Automatic stacking equipment

A palletizing and equipment technology, applied in the field of logistics transportation machinery and equipment, can solve the problems of easily damaged goods, low income and expenditure, and difficult promotion, and achieve stable and compact stacking, efficient palletizing action, and high input-income ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described with reference to the drawings.

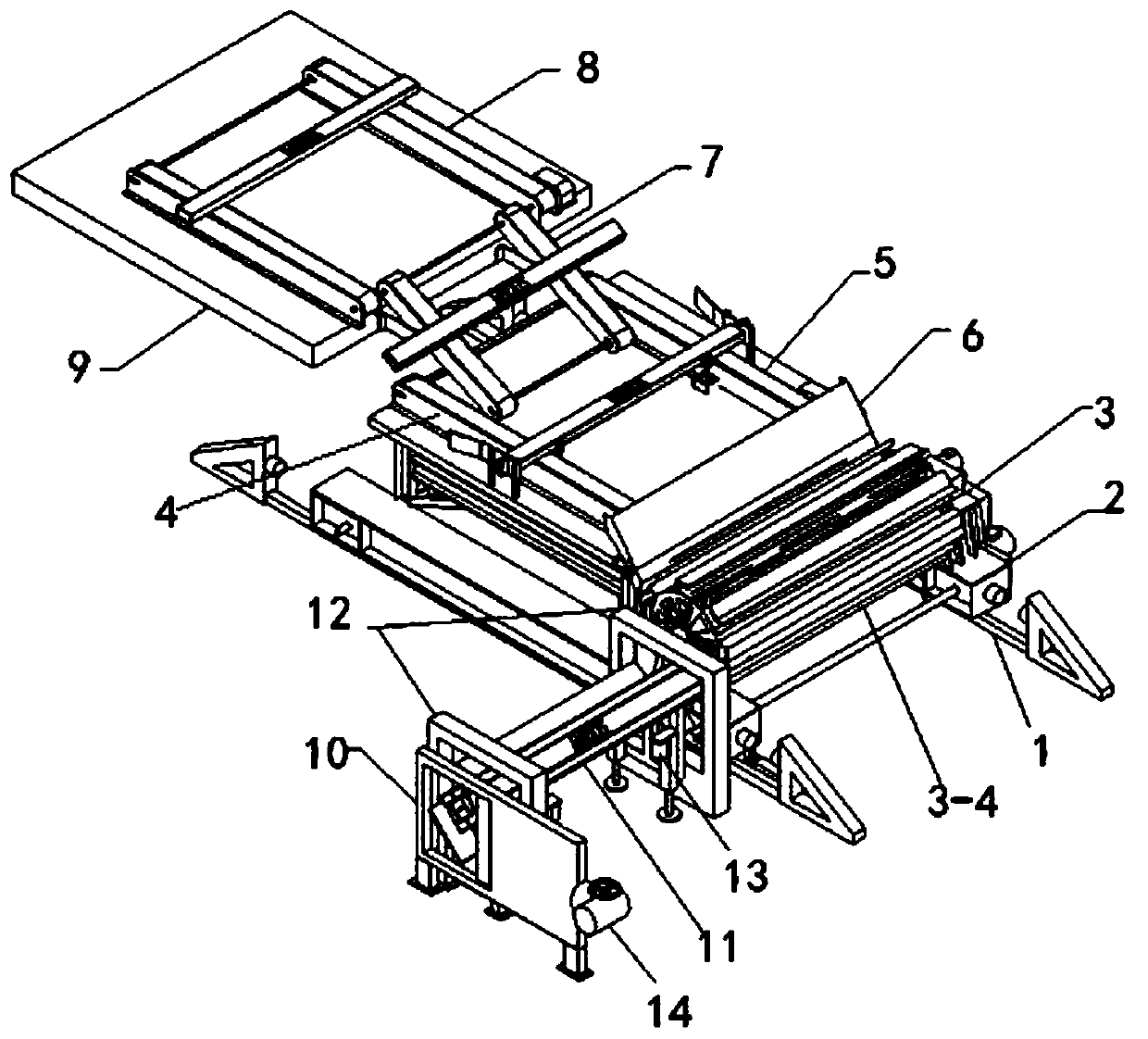

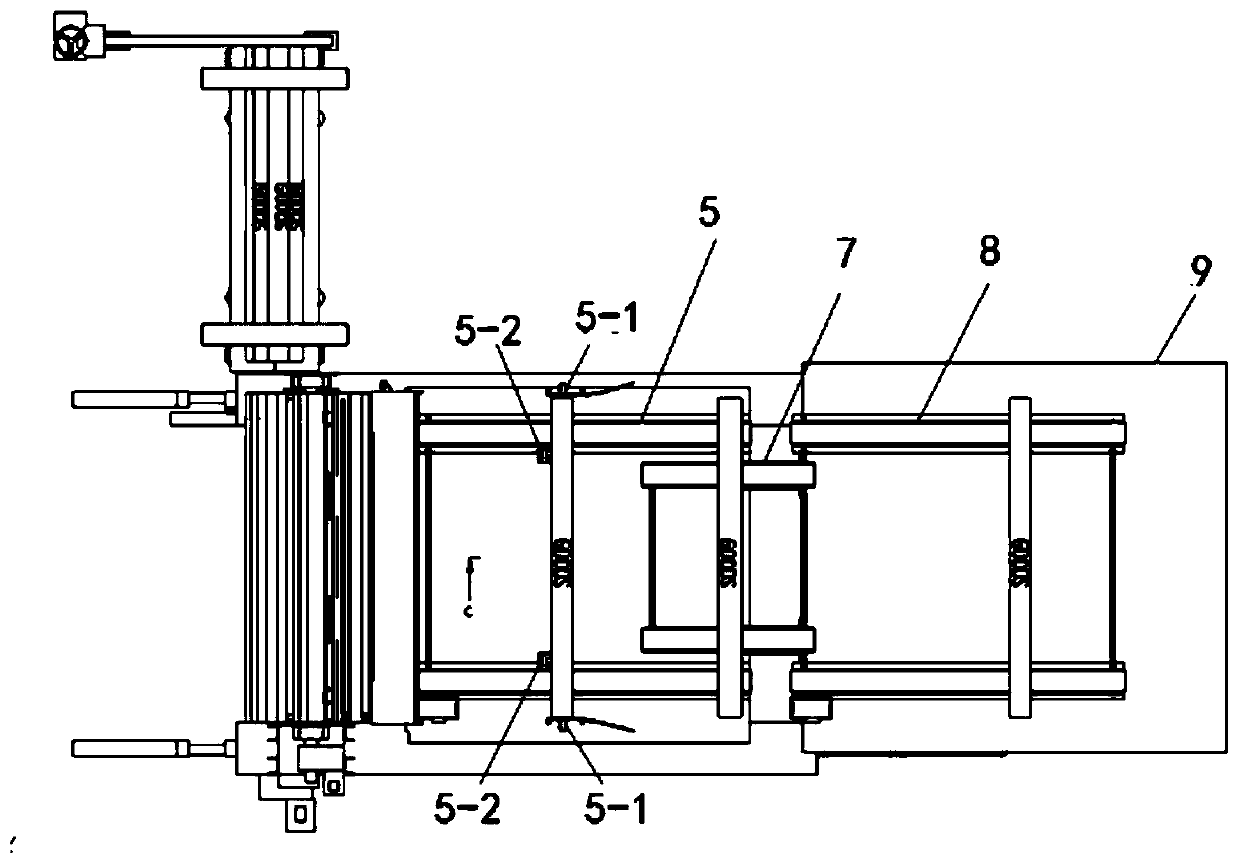

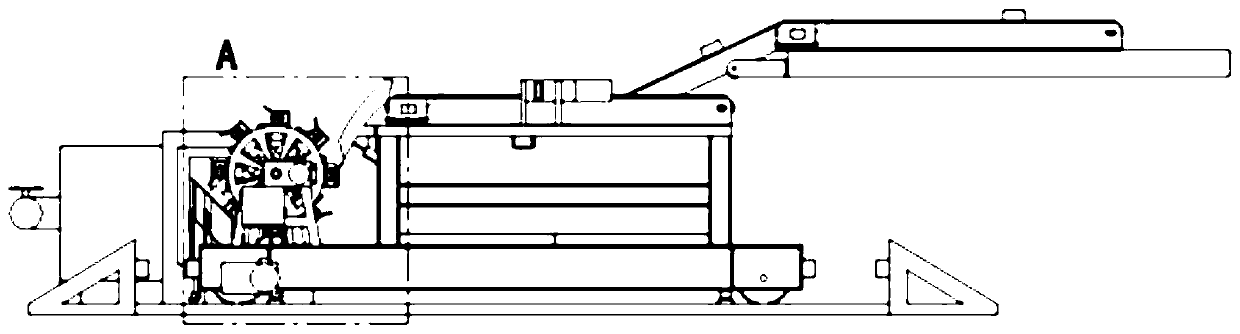

[0037] See Figure 1~8 , The present invention designs an automatic palletizing equipment, including a fixed belt conveyor, an inclined belt conveyor, a queuing belt conveyor composed of queuing feeder modules, a cargo posture adjustment module mainly composed of a rotating mechanism, a horizontal walking mechanism, Track and palletizing platform, track 1 is fixed on the ground, the track 1 is matched with a horizontal walking mechanism 2, a rotating mechanism 3 is fixed on the horizontal walking mechanism 2, and a frame 4 is installed in front of the rotating mechanism 3, and the frame 4 is also fixed On the horizontal traveling mechanism 2, a queuing belt conveyor 5 is fixed on the frame 4, and the front end of the queuing belt conveyor 5 and the rotating mechanism 3 are connected by a feeding chute 6, which is provided with There are open and close doors, which are controlled by air cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com