Patents

Literature

75results about How to "Reduce production area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

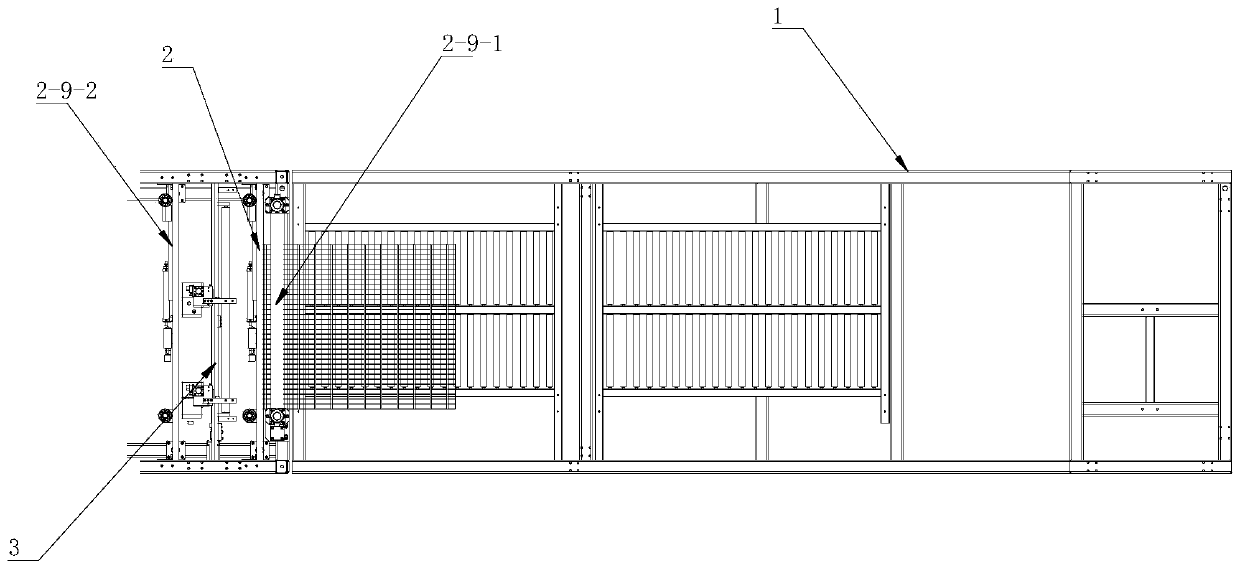

Automatic production line suitable for packaging magnetic shoes and realization method of automatic production line

ActiveCN105947293ASimple structureImprove product qualityWrappers shrinkageBinding material applicationProduction lineManipulator

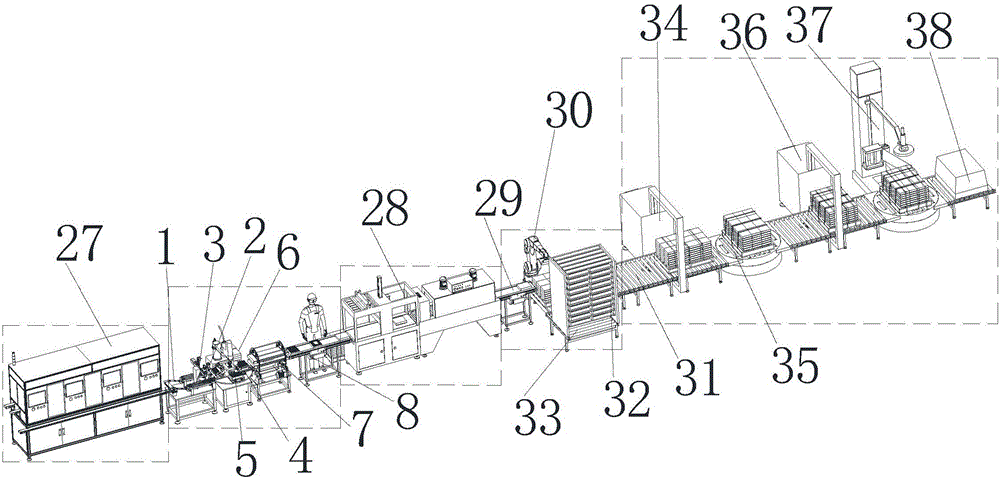

The invention discloses an automatic production line suitable for packaging magnetic shoes. The automatic production line comprises automatic appearance detecting equipment, a controller, a magnetic shoe distributing device, a magnetic shoe finishing device, a transplanting and encasing manipulator, a magnetic shoe arranging device, a placement robot, a box body turnover device, a magnetic shoe full-box conveyor belt, a thermal shrinkage film sealing machine, a palletizing conveying belt, a palletizing robot and a binding / film winding system. The invention also discloses a realization method of the automatic production line suitable for packaging the magnetic shoes. The automatic production line and the realization method thereof disclosed by the invention have the characteristics of simple structure, good quality of products, high production efficiency, small production area, low production cost, time conservation, labor conservation and the like.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

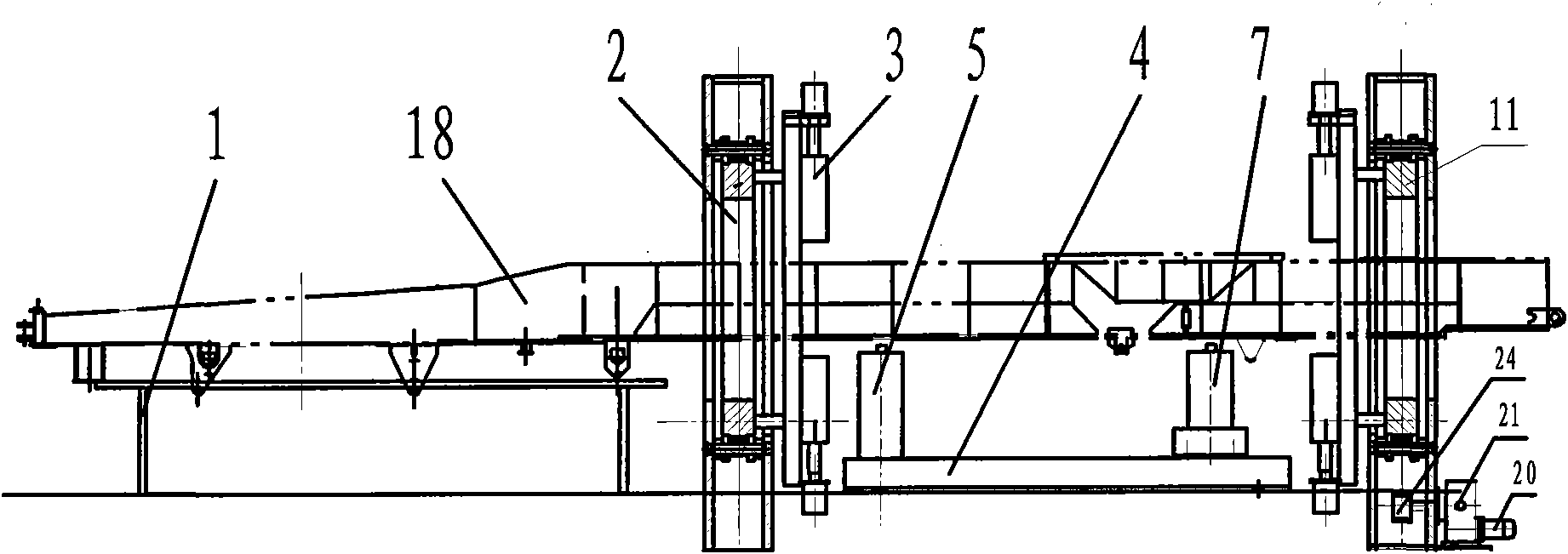

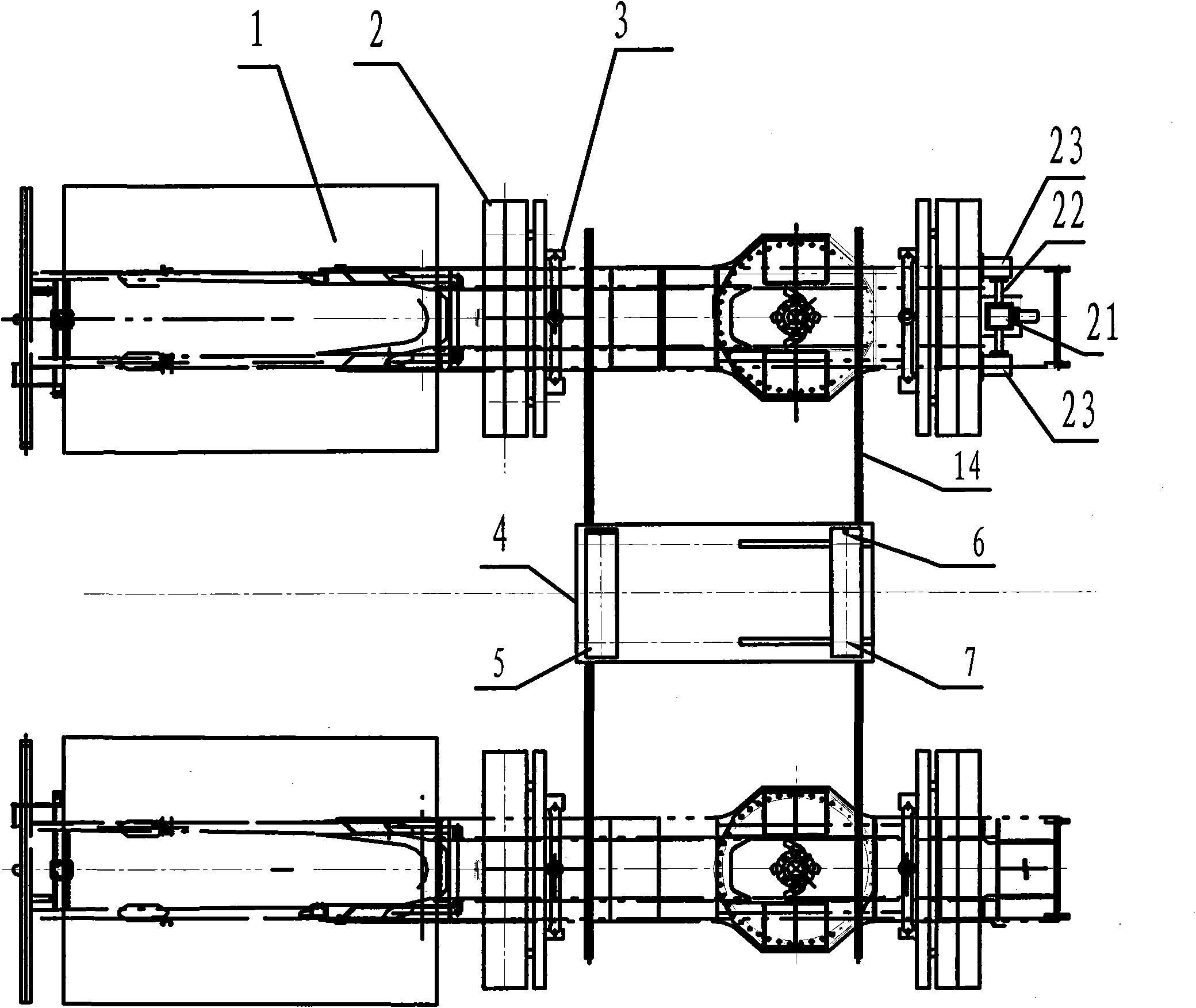

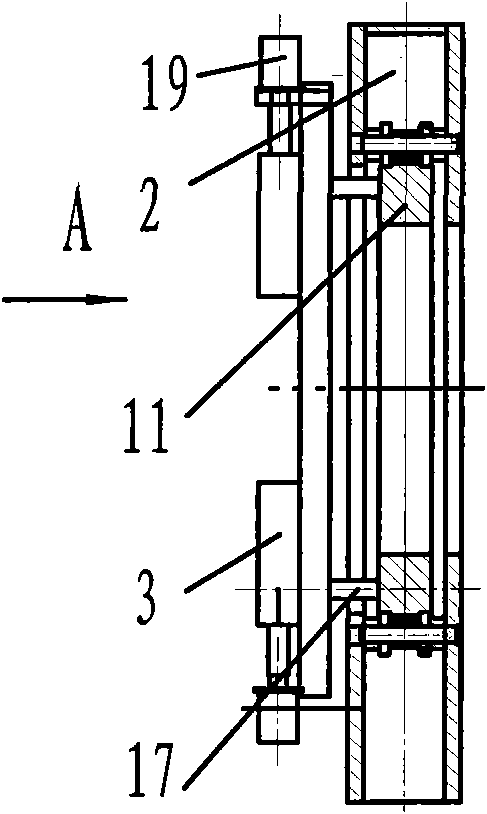

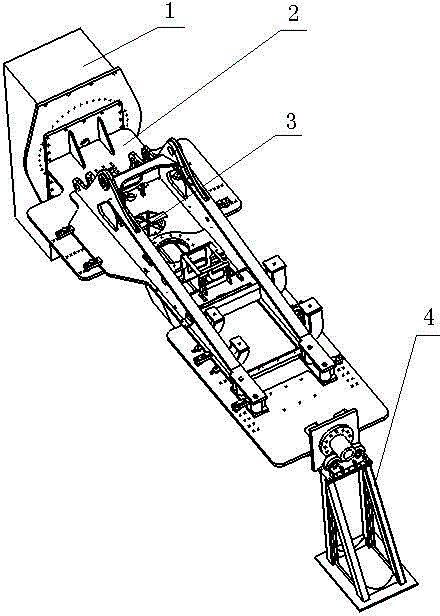

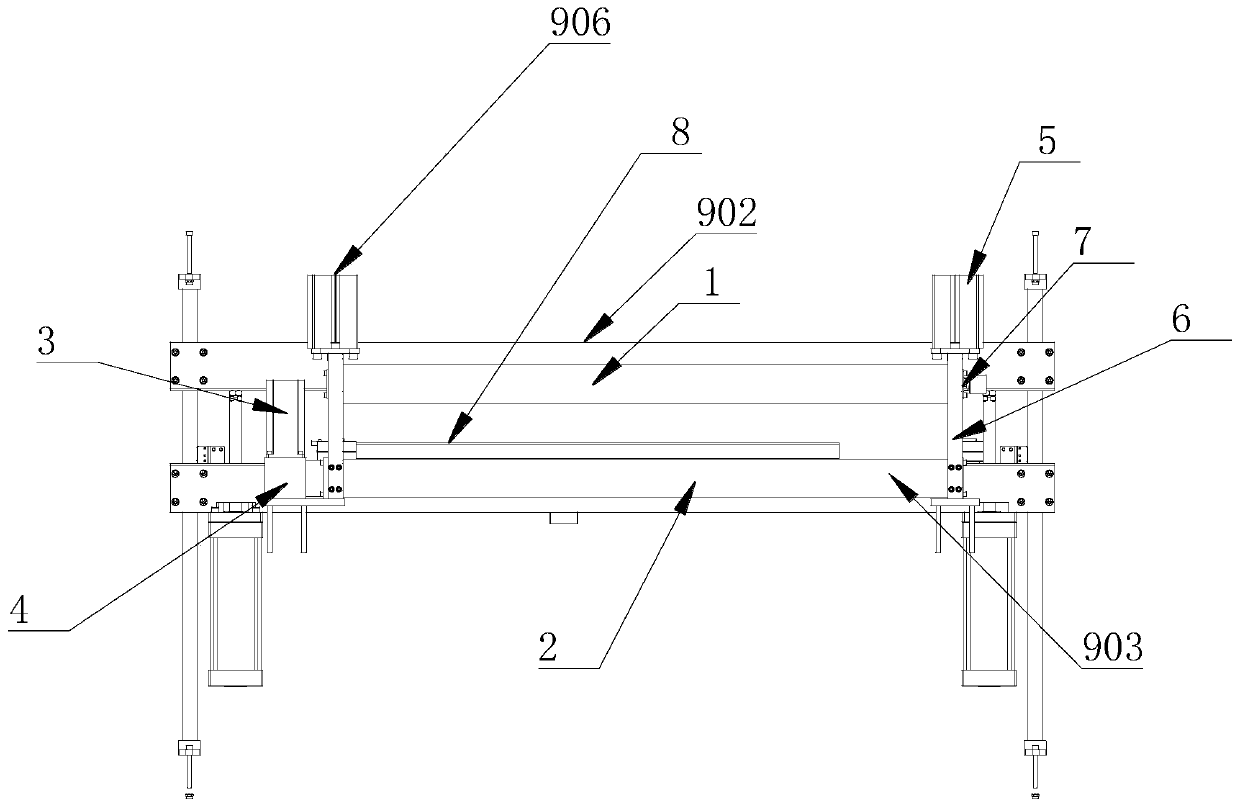

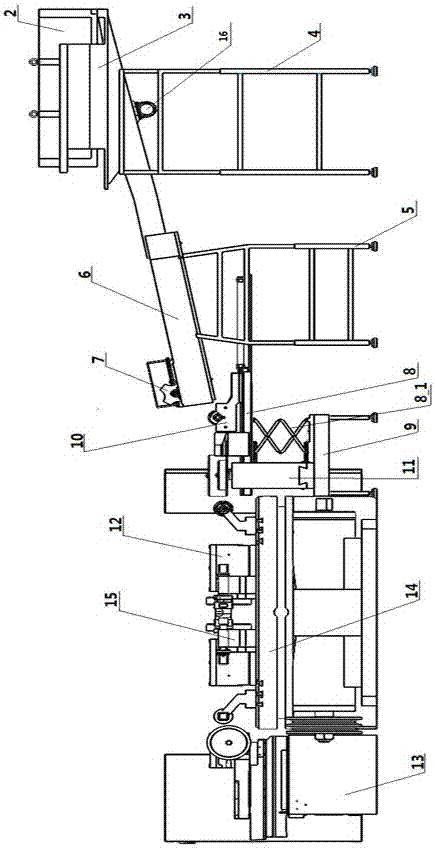

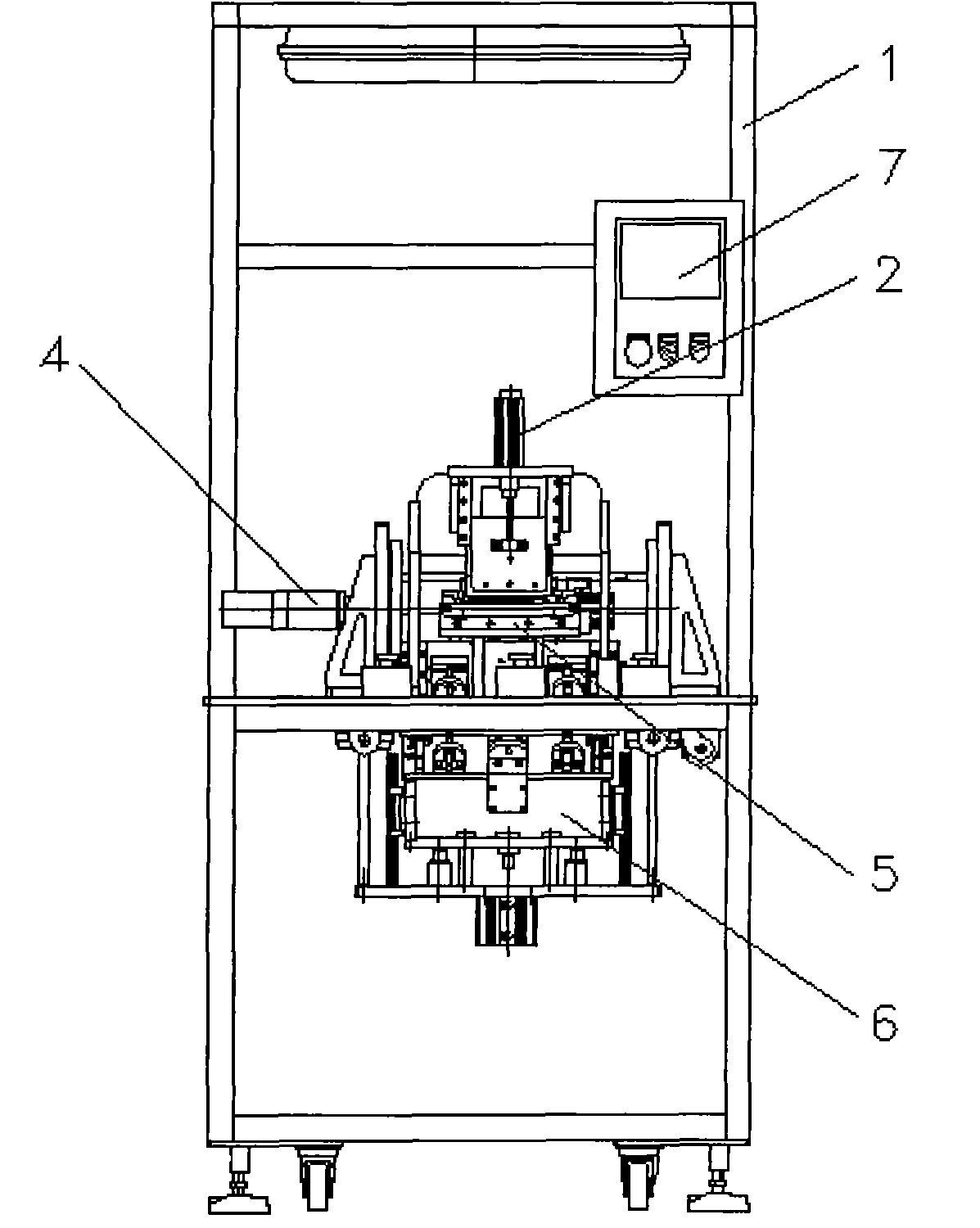

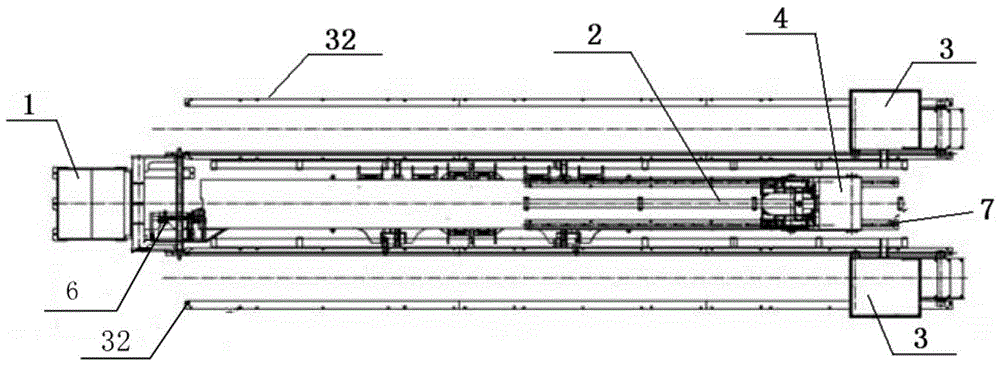

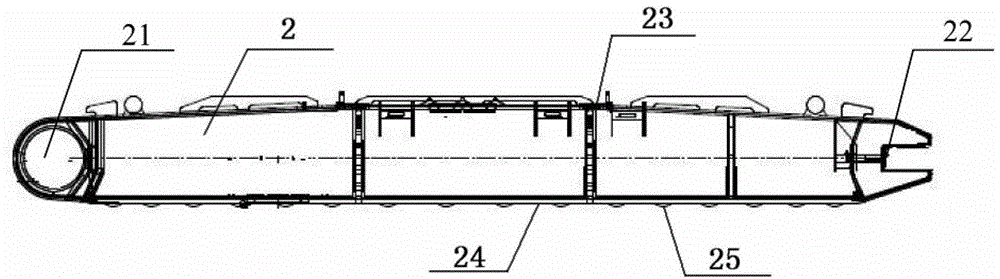

Side open type carriage welding turnover work center

InactiveCN101890608AConvenient welding operationGuaranteed coincidenceWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention discloses a side open type carriage welding turnover work center belonging to automobile crane carriage welding displacement equipment. The turnover center comprises a side open welding positioner, a three-dimensional feeding trolley, a lifting platform and an electric control system, wherein the three-dimensional feeding trolley is located in the middle of the side open welding positioner, the lifting platform is arranged in front of the side open welding positioner, the three-dimensional feeding trolley is arranged on rails which are perpendicular to the side open welding positioner, and the electric control system is simultaneously connected with the three-dimensional feeding trolley, the lifting platform and the side open welding positioner. The side open type carriage welding turnover work center has the advantages that firstly, two side open tilters commonly use one feeding trolley, thus the turnover work center is compact in structure, secondly, the lateral faces of the tilters are open for realizing the positioning of work-pieces, thirdly, the work-pieces can be automatically clamped, and production efficiency are high, fourthly, 180-degree idle rotation can be realized in a turnover ring, which realizes the requirement that carriages are positively fed and reversely discharged, and fifthly, welding operations of workers are convenient.

