Patents

Literature

33results about How to "Realize automatic strapping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

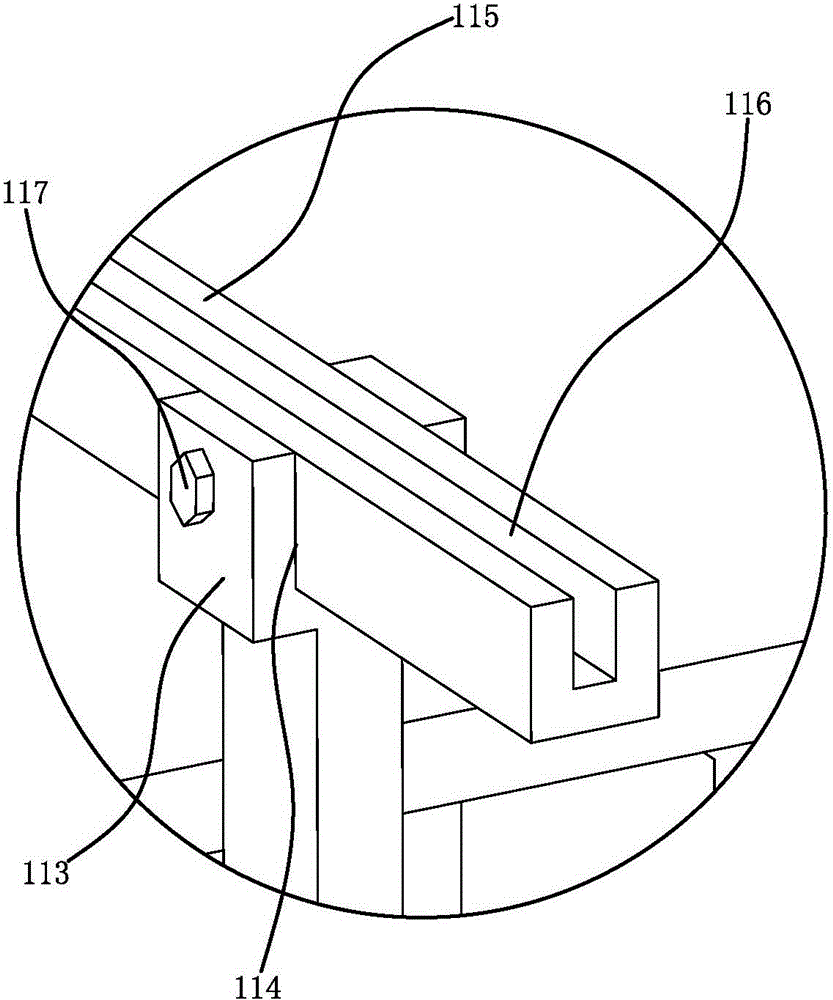

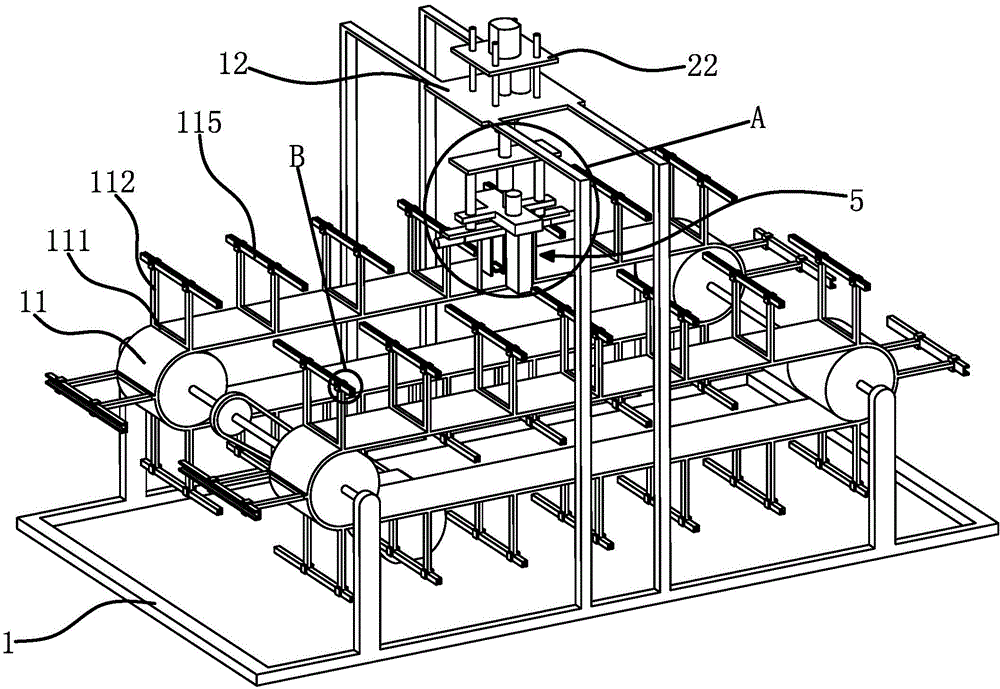

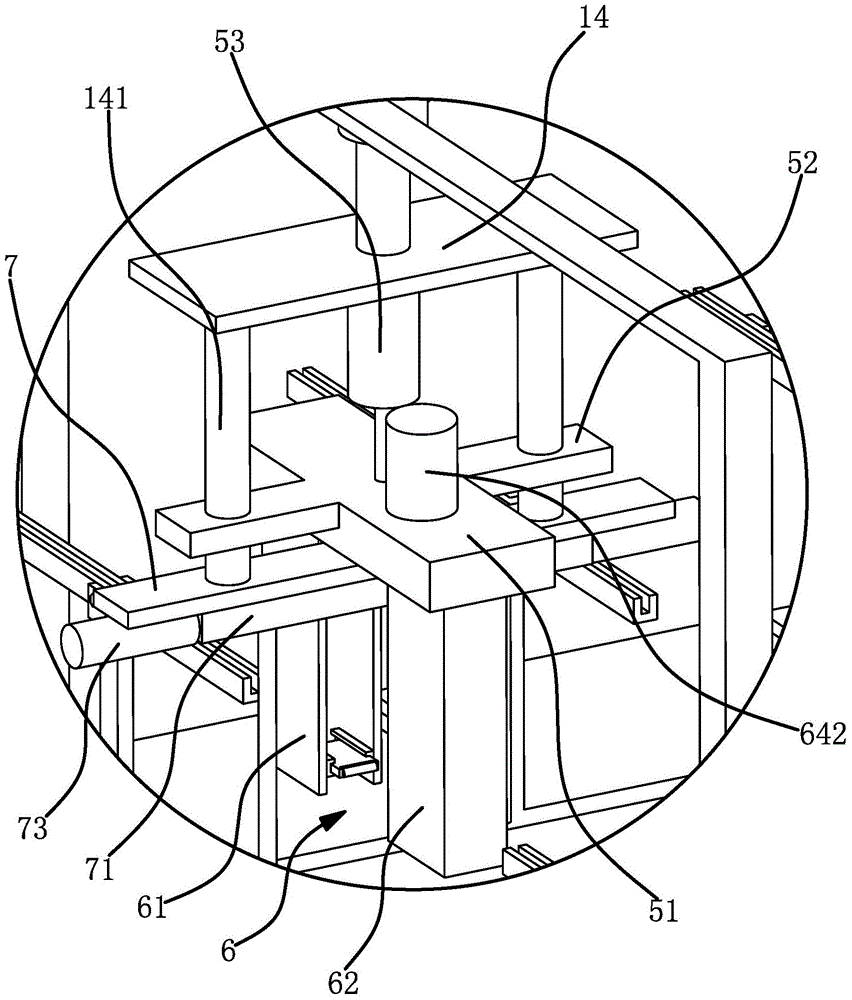

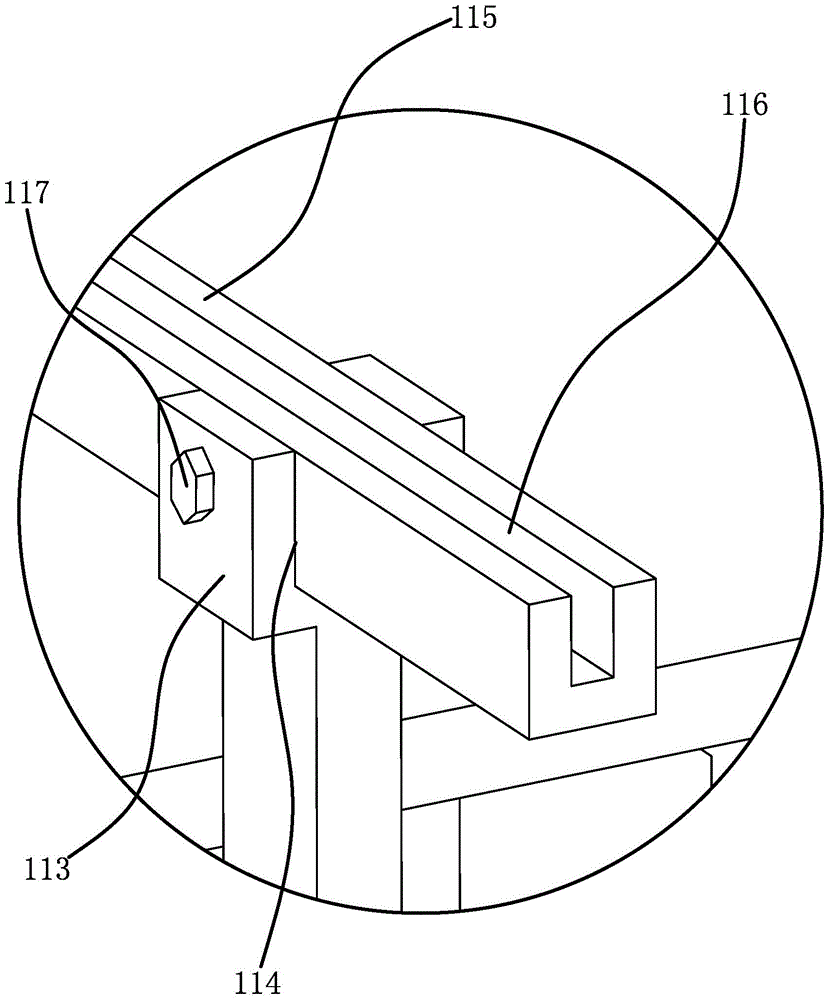

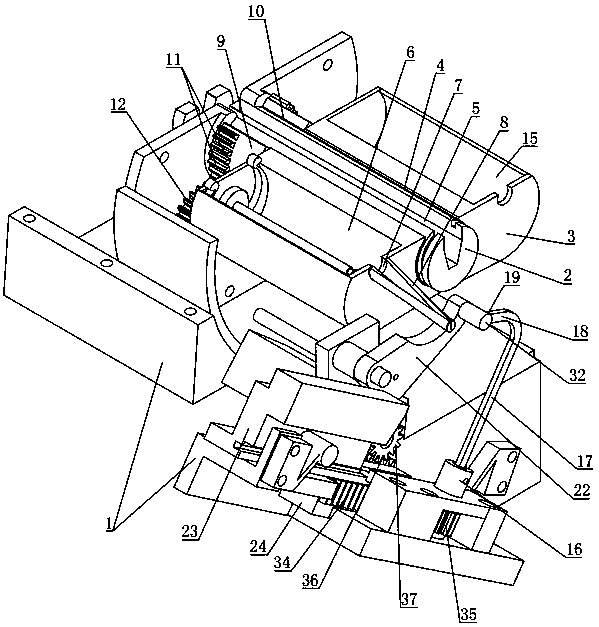

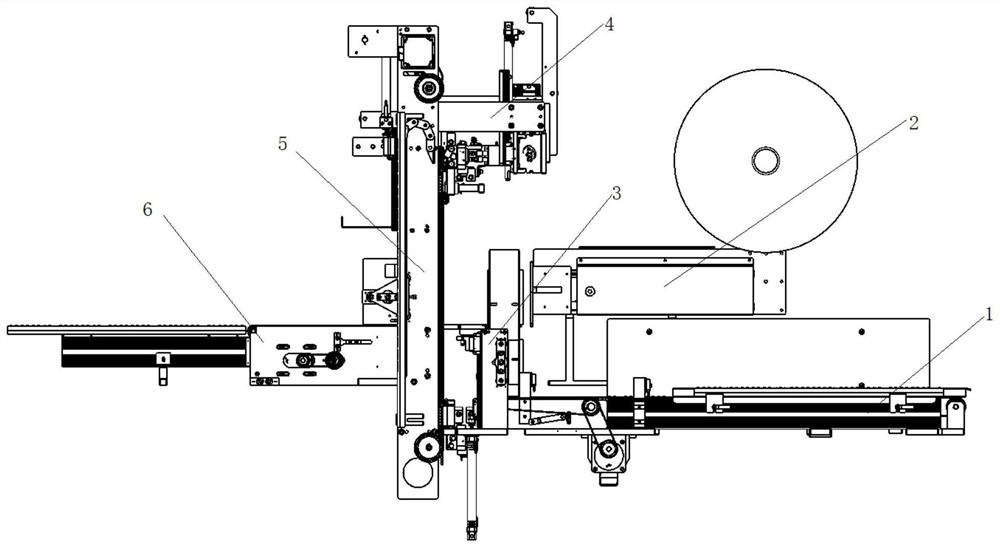

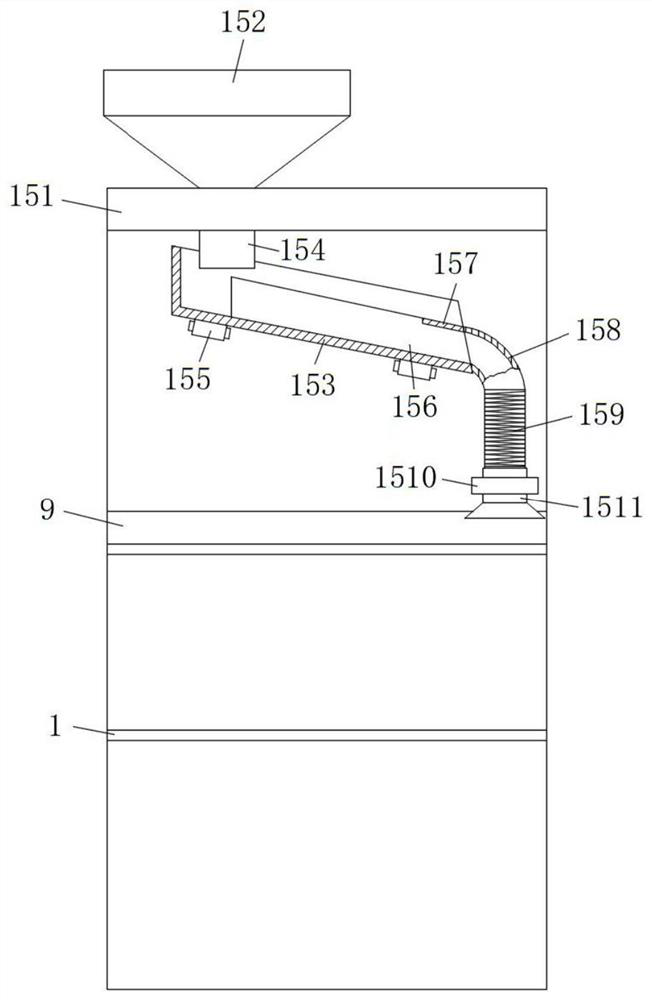

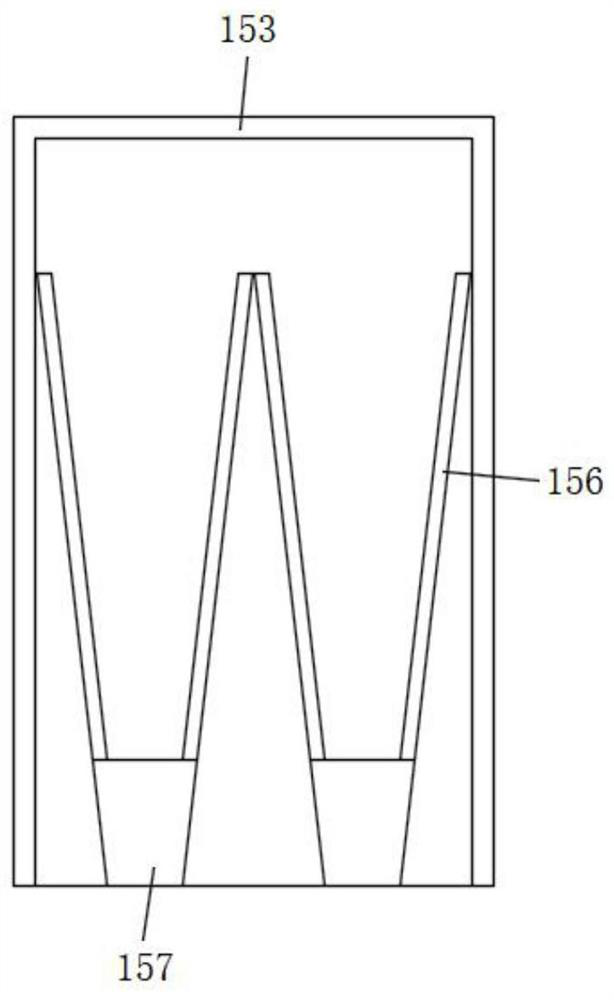

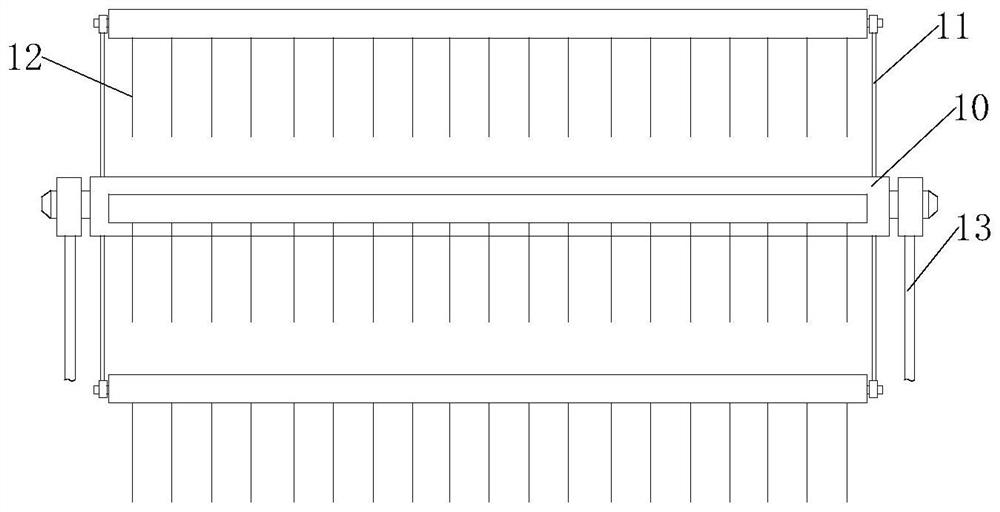

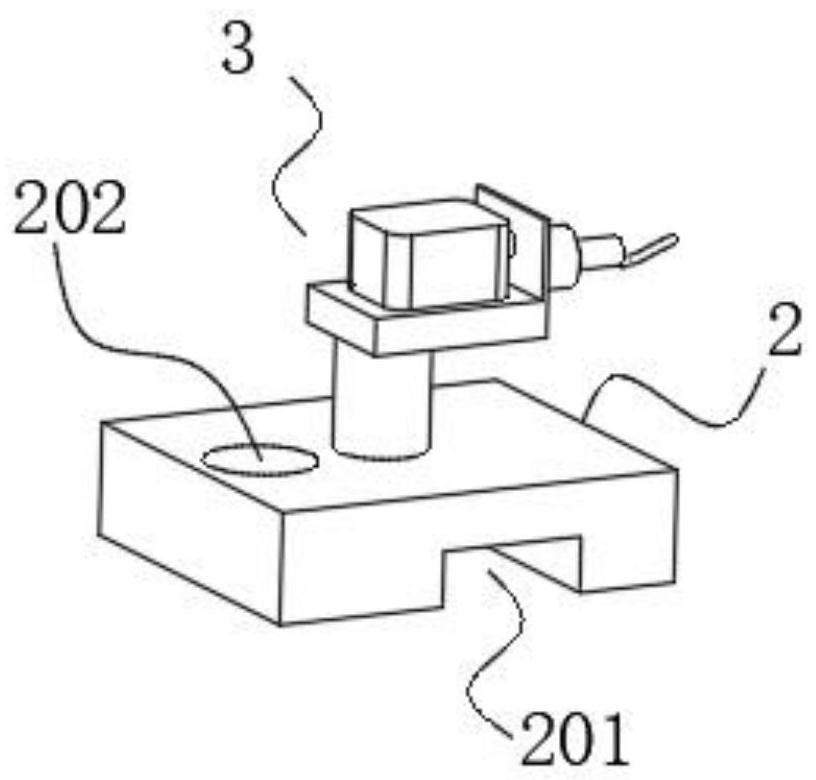

Automatic bundling device of plastic bag making machine

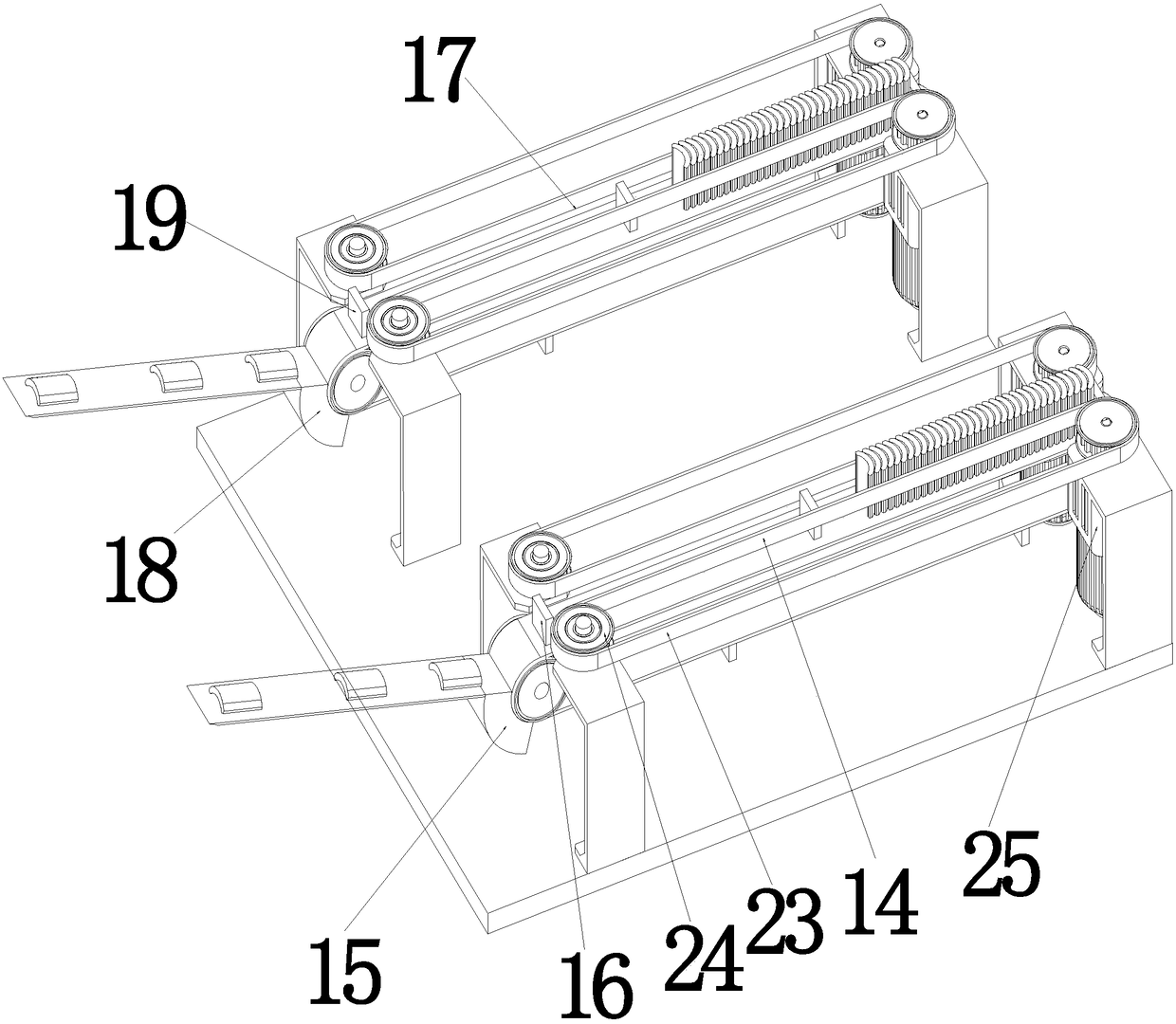

PendingCN108773518ARealize automatic strappingPrevent accumulation and cloggingPaper article packagingBinding material applicationEngineeringTransfer mechanism

