Kickback voltage suppression circuit

A technology for suppressing circuits and kickback voltages, applied in circuit devices, emergency protection circuit devices for limiting overcurrent/overvoltage, emergency protection circuit devices, etc., can solve problems such as increasing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

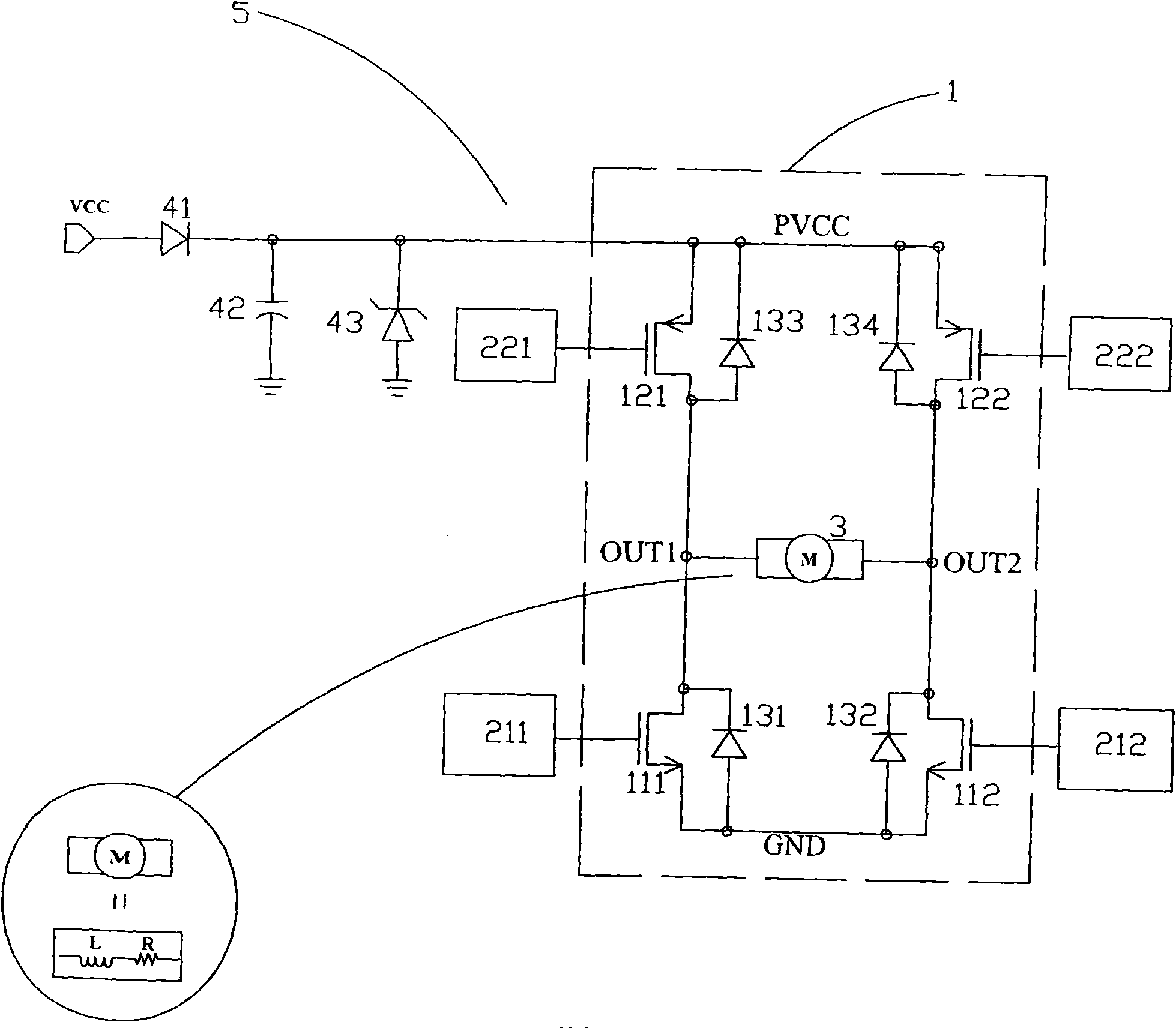

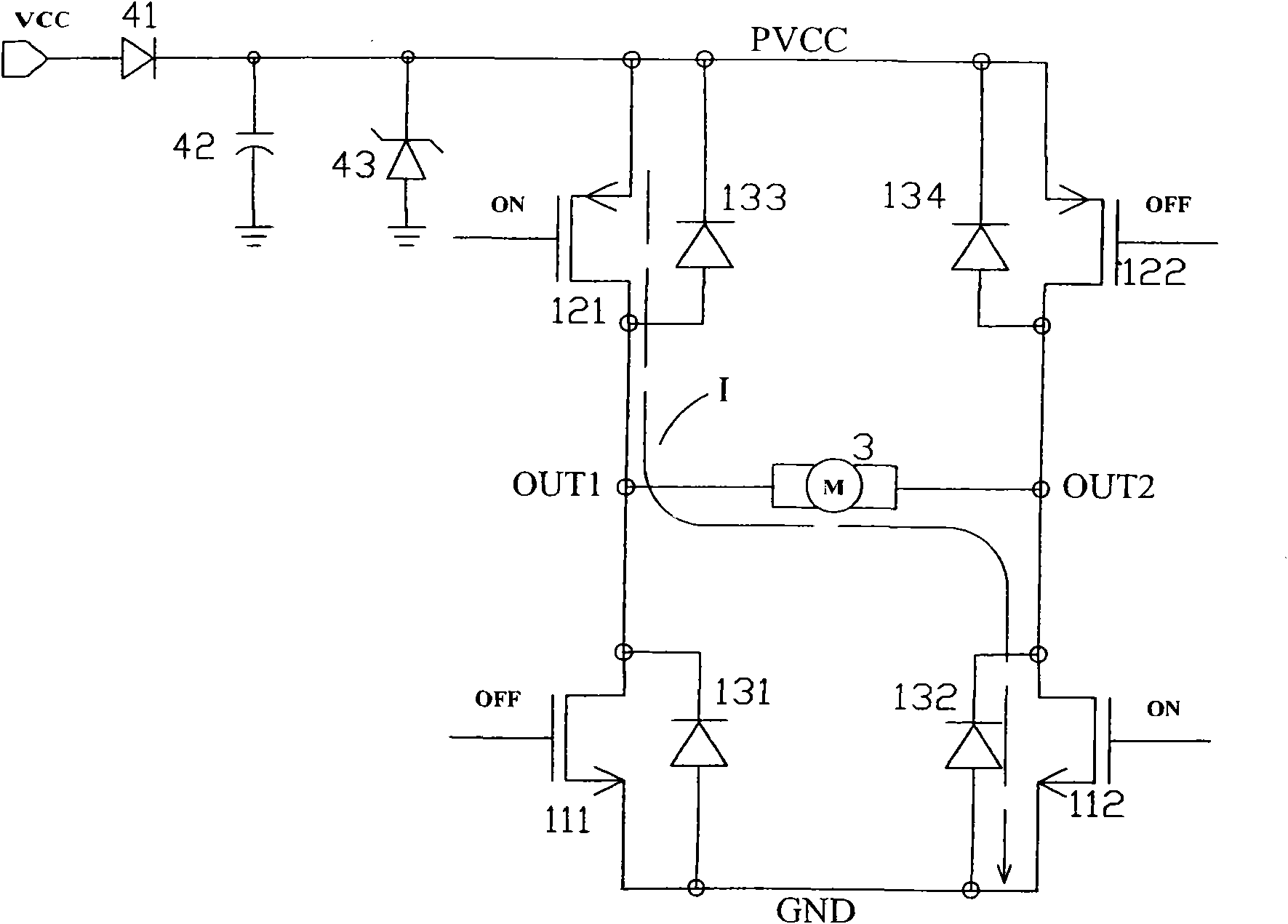

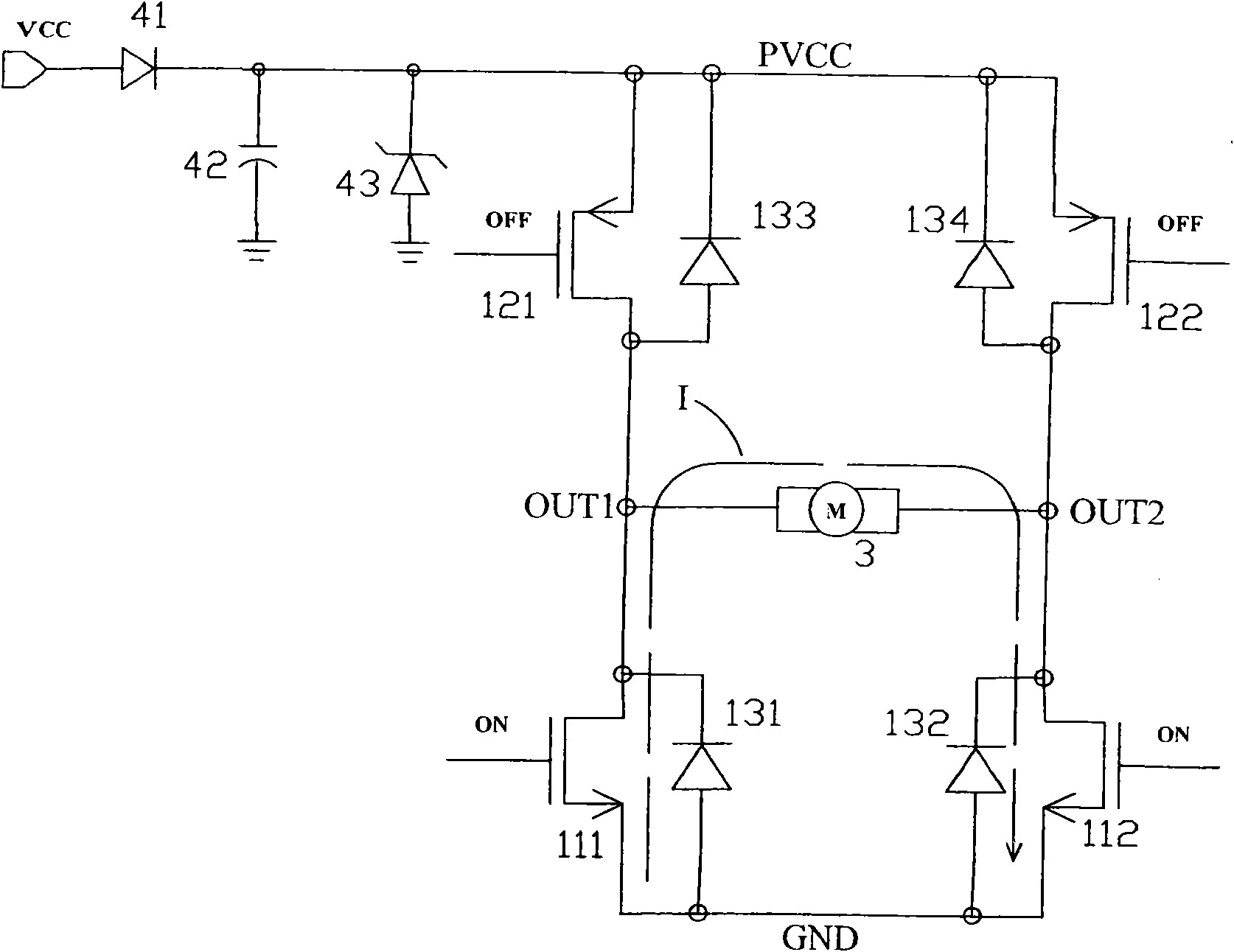

[0094] Example 1, please refer to Figure 5-6 , the kickback (kickback) voltage suppression circuit (5), including: a H-bridge (H-Bridge) power transistor group (1), two high-speed comparators (61) (62), two logic circuits (211) (212), two control circuits (221) (222); the H-Bridge power transistor group (1) is provided with four input system terminals (12P1) (12P2) (11P1) (11P2), two output drive terminals (OUT1) (OUT2), a power supply terminal (PVCC), a ground terminal (GND); these high-speed comparators (61) (62) are all provided with a positive input terminal (61P1) / (62P1), a negative input terminal (61P2) / (62P2) and an output terminal (61P3) / (62P3); these logic circuits (211)(212) are provided with two logic input terminals (211P1)(211P2) / (212P1)(212P2) 1. A logic output terminal (211P3) / (212P3); these control circuits (221)(222) are provided with a logic input terminal (221P1) / (222P1) and a logic output terminal (221P2) / (222P2).

[0095] The H-Bridge power transistor g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com