Owner:XUZHOU HEAVY MASCH CO LTD

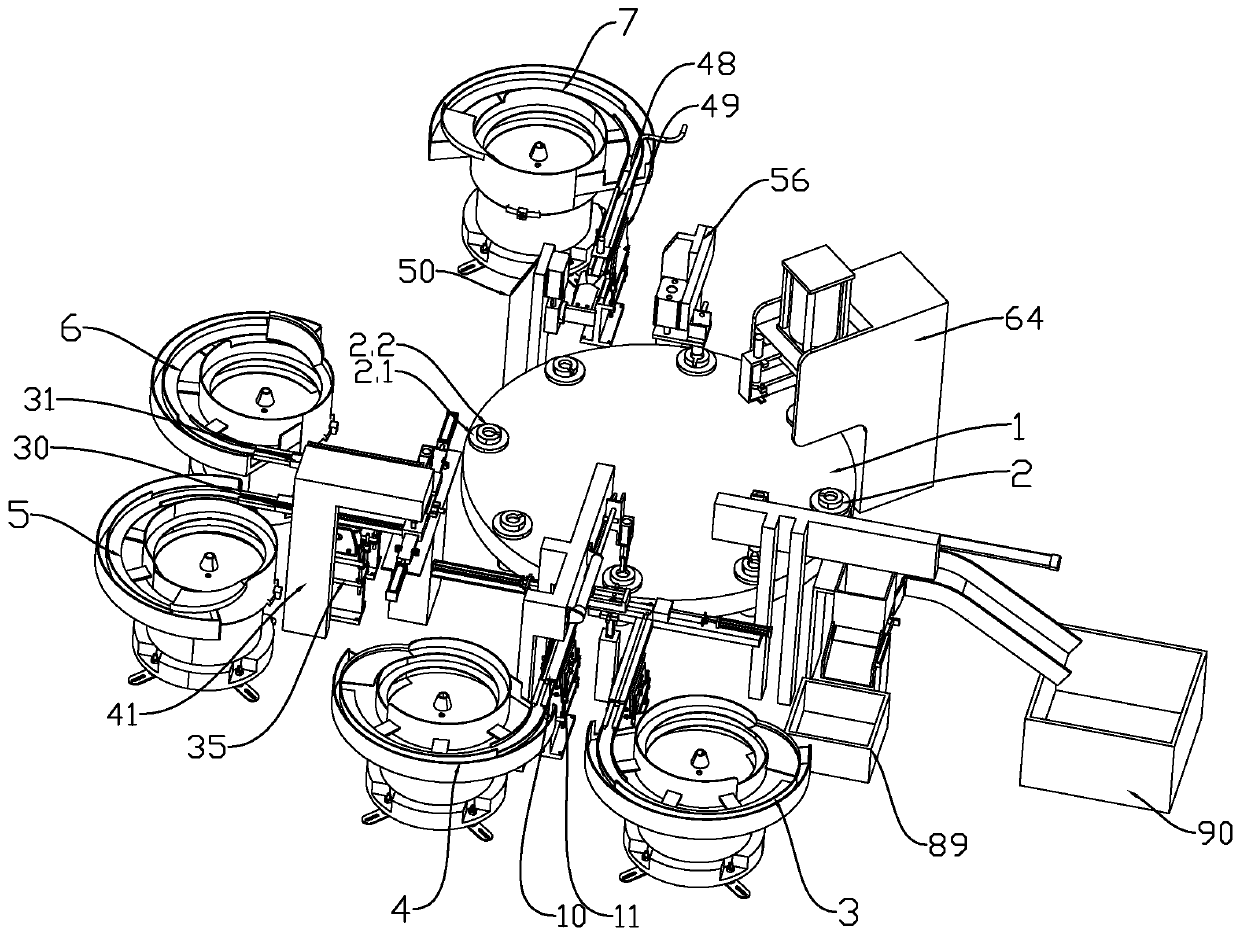

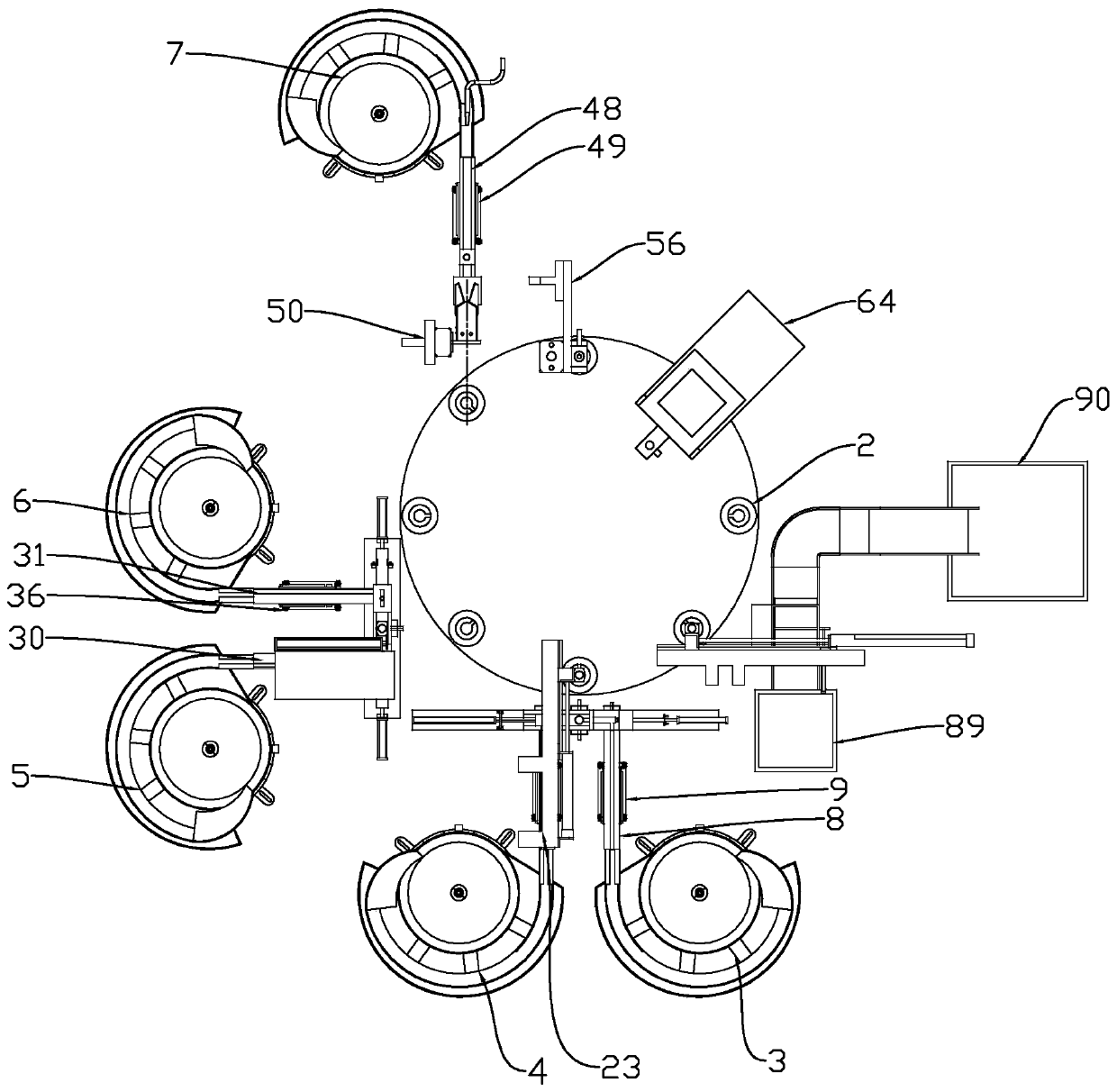

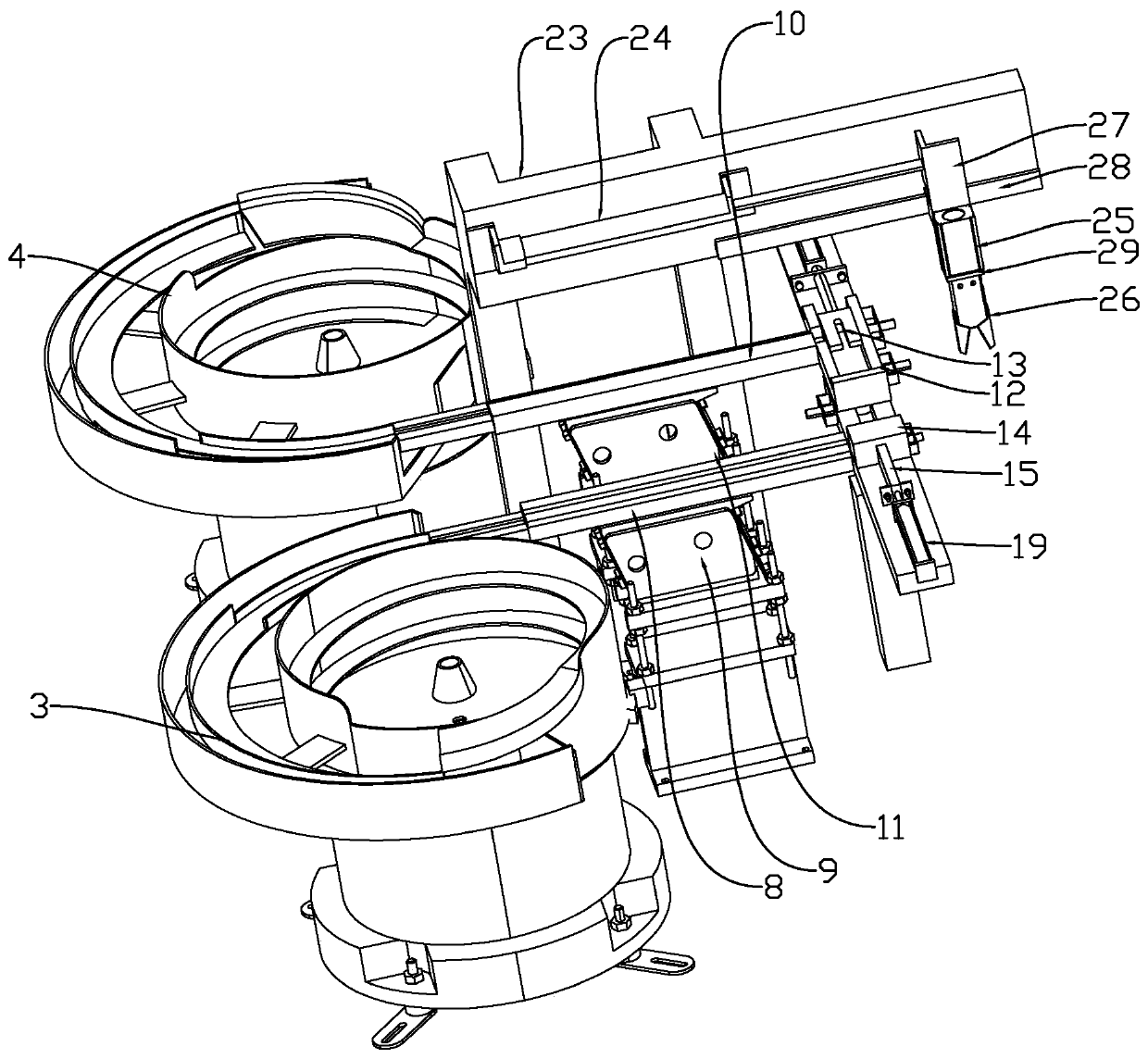

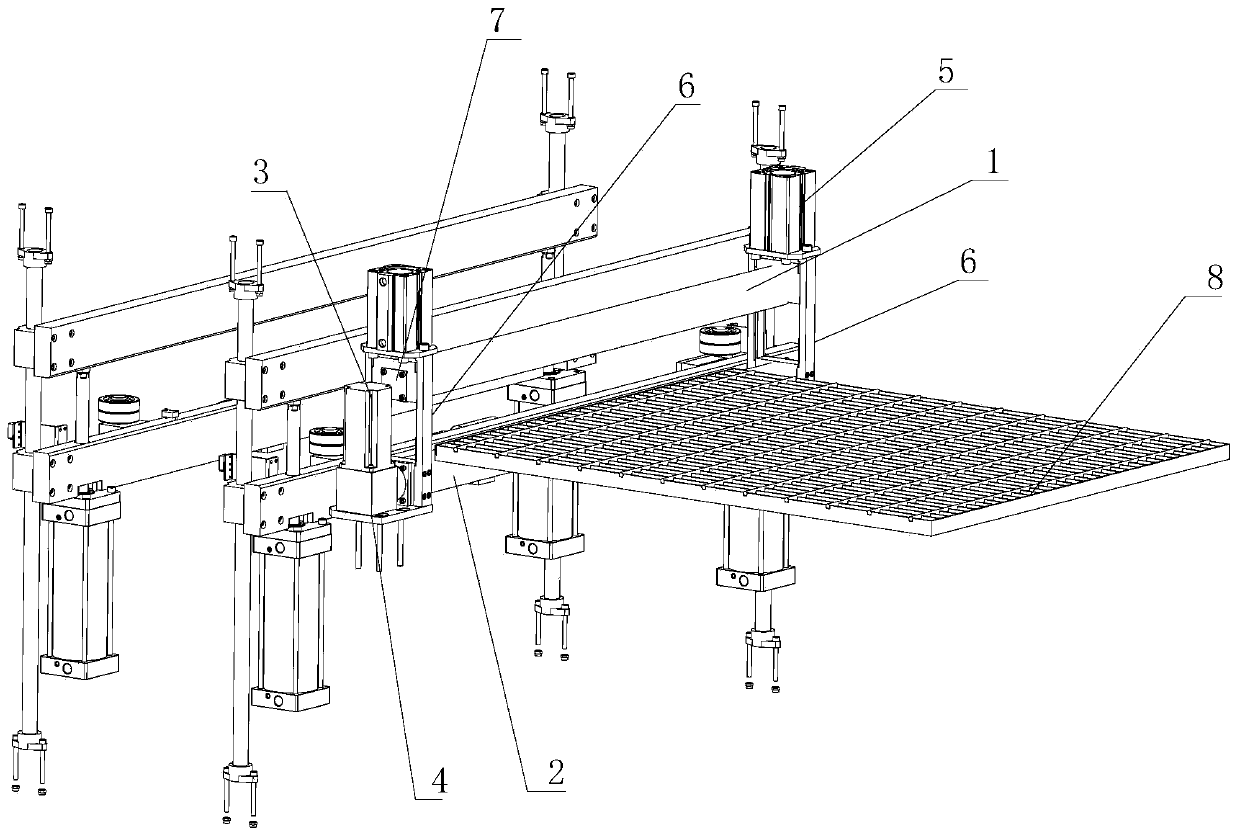

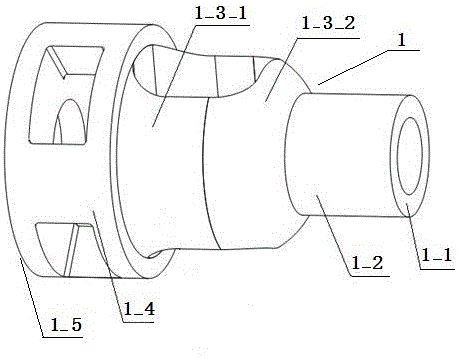

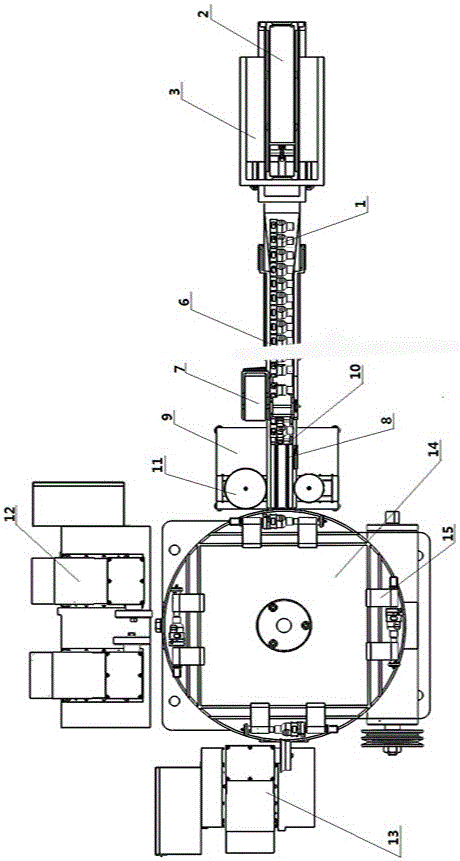

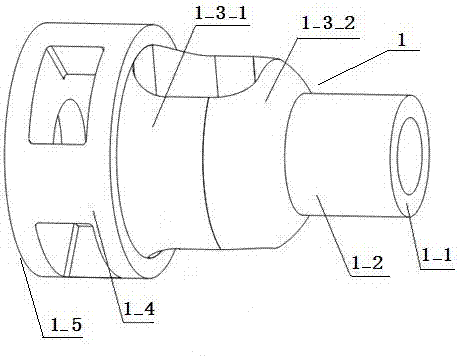

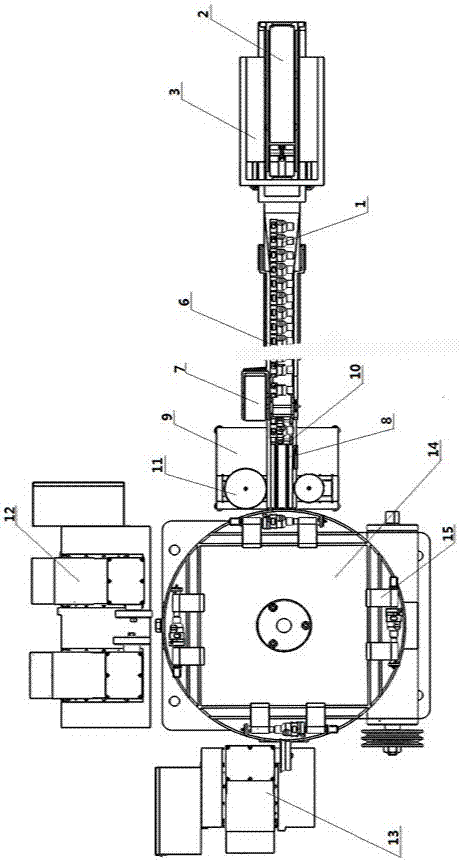

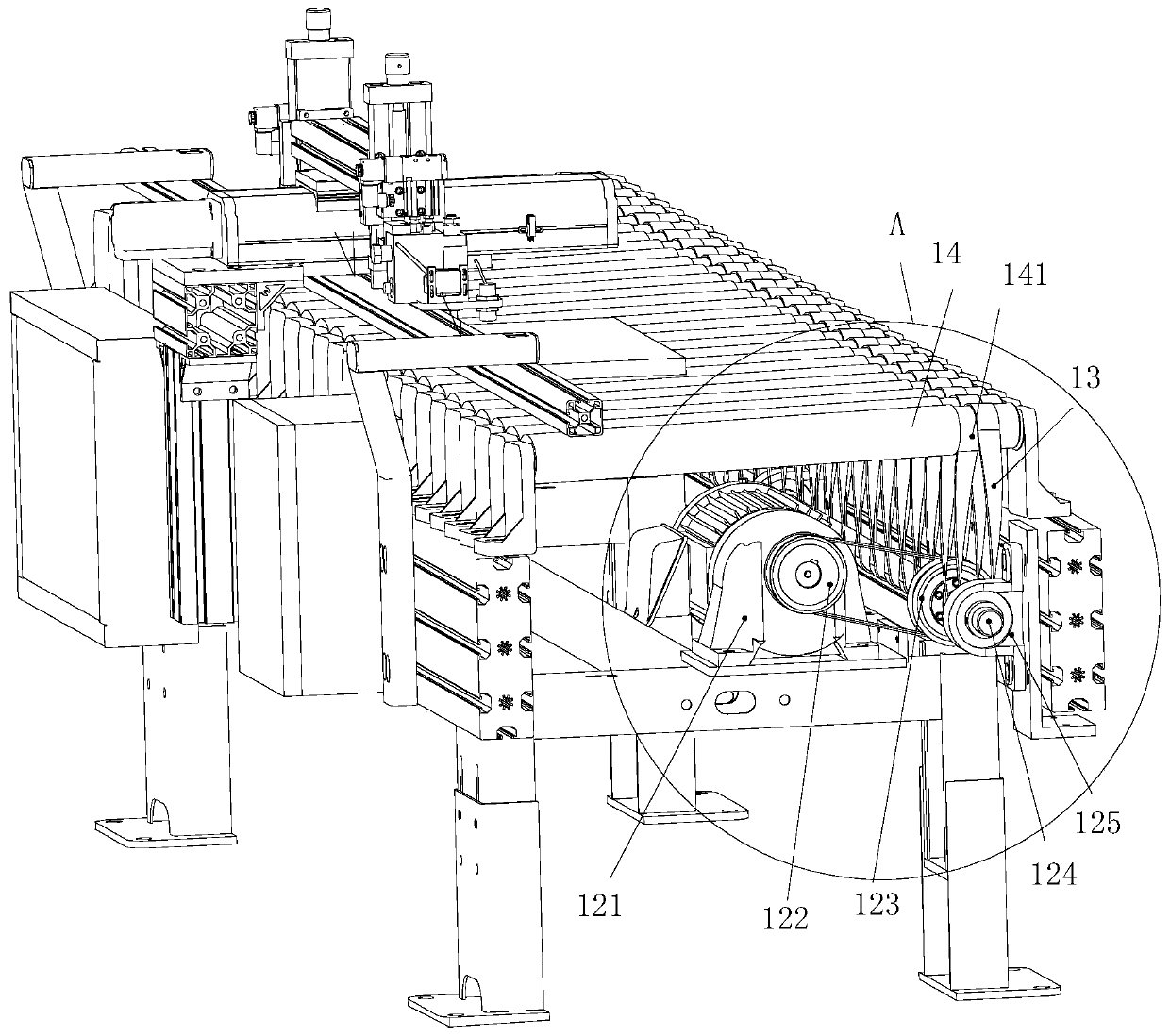

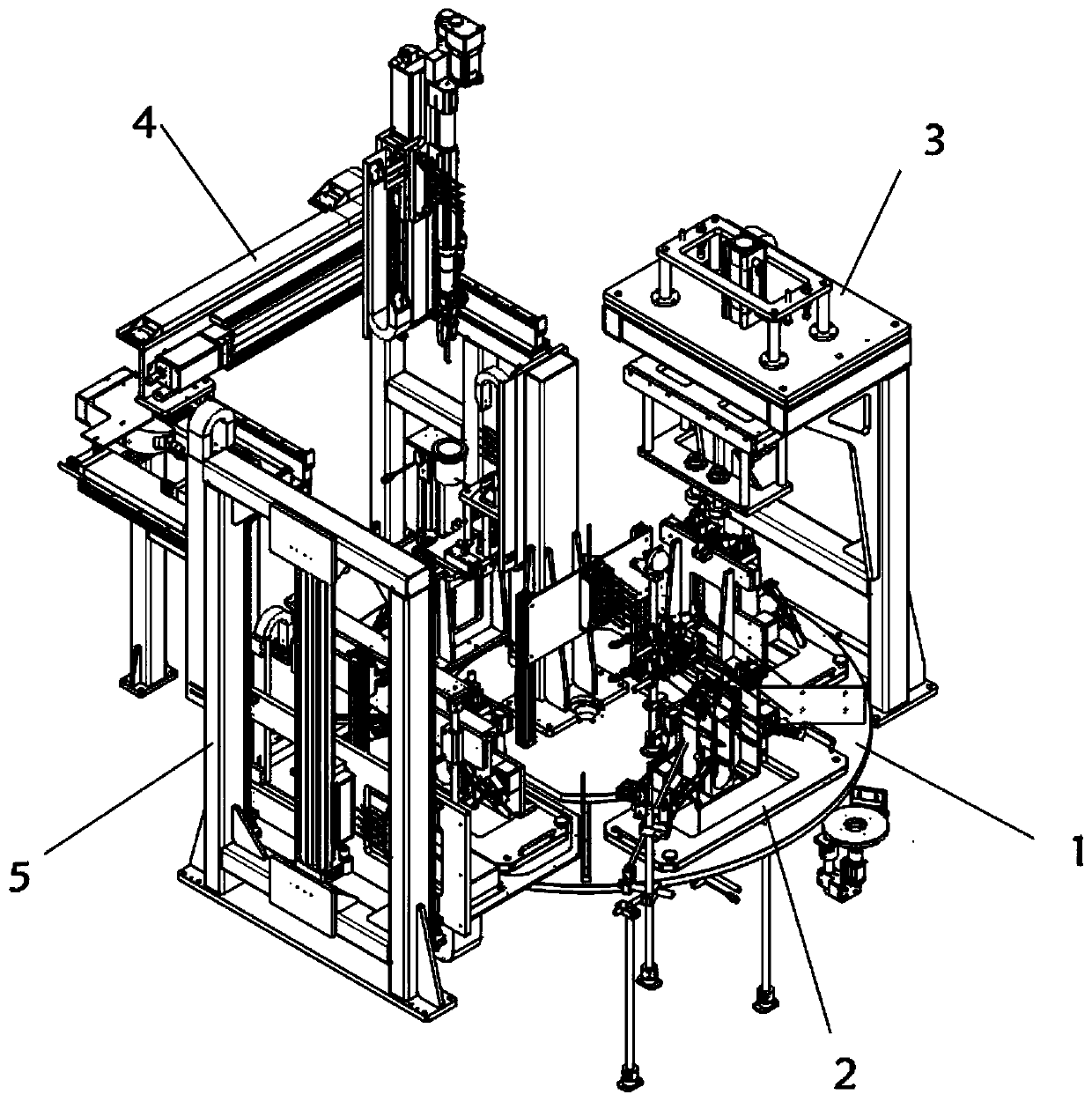

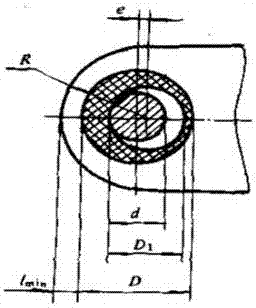

Multi-station rotary disc type automatic assembly production line of combined roller

PendingCN110919361AReduce chanceReduce production areaAssembly machinesMetal working apparatusProduction lineEngineering

The invention relates to a combined roller and particularly relates to a multi-station rotary disc type automatic assembly production line of the combined roller. The combined roller comprises a rotary disc, a bolt feeding mechanism, a bearing feeding mechanism, a gasket feeding mechanism, a clamping ring feeding mechanism, a press fitting mechanism and a rotary disc discharging mechanism, whereinthe rotary disc is connected with a rotation driving mechanism, the rotation driving mechanism can drive the rotary disc to rotate, the bolt feeding mechanism, the bearing feeding mechanism, the gasket feeding mechanism, the clamping ring feeding mechanism, the press fitting mechanism and the rotary disc discharging mechanism are sequentially arranged on the periphery of the rotary disc, and bearing seats are arranged at area positions, facing the bolt feeding mechanism, the gasket feeding mechanism, the clamping ring feeding mechanism, the press fitting mechanism and the rotary disc discharging mechanism, of an upper face of the rotary disc respectively. The combined roller is advantaged that the conveying mechanism and the assembling mechanism of all parts of a combined roller are distributed along the rotary disc, so the combined roller is continuously and automatically assembled in a relatively concentrated area, the occupied production area is small, and production cost is reduced.