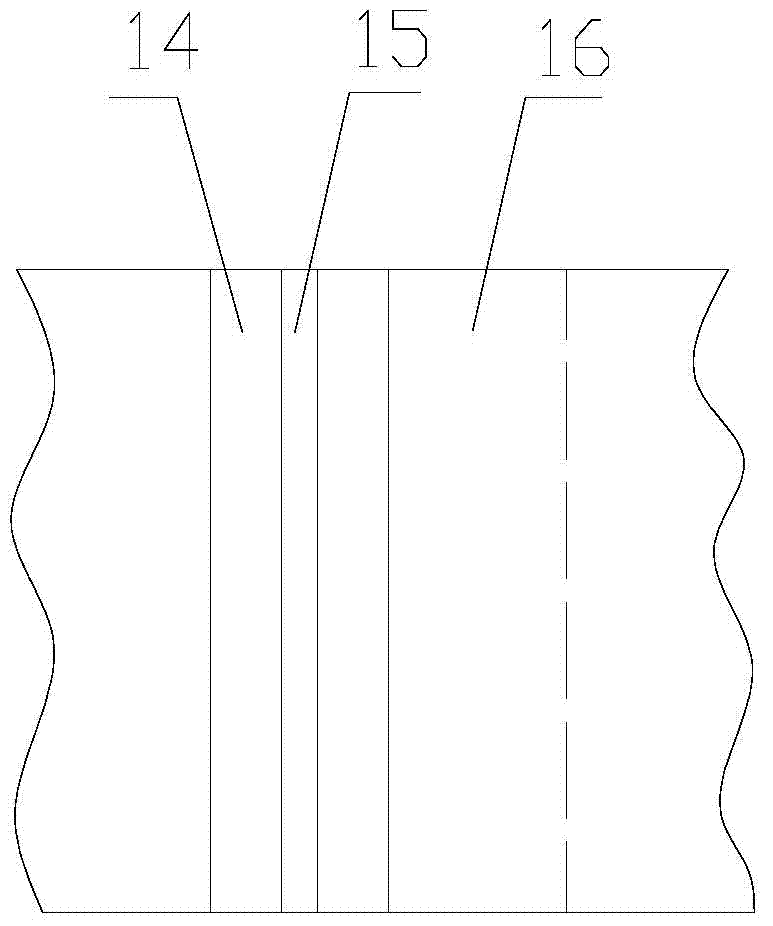

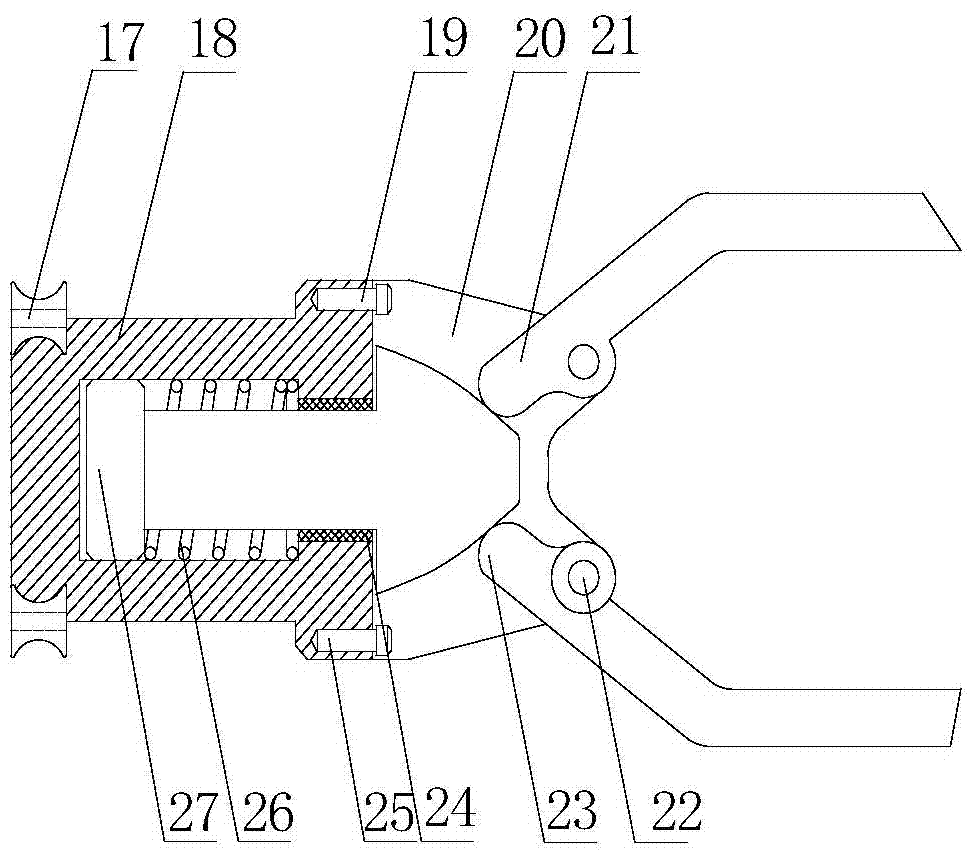

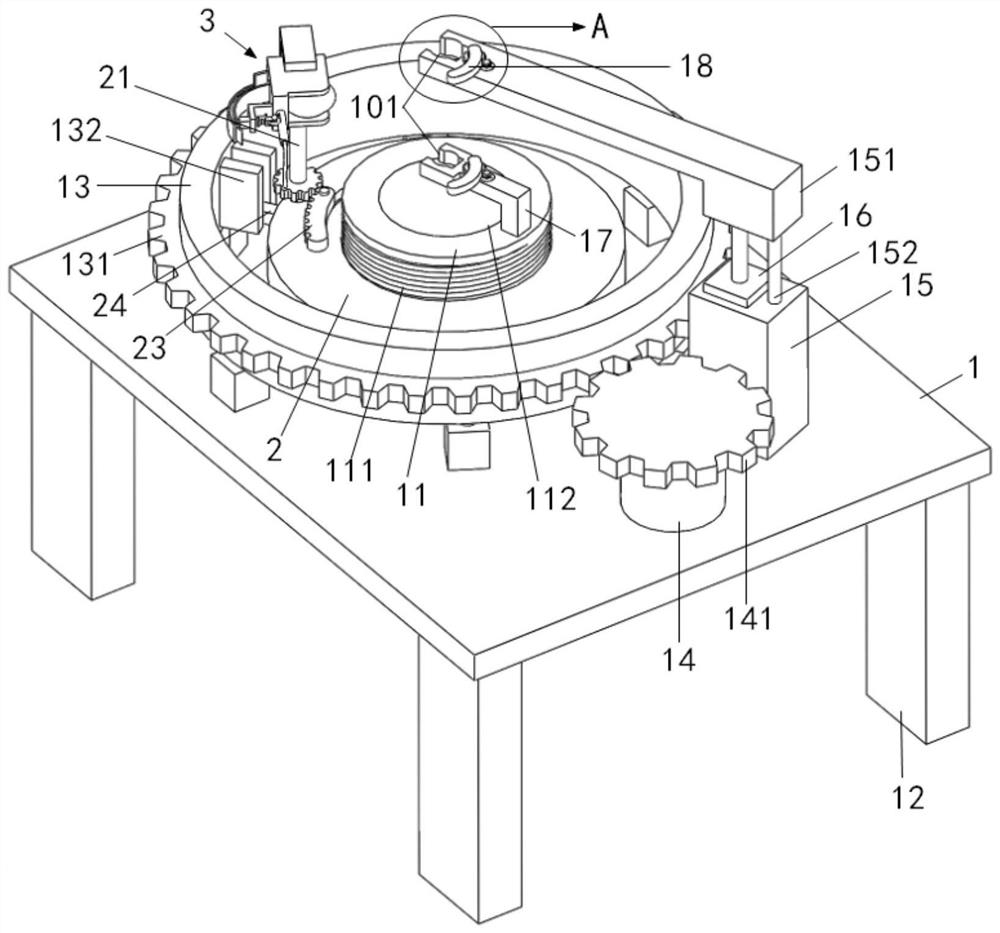

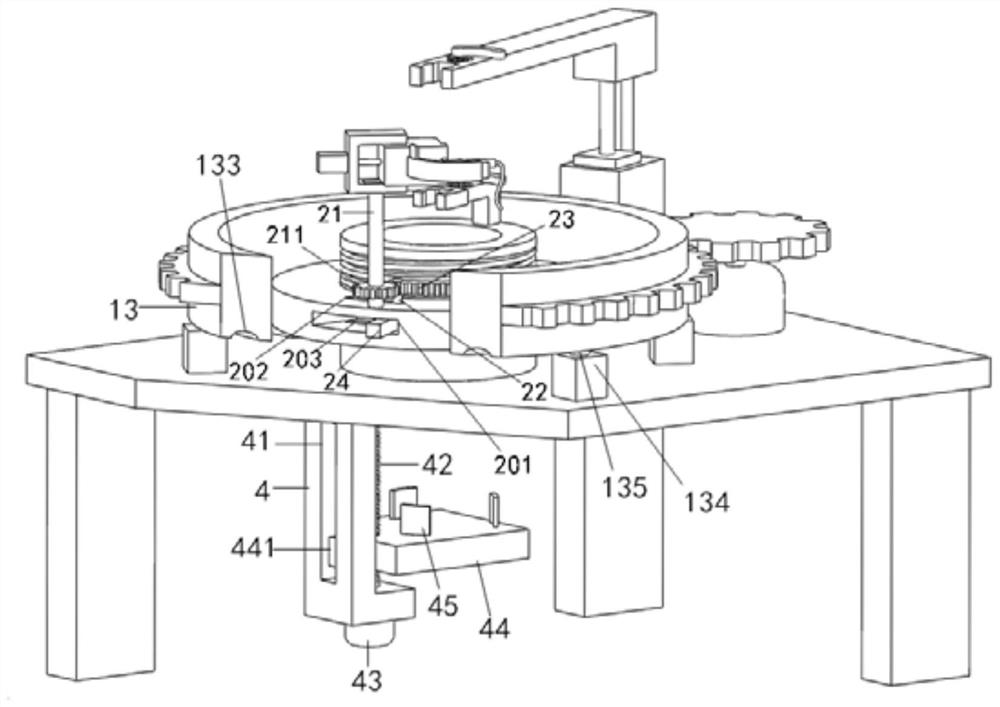

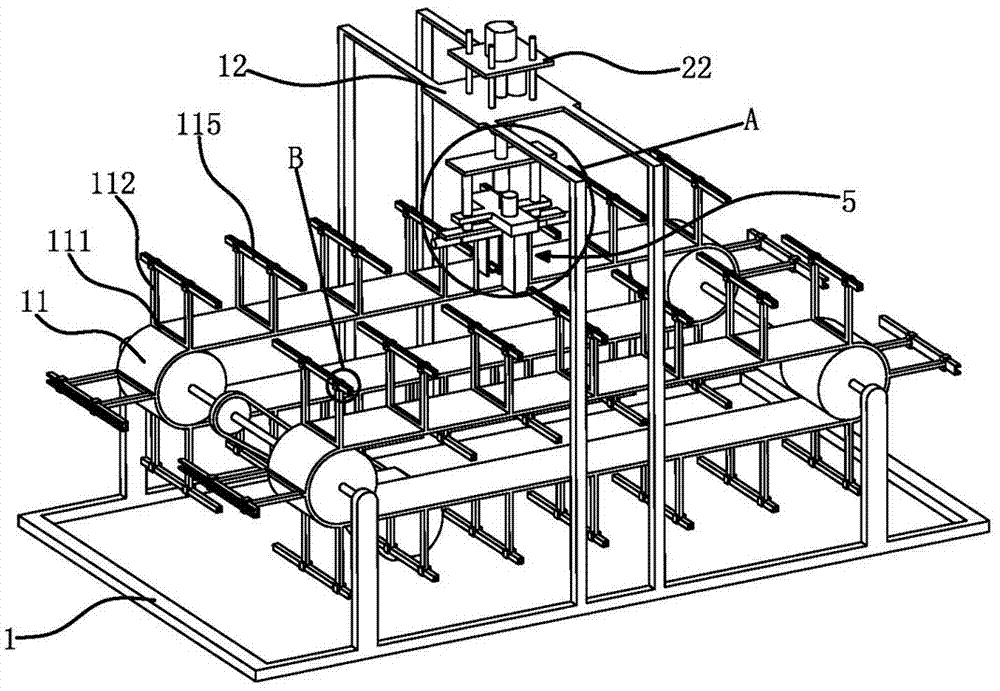

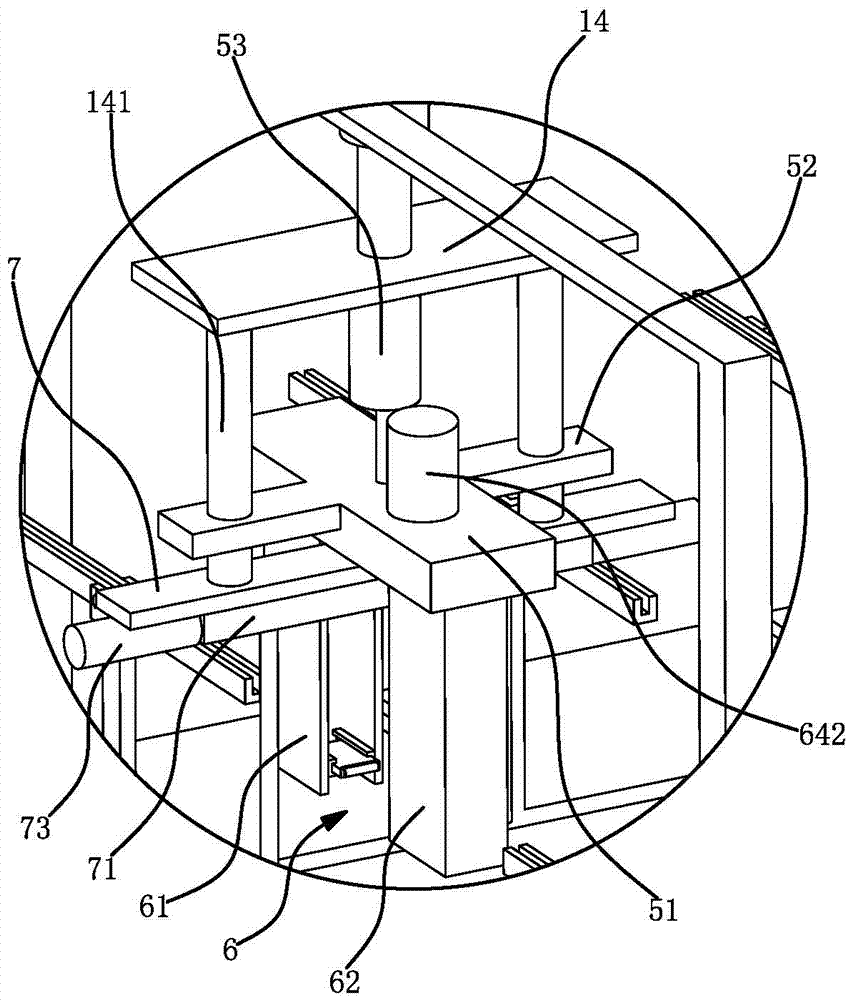

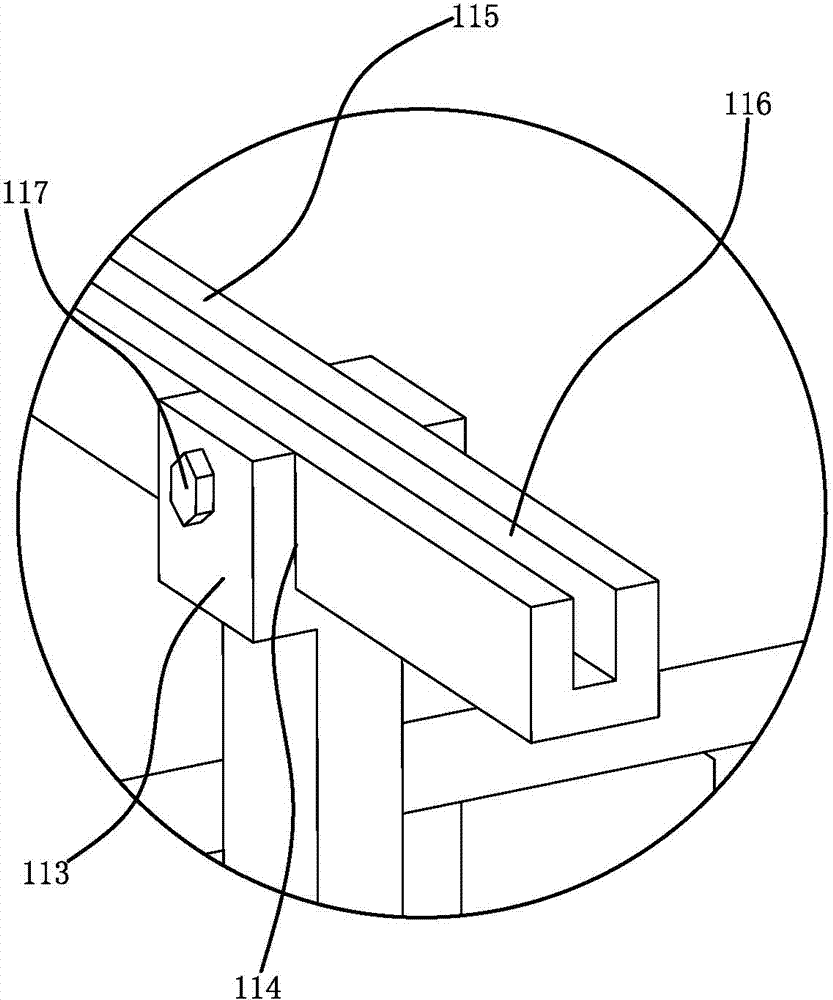

The invention provides an automatic bundling device of a plastic bag making machine. The automatic bundling device comprises a plastic bag feeding mechanism, a rubber band arranging and output mechanism and a bundling mechanism. The bundling mechanism comprises an opening device and a rubber band transfer mechanism. The rubber band transfer mechanism is used for transferring rubber bands output bythe rubber band arranging and output mechanism to the opening device. The opening device is used for opening each rubber band and sleeving the rubber band onto a stack of plastic bags. The automaticbundling device has the advantages that the automatic bundling device can implement automatic bundling of soft thin film products and improves the working efficiency; through arranging of a lower rubber band output channel of the rubber band arranging and output mechanism, the rubber bands can be prevented from getting accumulated and blocked and can be conveyed smoothly; through the combination effect of band release convex heads of band release plates arranged on the outer side of a band release plate of the opening device and brace rod grooves formed in the circumferential surfaces of rubber band brace rods, the situation that rubber bands cannot be kept away from the rubber band brace rods can be effectively prevented, and the working reliability of band release is improved.

