A sorting, sorting, counting and binding system for plastic pipes

A plastic tube and automatic bundling technology, which is applied in the direction of bundling objects, bundling materials, packaging/bundling items, etc., can solve the problems of low bundling and packaging efficiency, weak rigidity, and large space occupation, and achieves high counting and sorting efficiency. The effect of high utilization rate and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

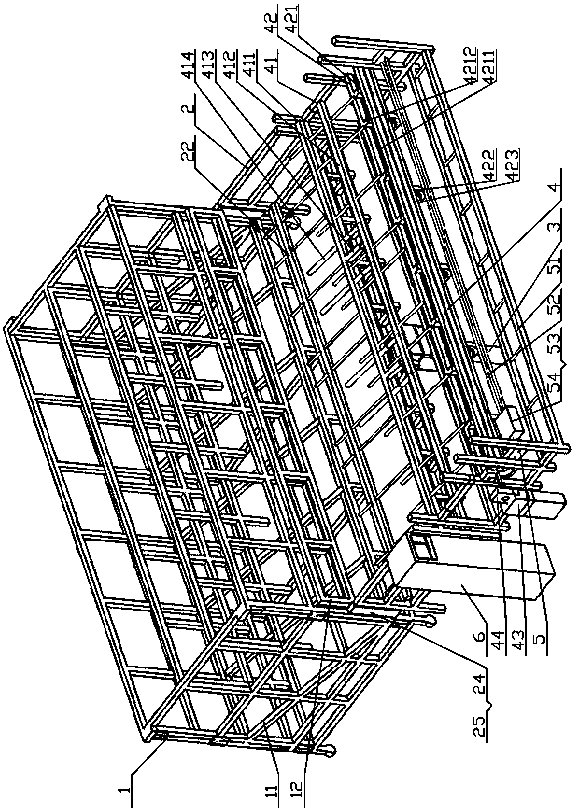

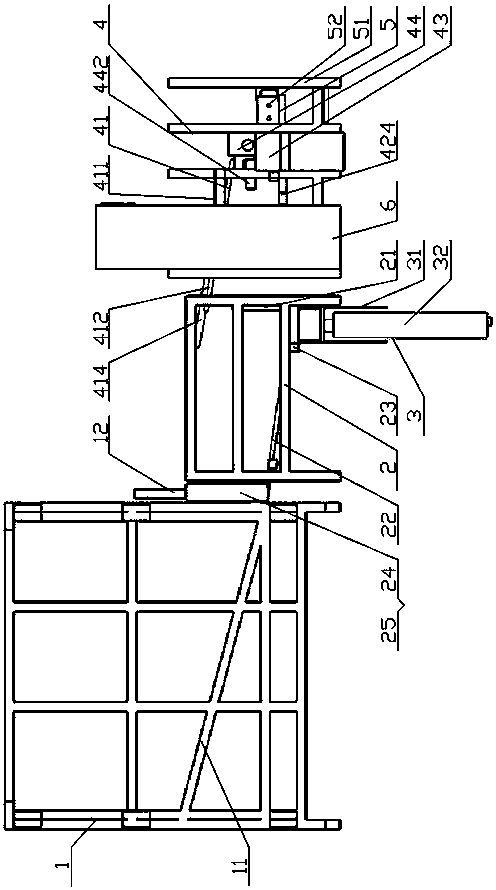

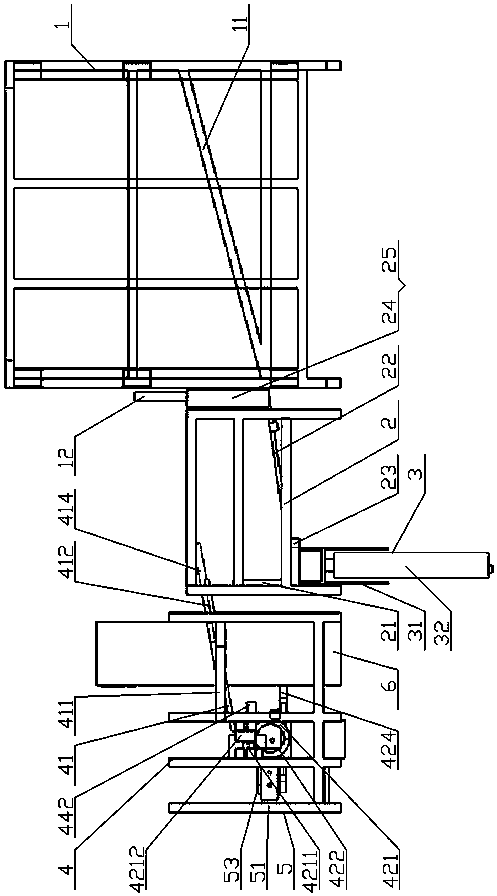

[0044] Such as Figure 1 to Figure 5 As shown, the plastic pipe retrieving, sorting, counting and binding system includes a feed bin 1, a transition bin 2, a lifting device 3, a sorting and counting device 4, an automatic strapping device 5 and an electric control device 6 (described below for further details) The direction of material silo 1 in the entire plastic pipe retrieving, sorting, counting and binding system is described later).

[0045] The feed silo 1 is a box-shaped structure, and its internal width in the left and right directions matches the length of the plastic pipe. A discharge door 12 is provided at the lower part of the panel.

[0046] The transition silo 2 is arranged in front of the feed silo 1, and is a frame structure with closed left and right sides, its internal left and right width dimensions match the internal left and right width dimension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com