Owner:无锡阿尔法精密机械制造有限公司

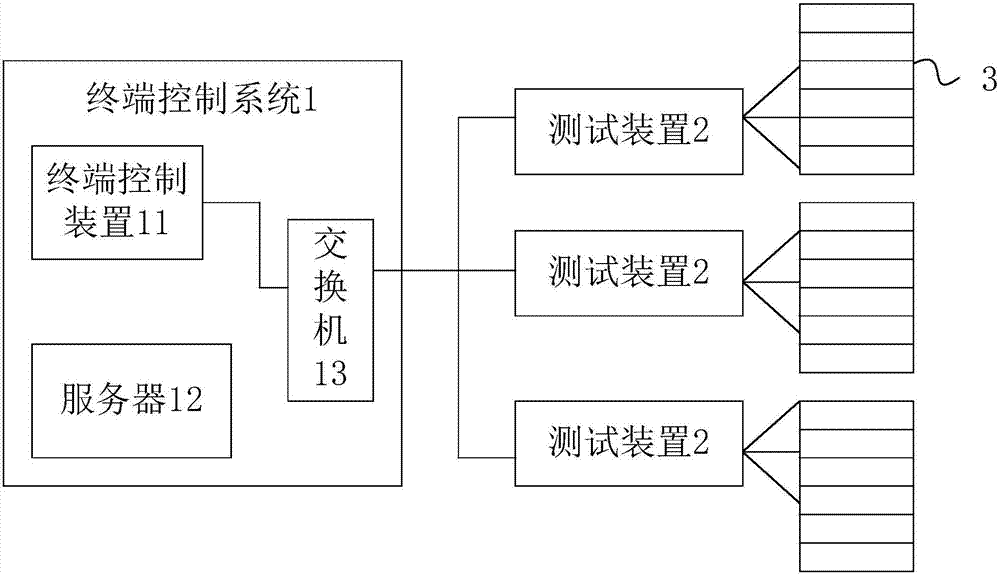

Full-automatic testing system applicable to solid hard disc and method of full-automatic testing system

The invention relates to a full-automatic testing system applicable to a solid hard disc and a method of the full-automatic testing system. The full-automatic testing system comprises a terminal control system, a plurality of testing devices and a plurality of testing bases, wherein the testing devices are arranged with the testing bases in a one-to-one correspondence manner; the testing devices are connected with the testing bases through data wires; each testing device is an independent device; and all testing devices are in data communication with the terminal control system and are used for testing whether a tested product is qualified or not through automatic analysis. The full-automatic testing system has functions of full-automatic testing, analysis and testing result output, and the production efficiency is greatly improved.

Owner:苏州科美信息技术有限公司

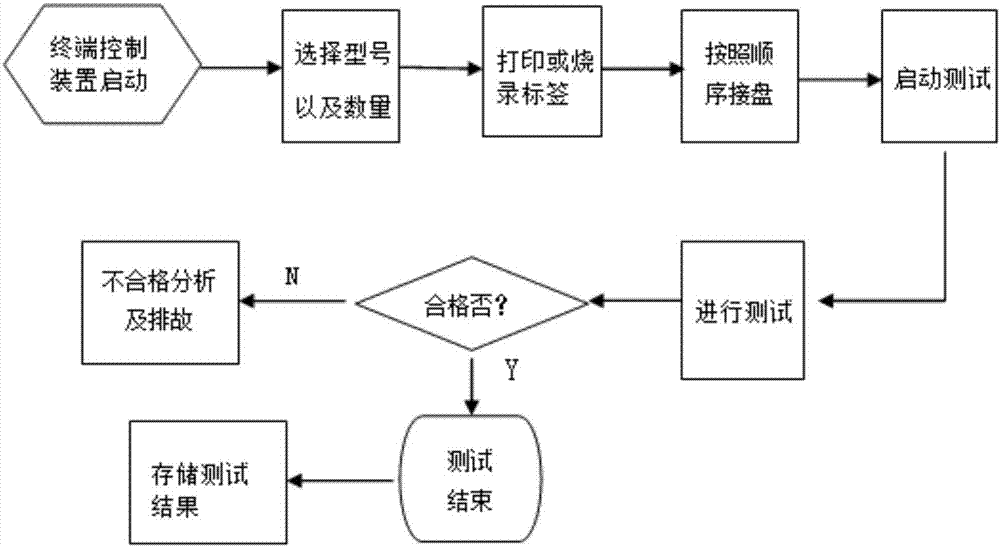

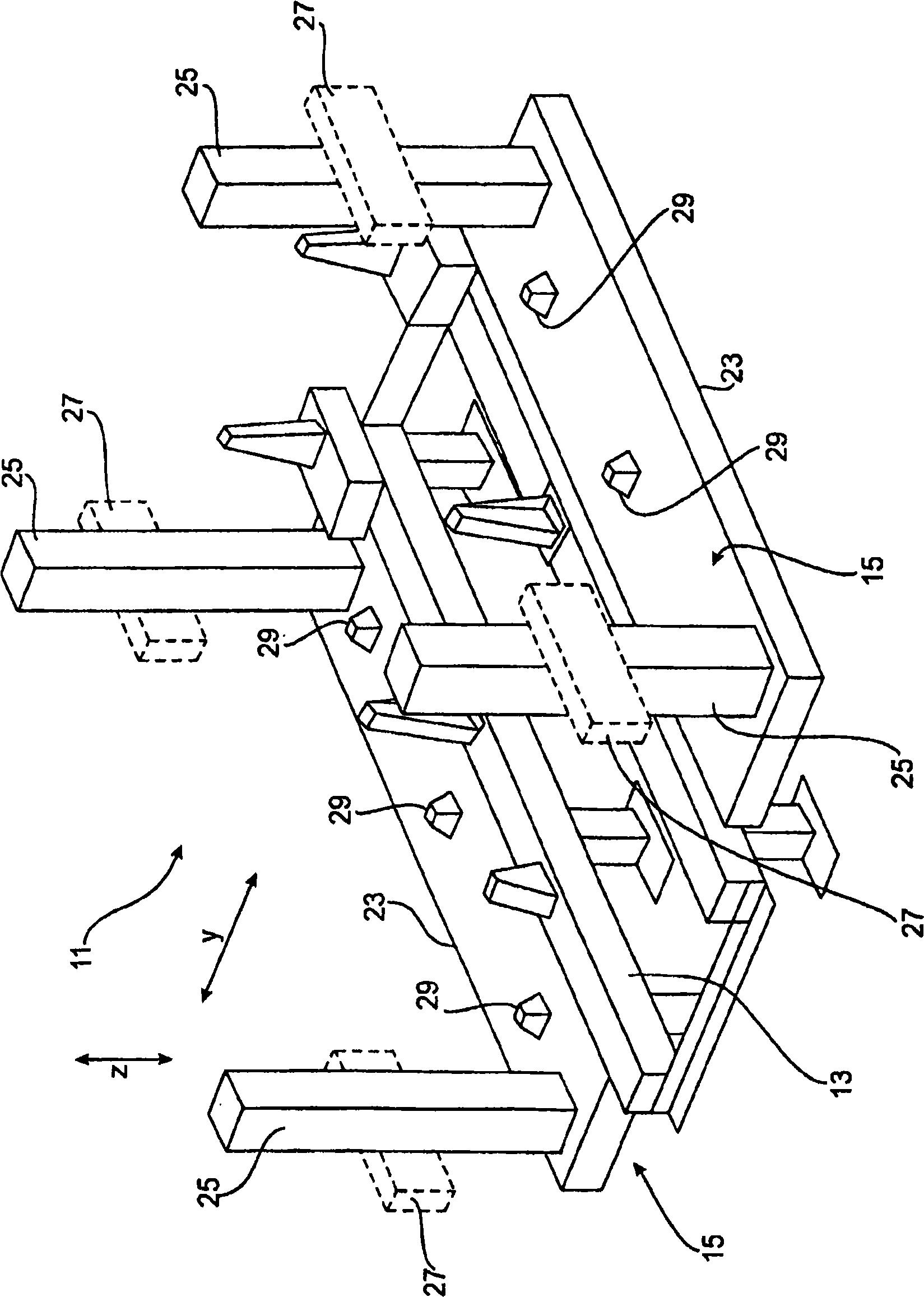

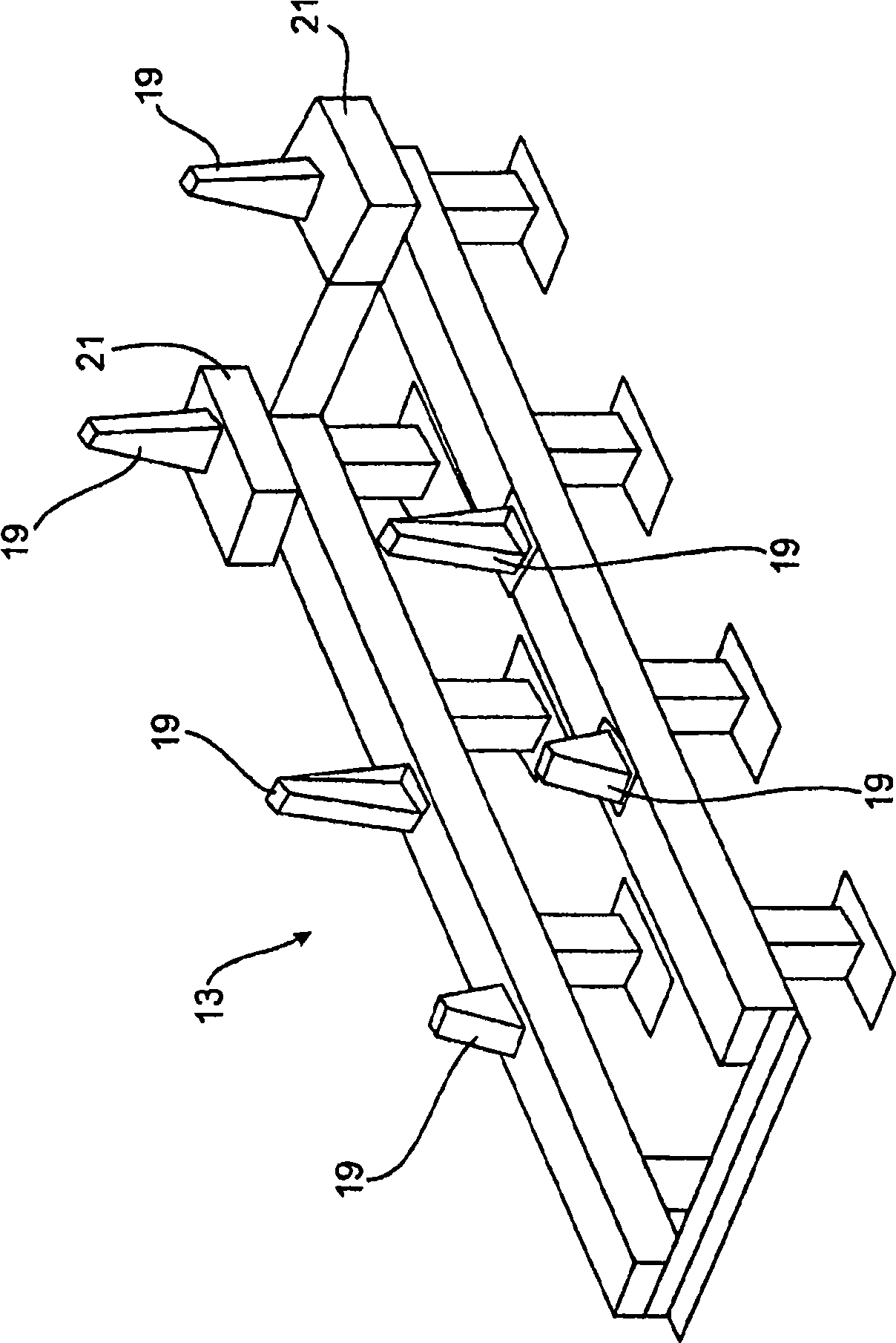

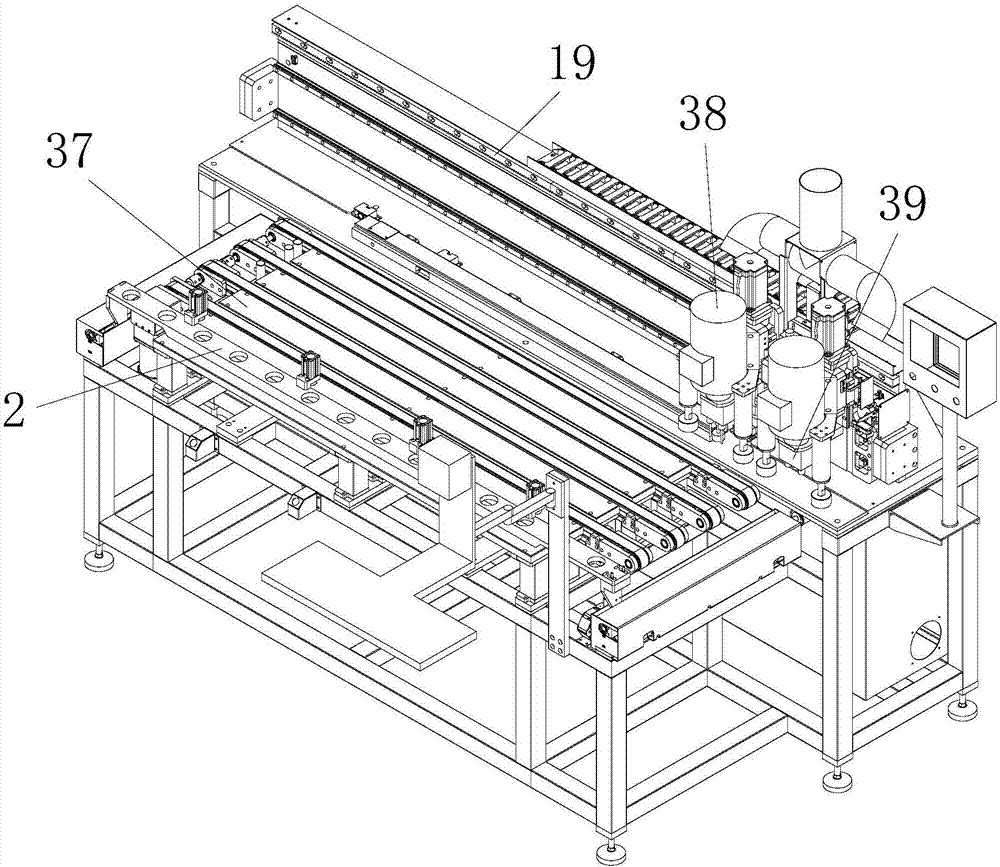

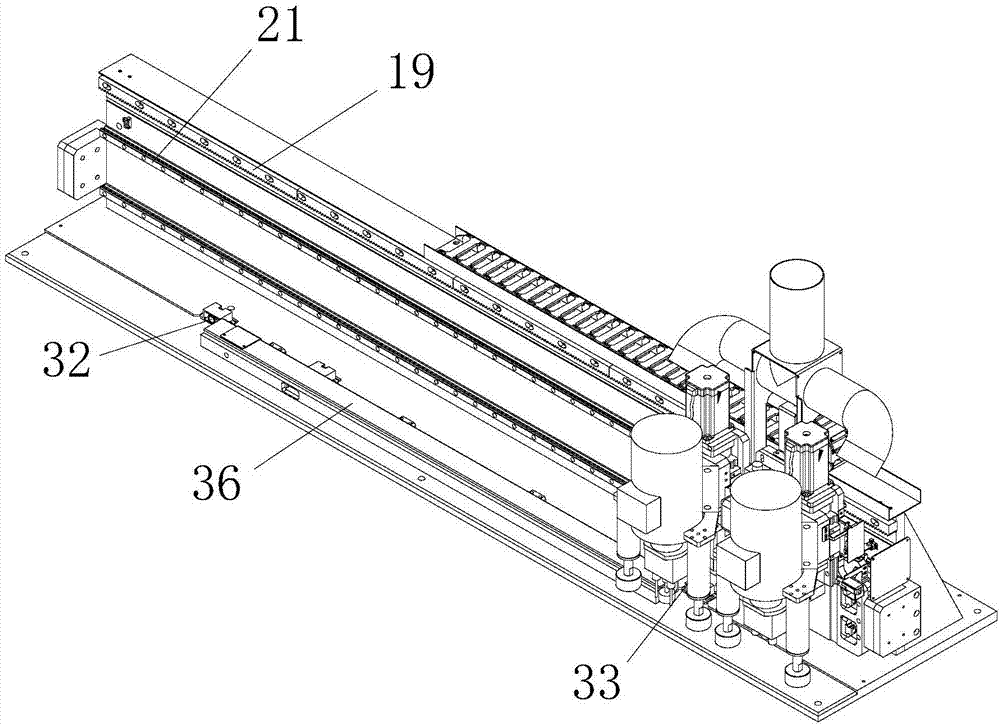

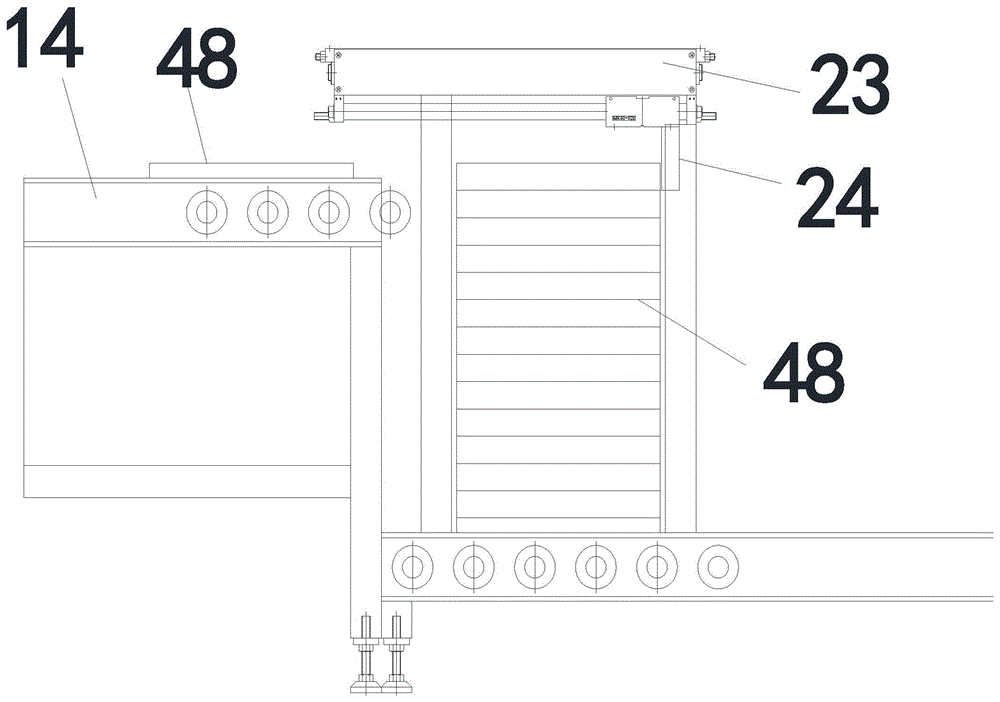

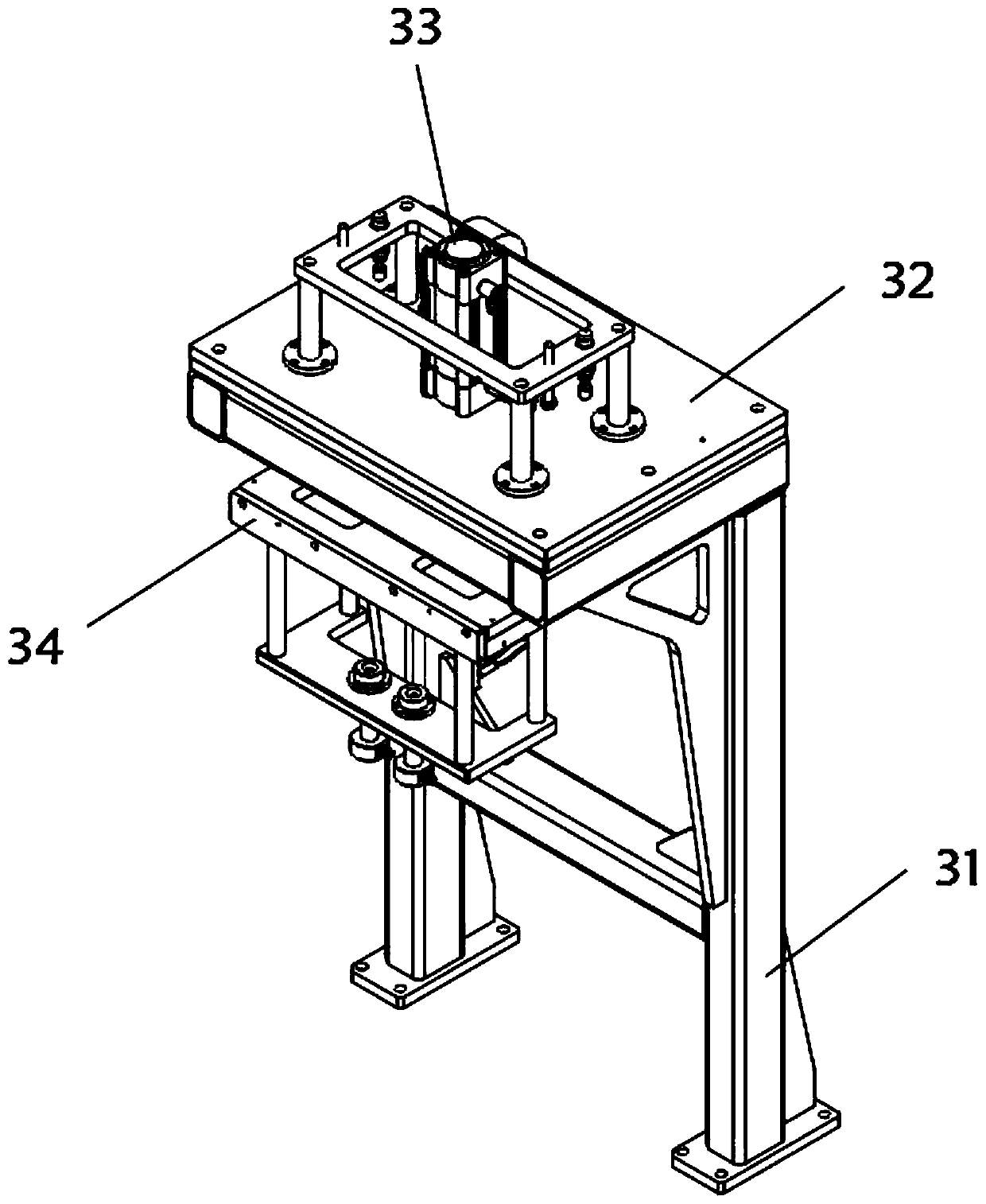

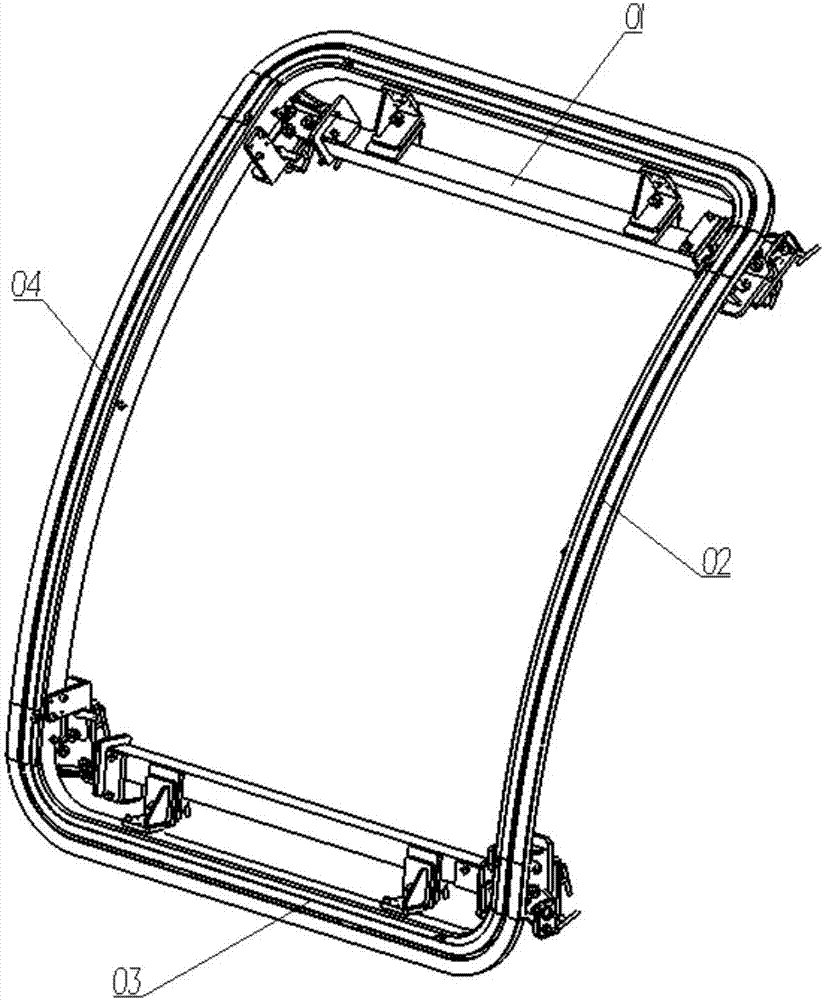

Work station for joining body parts of a motor vehicle, assembly line comprising such a work station, and method for delivering/replacing clamping frames in a work station

The invention relates to a work station of an assembly line for joining body parts (3, 9) of a motor vehicle, especially for joining at least one lateral part (9) to a body structure (3, 51). Said work station has a clamping frame storage area (39) used to provide clamping frames (A, B, C, D) and comprising at least one carriage (37) for moving at least one clamping frame (A, B, C, D) in the clamping frame storage area (39), and a lifting device (35) for moving the clamping frames (A, B, C, D) between the clamping frame storage area (39) and the work station (5). According to the invention, the carriage (37) and the lifting device (35) form a movably-coupled structural unit (47) containing the clamping frames (A, B, C, D).