Owner:王根乐

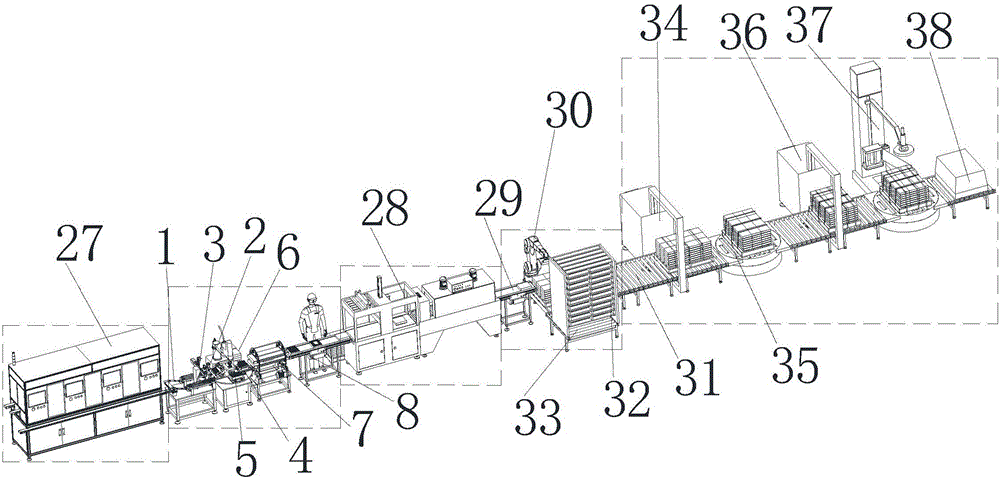

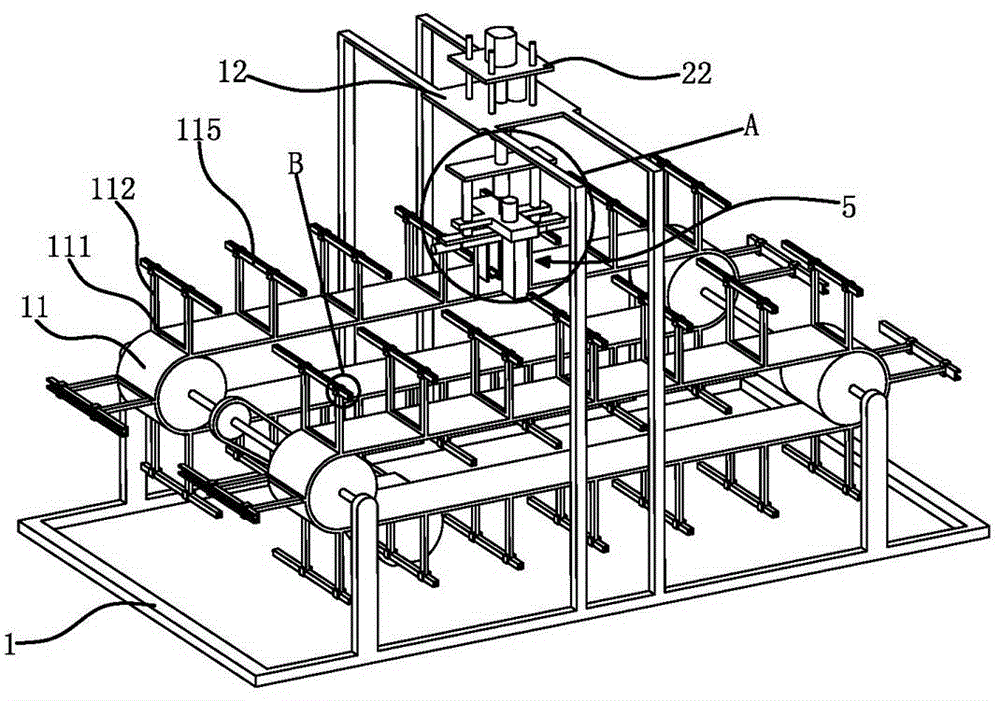

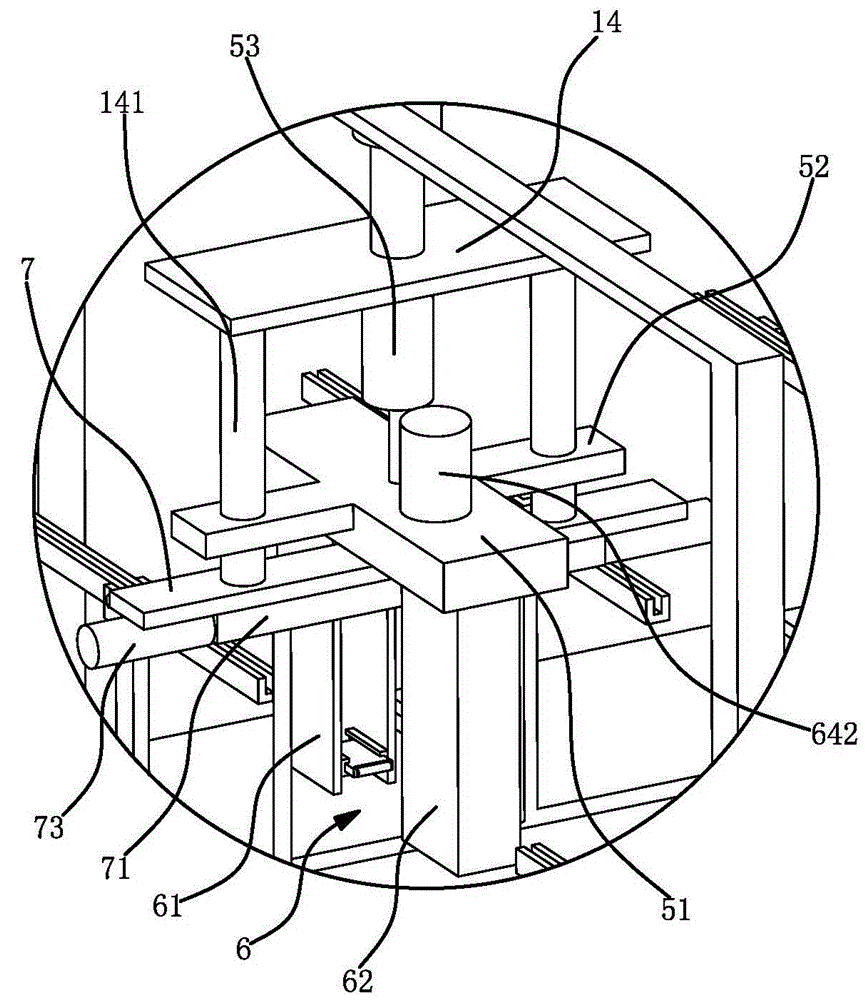

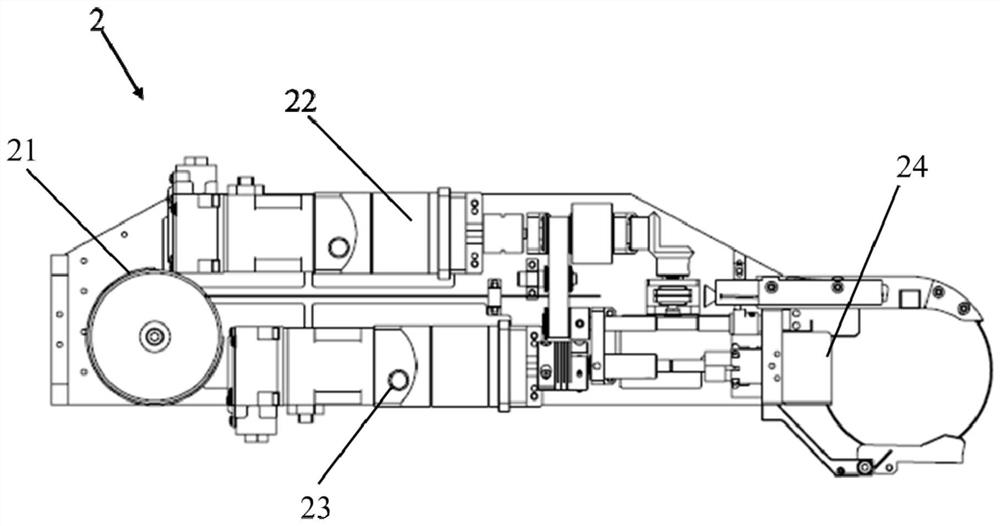

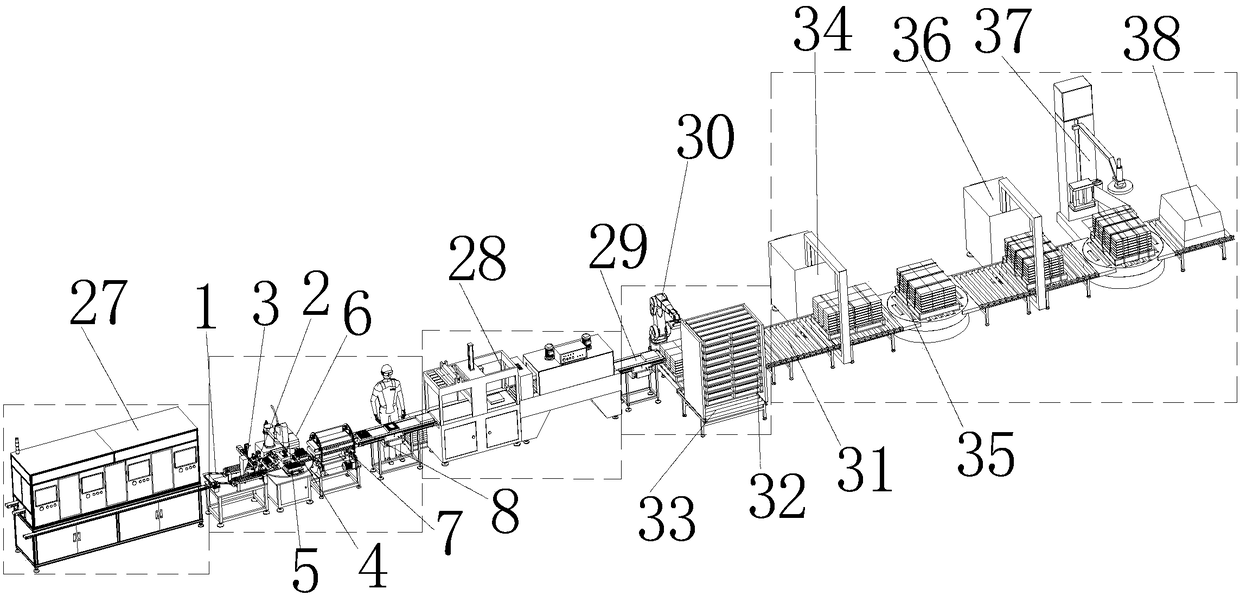

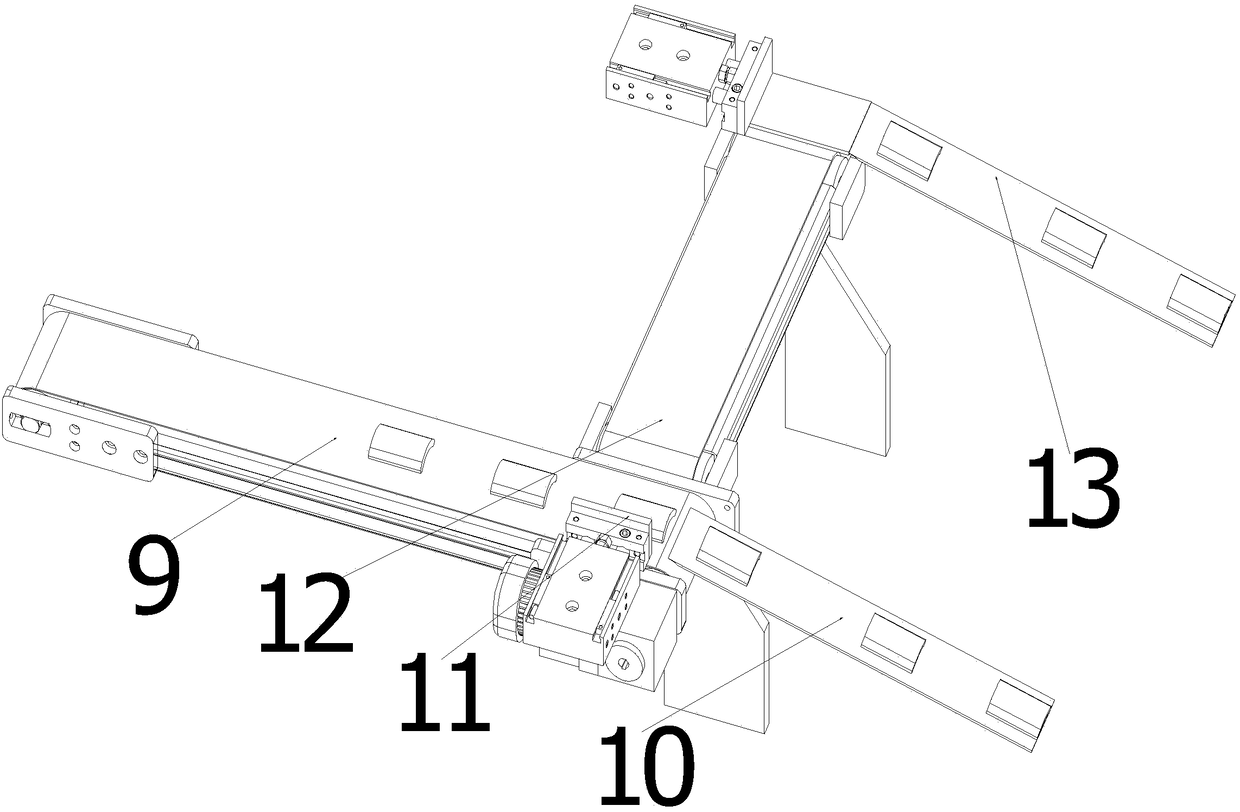

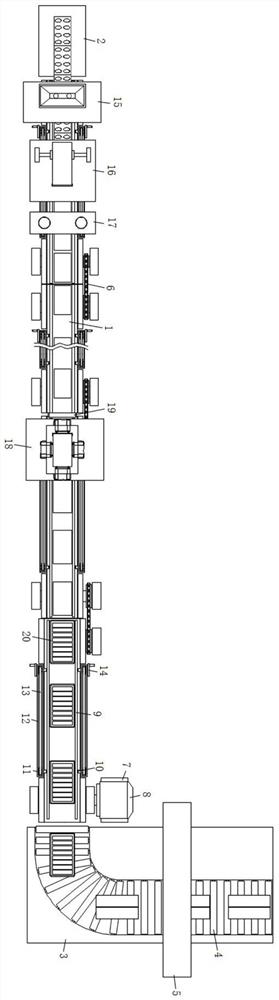

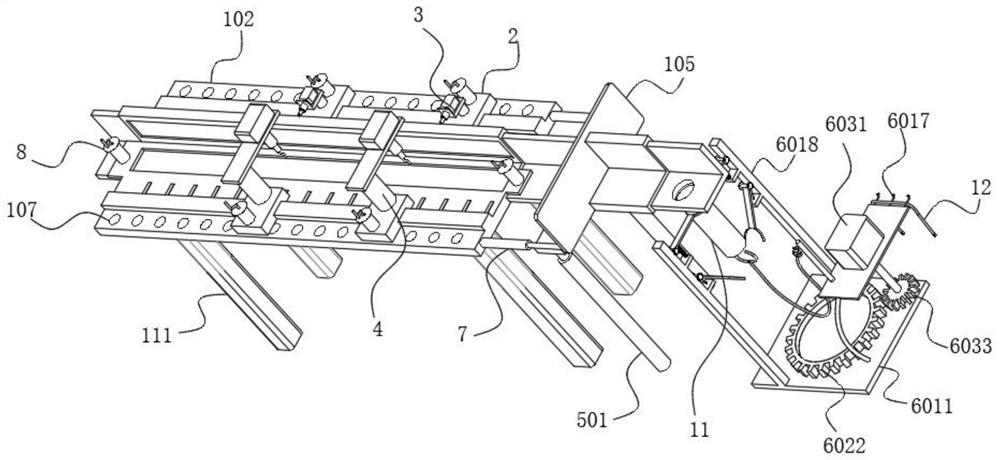

Automatic production line suitable for packaging magnetic shoes and realization method of automatic production line

ActiveCN105947293ASimple structureImprove product qualityWrappers shrinkageBinding material applicationProduction lineManipulator

The invention discloses an automatic production line suitable for packaging magnetic shoes. The automatic production line comprises automatic appearance detecting equipment, a controller, a magnetic shoe distributing device, a magnetic shoe finishing device, a transplanting and encasing manipulator, a magnetic shoe arranging device, a placement robot, a box body turnover device, a magnetic shoe full-box conveyor belt, a thermal shrinkage film sealing machine, a palletizing conveying belt, a palletizing robot and a binding / film winding system. The invention also discloses a realization method of the automatic production line suitable for packaging the magnetic shoes. The automatic production line and the realization method thereof disclosed by the invention have the characteristics of simple structure, good quality of products, high production efficiency, small production area, low production cost, time conservation, labor conservation and the like.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

