Horizontal packing machine allowing automatic waste paper compression and binding

A waste paper baler and automatic technology, which is applied in the field of balers, can solve the problems such as the inability to realize automatic bundling of waste paper, and achieve the effect of high-efficiency compression.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

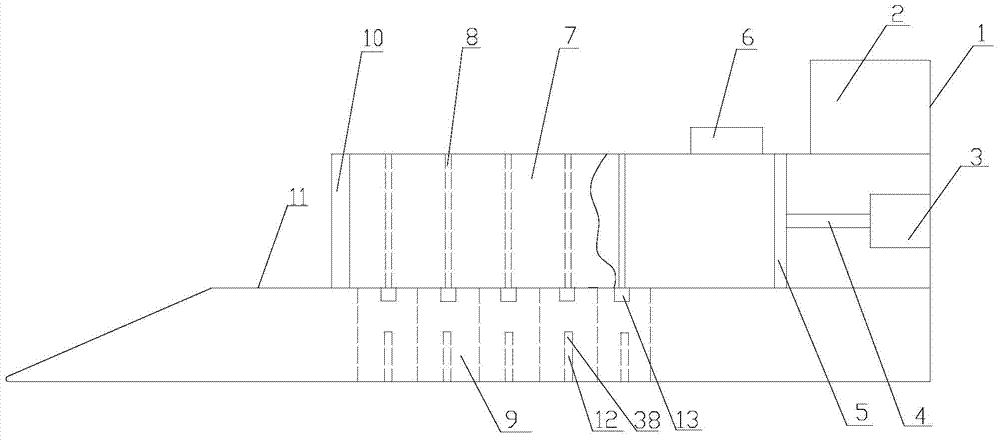

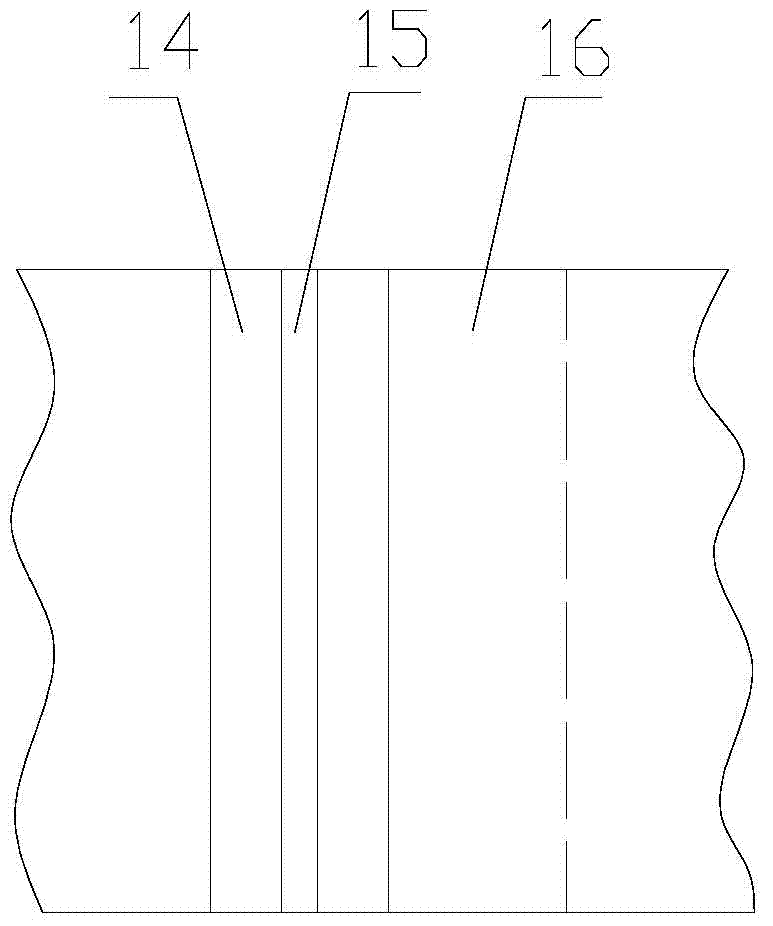

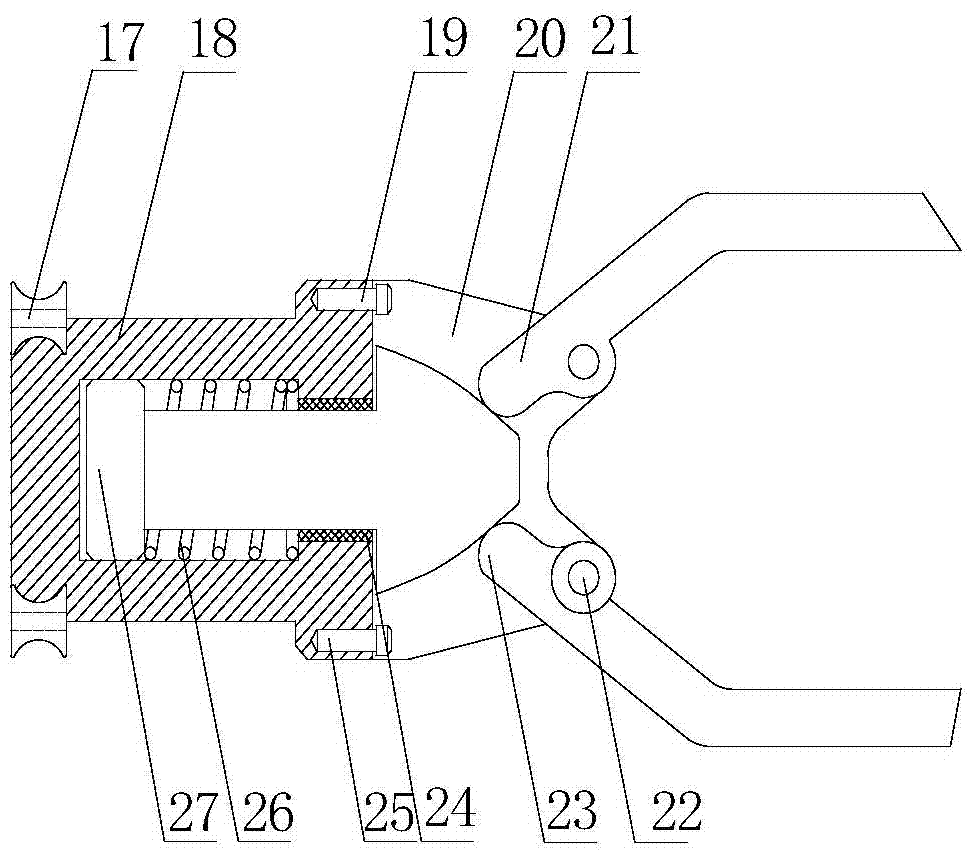

[0016] Such as figure 1 As shown, the horizontal automatic compression binding waste paper baler of the present invention includes a frame 1, an electrical box 2, a hydraulic cylinder 3, a hydraulic rod 4, a push plate 5, a feed port 6, a compression box 7, an automatic Wire threading track 8, iron wire placement box 9, discharge door 10 with lock, conveyor belt 11, twisting and shearing device 12, wire threading clamping device 13. The specific structure and connection method are:

[0017] The frame 1 is welded to the hydraulic cylinder 3, the hydraulic cylinder 3 is connected to the hydraulic rod 4, the hydraulic rod 4 is connected to the push plate 5, the feed port 6 is integrated with the frame 1, and five automatic wire threading rails 8 are placed inside the compression box 7 , the automatic wire threading track 8 connects the iron wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com