Sheathed circular truncated cone type filter press

A filter press and table-top technology, which is applied in the field of table-top filter presses, can solve the problems of poor pressure resistance of the plate frame/box frame of the filter press, inability to efficiently automate production, increase reproduction resistance, etc., and achieve cleanliness Production, improvement of pressure resistance, and the effect of improving the pressure resistance of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

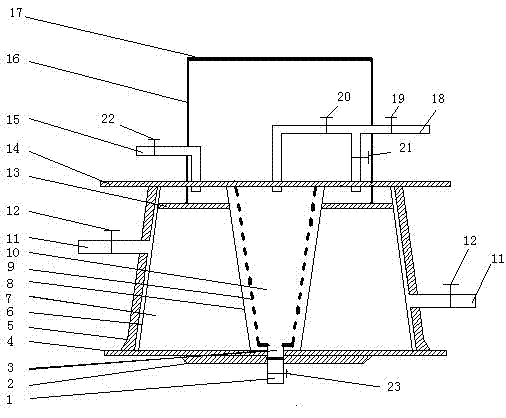

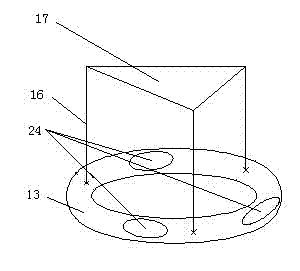

[0015] like figure 1 As shown, the table-type filter press of the present invention is mainly composed of an outer circular platform sleeve 5 and an inner circular platform sleeve 9. The outer circular platform sleeve 5 with a large bottom opening and a small upper opening is provided with The bottom cover 4 is provided with an upper cover 14, and the middle part of the outer circular frustum-shaped sleeve 5 is provided with an inner circular frustum-shaped sleeve 9 with a large upper opening and a smaller lower opening. The inner wall of the outer cylindrical frustum-shaped sleeve 5 is provided with a filter press rubber sleeve 6 The outer frustum-shaped sleeve 5 and the filter press rubber sleeve 6 form an air-intake interlayer space; the inner frustum-shaped sleeve 9 is provided with a number of small holes for the passage of filtrate and backwashing, T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com