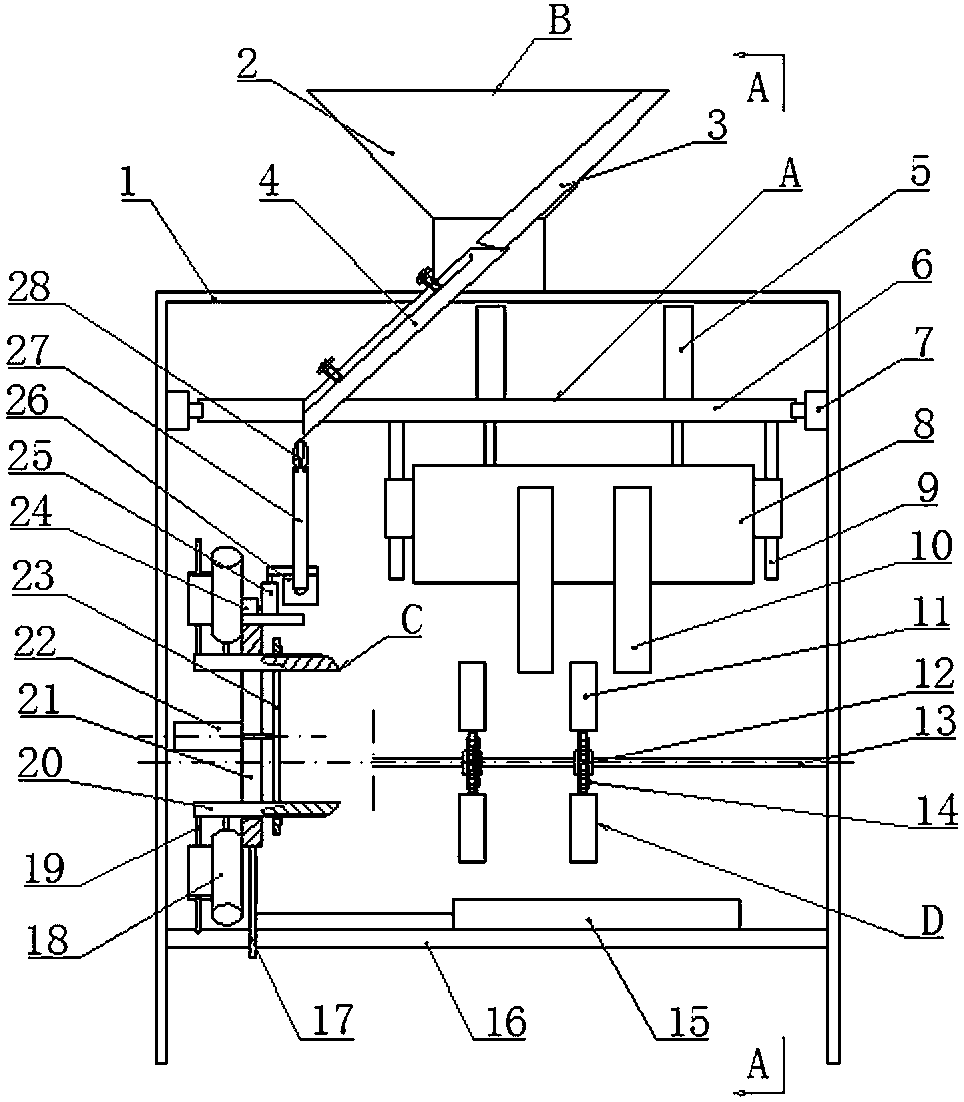

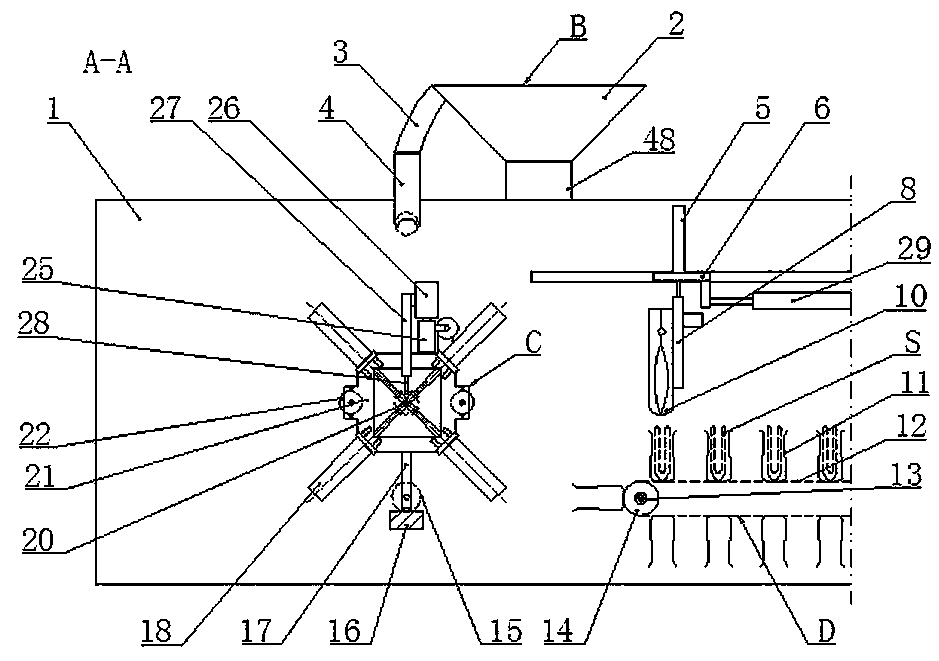

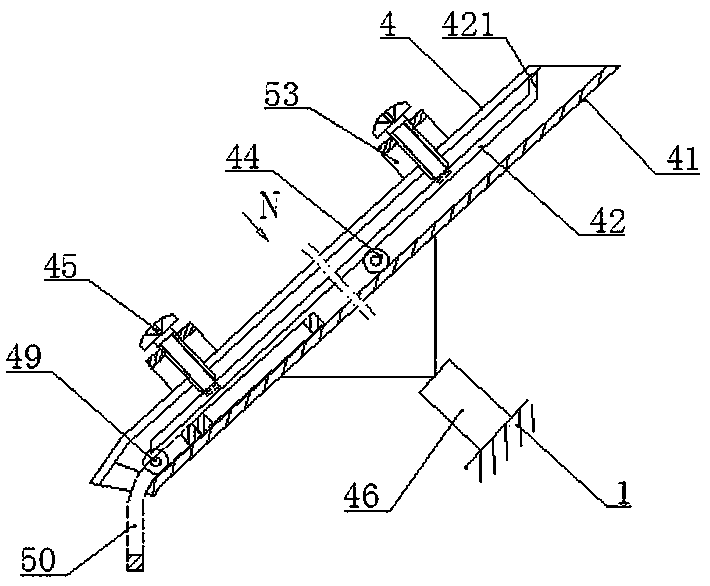

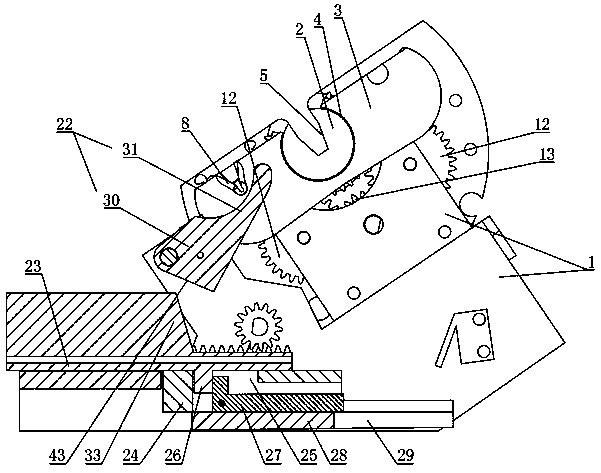

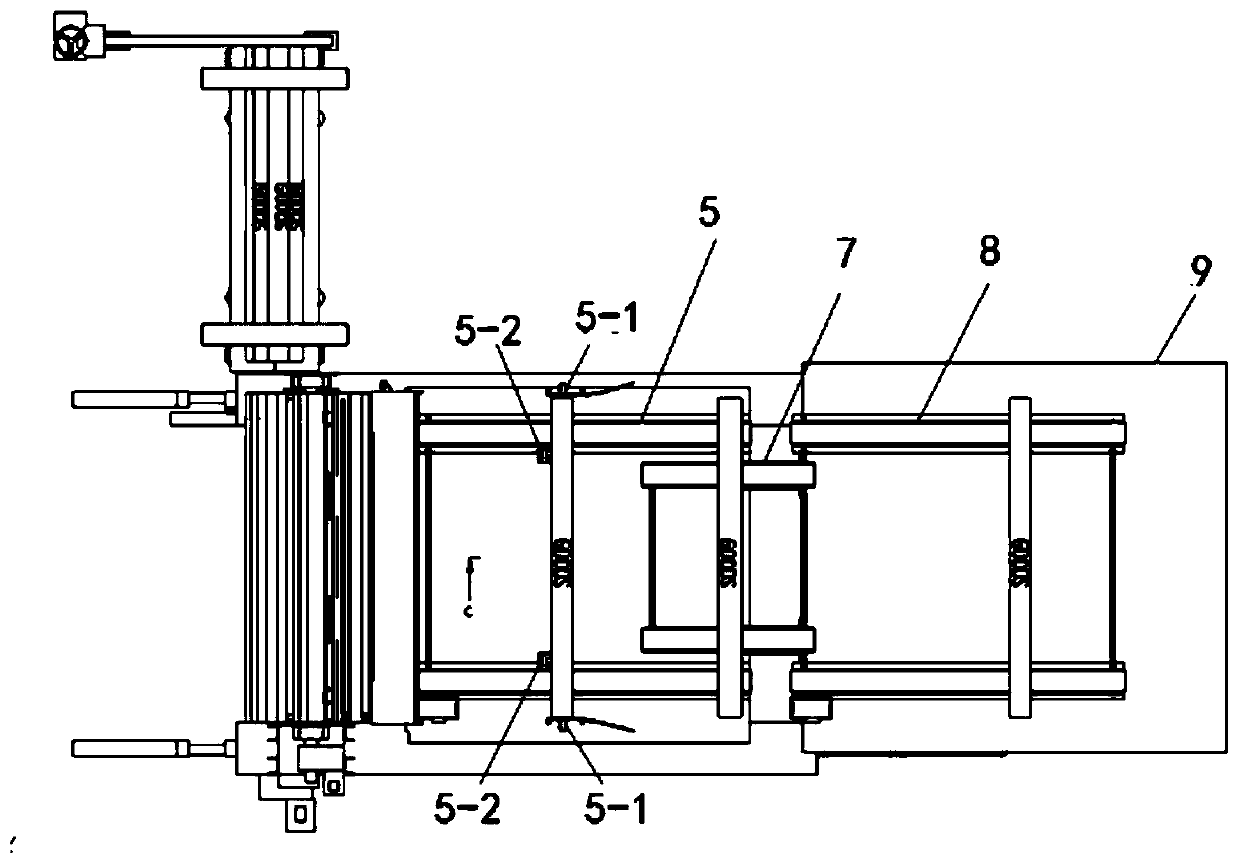

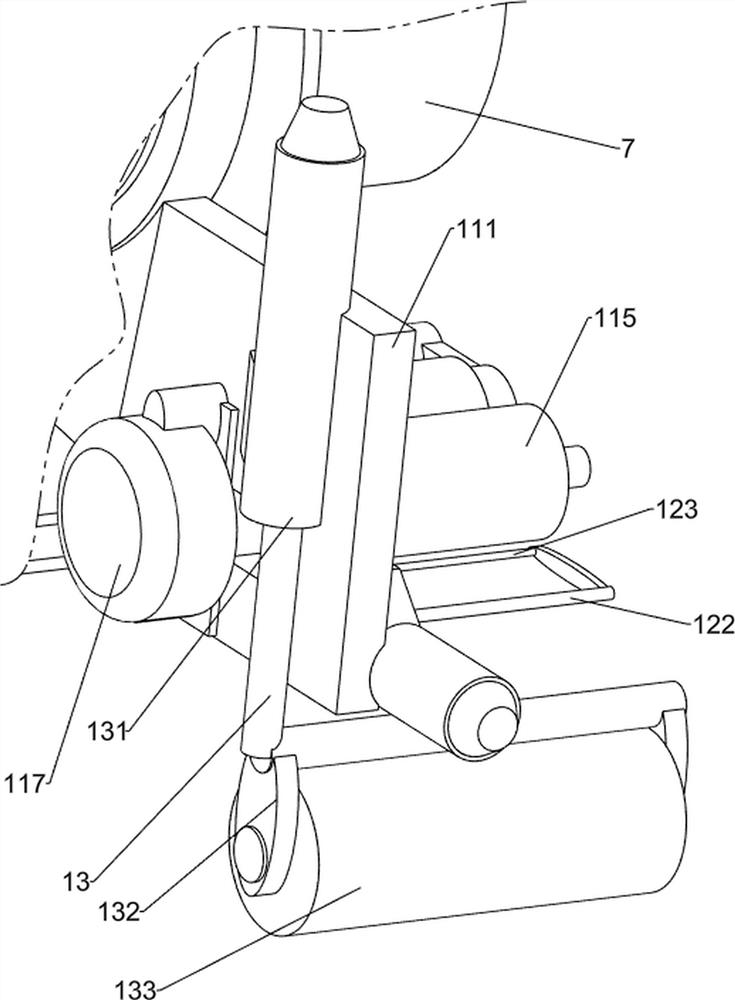

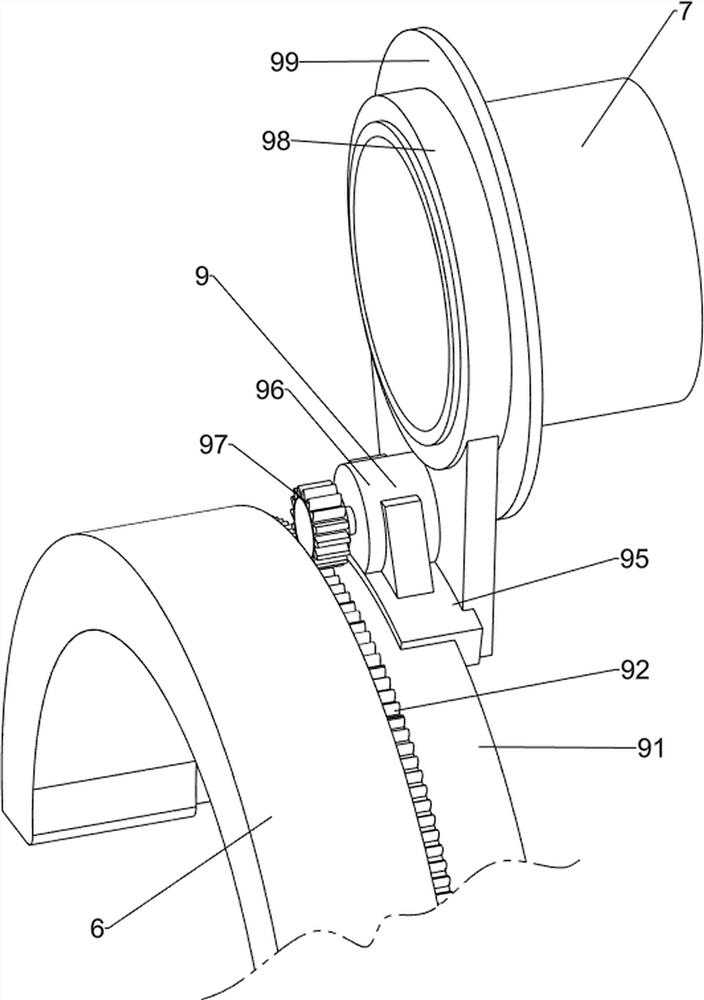

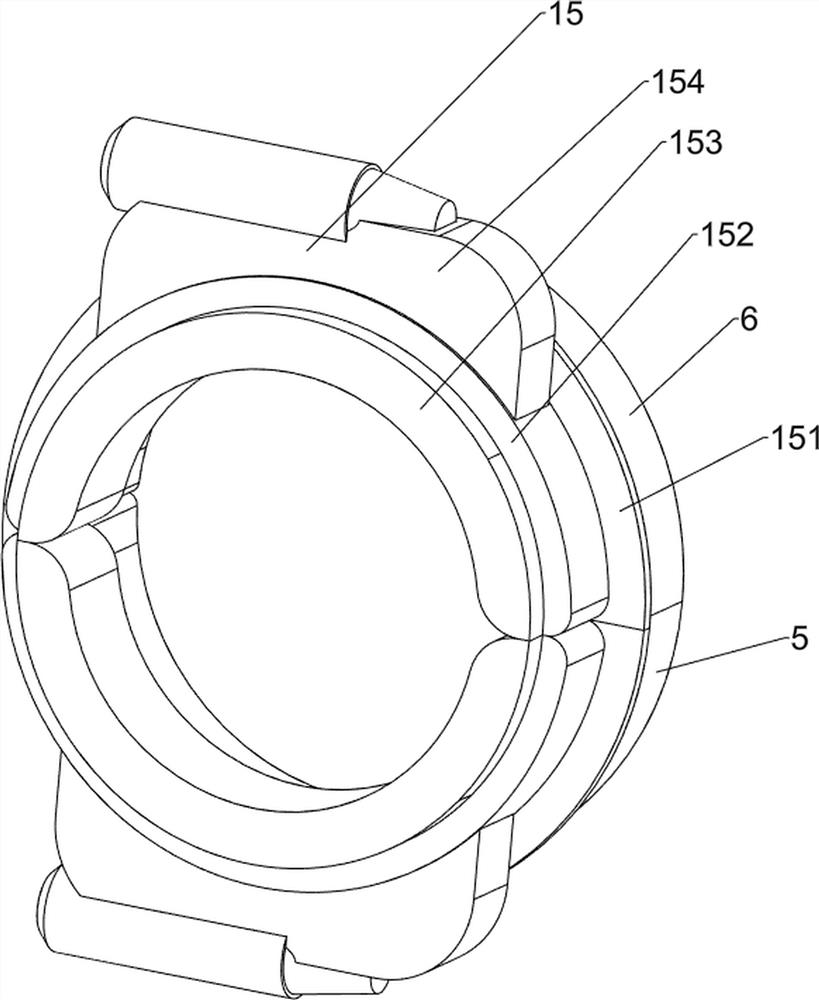

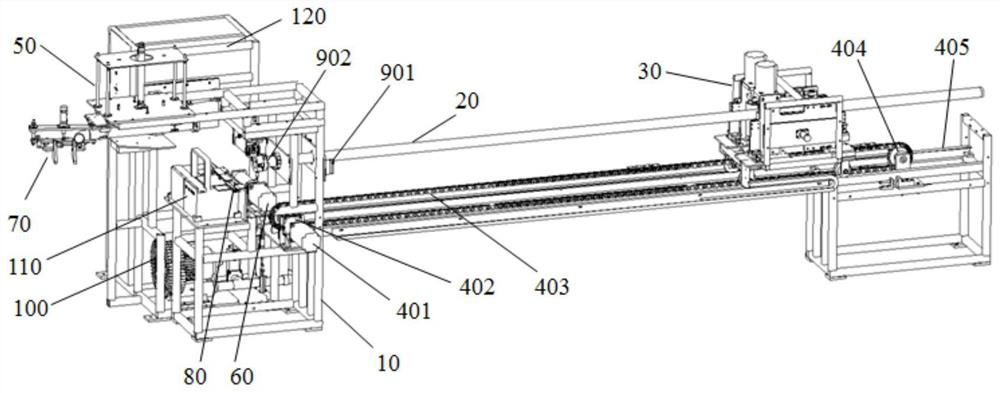

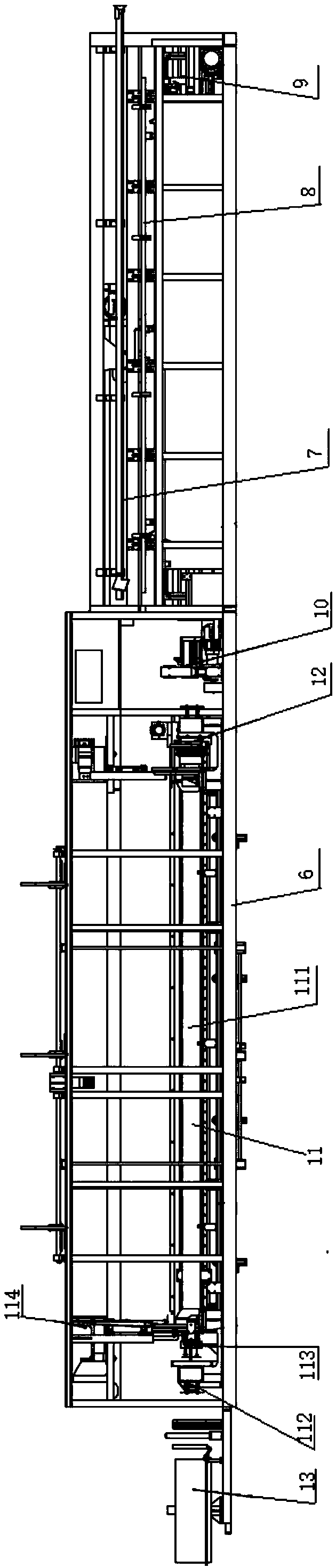

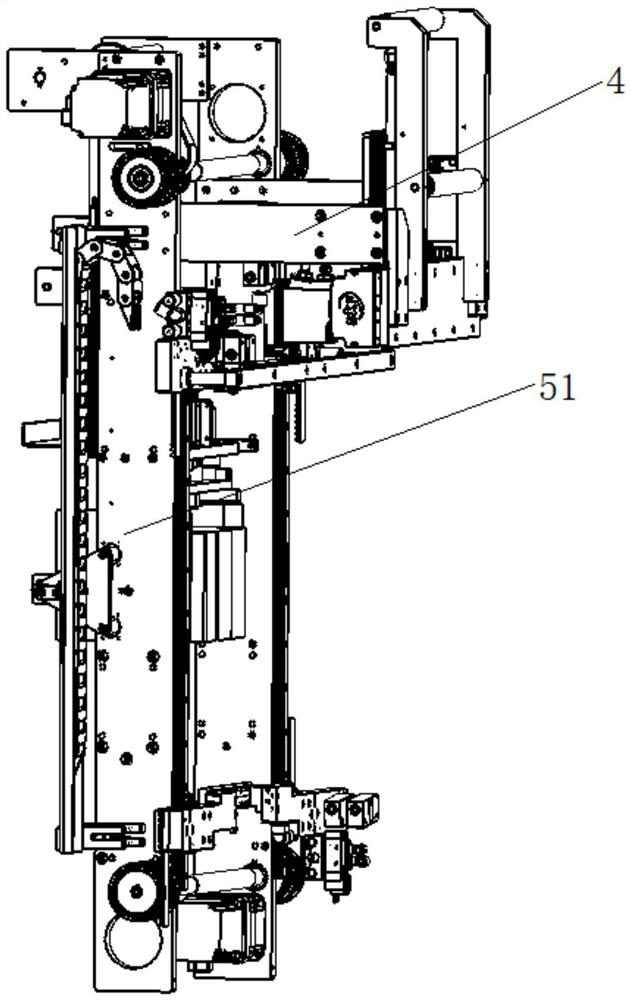

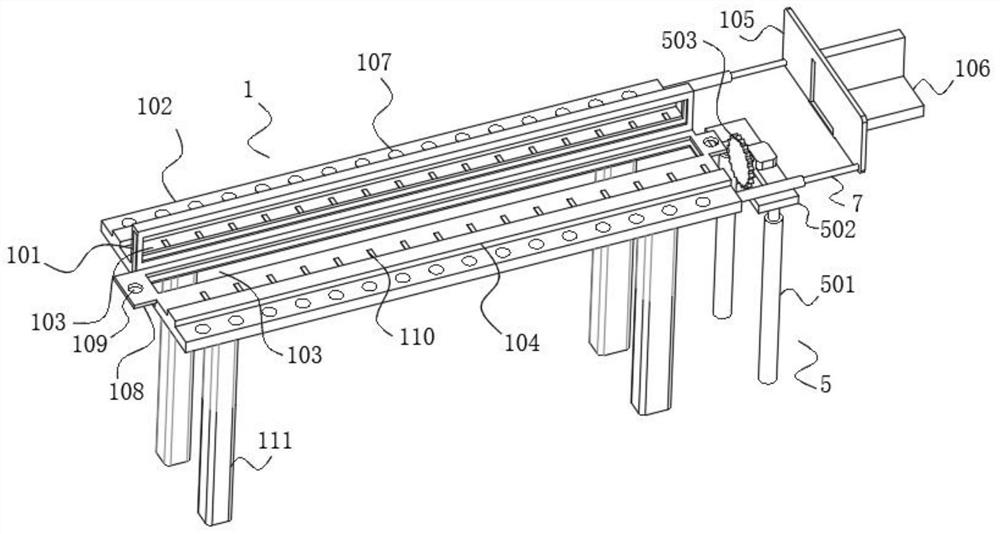

Winding binding machine for medical infusion tube

InactiveCN104015952AHigh degree of automationRealize automatic strappingBinding material applicationPaper/cardboard containersEngineeringConductor Coil

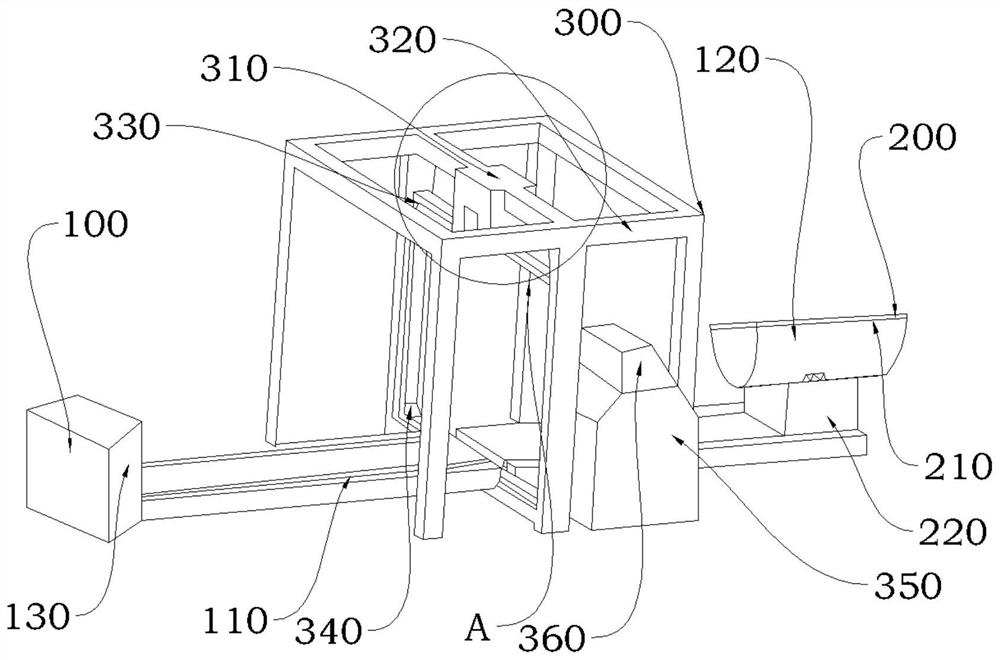

The invention provides a winding binding machine for a medical infusion tube and belongs to the technical field of medical device processing equipment. The winding binding machine for the medical infusion tube solves the problems that the existing infusion tube winding binding quality is low and efficiency is low. The winding binding machine for the medical infusion tube comprises a rack, wherein two conveyor belts are rotatably connected with the rack, a plurality of material carrying rods are respectively fixedly connected on the two conveyor belts, the rack is fixedly connected with one working platform, the working platform is connected with a main shaft in a sliding way along the vertical direction, a driving mechanism I and a driving mechanism II are arranged on the working platform, the main shaft is fixedly connected with a mainboard, the mainboard is connected with two winding rods, each material carrying rod is provided with a clamping mechanism, the mainboard is connected with a binding main body, and a binding device is arranged on the binding main body. The winding binding machine for the medical infusion tube can automatically wind the medical infusion tube and then automatically bind the medical infusion tube after winding, automation degree is high, and production efficiency is improved.

Owner:杨丽华

Winding and strapping machine for medical infusion tube

InactiveCN104085554AHigh degree of automationIncrease productivityBinding material applicationBundling machine detailsEngineeringMedical equipment

The invention provides a winding and strapping machine for a medical infusion tube, and belongs to the technical field of processing equipment of medical equipment. The winding and strapping machine solves the problems that an existing infusion tube is low in winding and strapping quality and efficiency. The winding and strapping machine for the medical infusion tube comprises a rack. The rack is connected with two conveying belts in a rotating mode, each conveying belt is fixedly connected with multiple material supporting rods, the rack is fixedly connected with a working table, the working table is connected with a main shaft in a sliding mode in the vertical direction and provided with a first driving mechanism and a second driving mechanism, the main shaft is fixedly connected with a main plate which is connected with two winding rods, a clamping mechanism is arranged on the material supporting rods, the main plate is connected with a strapping body, and the strapping body is provided with a strapping device. The winding and strapping machine for the medical infusion tube can wind the infusion tube automatically and strap the infusion tube automatically after the infusion tube is wound, is high in automation degree and improves production efficiency.

Owner:郭嘉川

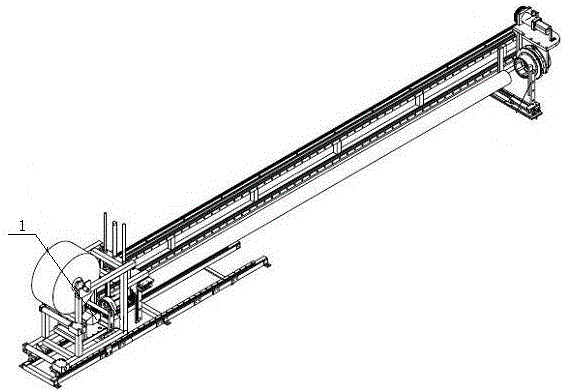

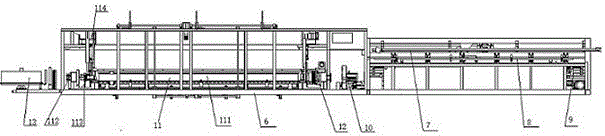

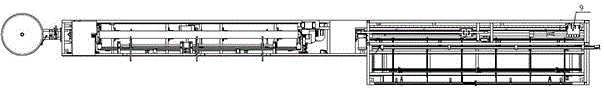

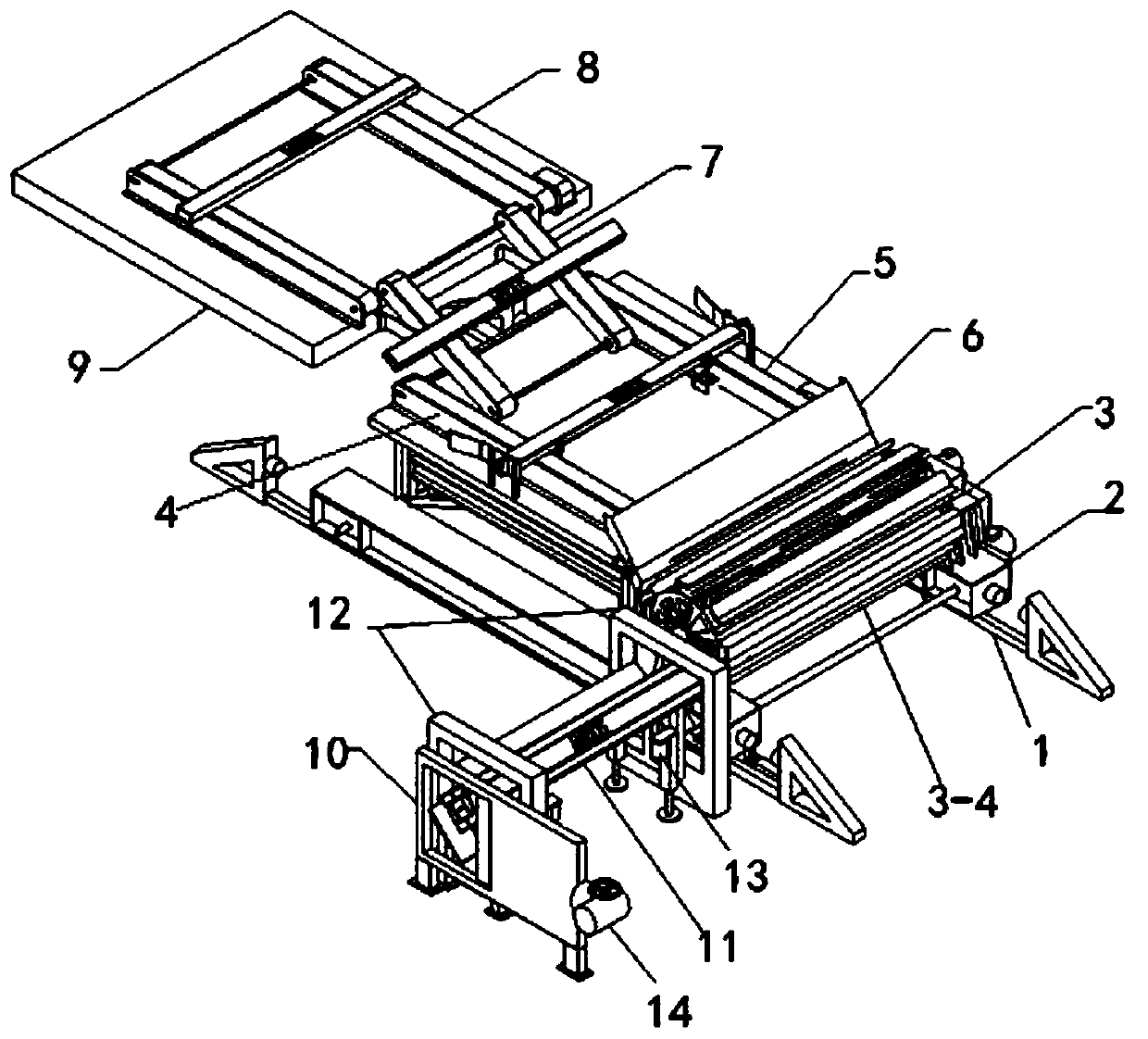

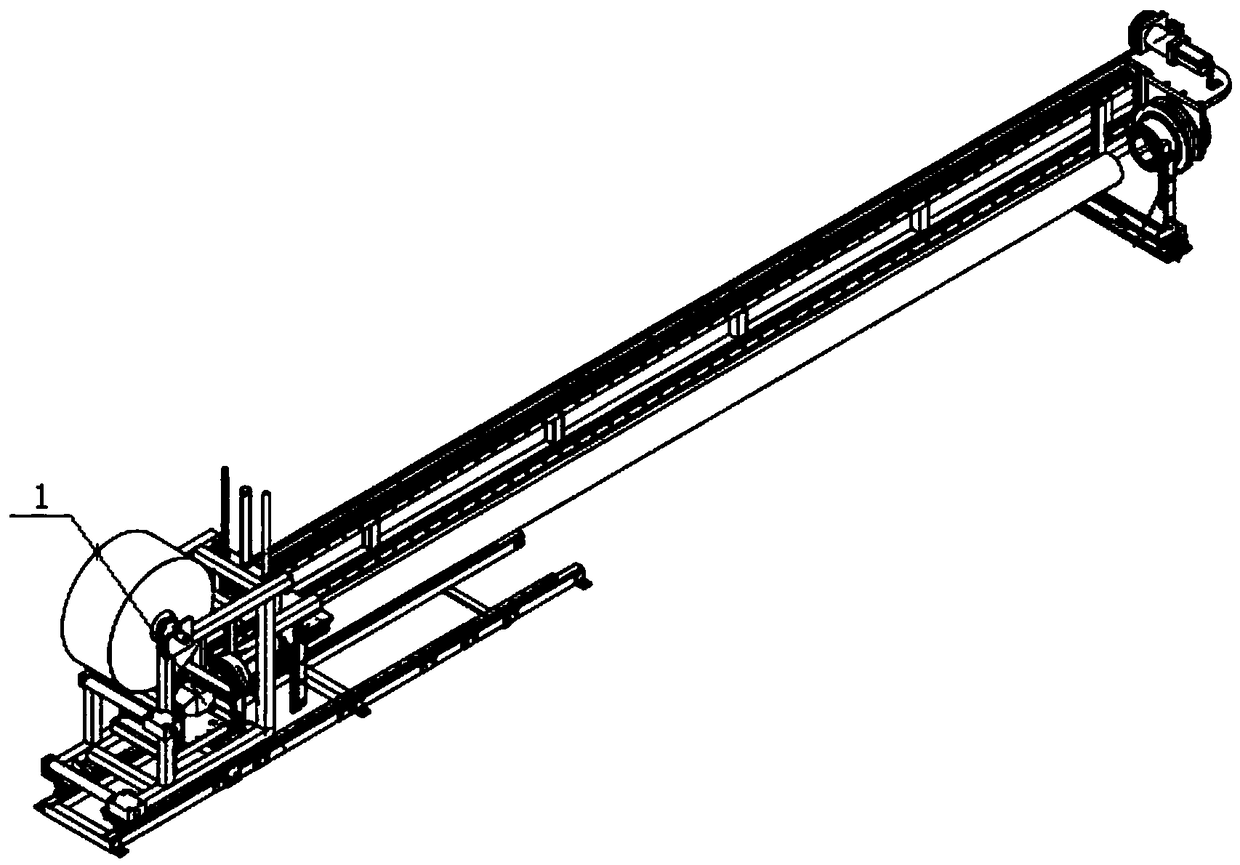

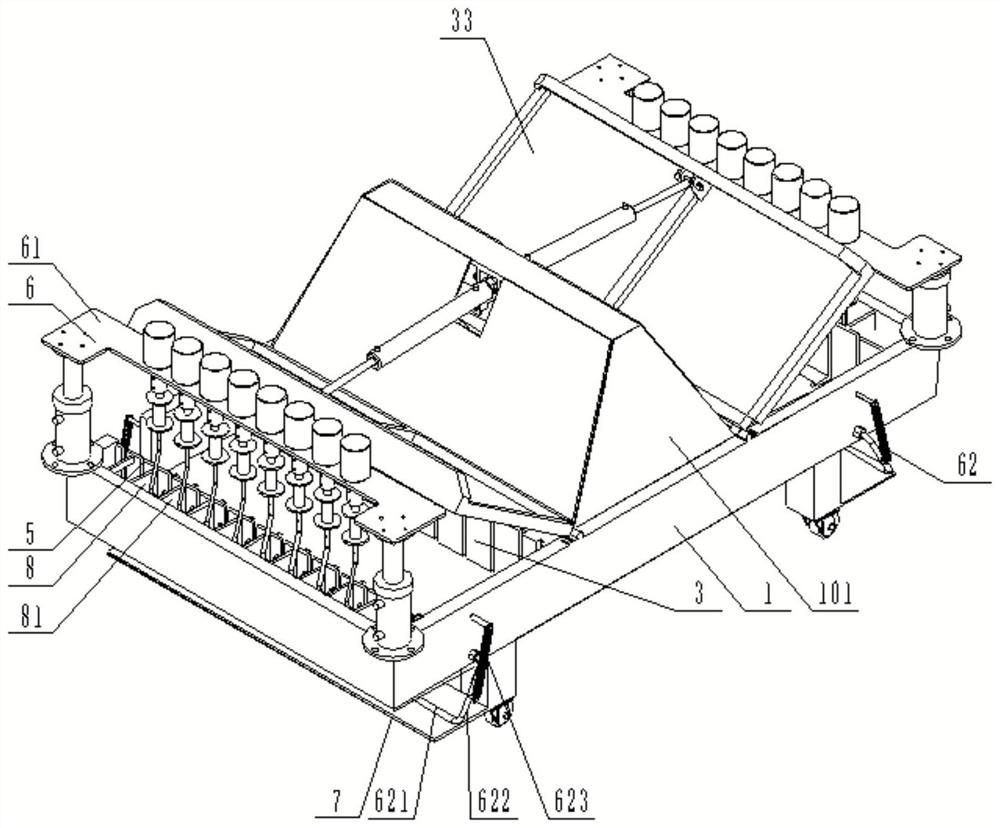

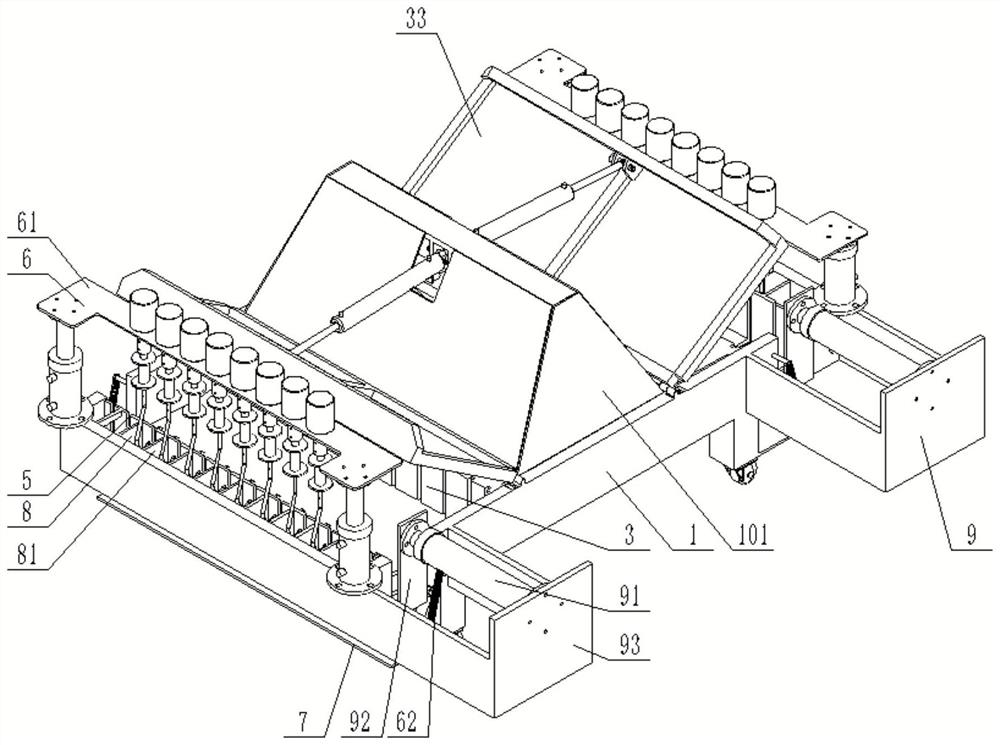

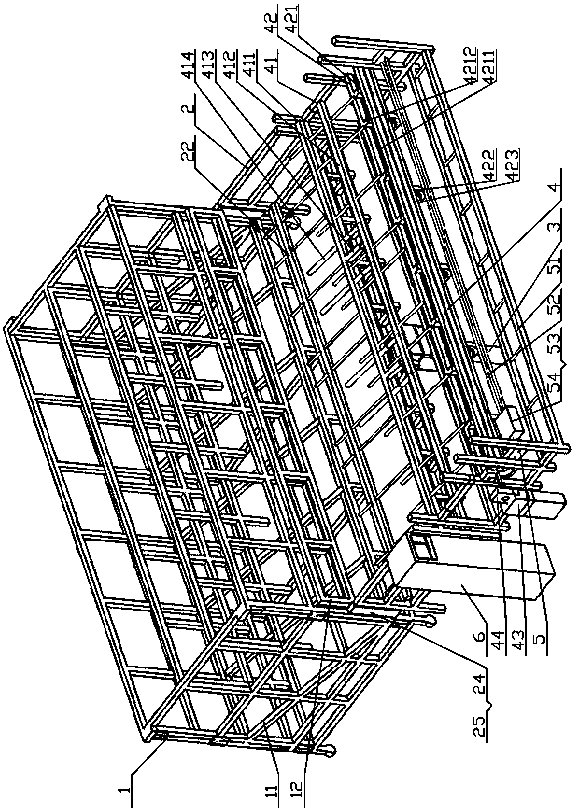

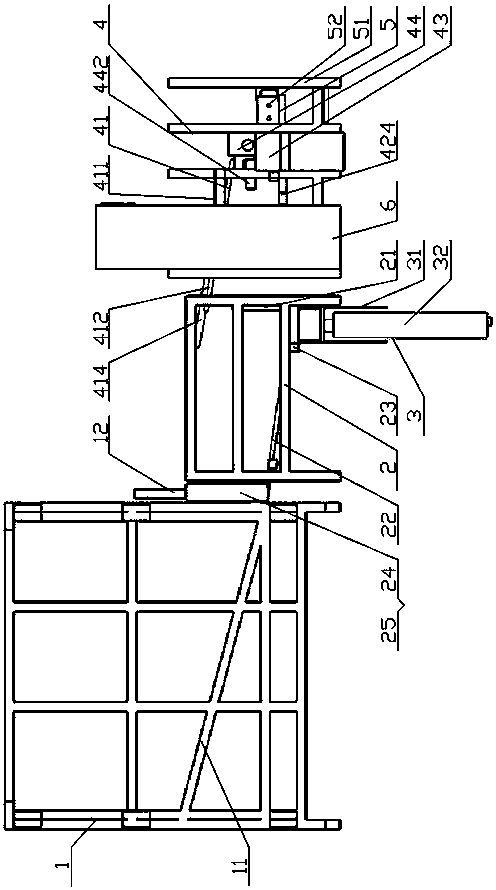

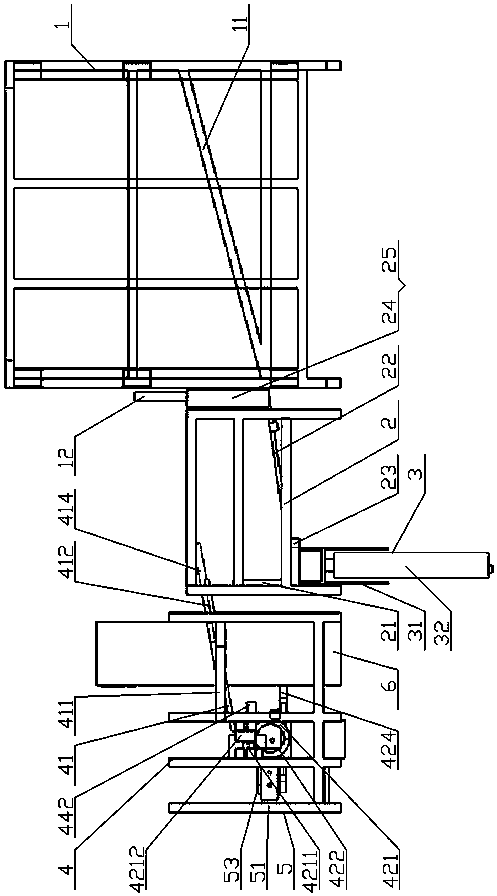

Automatic bundling, woven bag filling, labeling, sewing and packaging machine for plastic pipes

ActiveCN106115023ARealize automatic strappingAccurate packagingWrapper twisting/gatheringPackaging machinesHorizontal axisTurning frames

The invention discloses an automatic bundling, woven bag filling, labeling, sewing and packaging machine for plastic pipes. The automatic bundling, woven bag filling, labeling, sewing and packaging machine comprises a rack. A material turning frame and a material supporting and pressing mechanism are arranged on the rack. A material push mechanism, a bundling mechanism and a bagging mechanism which are located in the same horizontal axis are sequentially arranged behind the material supporting and pressing mechanism from right to left. The bagging mechanism comprises a bagging region capable of containing the pipes. A bag expansion device is arranged at one end of the bagging region and used in cooperation with a bag clamping device arranged on the bagging region. A label conveying device is arranged on one side of the bagging region. A sewing device is arranged above the bagging region. The bag expansion device is used for expanding woven bags to contain the pipes. The label conveying device is used for labeling the positions, close to bag openings, of the woven bags after the pipes are put into the woven bags. The sewing device is used for sewing and packaging the bag openings of the woven bags. By the adoption of the automatic bundling, woven bag filling, labeling, sewing and packaging machine, a serious of working procedures of automatic bundling, woven bag filling, labeling, sewing and the like of the pipes are achieved.