Owner:AUDI AG

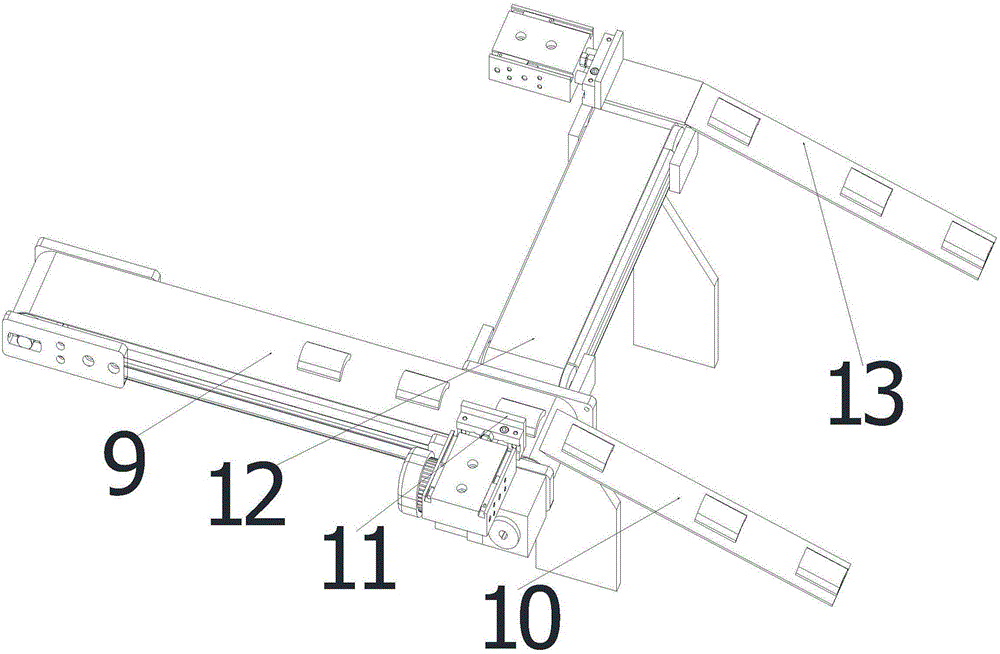

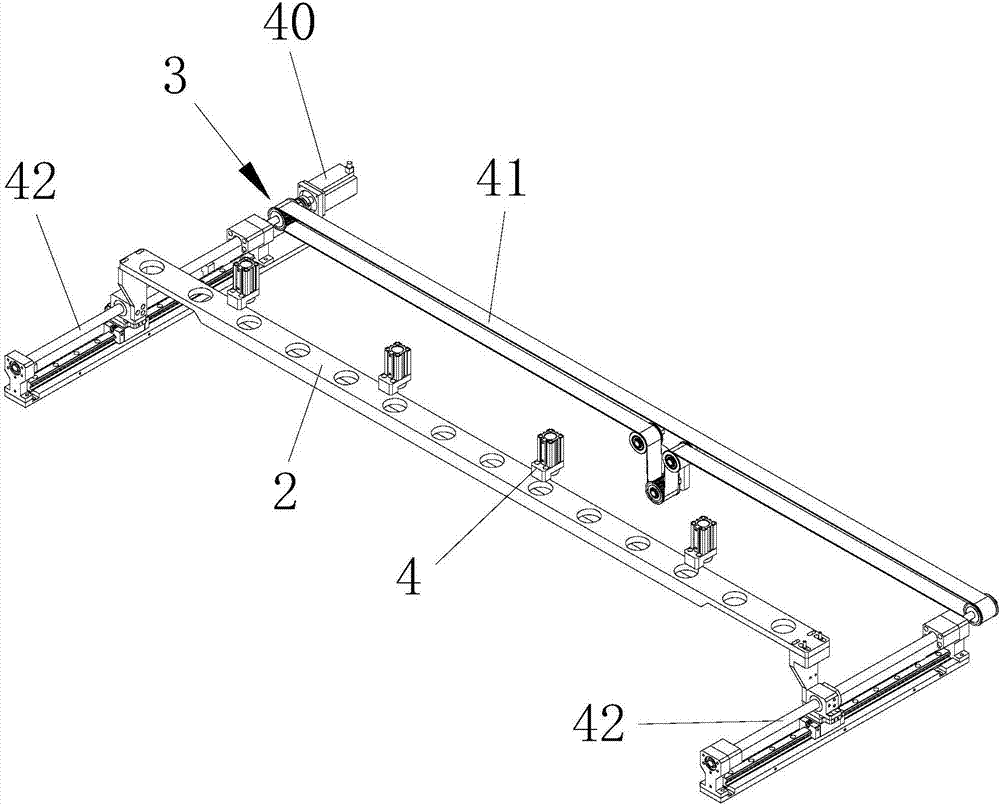

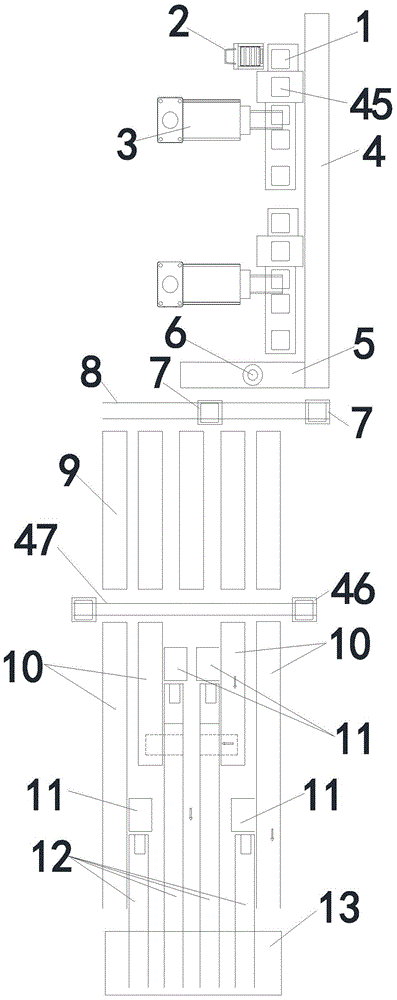

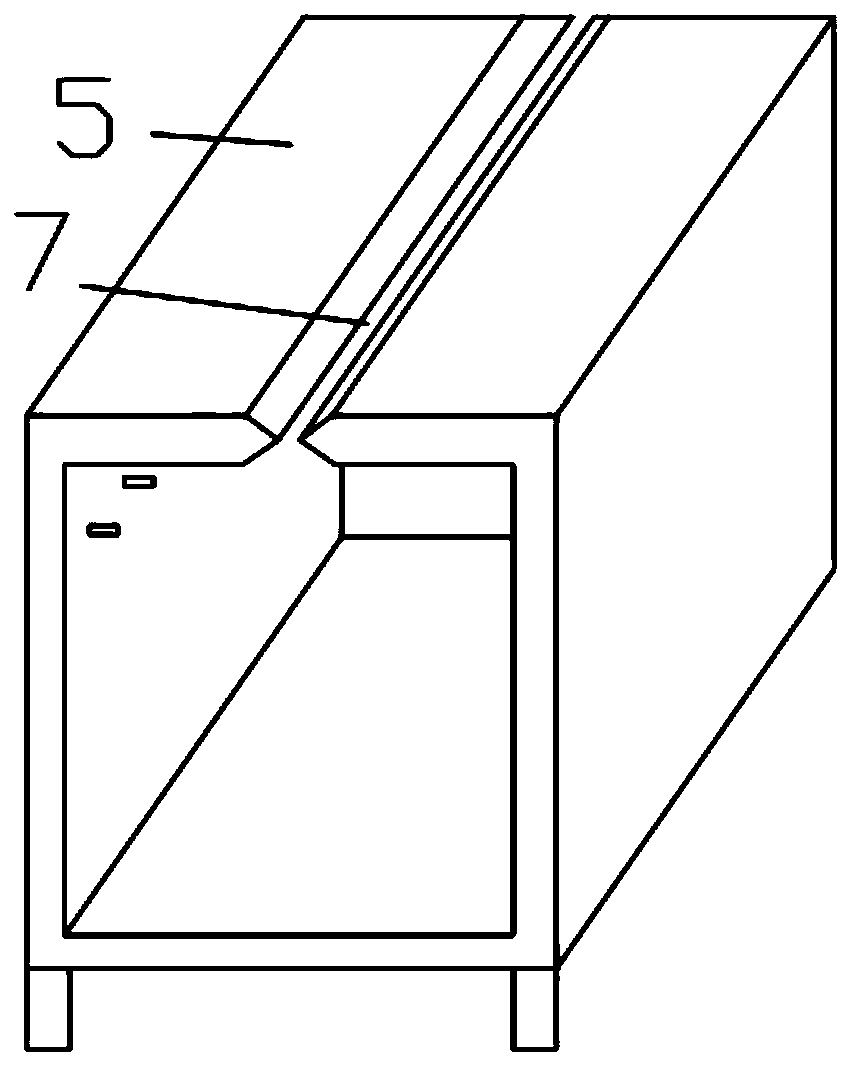

Numerical control equipment for machining plate-type custom furniture hinge hole

PendingCN107335835AImprove processing efficiencySolve production bottlenecksBoring/drilling machinesDrill holeManufacturing line

The invention discloses numerical control equipment for machining a plate-type custom furniture hinge hole. The numerical control equipment comprises a conveying device, a drilling mechanism, an X-direction moving mechanism, a Y-direction moving mechanism and a Z-direction moving mechanism; the Y-direction moving mechanism is installed on the X-direction moving mechanism, the Z-direction moving mechanism is installed on the Y-direction moving mechanism, and the drilling mechanism is installed on the Z-direction moving mechanism; the conveying device comprises a plate conveying mechanism, a plate pushing mechanism and a plate limiting mechanism, wherein the plate pushing mechanism is arranged on the plate conveying mechanism, the plate pushing mechanism comprises a pushing plate, a pushing plate driving mechanism and a plate pressing component, the pushing plate driving mechanism is connected with the pushing plate and is used for pushing a plate into the drilling mechanism, and the plate pressing component is installed on the pushing plate. The numerical control drilling is conducted on the plate-type custom furniture hinge hole, the production bottleneck problem caused by low hinge hole machining efficiency in automatic plate-type production line can be solved, and the requirement for large-scale production of a custom furniture order is met.

Owner:广州新居网家居科技有限公司

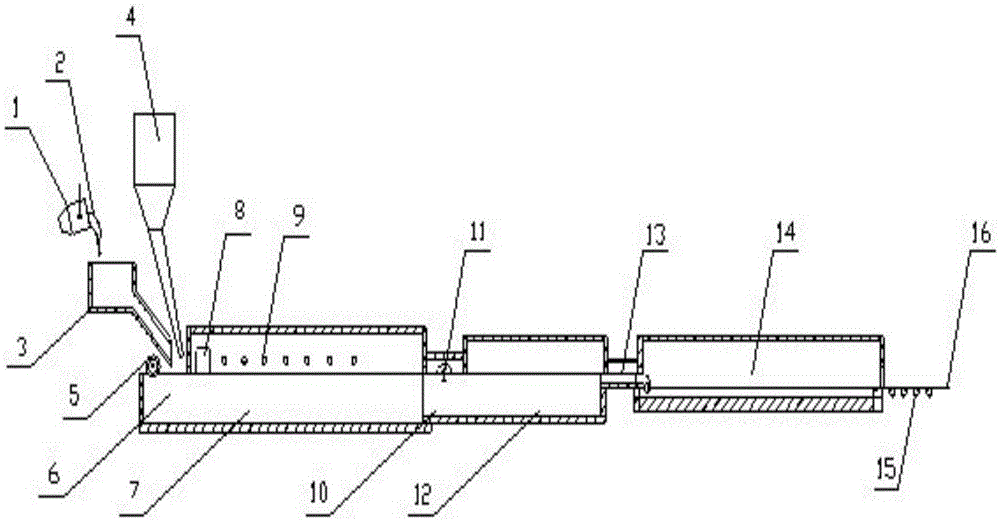

Method for directly preparing microcrystal glass through hot steel slag

The invention discloses a method for directly preparing microcrystal glass through hot steel slag. The method includes the steps that steel slag in the liquid state and auxiliary materials are mixed at a feeding opening and enter a melting portion of a glass melting furnace through a roller type feeding machine; heat is complemented through a total-oxygen burner, the melting temperature is kept at 1480-1560 DEG C, and the temperature is preserved for 10 hours; microwave homogenization is conducted on glass melt at the melting portion of the glass melting furnace; glass formation is conducted on the melted, clarified and homogenized glass melt; annealing is conducted through an annealing furnace, cooling is conducted till the temperature is 10-15 DEG C below the Tg temperature of the glass, and a glass panel is obtained; the cooled glass panel is directly subjected to temperature raising, coring and crystallization heat treatment in a roller kiln, cutting is conducted after the glass panel is cooled, and the microcrystal glass can be obtained. According to the method, the microcrystal glass is directly prepared through hot steel slag, the heat energy brought by high temperature of the liquid steel slag is fully utilized, in production, only the heat energy for heating additional raw materials to be melted is needed, and thus energy consumption is greatly lowered.

Owner:WUHAN UNIV OF TECH

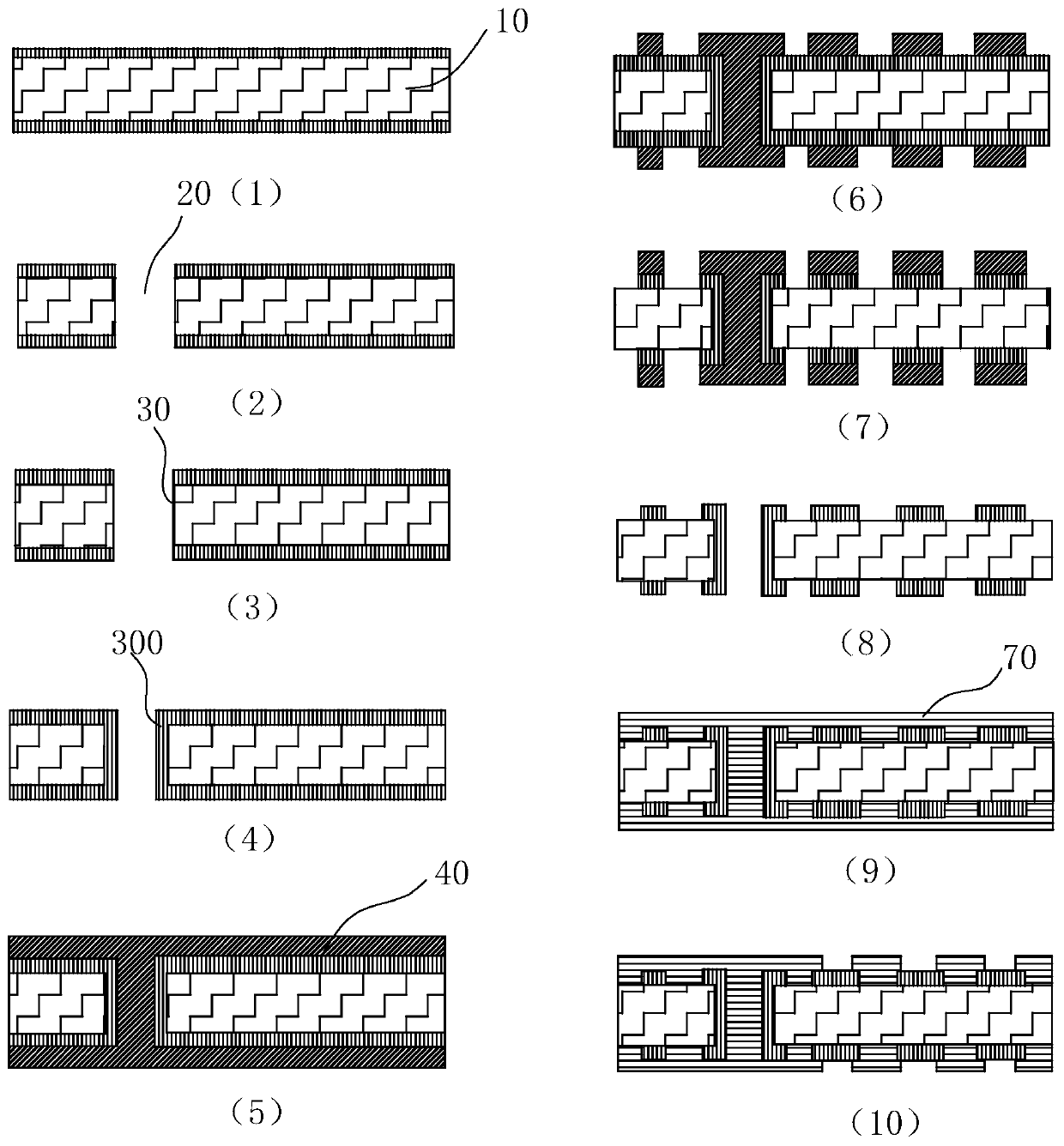

Manufacturing method of circuit board taking boss as bonding pad

ActiveCN110536564AHigh modulusHigh glass transition pointPrinted circuit aspectsElectrical connection printed elementsEngineeringElectroplating

The invention discloses a manufacturing method of a circuit board taking a boss as a bonding pad. The manufacturing method comprises the following steps of cutting and reducing copper; drilling a hole; carrying out copper deposition; pressing a film; exposing and developing; carrying out circuit electroplating; pressing the film; exposing and developing; electroplating the bonding pad; demouldingand removing copper; laminating an insulating layer; and grinding: grinding a surface of the insulating layer till that the bonding pad is exposed, and forming a top layer / bottom layer bonding pad through windowing. A thermosetting insulating material is adopted, cost is low, silk-screen is not needed, green and environmental protection performance is achieved, and simultaneously, a manufacturingprocess is simple, operation is easy, the bonding pad is directly manufactured through grinding, the bonding pad with a small area and a large density can be conveniently manufactured, a manufacturedcircuit board is smooth in surface, precise packaging is facilitated, circuit attachment is firm, and quality is good.

Owner:NINGBO HUAYUAN ELECTRONICS TECH

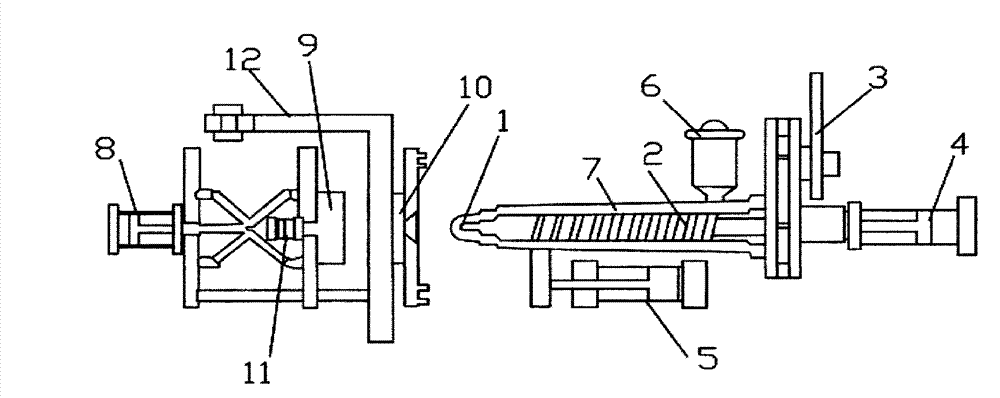

Automatic plastic molding machine

InactiveCN103085225AHigh dimensional accuracyGood dimensional stabilityControl systemPower control system

The invention discloses an automatic plastic molding machine, and belongs to the field of plastic processing. The automatic plastic molding machine consists of an injection device, a mold clamping device, a hydraulic system and a control system, wherein the injection device consists of a plasticizing component, a hopper, a charging barrel, a screw rod, a metering device, an injection cylinder and an injection base moving cylinder; the mold clamping device consists of a template, a draw bar, a mold clamping cylinder and an ejection cylinder; and the control system comprises a power control system, an action control system and a heating control system. By realizing the production process combined with a technology of the power control system, the action control system and the heating control system, the automatic plastic molding machine disclosed by the invention has the advantages of being capable of improving the product quality, appropriately reducing the operation technical level, improving the labor productivity, decreasing the number of substandard products, improving the size precision and the stability of products, improving the automating production process and saving the labor.

