Mechanism for bending filter cloth and discharging material and automatic material-discharging method

A technology of unloading mechanism and filter cloth, which is applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of complex structure, complicated replacement method, and inability to achieve top-down flushing of filter cloths of filter presses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

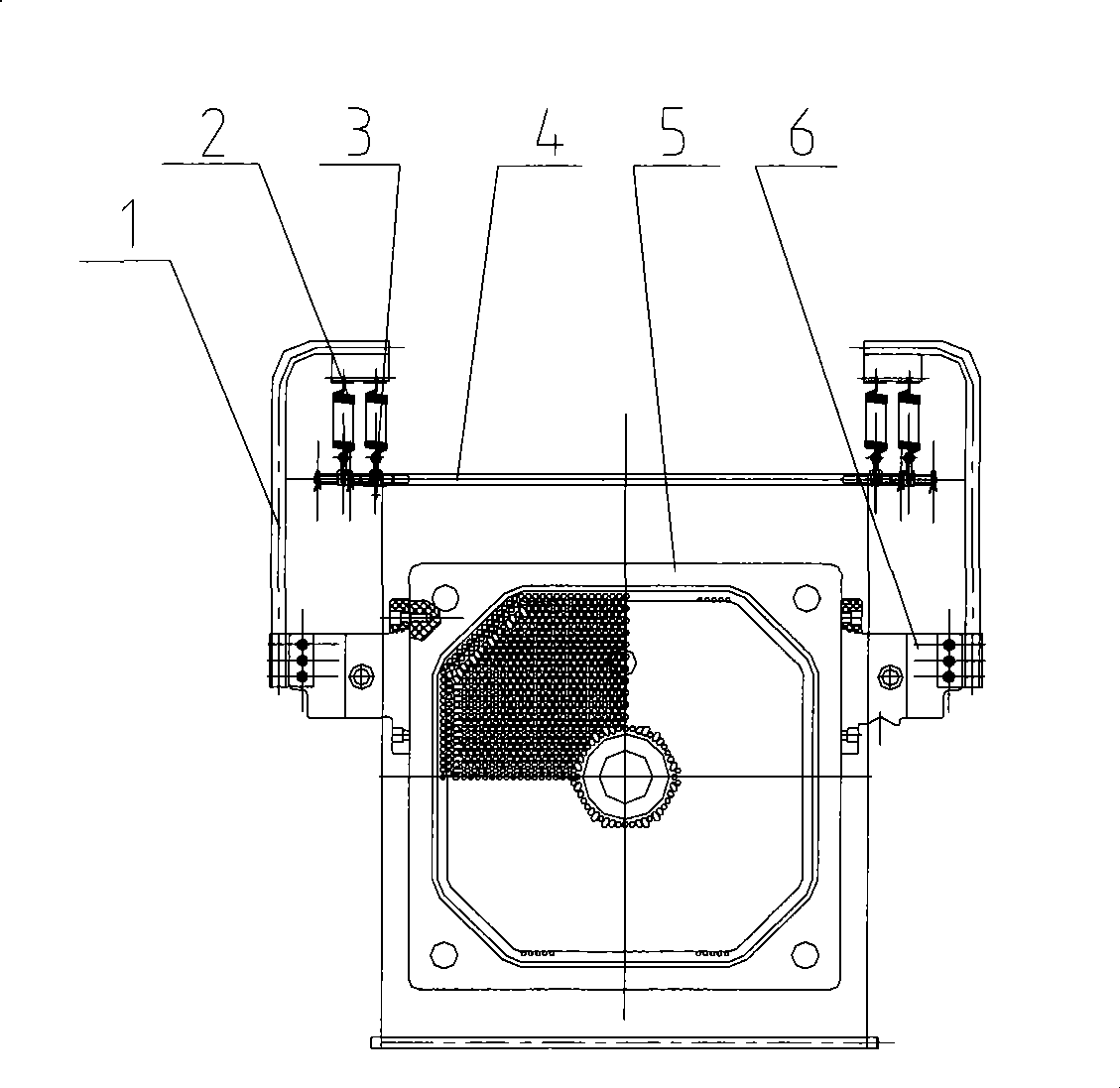

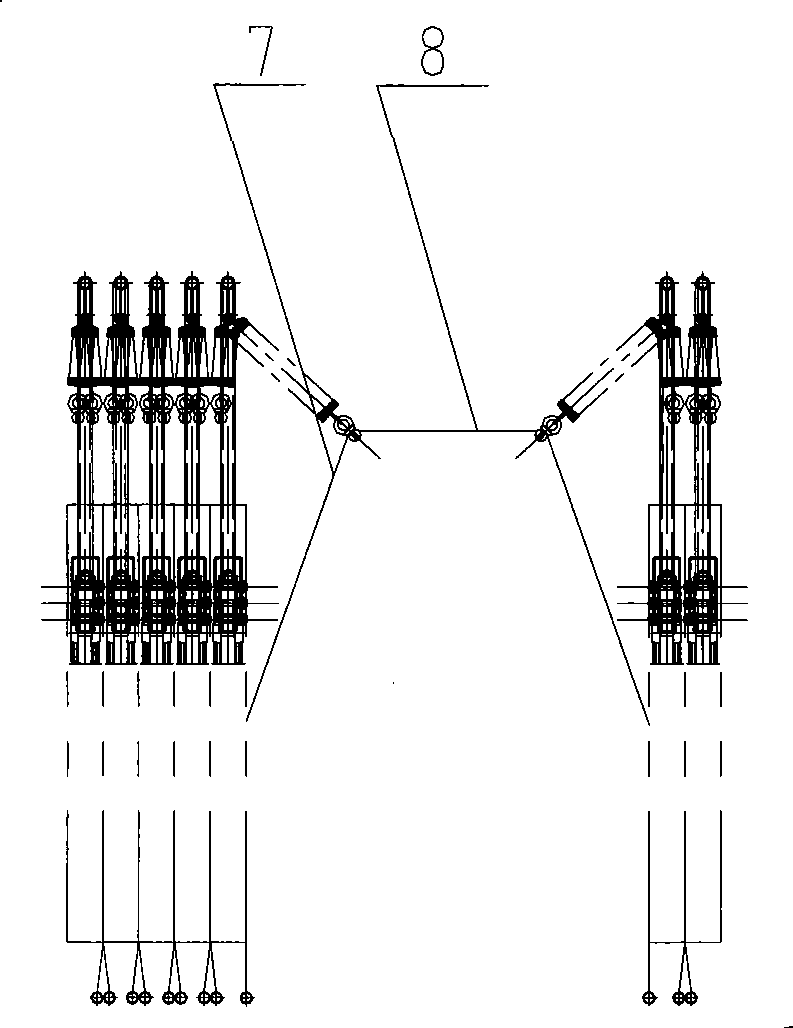

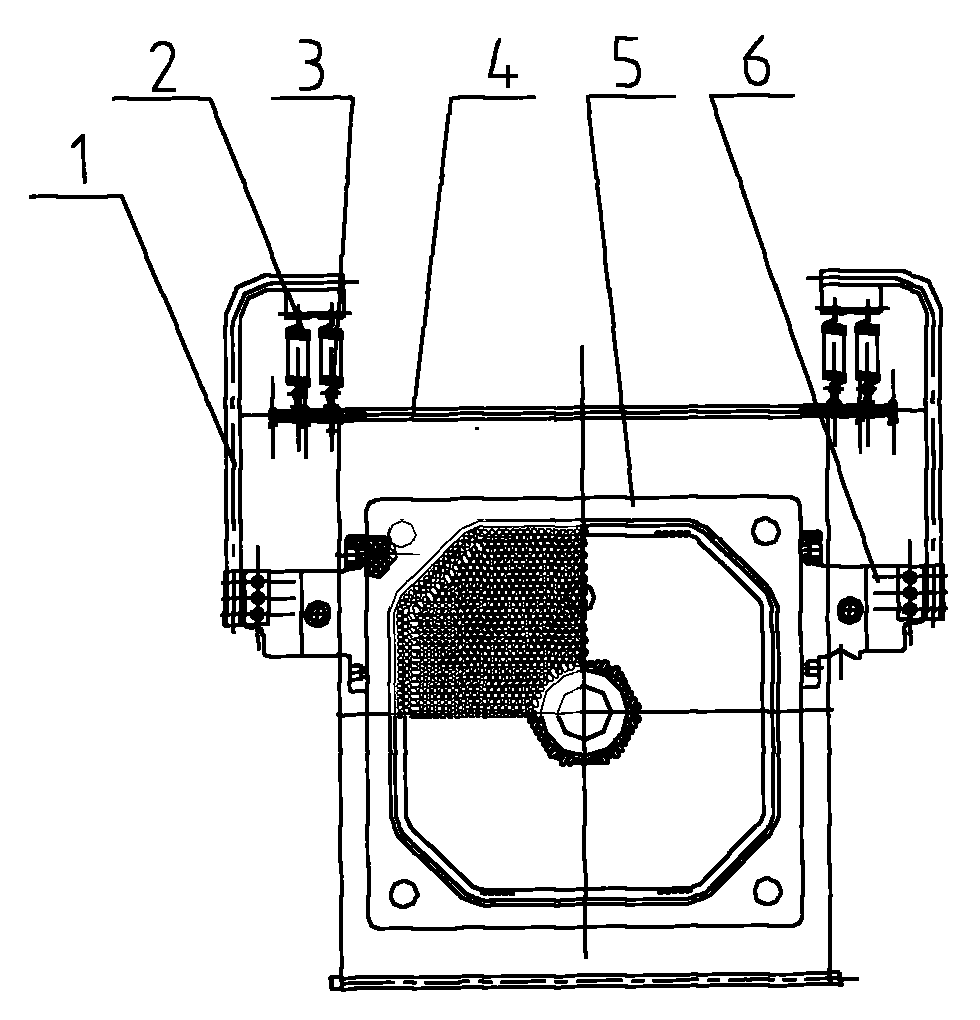

[0010] Embodiment 1: refer to figure 1 and 2 . The filter cloth varicose discharge mechanism, the two ends of the filter cloth suspender 4 and the two ends of the filter cloth suspender 4 are connected by a cloth belt 8, and the distance between the two suspenders 4 can be adjusted by the length of the cloth belt 8. The filter cloths 7 coated on the outer surfaces of the plurality of filter plates 5 respectively pass through the respective filter cloth suspenders 4, and the two ends of the two suspenders 4 are connected to each other by cloth belts 8, and the two ends of each suspender 4 are respectively installed Eyebolts 3 are provided, and the eyebolts 3 are respectively connected to respective varicose brackets 1 through tension springs 2, and the varicose brackets 1 and the handle of the filter plate 6 are directly connected by bolts. When multiple filter plates are pulled apart, the filter cloth 7 of the filter plate 5 is pulled apart by a certain angle through their r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com