Owner:GUANGDONG LIANSU MACHINERY MFG

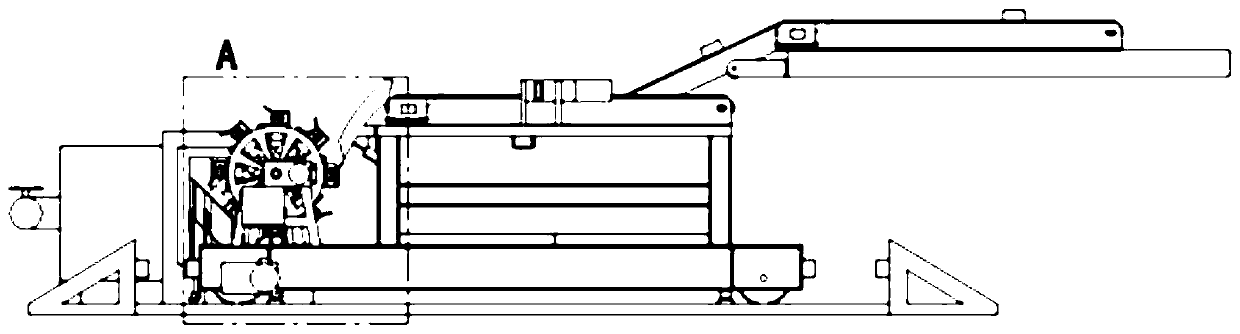

Horizontal packing machine allowing automatic waste paper compression and binding

InactiveCN103693223AEfficient compressionStrong and efficient compressionBinding material applicationPaper/cardboard containersEngineeringMechanical engineering

A horizontal packing machine allowing automatic waste paper compression and binding comprises a machine frame, an electric appliance box, a hydraulic cylinder, a hydraulic rod, a push plate, a feeding port, a compression box body, an automatic wire feeding track, an iron wire arranging box, a discharging door with a lock, a conveyor belt, a torsion shearing device, a wire feeding clamping device and a wire feeding mechanism. The machine frame is welded to the hydraulic cylinder connected with the hydraulic rod connected with the push plate, the feeding port is integrated with the machine frame, the automatic wire feeding track is arranged in the compression box body and connected with the iron wire arranging box, the torsion shearing device is hinged to the inner wall of the iron arranging box, and the discharging door with the lock, the conveyor belt and the machine frame are connected into a whole. The horizontal packing machine is capable of achieving forceful compression and automatic binding of a large amount of waste paper and can be applied to waste recycle enterprises.

Owner:GUANGXI UNIV

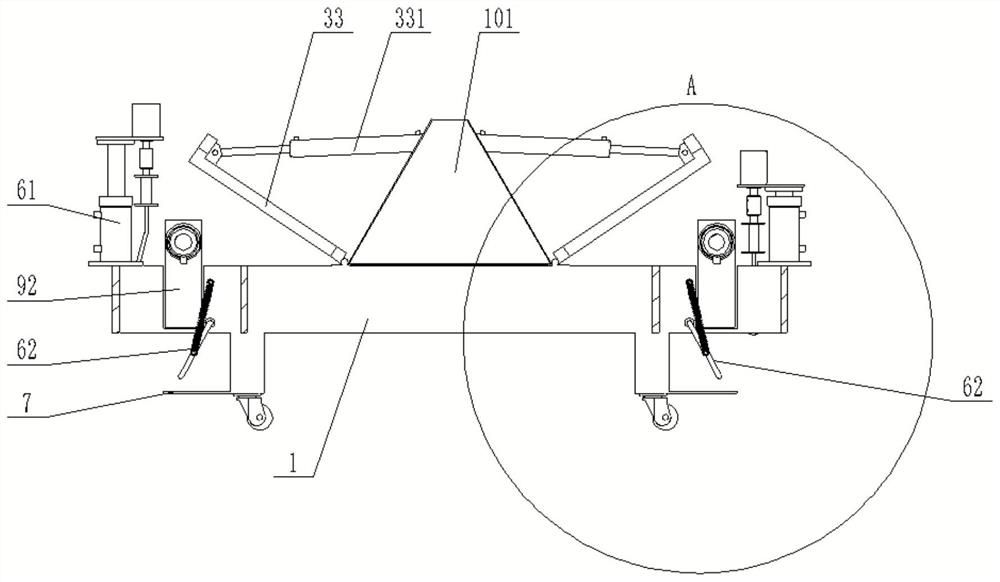

Rope binding auxiliary device

InactiveCN112249396ARealize automatic strappingHigh degree of automationBundling machine detailsRotary stageClassical mechanics

The invention discloses a rope bundling auxiliary device. The rope bundling auxiliary device comprises a bottom plate and supporting legs, wherein a fixed circular truncated cone is arranged on the top surface of the bottom plate, a rotating table is rotationally arranged on the fixed circular truncated cone, a supporting rotating column is rotationally arranged on the top surface of the rotatingtable, a rope winding mechanism is fixed to the top of the supporting rotating column, a movable ring base is rotationally arranged above the bottom plate, a fixed supporting clamping frame and a movable supporting clamping frame are arranged on the top face of the fixed circular truncated cone, and the front end of a top plate of the fixed supporting clamping frame and the front end of a top plate of the movable supporting clamping frame are provided with same clamping groove openings. The rope bundling auxiliary device has the advantages that the opening end of a packaging bag can be shrunkand clamped and kept in a vertical state through the fixed supporting clamping frame and the movable supporting clamping frame, the rope winding mechanism can automatically rotate one end of a rope tothe position near the opening end of the packaging bag and can wind and tightly wind the opening end, so that automatic bundling of the packaging bag is achieved, and the bundling efficiency is greatly improved.

Owner:王红星

Auxiliary device used for hair extension

InactiveCN110215045ARealize automatic strappingImprove work efficiencyPackaging toiletriesPackaging cosmeticsWork periodEngineering

The invention discloses an auxiliary device used for hair extension. The device comprises a rack, a fixed shaft extending forwards and backwards is arranged on the rack, a rotation base capable of rotating around the fixed shaft is mounted on the rack, a hair bundle placing channel penetrating through the front and rear end faces of the fixed shaft is arranged on the fixed shaft, a rope placing cavity is arranged on the rotation base, a rope guide-out hole communicating with the rope placing cavity is arranged at the front end of the rotation base, and the rack is provided with a rotation basedriving device for driving the rotation base to rotate. For the auxiliary device used for hair extension provided by the invention, the work of winding hair bundles with ropes can be realized, so that the follow-up knotting is facilitated, the movement of artificially winding the ropes is tiny and time-wasting, therefore, after the auxiliary device provided by the invention is used, the work efficiency of hair extension can be greatly improved. With the device, the automatic binding and automatic knotting of the ropes during the hair extension process can be realized, after the auxiliary device provided by the invention is used, the work efficiency of hair extension can be improved, and the work time is saved.

Owner:李连福

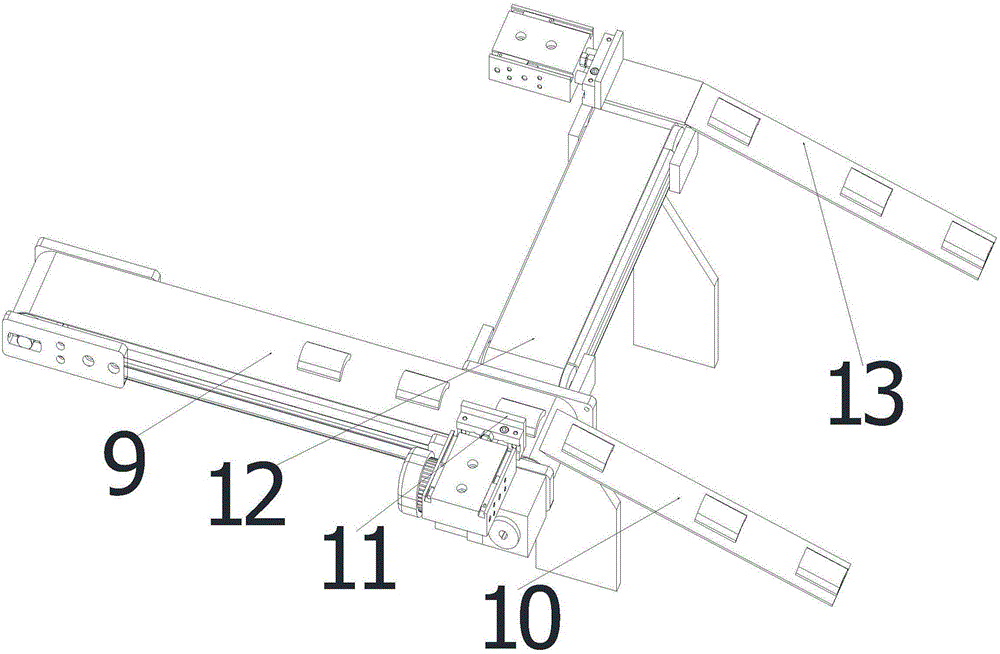

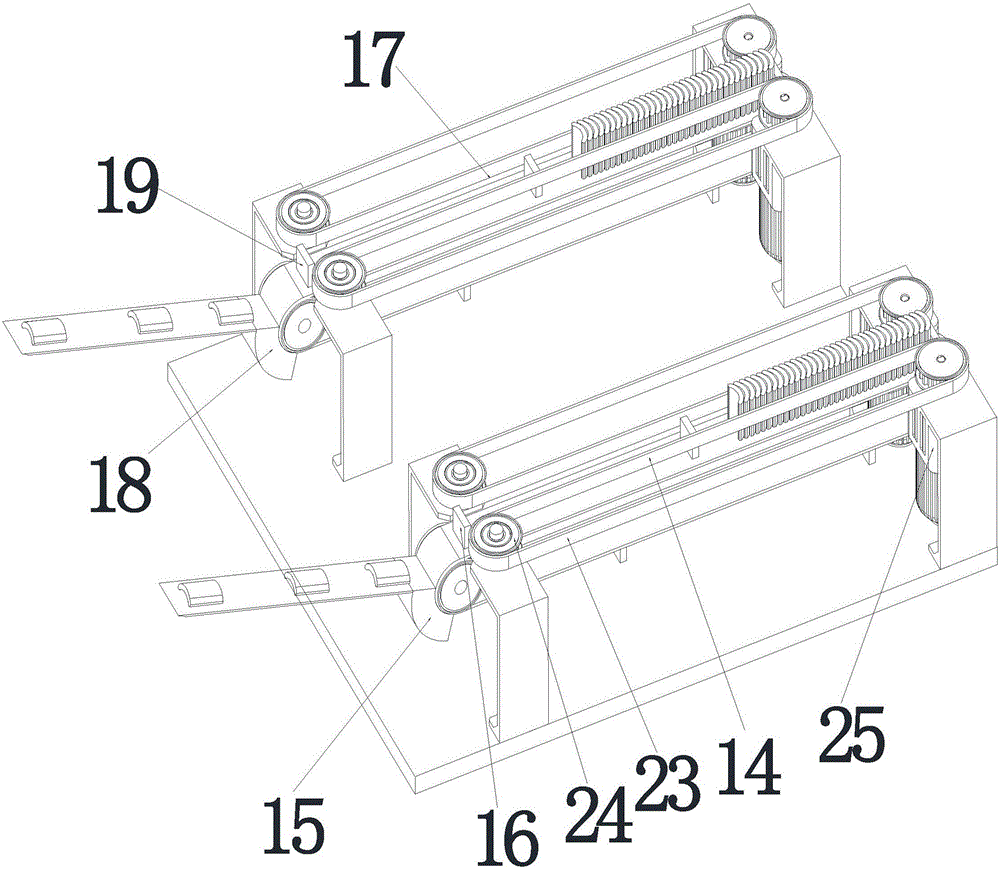

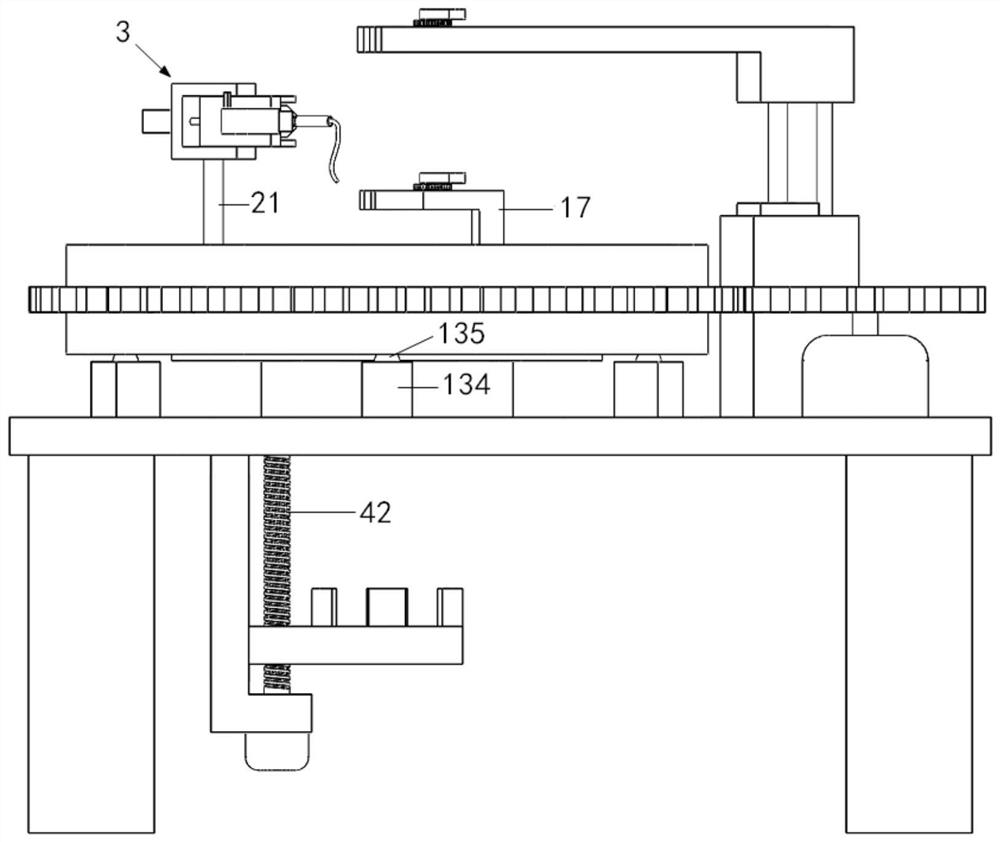

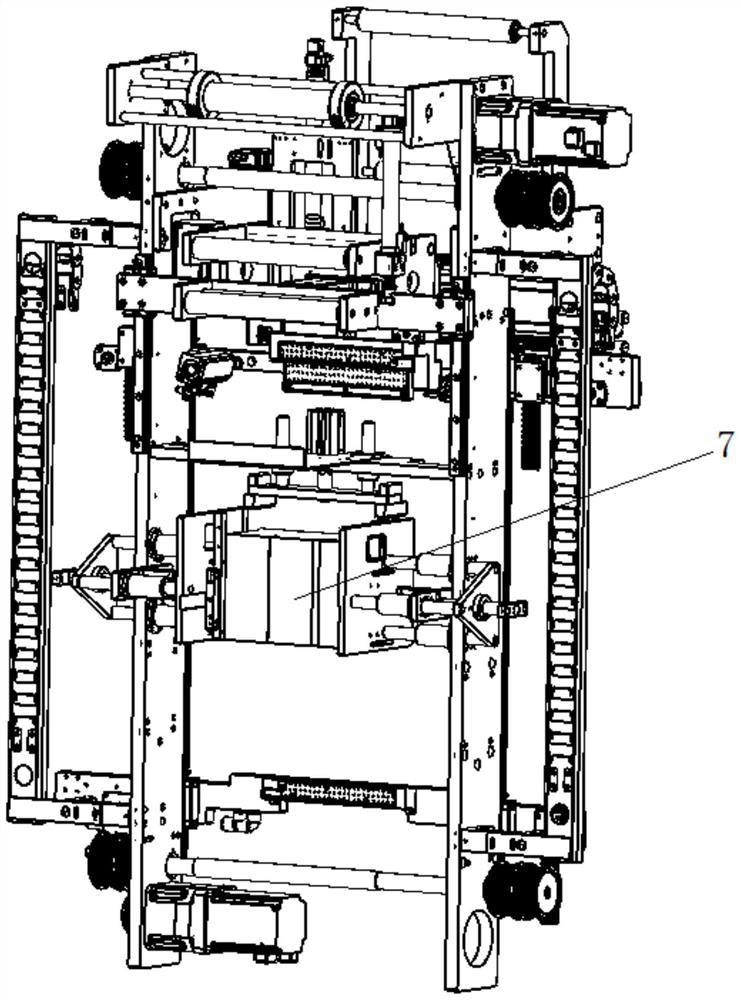

Automatic stacking equipment

PendingCN109809152ACompact structureEasy maintenanceControl devices for conveyorsStacking articlesReturn ratioModular design

The invention relates to the technical field of logistics transportation mechanical equipment, in particular to automatic stacking equipment. A track is provided with a transverse walking mechanism ina cooperative manner. The transverse walking mechanism is fixedly provided with a rotating mechanism. A rack is arranged in front of the rotating mechanism. The rack is fixedly provided with a liningbelt conveyor. The front end of the lining belt conveyor is connected with the rotating mechanism through a piece supplying sliding groove. The rear end of the lining belt conveyor is connected witha fixing belt conveyor through an oblique belt conveyor. The fixing belt conveyor is fixedly installed on a platform. The platform is fixedly connected to a rack of the oblique belt conveyor through aconnecting rod. A stacking mechanism is arranged beside the transverse walking mechanism. By means of the automatic stacking equipment, complex and expensive industrial robots and manipulators are not needed, the structure is compact, maintaining is convenient through modular design, efficient full-automatic stacking action can be achieved only through several small ordinary air cylinders and electric pushing rods, the input return ratio is high, and the stability and compactness of stacking are guaranteed.

Owner:BEUMER MACHINERY MFG SHANGHAI

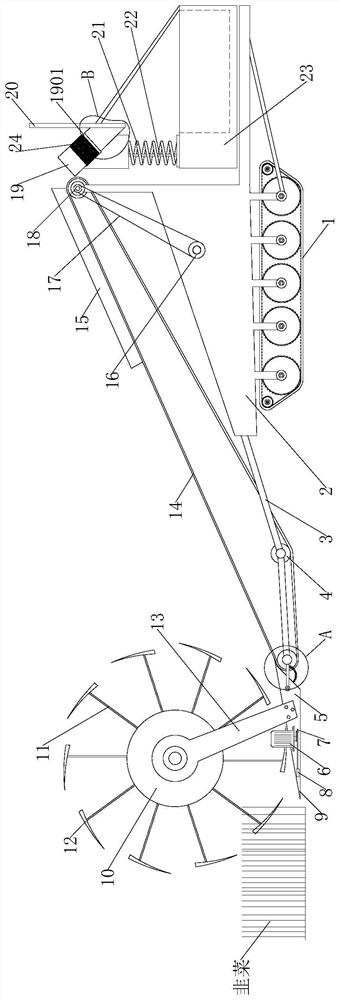

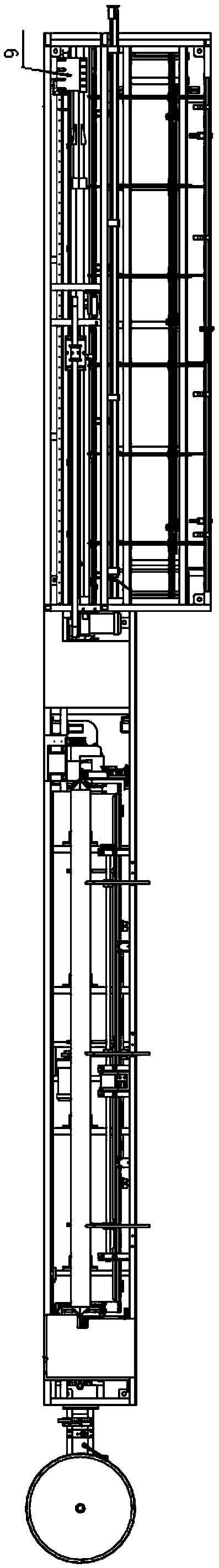

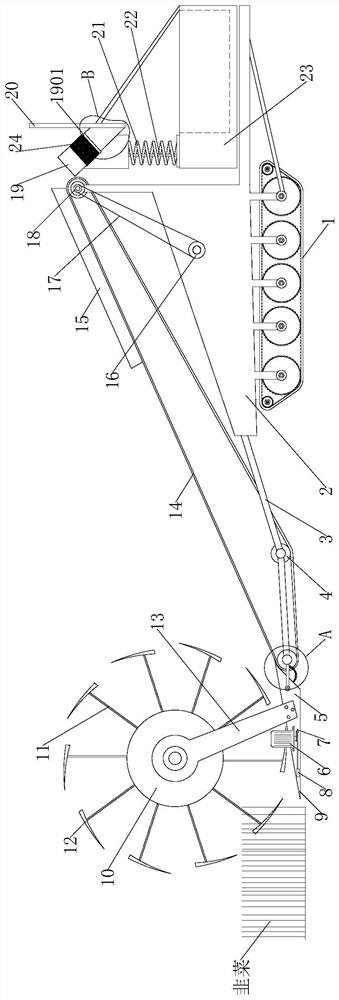

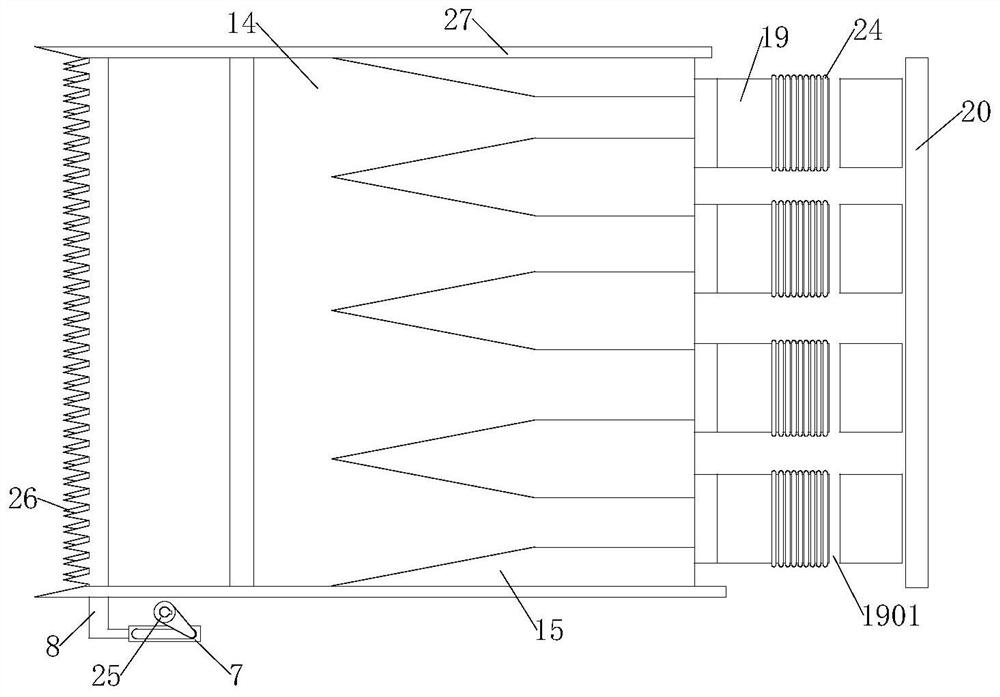

Automatic harvesting device for greenhouse vegetable planting

ActiveCN111771520AReduce deliveryRealize automatic strappingMowersReaper-bindersAgricultural engineeringAgricultural science

The invention provides an automatic harvesting device for greenhouse vegetable planting, and relates to the technical field of vegetable planting. The automatic harvesting device for greenhouse vegetable planting comprises walking wheels, wherein a supporting base is installed on the middle portions of the top ends of the walking wheels, a conveyor belt which is obliquely placed is installed at the top end of the supporting base, first rollers are installed on an inner ring of the conveyor belt at equal intervals, two ends of each first roller are installed on a first roller support through corresponding bearings, and the bottom end of the first roller support is fixedly installed on the supporting base; and a belt pulley is installed at the top end of one first roller, a second motor is fixedly installed on the front side of the supporting base, and an output shaft of the second motor extends to the outer portion. According to the automatic harvesting device for greenhouse vegetable planting, strapping openings are formed in the middle portions of fragrant-flowered garlic strapping cylinders, the middle portions of fragrant-flowered garlic which is put into fragrant-flowered garlic put openings are strapped, and strapping conducted through strapping rubber bands has the advantages that movements with the strapping rubber bands are flexible, the strapping efficiency is high, the strapping speed is high, the strapping firmness is high, and the cost is low.