Owner:南宁燎旺车灯股份有限公司

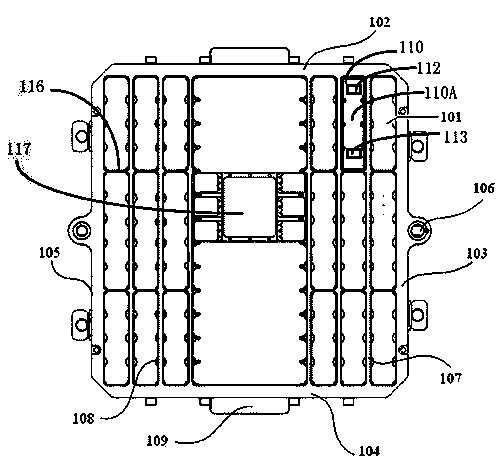

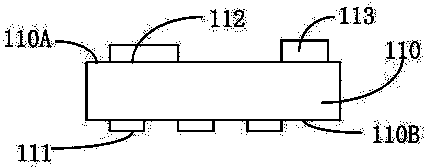

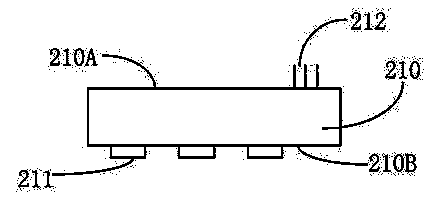

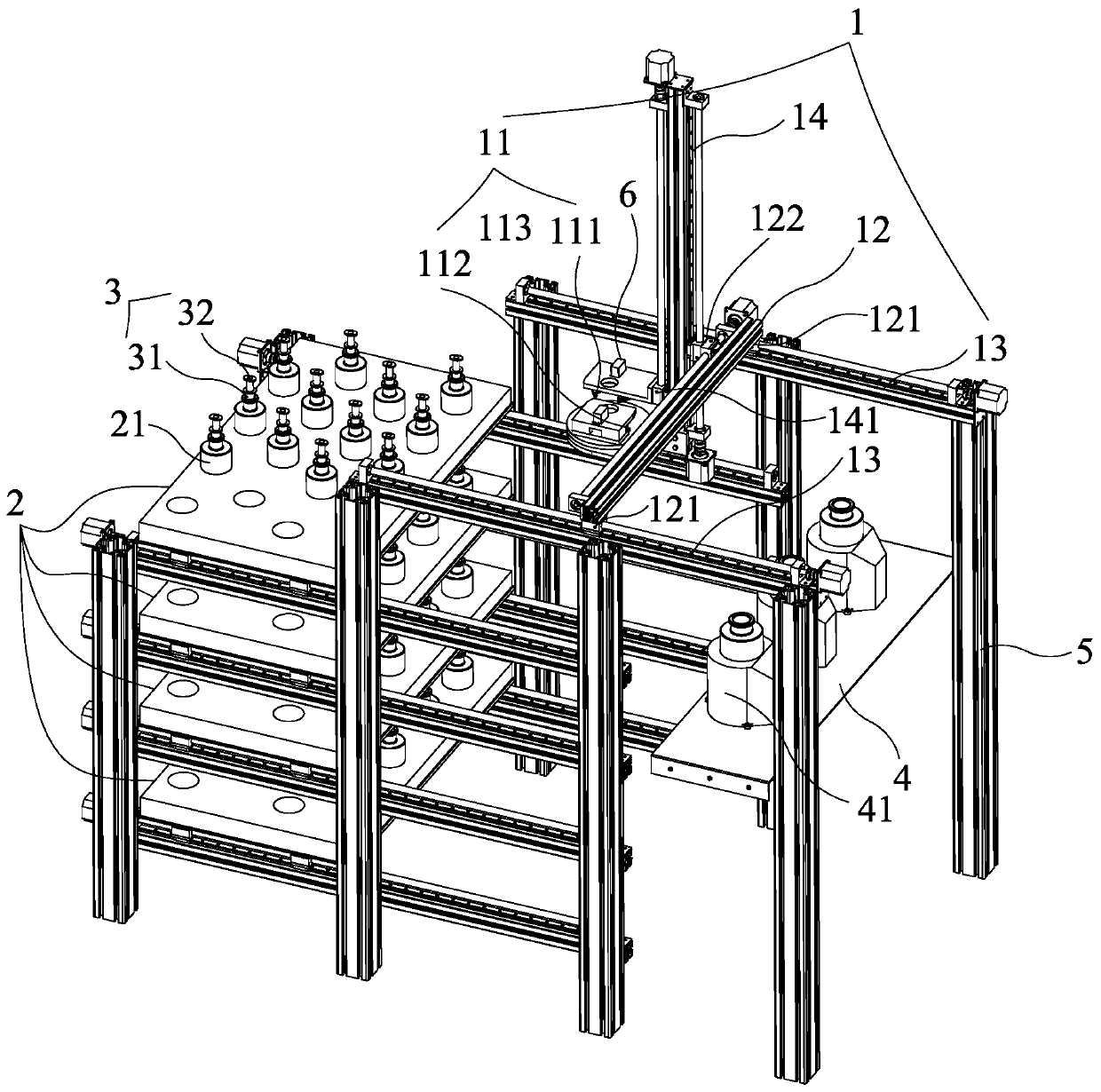

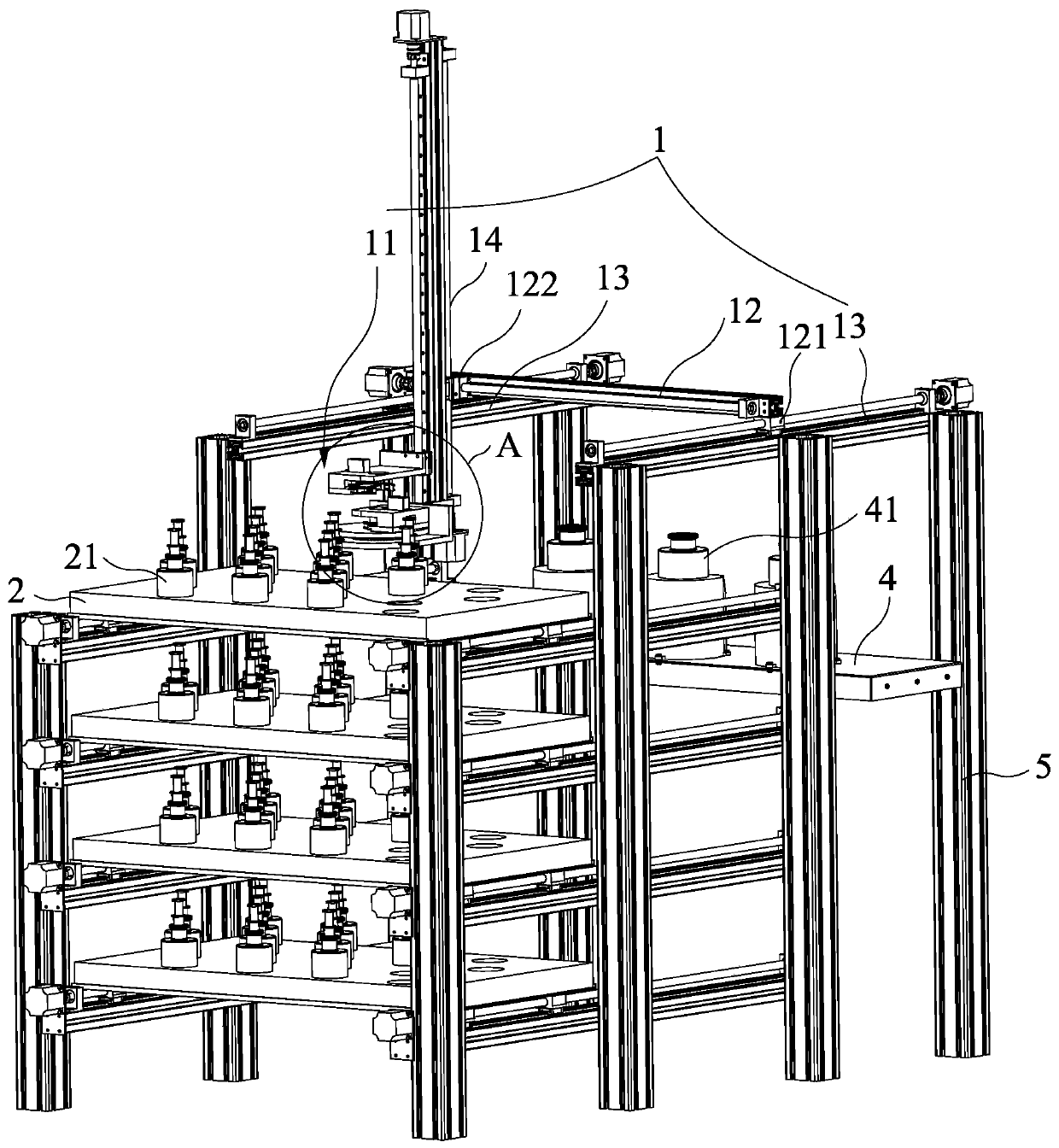

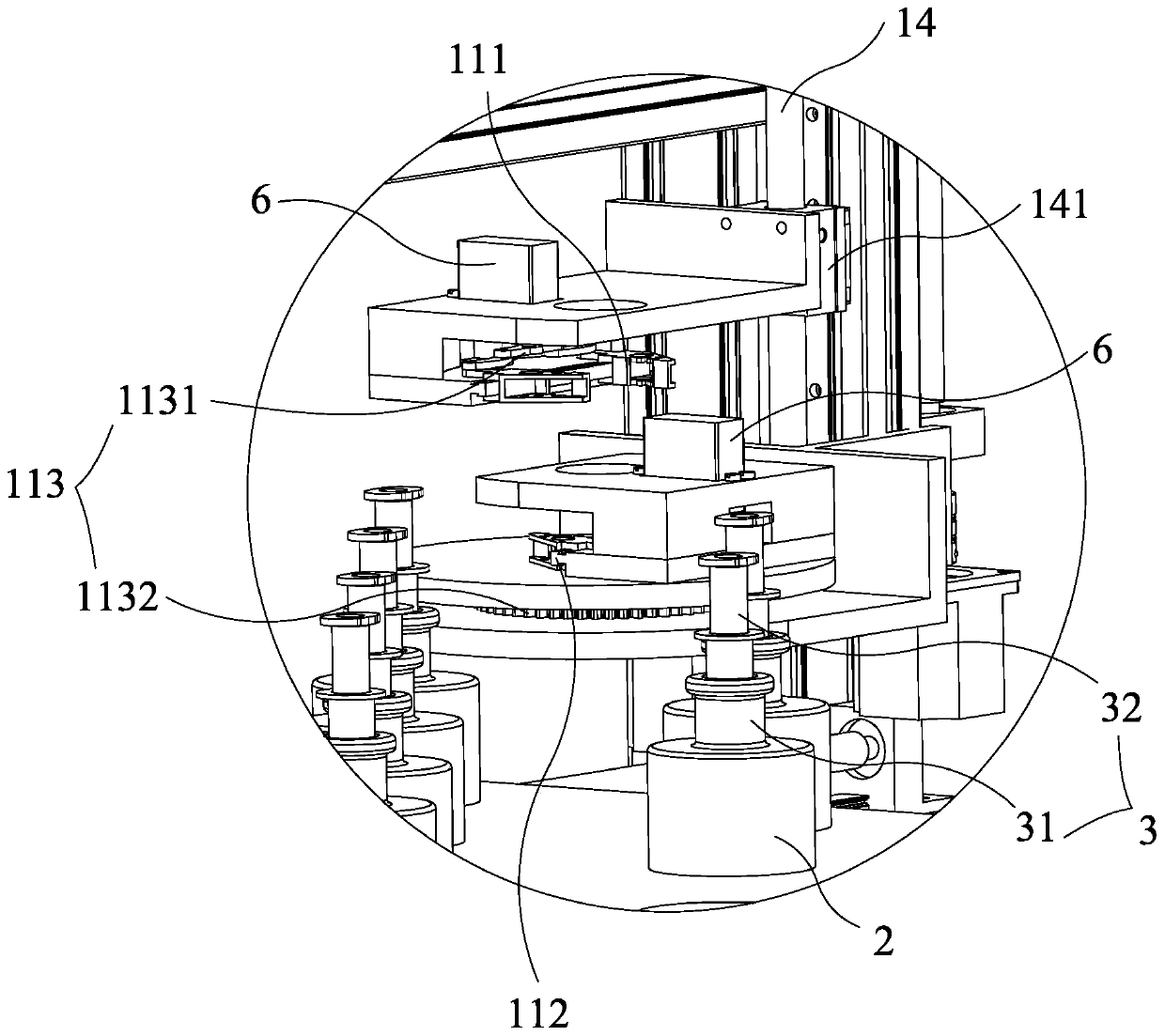

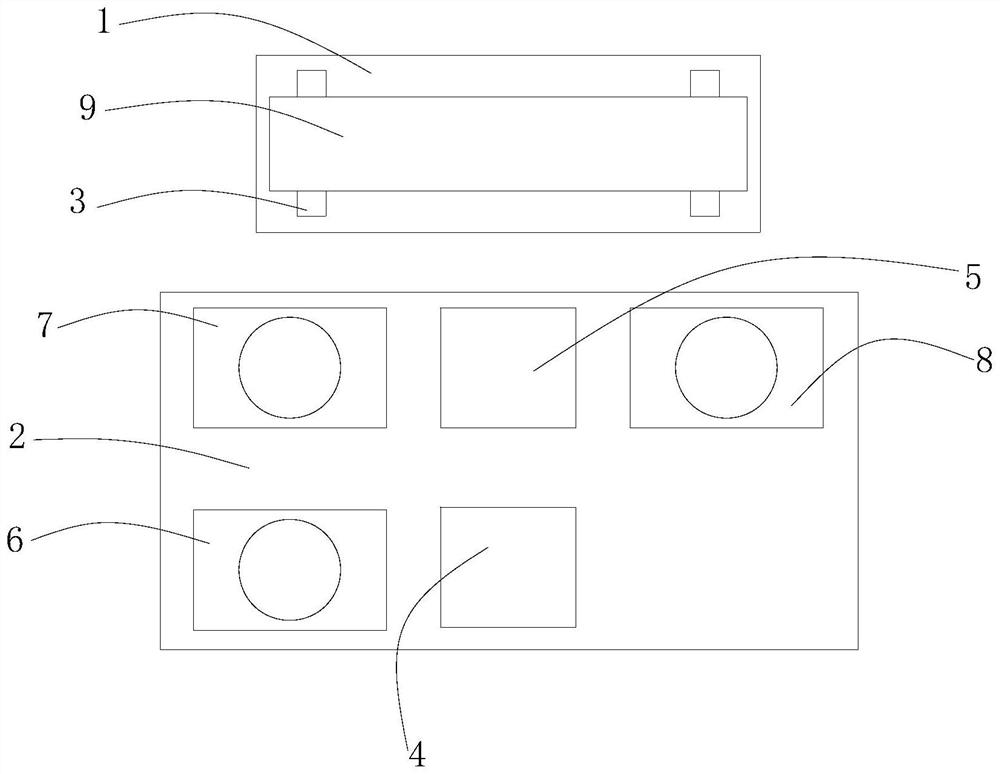

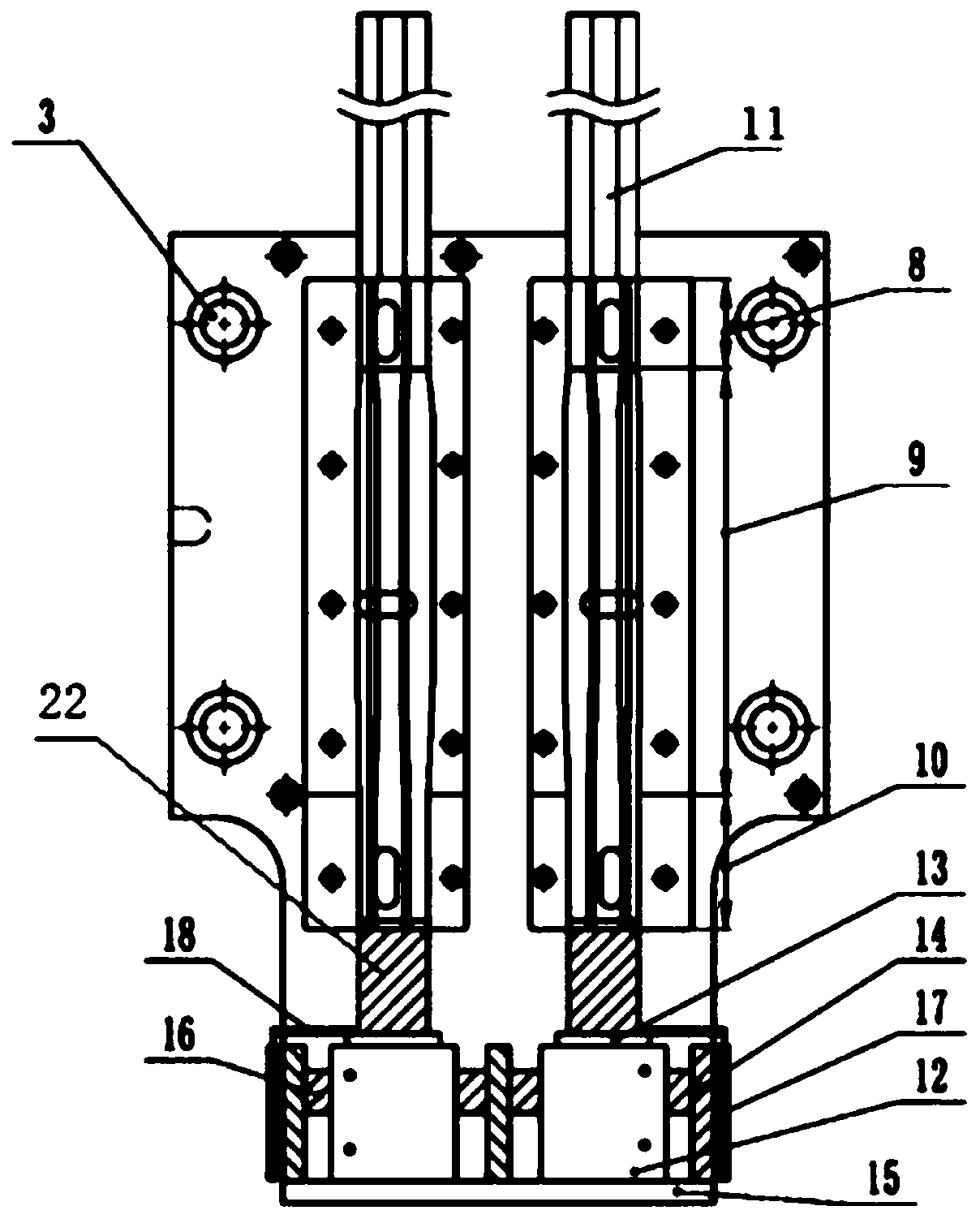

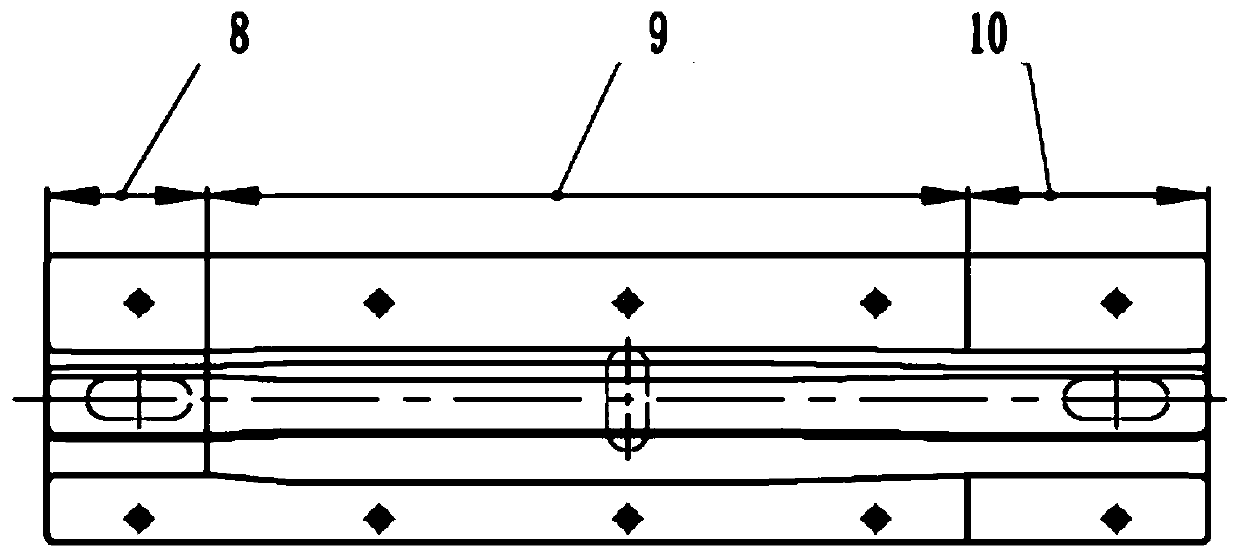

Chip test board and chip test system

ActiveCN104316731AReduce production areaEasy to disassembleElectronic circuit testingElectrical measurement instrument detailsEmbedded systemTest board

The invention provides a chip test board and a chip test system. The chip test board comprises a fixing frame formed by sequentially and vertically connecting a first cross rod, a second cross rod, a third cross rod and a fourth cross rod, and at least one PCB detachably connected with the fixing frame, wherein the PCB can be selectively arranged in the fixing frame. At least one PCB is detachably connected to the fixing frame, corresponding sizes of PCBs are designed according to the test demands of different devices, different quantities of PCBs can be further selected according to the actual demand, a plurality of PCBs are combined in use to share test resources and achieve resource reuse, the manufacturing area of the single PCB is decreased, cost is reduced, and the PCB is selectively arranged in the fixing frame, so that resources on a testing machine are reasonably utilized. The PCB and the fixing frame are simple to mount and dismount and convenient to operate.

Owner:SINO IC TECH

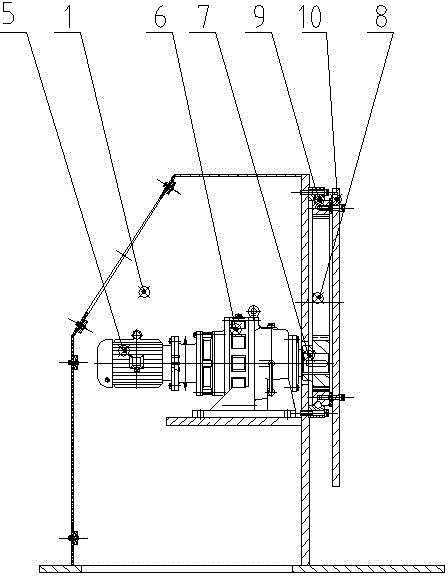

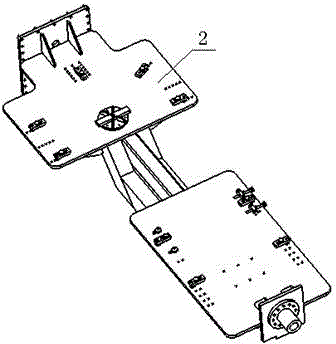

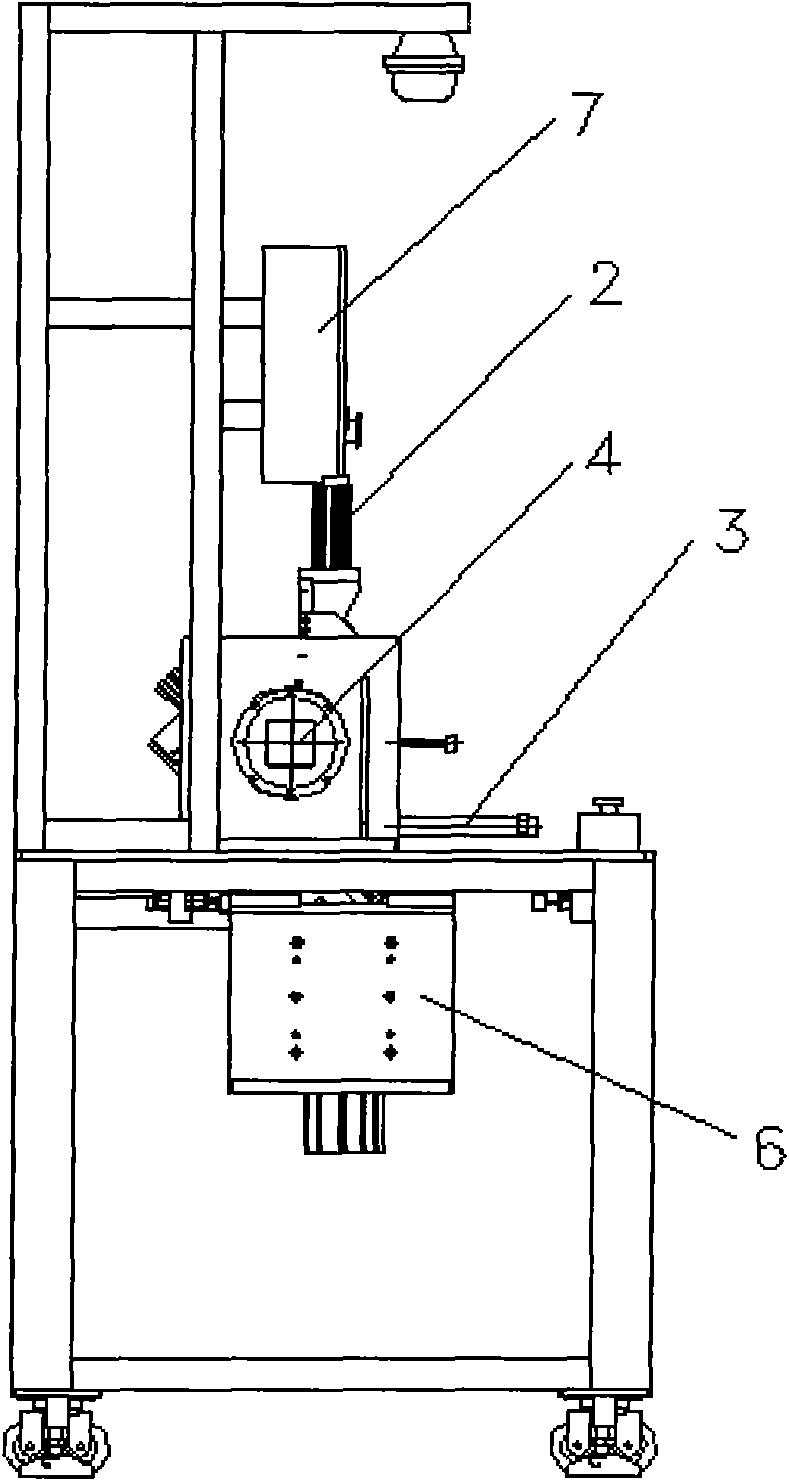

Practical positioner

InactiveCN103600195AEasy accessReduce welding distortionWelding/cutting auxillary devicesWork holdersReducerEngineering

The invention discloses a practical positioner comprising a rotary system, a overturning frame and a driven seat. One end of the overturning frame is connected to the rotary system, and the other end is connected to the driven seat. The rotary system is fixed on an main overturning seat. The rotary system comprises a motor, a reducer and a rotary support. One end of the reducer is connected to the motor, and the other end is connected to the rotary support connected to the overturning frame. The rotary support comprises a rotary support inner gear ring and a rotary support outer gear ring. The rotary support outer gear ring is connected to the overturning frame, and the rotary support inner gear ring is connected to the main overturning seat through a connecting disc and is engaged with the rotary support outer gear ring. A positioning clamping device is mounted on the overturning frame. The practical positioner is simple in structure and safe to operate, can meet positioning requirements of varieties of excavator rotary platforms, has better generality, can overturn more stably, can overturn and position a workpiece in 360 degrees, is operated with a limit clamping device, meets positioning and clamping requirements of the excavator rotary platforms, and meets the welding requirements of the rotary platforms.

