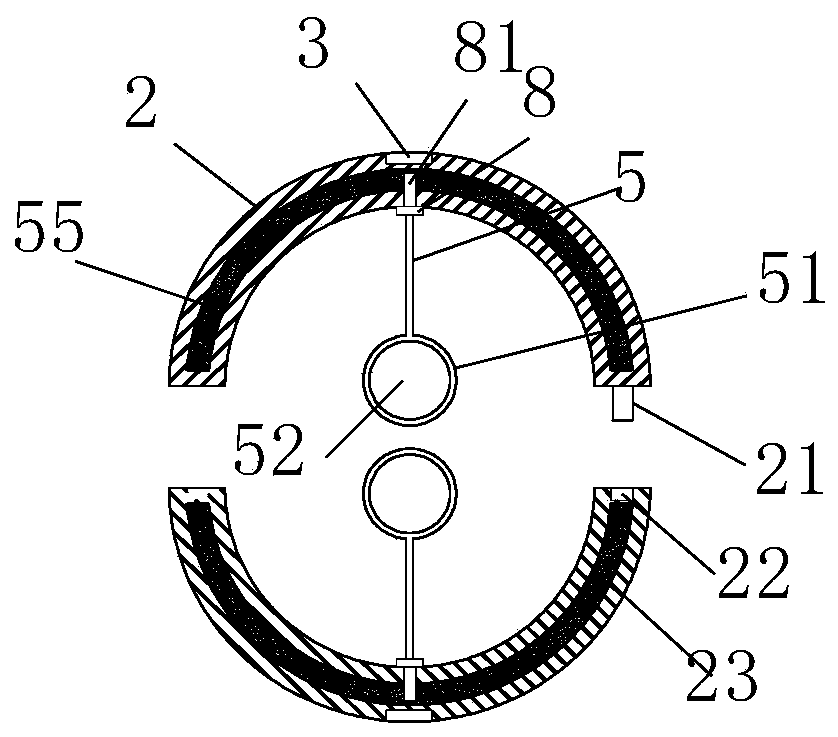

[0022] Such as figure 1 and figure 2 As shown, the composite fireproof cable includes more than one assembled cable and a cable body formed by splicing more than one connector 1, the cable body is suspended from the top and installed, and each assembled cable includes the first outer layer 2 and the second Two outer layers 23, the first outer layer 2 and the second outer layer 23 are spliced into a circular cable outer layer;

[0023] Both end faces of the first outer covering layer 2 and the second outer covering layer 23 are rotatably connected to the connecting piece 1 through a rotating structure, and a through hole 101 is opened in the middle of the connecting piece 1, and a cable is formed in the middle of the outer covering layer of the cable. The installation cavity, the cable core wire 4 is arranged in the cable installation cavity and passes through the through holes of the connectors 1, the cable core is supported by the connectors 1, and the opposite surfaces o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com