Owner:WEIFANG UNIVERSITY

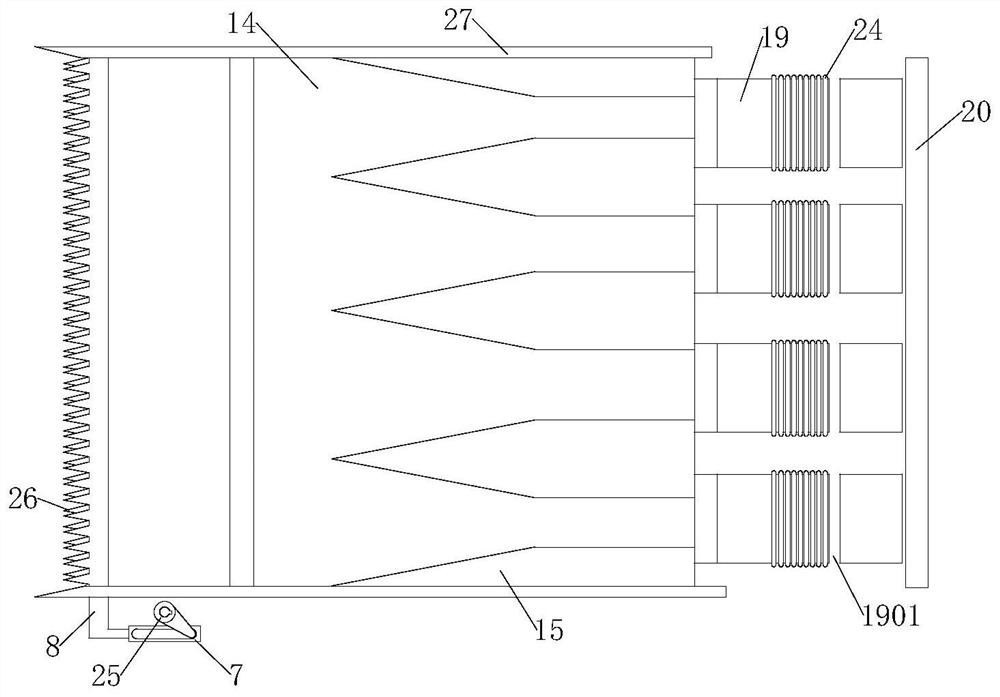

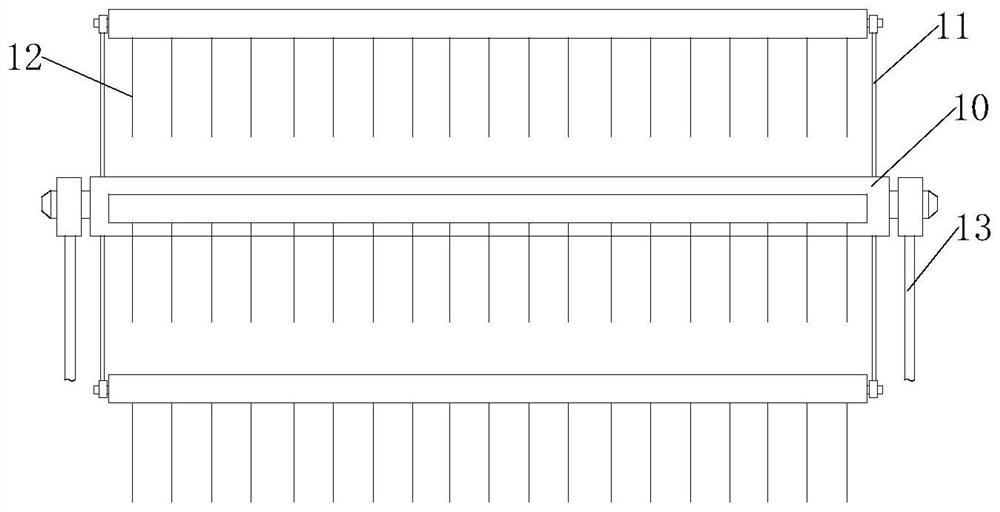

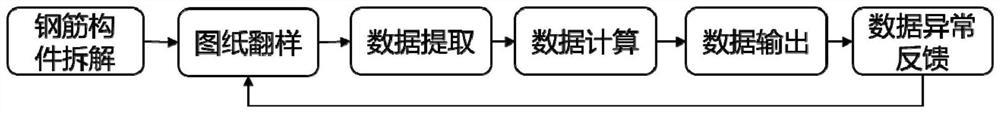

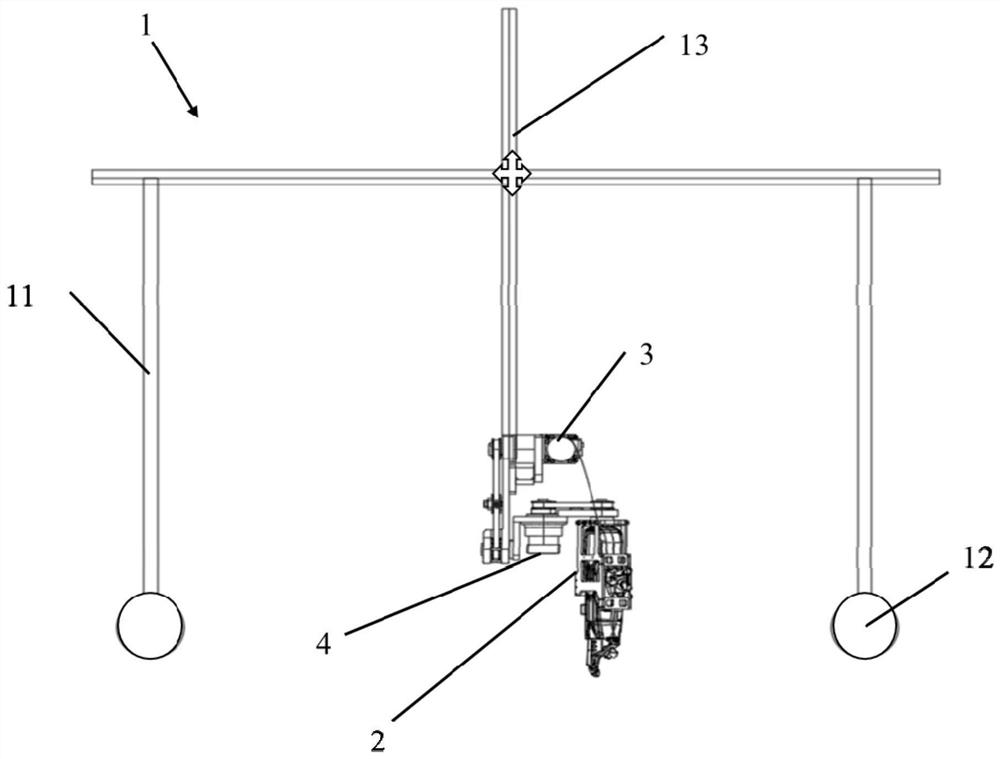

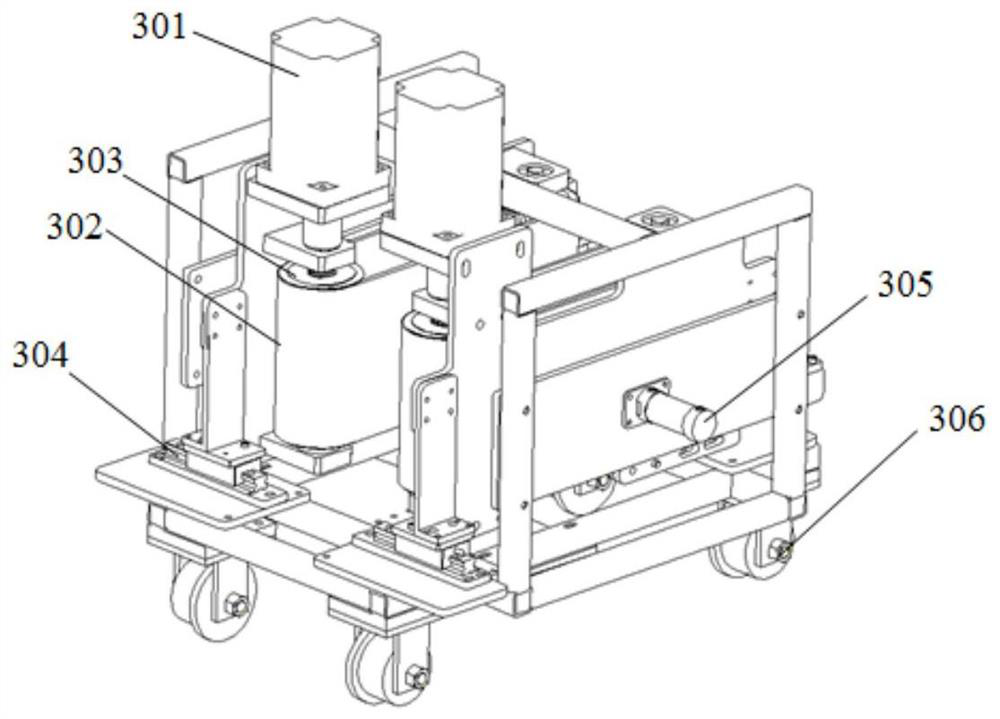

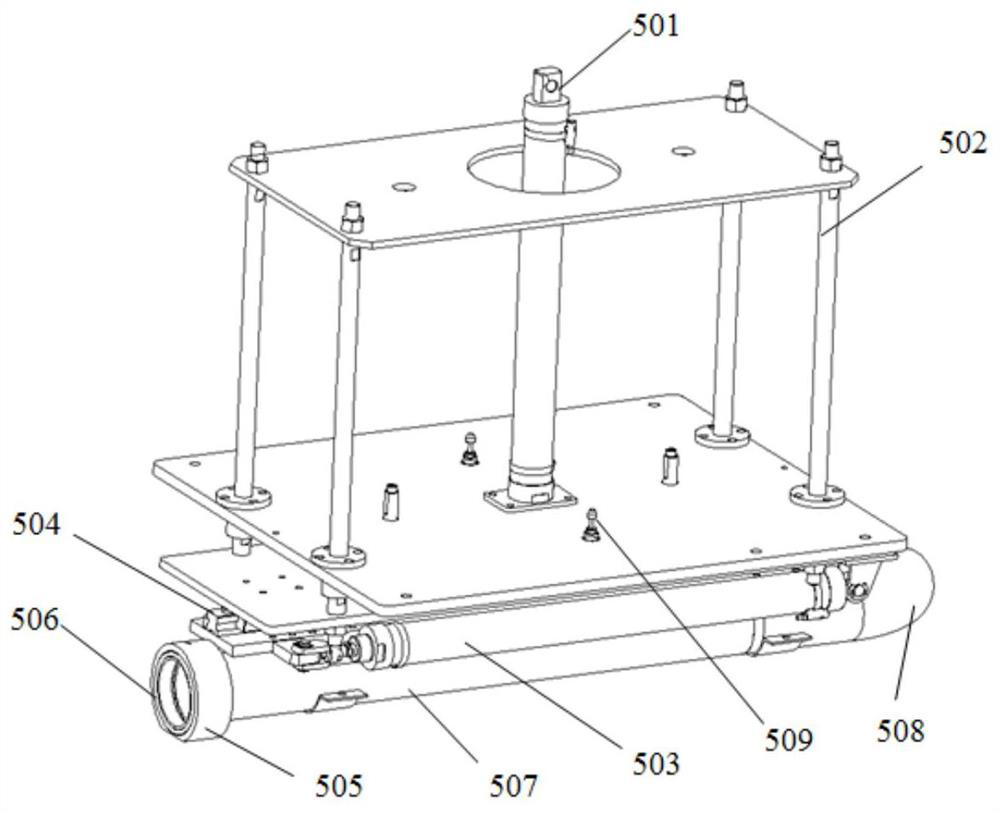

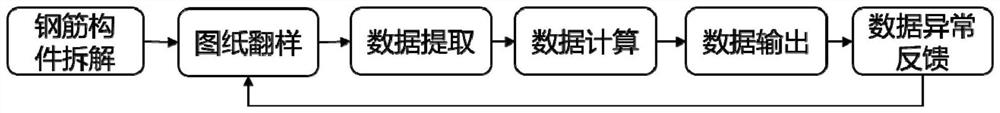

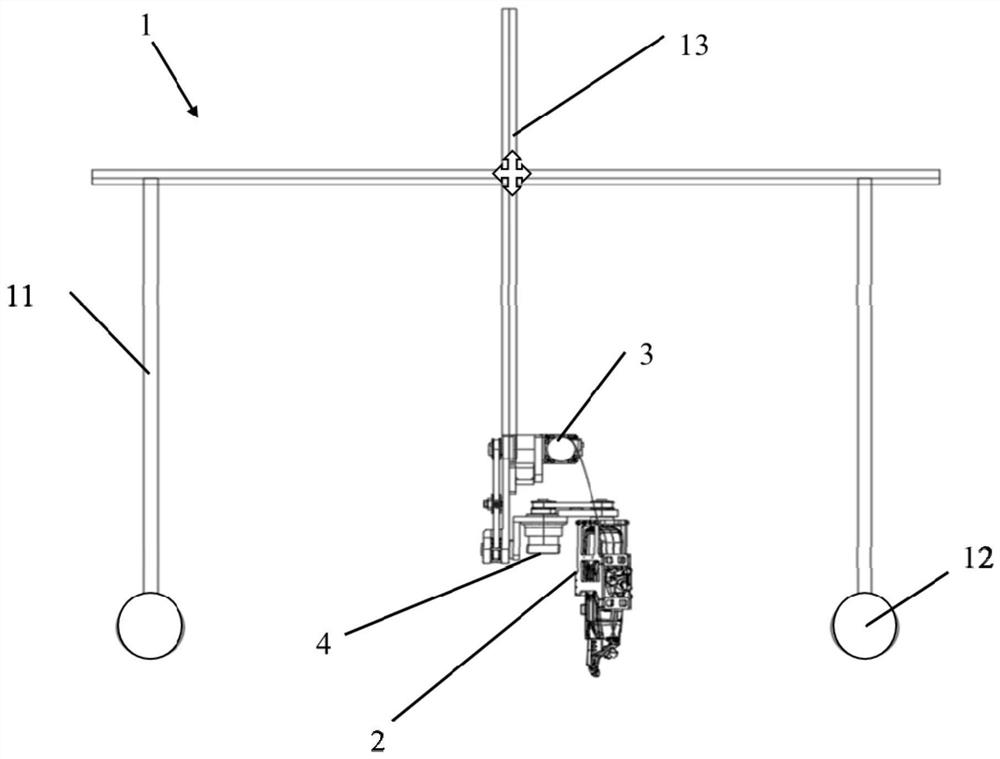

Steel bar binding system and steel bar binding method

ActiveCN111749472ARealize automatic strappingImprove bundling efficiencyBuilding material handlingSoftware engineeringRebar

The invention relates to the technical field of building machinery, in particular to a steel bar binding system and a steel bar binding method. The steel bar binding system involves a BIM data importing and scheduling module, a visual positioning module and an execution module, wherein the BIM data importing and scheduling module can store and real-time updates calibration coordinate data of steelbar joints; the visual positioning module is in communication connection with the BIM data importing and scheduling module, the visual positioning module can collect actual coordinate data of the steel bar joints and obtain compensation data according to the actual coordinate data and the calibration coordinate data, and the BIM data importing and scheduling module can optimize the calibration coordinate data according to the compensation data; and the execution module is in communication connection with the BIM data importing and scheduling module, and the execution module can move and bindthe steel bar joints according to the optimized calibration coordinate data. Automatic steel bar binding is achieved, labor force is effectively released, and the steel bar binding efficiency and binding quality are improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