Owner:SHANDONG LISHIDE MACHINERY

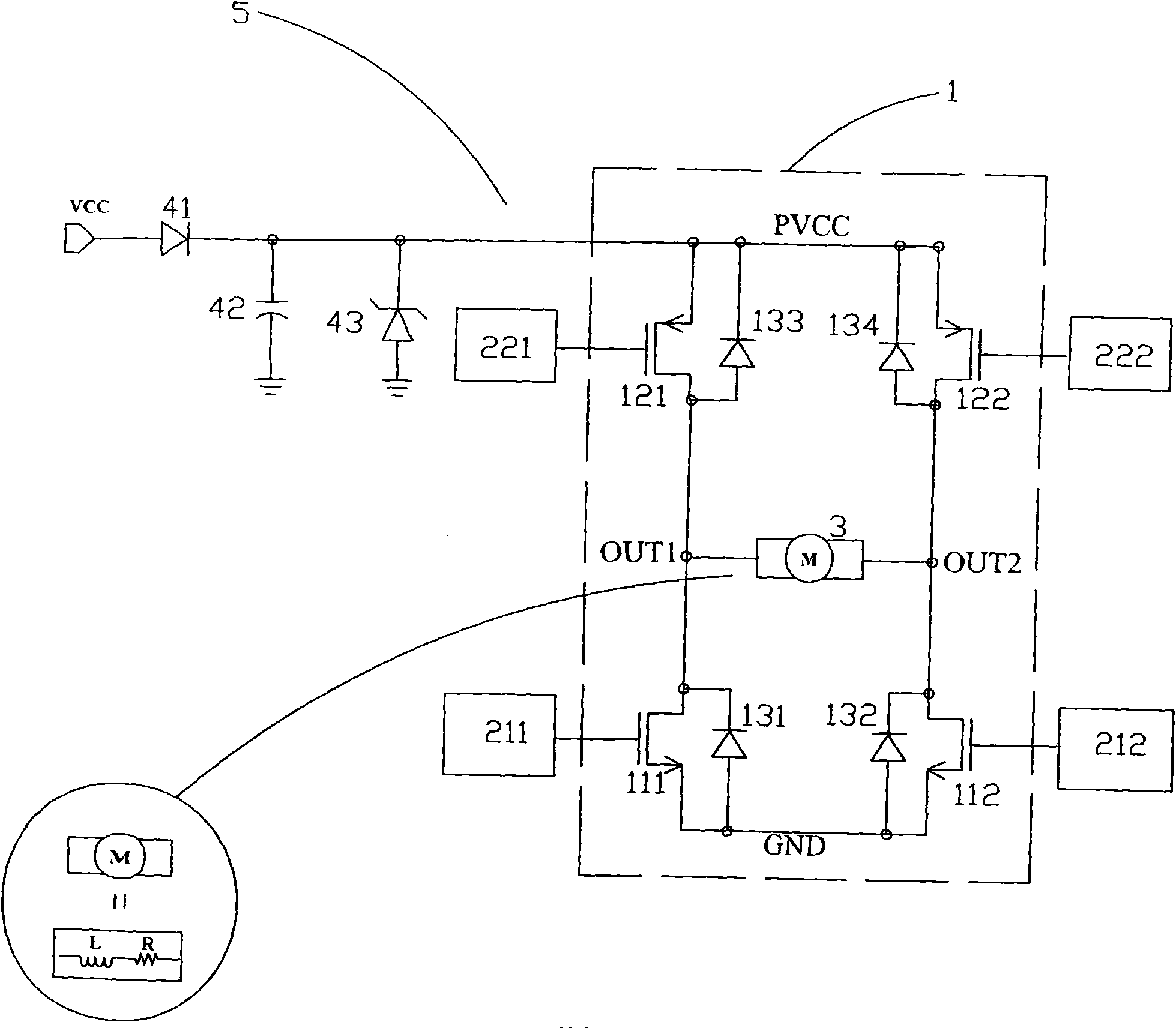

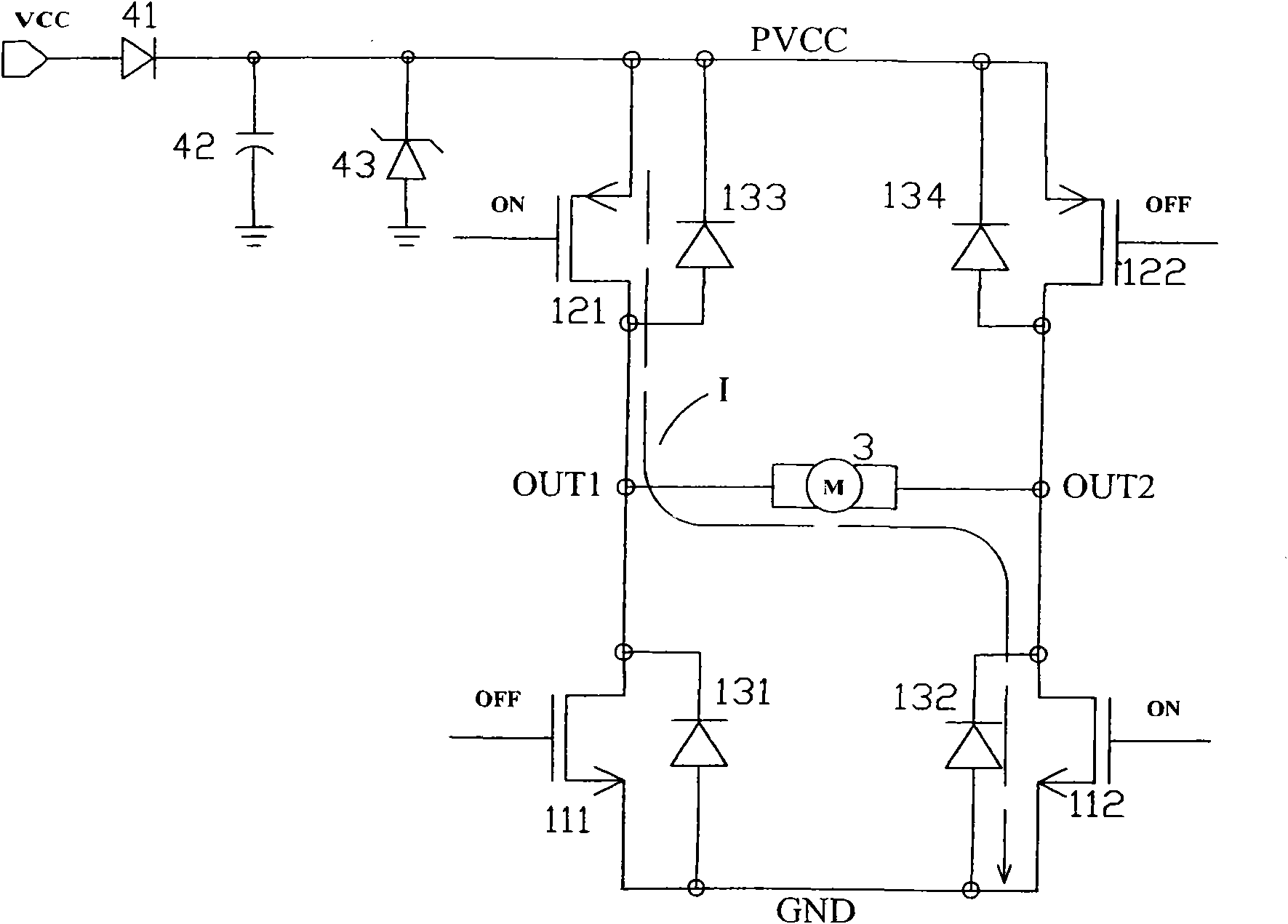

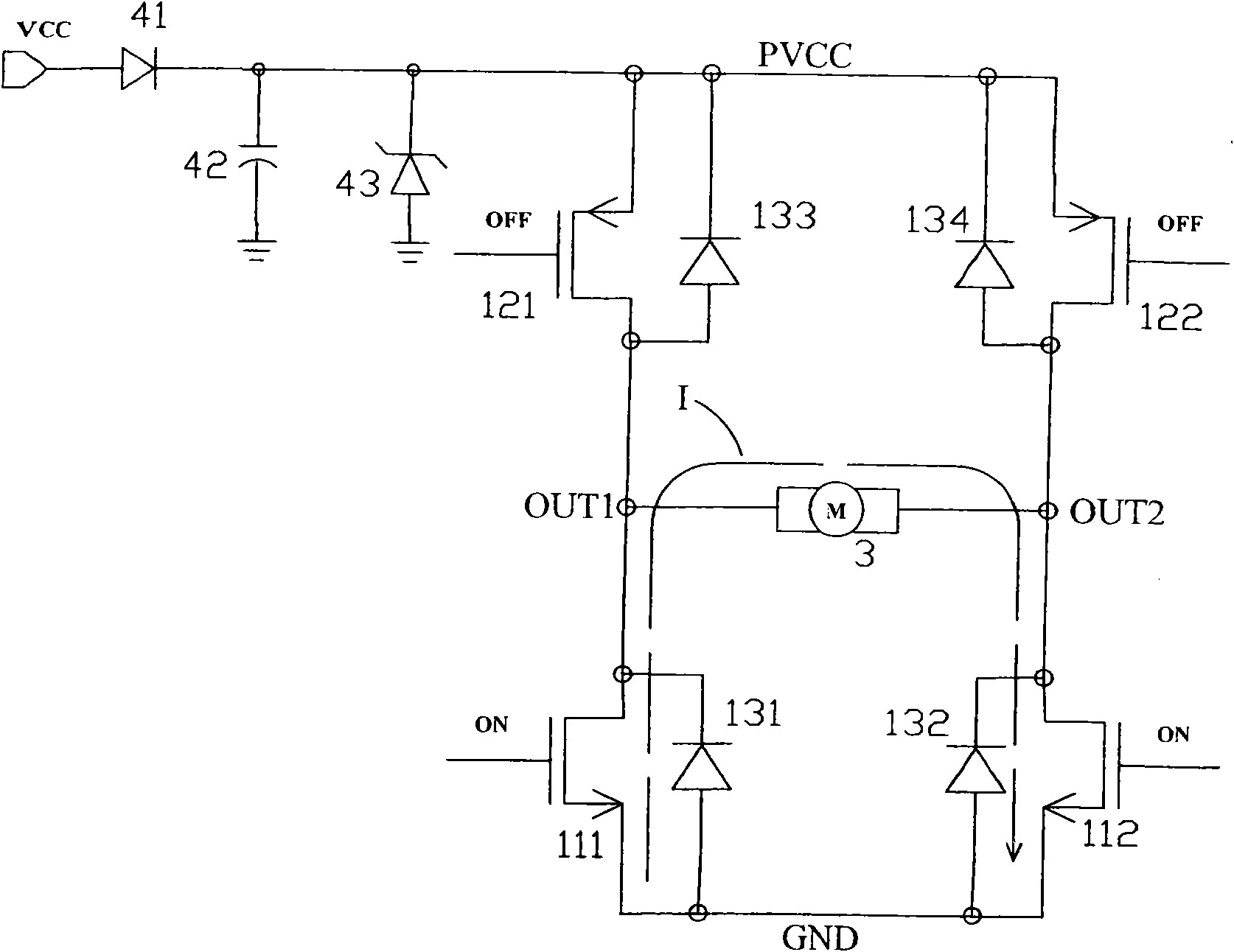

Kickback voltage suppression circuit

InactiveCN101515714AIncrease response speedReduce usageEmergency protective arrangements for limiting excess voltage/currentControl signalComparator

The invention provides a kickback voltage suppression circuit, which comprises an output stage driving power transistor serving as a current path, high-speed comparators for detecting a kickback voltage and a plurality of logic circuits. To reduce the area of the kickback voltage suppression circuit, the output stage driving power transistor serving as a current path can be realized by using an H-bridge power transistor group. When the difference of the output voltage of the H-bridge power transistor group and the voltage of a power supply end reaches a preset value, the output voltages of the compactors reverse to allow the related logic circuit to generate control signals to open or close the correspondingly connected power transistors. Thus, the current in an inductive load flows in a constant direction and is gradually used out.

Owner:EUTECH MICROELECTRONICS

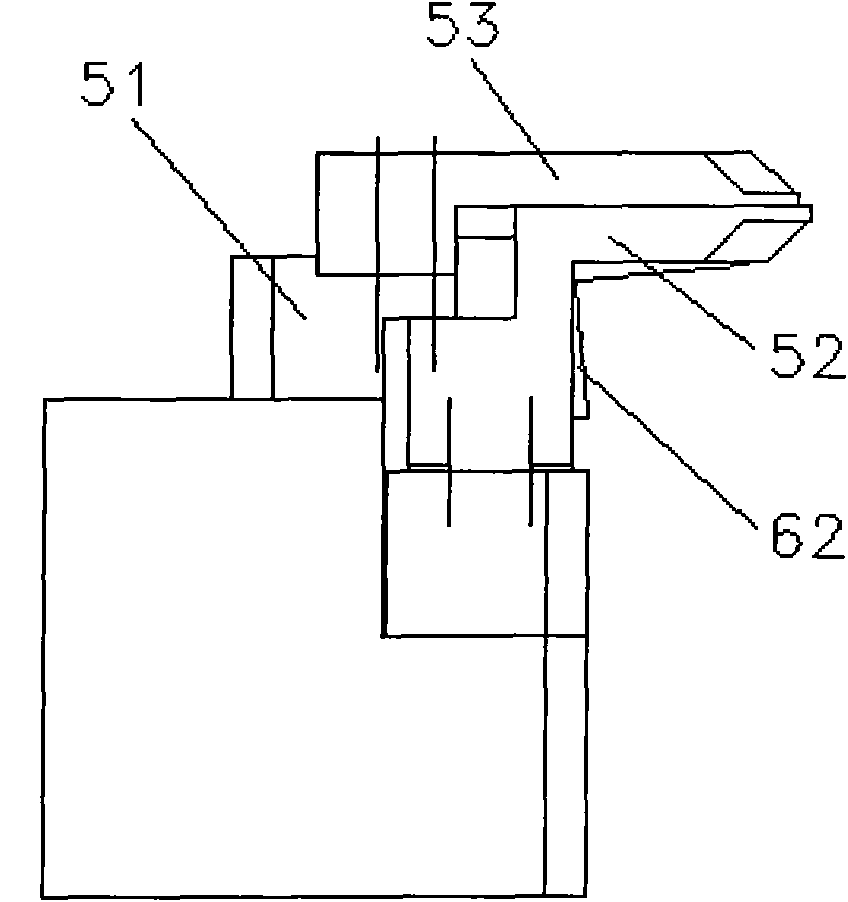

Automatic shearing system, automatic shearing method and automatic production line for steel grid plate as well as manufacturing method

PendingCN110142448AImprove shear efficiencyImprove quality and efficiencyMetal-working feeding devicesShearing machinesProduction lineHydraulic cylinder

The invention discloses an automatic shearing system, an automatic shearing method and an automatic production line for a steel grid plate as well as a manufacturing method. The automatic shearing system comprises a pedestal, wherein a feeding mechanism and a shearing device are mounted on the pedestal; the shearing device comprises a shearing mechanism; the shearing mechanism comprises a mountingplate; an upper shearing head and a lower shearing head which are symmetrical mutually are fixedly mounted on the mounting plate; slot holes are symmetrically formed in the upper shearing head and the lower shearing head; a fixed blade and a movable blade are mounted in the slot holes of the upper shearing head to form shearing angles; the upper shearing head is movably mounted on the mounting plate, and is driven by a Z-direction transmission mechanism to move on the mounting plate; and the shearing mechanism further comprises a power mechanism for pushing the movable blade to move. The automatic shearing system meets shearing requirements of steel grid plates of different models by changing telescopic distance of piston rods of hydraulic cylinders, greatly improves production efficiency, greatly increases a material utilization rate of the steel grid plate, and effectively improves production environment.

Owner:冯艳

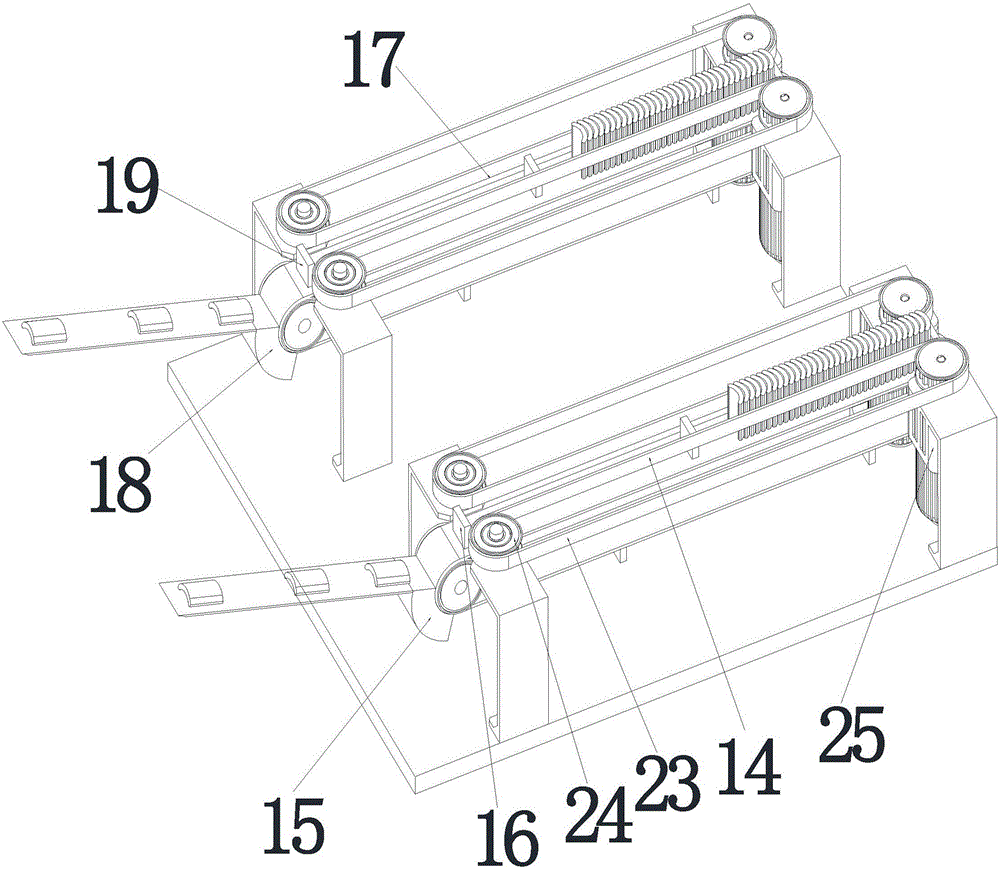

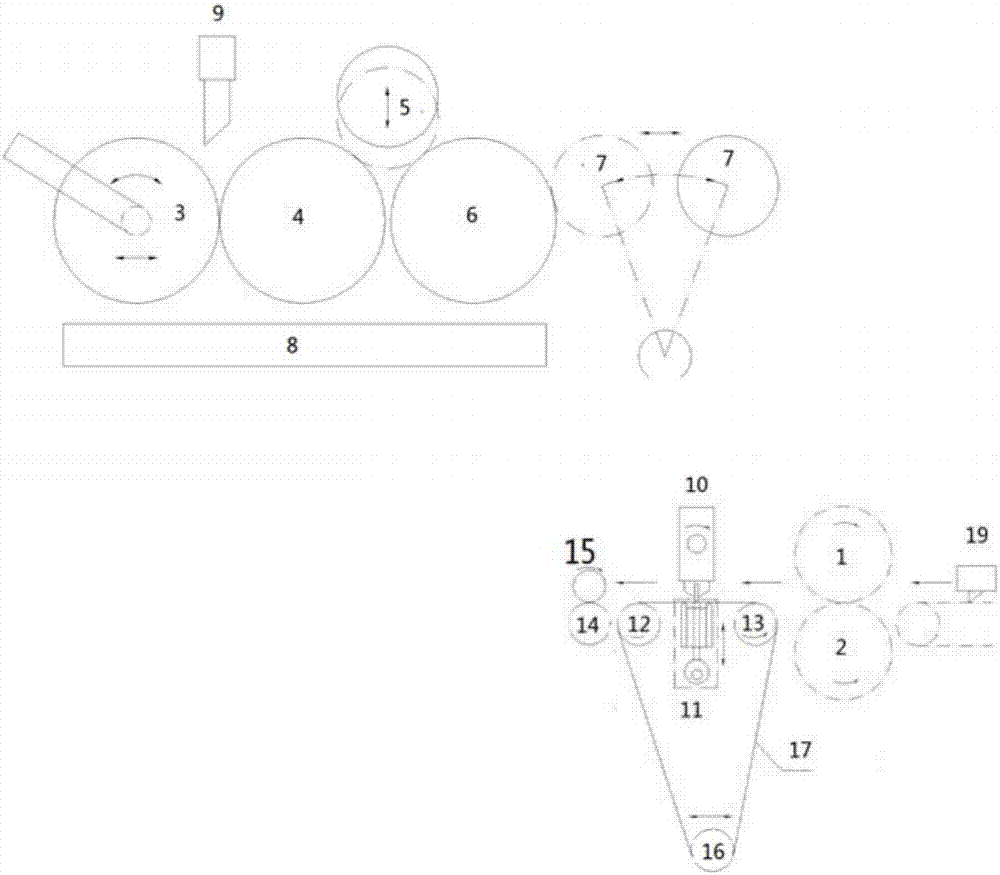

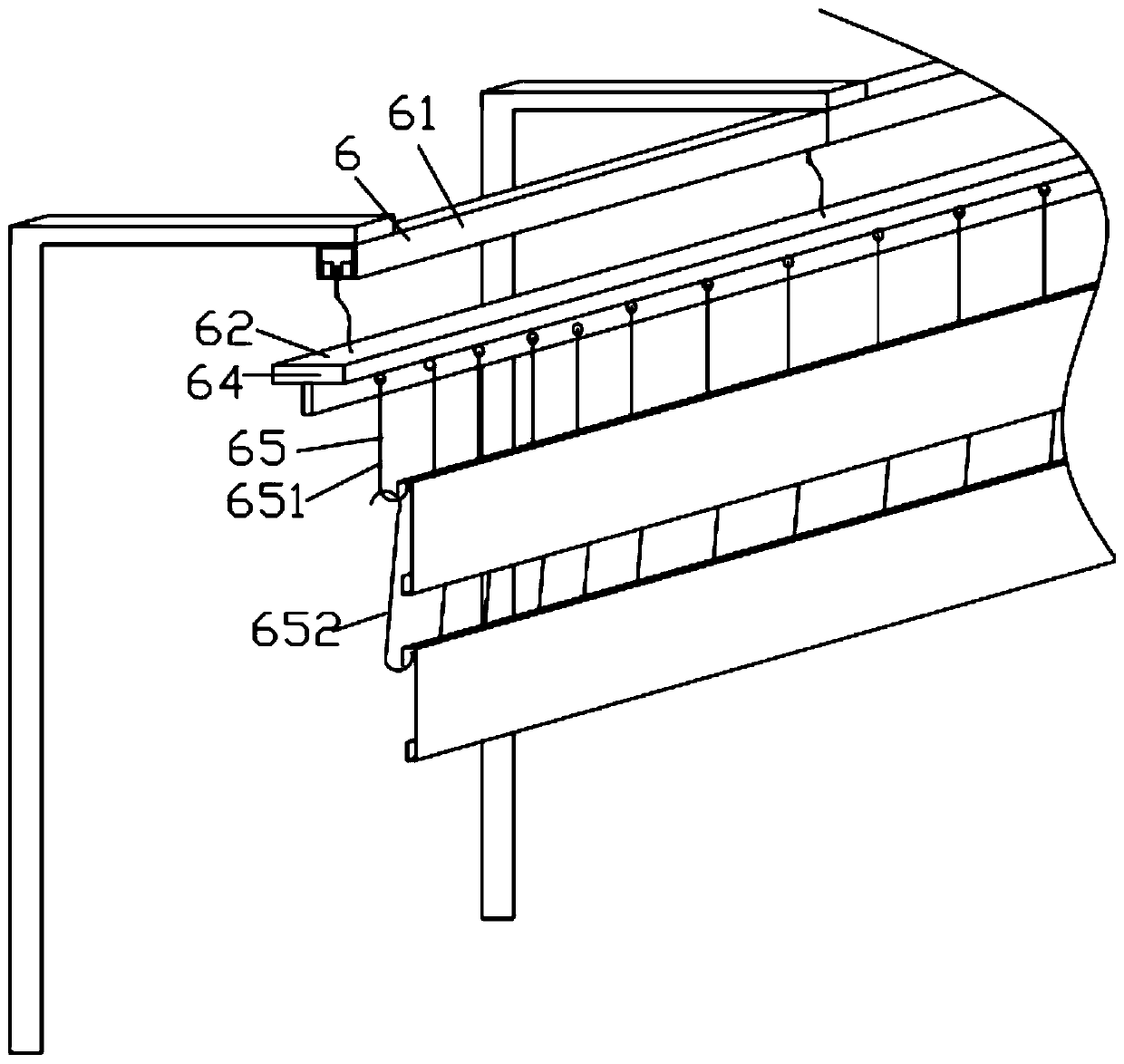

Film coating heat knife slitting device

ActiveCN107128067AOccupies a small production areaReduce production areaRotary pressesPrinting press partsCoating systemEngineering

The invention provides a film coating heat knife slitting device. The device comprises a bonding system consisting of a bonding steel roller and a bonding rubber roller, a coating system consisting of a metering steel roller, a glue transfer steel roller, a glue transfer rubber roller, a coating metering steel roller, a coating glue pressing roller, a glue basin and a glue spraying system, and a heat knife slitting system consisting of a rotating heat knife, an adjusting part, a first transmission roller, a second transmission roller, a stripping roller, a pressing wheel set, a tension roller, a transmission net belt, a machine wall plate and a laser sensor; the coating system is positioned above the heat knife slitting system; and the bonding system and the heat knife slitting system are adjacently and horizontally arranged. The device is small in occupied production area and high in production efficiency, can increase the product pass percent, and prevents manual damage of printed products.

