Bilateral assembly positioner

A positioner, bilateral technology, used in assembly machines, workbenches, metal processing equipment, etc., can solve problems such as unfavorable assembly, inability to achieve assembly, large impact force, etc., to achieve convenient workpiece picking, saving production area, mechanism simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

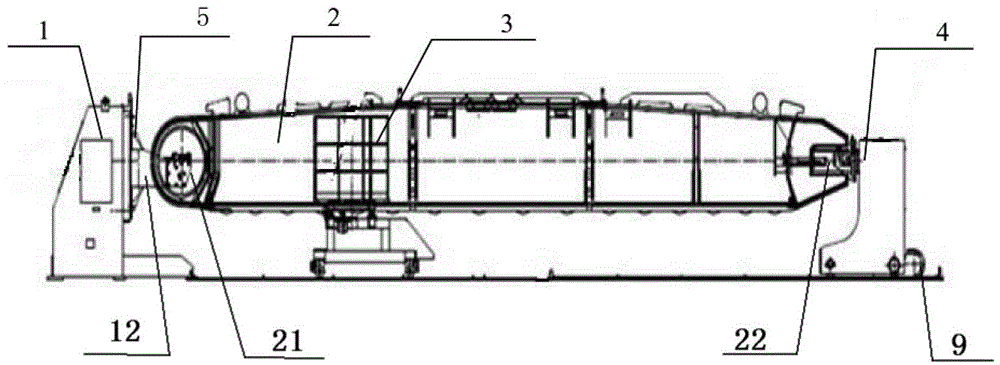

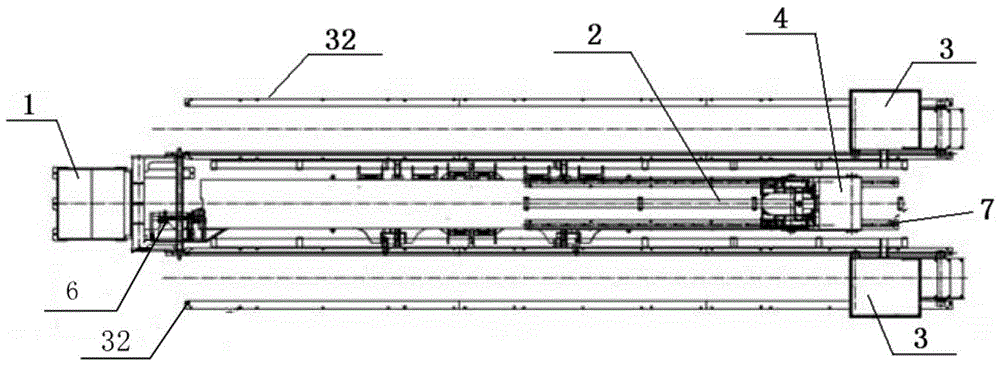

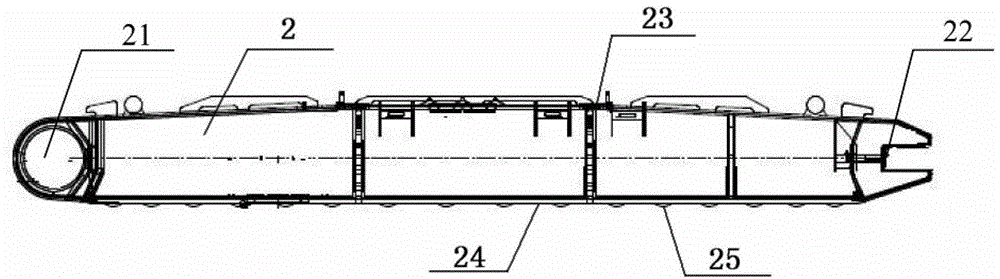

[0043] The working principle and specific structure of the connection plate assembly proposed according to the present invention and the double-sided assembly positioner with the connection plate assembly will be described in detail below in conjunction with the accompanying drawings.

[0044] The principle of the bilateral assembly positioner of the present invention mainly adopts mechanical transmission. The connection between the crawler beam 2 and the double-sided assembly positioner is divided into two steps: the first step is to connect the connection plate assembly 6 with the drive frame 21 of the track beam 2, the main purpose is to reduce the assembly time on the positioner and improve the turnover The utilization rate of the machine; the second step is to connect the connecting plate assembly 6 with the rotating base 1 of the positioner, and then connect the moving base 4 with the fork end 22 of the crawler beam 2 to achieve the purpose of fixing the crawler beam 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com