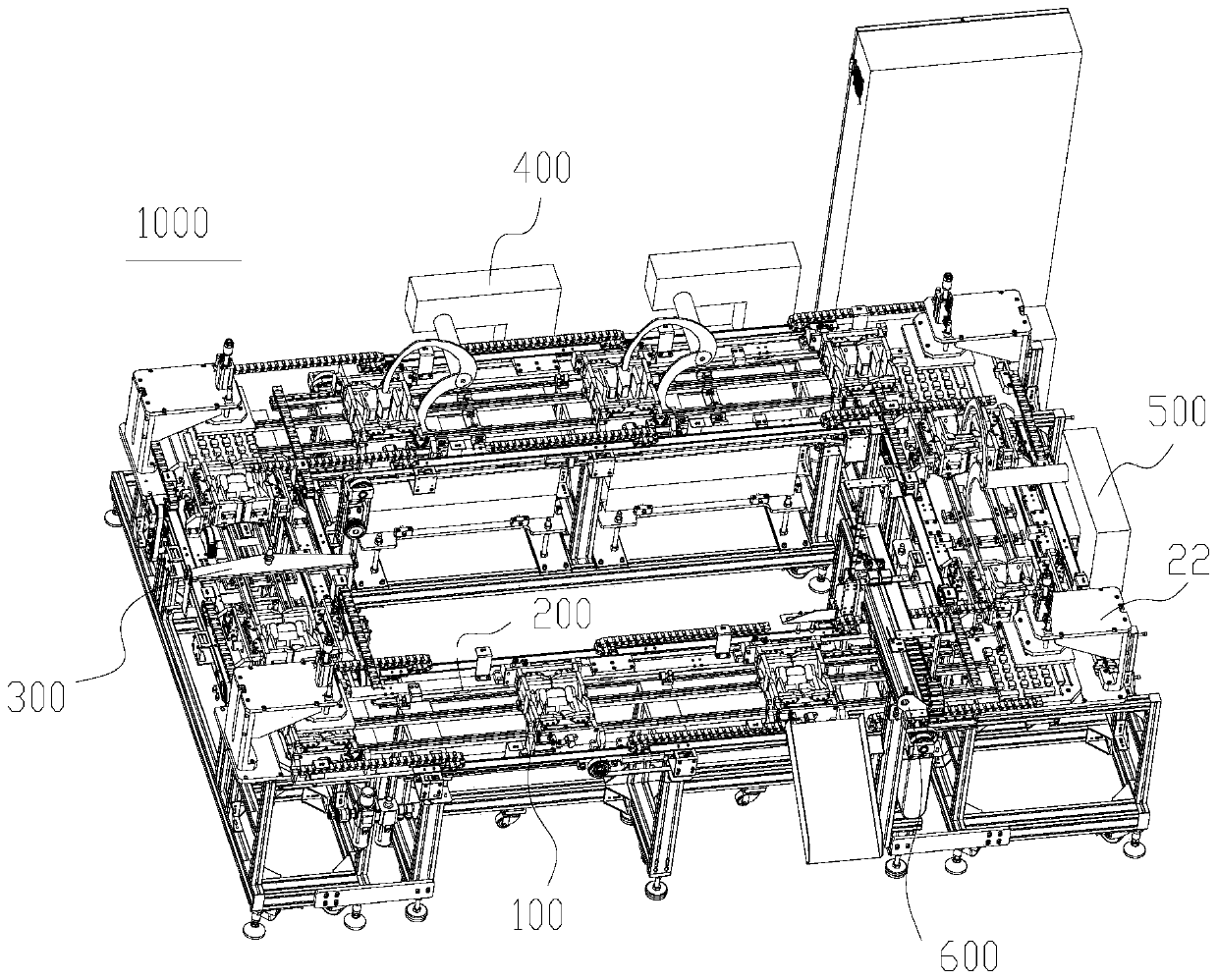

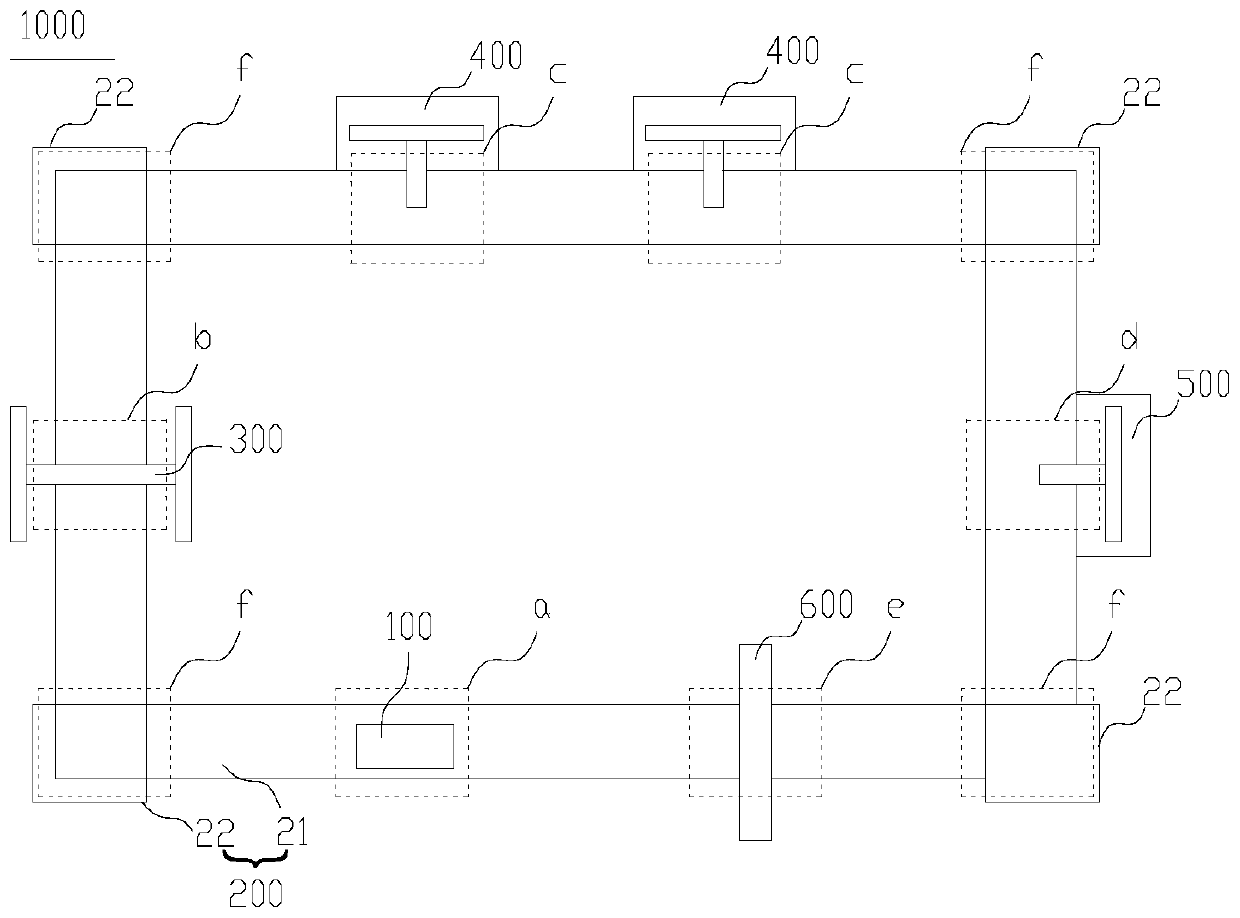

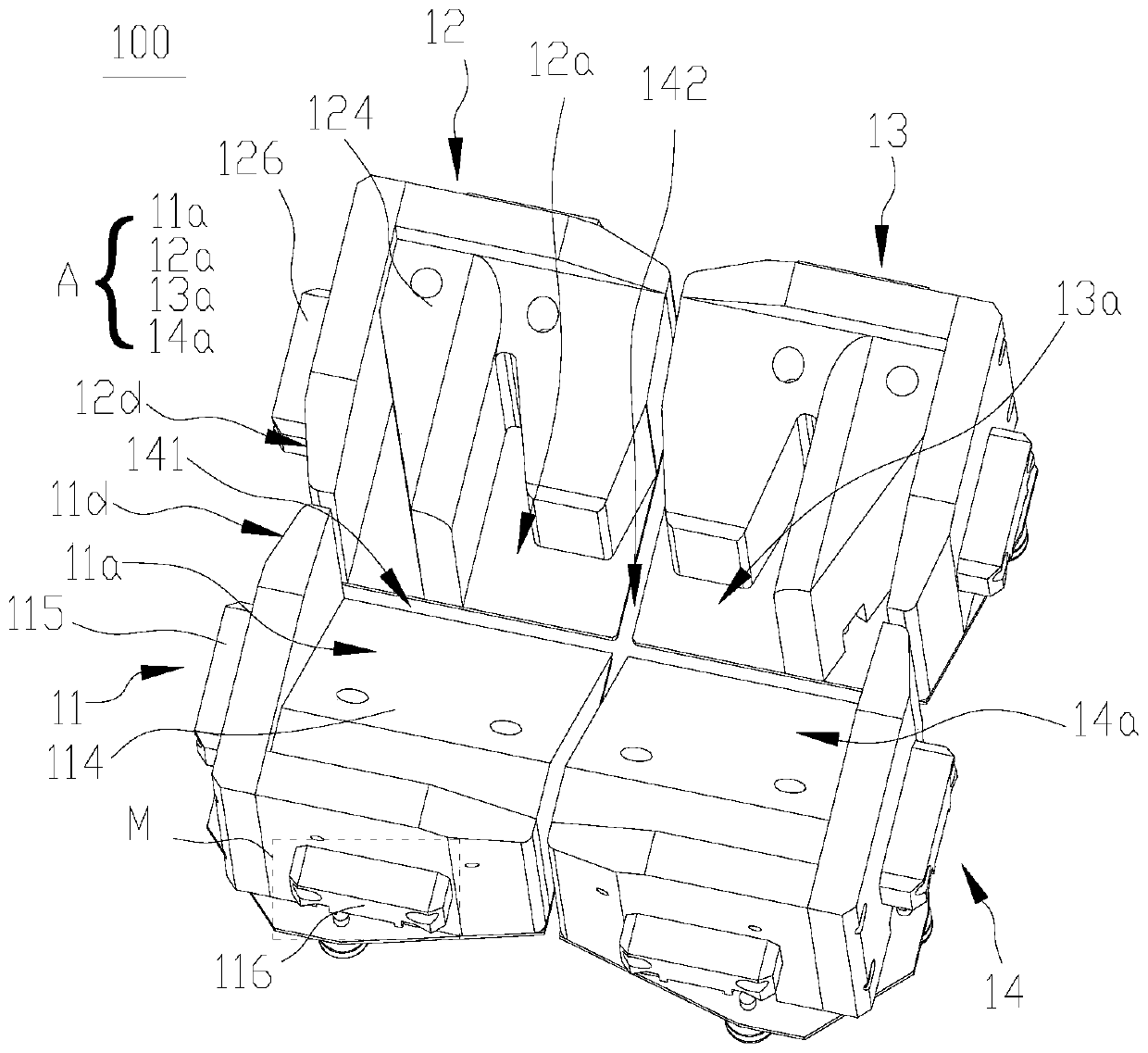

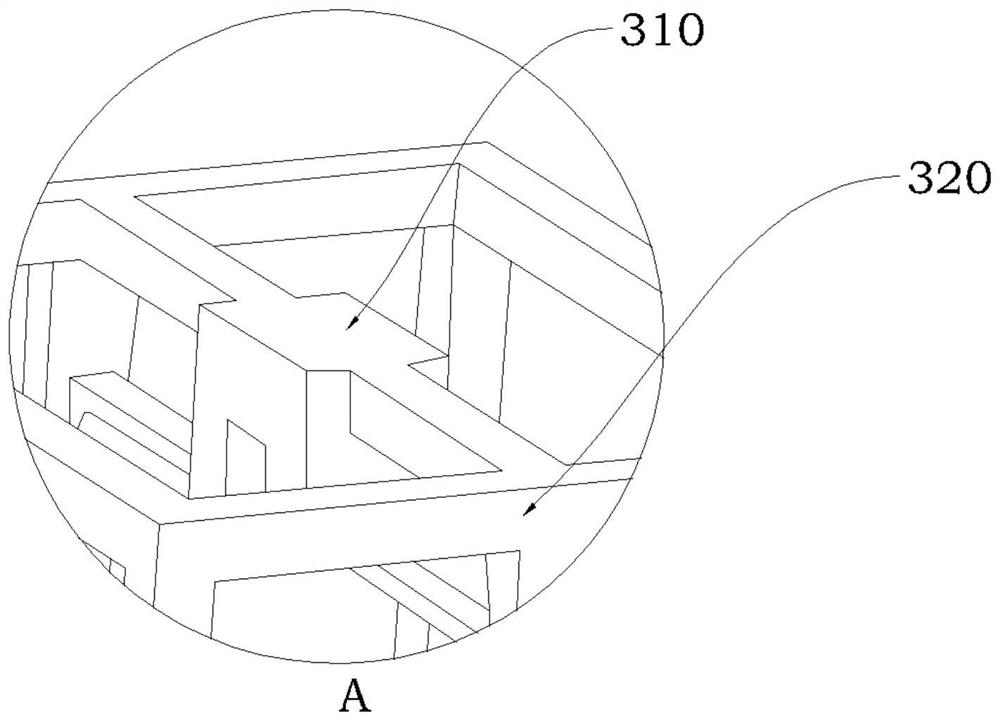

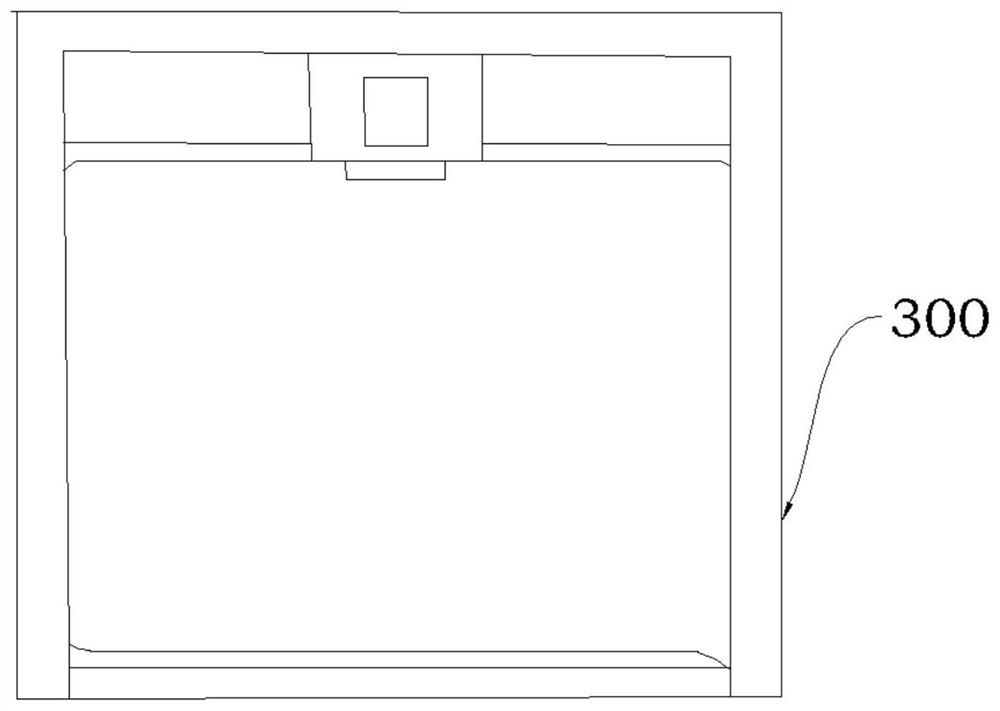

Bundling equipment

ActiveCN110589140ARealize automatic strappingSolve time-consuming technical problemsFinal product manufactureBinding material applicationEngineeringMechanical engineering

The invention provides bundling equipment. The bundling equipment comprises a plurality of carriers, a conveying mechanism and at least one first bundling mechanism. The carriers are used for containing and fixing bundling objects. The conveying mechanism is provided with a feeding station, at least one first bundling station and an unloading station and used for sequentially conveying the carriers to the first bundling station and the unloading station from the feeding station. One first bundling mechanism is correspondingly arranged at one first bundling station and used for bundling the bundling objects in the first direction. The conveying mechanism is used for sequentially conveying the carriers loaded with the bundling objects to the unloading station from the feeding station, the detecting station and the first bundling station, corresponding station operation is conducted, and accordingly automatic bundling object bundling is achieved.

Owner:SHENZHEN S F TAISEN HLDG (GRP) CO LTD

Communication cable arranging and binding device

ActiveCN113978789ARealize automatic strappingAvoid affecting the binding workBinding material applicationPackaging automatic controlAdhesive beltEngineering

The invention relates to a binding device, in particular to a communication cable arranging and binding device. The technical problem of the invention is to provide the communication cable arranging and binding device which is convenient to bind and low in labor intensity. According to the technical scheme, the communication cable arranging and bundling device comprises a handle, a clamping key, a loosening key, a first clamping plate, a second clamping plate and a positioning ring, wherein the clamping key is arranged on one side of the handle, the loosening key is arranged on one side of the handle, the first clamping plate is arranged at the top of the handle, and one side of the top of the first clamping plate is rotationally connected with the second clamping plate. Through cooperation of a clamping mechanism, a winding mechanism and a power transmission mechanism, an adhesive tape can be automatically bundled on the outer side of a communication cable, and the communication cable can be clamped in the binding process.

Owner:青岛华强电缆有限公司

Automatic turn-over device for long-roll sock legs and control method

ActiveCN111876980AGuarantee product qualityReduce labor intensityMechanical cleaningPressure cleaningControl engineeringProcess engineering

The invention discloses an automatic turn-over device for long-roll sock legs and a control method. The automatic turn-over device comprises a sock tube fixed to a rack, and further comprises a feeding compression mechanism, a chain driving mechanism, a lifting air suction mechanism, a material collecting winding roller mechanism, a mechanical arm mechanism, a sock head clamping mechanism, a detection sensor set, an automatic binding machine and a control cabinet. According to the automatic turn-over device, in the feeding process, the return speed of the feeding compression mechanism and therunning speed of a conveying belt are controlled according to the load torque change of a servo motor, the quality of sock materials is guaranteed, and meanwhile the long-roll sock legs with differentthicknesses and different lengths can be stacked on the sock tube; and in the material turning process, automatic identification and automatic binding of sock heads and sock tails are achieved in combination with detection of the detection sensor set and cooperative action of the lifting air suction mechanism, the material collecting winding roller mechanism, the sock head clamping mechanism andthe automatic binding machine. According to the automatic turn-over device, the processes of automatic feeding, automatic overturning, automatic head and tail recognition and bundling and precise conveying of a mechanical arm after manual sock sleeving can be achieved, the labor intensity is reduced, the sock product quality is effectively guaranteed, and the reliability and the production efficiency are improved.

Owner:安徽中科智能高技术有限责任公司

Steel bar binding system and steel bar binding method

ActiveCN111749472BRealize automatic strappingImprove bundling efficiencyBuilding material handlingControl engineeringRebar

The invention relates to the technical field of construction machinery, in particular to a steel bar binding system and a steel bar binding method. The steel bar binding system provided by the present invention includes a BIM data import and scheduling module, a visual positioning module and an execution module. The BIM data import and scheduling module can store and publish the calibration coordinate data of the steel bar nodes in real time; the visual positioning module and the BIM data import and execution module The scheduling module is connected by communication, the visual positioning module can collect the actual coordinate data of the steel bar nodes, and obtain the compensation data according to the actual coordinate data and the calibration coordinate data, the BIM data import and scheduling module can optimize the calibration coordinate data according to the compensation data; the execution module and the BIM The data import and scheduling module are connected by communication, and the execution module can move according to the optimized calibration coordinate data and bind the steel bar nodes, realize automatic binding of steel bars, effectively release labor force, and improve the efficiency and quality of steel bar binding.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

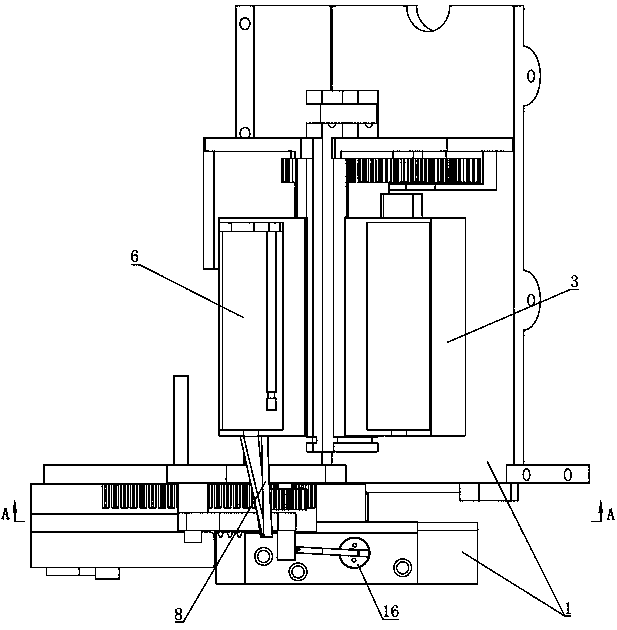

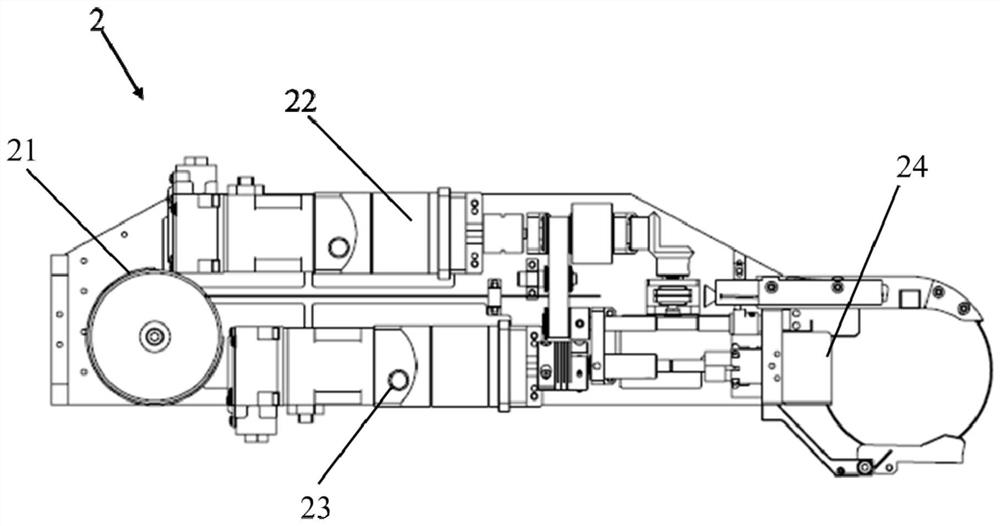

Hand-held automatic steel wire strapping equipment

ActiveCN109098451ARealize automatic deliveryReduce the amount of operationBuilding material handlingAssistive device/technologyStrapping

The invention discloses hand-held automatic steel wire strapping equipment, and belongs to the technical field of building construction auxiliary equipment. The hand-held automatic steel wire strapping equipment comprises a first mounting block, a second mounting block, a wire discharging mechanism, a limiting mechanism and a cutting mechanism, wherein the second mounting block is positioned at the front end of the first mounting block and is connected with the first mounting block in a rotary manner; a first connecting column and a second connecting column are arranged at the front end of thesecond mounting block; the wire outlet mechanism and the limiting mechanism are fixedly connected with the first connecting column and the second connecting column respectively; the limiting mechanism comprises a limiting component and a linkage component; the linkage component is mounted on the side of the second mounting block and is connected with the limiting component; the cutting mechanismcomprises a driving component and a cutting component; the driving component is connected with the cutting component; and the wire discharging mechanism comprises a feeding component and a wire discharging component. According to the invention, the working procedures of wire discharging, strapping and cutting can be automatically completed without manual auxiliary operation, so that the strappingefficiency of steel bars is higher, the structure is simple, and the cost and maintenance difficulty can be reduced.

Owner:广西盛隆钢铁材料研究院有限公司

A plastic pipe automatic strapping woven bag labeling sewing packaging machine

ActiveCN106115023BRealize automatic strappingAccurate packagingWrapper twisting/gatheringPackaging machinesTurning framesHorizontal axis

The invention discloses an automatic bundling, woven bag filling, labeling, sewing and packaging machine for plastic pipes. The automatic bundling, woven bag filling, labeling, sewing and packaging machine comprises a rack. A material turning frame and a material supporting and pressing mechanism are arranged on the rack. A material push mechanism, a bundling mechanism and a bagging mechanism which are located in the same horizontal axis are sequentially arranged behind the material supporting and pressing mechanism from right to left. The bagging mechanism comprises a bagging region capable of containing the pipes. A bag expansion device is arranged at one end of the bagging region and used in cooperation with a bag clamping device arranged on the bagging region. A label conveying device is arranged on one side of the bagging region. A sewing device is arranged above the bagging region. The bag expansion device is used for expanding woven bags to contain the pipes. The label conveying device is used for labeling the positions, close to bag openings, of the woven bags after the pipes are put into the woven bags. The sewing device is used for sewing and packaging the bag openings of the woven bags. By the adoption of the automatic bundling, woven bag filling, labeling, sewing and packaging machine, a serious of working procedures of automatic bundling, woven bag filling, labeling, sewing and the like of the pipes are achieved.

Owner:GUANGDONG LIANSU MACHINERY MFG

Cigarette packet kraft paper glue spraying, sealing and bundling method and device

PendingCN111994335ALow costRealize automatic strappingPaper article packagingBundling machine detailsAdhesive glueProcess engineering

The invention relates to a cigarette packet kraft paper glue spraying, sealing and bundling method and device. The method comprises the following steps of 1) spraying hot melt glue onto a kraft papersealing part; and 2) laminating the hot melt glue at the sealing part to finish bundling. The device comprises a kraft paper bundling mechanism for cutting kraft paper, wherein the kraft paper bundling mechanism is connected with a glue spraying module; the glue spraying module is used for spraying the hot melt glue onto a kraft paper sealing edge; and after completion of glue spraying, the kraftpaper bundling mechanism crosses the kraft paper sealing edge, and performs lamination with external force to finish bundling. According to the method and device, the hot melt glue is sprayed at the kraft paper sealing part before bundling, and the bent sealing edge is laminated and sealed with external force in order to achieve the sealing effect; automatic bundling is realized; and bundling of cigarette packet kraft paper of different sizes is met.

Owner:BEIJING FOCUSIGHT TECH

A straw baler with automatic bundling function

ActiveCN113079834BRealize two-way pressing operationIncrease profitBalingPunchingStructural engineering

The invention provides a straw baler with automatic bundling function, which comprises a working platform, a two-way punching assembly installed on the working platform in a horizontally movable manner, two sets of straw forming assemblies arranged at both ends of the two-way punching assembly, and a straw forming assembly connected with the working platform. Correspondingly arranged two groups of tying assemblies, the tying assemblies include a tying hook part with the functions of lifting the tying wire hook and tying the wire, and a bending part for bending the tying wire, the tying hook part is installed on the On the upper side of one end of the working platform, the bending part is rotatably arranged below the working platform. The invention has the advantages of high baling efficiency, simple and convenient operation, and solid and durable straw sticks.

Owner:湘潭县超豪农业发展有限公司 +1

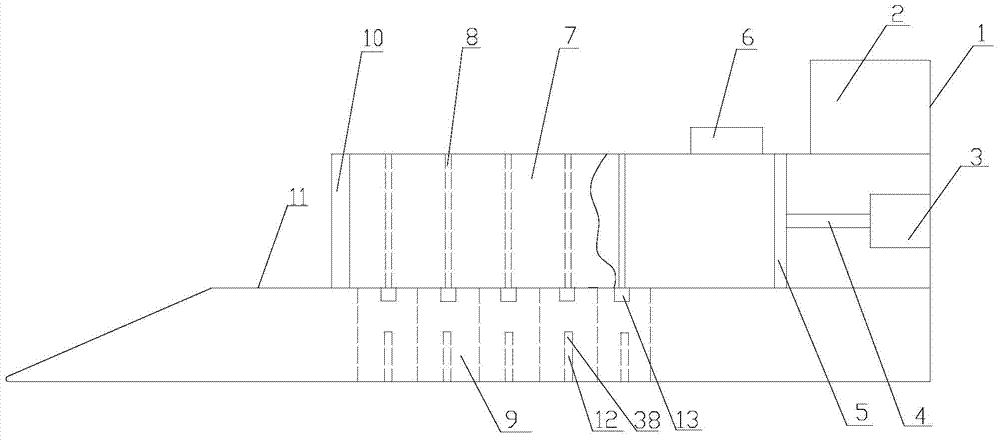

A sorting, sorting, counting and binding system for plastic pipes

ActiveCN104290973BAccurate countRealize automatic strappingBinding material applicationPackaging automatic controlProduction lineCounting Number

Owner:XUZHOU DKEC ELECTRICAL TECH

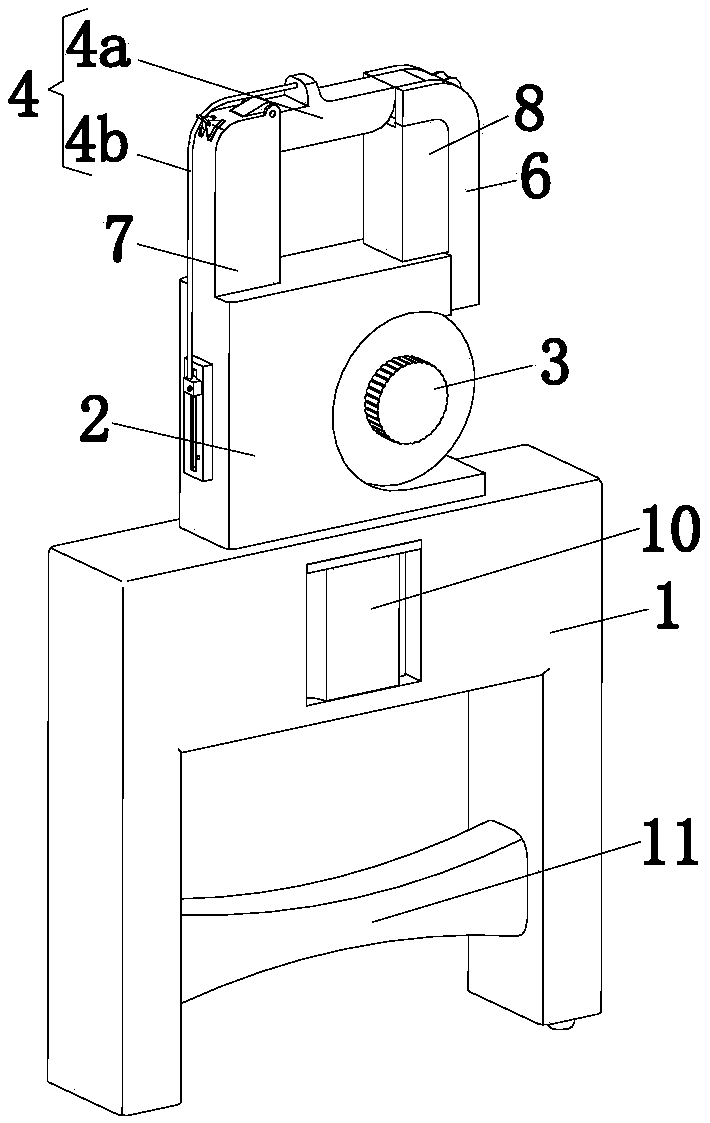

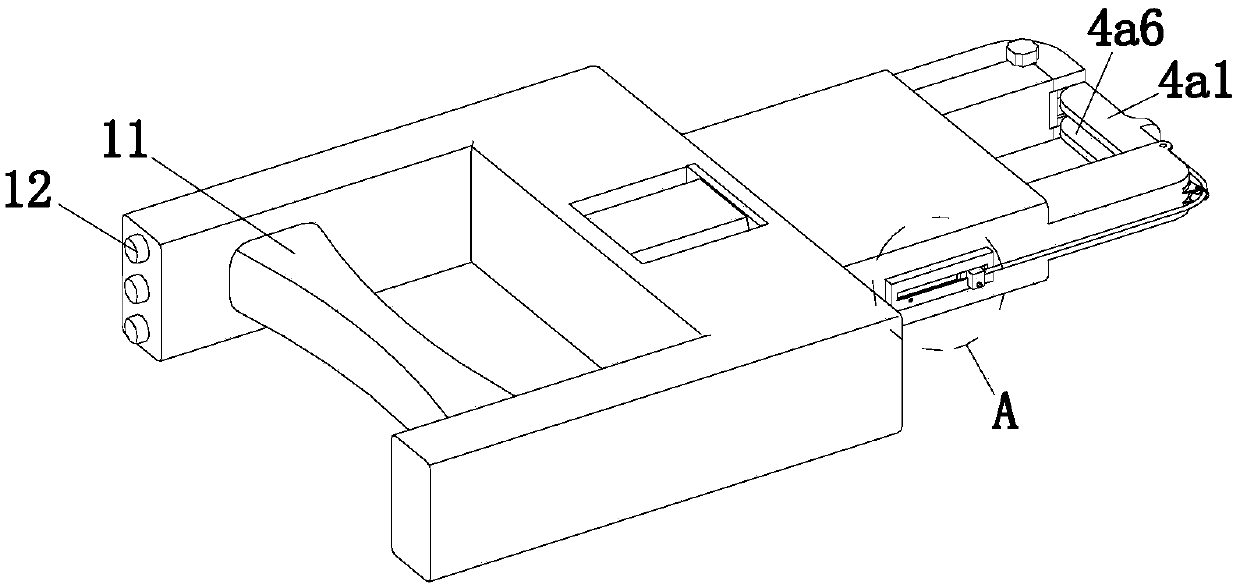

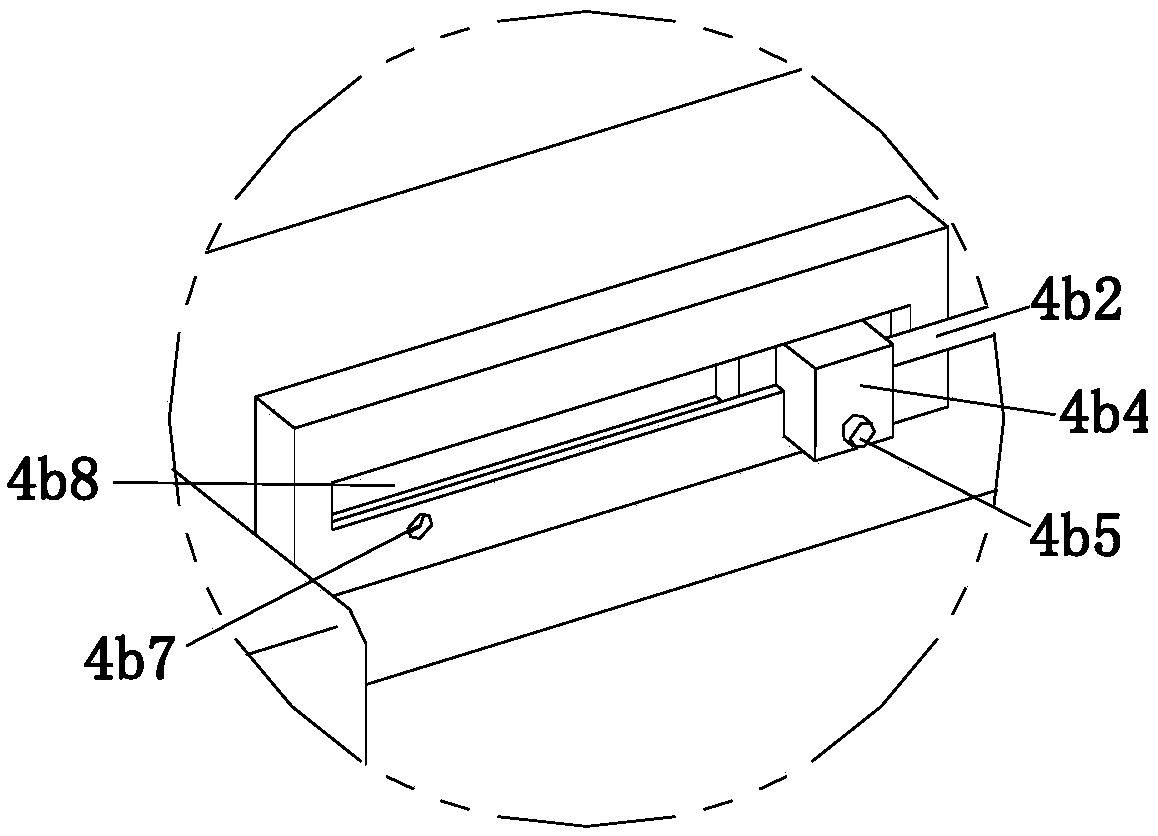

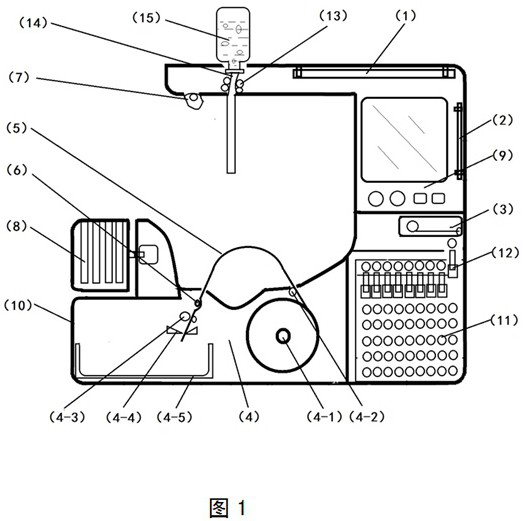

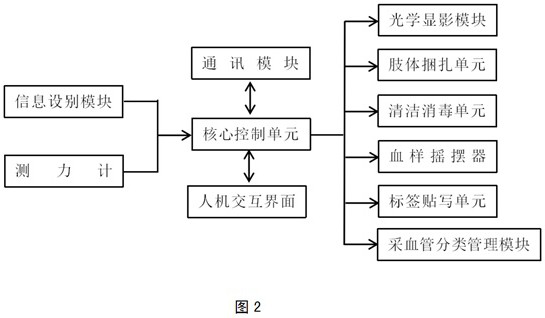

Blood sample extraction system capable of interacting with hospital information system and blood inspection equipment