Owner:盐城东科机械科技有限公司

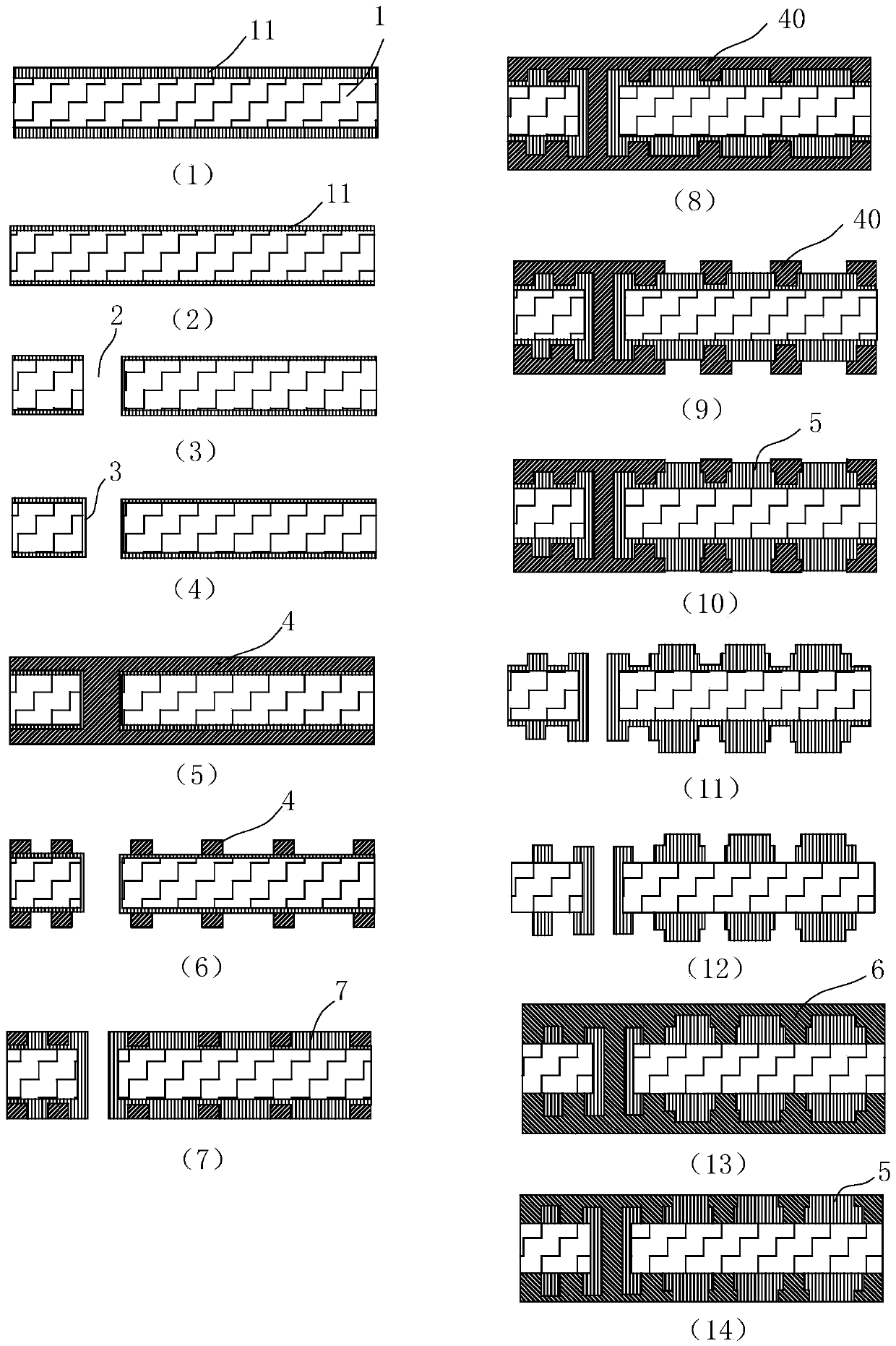

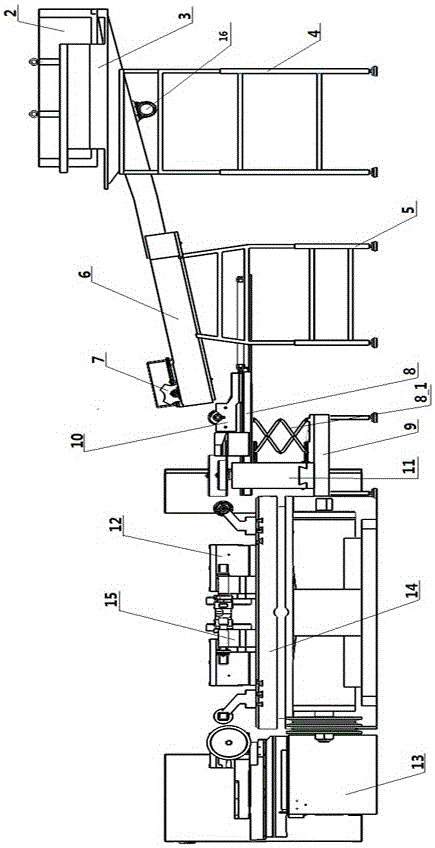

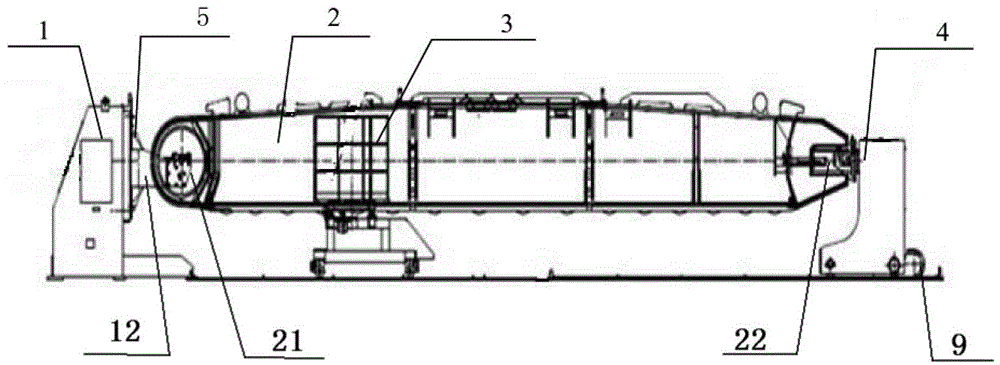

Automatic production line for forming to sintering of ferrite magnetic steel and implementation method

ActiveCN104590842ASimple structureImprove product qualityMechanical conveyorsProduction lineEngineering

The invention discloses an automatic production line for forming to sintering of ferrite magnetic steel. The automatic production line comprises a plurality of empty push plate warehouses, an empty push plate trolley, a blank fetching and arrangement machine, a pressing machine, a conveying belt, an image conveying belt, an image identifying device, a first lifting trolley, a first slide rail, a blank conveying belt, a second lifting trolley, a second slide rail, a kiln furnace inlet conveying belt, a kiln furnace inlet automatic plate pushing device, a kiln furnace conveying belt and a kiln furnace. The invention also discloses an implementation method for the automatic production line for forming to sintering of the ferrite magnetic steel. The automatic production line has the advantages that the structure is simple, the product quality is good, the production efficiency is high, the production area is small, the production cost is low, the production cycle is short, and the like.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Production process capable of improving toughness of aluminum profile

The invention provides a production process capable of improving the toughness of an aluminum profile. The production process comprises the following steps of: performing homogenization treatment on the aluminum profile, further performing solution treatment, and performing water quenching after the solution treatment to get a finished product, wherein the temperature for the solution treatment is 480-520 DEG C and the treatment time is 2-4 hours; clearing a solvent and performing acid cleaning; immersing the aluminum profile in the solvent for cleaning, and cleaning in clear water; selecting a spraying material, preliminarily setting sandblasting pressure as 200-250KPa, setting sandblasting distance as 160-180mm, setting sandblasting time as 8-15s and setting the number of turns of a product as 45-55RPM; repeatedly sandblasting the aluminum profile according to parameters; then performing surface processing on the aluminum profile and receiving the material; and packaging. According to the production process disclosed by the invention, harm to environmental pollution and health of a worker, which is caused by dust, can be greatly improved, and the production process can be directly mounted on a production line so as to save production area and be conducive to turnover of a workpiece.

Owner:RUGAO HUAYANG ALUMINUM PROD

Automatic liquid medicine mixing method

ActiveCN110975659AImprove securityQuick configurationTransportation and packagingMixer accessoriesProcess engineeringDrug product

The invention discloses an automatic liquid medicine mixing method. The method involves a liquid medicine preparation device, and the device comprises a PLC, a three-dimensional motion machine provided with a mechanical claw, a mother liquor workbench for storing a plurality of mother liquor bottles, injectors, a metering workbench for storing sample cups and a rack; and a weight sensor for metering is arranged below the sample cups, the bottlenecks of the mother liquor bottles are screwed with the injectors, each injector comprises an injector body and a piston, the mechanical claw comprisesa clamping and rotating mechanism, and the clamping and rotating mechanism is used for clamping and rotating the injector bodies and extracting the pistons. The working process of the device mainly comprises four steps of calling out, extracting, injecting and sending back, the movement of the injectors between the mother liquor bottles and the sample cups is realized by the aid of the mechanicalclaw in different preparation processes, and the process is mainly set by the PLC. The method and the device can replace manual operation to increase the working efficiency, reduce the labor intensityand ensure smooth development of research work, and are suitable for various medical and chemical enterprises.

Owner:ZHONGBEI UNIV

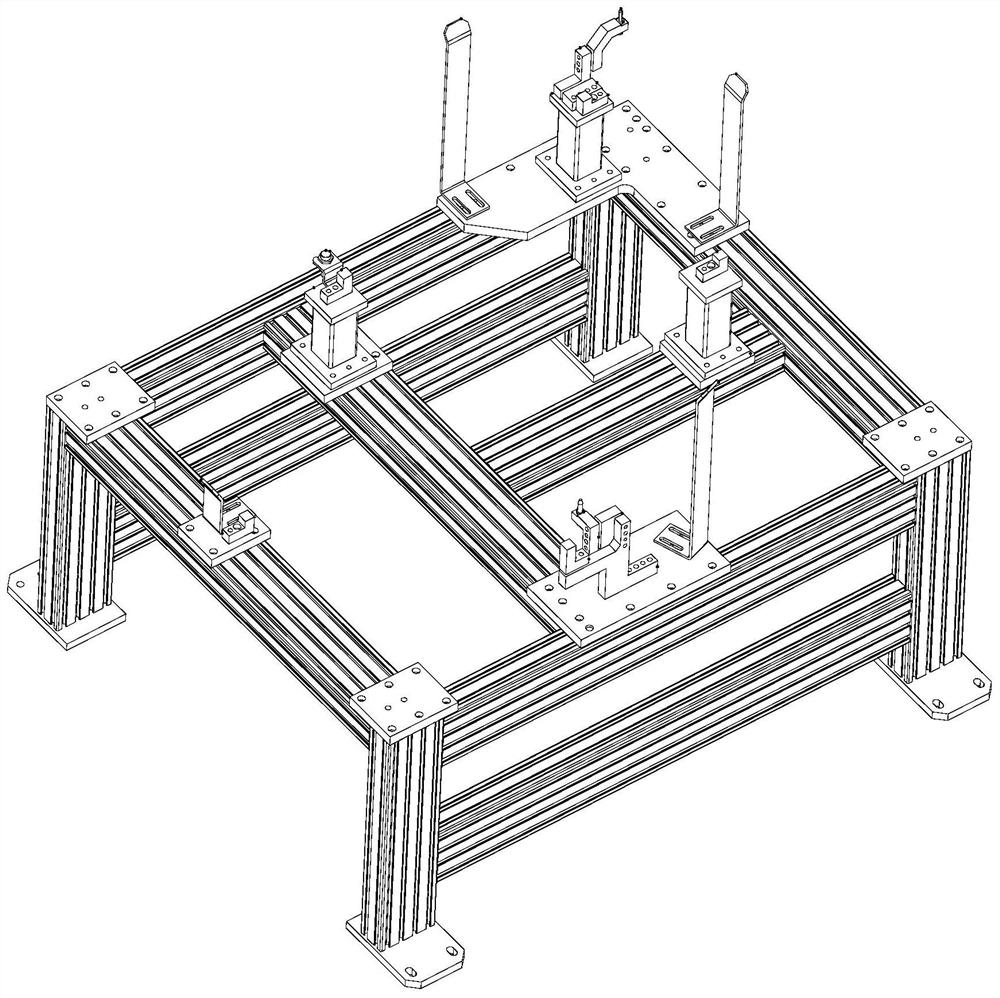

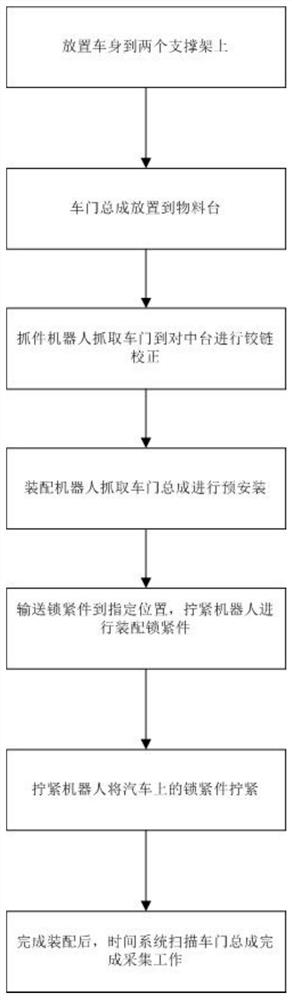

Automobile assembly station adopting industrial robot and working method of automobile assembly station

PendingCN113732679ASimple structureEasy to operateProgramme-controlled manipulatorMetal working apparatusIndustrial roboticsAssembly automation

The invention discloses an automobile assembly station adopting an industrial robot. The automobile assembly station is characterized by comprising a first base, a second base, a supporting frame, a material table, a hinge adjusting table, a feeding robot, a mobile robot and a tightening robot, wherein the first base and the second base are adjacently arranged, and the material table and the feeding robot are adjacently arranged; and a grabbing robot is provided with a visual system, the tail end of the mobile robot is provided with a gripper device, and the tightening robot is provided with a tightening system. The production area occupied by automatic assembly is much smaller than the working area for completing the same production task through manual assembly, traditional manual assembly and traditional semi-automatic assembly processes are replaced, the production efficiency is improved, and meanwhile, manual work is replaced to liberate labor force.

Owner:川崎(重庆)机器人工程有限公司

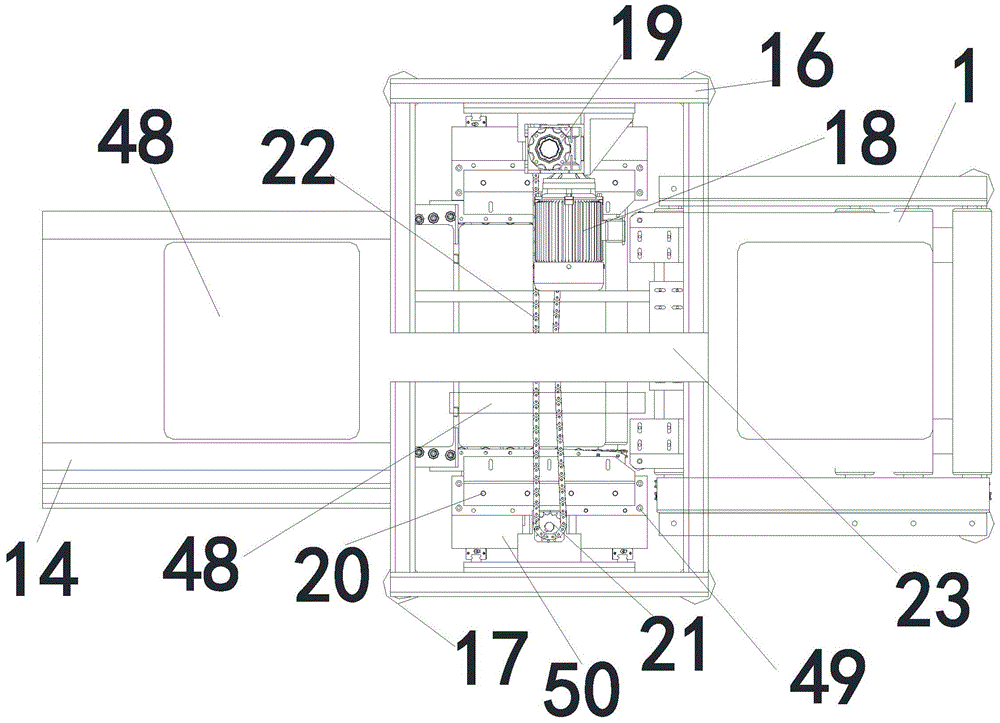

Grinding system and method for blank of shell of differential mechanism

ActiveCN106078439ACompact structureSave spaceGrinding machinesGrinding feedersEngineeringCylindrical grinding

The invention discloses a grinding system and method for a blank of a shell of a differential mechanism. A vibrator is arranged at the bottom of a hopper-shaped bin, a storage box can be placed on the upper part of the inside of the hopper-shaped bin, an outlet of the left end of the hopper-shaped bin is connected with an inlet of the right end of a storage groove, a drive plate mechanism is arranged at an outlet of the left end of the storage groove, a sliding table is arranged below the outlet of the left end of the storage groove, a first clamping mechanism capable of sliding along the sliding table in the left-right direction is arranged on the sliding table and is fixedly connected with the left end of a piston of a steam cylinder of the sliding table, a shear type lifter is arranged below the sliding table, an end surface grinding machine is arranged on the left side of the shear type lifter, and a rotary working table is arranged on the ground of the left side of a grinding machine supporting table; four second clamping mechanisms which are the same are uniformly arranged on a circular table board of the rotary working table in the peripheral direction; a cylindrical grinding machine is arranged on the rear side of the rotary working table; a grinding machine for a special-shaped surface is arranged on the left side of the rotary working table. Two end surfaces and the outer surface of the shell of the differential mechanism are ground automatically, and automatic level of production, production efficiency and quality of products are improved.

Owner:JIANGSU UNIV OF SCI & TECH

Grinding system and method for differential case blank

ActiveCN106078439BCompact structureSave spaceGrinding machinesGrinding feedersEngineeringCylindrical grinding

The invention discloses a grinding system and method for a blank of a shell of a differential mechanism. A vibrator is arranged at the bottom of a hopper-shaped bin, a storage box can be placed on the upper part of the inside of the hopper-shaped bin, an outlet of the left end of the hopper-shaped bin is connected with an inlet of the right end of a storage groove, a drive plate mechanism is arranged at an outlet of the left end of the storage groove, a sliding table is arranged below the outlet of the left end of the storage groove, a first clamping mechanism capable of sliding along the sliding table in the left-right direction is arranged on the sliding table and is fixedly connected with the left end of a piston of a steam cylinder of the sliding table, a shear type lifter is arranged below the sliding table, an end surface grinding machine is arranged on the left side of the shear type lifter, and a rotary working table is arranged on the ground of the left side of a grinding machine supporting table; four second clamping mechanisms which are the same are uniformly arranged on a circular table board of the rotary working table in the peripheral direction; a cylindrical grinding machine is arranged on the rear side of the rotary working table; a grinding machine for a special-shaped surface is arranged on the left side of the rotary working table. Two end surfaces and the outer surface of the shell of the differential mechanism are ground automatically, and automatic level of production, production efficiency and quality of products are improved.

Owner:JIANGSU UNIV OF SCI & TECH

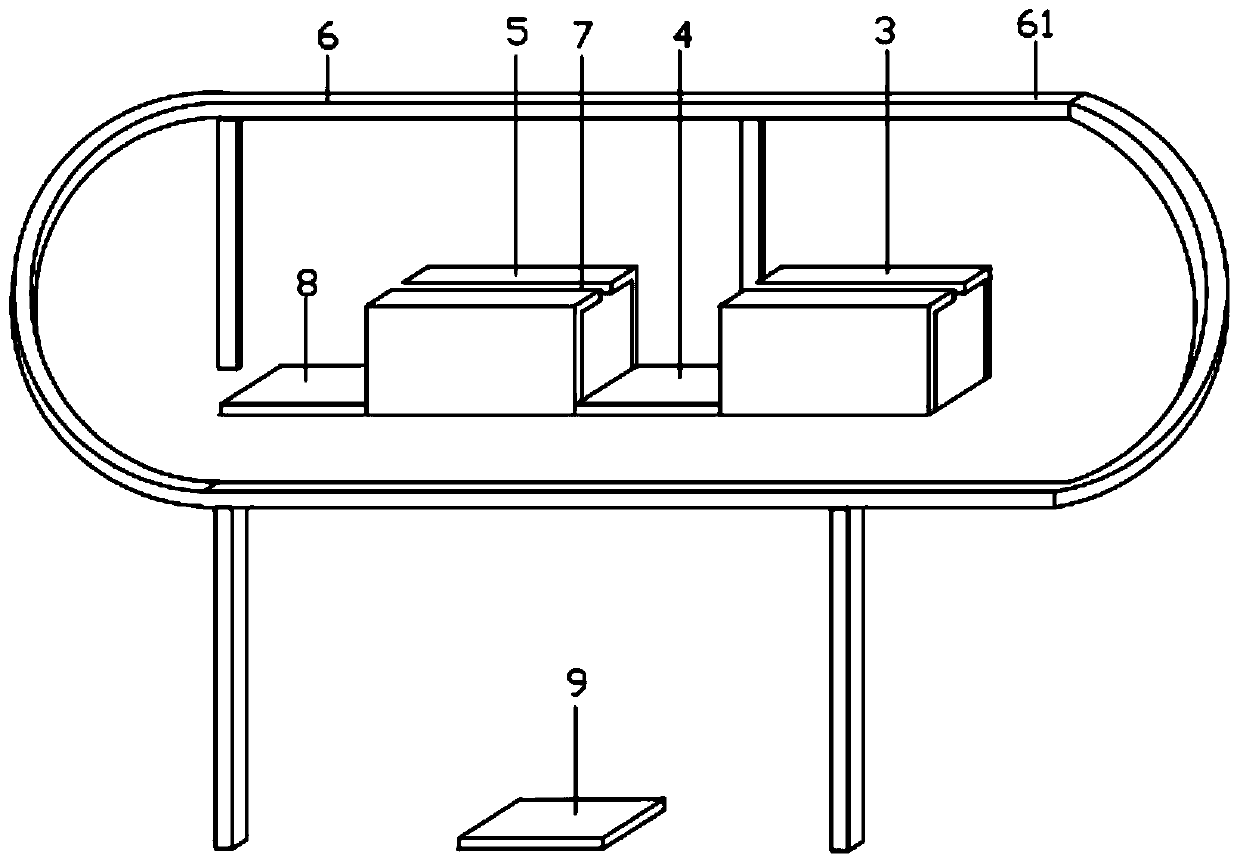

Wood-grain-printed aluminum material production line and production process thereof

PendingCN110090755AReduce processing costsImprove continuityTransfer printingPretreated surfacesProduction lineAlloy

The invention relates to the technical field of aluminum alloy profiles, and particularly discloses a wood-grain-printed aluminum material production line and a production process thereof. The production line comprises a heating channel which is used for carrying out baking and heat transfer printing to aluminum material coated with wood grain paper, a cooling channel for cooling the heat transferprinting finished aluminum material is arranged at the downstream end of the heating channel, an inspection table used for detecting the heat transfer printing degree of the aluminum material is arranged between the heating channel and the cooling channel, the production line is further provided with a suspension conveying mechanism for conveying the aluminum material, wherein the suspension conveying mechanism comprises an annular circulation rail which is connected with the heating channel, the inspection table and the cooling channel in sequence, suspension assemblies are arranged on the annular circulation rail in a sliding mode, and the tops of the heating channel and the cooling channel are provided with slits allowing the suspension assemblies to penetrate through and to extend into the heating channel or the cooling channel. The production line is suitable for the aluminum materials of more specifications and sizes, the cost is low, the connection between all the procedures issmooth, the annular arrangement is adopted, the continuity of the production line is improved, and the production area is effectively reduced.