PendingCN111991007AImprove extraction efficiencyImprove the level of informatizationDiagnostics using lightMedical devicesInformatizationHematological test

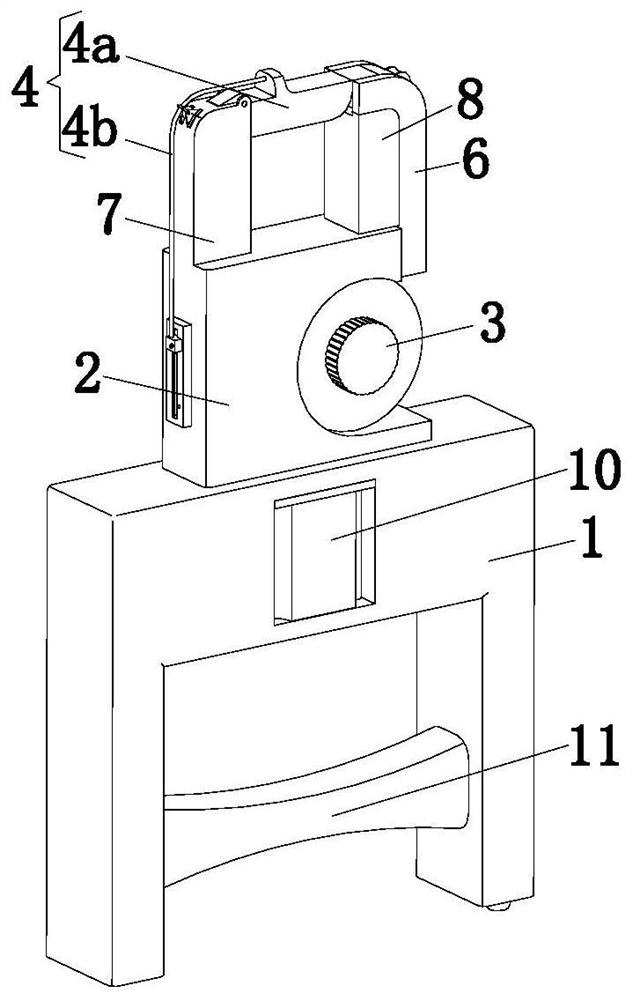

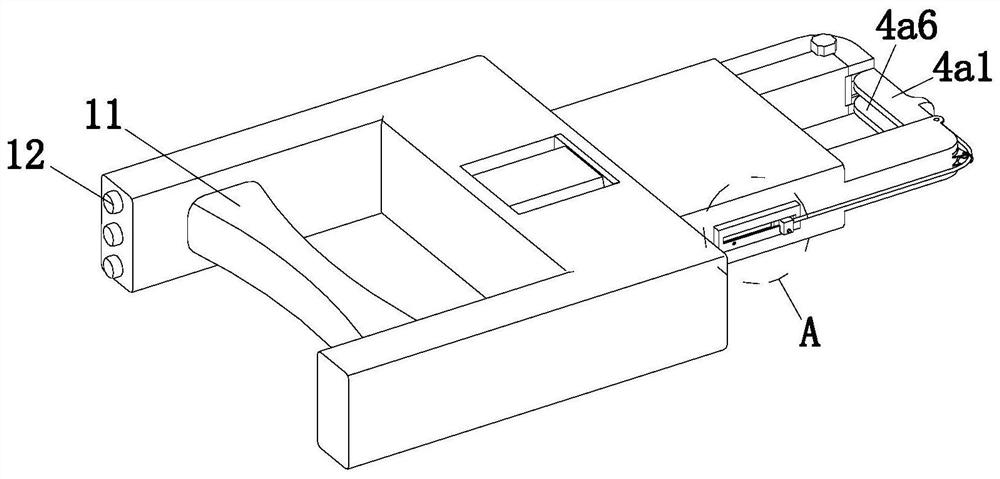

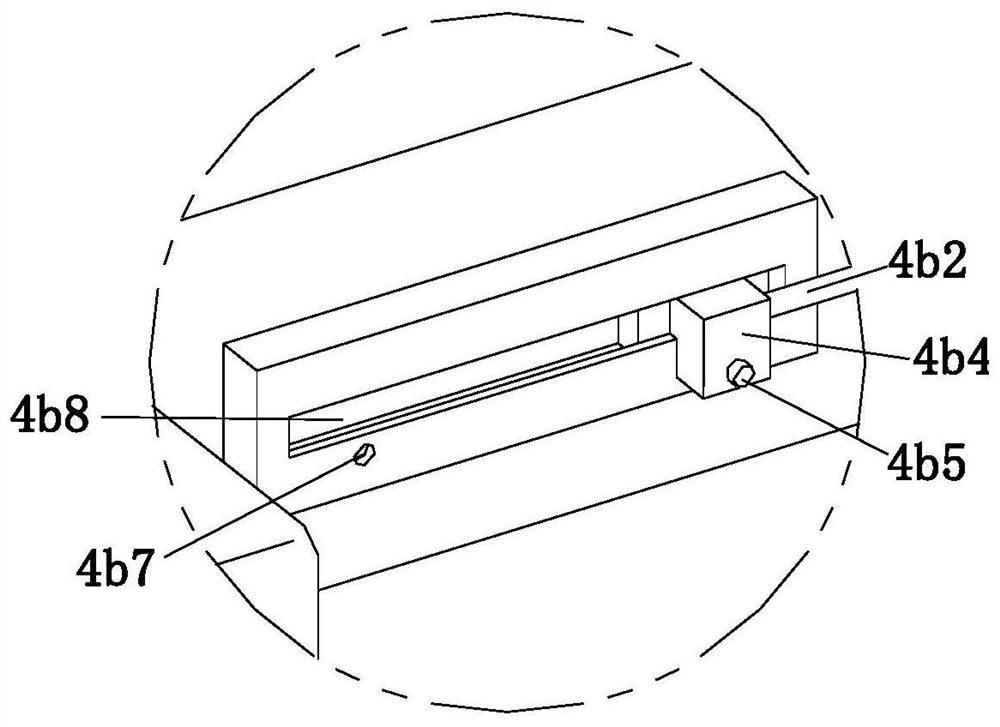

The invention relates to a blood sample extraction system capable of interacting with a hospital information system and blood inspection equipment. The blood sample extraction system mainly comprisesa core control unit (1), a communication module, an information identification module (2), a limb binding unit (4), a dynamometer (6), an optical developing module (7), a blood sample rocker (8), a human-computer interaction interface (9) and a protective shell (10). By application of an embodiment of the invention, the blood sample extraction efficiency is improved, the queuing time of patients is shortened, the labor intensity of medical personnel is reduced, meanwhile, the accuracy of inspection information of the patients is improved, and the informatization level of the blood sample extraction process is improved.

Owner:XIAN WINZISS MEDICAL GRP CO LTD

An automatic production line suitable for magnetic tile packaging and its realization method

ActiveCN105947293BSimple structureImprove product qualityWrappers shrinkageBinding material applicationProduction lineManipulator

The invention discloses an automatic production line suitable for packaging magnetic shoes. The automatic production line comprises automatic appearance detecting equipment, a controller, a magnetic shoe distributing device, a magnetic shoe finishing device, a transplanting and encasing manipulator, a magnetic shoe arranging device, a placement robot, a box body turnover device, a magnetic shoe full-box conveyor belt, a thermal shrinkage film sealing machine, a palletizing conveying belt, a palletizing robot and a binding / film winding system. The invention also discloses a realization method of the automatic production line suitable for packaging the magnetic shoes. The automatic production line and the realization method thereof disclosed by the invention have the characteristics of simple structure, good quality of products, high production efficiency, small production area, low production cost, time conservation, labor conservation and the like.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

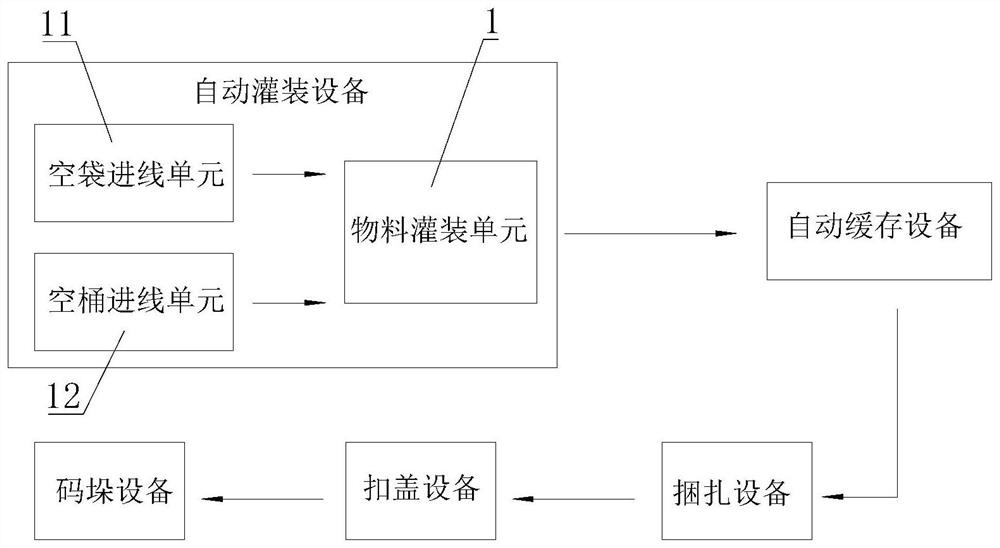

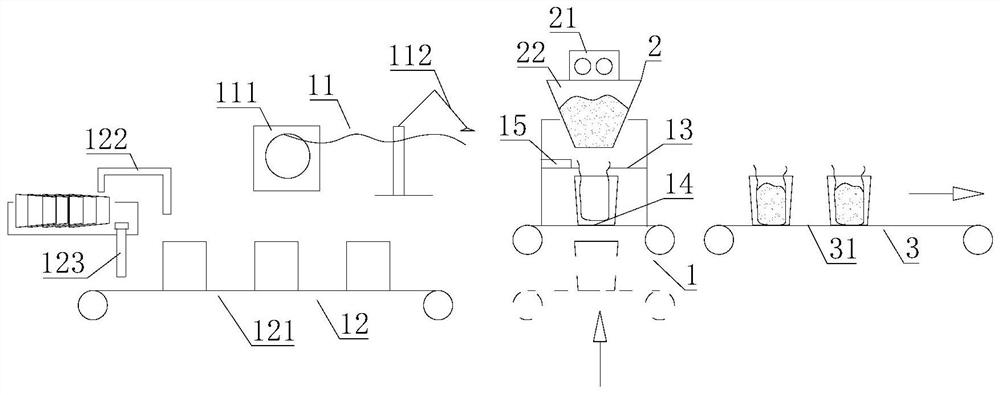

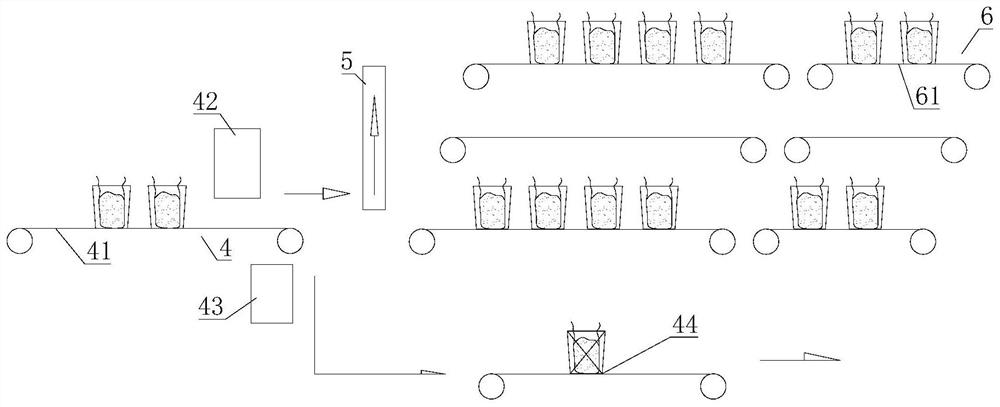

An automatic packaging and transmission system suitable for bleaching powder

ActiveCN112429285BEasy accessFilling does not affectPackaging by pressurising/gasifyingWrapper twisting/gatheringProcess engineeringMechanical engineering

The invention belongs to the technical field of bleaching powder production, and in particular relates to an automatic packaging and transmission system suitable for bleaching powder. The present invention includes automatic filling equipment, automatic caching equipment, binding equipment, capping equipment and stacking equipment arranged in sequence; the automatic filling equipment includes a material filling unit, and a weighing feeding unit is arranged above the material filling unit, The material filling unit includes an inner bag clamping device for clamping the inner bag and a jacking device for jacking up the outer barrel; the automatic buffering device includes a detection unit, the output side of the detection unit is provided with a lifting unit, and the other side of the lifting unit is provided with a The conveying unit; the binding device includes a sensing detection unit, the output end of the sensing detection unit is provided with a conveying unit, a grasping unit is disposed above the conveying unit, and a rope unit is disposed below the grasping unit. The invention provides an automatic packaging and transmission system suitable for bleaching powder which can ensure smooth automatic filling, automatic buffering and automatic binding.

Owner:CHINA CHENGDA ENG

A hand-held automatic steel wire binding equipment

ActiveCN109098451BRealize automatic deliveryReduce the amount of operationBuilding material handlingStrappingHand held

The invention discloses hand-held automatic steel wire strapping equipment, and belongs to the technical field of building construction auxiliary equipment. The hand-held automatic steel wire strapping equipment comprises a first mounting block, a second mounting block, a wire discharging mechanism, a limiting mechanism and a cutting mechanism, wherein the second mounting block is positioned at the front end of the first mounting block and is connected with the first mounting block in a rotary manner; a first connecting column and a second connecting column are arranged at the front end of thesecond mounting block; the wire outlet mechanism and the limiting mechanism are fixedly connected with the first connecting column and the second connecting column respectively; the limiting mechanism comprises a limiting component and a linkage component; the linkage component is mounted on the side of the second mounting block and is connected with the limiting component; the cutting mechanismcomprises a driving component and a cutting component; the driving component is connected with the cutting component; and the wire discharging mechanism comprises a feeding component and a wire discharging component. According to the invention, the working procedures of wire discharging, strapping and cutting can be automatically completed without manual auxiliary operation, so that the strappingefficiency of steel bars is higher, the structure is simple, and the cost and maintenance difficulty can be reduced.

Owner:广西盛隆钢铁材料研究院有限公司

Integrated packaging production line for clinopodium polycephalum tablet aluminum foil

ActiveCN113682509AImprove the efficiency of factory packagingEasy to adjustWrappingBundling machine detailsClinopodium polycephalumStructural engineering

The invention discloses an integrated packaging production line for a clinopodium polycephalum tablet aluminum foil, which comprises conveying belt bodies; a feeding table and a packaging table are arranged on the two sides of the conveying belt bodies respectively; a guiding conveying roller is installed on the packaging table; a bundling packaging machine is further erected on the upper side of the packaging table; conveying chains are rotatably connected between the conveying shafts of every two adjacent conveying belt bodies; a fixed base is arranged on one side of the rear end of each conveying belt body; a servo motor is fixedly connected to the top face of the fixed base through a screw; limiting plates are attached to the front side and the rear side of the top face of each conveying belt body; threaded rods are fixedly connected to the ends, away from the center of the conveying belt bodies, of the limiting plates; and threaded barrels are connected to the outer walls of the threaded rods through threads. The integrated packaging production line provided by the invention is reasonable in design, stable in operation and high in automation degree, so that the factory packaging efficiency of clinopodium polycephalum tablets is greatly improved, packaging boxes of different specifications are convenient to adjust when being used, and the use flexibility of the device is greatly improved.

Owner:HUIYINBI GROUP ANHUI PHARMA

A greenhouse vegetable planting automatic harvesting device

ActiveCN111771520BRealize fully automatic strappingImprove harvesting efficiencyMowersReaper-bindersAgricultural scienceGreenhouse

The invention provides an automatic harvesting device for vegetable planting in greenhouses, which relates to the technical field of vegetable planting and includes a walking wheel, a supporting base is installed in the middle of the top of the walking wheel, and a conveyor belt placed obliquely is installed on the top of the supporting base. The inner ring of the conveyor belt is equidistantly installed with a No. 1 roller, and the two ends of each No. 1 roller are mounted on the No. 1 roller support through bearings, and the bottom end of the No. 1 roller support is fixedly installed on the supporting base; The top of one of the No. 1 rollers is equipped with a pulley, and the No. 2 motor is fixedly installed on the front side of the support base, and the No. 2 motor stretches out to the outside with an output shaft; The middle part of the barrel is used to bundle the middle part of the leeks put in the leek feeding port, and the bundling by bundling rubber bands has the advantages of sensitive action of bundling rubber bands, high bundling efficiency, fast bundling speed, high bundling firmness and low cost.

Owner:WEIFANG UNIVERSITY

Bundling device for mechanical parts

ActiveCN113478240ARealize positioning punchingRealize positioning cuttingOther manufacturing equipments/toolsHydraulic cylinderPunching

The invention discloses a bundling device for mechanical parts, and relates to the technical field of bundling devices. The device comprises a drilling table, sliding plates, a first drilling machine, a second drilling machine, a cutting assembly and a bundling assembly. The sliding plates are in sliding fit with the drilling table; and the cutting assembly is fixedly installed between the drilling tables and the bundling assembly. Angle steel is placed in a first angle steel sleeve plate, the punching position is adjusted by moving the sliding plates, and the drilling machines are started to punch the two surfaces of angle steel; and the cutting length is adjusted by adjusting a first hydraulic cylinder, the angle steel is pushed to push a cut angle steel block into a second angle steel sleeve plate, the angle steel block penetrates through a guide bar and sequentially penetrates through all fixing clamps, a hole of the angle steel block falls onto bundling steel wires, one ends of the bundling steel wires on a second lifting hook are hung on a first lifting hook, a servo motor is started to drive a storage box to rotate, the bundling steel wires are driven to rotate to achieve bundling, and one ends of the bundled bundling steel wires are cut off.

Owner:深圳市诚创赢自动化科技有限公司

A winding and binding machine for medical infusion tube

InactiveCN104015952BHigh degree of automationRealize automatic strappingBinding material applicationPaper/cardboard containersEngineeringConductor Coil

The invention provides a winding binding machine for a medical infusion tube and belongs to the technical field of medical device processing equipment. The winding binding machine for the medical infusion tube solves the problems that the existing infusion tube winding binding quality is low and efficiency is low. The winding binding machine for the medical infusion tube comprises a rack, wherein two conveyor belts are rotatably connected with the rack, a plurality of material carrying rods are respectively fixedly connected on the two conveyor belts, the rack is fixedly connected with one working platform, the working platform is connected with a main shaft in a sliding way along the vertical direction, a driving mechanism I and a driving mechanism II are arranged on the working platform, the main shaft is fixedly connected with a mainboard, the mainboard is connected with two winding rods, each material carrying rod is provided with a clamping mechanism, the mainboard is connected with a binding main body, and a binding device is arranged on the binding main body. The winding binding machine for the medical infusion tube can automatically wind the medical infusion tube and then automatically bind the medical infusion tube after winding, automation degree is high, and production efficiency is improved.

Owner:杨丽华

Bundling equipment for metal wire production

InactiveCN112141392ARealize automatic strappingHigh degree of automationBinding material applicationBundling machine detailsElectric machineryDrive motor

The invention discloses bundling equipment for metal wire production. The bundling equipment comprises an operation table, a transportation assembly, a pressing assembly and a bundling assembly, the transportation assembly and the bundling assembly are both arranged on the operation table, the transportation assembly is arranged on the binding assembly in a penetrating manner, and the pressing assembly is arranged on the transportation assembly; and the bundling assembly comprises a first driving motor, a supporting frame, a bundling belt and a bundling claw, the first driving motor is connected to one side of the supporting frame, the driving end of the first driving motor is connected to the bundling claw, the bundling claw is installed in the supporting frame, and the bundling belt is connected to the bundling claw in an attached mode. According to the bundling equipment, a control device is arranged, so that metal wires are automatically bundled, and the automation degree is high;and the multiple driving motors are arranged, each assembly can be independently controlled, workers do not need to adjust the positions of the metal wires multiple times, and the working efficiency is high.

Owner:邯郸一三高研科技有限公司

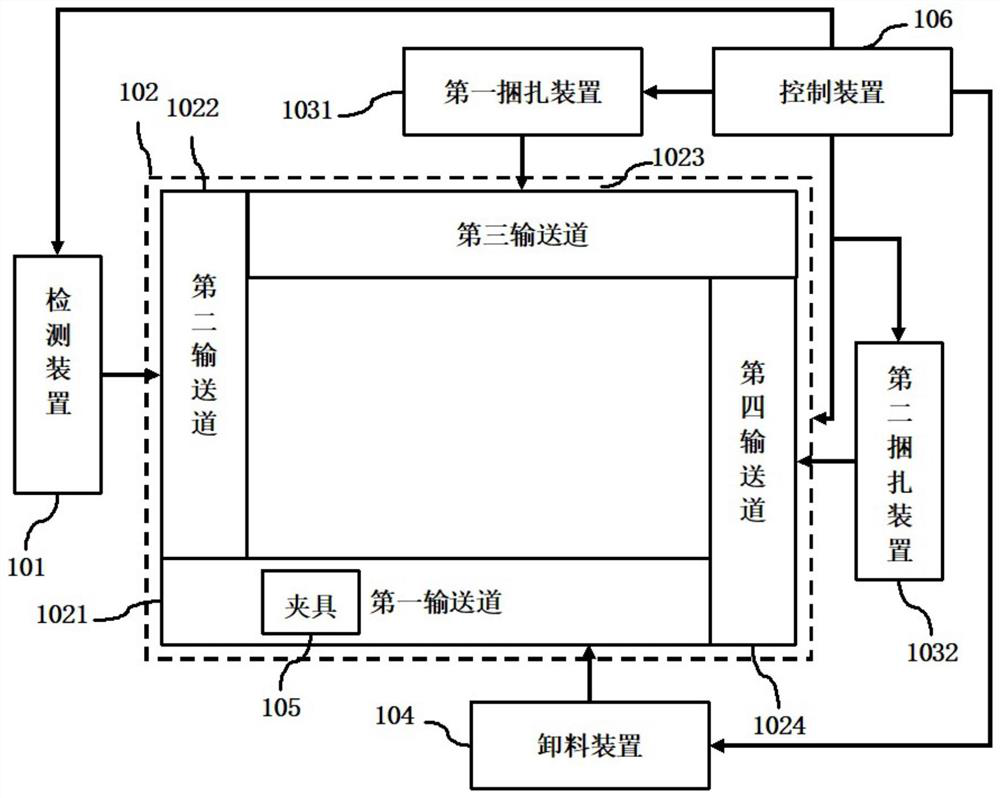

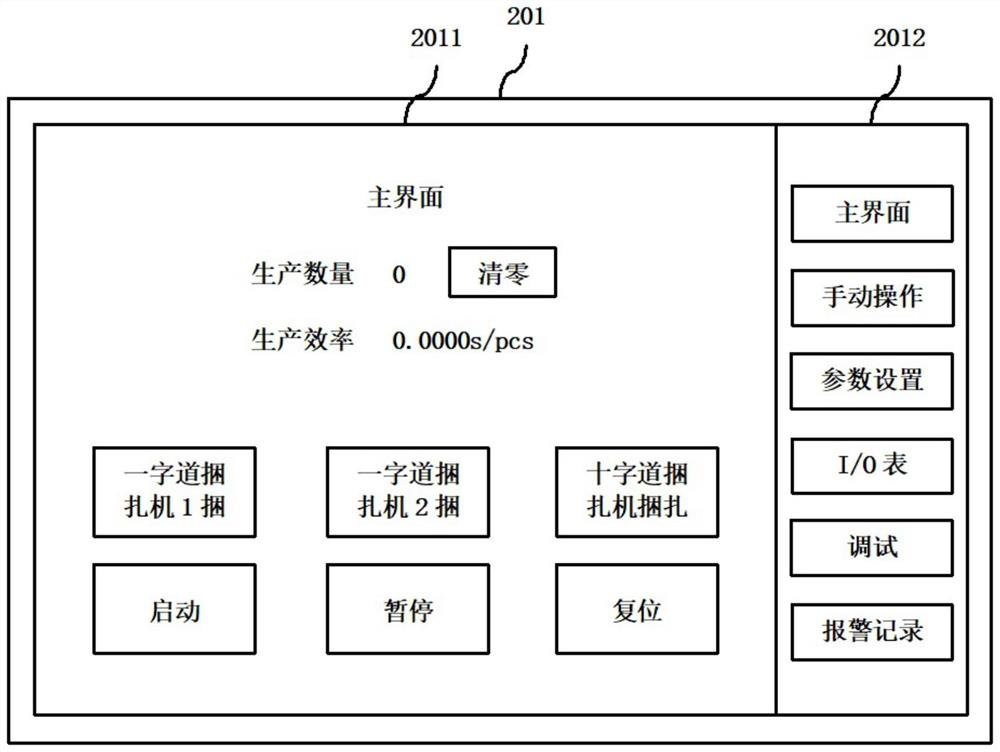

Binding machine control method and device, binding machine and storage medium

InactiveCN112706972ARealize automatic strappingEasy to controlBinding material applicationPackaging automatic controlControl engineeringProcess engineering

The embodiment of the invention discloses a binding machine control method and device, a binding machine and a storage medium. The binding machine comprises a conveying device, a clamp, a detecting device, a binding device and a discharging device. The method comprises the steps that the conveying device is controlled to convey the clamp loaded with to-be-bound articles to a binding position; the binding device is controlled to bind the to-be-bound articles in the clamp; the conveying device is controlled to convey the clamp loaded with the bound articles to a discharging position; and the discharging device is controlled to take out the bound articles from the clamp. According to the binding machine control method and device, the binding machine and the storage medium, the binding machine can be controlled.

Owner:顺启和(深圳)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com