Owner:佛山市南海正基木纹制品有限公司

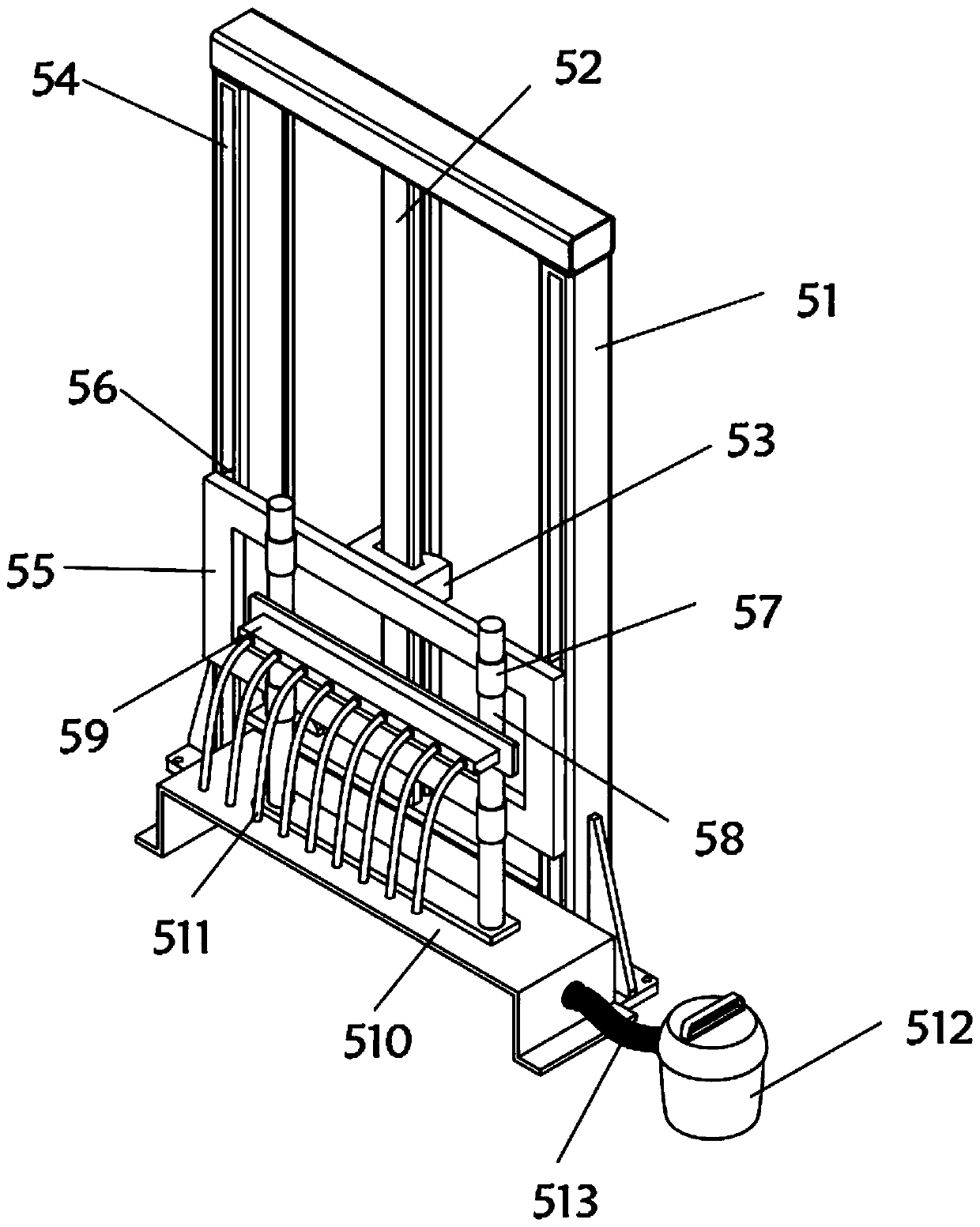

Equipment for processing end pin of integrated circuit board

InactiveCN102064454ASolve the problem of bending angle differenceImprove bending accuracyContact member assembly/disassemblyEngineeringPrinted circuit board

The invention discloses equipment for processing an end pin of an integrated circuit board, relates to the technical field of automotive electronics, improves the bending precision of the end pin and reduces the production cost. The equipment comprises a machine frame, a clamp tool, an anti-deformation mechanism, a rotating mechanism and an end pin clamping mechanism, wherein the rotating mechanism comprises a servo motor and a revolving shaft; the end pin clamping mechanism comprises a clamping jaw air cylinder, a fixed knife edge and a moveable knife edge; the fixed knife edge is fixed on a revolving shaft; the clamping jaw air cylinder is arranged on the fixed knife edge; the moveable knife edge is fixed on a power arm of the clamping jaw air cylinder; a plurality of groups of trimming components are arranged on the fixed knife edge; each trimming component consists of an arc-shaped chute with one end opened to the clamping face of the fixed knife edge, a trimming knife edge, a fastening bolt and a trimming bolt; one end of the trimming knife edge is pivoted with the fixed knife edge and the other end is inserted into the arc-shaped chute; and the fastening bolt and the trimming bolt are arranged on the fixed knife edge. The device provided by the invention can reduce the production cost.

Owner:上海龙能自动化设备有限公司

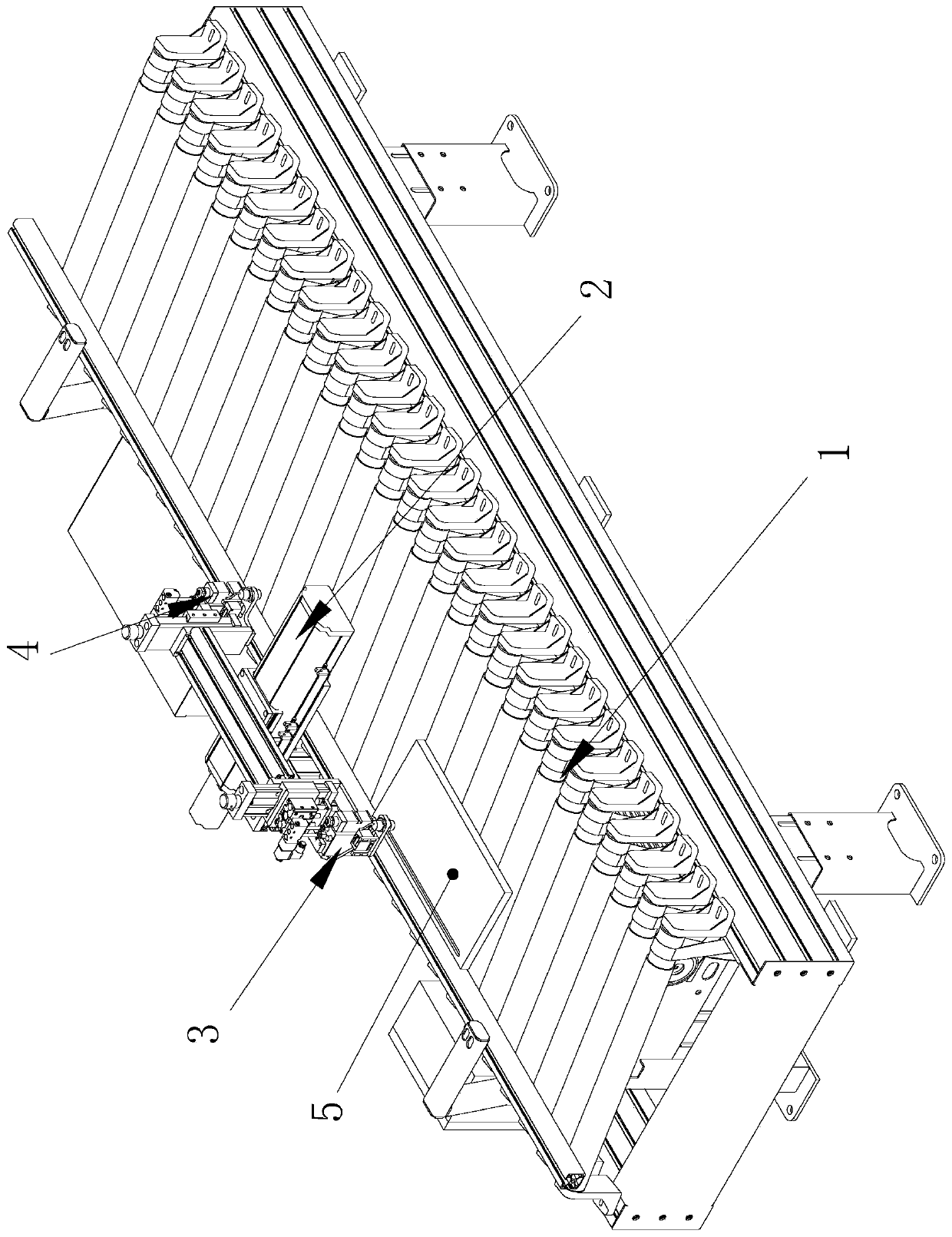

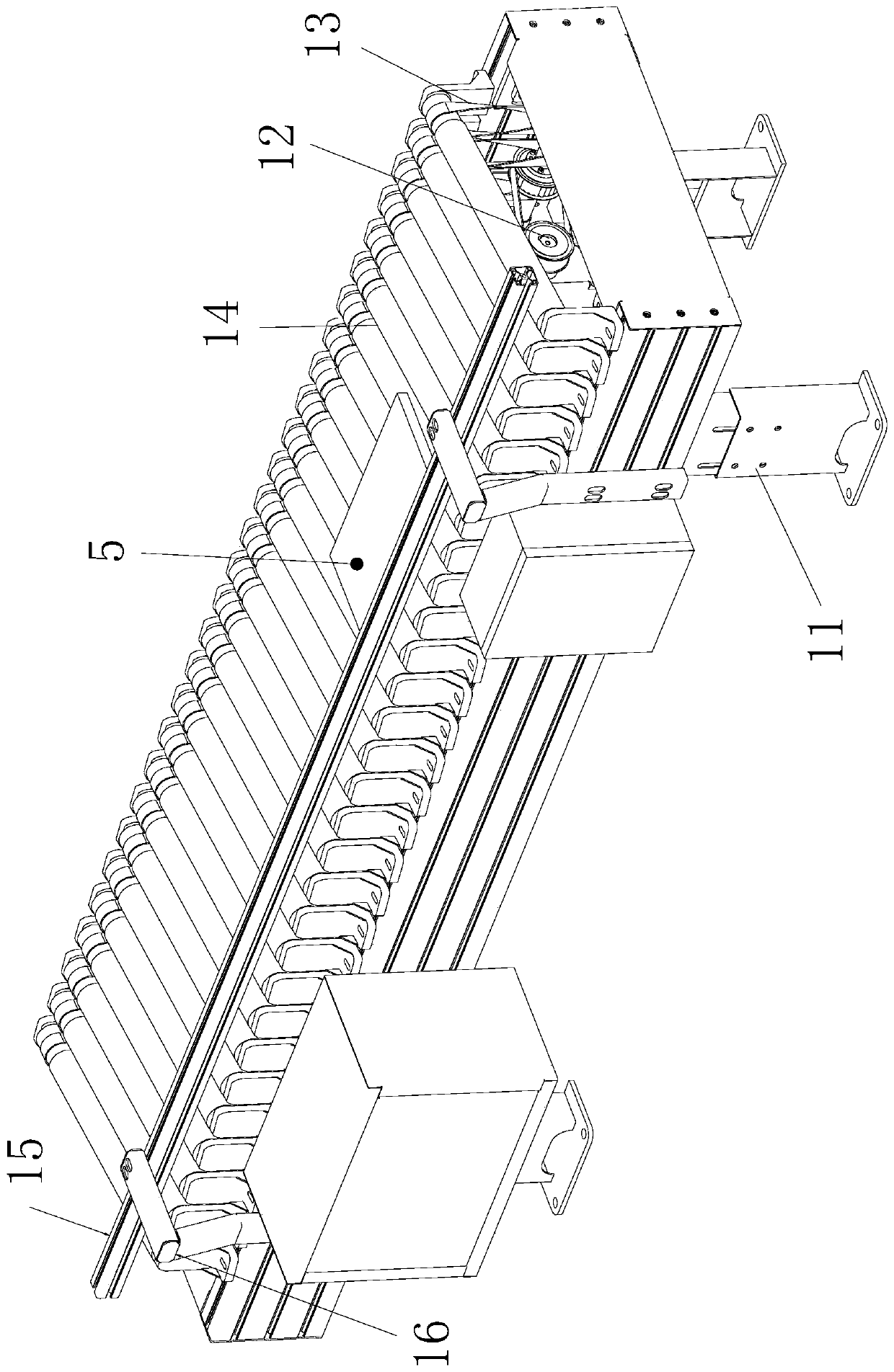

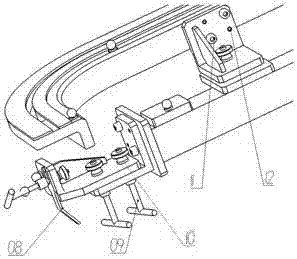

Bilateral assembly positioner

ActiveCN103659262BSimple organizationCompact structureAssembly machinesWork benchesEngineeringDISC assembly

Owner:XCMG CONSTR MACHINERY

Method for sealing of furniture plate groove body and numerical control equipment for realizing same

ActiveCN110694823AImprove the level of environmental protectionInhibition releaseOther plywood/veneer working apparatusLiquid spraying apparatusNumerical controlSealing wax

The invention provides a method for sealing of a furniture plate groove body and numerical control equipment for realizing the same. The method is characterized in that sealing wax is sprayed in theplate groove body, so that a wax layer is formed in cutting surfaces of the plate groove body to realize sealing; and thus free formaldehyde and bonder gas in a plate are prevented from being released. By adopting the method, the problem that the free formaldehyde and bonder gas are released because sealing performance is lost after grooving of the plate can be solved; the technique is simple; andmachining efficiency is high. The invention further provides a numerical control equipment for realizing the method; wax spraying operation is realized; labor cost is reduced; production efficiency is improved; and wax spraying technological quality and wax spraying machining uniformity are improved.

Owner:佛山维尚家具制造有限公司 +1

Method for brewing vinegar in one step through saccharification and alcohol fermentation

InactiveCN103468560AAvoid adverse effectsEasy to saccharifyMicroorganism based processesVinegar preparationChemistryProduction cycle

The invention relates to a method for brewing vinegar in one step through saccharification and alcohol fermentation and belongs to the method for brewing the vinegar. The method includes the steps of screening and cleaning corn kernels, carrying out degerming on the corn kernels, keeping skins of the corn kernels, smashing the core kernels with the skins to obtain high-fiber corn flour in a certain grain size, adding water into the corn flour according to a certain material-to-water ratio to make into corn flour milk with a certain concentration, carrying out high-temperature processing, high-shear processing, gelatinizing, liquifying, sterilizing, cooling, smashing and mixing on the corn flour milk, adding amylase and saccharomyces cerevisiae into the corn flour milk to carry out saccharification and alcohol fermentation, and completing saccharification and vinegar and alcohol fermentation in one step. By adoption of the method, water and time are saved, energy consumption is low, the production environment is clean, the production cycle is greatly shortened, and production efficiency is improved. In the production process, conditions are mild, no pollution and no hazardous substances generate, any chemical reagent is not used, and products are convenient and safe to use.

Owner:BEIKANG BREWING FOOD

Synchronizer toothed-ring abrasion blasting technique

A sandblast technology for alligatoring rings of a synchronizer is used for performing sandblast to processed alligatoring rings, and has the advantages that tiny burrs on the surfaces of workpieces can be removed, thereby smoothing the surfaces of the workpieces, eliminating the harm brought by the burrs, and improving the grade of the workpieces; tiny and even concave and convex surfaces are generated on the surfaces of spare parts for storing lubricating oil, thereby improving the lubricating condition and reducing the noise; and the fatigue value and the wear resistance of the spare partsare enhanced remarkably.

Owner:WUHAN KYOWA SYNCHRONIZER RING

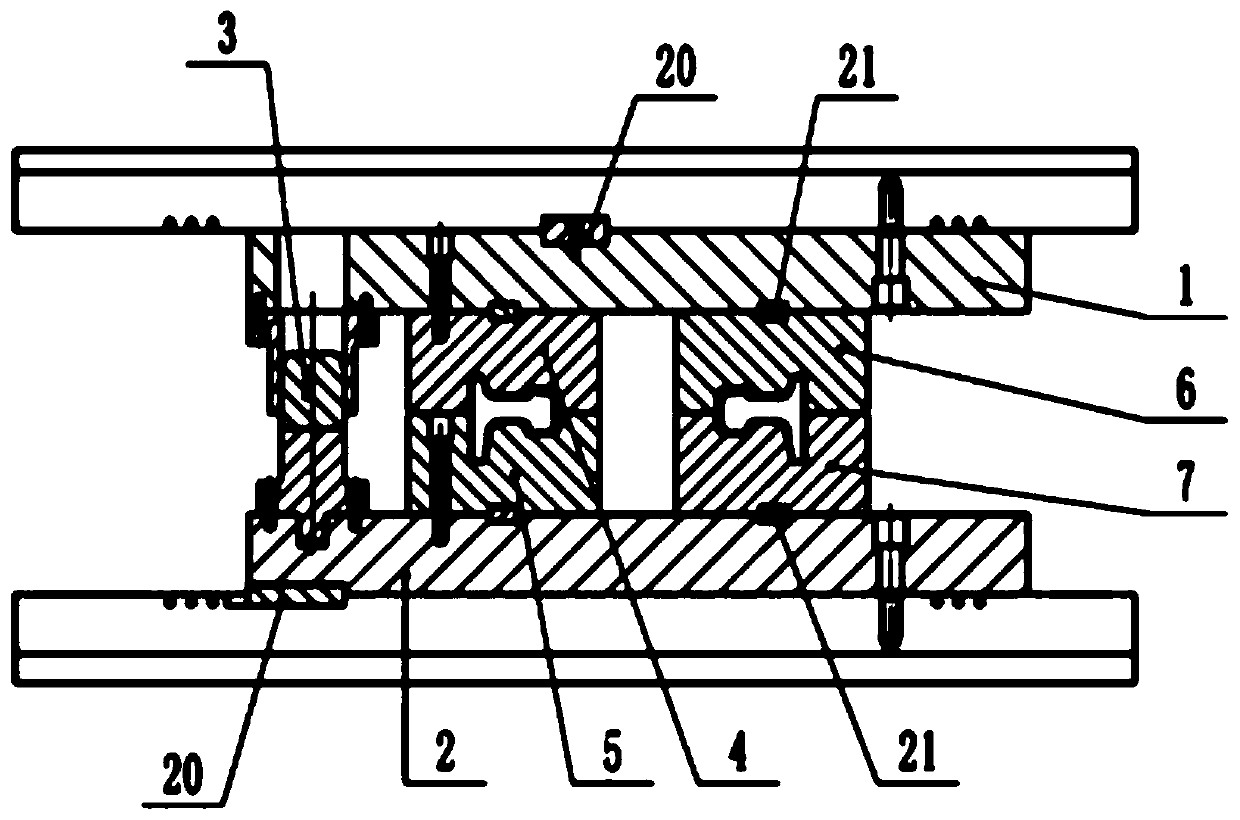

Upsetting device for steel rail with asymmetric section

PendingCN109877266APrecise control of upsetting amountMeet the requirements of process designRailway componentsForging/hammering/pressing machinesStructural engineeringProcess design

The invention discloses an upsetting device for a steel rail with a symmetric section. Upper and lower moulding boards are connected through a guide device; two upper moulds and two lower moulds are arranged between the upper and lower moulding boards; the two upper moulds are fixedly arranged on the lower end surface of the upper moulding board, the two lower moulds are fixedly arranged on the upper end surface of the lower moulding board, and the two upper moulds are separately positioned right on the two lower moulds; the two upper moulds and the two lower moulds are closed to separately form two mould cavities; each mould cavity sequentially consists of a clamping mould cavity section, an upsetting mould cavity section and a guide mould cavity section, wherein the clamping mould cavity section, the upsetting mould cavity section and the guide mould cavity section are separately in a close-fit state, an clearance fit state and a sliding fit state with a to-be-upset steel rail; twoupsetting oil cylinders are fixedly arranged on the lower moulding boards; and piston rods of the two upsetting oil cylinders are separately opposite to the two guide mould cavity sections. Integral upsetting for different product types of the steel rail with the symmetric section is accomplished through a set of tool moulds; and meanwhile, a ball grid digital display system is utilized to precisely control steel rail upsetting amount, so that process design requirements are met.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

Assembling system of vehicle-mounted charging machine and modules for integrated functions of vehicle-mounted charging machine

The invention relates to the technical field of machines, in particular to an assembling system of a vehicle-mounted charging machine and modules for integrated functions of the vehicle-mounted charging machine. A rotating disk is included, and a manual feeding station, a marking mechanism, an automatic screw hitting mechanism and a dust removing mechanism are correspondingly arranged around the rotating disk. In the assembling system of the vehicle-mounted charging machine and the modules for the integrated functions of the vehicle-mounted charging machine, due to the arrangement of the marking mechanism, the automatic screw hitting mechanism, the dust removing mechanism, an automatic adhesive dispensing mechanism and a three-axis screw hitting mechanism, assembling of the vehicle-mountedcharging machine and the modules of the integrated functions of the vehicle-mounted charging machine is automatically completed, interference of manual work on the product quality can be reduced, theinventory is reduced, the production area is reduced, the product quality is improved, and the production efficiency is improved.

Owner:SUZHOU SURUN MACHINERY TECH

Detachable combined notch template and application method thereof

ActiveCN107052876ACompact structureClear functionMilling equipment detailsPositioning apparatusAviationStructural engineering

The invention belongs to the field of aeronautical manufacture engineering, and provides a detachable combined notch template and an application method thereof. The detachable combined notch template comprises four milling and cutting template assemblies forming a continuous closed loop. Every two adjacent milling and cutting template assemblies share one positioning basic hole, in other words, the number of the positioning basic holes is four, each positioning basic hole is used by each of the two corresponding milling and cutting template assemblies once, and therefore the four milling and cutting template assemblies are independently used. The four milling and cutting template assemblies each mill and cut a gate frame skin by a distance when independently used, a complete closed loop can be formed by the four milled and cut parts of the gate frame skin, and the milling and cutting work of the whole gate frame skin is completed. The detachable combined notch template is simple in structure and can be repeatedly detached and used, the allowance selection of a metal plate skin is sufficiently considered during design, and the field operation can be more user-friendly.

Owner:SHENYANG AIRCRAFT CORP

Method for dynamically separating epoxidized soybean oil at high speed

ActiveCN102250688ASmall footprintReduce production areaFatty-oils/fats refiningSolvent freeWork in process

The invention relates to a method for dynamically separating epoxidized soybean oil at a high speed, in particular to a method for refining epoxidized soybean oil after epoxidation preparation. The method comprises: producing epoxidized soybean oil, which has an epoxide number of more than or equal to 6.0 percent and a water content of 10 to 30 weight percent, by using crude soybean oil as a raw material and by a solvent-free process; and heating the epoxidized soybean oil to 70 to 100 DEG C, feeding the epoxidized soybean oil to a disc centrifugal separator at a flow rate of 2 to 8t / h, and after separation, obtaining semi-finished epoxidized soybean oil in which the water content is less than 2 percent. In the invention, the separation process is optimized, the oil and water separation speed of the epoxidized soybean oil (ESO) is increased, the floor area of the plant is reduced, the production efficiency and competitive power are increased, and the promotion and use are convenient.

Owner:新锦龙生物基材料(湖北)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com